Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances

Abstract

:1. Introduction

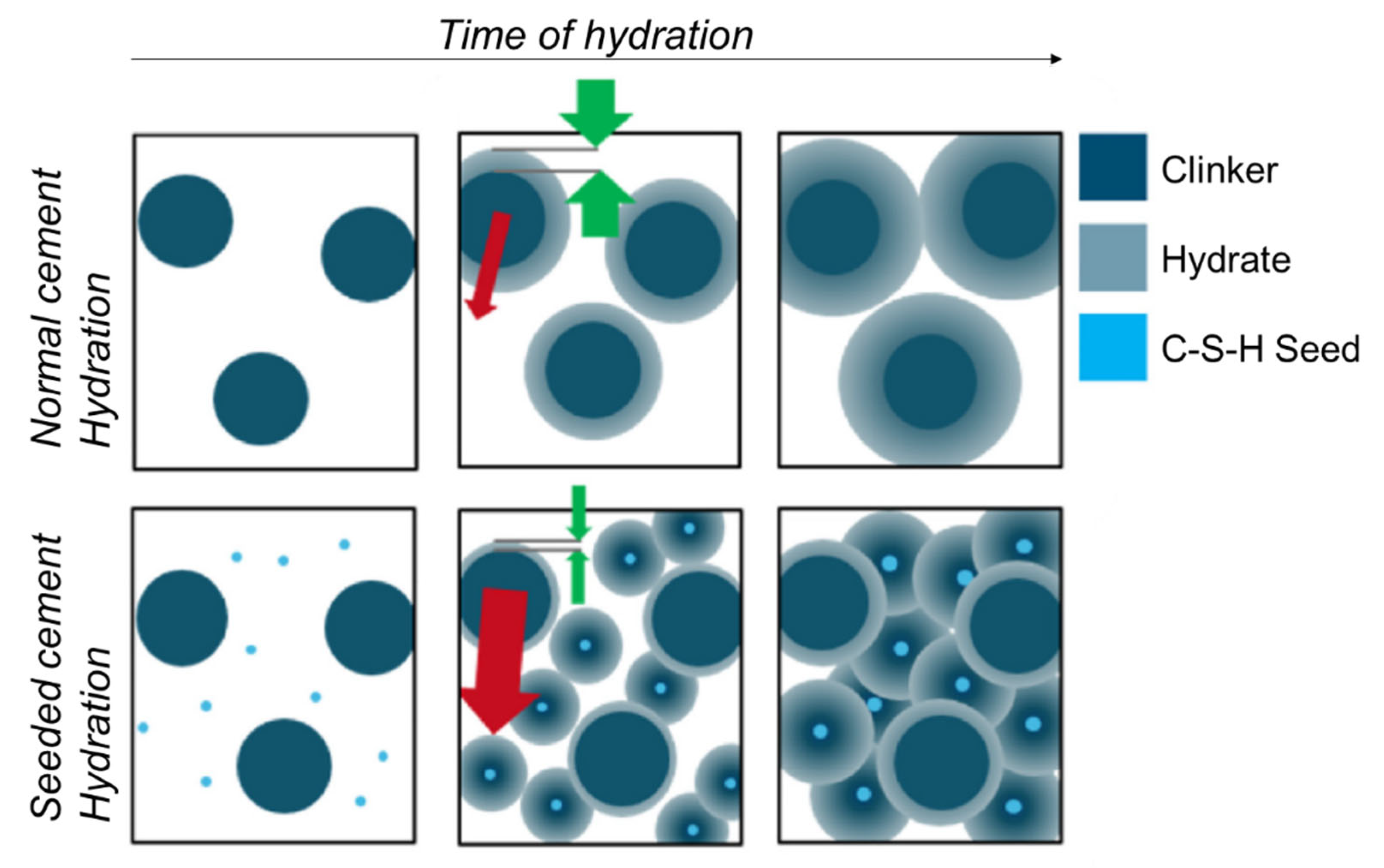

2. Brief Discussion on C-S-H Nucleation Seeding Mechanism as It Was Known before 2020

3. Review Objective and Methodology

4. Data Collection and Categorizing

5. C-S-H Nucleation Seeds

5.1. Commercial C-S-H Nucleation Seed Admixtures

| Product # Name [Solid Content, wt%]/Year | Dosage @ (wt%) | Binder | w/b | Selected Details | Ref |

|---|---|---|---|---|---|

| Master X-Seed 100 * [24]/2016 | 0.04–3.0 0.16–12.3 | CEM I 52.5N | 0.45 | Calorimetry study comparing the hastening performances of 12 accelerator admixtures | [15] |

| Master X-Seed 100 [-]/2018 | - 3.7 | CEM II/A-LL 42.5 | 0.50 | Comparing 3 admixtures for plastic shrinkage cracking mitigation in concretes | [60] |

| Master X-Seed 100 [-]/2018 | - 4.0 | CEM I 32.5R—FA | 0.36, 0.40 | t-dependent (4 h to 28 d) compressive strength improvement for concretes | [61] |

| Master X-Seed 100 [-]/2019 | - 2.0 | CEM V/A | 0.30, 0.50 | t-dependent (12 h to 28 d) compressive strength improvement for mortars with SCMs | [62] |

| Master X-Seed 100 [-]/2020 | - 0.5–5.0 | PC G-type OWC | 0.44 | Acceleration studies for pastes (calorimetry and UPV) at 25 °C, 40 °C, and 60 °C | [63] |

| Master X-Seed 100 [-]/2020 | - 4.0 | CEM I 32.5R—FA | 0.30 | t-dependent (8 h to 28 d) compressive strength improvement for pastes with FA | [64] |

| Master X-Seed 100 [-]/2020 | - 2.0 | CEM I 42.5R | 0.29 | t-dependent (6 h to 28 d) compressive strength increase for concretes | [65] |

| Master X-Seed 100 [-]/2021 | - 1.2 | PC M 400-D0 | 0.26 | t-dependent (2 h to 14 h) strength evolution for concretes | [66] |

| Master X-Seed 100 [-]/2021 | - 4.0 | CEM I 32.5R—FA | 0.26 | Mechanical strength values from [64] plus new rheological and SEM data | [67] |

| Master X-Seed 55 [-]/2021 | 0.07 1.0 | PC A3000—MK | 0.40 | PC with low grade MK. Compressive strength improvement for pastes, 1–28 d | [40] |

| Master X-Seed 120 [0.14]“/2020 | - 1.0–3.0 | CEM I 42.5N—CC | 0.50 | Accelerators: nitrate-free C-S-H seeds and micro-limestone. Complete calorimetric study | [68] |

| Master X-Seed 1500 [23] =/2021 | 0.12–0.35 0.5–1.5 | PC—FA | ≈0.26 | Acceleration of high-volume FA concretes, 1–14 d. Environmental impact calculations | [69] |

| Master X-Seed 1500 [23] =/2021 | 0.12–0.35 0.5–1.5 | PC—FA | ≈0.25 | Strength data at 14 d in [69] are replaced by values at 28 d. Paste microstructures studied in detail | [70] |

