Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses

Abstract

:1. Introduction

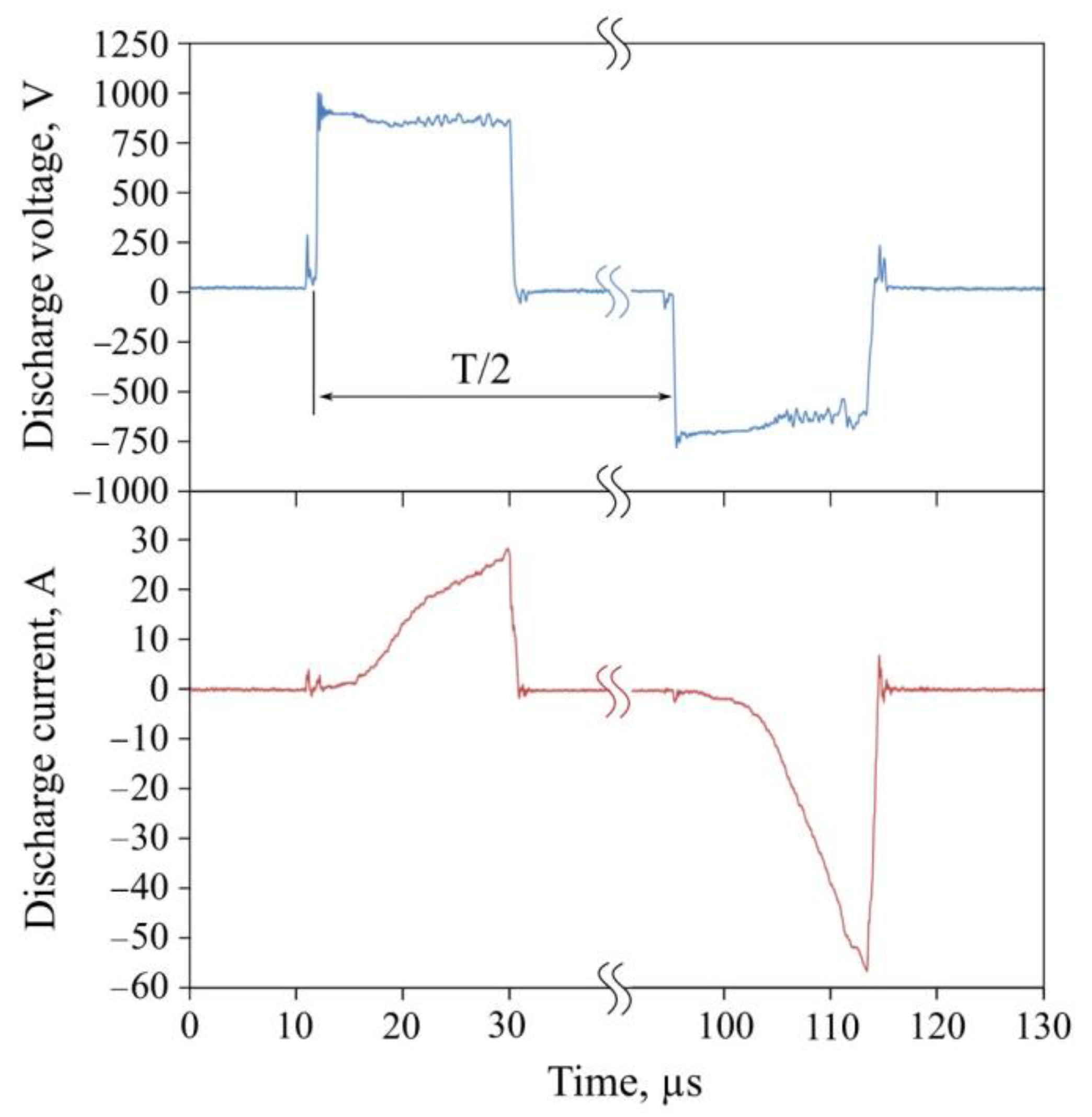

2. Materials and Methods

2.1. Preparation of TiAlN Coatings

2.2. Investigation Methods

3. Results and Discussion

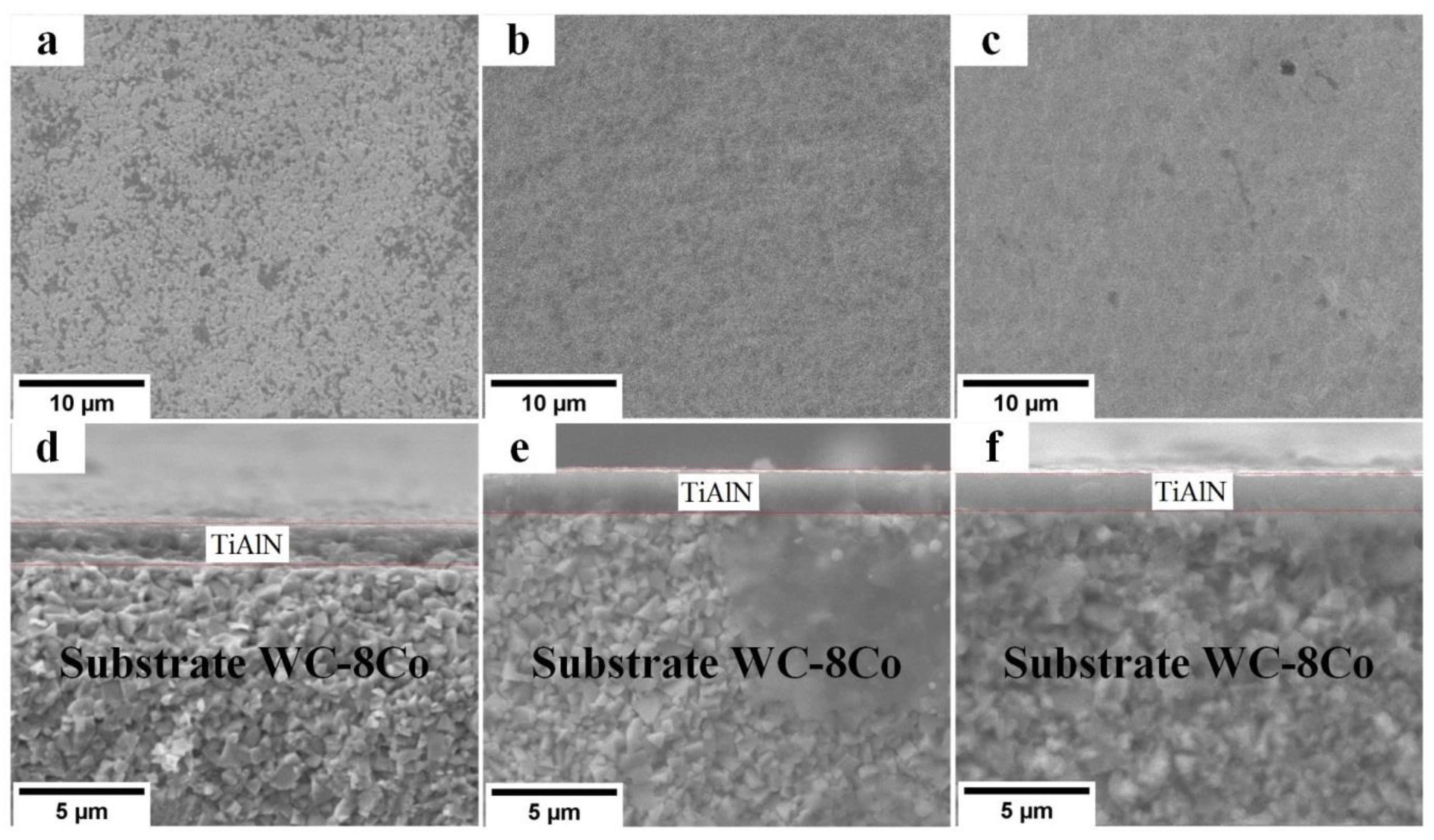

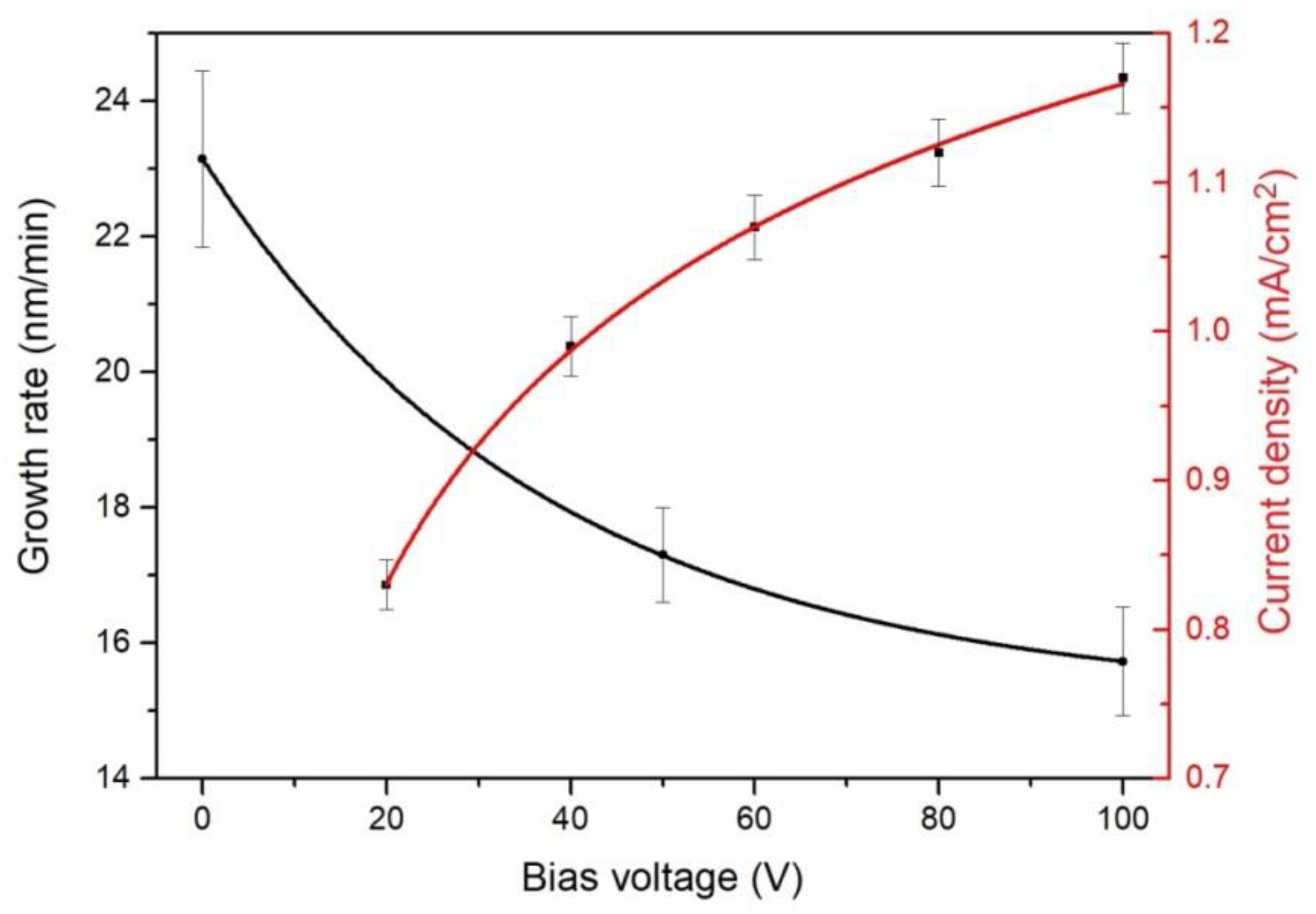

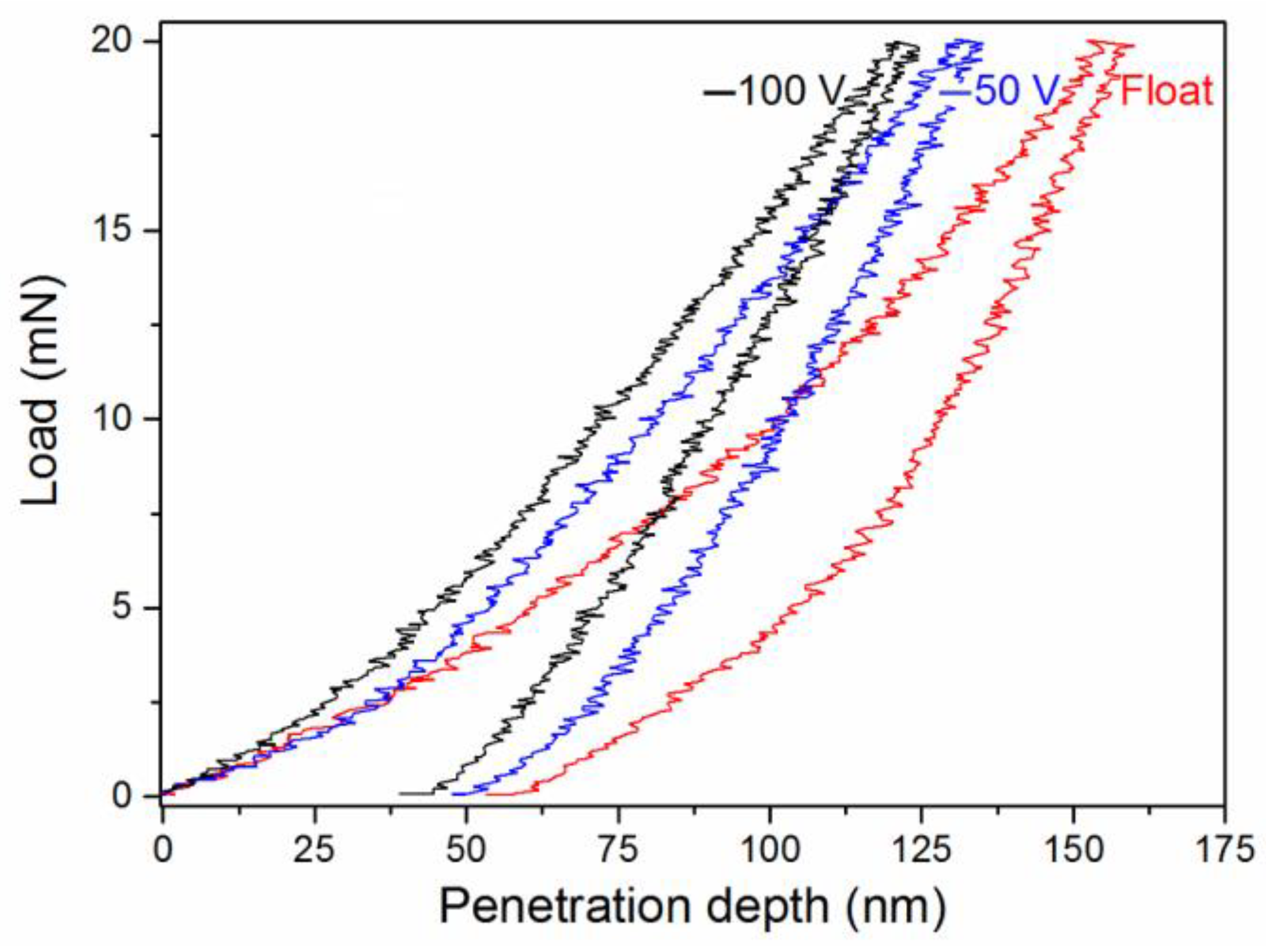

