Optimization of Structural Damage Repair with Single and Double-Sided Composite Patches through the Finite Element Analysis and Taguchi Method

Abstract

:1. Introduction

2. Finite Element Method

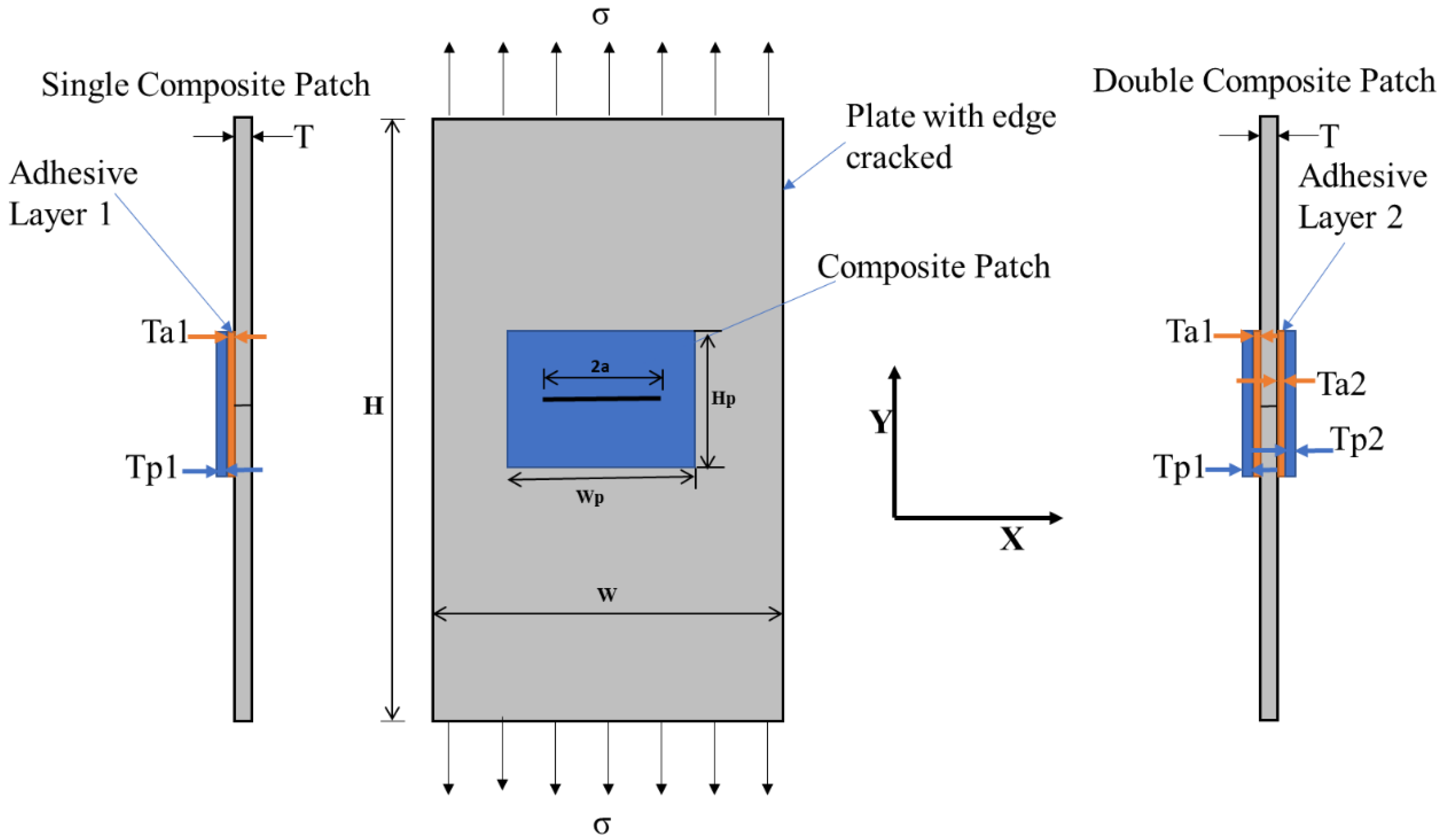

2.1. Geometry and Modelling

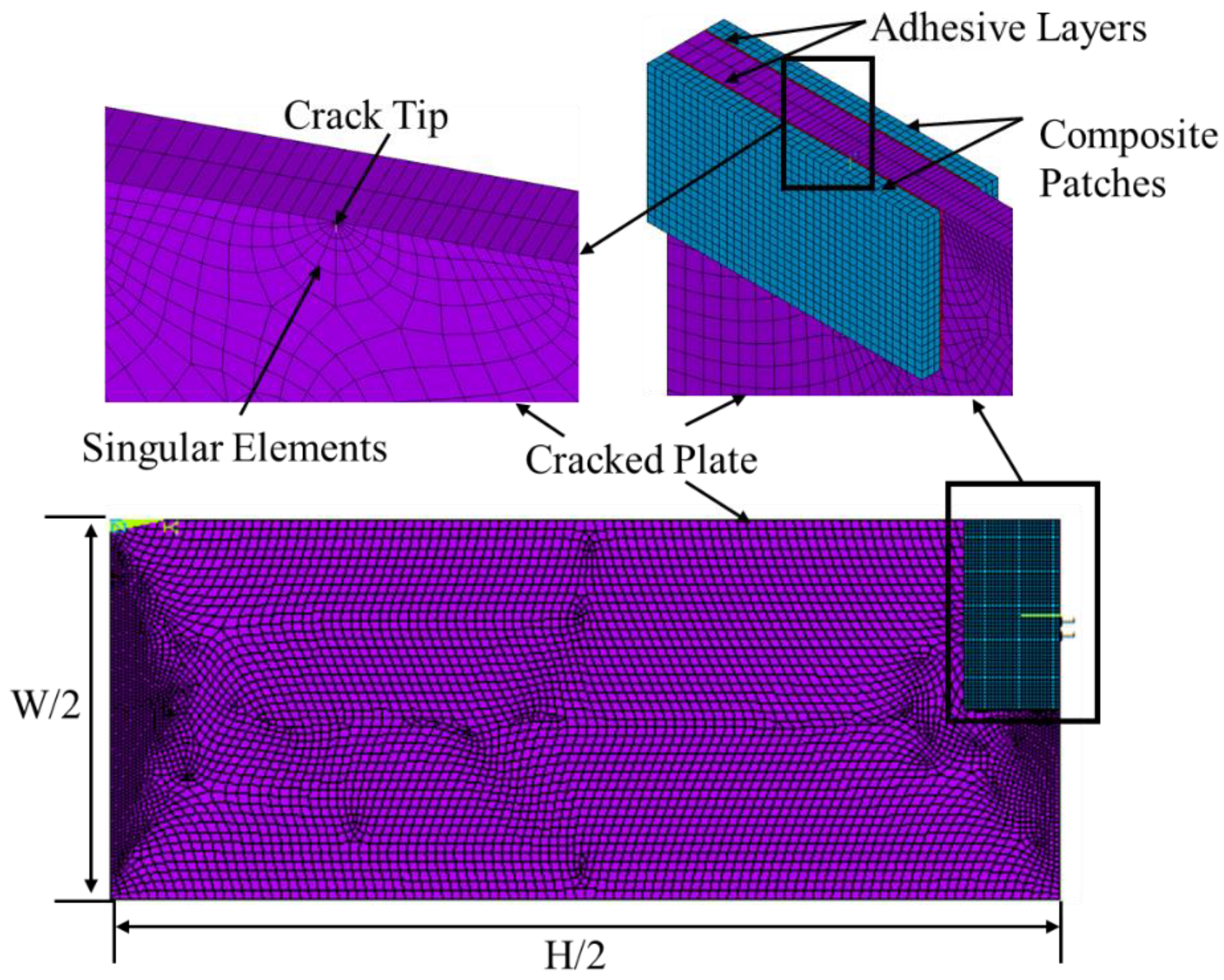