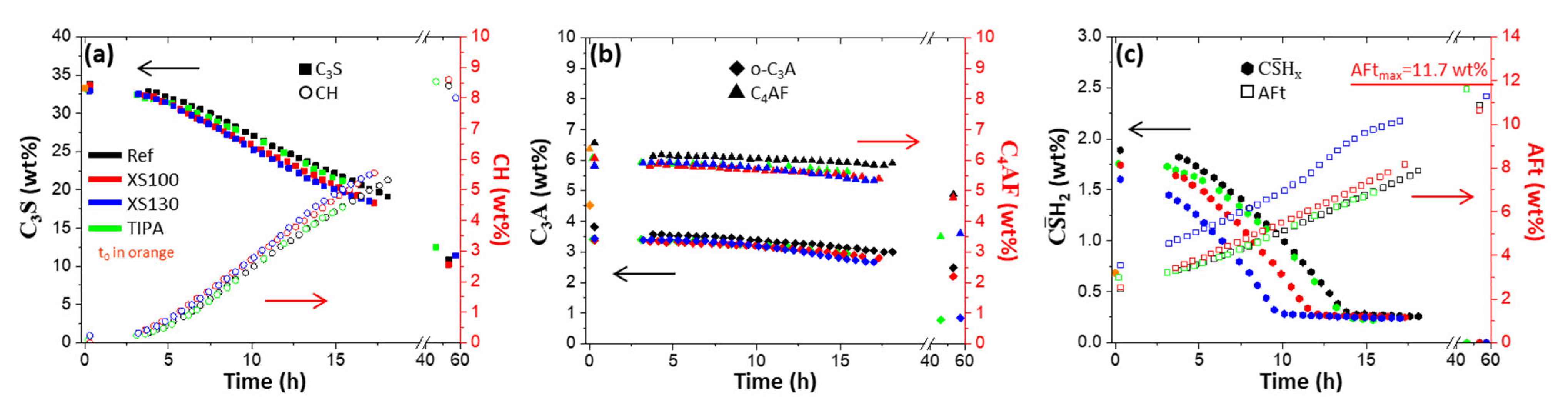

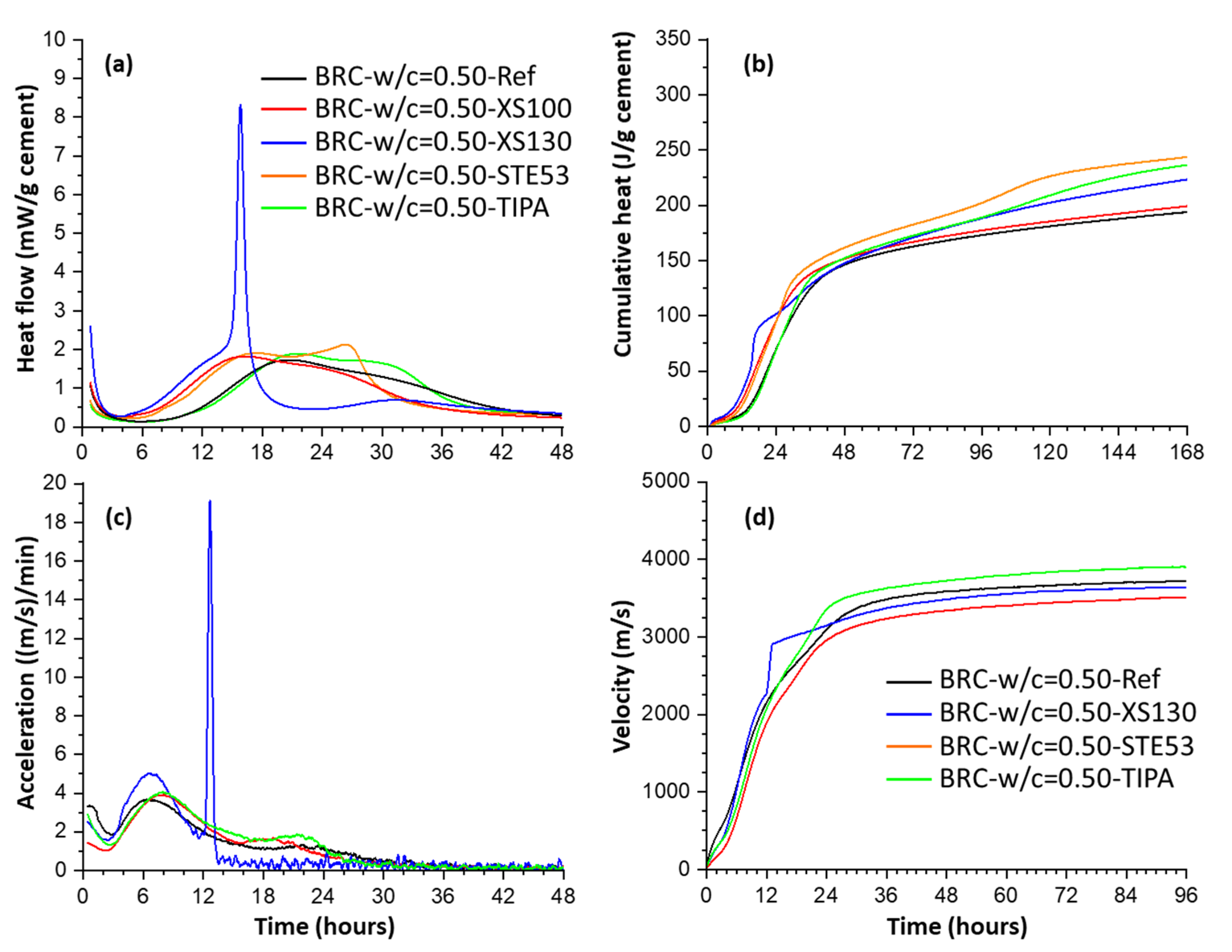

| Master X-Seed 130 [≈28]/2022 | 0.60 2.0 | CEM I 42.5R & BRC | 0.50 | In situ SXRPD study also using XS100 and TIPA as reference admixtures. Comparison of calorimetries for pastes with UPV for mortars | [71] |

| Master X-Seed 130 [24]/2022 | 0.48 2.0 | CEM I 52.5R | 0.35 | GBFS as fine aggregate, substitution 25–100%. LT curing. Frost and acid attack resistances | [72] |

| Master X-Seed 130 [24]/2022 | 0.12–1.44 0.5–6.0 | CEM I 52.5R | 0.23, 0.27 | LT curing. Antifreeze admixture. Compressive strengths. Some durability data | [73] |

| Master X-Seed 130 [24]/2022 | 0.48, 1.2 2.0, 5.0 | CEM I 52.5R—GGBFS | 0.27 | T = 0 °C curing. Compressive strength and frost resistance improvements by C-S-H seeding | [74] |

| Master X-Seed 130 [23]/2022 | 2.3 10 | CEM I 52.5R—GGBFS | 0.42 | NaNO3 as antifreeze admixture. Curing at −15 °C. UPV data. Compressive strength data | [75] |

| Master X-Seed 130 [-]/2022 | - 1.5, 2.0 | CEM I 52.5R—SF | 0.21 | Comparison of four accelerators for 3D printed concretes | [76] |

| Master X-Seed 130 [≈28]/2023 | - 2.0 | BRC-LC3 | 0.40 | Improvement of mechanical performances in mortars. RQPA, TA, and MIP data for pastes | [77] |

| Master X-Seed STE53 [≈28]/2022 | 0.60 2.0 | CEM I 42.5R & BRC | 0.40, 0.50 | RQPA, TA and MIP data at 1 d, 7 d, and 28 d, for pastes, respectively. Compressive strengths for mortars. It also contains data for XS130 | [78] |

| HyCon® S $ 3200 F [100]/2020 | 2.0 2.0 | CEM I 52.5N | 0.30, 0.35 | Impact of seeding in autogenous shrinkage. Use of SAP. MIP and X-ray microtomography | [79] |

| HyCon® S $ 7042 F [100]/2022 | 1.5, 3.0 1.5, 3.0 | CEM I 52.5R—GGBFS | 0.40, 0.50 | Strength enhancement up to 180 d. Degree of hydration are reported. RQPA and MIP data | [80] |

| C-S-H from Sunrise % [99.8]/2020 | 0.5-2.0 0.5–2.0 | P.I 42.5 | 0.50 | Improving setting and early strengths for pastes and mortars containing EVA copolymer | [81] |

| C-S-H from Sunrise % [-]/2021 | - 0.5, 1.0 | P·I 42.5—FA | 0.40 | Synergic action of C-S-H seeding and TEA addition in a FA-containing blend | [82] |

| C-S-H from Sunrise % [-]/2021 | - 1.0 | PC G-type OWC—FA | 0.44 | Curing at 10 °C. Several types of additions | [83] |

| C-S-H from Sunrise % [-]/2021 | - 0.5–2.0 | P·II 42.5 | 0.40 | C-S-H, TIPA and NaCl additions. Chloride binding capacity measurements | [84] |

| C-S-H from Sunrise % [-]/2021 | - 0.5-2.0 | P·I 42.5 | 0.50 | Combined use of C-S-H seeding and sodium sulphate addition for hydration acceleration | [85] |

| C-S-H from Sunrise % [-]/2021 | - 0.5–2.0 | P·I 42.5 | 0.50 | Combined use of EVA, TEA, and C-S-H seeding in PC hydration | [86] |

| C-S-H from Sunrise % [99.8]/2020 | 0.5–2.0 0.5–2.0 | P·I 42.5 | 0.50 | Study of the synergistic effect of TIPA and C-S-H seeding on PC hydration | [87] |

| C-S-H from Sunrise % [20]/2021 | 0.8–1.2 4.0–6.0 | Four P·I 42.5 cements | 0.42–0.48 | LT curing, 5–20 °C, of shotcrete also containing alkali free liquid accelerator | [88] |

| Mapefast Ultra & [23]/2022 | - | - | - | Cu doped C-S-H seeds studied by SAXS and Total X-ray scattering. No works in mortars yet | [89] |

| Nano C-S-H ? [20]/2021 | 0.25–0.75 1.25–3.75 | PC 42.5 | 0.36 | Autogenous shrinkage. Compressive strength data for pastes. MIP data | [90] |

