Influence of the Addition of Alumina Nanofibers on the Strength of Epoxy Resins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Nanocomposite Samples

2.3. Mechanical Tests

2.4. Differential Mechanical Analysis

2.5. Electron Microscopy

3. Results

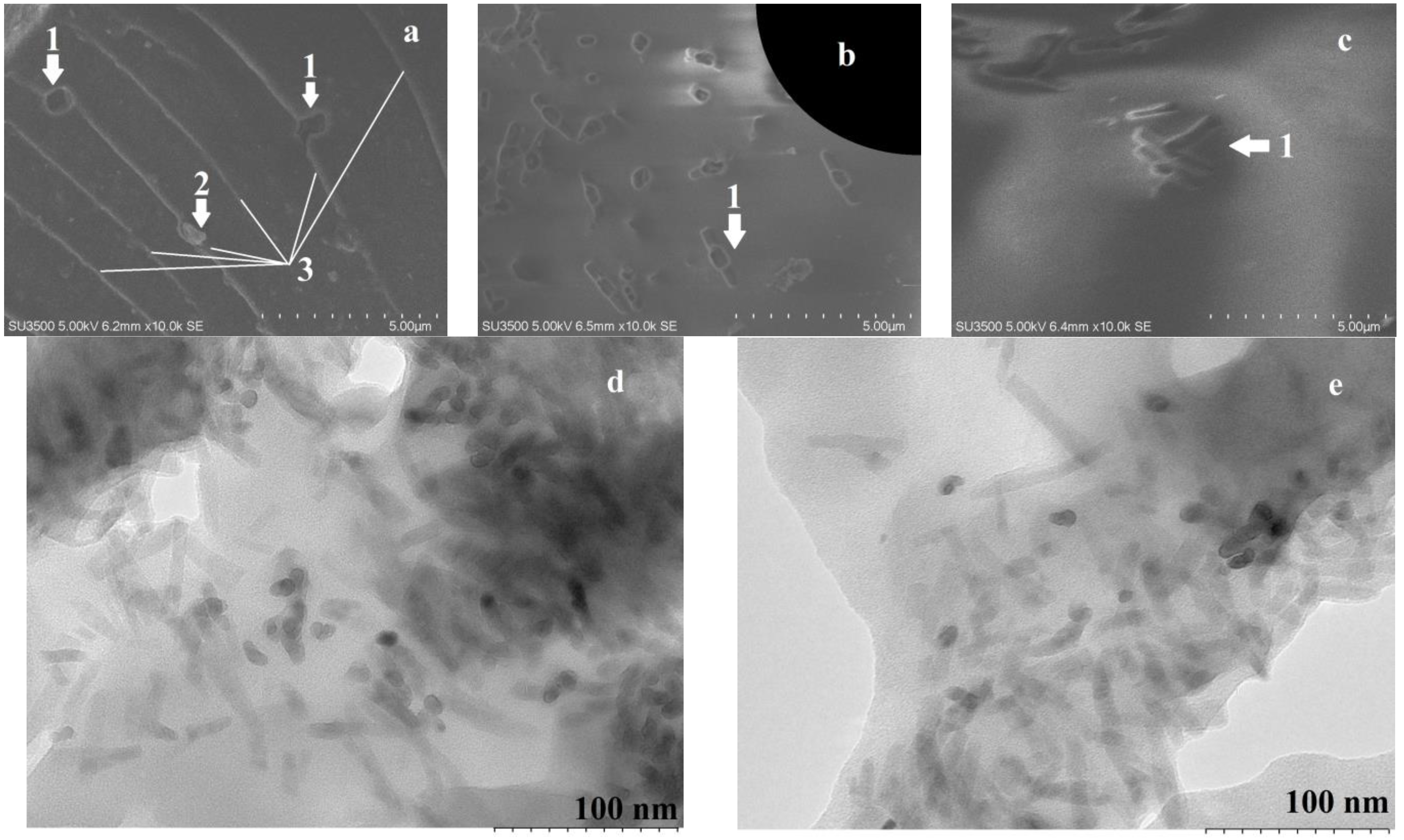

3.1. Morfology of Additive in Resin

3.2. Mechanical Properties of Nanocomposite

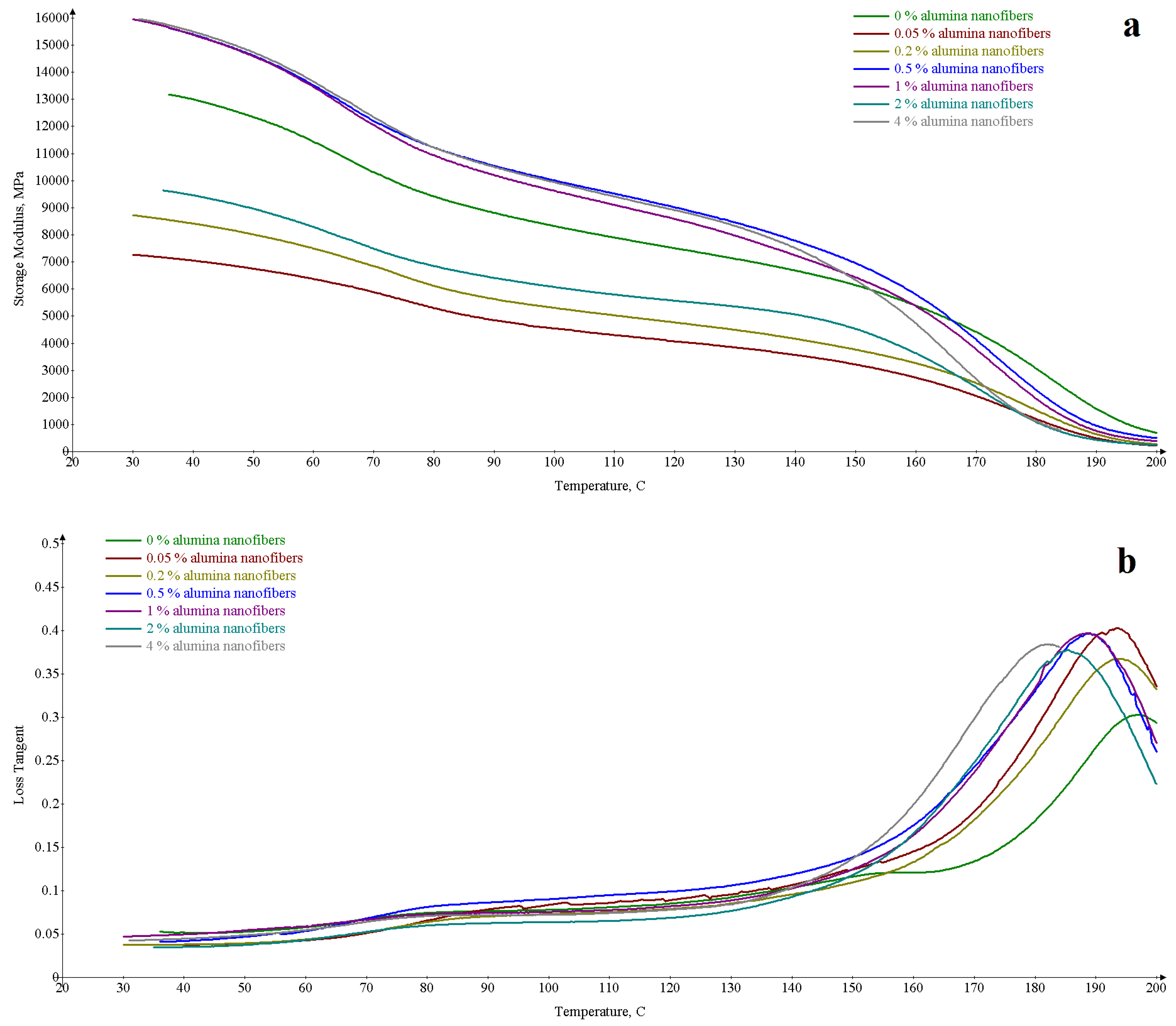

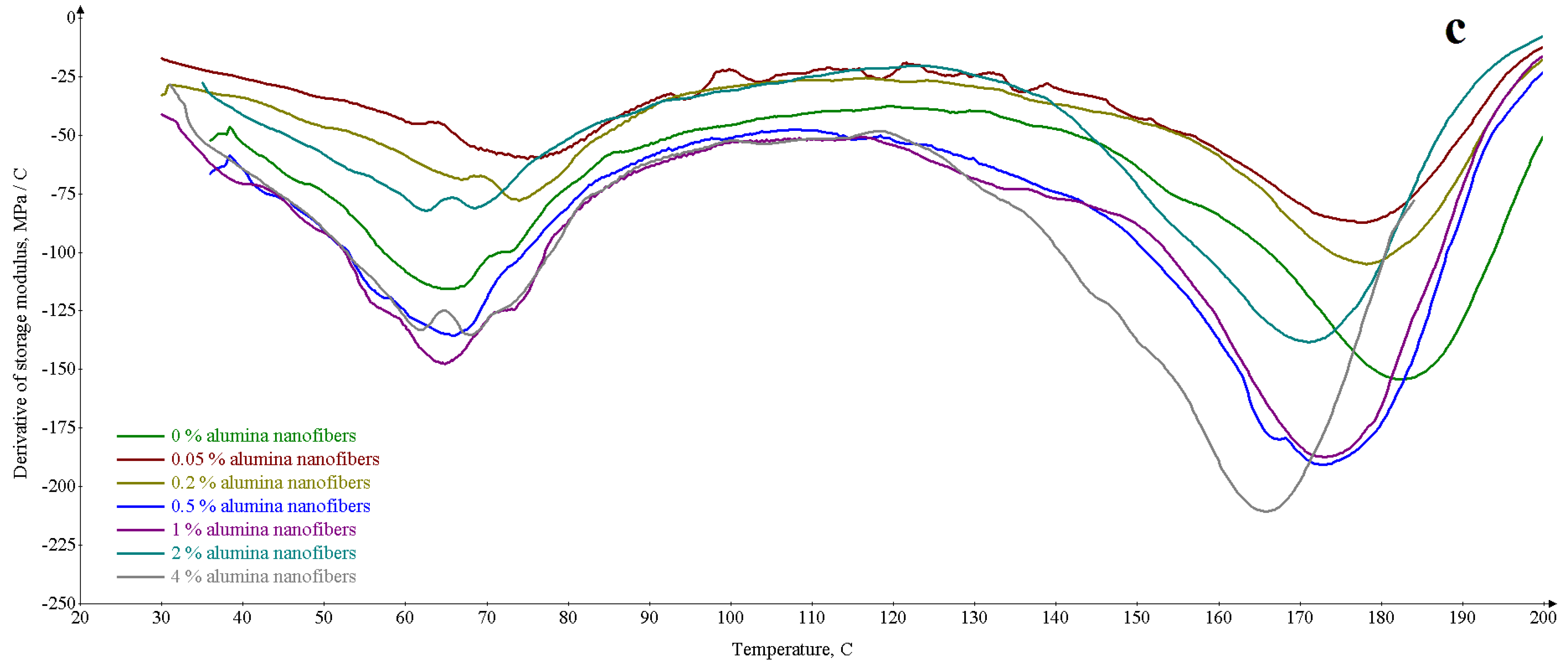

3.3. Effect of Temperature on the Mechanical Properties of the Nanocomposite

4. Conclusions

- Obtained nanocomposite samples with different concentrations of alumina nanofibers

