Effects of Scanning Speed on the Polished Surface Quality of Mold Steel by Dual-Beam Coupling Nanosecond Laser

Abstract

1. Introduction

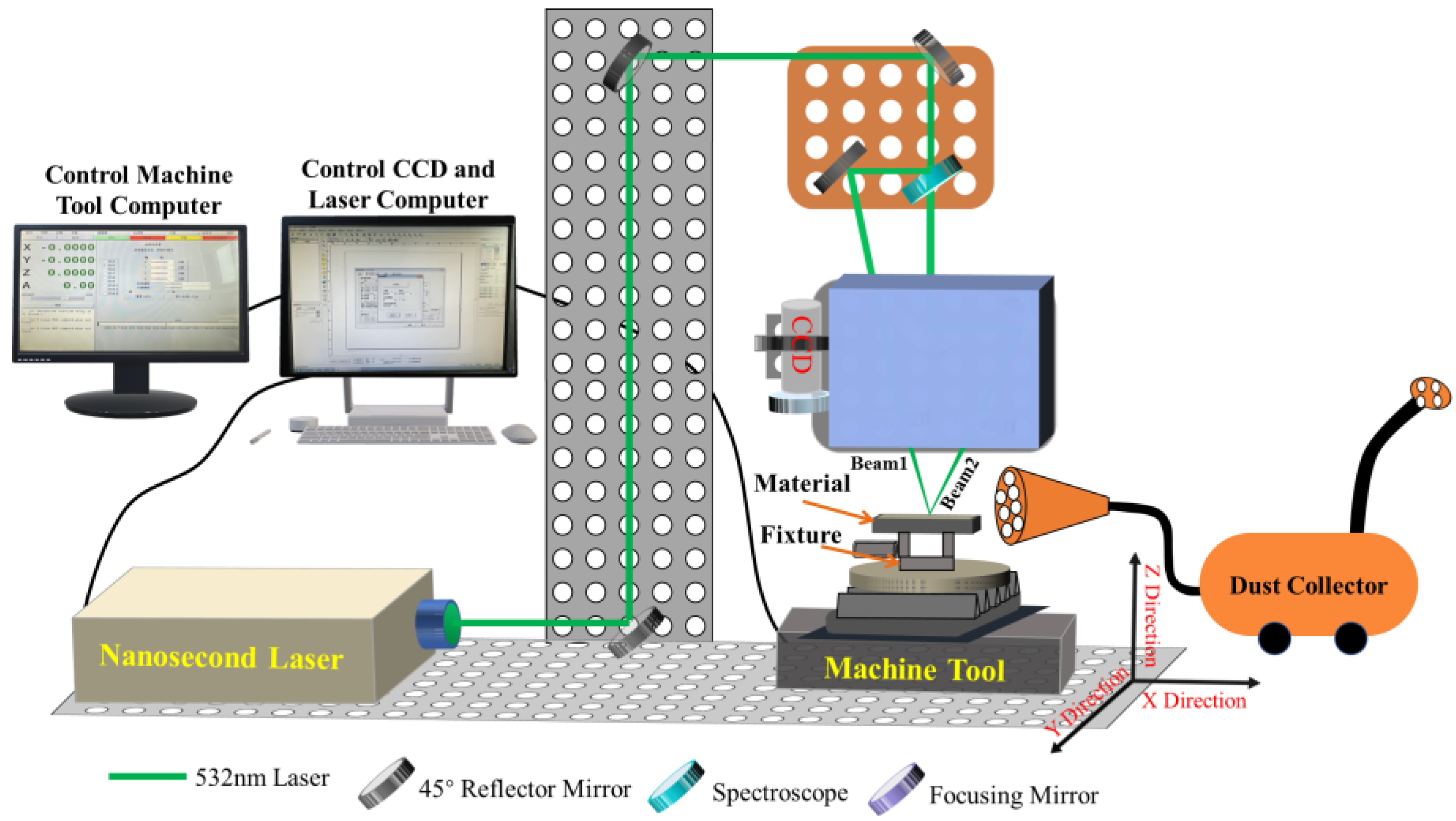