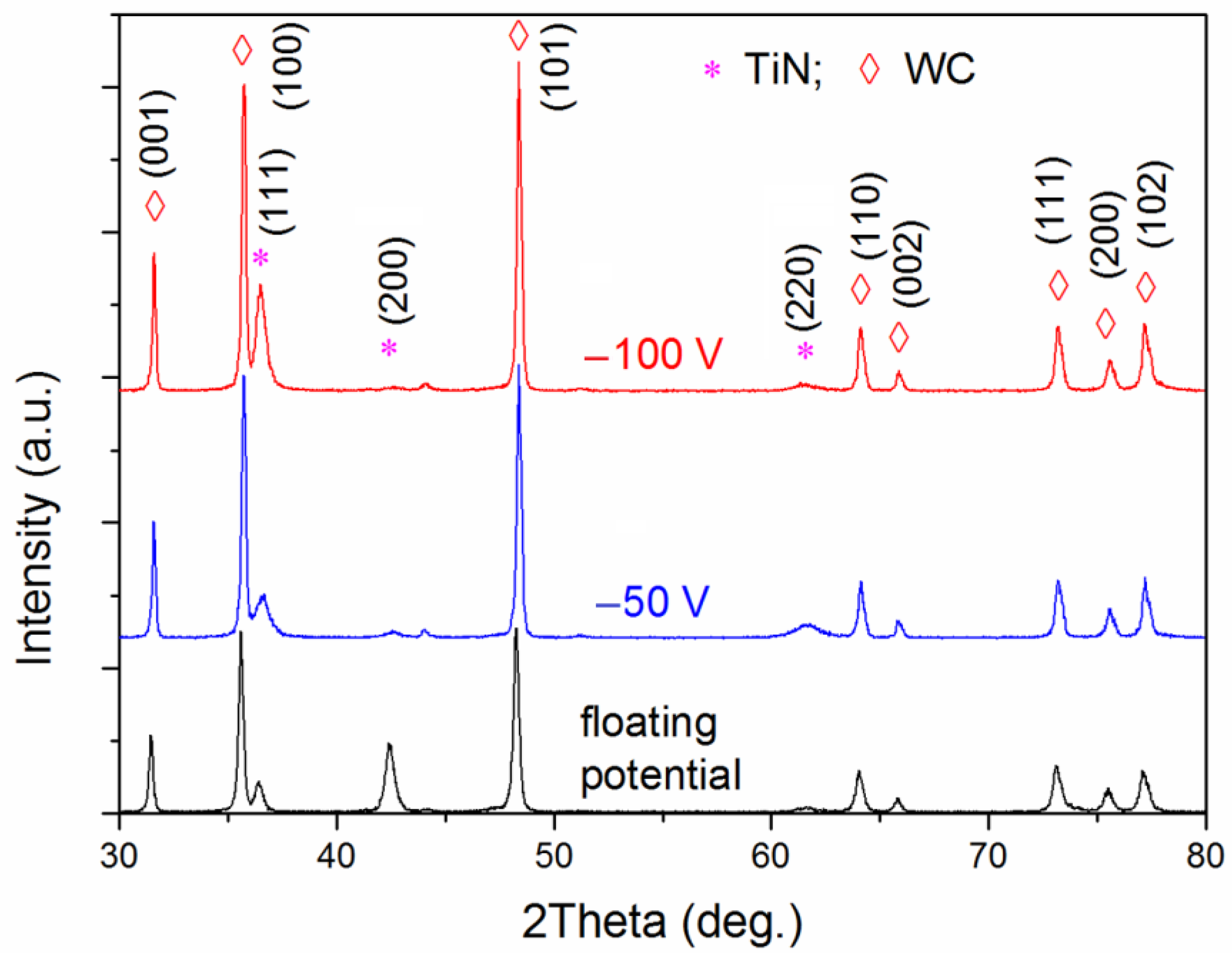

3.1. TiAlN Coatings Deposited by the Al Magnetron at 30 W of Power

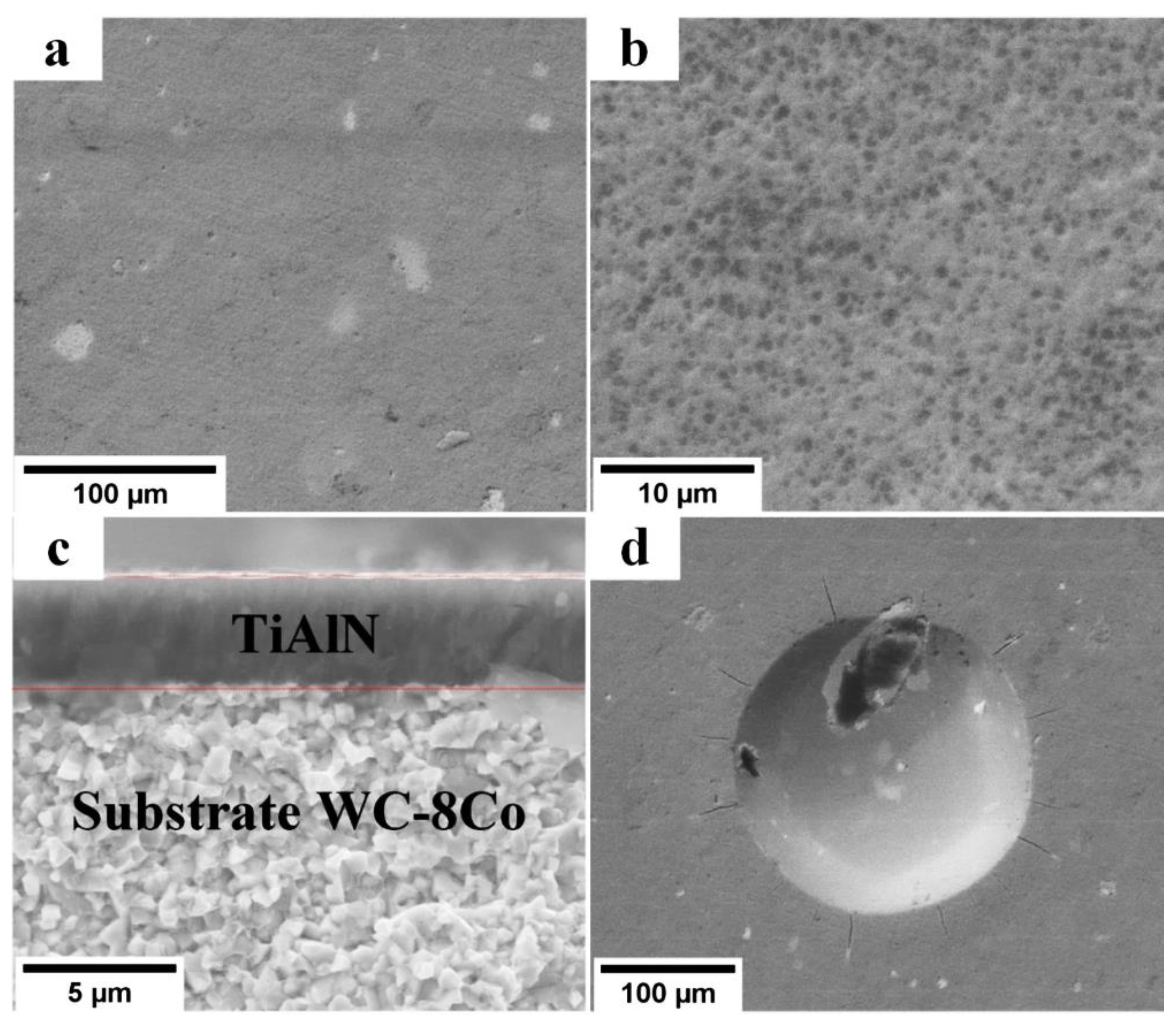

3.2. TiAlN Coatings Deposited by the Al Magnetron at 1 kW of Power

3.3. Heat-Resistance of TiAlN Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, S.; Guha, S.; Ghadai, R.; Swain, B.P. A comparative analysis over different properties of TiN, TiAlN and TiAlSiN thin film coatings grown in nitrogen gas atmosphere. Mater. Chem. Phys. 2021, 258, 123866. [Google Scholar] [CrossRef]

- Yongqiang, W.; Xiaoya, Z.; Zhongzhen, W.; Xiubo, T.; Chunzhi, G.; Shiqin, Y.; Zhiqiang, J.; Liangji, C. Effects of modulation ratio on microstructure and properties of TiN/TiAlN multilayer coatings. Surf. Coat. Technol. 2013, 229, 191–196. [Google Scholar]

- Ben Hassine, M.; Andrén, H.-O.; Iyer, A.H.S.; Lotsari, A.; Bäcke, O.; Stiens, D.; Janssen, W.; Manns, T.; Kümmel, J.; Halvarsson, M. Growth model for high-Al containing CVD TiAlN coatings on cemented carbides using intermediate layers of TiN. Surf. Coat. Technol. 2021, 421, 127361. [Google Scholar] [CrossRef]