- The effectiveness of the use of alumina nanofibers with functionalized epoxypopyl groups has been shown

- To strengthen the epoxy resin from 41 to 71 MPa in bending and from 0.643 to 0.862 GPa, 0.2 wt% of alumina nanofibers is sufficient

- The dependence of the mechanical characteristics of the samples on the proportion of the additive was obtained

- It is shown that with an increase in the number of alumina nanofibers, the glass transition temperature decreases

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Bello, S.A.; Agunsoye, J.O.; Hassan, S.B.; Kana, M.G.Z.; Raheem, I.A. Epoxy Resin Based Composites, Mechanical and Tribological Properties: A Review. Tribol. Ind. 2015, 37, 500–524. [Google Scholar]

- Rajak, D.K.; Wagh, P.H.; Linul, E. A Review on Synthetic Fibers for Polymer Matrix Composites: Performance, Failure Modes and Applications. Materials 2022, 15, 4790. [Google Scholar] [CrossRef]

- Saghafi, H.; Fotouhi, M.; Minak, G. Improvement of the Impact Properties of Composite Laminates by Means of Nano-Modification of the Matrix—A Review. Appl. Sci. 2018, 8, 2406. [Google Scholar] [CrossRef]

- Hales, T.C. A proof of the Kepler conjecture. Ann. Math. 2005, 162, 1065–1185. [Google Scholar] [CrossRef]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Abdel Hamid, Z. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef]

