A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting

Abstract

:1. Introduction

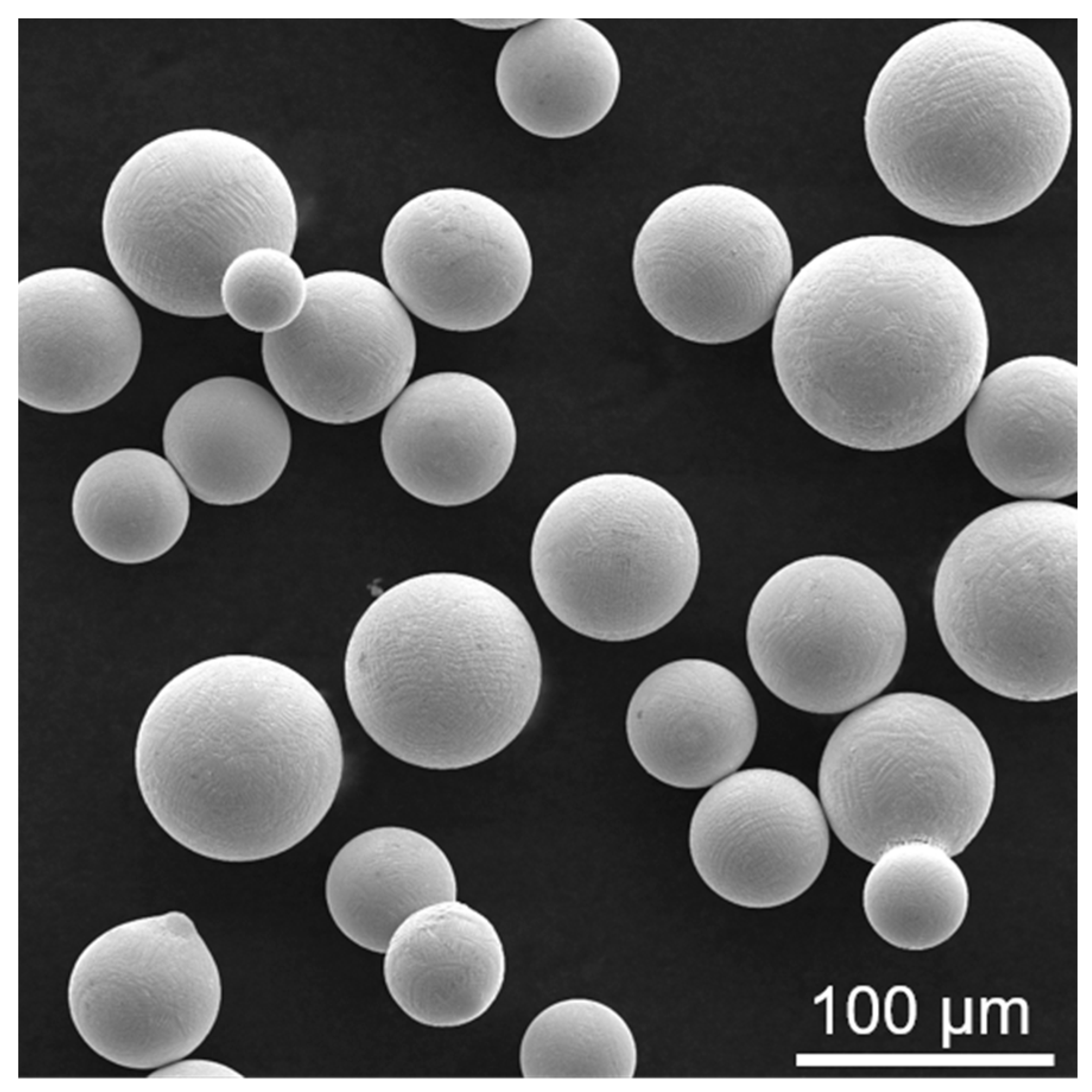

2. Materials and Methods

2.1. Material Preparation

2.2. Tensile and Corrosion Tests

2.3. Characterization

3. Results and Discussion

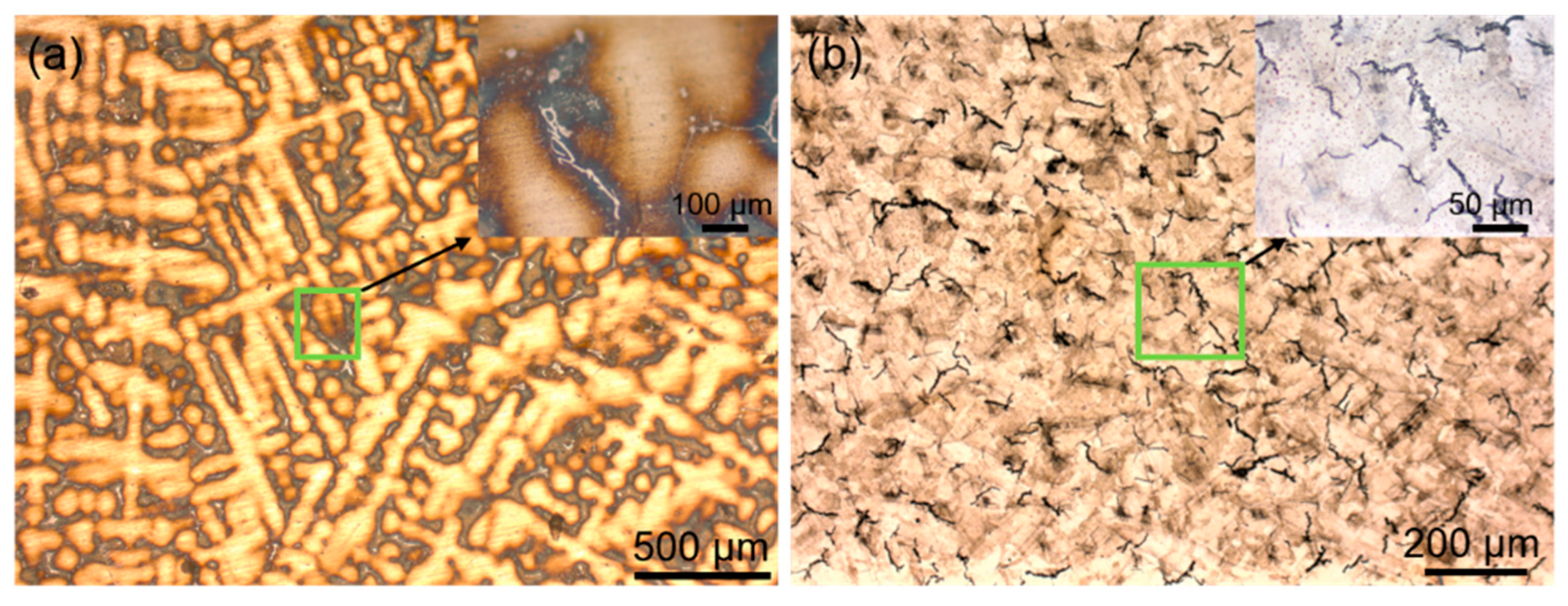

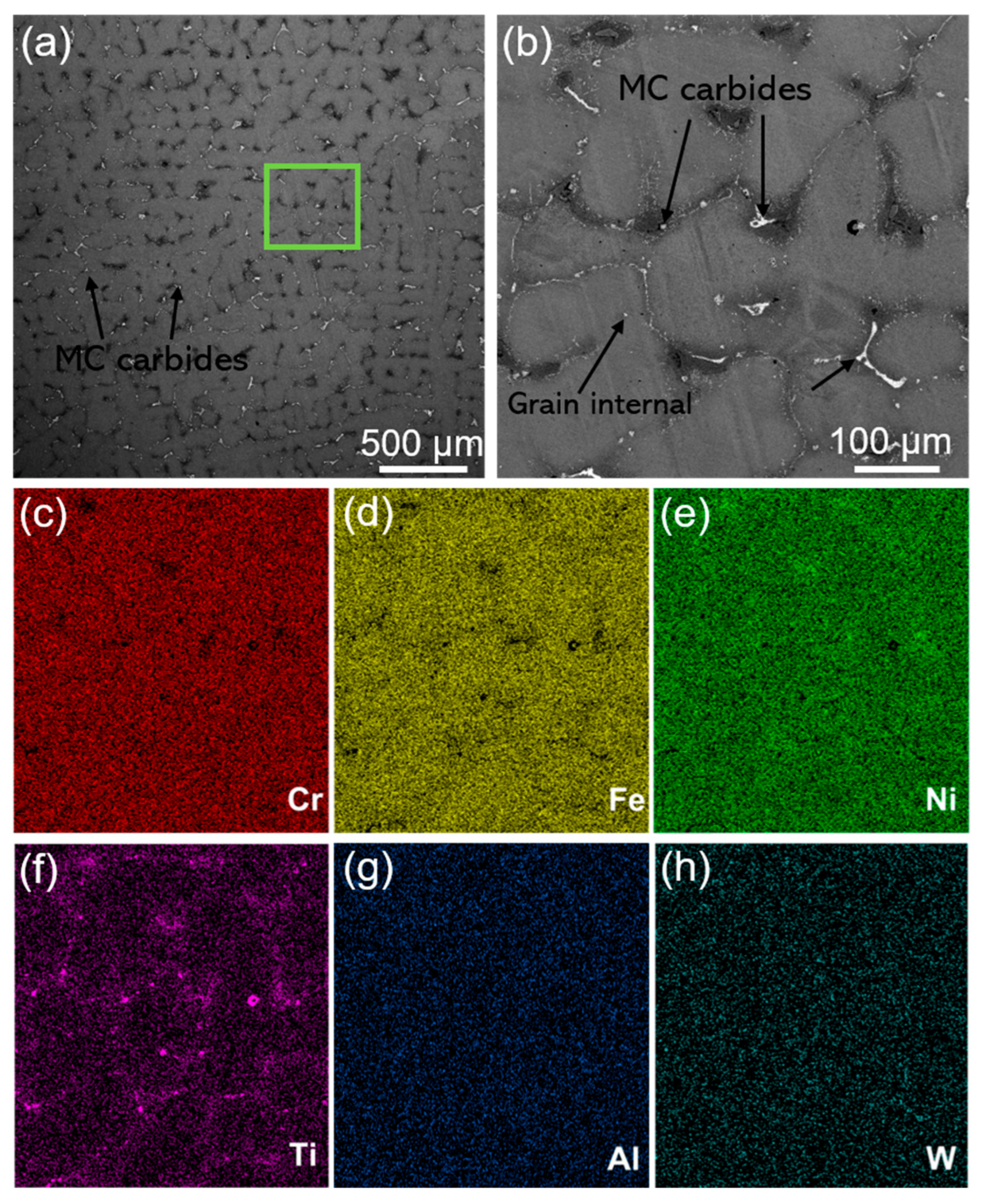

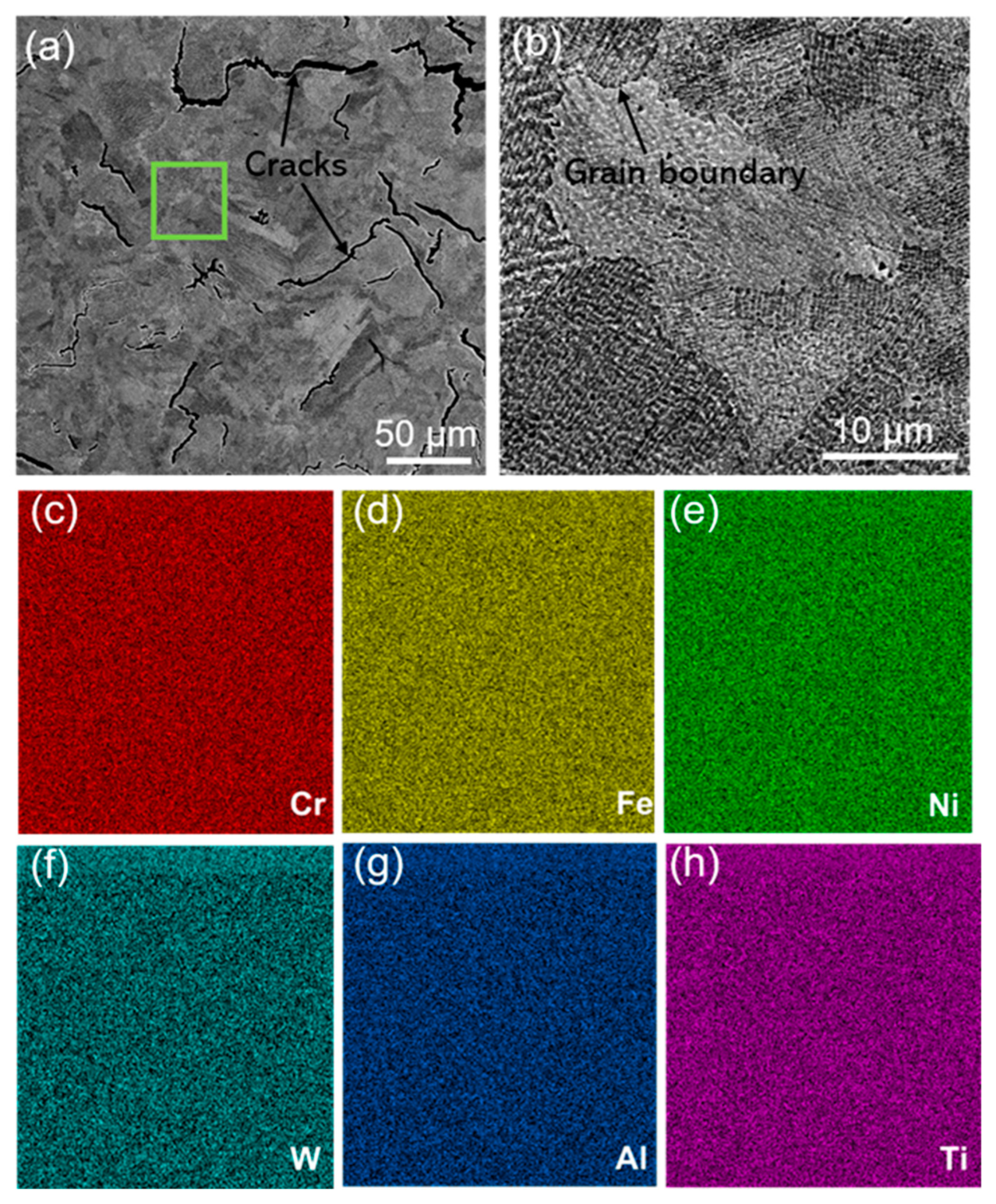

3.1. Microstructure Characterization