2. Materials and Methods

2.1. Experimental Materials

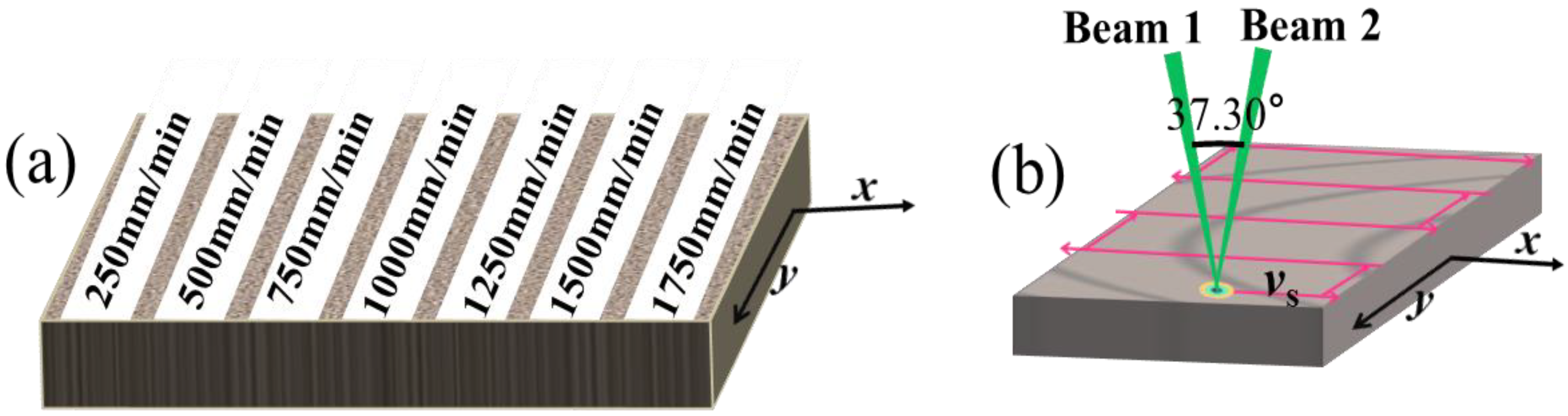

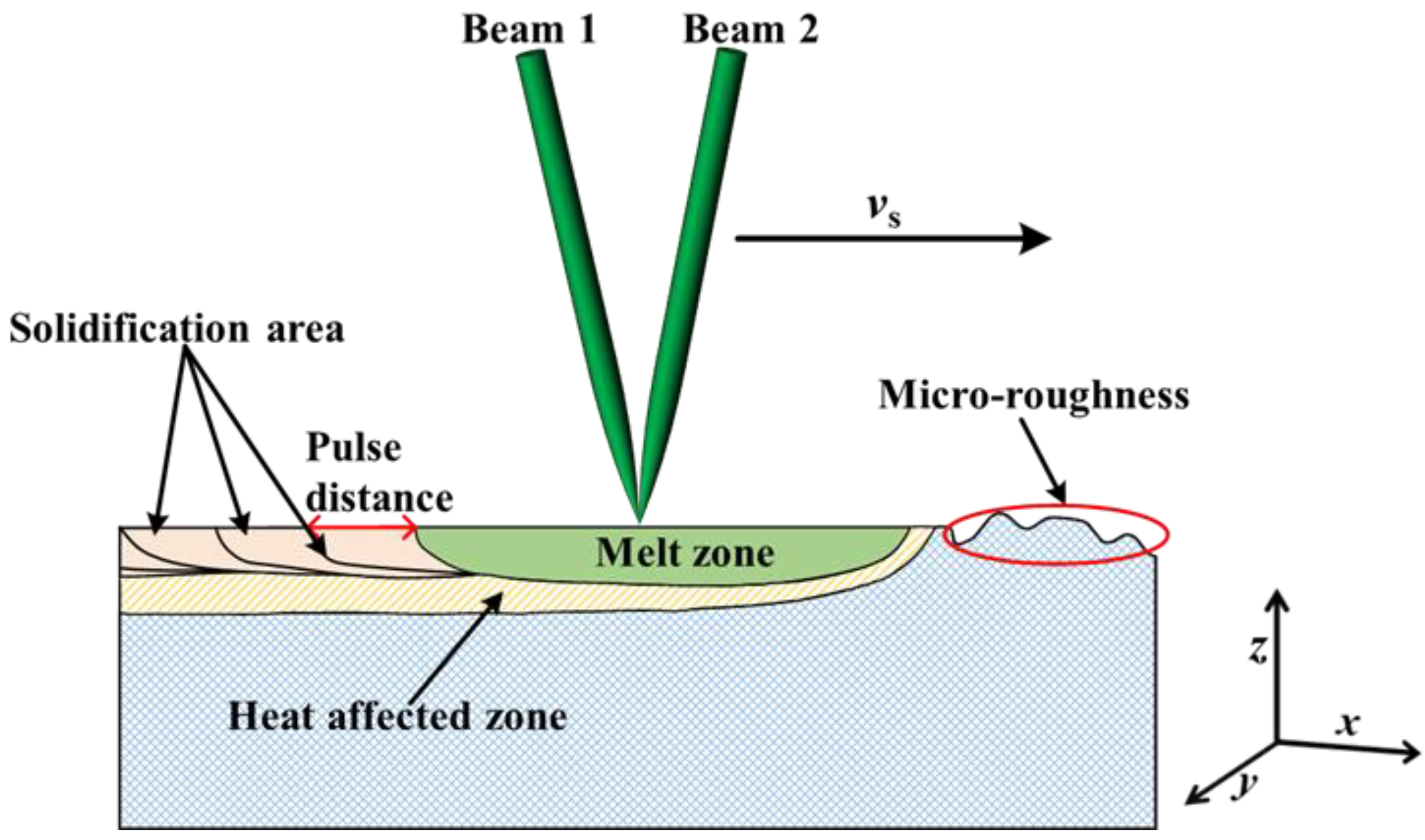

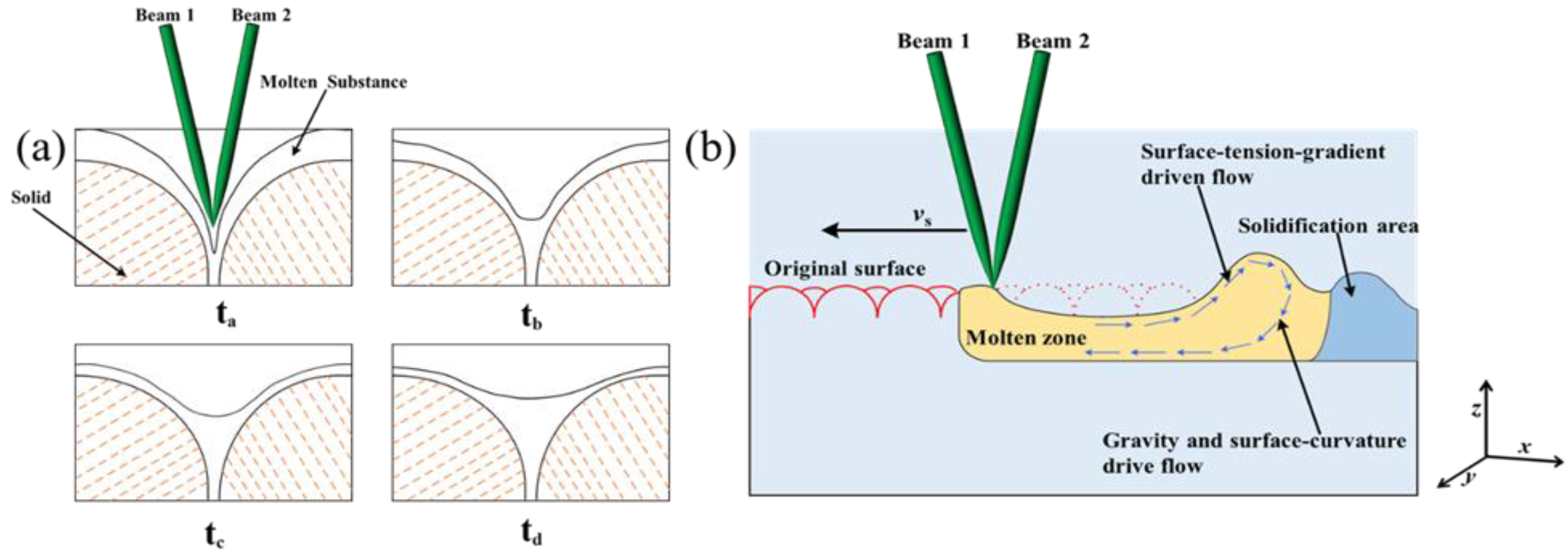