- Alhafian, M.-R.; Chemin, J.-B.; Fleming, Y.; Bourgeois, L.; Penoy, M.; Useldinger, R.; Soldera, F.; Mücklich, F.; Choquet, P. Comparison on the structural, mechanical and tribological properties of TiAlN coatings deposited by HiPIMS and Cathodic Arc Evaporation. Surf. Coat. Technol. 2021, 423, 127529. [Google Scholar] [CrossRef]

- Hsu, C.-H.; Chen, M.-L.; Lai, K.-L. Corrosion resistance of TiN/TiAlN-coated ADI by cathodic arc deposition. Mater. Sci. Eng. A 2006, 421, 182–190. [Google Scholar]

- Anders, A. A review comparing cathodic arcs and high power impulse magnetron sputtering (HiPIMS). Surf. Coat. Technol. 2014, 257, 308–325. [Google Scholar] [CrossRef]

- Karpov, D.A. Cathodic arc sources and macroparticle filtering. Surf. Coat. Technol. 1997, 96, 22–33. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, G.; Xiao, J.; Lang, W.; Dong, C.; Gong, J.; Sun, C. Synthesis of titanium nitride thin films deposited by a new shielded arc ion plating. Appl. Surf. Sci. 2011, 257, 5694–5697. [Google Scholar] [CrossRef]

- Harlin, P.; Bexell, U.; Olsson, M. Influence of surface topography of arc-deposited TiN and sputter-deposited WC/C coatings on the initial material transfer tendency and friction characteristics under dry sliding contact conditions. Surf. Coat. Technol. 2009, 203, 1748–1755. [Google Scholar] [CrossRef]

- Tkadletz, M.; Mitterer, C.; Sartory, B.; Letofsky-Papst, I.; Czettl, C.; Michotte, C. The effect of droplets in arc evaporated TiAlTaN hard coatings on the wear behavior. Surf. Coat. Technol. 2014, 257, 95–101. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Liu, F.; Luo, W.; Fugang Qi, F.; Zhao, N.; Ouyang, X.; Liao, B. Microstructure, mechanical and tribological properties of multilayer TiAl/TiAlN coatings on Al alloys by FCVA technology. Ceram. Int. 2022, 48, 5476–5487. [Google Scholar] [CrossRef]

- Aksenov, I.I.; Belous, V.A.; Padalka, V.G.; Khoroshikh, V.M. Transport of plasma streams in a curvilinear plasma-optics system. Sov. J. Plasma Phys. 1978, 4, 425–428. [Google Scholar]

- Yanhui, Z.; Shengsheng, Z.; Ling, R.; Denisov, V.V.; Koval, N.N.; Ke, Y.; Baohai, Y. Effect of Substrate Pulse Bias Voltage on the Microstructure and Mechanical and Wear-resistant Properties of TiN/Cu Nanocomposite Films. Rare Met. Mater. Eng. 2018, 47, 3284–3288. [Google Scholar] [CrossRef]

- Swift, P.D. Macroparticles in films deposited by steered cathodic arc. J. Phys. D Appl. Phys. 1996, 29, 2025–2031. [Google Scholar] [CrossRef]

- Kimura, K.; Takikawa, H.; Sakakibara, T. Discharge characteristics of vacuum arc with pulse current and efficiency of macroparticle suppression. J. IAPS 1999, 7, 3–10. [Google Scholar]

- Tiron, V.; Velicu, I.-L.; Vasilovici, O.; Popa, G. Optimization of deposition rate in HiPIMS by controlling the peak target current. J. Phys. D Appl. Phys. 2015, 48, 495204. [Google Scholar] [CrossRef]

- Chang, C.-L.; Shih, S.-G.; Chen, P.-H.; Chen, W.-C.; Ho, C.-T.; Wu, W.-Y. Effect of duty cycles on the deposition and characteristics of high power impulse magnetron sputtering deposited TiN thin films. Surf. Coat. Technol. 2014, 259, 232–237. [Google Scholar] [CrossRef]

- Alami, J.; Maric, Z.; Busch, H.; Klein, F.; Grabowy, U.; Kopnarski, M. Enhanced ionization sputtering: A concept for superior industrial coatings. Surf. Coat. Technol. 2014, 255, 43–51. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Ghailane, A.; Larhlimi, H.; Tamraoui, Y.; Makha, M.; Busch, H.; Fischer, C.B.; Alami, J. The effect of magnetic field configuration on structural and mechanical properties of TiN coatings deposited by HiPIMS and dcMS. Surf. Coat. Technol. 2020, 404, 126572. [Google Scholar] [CrossRef]

- Tiron, V.; Velicu, I.-L.; Cristea, D.; Lupu, N.; Stoian, G.; Munteanu, D. Influence of ion-to-neutral flux ratio on the mechanical and tribological properties of TiN coatings deposited by HiPIMS. Surf. Coat. Technol. 2017, 352, 690–698. [Google Scholar] [CrossRef]

- Chang, C.-L.; Luo, G.-J.; Yang, F.-C.; Tang, J.-F. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS. Vacuum 2021, 192, 110449. [Google Scholar] [CrossRef]

- Badini, C.; Deambrosis, S.M.; Ostrovskaya, O.; Zin, V.; Padovano, E.; Miorin, E.; Castellino, M.; Biamino, S. Cyclic oxidation in burner rig of TiAlN coating deposited on Ti-48Al-2Cr-2Nb by reactive HiPIMS. Ceram. Int. 2017, 43, 5417–5426. [Google Scholar] [CrossRef]

- Deambrosis, S.M.; Montagner, F.; Zin, V.; Fabrizio, M.; Badini, C.; Padovano, E.; Sebastiani, M.; Bemporad, E.; Brunelli, K.; Miorin, E. Ti1−xAlxN coatings by reactive High Power Impulse Magnetron Sputtering: Film/substrate interface effect on residual stress and high temperature oxidation. Surf. Coat. Technol. 2018, 354, 56–65. [Google Scholar] [CrossRef]

- Gibson, D.R.; Brinkley, I.; Waddell, E.M.; Walls, J.M. Closed field magnetron sputtering: New generation sputtering process for optical coatings. In Proceedings of the SPIE 7101 Advances in Optical Thin Films III, Glasgow, UK, 2–5 September 2008; Volume 7101, p. 710108. [Google Scholar]