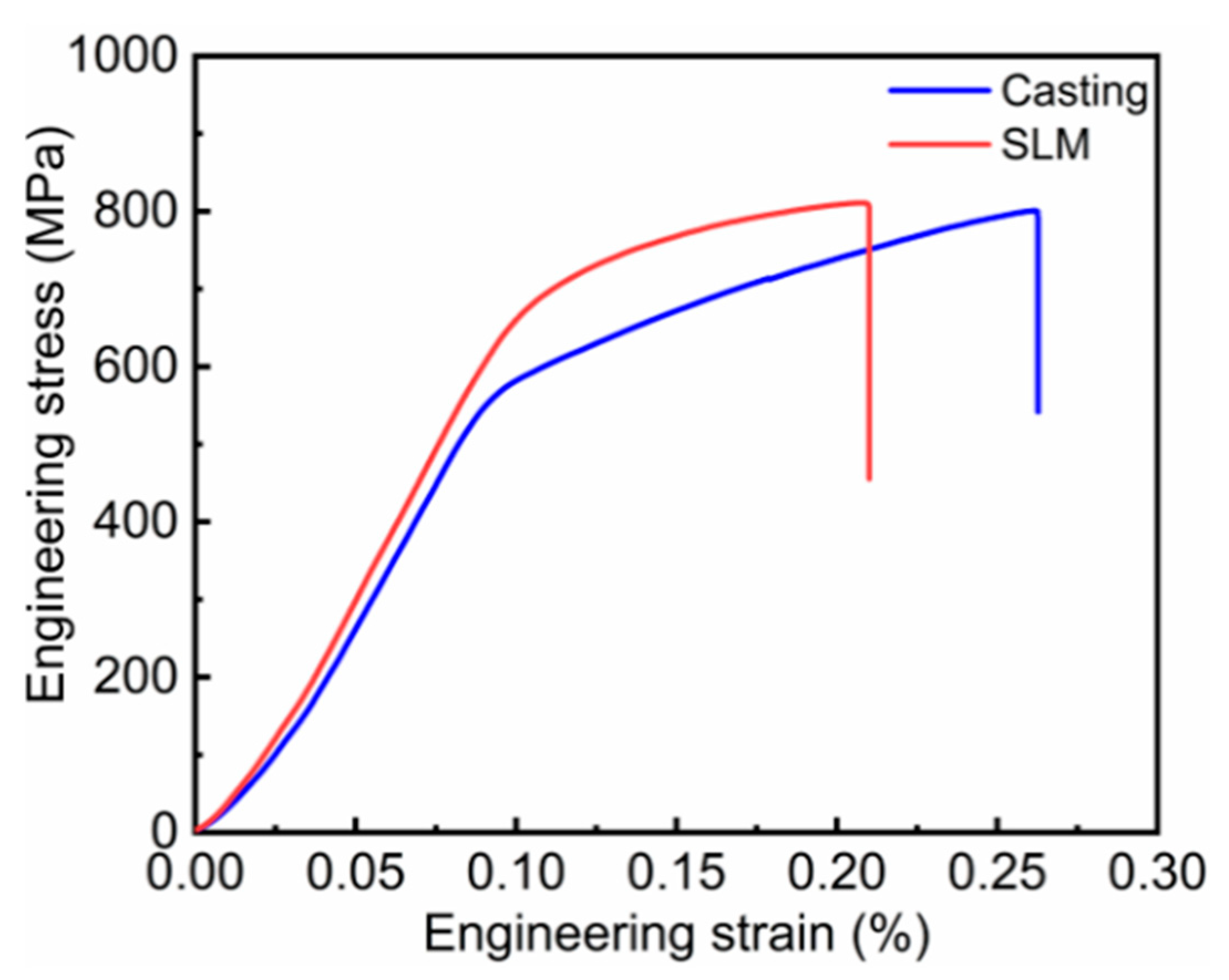

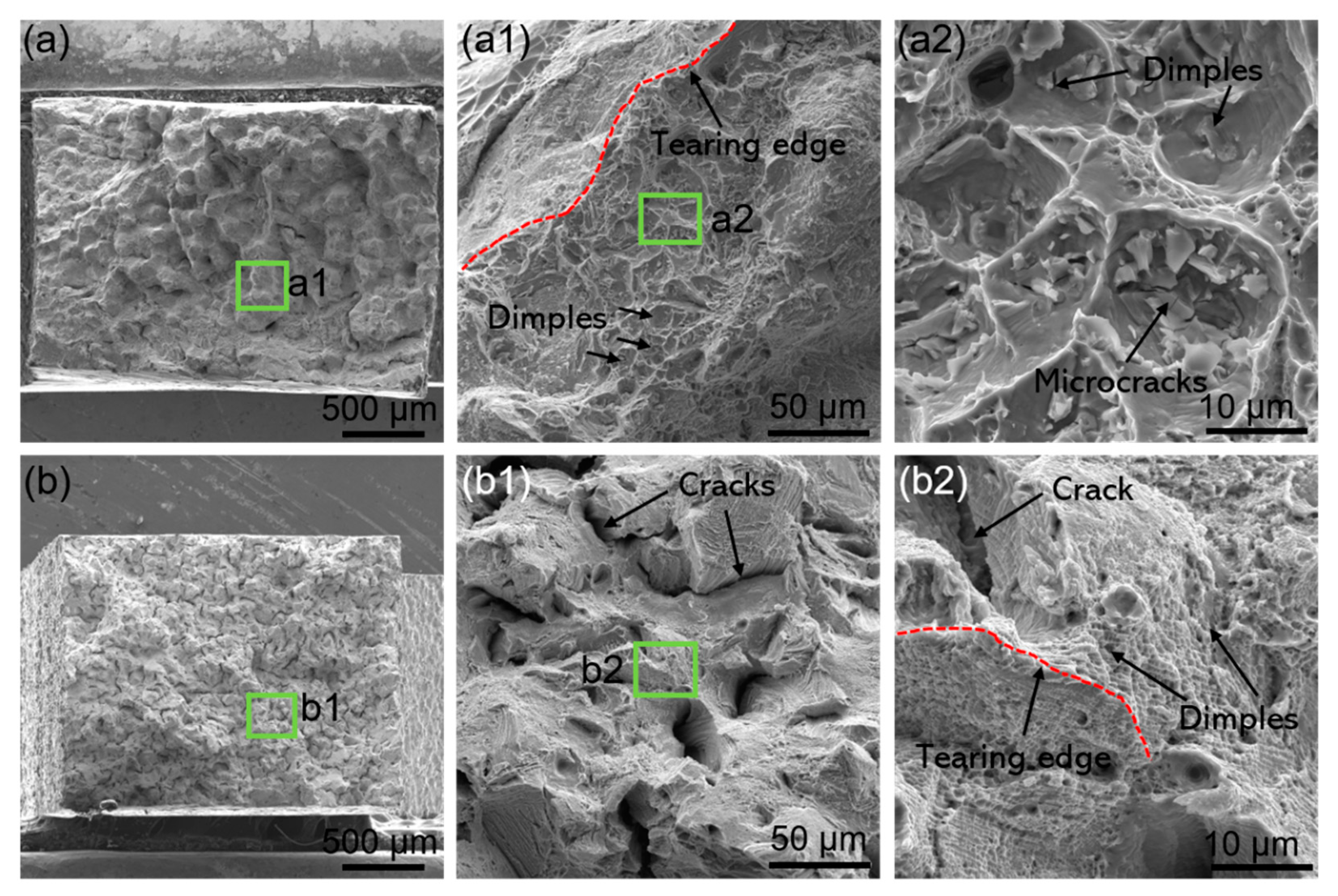

3.2. Mechanical Properties

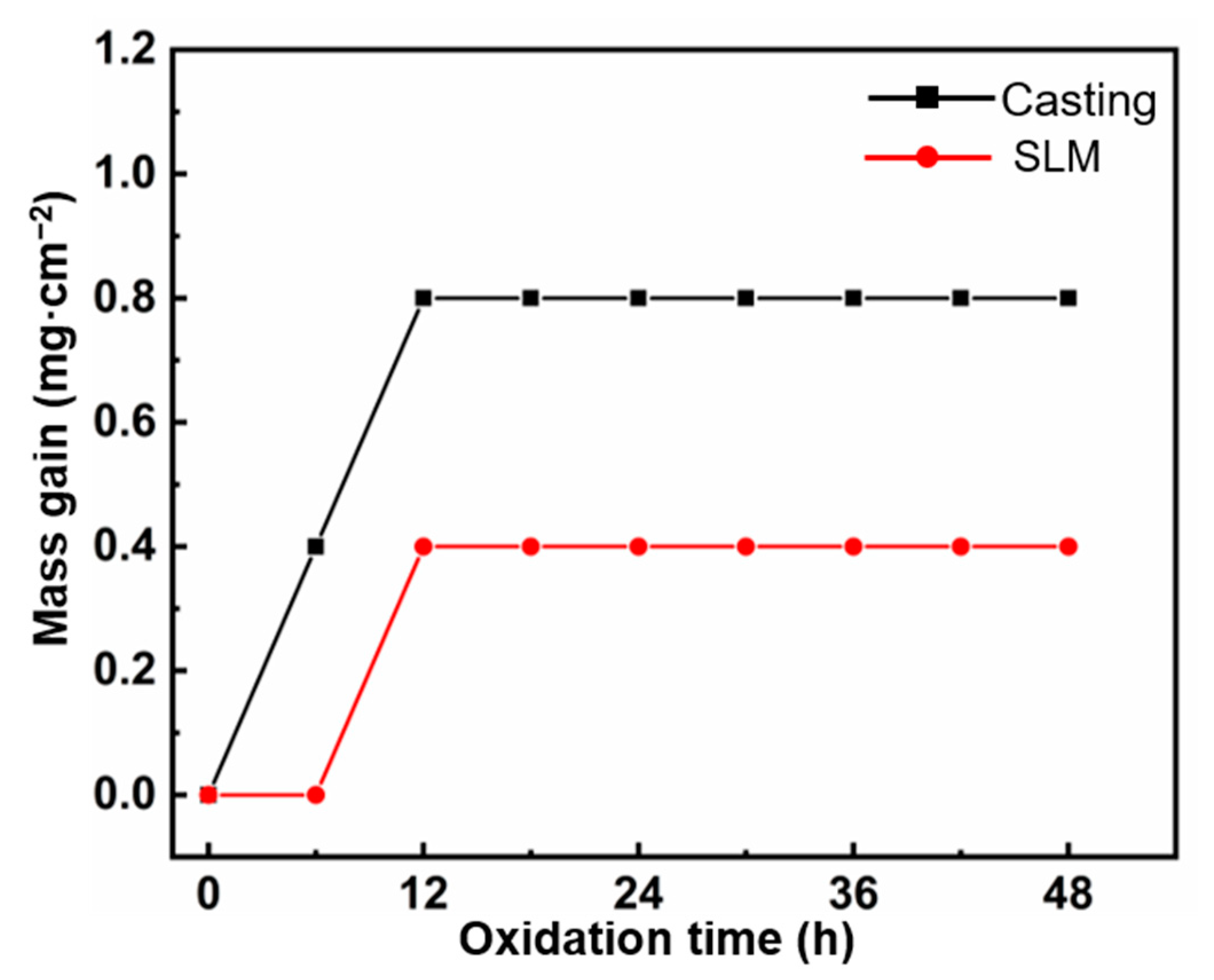

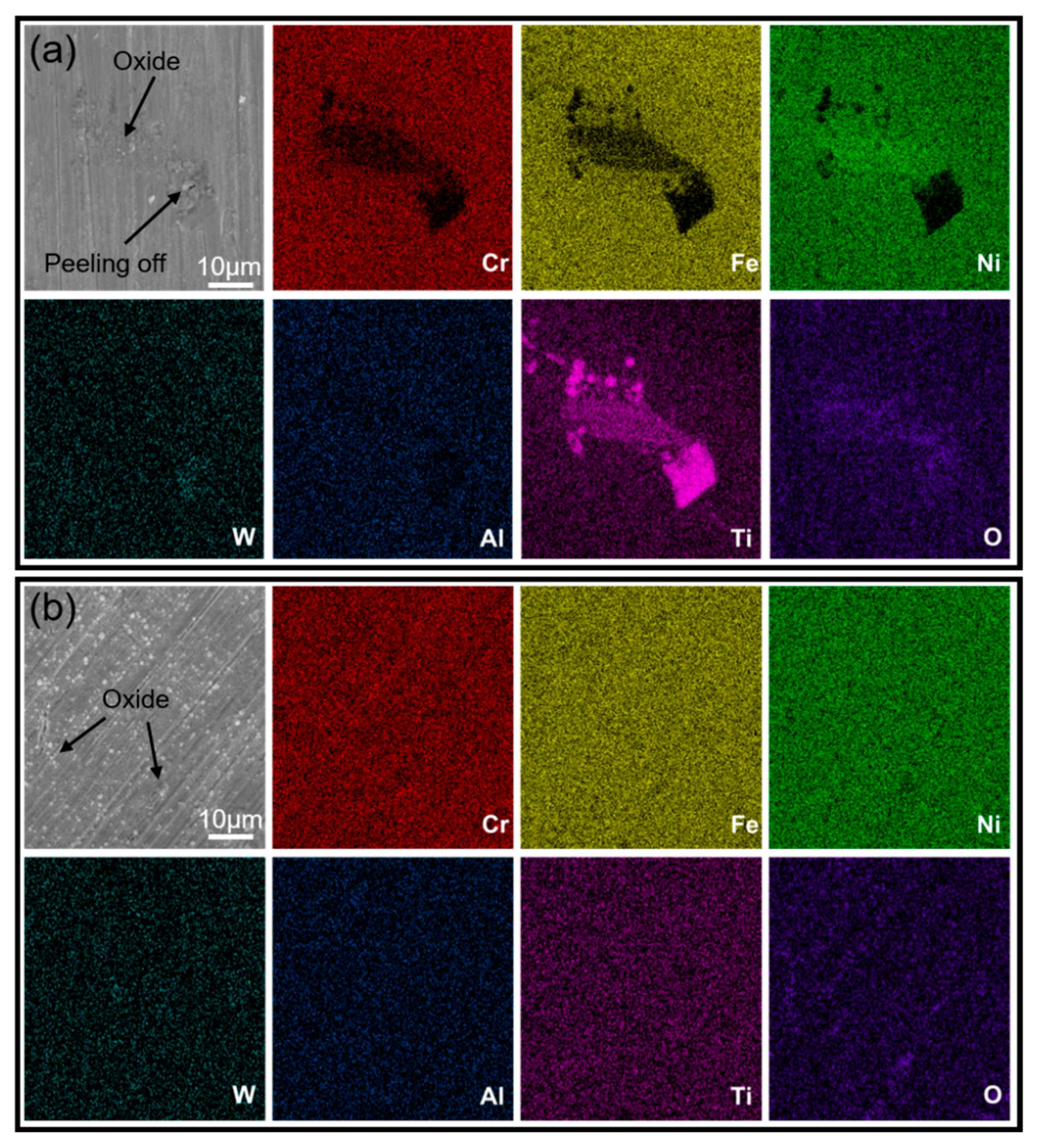

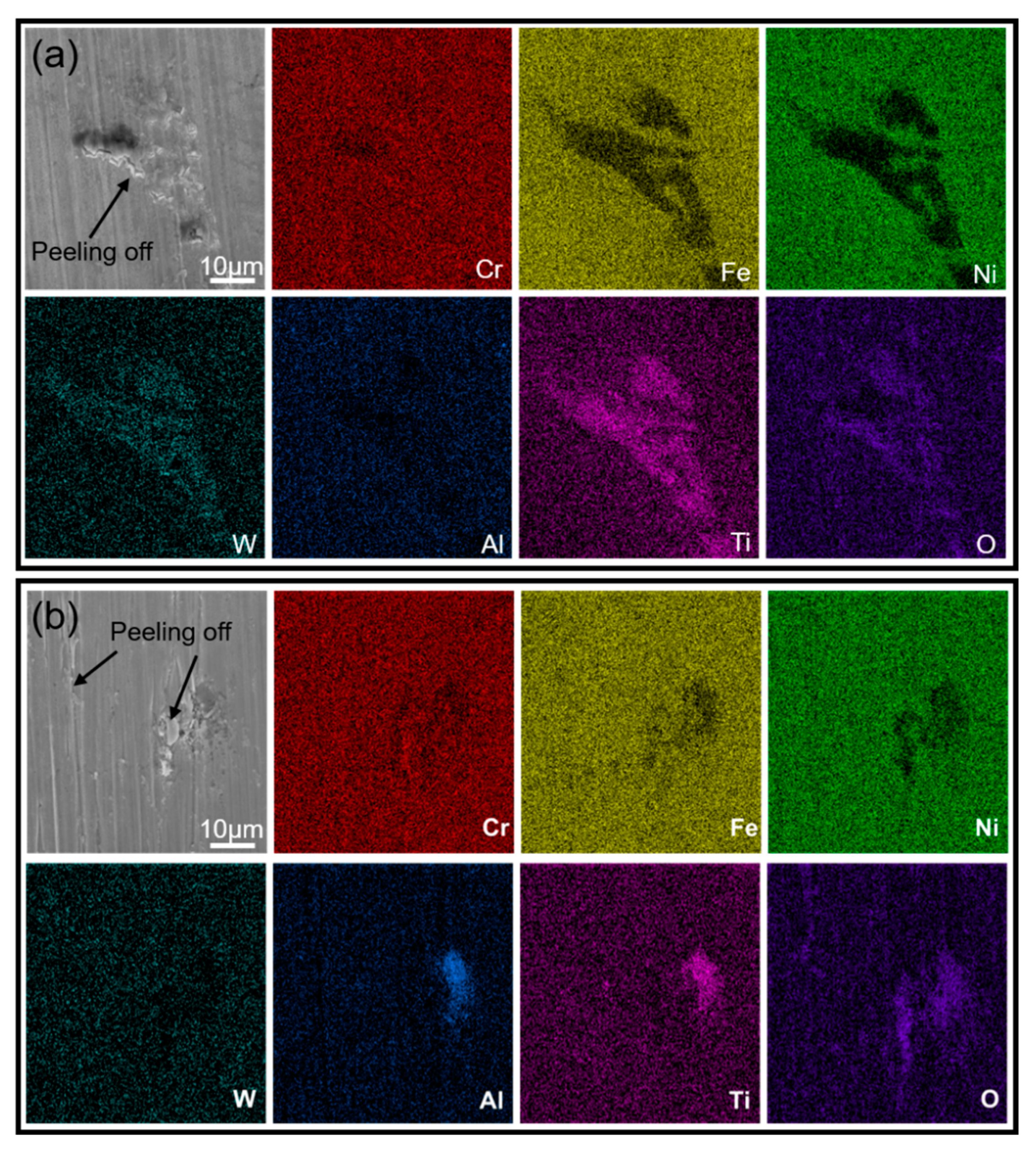

3.3. High-Temperature Oxidation Resistance

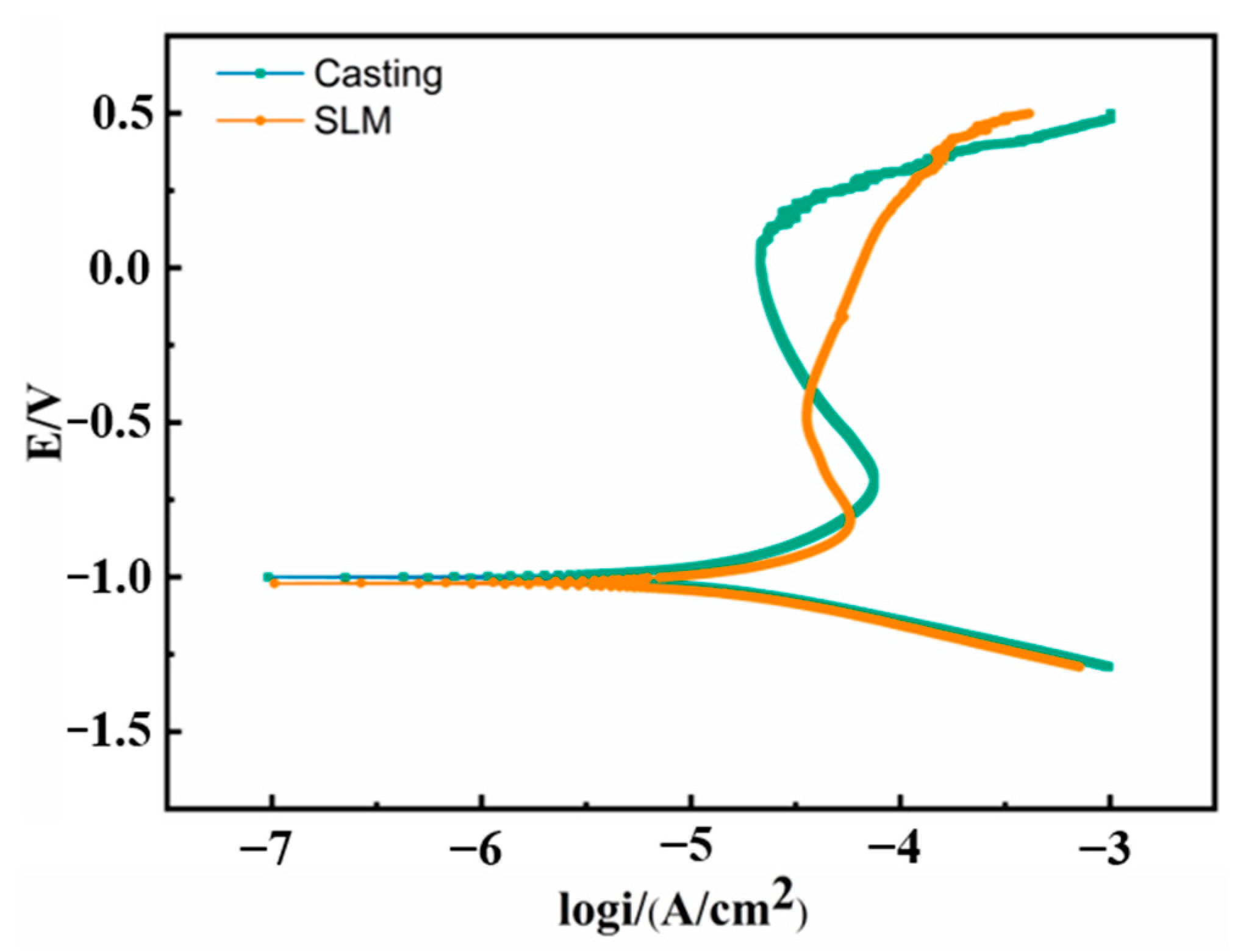

3.4. Potentiodynamic Polarization Behavior

4. Conclusions

- (1)