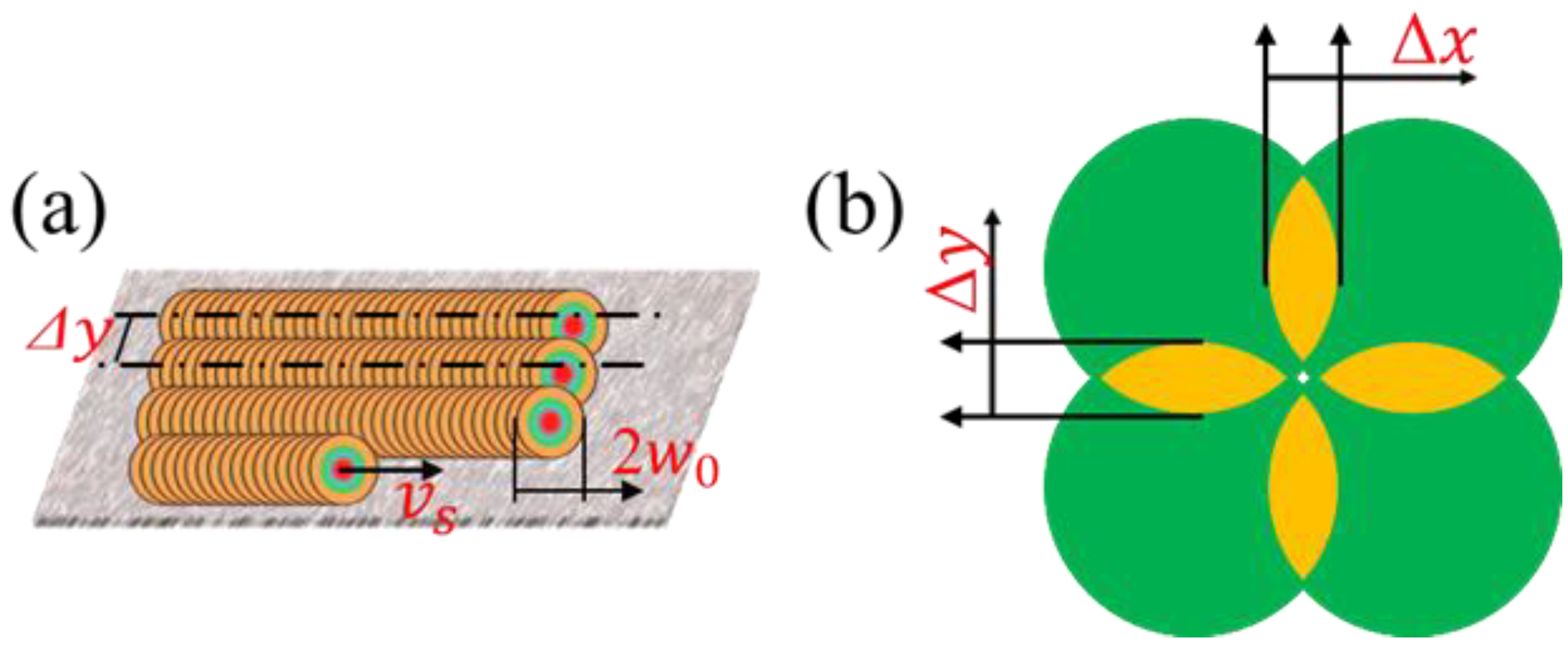

2.2. Experimental Methods

3. Results and Discussion

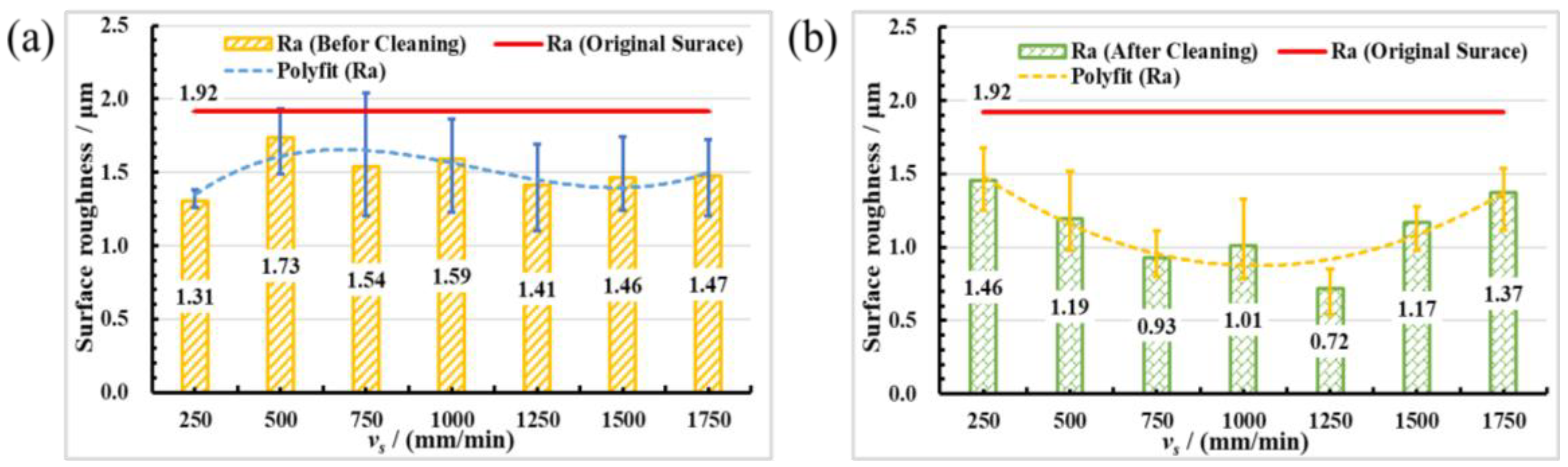

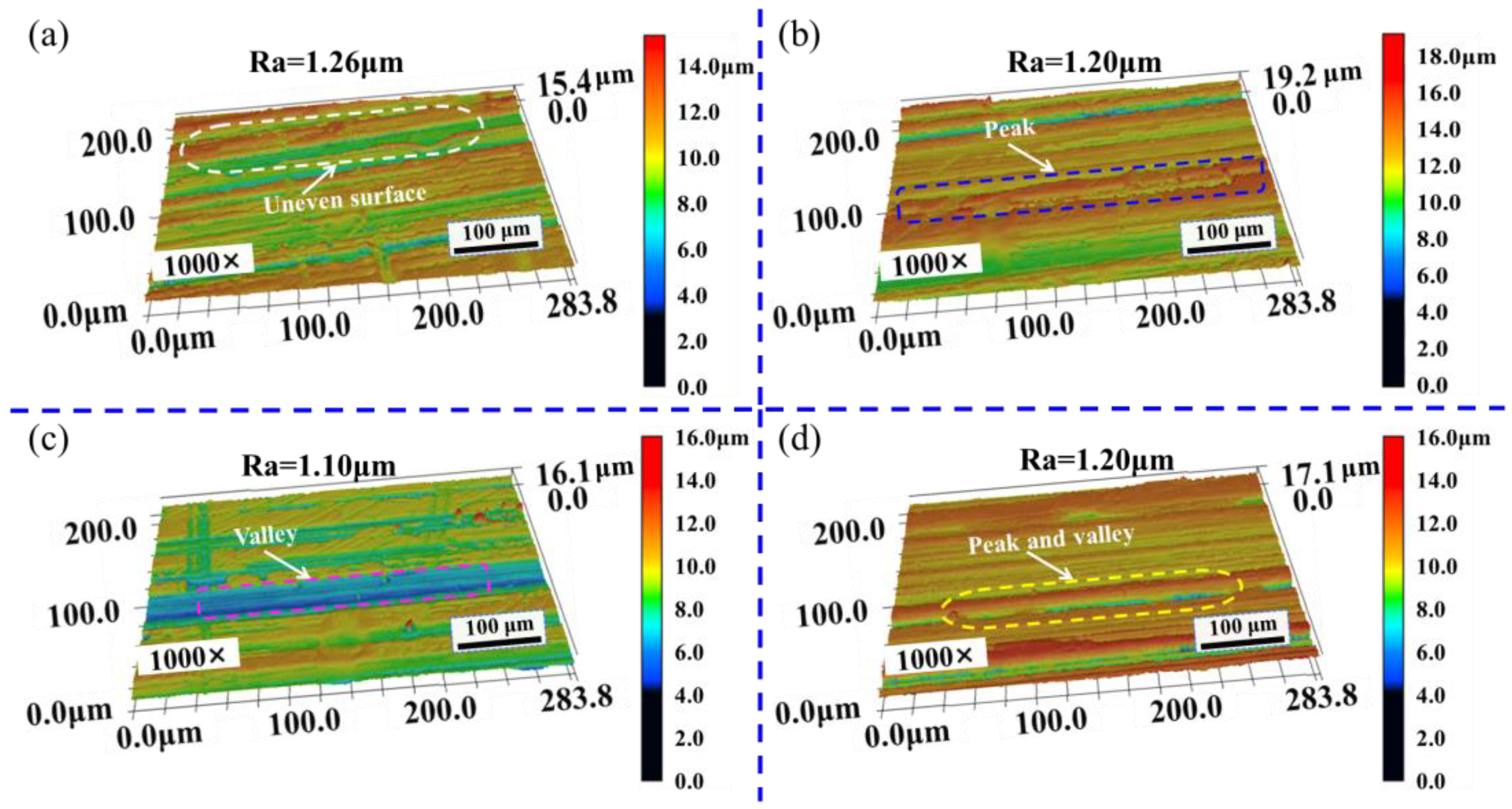