- Laing, K.; Hampshire, J.; Teer, D.; Chester, G. The effect of ion current density on the adhesion and structure of coatings deposited by magnetron sputter ion plating. Surf. Coat. Technol. 1999, 112, 177–180. [Google Scholar] [CrossRef]

- Baranov, O.O.; Fang, J.; Rider, A.E.; Kumar, S.; Ostrikov, K. Effect of ion current density on the properties of vacuum arc-deposited TiN coatings. IEEE Trans. Plasma Sci. 2013, 41, 3640–3644. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Pavlov, A.P.; Solovyev, A.A.; Semenov, V.A.; Rabotkin, S.V. Hybrid HIPIMS+MFMS power supply for dual magnetron sputtering systems. Vacuum 2020, 181, 109670. [Google Scholar] [CrossRef]

- Oskirko, V.O.; Zakharov, A.N.; Semenov, V.A.; Pavlov, A.P.; Grenadyorov, A.S.; Rabotkin, S.V.; Solovyev, A.A. Short-pulse high-power dual magnetron sputtering. Vacuum 2022, 200, 111026. [Google Scholar] [CrossRef]

- Grenadyorov, A.; Oskirko, V.; Zakharov, A.; Oskomov, K.; Solovyev, A. (Cr1−xAlx)N coating deposition by short-pulse high-power dual magnetron sputtering. Materials 2022, 15, 8237. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Vidakis, N.; Antoniadis, A.; Bilalis, N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds. J. Mater. Process. Technol. 2003, 143–144, 481–485. [Google Scholar]

- Shugurov, A.R.; Panin, A.V.; Lyazgin, A.O.; Shesterikov, E.V. Wear of electroplated gold-based coatings. Phys. Mesomech. 2016, 19, 407–419. [Google Scholar] [CrossRef]

- De Hosson, J.T.M.; Carvalho, N.J.M.; Pei, Y.; Galvan, D. Electron microscopy characterization of nanostructured coatings. In Nanostructured Coatings. Nanostructure Science and Technology; Cavaleiro, A., De Hosson, J.T.M., Eds.; Springer: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Pandian, R.; Dash, S.; Ravindran, T.R.; Arivuoli, D.; Tyagi, A.K. Tribological properties and deformation mechanism of TiAlN coating sliding with various counterbodies. Tribol. Int. 2013, 66, 143–149. [Google Scholar] [CrossRef]

- Takagi, T. Ion–surface interactions during thin film deposition. J. Vac. Sci. Technol. A Vac. Surf. Films 1984, 2, 382–388. [Google Scholar]

- Kong, Q.; Ji, L.; Li, H.; Liu, X.; Wang, Y.; Chen, J.; Zhou, H. Influence of substrate bias voltage on the microstructure and residual stress of CrN films deposited by medium frequency magnetron sputtering. Mater. Sci. Eng. B 2011, 176, 850–854. [Google Scholar] [CrossRef]

- Greczynski, G.; Petrov, I.; Greene, J.E.; Hultman, L. Paradigm shift in thin-film growth by magnetron sputtering: From gas-ion to metal-ion irradiation of the growing film. J. Vac. Sci. Technol. A 2019, 37, 060801. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A Vac. Surf. Films 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Musil, J.; Vlček, J. Magnetron sputtering of hard nanocomposite coatings and their properties. Surf. Coat. Technol. 2001, 142–144, 557–566. [Google Scholar] [CrossRef]

- Musil, J.; Čiperová, Z.; Čerstvý, R.; Kos, Š. Hard alloy films with enhanced resistance to cracking. Vacuum 2021, 188, 110186. [Google Scholar]

- Morozov, E.M.; Zernin, M.V. Contact Problems of Fracture Mechanics; Mashinostroenie: Moscow, Russia, 1999. [Google Scholar]

- Lattemann, M. Fully dense, non-faceted 111-textured high power impulse magnetron sputtering TiN films grown in the absence of substrate heating and bias. Thin Solid Films 2010, 518, 5978–5980. [Google Scholar] [CrossRef]

- Gall, D.; Kodambaka, S.; Wall, M.A.; Petrov, I.; Greene, J.E. Pathways of atomistic processes on TiN(001) and (111) surfaces during film growth: An ab initio study. J. Appl. Phys. 2003, 93, 9086–9094. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Immich, P.; Bolz, S.; Alami, J.; Cremer, R. Advantages of nanocomposite coatings deposited by high power pulse magnetron sputtering technology. J. Mater. Process. Technol. 2009, 209, 165–170. [Google Scholar] [CrossRef]

- Jafari, M.; Rogström, L.; Andersson, J.M.; Birch, J.; Gibmeier, J.; Jöesaar, M.J.; Kiefer, D.; Odén, M. Thermal degradation of TiN and TiAlN coatings during rapid laser treatment. Surf. Coat. Technol. 2021, 422, 127517. [Google Scholar] [CrossRef]

- Greczynski, G.; Hultman, L.; Odén, M. X-ray photoelectron spectroscopy studies of Ti1−xAlxN (0 ≤ x ≤ 0.83) high-temperature oxidation: The crucial role of Al concentration. Surf. Coat. Technol. 2019, 374, 923–934. [Google Scholar] [CrossRef]

- Chavee, L.; Serag, E.; Pires, M.d.S.; Lucas, S.; Haye, E. A mechanistic approach of oxidation resistance, structural and mechanical behaviour of TiAlN coatings. Appl. Surf. Sci. 2022, 586, 152851. [Google Scholar] [CrossRef]

- Hörling, A.; Hultman, L.; Odén, M.; Sjölén, J.; Karlsson, L. Thermal stability of arc evaporated high aluminum-content Ti1−xAlxN thin films. J. Vac. Sci. Technol. A Vac. Surf. Films 2002, 20, 1815–1823. [Google Scholar] [CrossRef]