2.2. Meshing and Boundary Conditions

2.3. Mesh Independence Study

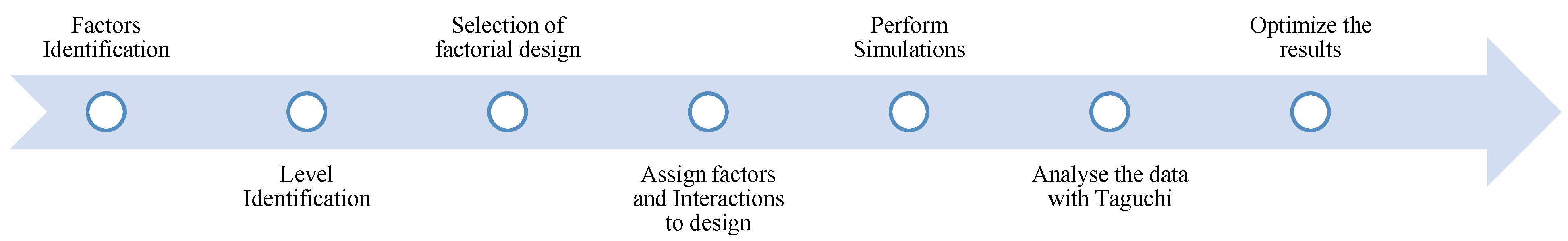

3. Taguchi Method

4. Results and Discussion

4.1. Determination of Normalized SIF

- = Normalized Stress Intensity Factor

- = Patched Stress Intensity Factor (Repaired)

- = Damaged Plate (Unrepaired)

- = Applied load.