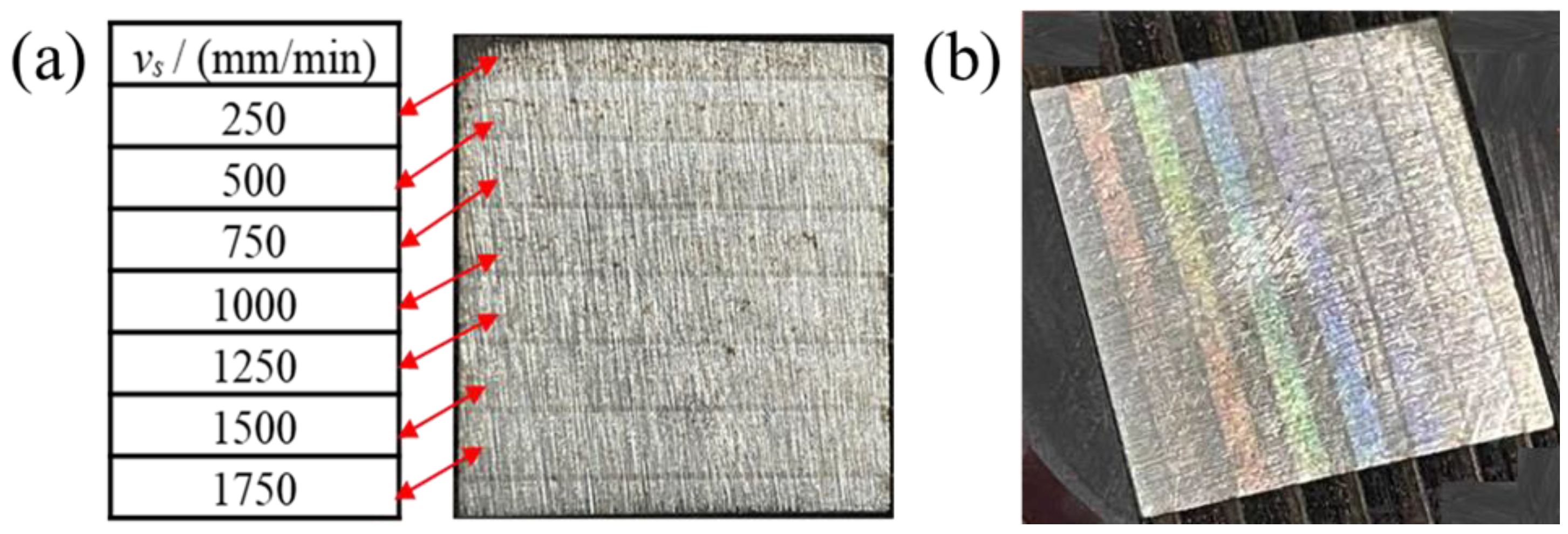

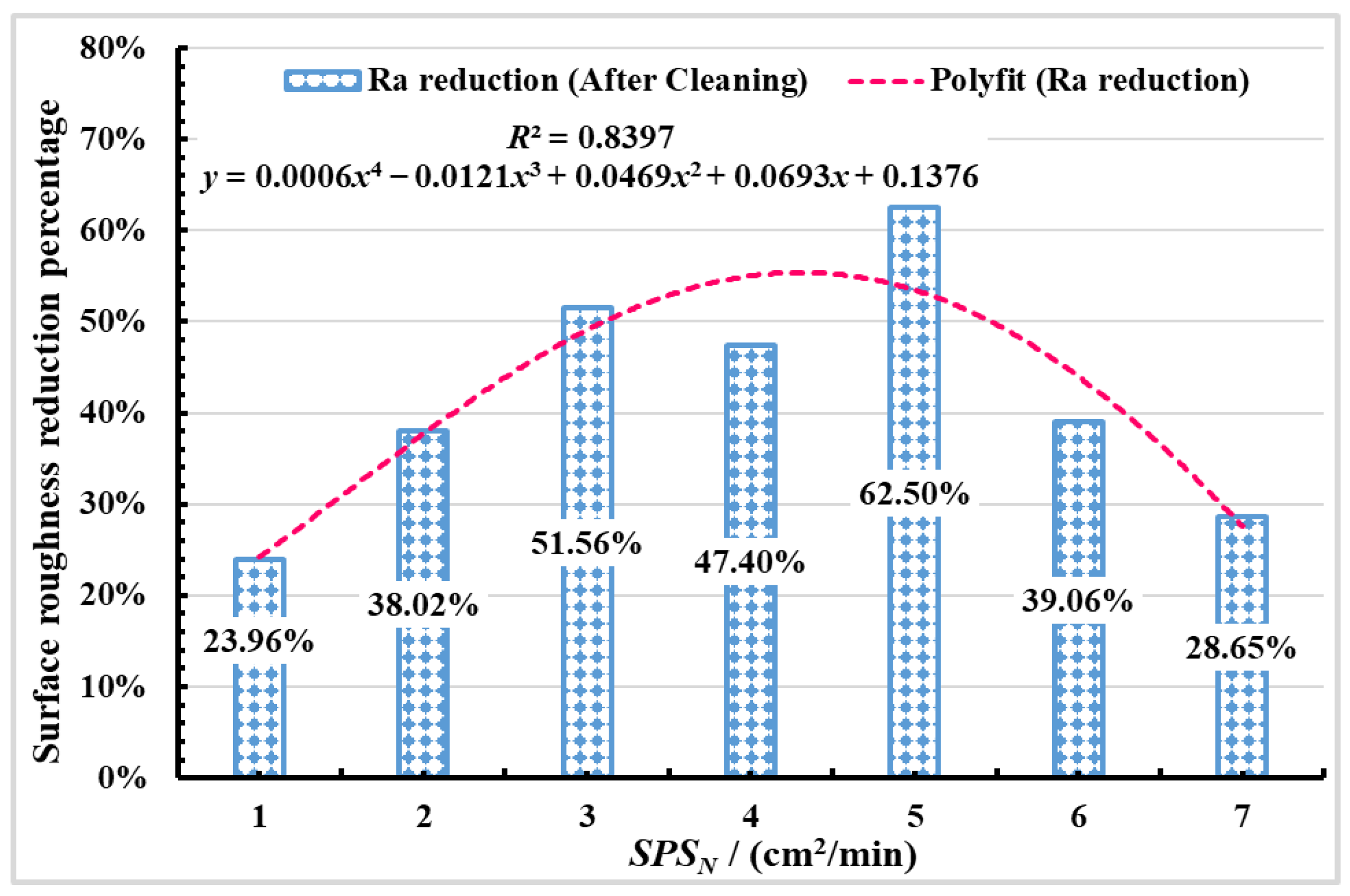

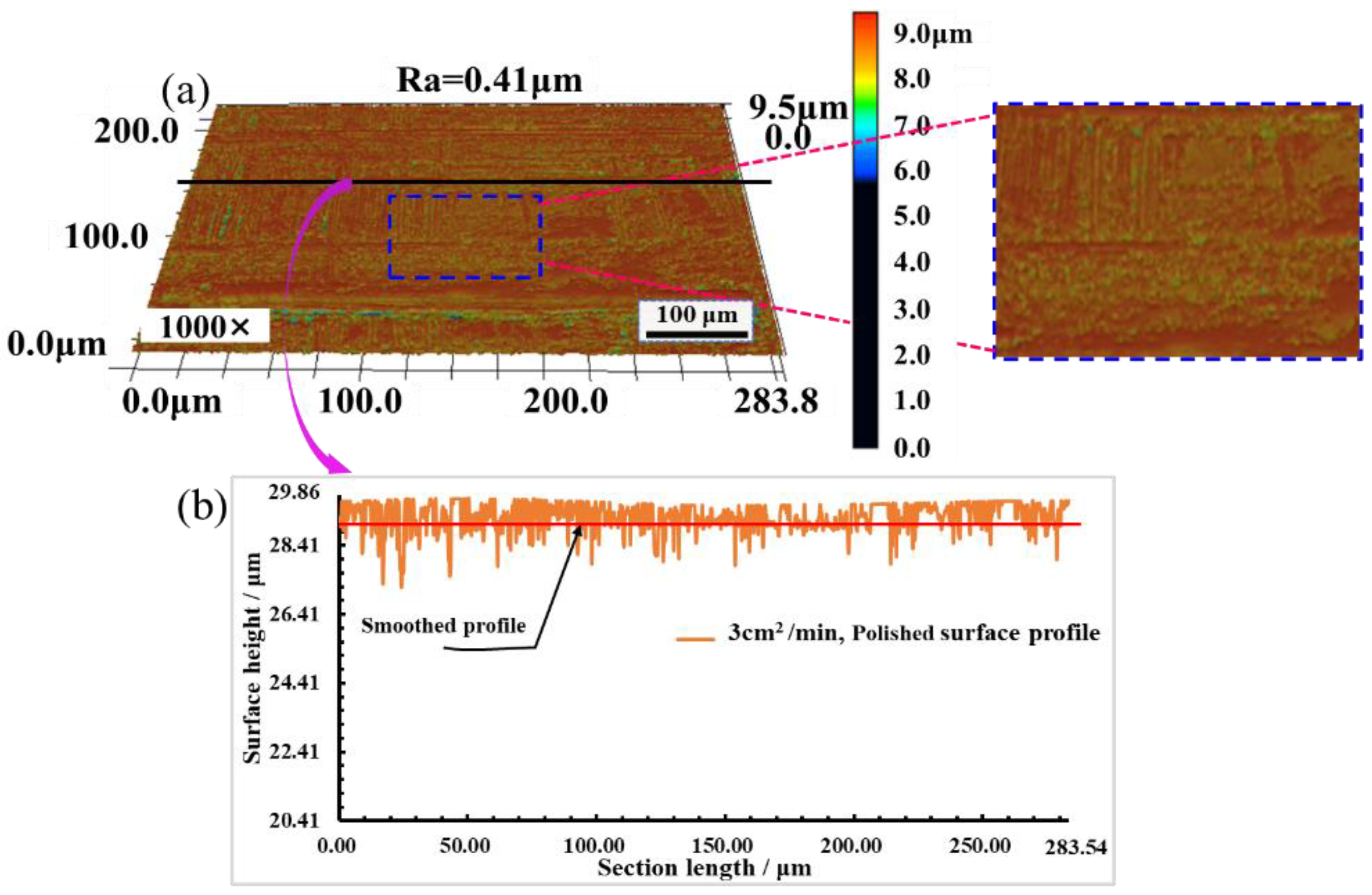

3.1. Effects of Scanning Speed on Polishing Quality

- (1)