5.2. Laboratory Synthesis of C-S-H Nucleation Seeds

5.2.1. Stabilised C-S-H Seed Composites

5.2.2. Stabilised Metal-Substituted C-S-H Seed Composites

5.2.3. C-S-H Coated Nanomaterial Seed Composites

5.3. Crystalline Calcium Silicate Hydrate Phases as Nucleation Seeds

6. Activation of Cement Hydration by C-S-H Nucleation Seeding

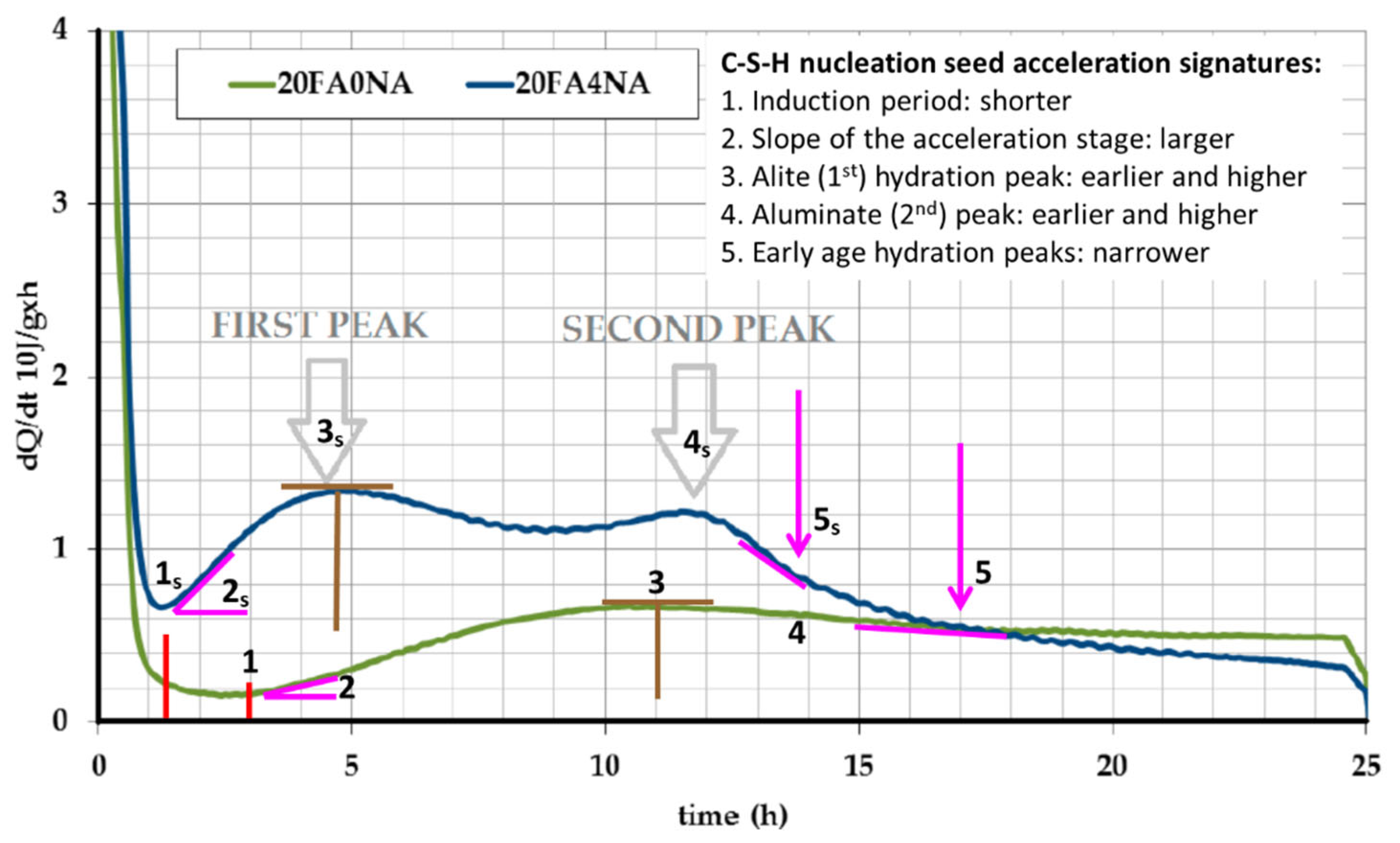

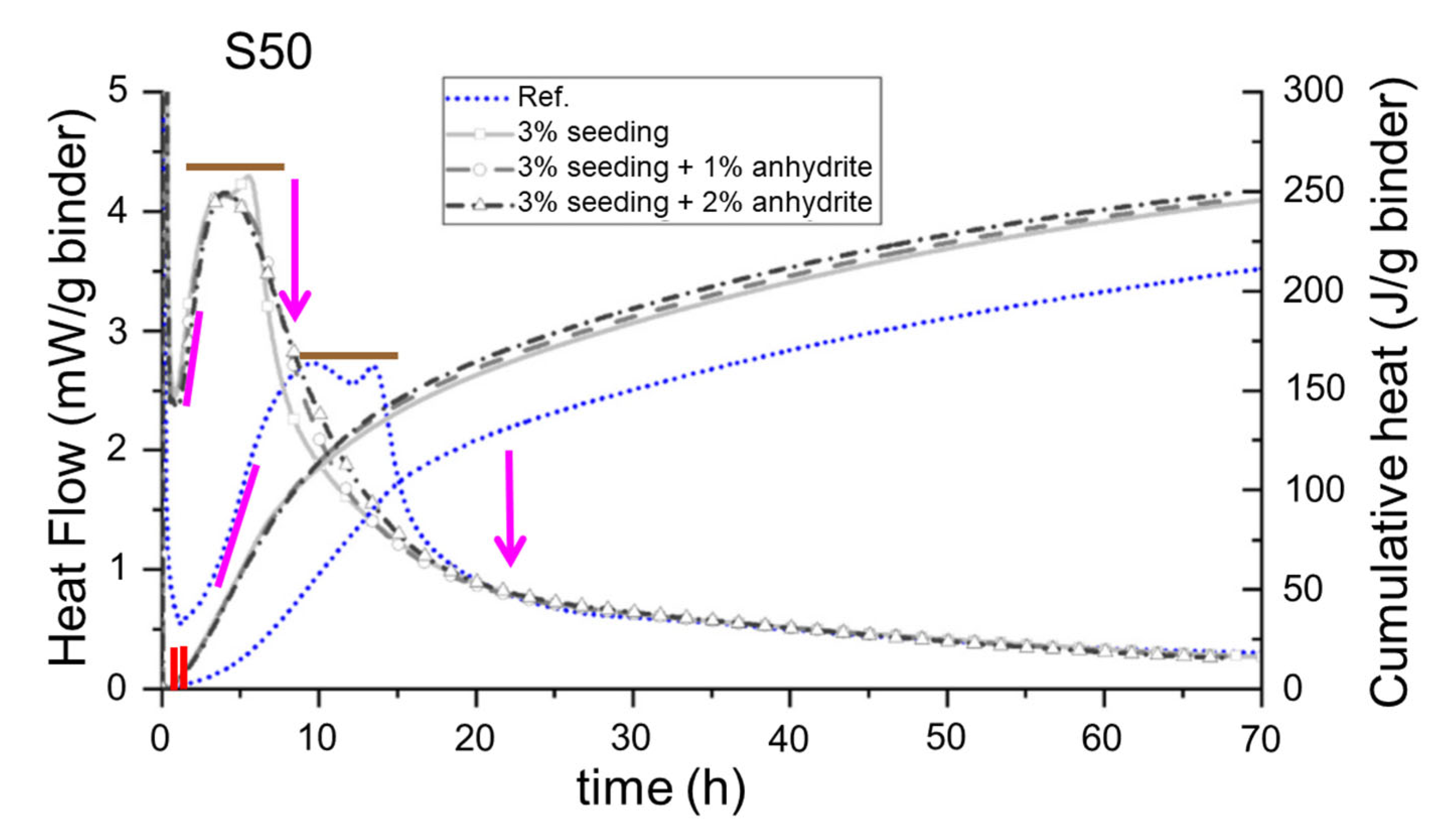

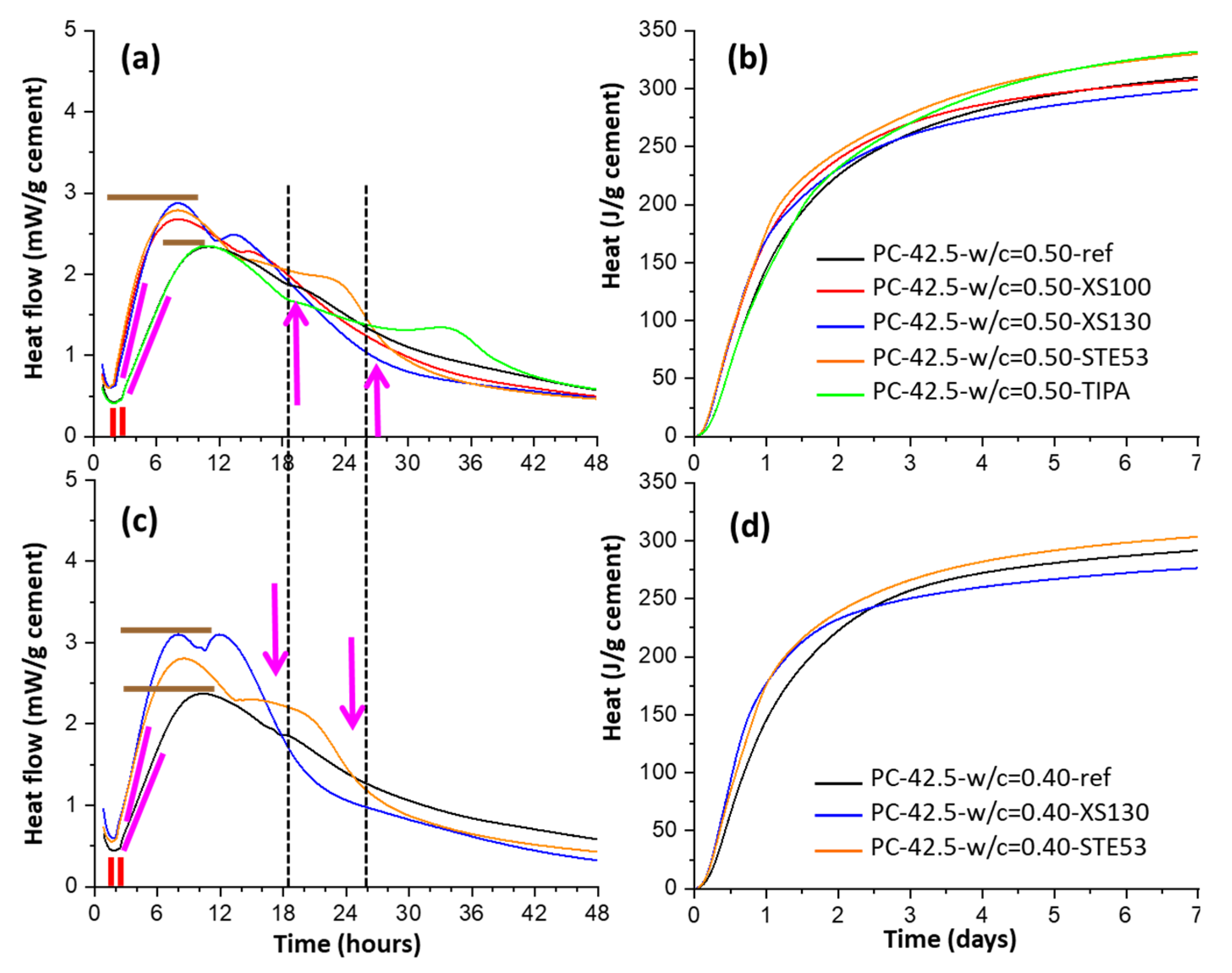

6.1. Acceleration of Cement Hydration at Early Ages

6.2. Improving Mechanical Strength Performances at Early and Later Ages

| Admixture $ | Sample | Dosage # | Binder | w/b | Compr. Strengths Variation (%) @ | Ref | ||

|---|---|---|---|---|---|---|---|---|

| (wt%) | 12 h | 1 d | 28 d | |||||

| XS100 | concretes | 0.88 | CEM I 32.5R | 0.40 | +70 | +9 | +14 | [61] |

| XS100 | concretes | 0.44 | 80%CEM I 32.5R—20%FA | 0.40 | +100 | +18 | +3 | [61] |

| XS100 | concretes | 0.44 | CEM V/A with MS | 0.30 | +71 | +36 | +3 | [62] |

| XS100 | pastes | 0.88 | 80%CEM I 32.5R—20%FA | 0.30 | +173 | +72 | +2 | [64] |

| XS100 | concretes | 0.44 | CEM I 42.5R | 0.29 | +26 | +21 | +12 | [65] |

| XS100 | mortars | 0.44 | aBRC 42.5 | 0.50 | - | −2 | +2 | [71] |

| XS55 | pastes | 0.22 | PC A3000 | 0.40 | - | +23 | +15 | [40] |

| XS55 | pastes | 0.22 | 80%PC A3000—20%MK | 0.40 | - | +34 | +8 | [40] |

| XS55 | pastes | 0.22 | 60%PC A3000—40%MK | 0.40 | - | +28 | +7 | [40] |

| XS120 | mortars | 0.42 | 80%CEM I 42.5N—20%CC | 0.50 | - | ≈+40 | ≈0 | [68] |

| XS1500 | concretes | 0.23/0.35 | 40%PC—60%FA | ≈0.25 | - | ≈+19/+8 | ≈+9/−3 | [70] |

| XS1500 | concretes | 0.23/0.35 | 30%PC—70%FA | ≈0.25 | - | ≈−6/+8 | ≈+4/−7 | [70] |

| XS130 | mortars | 0.56 | CEM I 42.5R | 0.50 | - | +57 | +2 | [71] |

| XS130 | mortars | 0.56 | aBRC 42.5 | 0.50 | - | +29 | +17 | [71] |