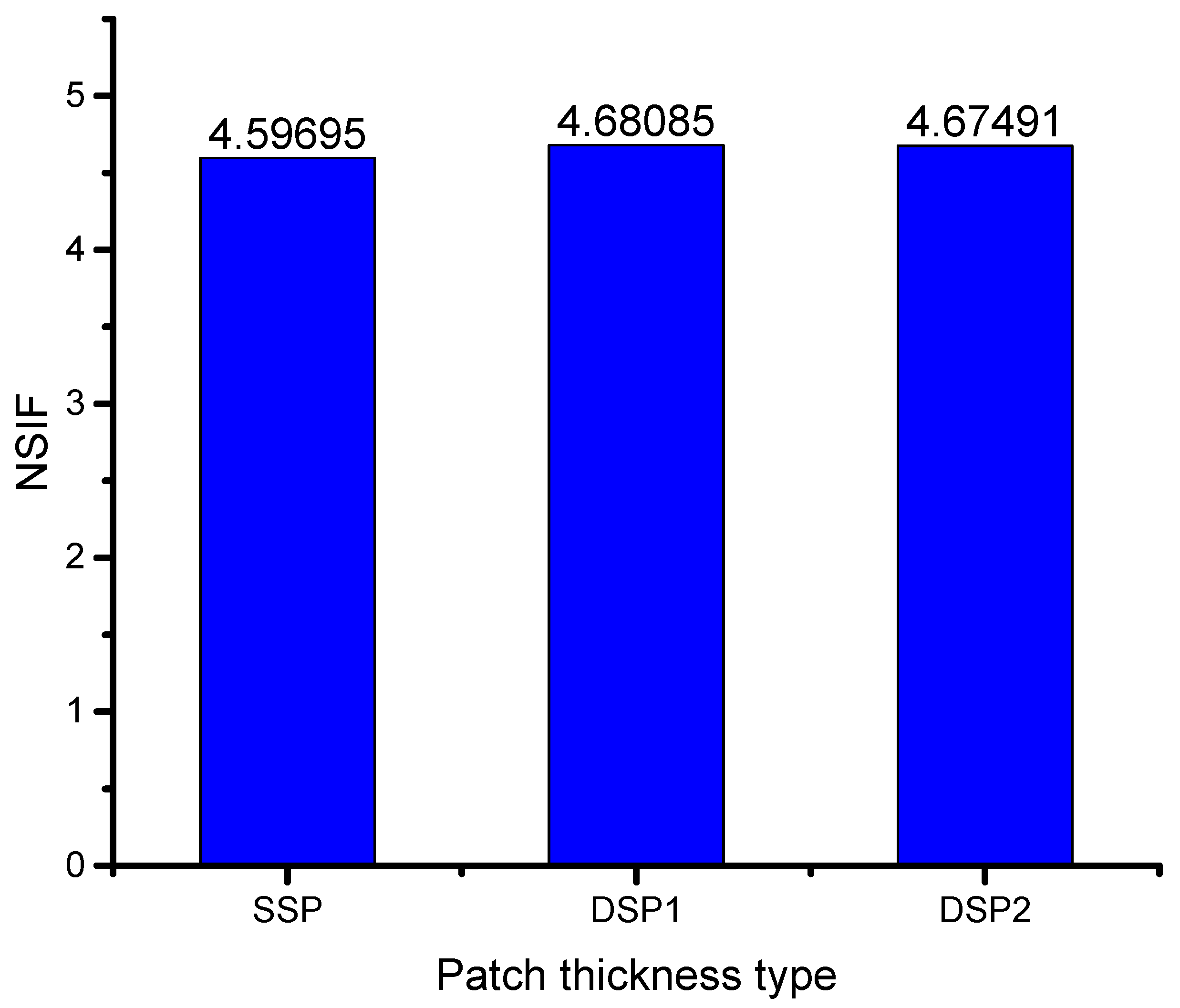

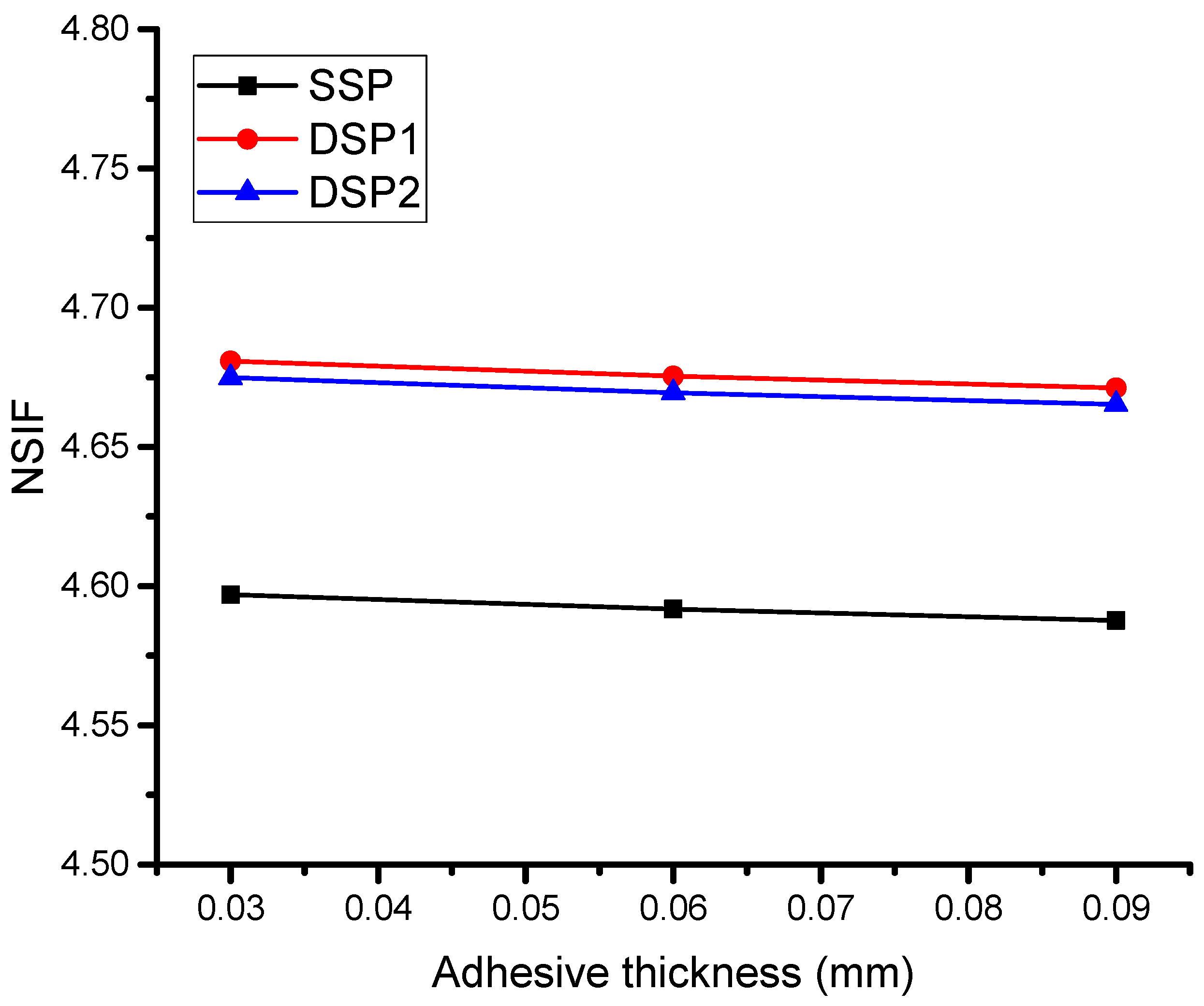

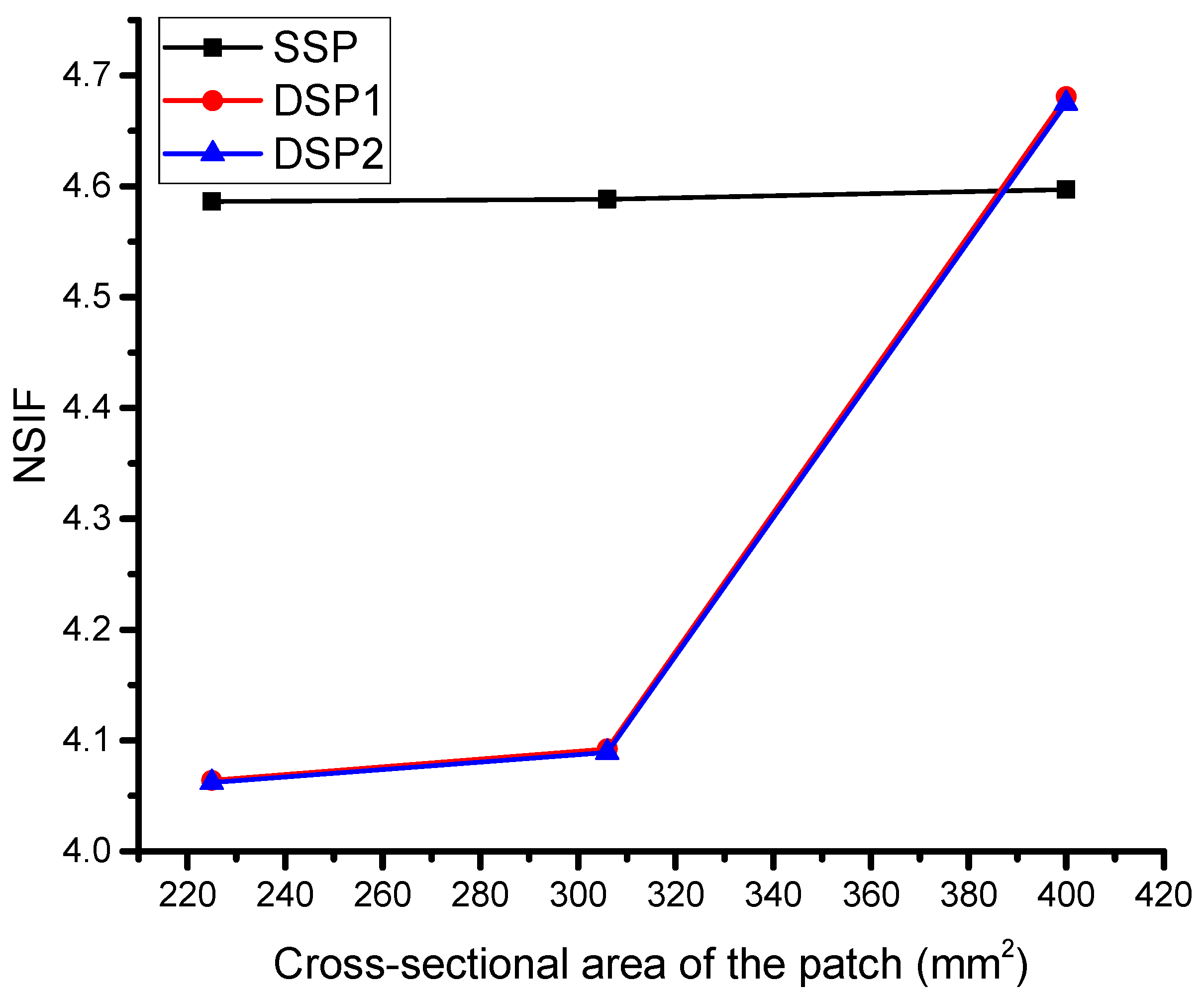

4.2. Finite Element Results

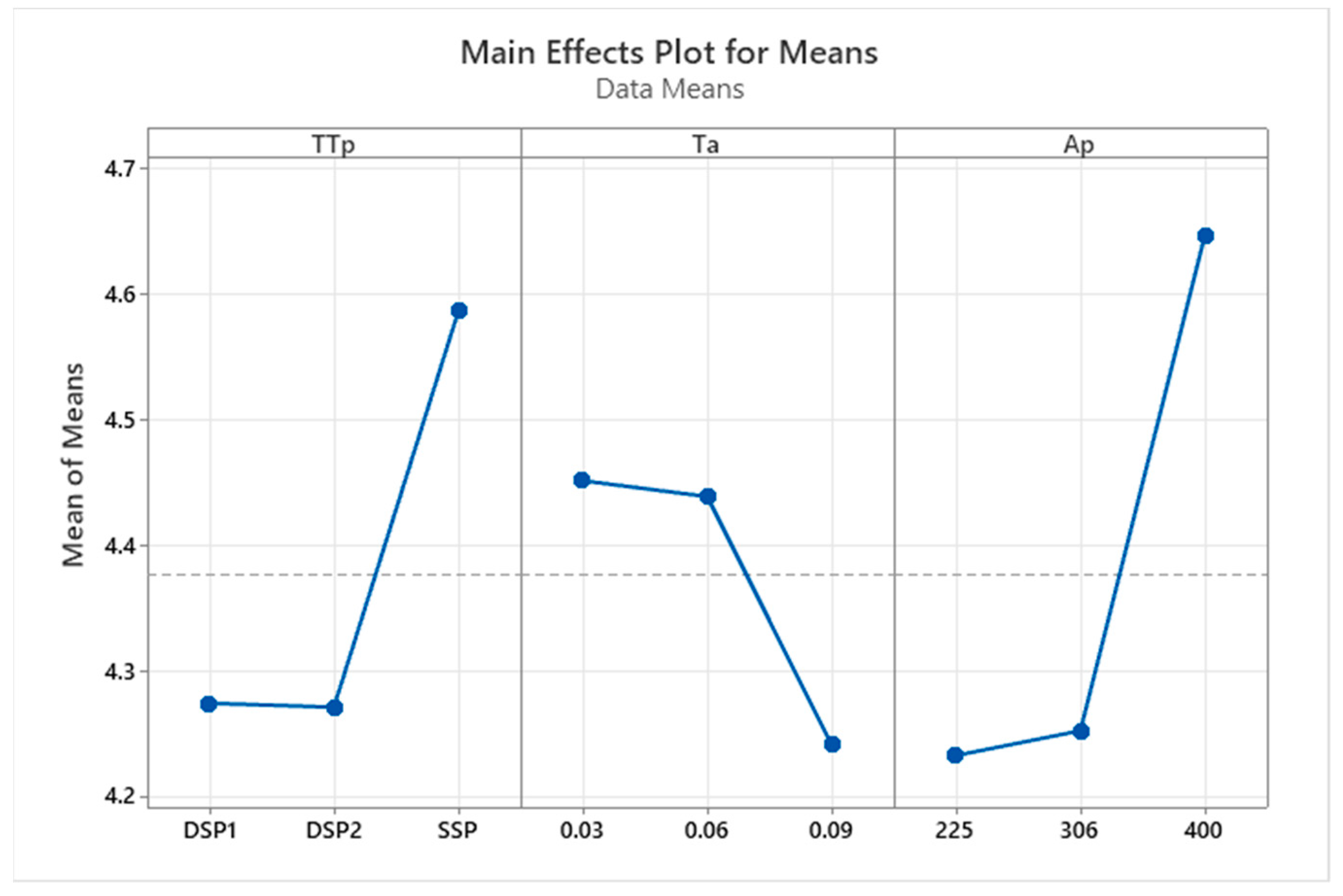

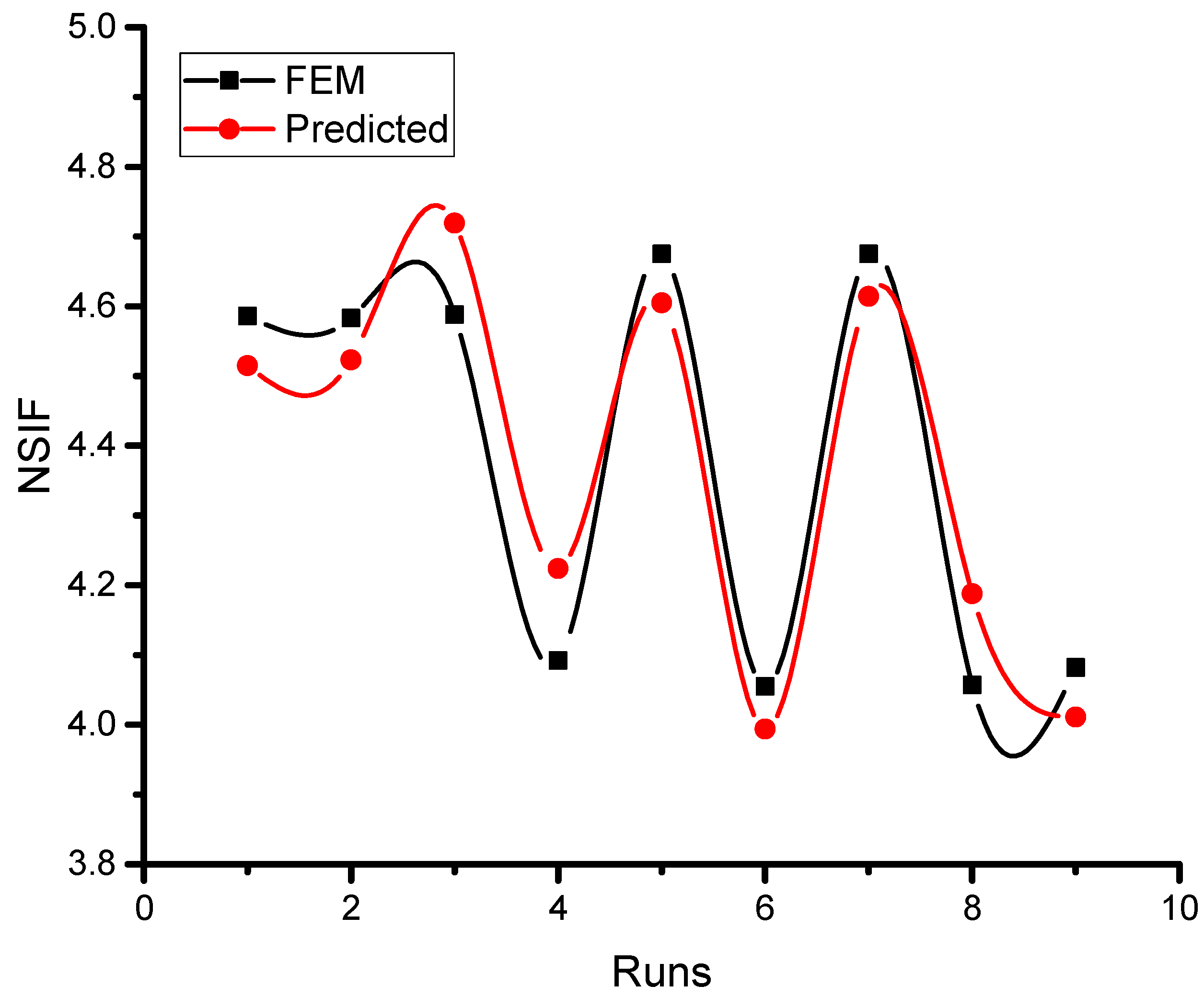

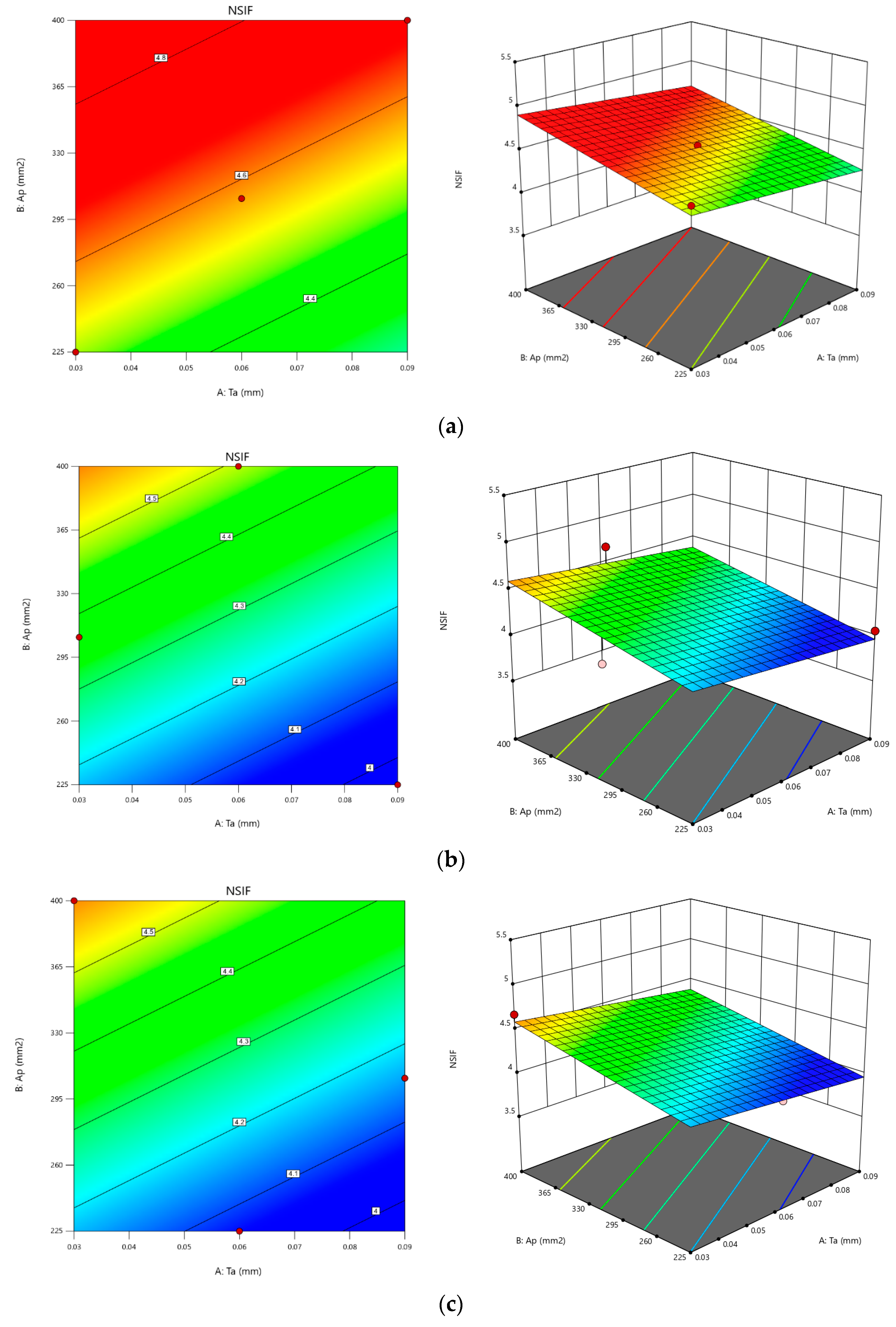

4.3. Optimization Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Achour, T.; Bouiadjra, B.; Serier, B. Numerical analysis of the performances of the bonded composite patch for reducing stress concentration and repairing cracks at notch. Comput. Mater. Sci. 2003, 28, 41–48. [Google Scholar] [CrossRef]