- Münz, W. Titanium aluminum nitride films: A new alternative to TiN coatings. J. Vac. Sci. Technol. A 1986, 4, 2717–2725. [Google Scholar] [CrossRef]

| Substrate Biasing | Ti, at.% | Al, at.% | W, at.% | Co, at.% | N, at.% | (Ti+Al)/N | Chemical Composition |

|---|---|---|---|---|---|---|---|

| Floating potential | 53.4 | 3.9 | 4.6 | 1.9 | 36.2 | 1.58 | Ti0.93Al0.07N |

| −50 V | 50.4 | 4.5 | 4.0 | 1.5 | 39.6 | 1.38 | Ti0.92Al0.08N |

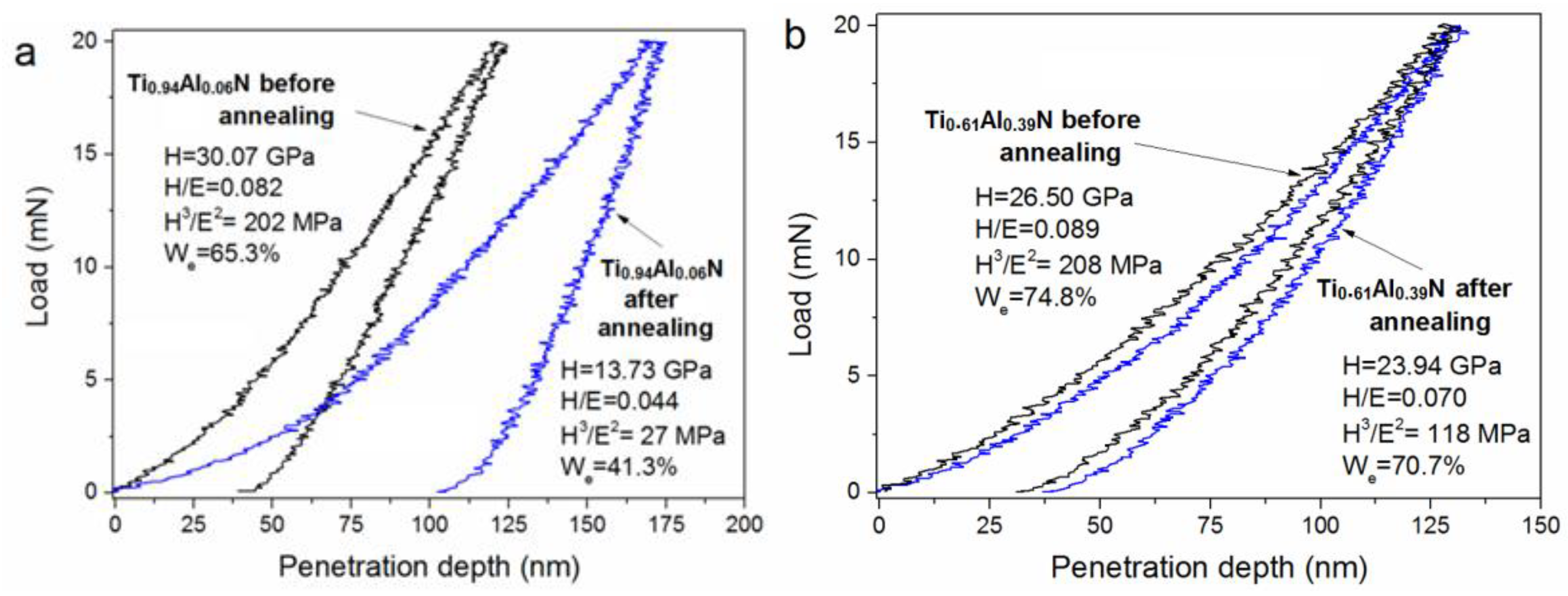

| −100 V | 48.9 | 3.0 | 4.7 | 1.8 | 41.7 | 1.24 | Ti0.94Al0.06N |

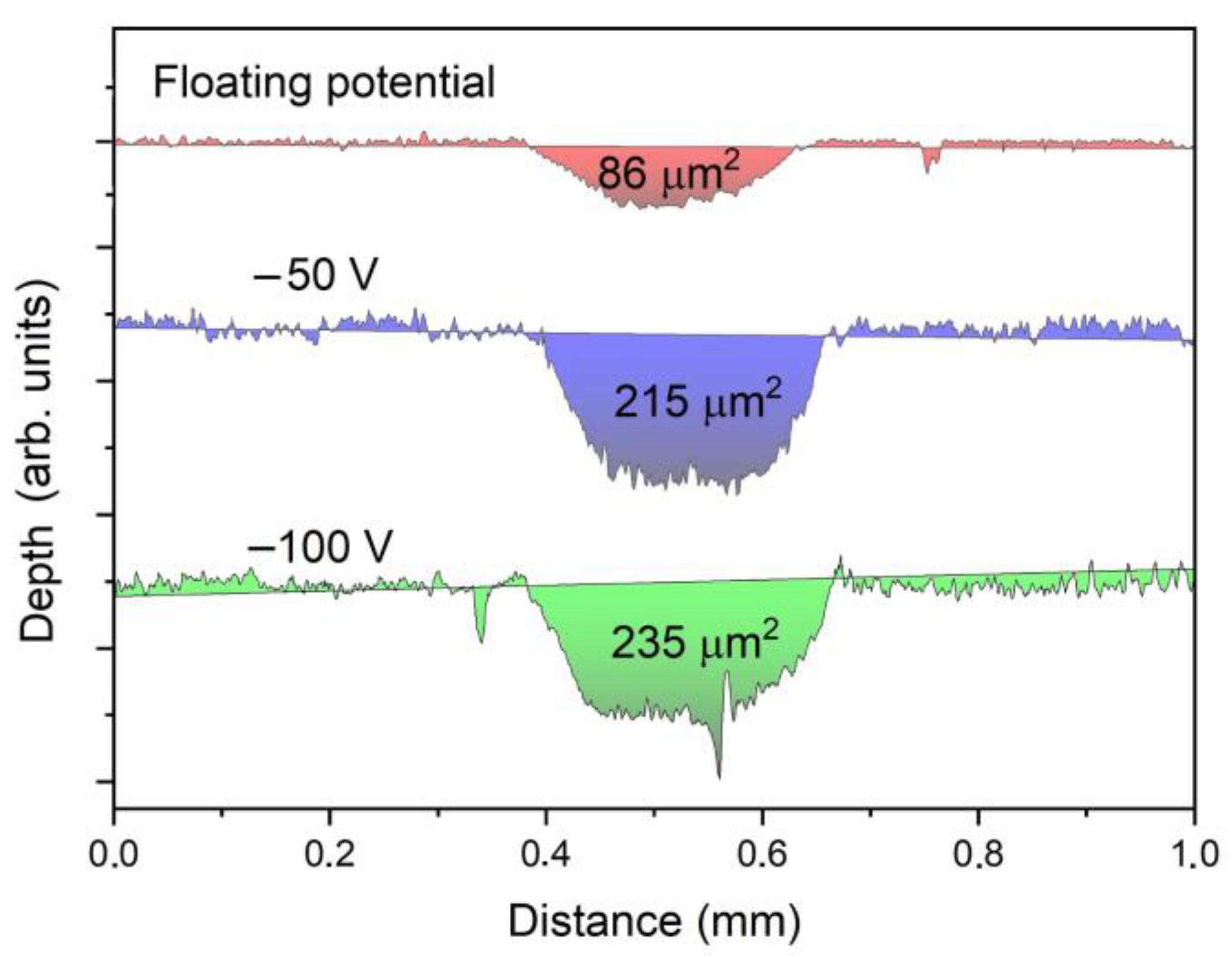

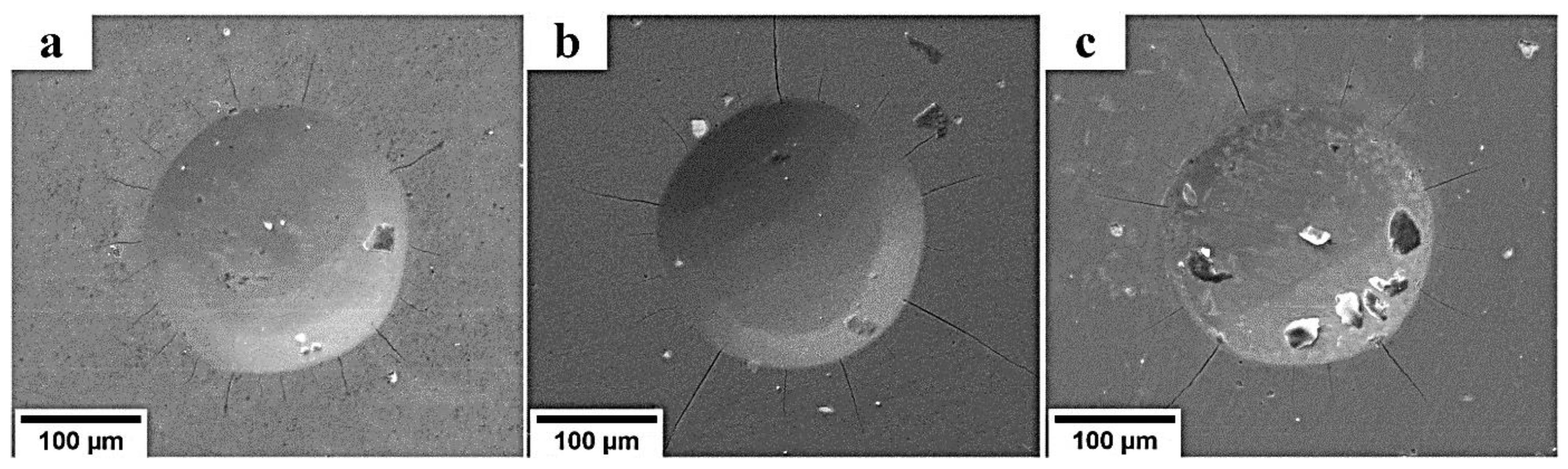

| Substrate Biasing | H, GPa | E, GPa | H/E | H3/E2, MPa | a, µm | Pmax, GPa | k, mm3·N−1·m−1 |

|---|---|---|---|---|---|---|---|

| Floating potential | 17.01 ± 1.7 | 297.1 ± 17.2 | 0.057 | 56 | 80 | 1.49 | 1.8∙10−6 |

| −50 V | 25.65 ± 2.16 | 333.4 ± 18.9 | 0.077 | 152 | 79 | 1.55 | 4.5∙10−6 |

| −100 V | 30.07 ± 2.83 | 366.7 ± 11.6 | 0.082 | 202 | 77 | 1.60 | 4.9∙10−6 |

| Ti, at.% | Al, at.% | W, at.% | Co, at.% | N, at.% | (Ti+Al)/N | Chemical Composition |

|---|---|---|---|---|---|---|

| 24.6 | 15.6 | 11.0 | 3.9 | 45.1 | 0.89 | Ti0.61Al0.39N |