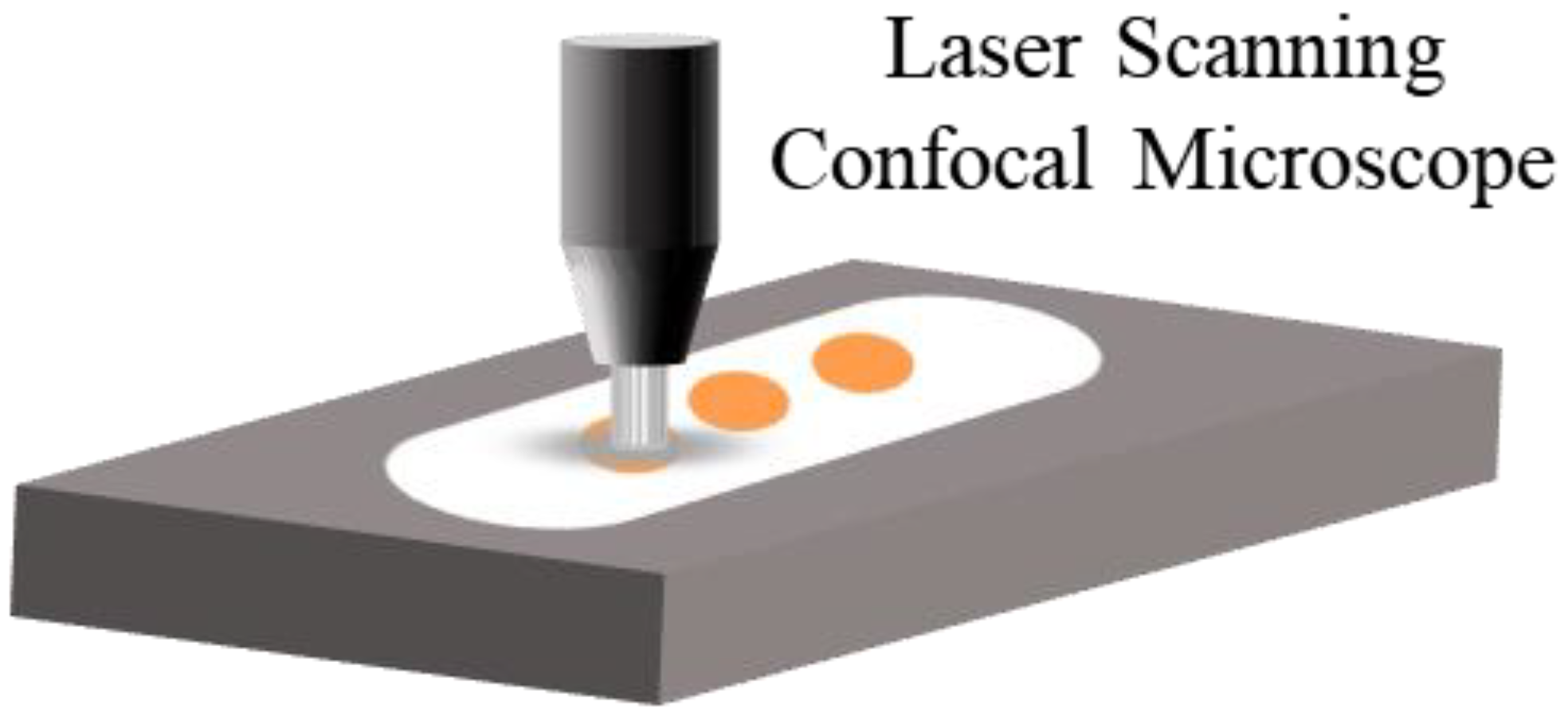

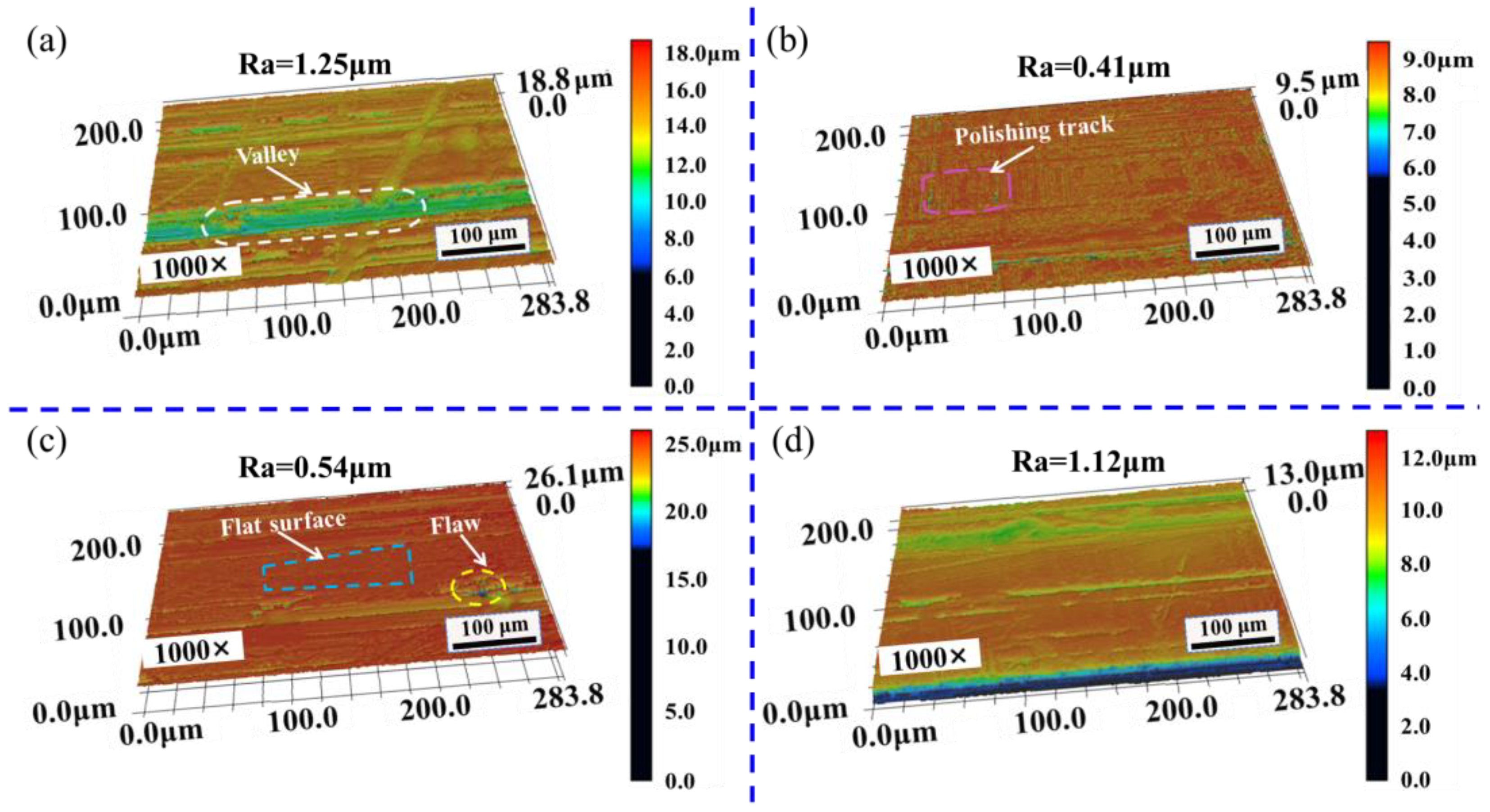

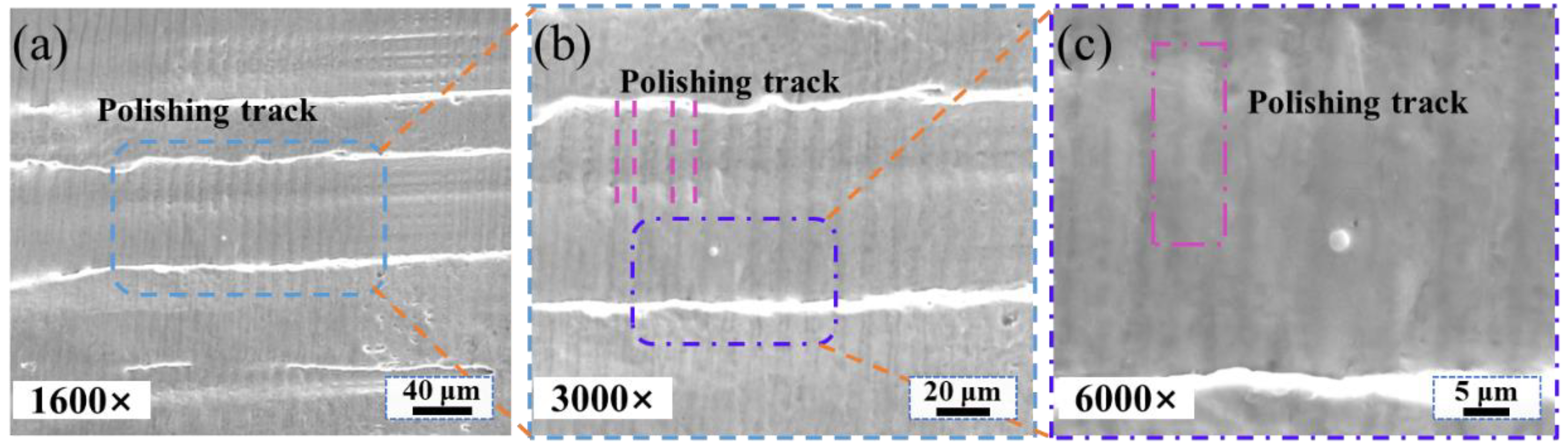