- Albedah, A.; Bouiadjra, B.B.; Mhamdia, R.; Benyahia, F.; Es-Saheb, M. Comparison between double and single sided bonded composite repair with circular shape. Mater. Des. 2011, 32, 996–1000. [Google Scholar] [CrossRef]

- Ergun, E.; Tasgetiren, S.; Topcu, M. Stress intensity factor estimation of repaired aluminum plate with bonded composite patch by combined genetic algorithms and FEM under temperature effects. Indian J. Eng. Mater. Sci. 2012, 19, 17–23. [Google Scholar]

- Kwon, Y.W.; Lee, W.Y.; McGee, A.S.; Hart, D.C.; Loup, D.C.; Rasmussen, E.A. Analytical model for prediction of reduced strain energy release rate of single-side-patched plates. Appl. Compos. Mater. 2013, 20, 1321–1339. [Google Scholar] [CrossRef]

- Aabid, A.; Hrairi, M.; Ali, J.S.M.; Abuzaid, A. Stress concentration analysis of a composite patch on a hole in an isotropic plate. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 6, 249–255. [Google Scholar]

- Aabid, A.; Hrairi, M.; Ali, J.S.M.; Abuzaid, A. Numerical analysis of cracks emanating from hole in plate repaired by composite patch. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 4, 238–243. [Google Scholar]

- Taghizadeh, H.; Chakherlou, T.N. Fatigue behavior of interference fitted Al-alloy 7075-T651 specimens subjected to bolt tightening. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1879–1893. [Google Scholar] [CrossRef]

- Seriari, F.Z.; Benachour, M.; Benguediab, M. Fatigue crack growth of composite patch repaired Al-alloy plates under variable amplitude loading. Frat. Integrità Strutt. 2018, 12, 43–56. [Google Scholar] [CrossRef]

- Yala, A.A.; Megueni, A. Optimisation of composite patches repairs with the design of experiments method. Mater. Des. 2009, 30, 200–205. [Google Scholar] [CrossRef]