| XS130 | mortars | 0.56 | BRC 42.5 | 0.50 | - | +13 | +13 | [71] |

| XS130 | mortars | 0.56 | aBRC-LC3-32 | 0.40 | - | +292d | +19 | [77] |

| XS130 | mortars | 0.56 | aBRC-LC3-48 | 0.40 | - | +232d | +18 | [77] |

| XS130 | mortars | 0.56 | CEM I 42.5R | 0.40 | - | +42 | 0 | [78] |

| XS130 | mortars | 0.56 | aBRC 42.5 | 0.40 | - | +21 | −11 | [78] |

| STE53 | mortars | 0.56 | CEM I 42.5R | 0.50 | - | +47 | +17 | [78] |

| STE53 | mortars | 0.56 | CEM I 42.5R | 0.40 | - | +42 | +9 | [78] |

| STE53 | mortars | 0.56 | aBRC 42.5 | 0.50 | - | +41 | +7 | [78] |

| STE53 | mortars | 0.56 | aBRC 42.5 | 0.40 | - | 0 | +2 | [78] |

| HyCon | mortars | 2.0 | CEM I 52.5N | 0.30 | - | 0 | ≈−8 | [79] |

| HyCon | mortars | 2.0 | CEM I 52.5N | 0.35 | - | ≈+19 | 0 | [79] |

| HyCon | mortars | 1.5/3.0 | 50%CEM I—50%GGBFS | 0.50 | - | +110/+159 | −2/+5 | [80] |

| HyCon | mortars | 1.5/3.0 | 25%CEM I—75%GGBFS | 0.50 | - | +179/+297 | +7/+29 | [80] |

| HyCon | mortars | 1.5/3.0 | 05%CEM I—95%GGBFS | 0.50 | - | +106/+221 | +50/+82 | [80] |

| VIVID | mortars | 0.5/1.0 | P·I 42.5 & 2% EVA | 0.50 | - | +31/+413d | +1/+2 | [81] |

| VIVID | mortars | 1.0/2.0 | P·I 42.5 & 6% EVA | 0.50 | - | +49/+1263d | +11/+60 | [81] |

| VIVID | pastes | 0.21/0.42 | P·II 42.5 & 0.05% TIPA | 0.40 | - | +8/+127d | +12/+15 | [84] |

| VIVID | pastes | 0.21/0.42 | P·II 42.5 & 0.10% TIPA | 0.40 | - | +8/+127d | +6/+13 | [84] |

| VIVID | mortars | 0.21/0.42 | P·I 42.5 | 0.50 | - | +21/+533d | +9/+20 | [85] |

| VIVID | mortars | 0.21/0.42 | P·I 42.5 & 1% Na2SO4 | 0.50 | - | +36/+553d | +10/+21 | [85] |

| VIVID | mortars | 1.0/2.0 | P·I 42.5 & 0.05% TIPA | 0.50 | +93/+159 | +20/+68 | +3/+5 | [87] |

| VIVID | mortars | 1.0/2.0 | P·I 42.5 & 0.10% TIPA | 0.50 | +81/+150 | +17/+60 | +4/+2 | [87] |