- During the melting process of the K213 alloy, the segregation of Ti occurs in the grain interior and grain boundaries, and MC carbides are formed. However, the composition of the SLM K213 alloy is uniform, although cracks are formed in the matrix.

- (2)

- The as-cast K213 alloy has a relatively good combined effect of strength and plasticity. The main factors limiting the mechanical properties of the as-cast and SLM K213 alloys are carbides and cracks, respectively. The reason is that there is deformation incompatibility between the carbides and matrix in the as-cast sample, and the cavity defect is easy to occur during the tensile process. Stress concentration is easy to occur in the crack area of the SLM specimen, which leads to early fracture.

- (3)

- The SLM sample has relatively well high-temperature oxidation resistance. The MC precipitates in the as-cast K213 alloy accelerate the high-temperature oxidation. In addition, due to the different solidification segregations in the alloy, different oxides are formed during the oxidation process for the two samples. Cracks in the SLM alloy weaken the electrochemical corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Li, D.; Chen, X.; Wang, J.; Chen, B.; Ma, X.; Qu, X. Preparation of MIM213 turbine wheel with hollow internal structure. Mater. Design. 2015, 86, 474–481. [Google Scholar] [CrossRef]

- Martischius, D.; Wohlfromm, H.; Kern, A.; Maat, J.; Blmacher, M. Turbocharger technology presents new opportunities for metal injection moulding (MIM). Powder Inject. Mould. Int. 2009, 3, 68–70. [Google Scholar]

- Miura, H.; Ikeda, H.; Iwahashi, T.; Osada, T. High temperature and fatigue properties of injection moulded superalloy compacts. Powder Inject. Mould. Int. 2010, 4, 4. [Google Scholar]

- Davies, P.; Dunstan, G.; Howells, R.; Hayward, A. Aerospace adds lustre to appeal of master alloy MIM feedstocks. Met. Powder Rep. 2004, 59, 14–19. [Google Scholar] [CrossRef]

- Bharambe, C.; Jaybhaye, M.; Dalmiya, A.; Daund, C.; Shinde, D. Analyzing casting defects in high-pressure die casting industrial case study. Mater. Today Proc. 2022, 72, 2214–7853. [Google Scholar] [CrossRef]