- Fekih, S.M.; Albedah, A.; Benyahia, F.; Belhouari, M.; Bouiadjra, B.B.; Miloudi, A. Optimisation of the sizes of bonded composite repair in aircraft structures. Mater. Des. 2012, 41, 171–176. [Google Scholar] [CrossRef]

- Liu, X.; He, Y.; Qiu, D.; Yu, Z. Numerical optimizing and experimental evaluation of stepwise rapid high-pressure microwave curing carbon fiber/epoxy composite repair patch. Compos. Struct. 2019, 230, 111529. [Google Scholar] [CrossRef]

- Aabid, A.; Hrairi, M.; Abuzaid, A.; Ali, J.S.M. Estimation of stress intensity factor reduction for a center-cracked plate integrated with piezoelectric actuator and composite patch. Thin-Walled Struct. 2020, 158, 107030. [Google Scholar] [CrossRef]

- Aabid, A.; Hrairi, M.; Ali, J.S.M.; Sebaey, T.A. A review on reductions in the stress-intensity factor of cracked plates using bonded composite patches. Materials 2022, 15, 3086. [Google Scholar] [CrossRef]

- Kalagi, G.; Buradi, A.; Kaladgi, A.R.; Madhusudhana, H.; Prasanna, H.U.; Yadav, R.Y.; Afzal, A.; Saleel, C.A. Erosion wear behavior of glass fiber hybridized flax and sisal fabric hybrid composites with taguchi experimental design. Mater. Today: Proc. 2021, 47, 5901–5906. [Google Scholar] [CrossRef]

- Zarrinzadeh, H.; Kabir, M.; Deylami, A. Experimental and numerical fatigue crack growth of an aluminium pipe repaired by composite patch. Eng. Struct. 2017, 133, 24–32. [Google Scholar] [CrossRef]

- Otani, T.; Sumihira, W.; Kobayashi, Y.; Tanaka, M. Density-based topology optimization of thin plate structure with geometric nonlinearity using a three-dimensional corotational triangle element formulation. Struct. Multidiscip. Optim. 2022, 65, 282. [Google Scholar] [CrossRef]

- Şimşek, S.; Kahya, V.; Adıyaman, G.; Toğan, V. Damage detection in anisotropic-laminated composite beams based on incomplete modal data and teaching–learning-based optimization. Struct. Multidiscip. Optim. 2022, 65, 332. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Jiang, B.; Wang, R.; Liu, Y.; Jia, L. Mechanical properties prediction of composite laminate with FEA and machine learning coupled method. Compos. Struct. 2022, 299, 116086. [Google Scholar] [CrossRef]

- Berrahou, M.; Benzineb, H.; Serier, M. Analysis of the adhesive damage for different shapes and types patch’s in Aircraft Structures corroded with an inclined crack. Frat. Integrità Strutt. 2022, 60, 331–345. [Google Scholar] [CrossRef]

- Bouzitouna, W.N.; Oudad, W.; Belhamiani, M.; Belhadri, D.E.; Zouambi, L. Elastoplastic analysis of cracked aluminum plates with a hybrid repair technique using the bonded composite patch and drilling hole in opening mode I. Frat. Integrità Strutt. 2020, 14, 256–268. [Google Scholar] [CrossRef]

- Baghdadi, M.; Serier, B.; Salem, M.; Zaoui, B.; Kaddouri, K. Modeling of a cracked and repaired Al 2024T3 aircraft plate: Effect of the composite patch shape on the repair performance. Frat. Integrità Strutt. 2019, 13, 68–85. [Google Scholar] [CrossRef]

- El-Sagheer, I.; Taimour, M.; Mobtasem, M.; Abd-Elhady, A.; Sallam, H.E.-D.M. Finite element analysis of the behavior of bonded composite patches repair in aircraft structures. Frat. Integrità Strutt. 2020, 14, 128–138. [Google Scholar] [CrossRef]

- Rao, P.S.; Hardiman, M.; O’Dowd, N.P.; Sebaey, T.A. Comparison of progressive damage between thermoset and thermoplastic CFRP composites under in-situ tensile loading. J. Compos. Mater. 2021, 55, 1473–1484. [Google Scholar] [CrossRef]

- Alshahrani, H.; Sebaey, T.A. Effect of Embedded Thin-Plies on the Charpy Impact Properties of CFRP Composites. Polymers 2022, 14, 1929. [Google Scholar] [CrossRef]

- Ahmad, F.; Mehboob, H.; Abbassi, F.; Hong, J.W.; Zghal, J.; Mehboob, A. Numerical investigation to evaluate the energy effect on the impact resistance of an aircraft carbon fiber-reinforced polymer composite. Mech. Adv. Mater. Struct. 2022, 29, 4457–4467. [Google Scholar] [CrossRef]

- Alshahrani, H.; Sebaey, T.A.; Allah, M.M.A.; El-baky, M.A.A. Quasi-static axial crushing performance of thin-walled tubes with circular hole discontinuities. J. Compos. Mater. 2022, 56, 4195–4218. [Google Scholar] [CrossRef]

- Ouinas, D.; Bouiadjra, B.B.; Serier, B. The effects of disbonds on the stress intensity factor of aluminium panels repaired using composite materials. Compos. Struct. 2007, 78, 278–284. [Google Scholar] [CrossRef]

- Benyahia, F.; Albedah, A.; Bouiadjra, B.B. Analysis of the adhesive damage for different patch shapes in bonded composite repair of aircraft structures. Mater. Des. 2014, 54, 18–24. [Google Scholar] [CrossRef]

- Papadopoulos, G.A.; Badalouka, B.; Souyiannis, J. Experimental study of the reduction at crack-tip stress intensity factor KI by bonded patches. Int. J. Fract. 2008, 149, 199–205. [Google Scholar] [CrossRef]