- Zhu, T.T.; Zhou, C.H.; Kabwe, F.B.; Wu, Q.Q.; Li, C.S.; Zhang, J.R. Exfoliation of montmorillonite and related properties of clay/polymer nanocomposites. Appl. Clay Sci. 2019, 169, 48–66. [Google Scholar] [CrossRef]

- Srinivas, K.; Naidu, A.L.; Bahubalendruni, M.V.A.R. A Review on Chemical and Mechanical Properties of Natural Fiber Reinforced Polymer Composites. Int. J. Perform. Eng. 2017, 13, 189–200. [Google Scholar] [CrossRef]

- Pras, M.; Gérard, J.-F.; Golanski, L.; Quintard, G.; Duchet-Rumeau, J. Key Role of the Dispersion of Carbon Nanotubes (CNTs) within Epoxy Networks on their Ability to Release. Polymers 2020, 12, 2530. [Google Scholar] [CrossRef]

- Rosli, N.A.H.; Loh, K.S.; Wong, W.Y.; Yunus, R.M.; Lee, T.K.; Ahmad, A.; Chong, S.T. Review of Chitosan-Based Polymers as Proton Exchange Membranes and Roles of Chitosan-Supported Ionic Liquids. Int. J. Mol. Sci. 2020, 21, 632. [Google Scholar] [CrossRef]

- Onsager, L. The effects of shape on the interaction of colloidal particles. Ann. N. Y. Acad. Sci. 1949, 51, 627–659. [Google Scholar] [CrossRef]

- Minakov, A.V.; Pryazhnikov, M.I.; Simunin, M.M.; Dobrosmyslov, S.S.; Kuular, A.A.; Molokeev, M.S.; Volochaev, M.N.; Khartov, S.V.; Voronin, A.S. Rheological properties of colloidal suspensions of alumina nanofibers. J. Mol. Liq. Part A 2022, 367, 120385. [Google Scholar] [CrossRef]

- Kuular, A.A.; Simunin, M.M.; Bermeshev, T.V.; Voronin, A.S.; Dobrosmyslov, S.S.; Fadeev, Y.V.; Molokeev, M.S.; Volochaev, M.N.; Khartov, S.V. The Influence of Alumina Nanofibers on the Physical and Mechanical Properties of Mineral-Filled Polyethylene: An Experimental Study. Tech. Phys. Lett. 2020, 46, 1215–1218. [Google Scholar] [CrossRef]

- Sukhanova, A.; Boyandin, A.; Ertiletskaya, N.; Simunin, M.; Shalygina, T.; Voronin, A.; Vasiliev, A.; Nemtsev, I.; Volochaev, M.; Pyatina, S. Study of the Effect of Modified Aluminum Oxide Nanofibers on the Properties of PLA-Based Films. Materials 2022, 15, 6097. [Google Scholar] [CrossRef] [PubMed]

- Bravaya, N.M.; Saratovskikh, S.L.; Panin, A.N.; Faingol’d, E.E.; Zharkov, I.V.; Babkina, O.N.; Lobanov, M.V. Influence of silane coupling agent on the synthesis and properties of nanocomposites obtained via in situ catalytic copolymerization of ethylene and propylene in the presence of modified Nafen™ Al2O3 nanofibers. Polymer 2019, 174, 114–122. [Google Scholar] [CrossRef]

- Simunin, M.M.; Chirkov, D.Y.; Zaloga, A.N.; Kuular, A.A.; Fadeev, Y.V.; Voronin, A.S.; Chizhova, V.V. Reinforcement of Protective Coatings Based on Powder Paints with Alumina Nanofibers. Mater. Sci. Forum 2022, 1049, 138–143. [Google Scholar] [CrossRef]

- Simunin, M.M.; Voronin, A.S.; Fadeev, Y.V.; Mikhlin, Y.L.; Lizunov, D.A.; Samoilo, A.S.; Chirkov, D.Y.; Voronina, S.Y.; Khartov, S.V. Features of Functionalization of the Surface of Alumina Nanofibers by Hydrolysis of Organosilanes on Surface Hydroxyl Groups. Polymers 2021, 13, 4374. [Google Scholar] [CrossRef]

- Su, W.; Zou, J.; Sun, L. Effects of nano-alumina on mechanical properties and wear resistance of WC-8Co cemented carbide by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2020, 92, 105337. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Tun, K.S.; Gupta, M. Effect of Nano-Alumina and Copper Micron Size Particulates on Microstructure and Mechanical Properties of Magnesium Alloy AZ31. In Magnesium Technology; Mathaudhu, S.N., Sillekens, W.H., Neelameggham, N.R., Hort, N., Eds.; Springer: Cham, Switzerland, 2012. [Google Scholar] [CrossRef]