| Substrate Biasing | H, GPa | E, GPa | H/E | H3/E2, MPa | a, µm | Pmax, GPa | k, mm3·N−1·m−1 |

|---|---|---|---|---|---|---|---|

| −100 V | 26.5 ± 1.11 | 298.9 ± 6.8 | 0.089 | 208 | 80 | 1.49 | 5.2·10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grenadyorov, A.; Oskirko, V.; Zakharov, A.; Oskomov, K.; Rabotkin, S.; Semenov, V.; Solovyev, A.; Shmakov, A. Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses. Materials 2023, 16, 1348. https://doi.org/10.3390/ma16041348

Grenadyorov A, Oskirko V, Zakharov A, Oskomov K, Rabotkin S, Semenov V, Solovyev A, Shmakov A. Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses. Materials. 2023; 16(4):1348. https://doi.org/10.3390/ma16041348

Chicago/Turabian StyleGrenadyorov, Alexander, Vladimir Oskirko, Alexander Zakharov, Konstantin Oskomov, Sergey Rabotkin, Vyacheslav Semenov, Andrey Solovyev, and Alexander Shmakov. 2023. "Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses" Materials 16, no. 4: 1348. https://doi.org/10.3390/ma16041348

APA StyleGrenadyorov, A., Oskirko, V., Zakharov, A., Oskomov, K., Rabotkin, S., Semenov, V., Solovyev, A., & Shmakov, A. (2023). Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses. Materials, 16(4), 1348. https://doi.org/10.3390/ma16041348