6.3. Improving Durability Performances of Binders at Later Ages

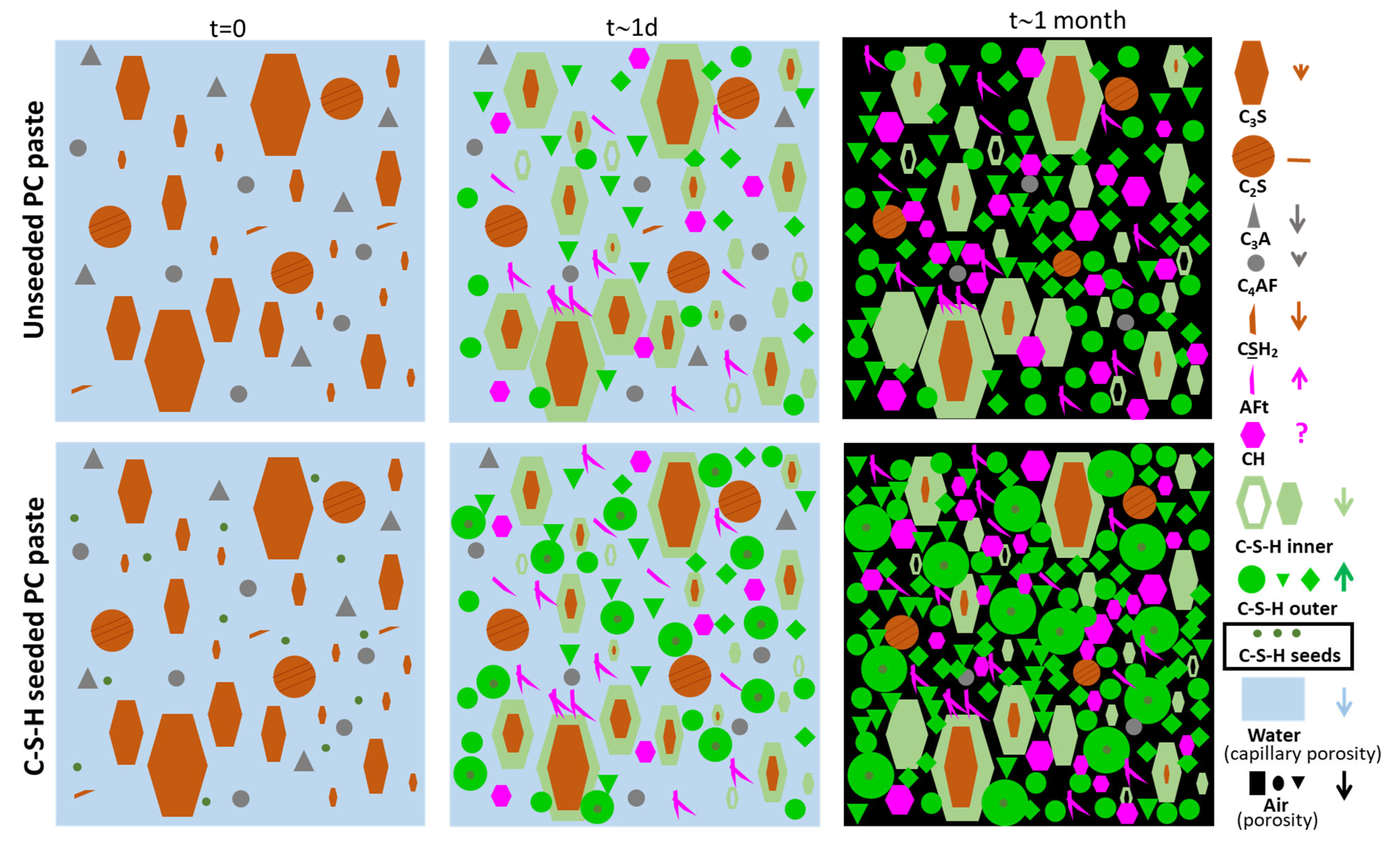

7. Current Understanding of C-S-H Nucleation Seeding in Cements

8. Conclusions and Future Research Need

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| aBRC | activated Belite Rich Cement |

| BRC | Belite Rich Cement |

| bwb | by weight of binder |

| bwc | by weight of cement |

| CC | Calcined Clay |

| C-S-H | (non-stoichiometric) Calcium Silicate Hydrate (gel) |

| DEIPA | Diethanolisopropanolamine |

| EDITA | Ethyldiisopropylamine |

| EVA | Ethylene Vinyl Acetate |

| EO | Ethylene Oxyde |

| FA | Fly Ash |

| GGBFS | Ground Granulated Blast Furnace Slag |

| HPEG | Methallyl Ether |

| IPEG | Isoprenol Ether |

| LC3 | Limestone Calcined Clay Cements |

| LT | Low Temperature |

| LXRPD | Laboratory X-ray powder diffraction |

| MPEG | Methacrylate Ester |

| MIP | Mercury Intrusion Porosimetry |

| MK | Metakaolin |

| MS | Micro-Silica |

| OWC | Oil Well Cement |

| PC | Portland Cement |

| PCE | Polycarboxylate Ether |

| PSE | Polysulfonate Ether |

| RQPA | Rietveld Quantitative Phase Analysis |

| SAP | Superabsorbent Polymers |

| SAXS | Small Angle X-ray Scattering |

| SCMs | Supplementary Cementitious Materials |

| SEM | Scanning Electron Microscopy |

| STE53 | Master X-Seed STE 53 |

| SXRPD | Synchrotron X-ray Powder Diffraction |

| TA | Thermal Analysis |

| TEA | Triethanolamine |

| THEED | N,N,N′,N′-tetrakis-(2-hydroxyethyl)-ethylenediamine |

| THPED | N,N,N′,N′-tetrakis-(2-hydroxypropyl)-ethylenediamine |

| TIPA | Tri-isopropanolamine |

| UPV | Ultrasonic Pulse Velocity |

| w/c | water to cement mass ratio |

| w/b | water to binder mass ratio |

| XS100 | Master X-Seed 100 |

| XS130 | Master X-Seed 130 |

References

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E. Eco-efficient cements: Potential, economically viable solutions for a low-CO2, cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Flatt, R.J.; Roussel, N.; Cheeseman, C.R. Concrete: An eco material that needs to be improved. J. Eur. Ceram. Soc. 2012, 32, 2787–2798. [Google Scholar] [CrossRef]

- Boscaro, F.; Palacios, M.; Flatt, R.J. Formulation of low clinker blended cements and concrete with enhanced fresh and hardened properties. Cem. Concr. Res. 2021, 150, 106605. [Google Scholar] [CrossRef]

- Cuesta, A.; Ayuela, A.; Aranda, M.A.G. Belite cements and their activation. Cem. Concr. Res. 2021, 140, 106319. [Google Scholar] [CrossRef]

- Aiticin, P.C. Accelerators. In Science and Technology of Concrete Admixtures; Aiticin, P.C., Flatt, R.J., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 405–413. ISBN 9780081006962. [Google Scholar]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, C.; Ma, Y.; Xiao, Y.; Liu, Y. Accelerators for shotcrete—Chemical composition and their effects on hydration, microstructure and properties of cement-based materials. Constr. Build. Mater. 2021, 281, 122557. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, L.; Liu, J.; Ma, Y.; Liu, Y.; Xiao, Z.; Shi, C. Accelerators for normal concrete: A critical review on hydration, microstructure and properties of cement-based materials. Cem. Concr. Compos. 2022, 134, 104762. [Google Scholar] [CrossRef]

- Dorn, T.; Blask, O.; Stephan, D. Acceleration of cement hydration—A review of the working mechanisms, effects on setting time, and compressive strength development of accelerating admixtures. Constr. Build. Mater. 2022, 323, 126554. [Google Scholar] [CrossRef]

- Bentz, D.P.; Zunino, F.; Lootens, D. Chemical vs. Physical Acceleration of Cement Hydration. Concr. Int. 2016, 38, 37–44. [Google Scholar]

- Bost, P.; Regnier, M.; Horgnies, M. Comparison of the accelerating effect of various additions on the early hydration of Portland cement. Constr. Build. Mater. 2016, 113, 290–296. [Google Scholar] [CrossRef]

- Gonzalez-Panicello, L.; Garcia-Lodeiro, I.; Puertas, F.; Palacios, M. Influence of Accelerating Admixtures on the Reactivity of Synthetic Aluminosilicate Glasses. Materials 2022, 15, 818. [Google Scholar] [CrossRef]

- Plank, J.; Ilg, M. The Role of Chemical Admixtures in the Formulation of Modern Advanced Concrete. In 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures Towards Smart Concrete; RILEM Bookseries; Boshoff, W., Ed.; Springer: Berlin/Heidelberg, Germany, 2019; Volume 24, pp. 143–157. [Google Scholar]

- Xu, Z.; Li, W.; Sun, J.; Hu, Y.; Xu, K.; Ma, S.; Shen, X. Research on cement hydration and hardening with different alkanolamines. Constr. Build. Mater. 2017, 141, 296–306. [Google Scholar] [CrossRef]

- Hirsch, T.; Lu, Z.; Stephan, D. Effect of different sulphate carriers on Portland cement hydration in the presence of triethanolamine. Constr. Build. Mater. 2021, 294, 123528. [Google Scholar] [CrossRef]

- Huang, H.; Li, X.; Avet, F.; Hanpongpun, W.; Scrivener, K. Strength-promoting mechanism of alkanolamines on limestone-calcined clay cement and the role of sulfate. Cem. Concr. Res. 2021, 147, 106527. [Google Scholar] [CrossRef]

- He, Y.; Liu, S.; Zhang, X.; Liu, W.; Liao, G.; Xu, M. Influence of triethanolamine on mechanical strength and hydration performance of blended cement containing fly ash, limestone and slag. J. Build. Eng. 2021, 44, 102879. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, L.; Hu, X.; Liu, Y.; Shi, C. Effect of diethanolisopropanolamine and ethyldiisopropylamine on hydration and strength development of Portland cement. Cem. Concr. Res. 2022, 162, 106999. [Google Scholar] [CrossRef]