- Ghabezi, P.; Farahani, M. A cohesive model with a multi-stage softening behavior to predict fracture in nano composite joints. Eng. Fract. Mech. 2019, 219, 106611. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H.; Tang, L.; Liu, G.; Zhang, D.; Zhou, L.; Zhang, Z. The Effects of Alumina Nanofillers on Mechanical Properties of High-Performance Epoxy Resin. J. Nanosci. Nanotechnol. 2010, 10, 1–7. [Google Scholar] [CrossRef]

- Kutuzov, M. Method and System for Alumina Nanofibers Synthesis from Molten Aluminum. ANF Technology Limited, assignee. U.S. Patent WO2013114183 A1, 8 August 2013. [Google Scholar]

- Balberg, I.; Binenbaum, N.; Wagner, N. Percolation Thresholds in the Three-Dimensional Sticks System. Phys. Rev. Lett. 1984, 52, 1465–1468. [Google Scholar] [CrossRef]

| Sample | Ultimate Stress | Elastic Modulus |

|---|---|---|

| MPa | GPa | |

| Epoxy reference | 41 | 0.643 |

| Epoxy + 0.05% NFA | 53 | 0.714 |

| Epoxy + 0.2% NFA | 71 | 0.862 |

| Epoxy + 0.5% NFA | 56 | 0.742 |

| Epoxy + 1% NFA | 43 | 0.704 |

| Epoxy + 2% NFA | 42 | 0.801 |

| Epoxy + 4% NFA | 42 | 0.868 |

| Sample | E (T = 40 °C) | E (T = 200 °C) | tg δmax | Tmax loss | Tmin dE/dT |

|---|---|---|---|---|---|

| MPa | MPa | °C | °C | ||

| Epoxy reference | 12998 | 690 | 0.3029 | 197 | 182 |

| Epoxy + 0.05% NFA | 7051 | 222 | 0.4022 | 194 | 178 |

| Epoxy + 0.2% NFA | 8418 | 276 | 0.3674 | 194 | 178 |

| Epoxy + 0.5% NFA | 15398 | 502 | 0.397 | 189 | 173 |

| Epoxy + 1% NFA | 15382 | 391 | 0.3969 | 189 | 173 |

| Epoxy + 2% NFA | 9460 | 250 | 0.3773 | 185 | 171 |

| Epoxy + 4% NFA | 15500 | 243 | 0.3843 | 182 | 166 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simunin, M.M.; Voronin, A.S.; Fadeev, Y.V.; Dobrosmyslov, S.S.; Kuular, A.A.; Shalygina, T.A.; Shabanova, K.A.; Chirkov, D.Y.; Voronina, S.Y.; Khartov, S.V. Influence of the Addition of Alumina Nanofibers on the Strength of Epoxy Resins. Materials 2023, 16, 1343. https://doi.org/10.3390/ma16041343

Simunin MM, Voronin AS, Fadeev YV, Dobrosmyslov SS, Kuular AA, Shalygina TA, Shabanova KA, Chirkov DY, Voronina SY, Khartov SV. Influence of the Addition of Alumina Nanofibers on the Strength of Epoxy Resins. Materials. 2023; 16(4):1343. https://doi.org/10.3390/ma16041343

Chicago/Turabian StyleSimunin, M. M., A. S. Voronin, Yu. V. Fadeev, S. S. Dobrosmyslov, A. A. Kuular, T. A. Shalygina, K. A. Shabanova, D. Yu. Chirkov, S. Yu. Voronina, and S. V. Khartov. 2023. "Influence of the Addition of Alumina Nanofibers on the Strength of Epoxy Resins" Materials 16, no. 4: 1343. https://doi.org/10.3390/ma16041343

APA StyleSimunin, M. M., Voronin, A. S., Fadeev, Y. V., Dobrosmyslov, S. S., Kuular, A. A., Shalygina, T. A., Shabanova, K. A., Chirkov, D. Y., Voronina, S. Y., & Khartov, S. V. (2023). Influence of the Addition of Alumina Nanofibers on the Strength of Epoxy Resins. Materials, 16(4), 1343. https://doi.org/10.3390/ma16041343