- Aabid, A.; Hrairi, M.; Ali, J.S.M.; Abuzaid, A. Effect of bonded composite patch on the stress intensity factors for a center-cracked plate. IIUM Eng. J. 2019, 20, 211–221. [Google Scholar] [CrossRef]

| Parameter | Host Plate | Boron/Epoxy | Adhesive FM 73 |

|---|---|---|---|

| Poisson’s Ratio (ʋ12) | 0.33 | 0.3 | |

| Poisson’s Ratio (ʋ13) | 0.28 | ||

| Poisson’s Ratio (ʋ23) | 0.28 | ||

| Young’s Modulus (E1) | 68.95 Gpa | 210 GPa | |

| Young’s Modulus (E2) | 19.6 GPa | ||

| Young’s Modulus (E3) | 19.6 GPa | ||

| Shear Modulus (G12) | 7.2 GPa | 0.42 GPa (Ga) | |

| Shear Modulus (G13) | 5.5 GPa | ||

| Shear Modulus (G23) | 5.5 GPa | ||

| Density | 2715 kg/m3 | 2000 kg/m3 | 1160 kg/m3 |

| Type of Mesh | Number of Elements | Number of Nodes | CPU Run Time | Computational Results, SIF KN/m3/2 | Experimental Result, SIF KN/m3/2 | Percentage Error |

|---|---|---|---|---|---|---|

| Coarse | 13,664 | 14,786 | 480 s | 58.4 | 60.2 | 2.99% |

| Medium | 66,360 | 69,123 | 981 s | 60.4 | 60.2 | 0.331% |

| Fine | 137,840 | 140,189 | 1564 s | 60.9 | 60.2 | 1.149% |

| Parameters/Levels | Patch Thickness Type (TTp) | Adhesive Thickness (Ta) | The Cross-Sectional Area of the Patch (Ap) |

|---|---|---|---|

| L1 | 2/0 (SSP) | 0.03 | 225 |

| L2 | 1/1 (DSP1) | 0.06 | 306 |

| L3 | 0.5/1.5 (DSP2) | 0.09 | 400 |

| Units | mm | mm | mm2 |

| Run | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Coded Values | A | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 3 | 3 |

| B | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| C | 1 | 2 | 3 | 2 | 3 | 1 | 3 | 1 | 2 | |

| Run | Patch Thickness Type (TTp) | Adhesive Thickness (Ta) | The Cross-Sectional Area of the Patch (Ap) | NSIF |

|---|---|---|---|---|

| 1 | SSP | 0.03 | 225 | 4.586136 |

| 2 | SSP | 0.06 | 306 | 4.583407 |

| 3 | SSP | 0.09 | 400 | 4.587675 |

| 4 | DSP1 | 0.03 | 306 | 4.092280 |

| 5 | DSP1 | 0.06 | 400 | 4.675351 |

| 6 | DSP1 | 0.09 | 225 | 4.055234 |

| 7 | DSP2 | 0.03 | 400 | 4.674911 |

| 8 | DSP2 | 0.06 | 225 | 4.056876 |

| 9 | DSP2 | 0.09 | 306 | 4.081635 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 0.62436 | 0.08919 | 1.53 | 0.555 |

| Linear | 4 | 0.48821 | 0.12205 | 2.09 | 0.473 |

| Ta | 1 | 0.06887 | 0.06887 | 1.18 | 0.474 |

| Ap | 1 | 0.25614 | 0.25614 | 4.38 | 0.284 |

| TTp | 2 | 0.16953 | 0.08476 | 1.45 | 0.506 |

| Square | 2 | 0.07578 | 0.03789 | 0.65 | 0.660 |

| Ta*Ta | 1 | 0.01701 | 0.01701 | 0.29 | 0.685 |

| Ap*Ap | 1 | 0.05877 | 0.05877 | 1.01 | 0.499 |

| 2-Way Interaction | 1 | 0.01945 | 0.01945 | 0.33 | 0.667 |

| Ta*Ap | 1 | 0.01945 | 0.01945 | 0.33 | 0.667 |

| Error | 1 | 0.05845 | 0.05845 | ||

| Total | 8 | 0.68281 |

| Variables | Settings | Value | Low Limit | High Limit | ||

|---|---|---|---|---|---|---|

| TTp | Free | SSP | DSP2 | |||

| Ta | Free | 0.03 | 0.09 | |||

| Ap | Free | 225 | 400 | |||

| Response | Goal | Lower | Target | Upper | Weight | Importance |

| NSIF | Target | 4.05523 | 4.68084 | 5.14289 | 1 | 1 |

| Solution | TTp | Ap | Ta | NSIF Fit | Composite Desirability | |

| 1 | DSP1 | 400 | 0.03 | 4.68084 | 1.00000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aabid, A.; Ibrahim, Y.E.; Hrairi, M.; Ali, J.S.M. Optimization of Structural Damage Repair with Single and Double-Sided Composite Patches through the Finite Element Analysis and Taguchi Method. Materials 2023, 16, 1581. https://doi.org/10.3390/ma16041581

Aabid A, Ibrahim YE, Hrairi M, Ali JSM. Optimization of Structural Damage Repair with Single and Double-Sided Composite Patches through the Finite Element Analysis and Taguchi Method. Materials. 2023; 16(4):1581. https://doi.org/10.3390/ma16041581

Chicago/Turabian StyleAabid, Abdul, Yasser E. Ibrahim, Meftah Hrairi, and Jaffar Syed Mohamed Ali. 2023. "Optimization of Structural Damage Repair with Single and Double-Sided Composite Patches through the Finite Element Analysis and Taguchi Method" Materials 16, no. 4: 1581. https://doi.org/10.3390/ma16041581

APA StyleAabid, A., Ibrahim, Y. E., Hrairi, M., & Ali, J. S. M. (2023). Optimization of Structural Damage Repair with Single and Double-Sided Composite Patches through the Finite Element Analysis and Taguchi Method. Materials, 16(4), 1581. https://doi.org/10.3390/ma16041581