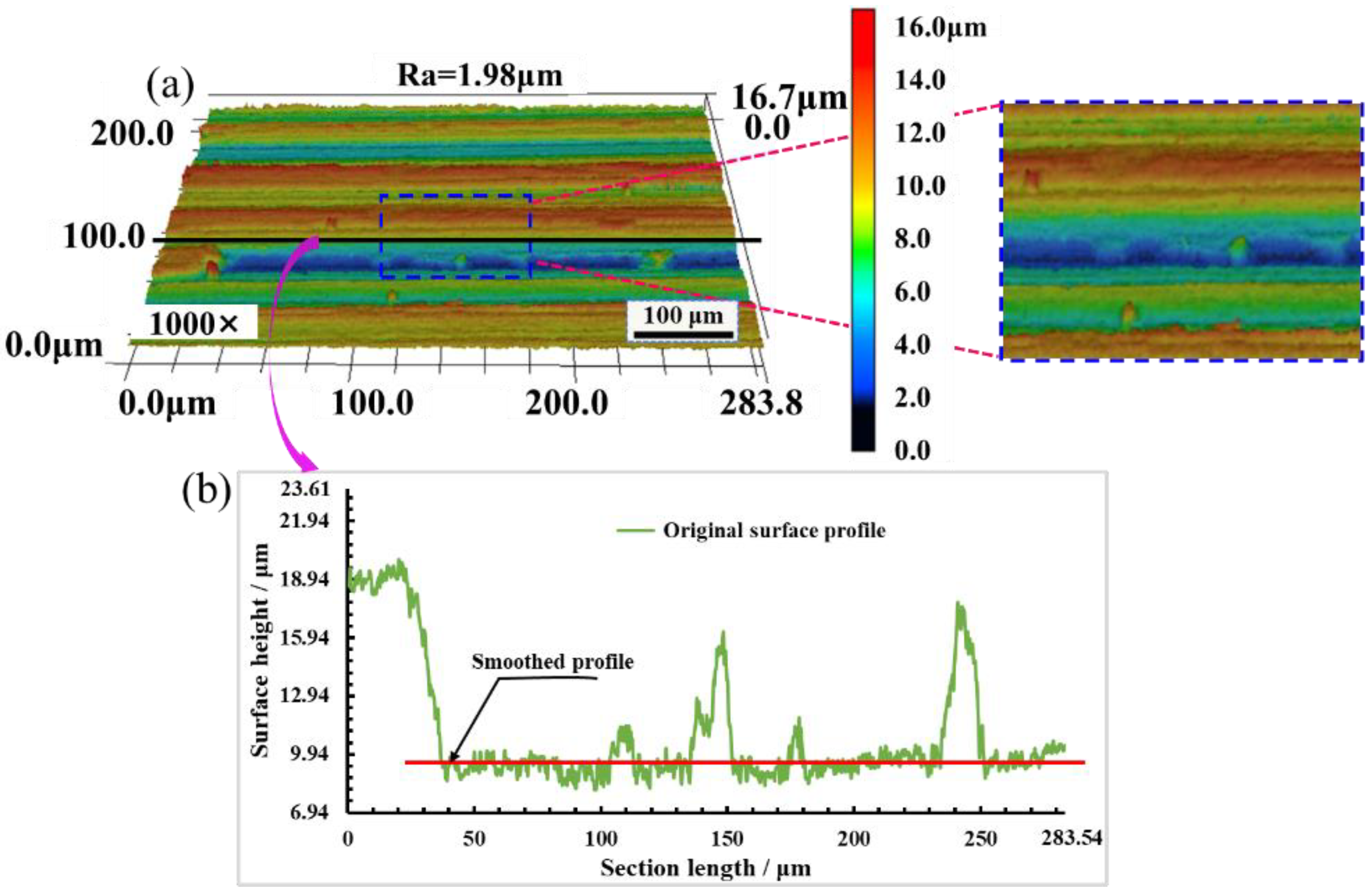

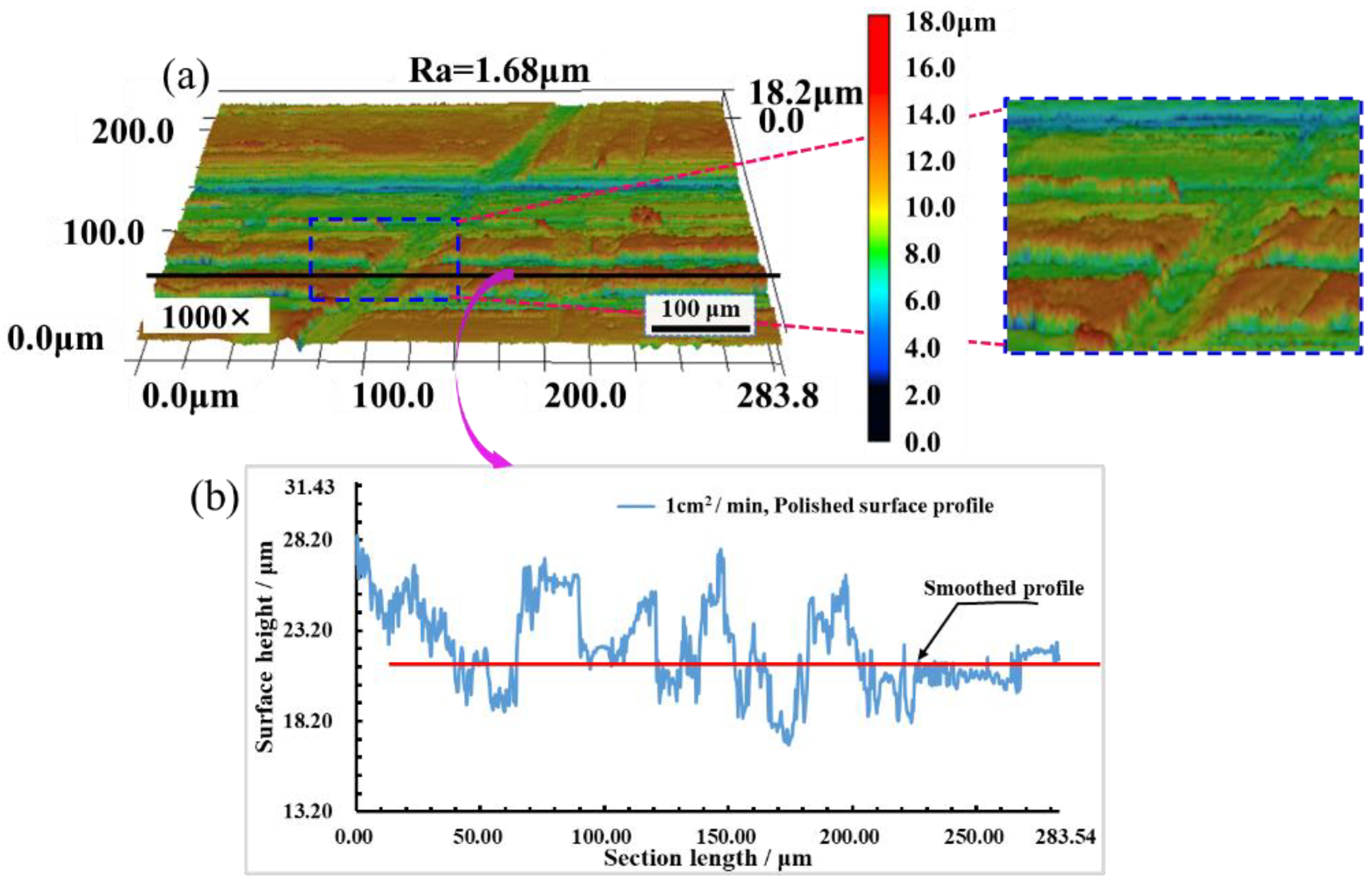

- Analysis of surface roughness and morphology

- (2)