- Thomas, J.J.; Jennings, H.M.; Chen, J.J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. C 2009, 113, 4327–4334. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh, R.; Raki, L.; Makar, J.M.; Beaudoin, J.J.; Moudrakovski, I. Hydration of tricalcium silicate in the presence of synthetic calcium-silicate-hydrate. J. Mater. Chem. 2009, 19, 7937–7946. [Google Scholar] [CrossRef]

- John, E.; Matschei, T.; Stephan, D. Nucleation seeding with calcium silicate hydrate—A review. Cem. Concr. Res. 2018, 113, 74–85. [Google Scholar] [CrossRef]

- Artioli, G.; Ferrari, G.; Dalconi, M.C.; Valentini, L. Nanoseeds as modifiers of the cement hydration kinetics. In Smart Nanoconcretes and Cement-Based Materials: Properties, Modelling and Applications; Shahir Liew, M., Nguyen-Tri, P., Nguyen, T.A., Kakooei, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 257–269. [Google Scholar]

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2015, 57, 64–67. [Google Scholar] [CrossRef]

- Zhang, P.; Wan, J.; Wang, K.; Li, Q. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review. Constr. Build. Mater. 2017, 148, 648–658. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.A.G.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Meng, T.; Ying, K.; Yang, X.; Hong, Y. Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials. Nanotechnol. Rev. 2021, 10, 370–384. [Google Scholar] [CrossRef]

- Kong, D.; Huang, S.; Corr, D.; Yang, Y.; Shah, S.P. Whether do nano-particles act as nucleation sites for C-S-H gel growth during cement hydration? Cem. Concr. Compos. 2018, 87, 98–109. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Nicoleau, L.; Schreiner, E.; Nonat, A. Ion-specific effects influencing the dissolution of tricalcium silicate. Cem. Concr. Res. 2014, 59, 118–138. [Google Scholar] [CrossRef]

- Pustovgar, E.; Mishra, R.K.; Palacios, M.; d’Espinose de Lacaillerie, J.-B.; Matschei, T.; Andreev, A.S.; Heinz, H.; Verel, R.; Flatt, R.J. Influence of aluminates on the hydration kinetics of tricalcium silicate. Cem. Concr. Res. 2017, 100, 245–262. [Google Scholar] [CrossRef]

- Wagner, D.; Bellmann, F.; Neubauer, J. Influence of aluminium on the hydration of triclinic C3S with addition of KOH solution. Cem. Concr. Res. 2020, 137, 106198. [Google Scholar] [CrossRef]

- Redondo-Soto, C.; Gastaldi, D.; Irico, S.; Canonico, F.; Aranda, M.A.G. Belite clinkers with increasing aluminium content: Effect of calcium aluminates on calcium silicate hydration. Cem. Concr. Res. 2022, 162, 107015. [Google Scholar] [CrossRef]

- Bérodier, E.M.J.; Muller, A.C.A.; Scrivener, K.L. Effect of sulfate on C-S-H at early age. Cem. Concr. Res. 2020, 138, 106248. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr. Build. Mater. 2016, 106, 296–304. [Google Scholar] [CrossRef]

- Artioli, G.; Valentini, L.; Dalconi, M.C.; Parisatto, M.; Voltolini, M.; Russo, V.; Ferrari, G. Imaging of nano-seeded nucleation in cement pastes by X-ray diffraction tomography. Int. J. Mater. Res. 2014, 105, 628–631. [Google Scholar] [CrossRef]

- Zhao, D.; Khoshnazar, R. Hydration and microstructural development of calcined clay cement paste in the presence of calcium-silicate-hydrate (C–S–H) seed. Cem. Concr. Compos. 2021, 122, 104162. [Google Scholar] [CrossRef]

- Valentini, L.; Ferrari, G.; Russo, V.; Štefančič, M.; Serjun, V.Z.; Artioli, G. Use of nanocomposites as permeability reducing admixtures. J. Am. Ceram. Soc. 2018, 101, 4275–4284. [Google Scholar] [CrossRef]

- Horgnies, M.; Fei, L.; Arroyo, R.; Chen, J.J.; Gartner, E.M. The effects of seeding C3S pastes with afwillite. Cem. Concr. Res. 2016, 89, 145–157. [Google Scholar] [CrossRef]

- Suraneni, P.; Flatt, R.J. Micro-reactors to study alite hydration. J. Am. Ceram. Soc. 2015, 98, 1634–1641. [Google Scholar] [CrossRef]

- Suraneni, P.; Palacios, M.; Flatt, R.J. New insights into the hydration of slag in alkaline media using a micro-reactor approach. Cem. Concr. Res. 2016, 79, 209–216. [Google Scholar] [CrossRef]

- Nicoleau, L. The acceleration of cement hydration by seeding: Influence of the cement mineralogy. ZKG Int. 2013, 1, 40–49. [Google Scholar]

- Tikalsky, P.J.; Scheetz, B.E.; Garvey, J.J.; Grant, B.; Thompson, J. Long-term influence of alkaline earth silicate admixtures on the microstructural development of structural concrete. In Proceedings of the 21st International Conference on Cement Microscopy, Las Vegas, NV, USA, 25–29 April 1999; pp. 266–272. [Google Scholar]

- Scheetz, B.E.; Tikalsky, P.J.; Badger., S. Control of the microstructure of concrete: A case for nanometer-sized seeding. In Proceedings of the 11th International Congress on the Chemistry of Cement, Durban, South Africa, 11–16 May 2003; Grieveand, G., Owens, G., Eds.; pp. 1692–1699. [Google Scholar]

- Nicoleau, L.; Jetzlsperger, E.; Fridrich, D.; Vierle, M.; Lorenz, K.; Albrecht, G.; Schmitt, D.; Wohlhaupter, T.; Dorfner, R.; Leitner, H.; et al. Plasticizer-Containing Hardening Accelerator Composition. WO2010026155A1, 11 March 2010. [Google Scholar]

- Nicoleau, L.; Albrecht, G.; Lorenz, K.; Jetzlsperger, E.; Fridrich, D.; Wohlhaupter, T.; Dorfner, R.; Leitner, H.; Vierle, M.; Schmitt, D.; et al. Hardening Accelerator Composition Containing Phosphated Polycondensates. WO2011026720A1, 10 March 2011. [Google Scholar]

- Nicoleau, L. Accelerated growth of calcium silicate hydrates: Experiments and simulations. Cem. Concr. Res. 2011, 41, 1339–1348. [Google Scholar] [CrossRef]

- Kutschera, M.; Nicoleau, L.; Bräu, M. Nano-optimized Construction Materials by Nano-seeding and Crystallization Control. In Nanotechnology in Civil Infrastructure; Springer: Berlin/Heidelberg, Germany, 2011; pp. 175–205. [Google Scholar]

- Nicoleau, L.; Nonat, A.; Perrey, D. The di- and tricalcium silicate dissolutions. Cem. Concr. Res. 2013, 47, 14–30. [Google Scholar] [CrossRef]

- Nicoleau, L.; Gädt, T.; Chitu, L.; Maier, G.; Paris, O. Oriented aggregation of calcium silicate hydrate platelets by the use of comb-like copolymers. Soft Matter 2013, 9, 4864–4874. [Google Scholar] [CrossRef]

- Pizoń, J.; Łaźniewska-Piekarczyk, B.; Miera, P. The Influence of the Acceleration Admixture Type and Composition of Cement on Hydration Heat and Setting Time of Slag Blended Cement. Materials 2022, 15, 2797. [Google Scholar] [CrossRef]

- He, W.; Liao, G. Effects of nano-C-S-H seed crystal on early-age hydration process of Portland cement. Fuller. Nanotub. Carbon Nanostructures 2022, 30, 365–372. [Google Scholar] [CrossRef]

- Zhang, G.; Yang, Y.; Li, H. Calcium-silicate-hydrate seeds as an accelerator for saving energy in cold weather concreting. Constr. Build. Mater. 2020, 264, 120191. [Google Scholar] [CrossRef]

- Augustyniak, A.; Sikora, P.; Jablonska, J.; Cendrowski, K.; John, E.; Stephan, D.; Mijowska, E. The effects of calcium–silicate–hydrate (C–S–H) seeds on reference microorganisms. Appl. Nanosci. 2020, 10, 4855–4867. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Application of the c-s-h phase nucleating agents to improve the performance of sustainable concrete composites containing fly ash for use in the precast concrete industry. Materials 2021, 14, 6514. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L.; Szostak, B. Strengthening the very early-age structure of cementitious composites with coal fly ash via incorporating a novel nanoadmixture based on C-S-H phase activators. Constr. Build. Mater. 2021, 312, 125426. [Google Scholar] [CrossRef]

- Ghourchian, S.; Wyrzykowski, M.; Baquerizo, L.; Lura, P. Performance of passive methods in plastic shrinkage cracking mitigation. Cem. Concr. Compos. 2018, 91, 148–155. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Effect of Nano Admixture of CSH on Selected Strength Parameters of Concrete Including Fly Ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 12105. [Google Scholar] [CrossRef]

- Kropyvnytska, T.; Rucinska, T.; Ivashchyshyn, H.; Kotiv, R. Development of Eco-Efficient Composite Cements with High Early Strength. In Proceedings of Civil and Environmental Engineering CEE 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 211–218. [Google Scholar]

- Pedrosa, H.C.; Reales, O.M.; Reis, V.D.; Paiva, M.d.D.; Fairbairn, E.M.R. Hydration of Portland cement accelerated by C-S-H seeds at different temperatures. Cem. Concr. Res. 2020, 129, 105978. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Improvement of Strength Parameters of Cement Matrix with the Addition of Siliceous Fly Ash by Using Nanometric C-S-H Seeds. Energies 2020, 13, 6734. [Google Scholar] [CrossRef]

- Sobczak-Piąstka, J.; Marushchak, U.; Mazurak, O.; Mazurak, A. Nanomodified rapid hardening concretes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 32058. [Google Scholar] [CrossRef]

- Turgunbaev, U.; Umirova, M. High-strength concrete technology for manufacturing reinforced concrete sleepers from prestressed reinforced concrete. E3S Web Conf. 2021, 264, 2040. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Rheology of cement pastes with siliceous fly ash and the csh nano-admixture. Materials 2021, 14, 3640. [Google Scholar] [CrossRef] [PubMed]

- Ouellet-Plamondon, C.; Scherb, S.; Köberl, M.; Thienel, K.C. Acceleration of cement blended with calcined clays. Constr. Build. Mater. 2020, 245, 118439. [Google Scholar] [CrossRef]

- Zhou, Z.; Sofi, M.; Liu, J.; Li, S.; Zhong, A.; Mendis, P. Nano-CSH modified high volume fly ash concrete: Early-age properties and environmental impact analysis. J. Clean. Prod. 2021, 286, 124924. [Google Scholar] [CrossRef]

- Zhou, Z.; Sofi, M.; Sabri, Y.; Liu, J.; Kang, S.; Mendis, P. Microstructural Investigation of High-Volume Fly Ash Composites Containing Nano-Calcium Silicate Hydrate Crystals. J. Mater. Civ. Eng. 2021, 33, 4021356. [Google Scholar] [CrossRef]

- Morales-Cantero, A.; Cuesta, A.; De la Torre, A.G.; Santacruz, I.; Mazanec, O.; Borralleras, P.; Weldert, K.S.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. C-S-H seeding activation of Portland and Belite Cements: An enlightening in situ synchrotron powder diffraction study. Cem. Concr. Res. 2022, 161, 106946. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Ahmed Shaikh, F.U.; Illikainen, M. Mechanical and durability properties of C–S–H-seeded cement mortar cured at fluctuating low temperatures with granulated blast furnace slag as fine aggregates. J. Build. Eng. 2022, 57, 104879. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Langås, I.; Arntsen, B.; Poikelispää, M.; Illikainen, M. Low-temperature (−10 °C) curing of Portland cement paste—Synergetic effects of chloride-free antifreeze admixture, C–S–H seeds, and room-temperature pre-curing. Cem. Concr. Compos. 2022, 125, 104319. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Illikainen, M. Improved strength development and frost resistance of Portland cement ground-granulated blast furnace slag binary binder cured at 0 °C with the addition of calcium silicate hydrate seeds. J. Build. Eng. 2022, 48, 103904. [Google Scholar] [CrossRef]

- Kothari, A.; Hedlund, H.; Illikainen, M.; Cwirzen, A. Effects of sodium nitrate and OPC-GGBS concrete mix composition on phase transition of pore water at subzero temperatures. Constr. Build. Mater. 2022, 327, 126901. [Google Scholar] [CrossRef]

- Gimenez-Carbo, E.; Torres, R.; Coll, H.; Roig-Flores, M.; Serna, P.; Soriano, L. Preliminary Study of the Fresh and Hard Properties of UHPC That Is Used to Produce 3D Printed Mortar. Materials 2022, 15, 2750. [Google Scholar] [CrossRef]

- Redondo-Soto, C.; Morales-Cantero, A.; Cuesta, A.; Santacruz, I.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. Limestone calcined clay binders based on a Belite-rich cement. Cem. Concr. Res. 2023, 163, 107018. [Google Scholar] [CrossRef]

- Morales-Cantero, A.; Cuesta, A.; la Torre, A.G.D.; Mazanec, O.; Borralleras, P.; Weldert, K.S.; Gastaldi, D.; Canonico, F.; Aranda, M.A.G. Portland and Belite Cement Hydration Acceleration by C-S-H Seeds with Variable w/c Ratios. Materials 2022, 15, 3553. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Assmann, A.; Hesse, C.; Lura, P. Microstructure development and autogenous shrinkage of mortars with C-S-H seeding and internal curing. Cem. Concr. Res. 2020, 129, 105967. [Google Scholar] [CrossRef]

- Li, X.; Bizzozero, J.; Hesse, C. Impact of C-S-H seeding on hydration and strength of slag blended cement. Cem. Concr. Res. 2022, 161, 106935. [Google Scholar] [CrossRef]

- Li, H.; Gu, L.; Dong, B.; Chen, Q.; Xu, C.; Yang, X.; Wang, W. Improvements in setting behavior and strengths of cement paste/mortar with EVA redispersible powder using C-S-Hs-PCE. Constr. Build. Mater. 2020, 262, 120097. [Google Scholar] [CrossRef]

- He, J.; Long, G.; Ma, K.; Xie, Y.; Cheng, Z. Improvement of the Hydration of a Fly Ash-Cement System by the Synergic Action of Triethanolamine and C-S-H Seeding. ACS Sustain. Chem. Eng. 2021, 9, 2804–2815. [Google Scholar] [CrossRef]

- Wang, D.H.; Yao, X.; Yang, T.; Xiang, W.R.; Feng, Y.T.; Chen, Y. Controlling the early-age hydration heat release of cement paste for deep-water oil well cementing: A new composite designing approach. Constr. Build. Mater. 2021, 285, 122949. [Google Scholar] [CrossRef]

- Tian, L.; Dai, S.; Yao, X.; Zhu, H.; Wu, Q.; Liu, Z.; Cheng, S. Effect of nucleation seeding and triisopropanolamine on the compressive strength, chloride binding capacity and microstructure of cement paste. J. Build. Eng. 2022, 52, 104382. [Google Scholar] [CrossRef]

- Li, H.; Xue, Z.; Liang, G.; Wu, K.; Dong, B.; Wang, W. Effect of C-S-Hs-PCE and sodium sulfate on the hydration kinetics and mechanical properties of cement paste. Constr. Build. Mater. 2021, 266, 121096. [Google Scholar] [CrossRef]

- Liang, G.; Ni, D.; Li, H.; Dong, B.; Yang, Z. Synergistic effect of EVA, TEA and C-S-Hs-PCE on the hydration process and mechanical properties of Portland cement paste at early age. Constr. Build. Mater. 2021, 272, 121891. [Google Scholar] [CrossRef]

- Li, H.; Xiang, Y.; Xu, C. Effect of C–S–H seed/PCE nanocomposites and triisopropanolamine on portland cement properties: Hydration kinetic and strength. J. Build. Eng. 2022, 57, 104946. [Google Scholar] [CrossRef]

- Xu, Y.; He, T.; Ma, X.; Yang, R. The research on mechanism of C-S-H nanocrystal improving early properties of shotcrete at low temperature by thermodynamic modelling. Constr. Build. Mater. 2022, 325, 126738. [Google Scholar] [CrossRef]

- Dal Sasso, G.; Dalconi, M.C.; Ferrari, G.; Pedersen, J.S.; Tamburini, S.; Bertolotti, F.; Guagliardi, A.; Bruno, M.; Valentini, L.; Artioli, G. An Atomistic Model Describing the Structure and Morphology of Cu-Doped C-S-H Hardening Accelerator Nanoparticles. Nanomaterials 2022, 12, 342. [Google Scholar] [CrossRef]

- He, W.; Liao, G. Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials. Nanotechnol. Rev. 2021, 10, 1374–1382. [Google Scholar] [CrossRef]

- Feng, Q.; Mao, Y.; Peng, Z.; Zheng, Y.; Wu, J. Preparation and Properties of Low-Temperature Early Strength Material for Nano-C-S-H Gel Seed. Arab. J. Sci. Eng. 2022, 47, 5567–5575. [Google Scholar] [CrossRef]

- Wang, Y.; Lü, L.; He, Y.; Wang, F.; Hu, S. Effect of Calcium Silicate Hydrate Seeds on Hydration and Mechanical Properties of Cement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2021, 36, 103–110. [Google Scholar] [CrossRef]