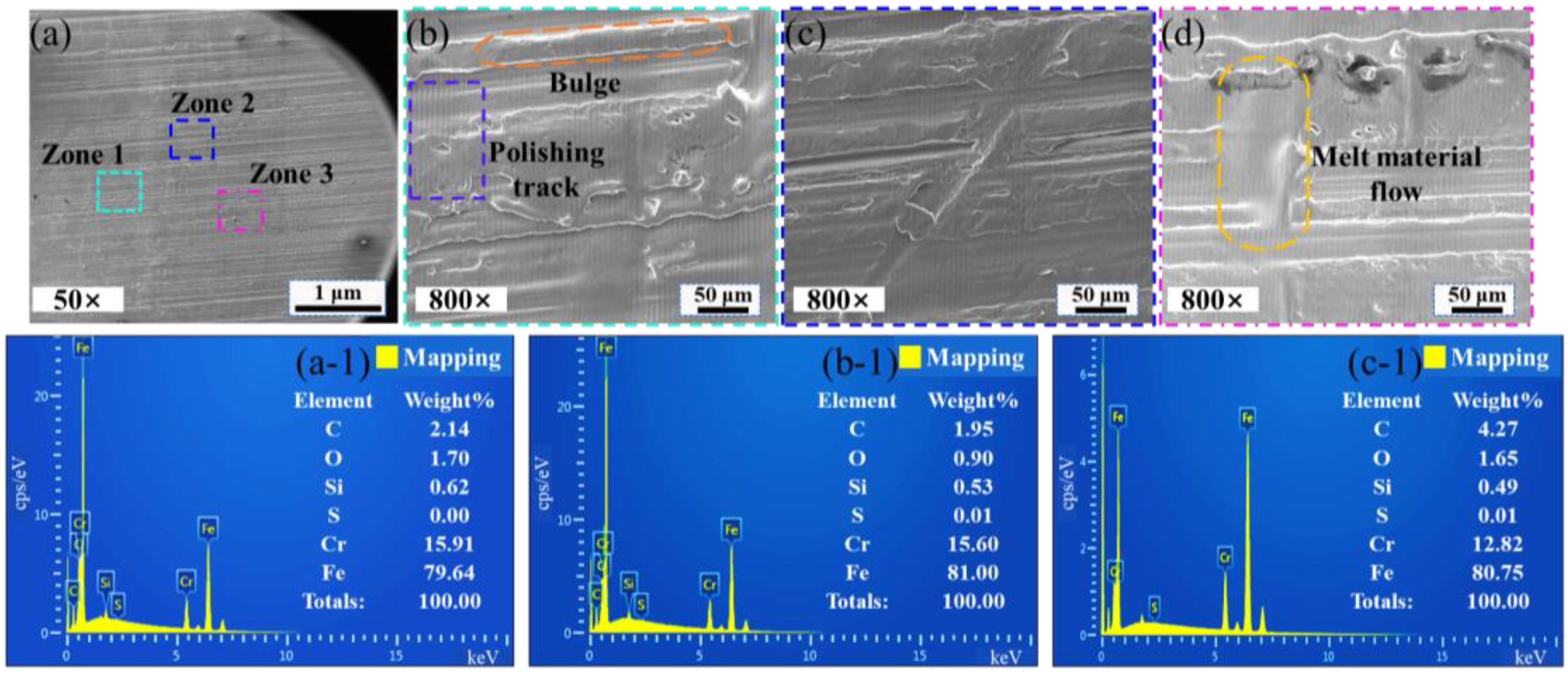

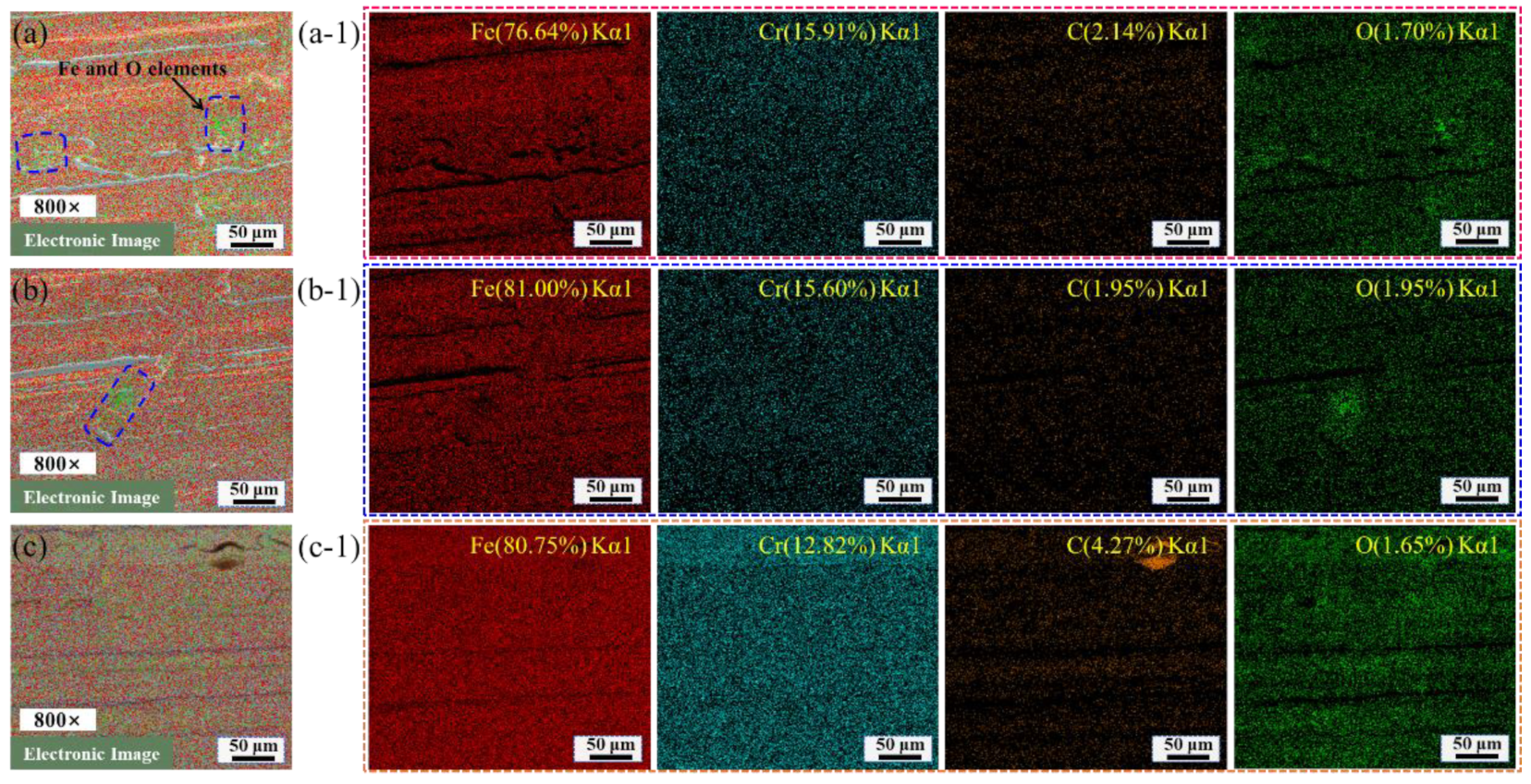

- Analysis of surface micro-morphology and element content

3.2. Analysis of Relationship between Surface Process Speed and Polished Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, M.; Lee, H. Local material removal mechanism considering curvature effect in the polishing process of the small aspherical lens die. J. Mater. Process. Technol. 2001, 116, 298–304. [Google Scholar] [CrossRef]

- Shao, T.; Hua, M.; Tam, H.Y.; Cheung, E.H. An approach to modelling of laser polishing of metals. Surf. Coatings Technol. 2005, 197, 77–84. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Ukar, E.; Arregi, B.; Figueras, J.M.; Soriano, C.; Segui, V.J. Parameter Optimization for Mould and Die Recovering Using Laser Cladding. In Proceedings of the AIP Conference Proceedings 2009, Ann Arbor, MI, USA, 29–30 July 2009; pp. 484–493. [Google Scholar] [CrossRef]

- Temmler, A.; Küpper, M.; Walochnik, M.A.; Lanfermann, A.; Schmickler, T.; Bach, A.; Greifenberg, T.; Oreshkin, O.; Willenborg, E.; Wissenbach, K.; et al. Surface structuring by laser remelting of metals. J. Laser Appl. 2017, 29, 012015. [Google Scholar] [CrossRef]

- Chen, C.; Tsai, H.-L. Fundamental study of the bulge structure generated in laser polishing process. Opt. Lasers Eng. 2018, 107, 54–61. [Google Scholar] [CrossRef]

- Kang, D.; Zou, P.; Wu, H.; Wang, W.; Xu, J. Research on ultrasonic vibration-assisted laser polishing of the 304 stainless steel. J. Manuf. Process. 2021, 62, 403–417. [Google Scholar] [CrossRef]

- Xu, J.; Zou, P.; Wang, W.; Kang, D. Study on the mechanism of surface topography evolution in melting and transition regimes of laser polishing. Opt. Laser Technol. 2021, 139, 106947. [Google Scholar] [CrossRef]

- Bordatchev, E.V.; Hafiz, A.M.K. Advanced measurement and analysis of surface textures produced by micro-machining processes. Meas. Sci. Technol. 2014, 25, 095601. [Google Scholar] [CrossRef]

- Xiao, Y.M.; Bass, M. Thermal stress limitations to laser fire polishing of glasses. Appl. Opt. 1983, 22, 2933–2936. [Google Scholar] [CrossRef]

- Tuckerman, D.; Weisberg, A. Planarization of gold and aluminum thin films using a pulsed laser. IEEE Electron Device Lett. 1986, 7, 1–4. [Google Scholar] [CrossRef]

- Ramos, J.A.; Murphy, J.; Wood, K.; Bourell, D.L.; Beaman, J.J. Surface Roughness Enhancement of Indirect-SLS Metal Parts by laser surface polishing. In Proceedings of the International Solid Freeform Fabrication Symposium 2001, Austin, TX, USA, 6–8 August 2001; pp. 28–38. [Google Scholar]

- Vega, F.; Lupon, N.; Cebrian, J.A.; Laguarta, F. Laser application for optical glass polishing. Opt. Eng. 1998, 37, 272–279. [Google Scholar] [CrossRef]