- Yang, J.; Yang, M.; He, X.; Ma, M.; Fan, M.; Su, Y.; Tan, H. Green reaction-type nucleation seed accelerator prepared from coal fly ash ground in water environment. Constr. Build. Mater. 2021, 306, 124840. [Google Scholar] [CrossRef]

- Zhang, J.; Pan, G.; Zheng, X.; Chen, C. Preparation and characterization of ultra-lightweight fly ash-based cement foams incorporating ethylene-vinyl acetate emulsion and waste-derived C-S-H seeds. Constr. Build. Mater. 2021, 274, 122027. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Xu, K.; Monteiro, P.J.M. Fibrillar calcium silicate hydrate seeds from hydrated tricalcium silicate lower cement demand. Cem. Concr. Res. 2020, 137, 106195. [Google Scholar] [CrossRef]

- Kong, D.; He, G.; Pan, H.; Weng, Y.; Du, N.; Sheng, J. Influences and mechanisms of Nano-C-S-H gel addition on fresh properties of the cement-based materials with sucrose as retarder. Materials 2020, 13, 2345. [Google Scholar] [CrossRef] [PubMed]

- Zou, F.; Hu, C.; Wang, F.; Ruan, Y.; Hu, S. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C–S–H seeds towards a greener binder. J. Clean. Prod. 2020, 244, 118566. [Google Scholar] [CrossRef]

- Zou, F.; Shen, K.; Hu, C.; Wang, F.; Yang, L.; Hu, S. Effect of Sodium Sulfate and C–S–H Seeds on the Reaction of Fly Ash with Different Amorphous Alumina Contents. ACS Sustain. Chem. Eng. 2020, 8, 1659–1670. [Google Scholar] [CrossRef]

- Huang, L.; Yang, Z. Hydration kinetics of tricalcium silicate with the presence of portlandite and calcium silicate hydrate. Thermochim. Acta 2019, 681, 178398. [Google Scholar] [CrossRef]

- John, E.; Epping, J.D.; Stephan, D. The influence of the chemical and physical properties of C-S-H seeds on their potential to accelerate cement hydration. Constr. Build. Mater. 2019, 228, 116723. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Jiang, L.; Wang, D. The acceleration mechanism of nano-C-S-H particles on OPC hydration. Constr. Build. Mater. 2020, 249, 118734. [Google Scholar] [CrossRef]

- Das, S.; Ray, S.; Sarkar, S. Early strength development in concrete using preformed CSH nano crystals. Constr. Build. Mater. 2020, 233, 117214. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Role of pH on the structure, composition and morphology of C-S-H–PCE nanocomposites and their effect on early strength development of Portland cement. Cem. Concr. Res. 2017, 102, 90–98. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Effectiveness of a calcium silicate hydrate—Polycarboxylate ether (C-S-H–PCE) nanocomposite on early strength development of fly ash cement. Constr. Build. Mater. 2018, 169, 20–27. [Google Scholar] [CrossRef]

- Theobald, M.; Plank, J. β-Naphthalene sulfonate formaldehyde-based nanocomposites as new seeding materials for Portland cement. Constr. Build. Mater. 2020, 264, 120240. [Google Scholar] [CrossRef]

- Theobald, M.; Plank, J. C–S–H–Polycondensate nanocomposites as effective seeding materials for Portland composite cements. Cem. Concr. Compos. 2022, 125, 104278. [Google Scholar] [CrossRef]

- Wang, F.; Kong, X.; Wang, D.; Wang, Q. The effects of nano-C-S-H with different polymer stabilizers on early cement hydration. J. Am. Ceram. Soc. 2019, 102, 5103–5116. [Google Scholar] [CrossRef]

- Sun, J.; Shi, H.; Qian, B.; Xu, Z.; Li, W.; Shen, X. Effects of synthetic C-S-H/PCE nanocomposites on early cement hydration. Constr. Build. Mater. 2017, 140, 282–292. [Google Scholar] [CrossRef]

- Sun, J.; Dong, H.; Wu, J.; Jiang, J.; Li, W.; Shen, X.; Hou, G. Properties evolution of cement-metakaolin system with C-S-H/PCE nanocomposites. Constr. Build. Mater. 2021, 282, 122707. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Liu, X.; Bai, X.; Zhou, W. Microstructure and Properties of C–S–H Synthesized in the Presence of Polycarboxylate Superplasticizer. Arab. J. Sci. Eng. 2023, 48, 1041–1052. [Google Scholar]

- You, Z.; Xu, J. Investigation on variables contributing to the synthesis of c-s-h/pce nanocomposites by co-precipitation method. Materials 2021, 14, 7673. [Google Scholar] [PubMed]

- Zhang, J.; Wang, Z.; Yao, Y.; Tang, R.; Li, S.; Liu, X.; Sun, D. The effect and mechanism of C–S–H-PCE nanocomposites on the early strength of mortar under different water-to-cement ratio. J. Build. Eng. 2021, 44, 103360. [Google Scholar]

- Ferrari, G.; Brocchi, A.; Castiglioni, F.; Bravo, A.; Moretti, E.; Salvioni, D.; Squinzi, M.; Artioli, G.; Dalconi, M.C.; Valentini, L.; et al. A new multifunctional additive for blended cements. Constr. Build. Mater. 2022, 354, 129086. [Google Scholar]

- Gu, X.; Tan, H.; He, X.; Zhang, J.; Li, M.; Su, Y.; Yang, J. Nano C-S-H seeds prepared from ground granulated blast-furnace slag-carbide slag and its application in Portland cement. Constr. Build. Mater. 2022, 329, 127204. [Google Scholar]

- Zou, F.; Zhang, M.; Hu, C.; Wang, F.; Hu, S. Novel C-A-S-H/PCE nanocomposites: Design, characterization and the effect on cement hydration. Chem. Eng. J. 2021, 412, 128569. [Google Scholar]

- Yao, S.; Zou, F.; Wang, F.; He, Y.; Hu, S.; Hu, C. Revealing the micro-mechanical characteristics of high early strength cement pastes. Constr. Build. Mater. 2022, 342, 128078. [Google Scholar]

- Zhu, H.; Zhang, M.; Zou, F.; Wang, F.; Hu, C. Calcium-silicate-hydrates/polycarboxylate ether nanocomposites doped by magnesium: Enhanced stability and accelerating effect on cement hydration. J. Am. Ceram. Soc. 2022, 105, 4930–4941. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, G.; Mi, R.; Zhan, M. Improving the properties of concrete using in situ-grown C-S-H. Constr. Build. Mater. 2021, 276, 122214. [Google Scholar]

- Yan, H.; Zhou, D.; Yang, Y.; Shu, X.; Yu, C.; Ran, Q. Tuning the Hydration Acceleration Efficiency of Calcium Carbonate by Pre-Seeding with Calcium Silicate Hydrate. Materials 2022, 15, 6726. [Google Scholar]

- Bellmann, F.; Sowoidnich, T.; Horgnies, M.; Gartner, E. Basic mechanisms of afwillite seeding for acceleration of tricalcium silicate hydration. Cem. Concr. Res. 2020, 132, 106030. [Google Scholar]

- John, E.; Lehmann, C.; Stephan, D. Xonotlite and hillebrandite as model compounds for calcium silicate hydrate seeding in cementitious materials. Transp. Res. Rec. 2021, 2675, 65–72. [Google Scholar]

- Aranda, M.A.G. Recent studies of cements and concretes by synchrotron radiation crystallographic and cognate methods. Crystallogr. Rev. 2016, 22, 150–196. [Google Scholar]

- Aranda, M.A.G.; Cuesta, A.; De la Torre, A.G.; Santacruz, I.; León-Reina, L. Diffraction and crystallography applied to hydrating cements. In Cementitious Materials: Composition, Properties, Application; Pöllmann, H., Ed.; De Gruyter: Berlin, Germany; Boston, MA, USA, 2017; pp. 31–60. ISBN 9783110473728. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuesta, A.; Morales-Cantero, A.; De la Torre, A.G.; Aranda, M.A.G. Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances. Materials 2023, 16, 1462. https://doi.org/10.3390/ma16041462

Cuesta A, Morales-Cantero A, De la Torre AG, Aranda MAG. Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances. Materials. 2023; 16(4):1462. https://doi.org/10.3390/ma16041462

Chicago/Turabian StyleCuesta, Ana, Alejandro Morales-Cantero, Angeles G. De la Torre, and Miguel A. G. Aranda. 2023. "Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances" Materials 16, no. 4: 1462. https://doi.org/10.3390/ma16041462

APA StyleCuesta, A., Morales-Cantero, A., De la Torre, A. G., & Aranda, M. A. G. (2023). Recent Advances in C-S-H Nucleation Seeding for Improving Cement Performances. Materials, 16(4), 1462. https://doi.org/10.3390/ma16041462