- Ramos-Grez, J.A.; Bourell, D.L. Reducing surface roughness of metallic freeform-fabricated parts using non-tactile finishing methods. Int. J. Mater. Prod. Technol. 2004, 21, 297–316. [Google Scholar] [CrossRef]

- Chang, C.-S.; Chen, T.-H.; Li, T.-C.; Lin, S.-L.; Liu, S.-H.; Lin, J.-F. Influence of laser beam fluence on surface quality, microstructure, mechanical properties, and tribological results for laser polishing of SKD61 tool steel. J. Mater. Process. Technol. 2016, 229, 22–35. [Google Scholar] [CrossRef]

- Guo, W.; Hua, M.; Tse, P.W.T.; Mok, C.K.A. Process parameters selection for laser polishing DF2 (AISI O1) by Nd:YAG pulsed laser using orthogonal design. Int. J. Adv. Manuf. Technol. 2011, 59, 1009–1023. [Google Scholar] [CrossRef]

- Hafiz, A.M.K.; Bordatchev, E.V.; Tutunea-Fatan, R. Experimental analysis of applicability of a picosecond laser for micro-polishing of micromilled Inconel 718 superalloy. Int. J. Adv. Manuf. Technol. 2013, 70, 1963–1978. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, B.; Wang, J.; Wang, Y.; Sheng, L.; Jiao, J.; Yao, J.; Huang, Y.; Zhang, W. Effects of incidence angle and optimization in femtosecond laser polishing of C/SiC composites. Ceram. Int. 2022, 48, 32290–32304. [Google Scholar] [CrossRef]

- Mikheev, G.M.; Zonov, R.G.; Kaluzhny, D.G. Pulse laser processing of metal thin films on glass substrates. In Proceedings of the Laser-Assisted Micro-and Nanotechnologies, St. Petersburg, Russia, 29 June–3 July 2003; pp. 179–183. [Google Scholar] [CrossRef]

- Jaritngam, P.; Tangwarodomnukun, V.; Qi, H.; Dumkum, C. Surface and subsurface characteristics of laser polished Ti6Al4V titanium alloy. Opt. Laser Technol. 2020, 126, 106102. [Google Scholar] [CrossRef]

- Chow, M.T.C.; Bordatchev, E.V.; Knopf, G.K. Experimental study on the effect of varying focal offset distance on laser micropolished surfaces. Int. J. Adv. Manuf. Technol. 2012, 67, 2607–2617. [Google Scholar] [CrossRef]

- Pfefferkorn, F.E.; Duffie, N.A.; Morrow, J.D.; Wang, Q. Effect of beam diameter on pulsed laser polishing of S7 tool steel. CIRP Ann. 2014, 63, 237–240. [Google Scholar] [CrossRef]

- Chen, Y.-D.; Tsai, W.-J.; Liu, S.-H.; Horng, J.-B. Picosecond laser pulse polishing of ASP23 steel. Opt. Laser Technol. 2018, 107, 180–185. [Google Scholar] [CrossRef]

- Bhaduri, D.; Penchev, P.; Batal, A.; Dimov, S.; Soo, S.L.; Sten, S.; Harrysson, U.; Zhang, Z.; Dong, H. Laser polishing of 3D printed mesoscale components. Appl. Surf. Sci. 2017, 405, 29–46. [Google Scholar] [CrossRef]

- Yung, K.C.; Zhang, S.S.; Duan, L.; Choy, H.S.; Cai, Z.X. Laser polishing of additive manufactured tool steel components using pulsed or continuous-wave lasers. Int. J. Adv. Manuf. Technol. 2019, 105, 425–440. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, H.; Zhao, Z.; Li, K.; Yin, J. Numerical Simulation and Verification of Laser-Polishing Free Surface of S136D Die Steel. Metals 2021, 11, 400. [Google Scholar] [CrossRef]

- Chang, C.-S.; Chung, C.-K.; Lin, J.-F. Surface quality, microstructure, mechanical properties and tribological results of the SKD 61 tool steel with prior heat treatment affected by the deposited energy of continuous wave laser micro-polishing. J. Mater. Process. Technol. 2016, 234, 177–194. [Google Scholar] [CrossRef]

- Folwaczny, M.; Mehl, A.; Haffner, C.; Hickel, R. Polishing and coating of dental ceramic materials with 308 nm XeCl excimer laser radiation. Dent. Mater. 1998, 14, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Nüsser, C.; Sändker, H.; Willenborg, E. Pulsed Laser Micro Polishing of Metals using Dual-beam Technology. Phys. Procedia 2013, 41, 346–355. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, Z.; Zhang, W.; Xiao, H.; Xu, X. Experiment Study of Rapid Laser Polishing of Freeform Steel Surface by Dual-Beam. Coatings 2019, 9, 324. [Google Scholar] [CrossRef]

- Ukar, E.; Lamikiz, A.; de Lacalle, L.L.; del Pozo, D.; Arana, J. Laser polishing of tool steel with CO2 laser and high-power diode laser. Int. J. Mach. Tools Manuf. 2010, 50, 115–125. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, W.; Wu, H.; Xu, Z.; Sheng, L.; Zou, Q.; Zhang, M.; Zhang, W.; Jiao, J. Improving surface quality and superficial microstructure of LDED Inconel 718 superalloy processed by hybrid laser polishing. J. Mater. Process. Technol. 2022, 300, 117428. [Google Scholar] [CrossRef]

- Sassmannshausen, A.; Brenner, A.; Finger, J. Ultrashort pulse laser polishing by continuous surface melting. J. Mater. Process. Technol. 2021, 293, 117058. [Google Scholar] [CrossRef]

- Lamikiz, A.; Sánchez, J.A.; de Lacalle, L.N.L.; del Pozo, D.; Etayo, J. Surface Roughness Improvement Using Laser-Polishing Techniques. Mater. Sci. Forum 2006, 526, 217–222. [Google Scholar] [CrossRef]

- Marinescu, N.I.; Ghiculescu, D.; Anger, C. Correlation between laser finishing technological parameters and materials absorption capacity. Int. J. Mater. Form. 2008, 1, 1359–1362. [Google Scholar] [CrossRef]

- Hafiz, A.M.K.; Bordatchev, E.V.; Tutunea-Fatan, R.O. Influence of overlap between the laser beam tracks on surface quality in laser polishing of AISI H13 tool steel. J. Manuf. Process. 2012, 14, 425–434. [Google Scholar] [CrossRef]

| Chemical Element | C | Si | Mn | P | S | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Mass Fraction (%) | 0.32~0.38 | 0.75~1.05 | ≤1.0 | ≤0.025 | ≤0.001 | 12.5~14.5 | ≥83 |

| Parameter | Value |

|---|---|

| P/W | 1.0 |

| f/kHz | 10 |

| w0/μm | 43.11 |

| Laser fluence/(J/cm2) | 1.71 |

| Number of passes | 1 |

| Scanning pitch/mm | 0.04 |

| Trajectory overlap ratio/% | 53.61 |

| vs/(mm/min) | 250~1750 |

| vs/(mm/min) | 250 | 500 | 750 | 1000 | 1250 | 1500 | 1750 |

|---|---|---|---|---|---|---|---|

| Spot overlap ratio/% | 99.52 | 99.03 | 98.55 | 98.07 | 97.58 | 97.10 | 96.62 |

| vs/(mm/min) | 250 | 500 | 750 | 1000 | 1250 | 1500 | 1750 |

|---|---|---|---|---|---|---|---|

| SPSN/(cm2/min) | 1.00 | 2.00 | 3.00 | 4.00 | 5.00 | 6.00 | 7.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Chen, X.; Zhang, W.; Ruan, D. Effects of Scanning Speed on the Polished Surface Quality of Mold Steel by Dual-Beam Coupling Nanosecond Laser. Materials 2023, 16, 1477. https://doi.org/10.3390/ma16041477

Zhang H, Chen X, Zhang W, Ruan D. Effects of Scanning Speed on the Polished Surface Quality of Mold Steel by Dual-Beam Coupling Nanosecond Laser. Materials. 2023; 16(4):1477. https://doi.org/10.3390/ma16041477

Chicago/Turabian StyleZhang, Huihui, Xiaoxiao Chen, Wenwu Zhang, and Dianbo Ruan. 2023. "Effects of Scanning Speed on the Polished Surface Quality of Mold Steel by Dual-Beam Coupling Nanosecond Laser" Materials 16, no. 4: 1477. https://doi.org/10.3390/ma16041477

APA StyleZhang, H., Chen, X., Zhang, W., & Ruan, D. (2023). Effects of Scanning Speed on the Polished Surface Quality of Mold Steel by Dual-Beam Coupling Nanosecond Laser. Materials, 16(4), 1477. https://doi.org/10.3390/ma16041477