- Tang, W.; Zhao, T.; Dou, R.; Wang, L. Additive manufacturing of low-shrinkage alumina cores for single-crystal nickel-based superalloy turbine blade casting. Ceram. Int. 2022, 48, 15218–15226. [Google Scholar] [CrossRef]

- Pang, K.; Yuan, H. Fatigue life assessment of a porous casting nickel-based superalloy based on fracture mechanics methodology. Int. J. Fatigue 2020, 136, 105575. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, L.; Zhang, Q.; Xiong, W. Phase transformations during continuous cooling in Inconel 718 alloys manufactured by laser powder bed fusion and suction casting. Mater. Charact. 2022, 185, 111764. [Google Scholar] [CrossRef]

- Zhong, H.; Wang, R.; Han, Q.; Fang, M.; Yuan, H.; Song, L.; Xie, X.; Zhai, Q. Solidification structure and central segregation of 6Cr13Mo stainless steel under simulated continuous casting conditions. J. Mater. Res. Technol. 2022, 20, 3408–3419. [Google Scholar] [CrossRef]

- Li, N.; Mao, W.; Geng, X.; Zhang, R.; Yan, B. Microstructure, segregation and fracture behavior of 6061 aluminum alloy samples formed by semi-solid or traditional high pressure die casting. Mater. Today Commun. 2022, 31, 103418. [Google Scholar] [CrossRef]

- Yue, T.; Zhang, S.; Wang, C.; Xu, W.; Xu, Y.; Shi, Y.; Zang, Y. Effects of selective laser melting parameters on surface quality and densification behaviours of pure nickel. Trans. Nonferrous Met. Soc. China 2022, 32, 2634–2647. [Google Scholar] [CrossRef]

- Xiong, Y.; Zhang, F.; Dai, T.; Shang, C.; Wan, Q. Crystal growth mechanism and mechanical properties of Ti-6Al-4 V alloy during selective laser melting. Mater. Charact. 2022, 194, 112455. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.; Yang, H.; Zhang, S.; Lin, X.; Huang, W. Microstructure and mechanical properties of Y2O3 strengthened Inconel 625 alloy fabricated by selective laser melting. Mater. Sci. Eng. A 2022, 854, 143813. [Google Scholar] [CrossRef]

- Cheng, B.; Liu, C.; Song, M. A comparison of the microstructures and mechanical properties of a GH648 superalloy fabricated by selective laser melting and casting. Mater. Sci. Eng. A 2021, 813, 141178. [Google Scholar] [CrossRef]

- Chen, H.; Li, W.; Huang, Y.; Xie, Z.; Zhu, X.; Liu, B.; Wang, B. Molten pool effect on mechanical properties in a selective laser melting 316L stainless steel at high-velocity deformation. Mater. Charact. 2022, 194, 112409. [Google Scholar] [CrossRef]

- Li, B.; Du, J.; Sun, Y.; Zhang, S.; Zhang, Q. On the importance of heat source model determination for numerical modeling of selective laser melting of IN625. Opt. Laser Technol. 2023, 158, 108806. [Google Scholar] [CrossRef]

- Chang, K.; Ma, L.; Li, P.; Lv, J.; You, X.; Zhang, Y.; Tan, Y. Effect of heat treatment on microstructure and mechanical properties of GH4099 superalloy fabricated by selective laser melting. J. Alloys Compd. 2022, 934, 167813. [Google Scholar] [CrossRef]

- Zhang, L.; Li, D.; Chen, X.; Qu, X.; Qin, M.; He, X.; Li, Z.; Wang, J. Microstructure and mechanical properties of MIM213 superalloy. Mater. Chem. Phys. 2015, 168, 18–26. [Google Scholar] [CrossRef]

- Mahalli, M.; Ahmadi, A.; Sabouri, M. Investigation of intergranular stress corrosion cracking in a failed 347H stainless steel furnace tube. Eng. Fail. Anal. 2022, 142, 106835. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, W.; Fu, H.; Li, J. The effect of corrosion evolution on the stress corrosion cracking behavior of mooring chain steel. Corros. Sci. 2022, 203, 110316. [Google Scholar] [CrossRef]

- Hu, Y.; Kang, W.; Zhang, H.; Chu, C.; Wang, L.; Hu, Y.; Ding, Y.; Zhang, D. Hot corrosion behavior of IN738LC alloy formed by selective laser melting. Corros. Sci. 2022, 198, 110154. [Google Scholar] [CrossRef]

- Luo, G.; Cheng, M.; Zhao, L.; Tang, Y.; Yao, J.; Cui, H.; Song, L. Preferential interdendritic oxidation of laser additively manufactured Inconel 718. Corros. Sci. 2021, 179, 109144. [Google Scholar] [CrossRef]

- Jiang, H.; Xiang, X.; Dong, J. The morphology and characteristics evolution of MC carbide during homogenization in hard-to-deform superalloy GH4975. J. Alloys Compd. 2022, 929, 167086. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.; Zhang, P.; Cao, K.; Wang, Z.; Chen, F.; Liu, D.; Tang, B.; Kou, H.; Li, J. Influence of heat treatment on Inconel 625 superalloy sheet: Carbides, γ″, δ phase precipitation and tensile deformation behavior. J. Alloys Compd. 2023, 930, 167522. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Xu, L.; Xu, J.; Ren, X.; Chen, X. Cracking mechanism and susceptibility of laser melting deposited Inconel 738 superalloy. Mater. Design. 2019, 183, 108105. [Google Scholar] [CrossRef]

| Ni | Cr | Ti | W | Al | Mn | S | Si | C | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 37.25 | 15.13 | 3.88 | 5.365 | 1.585 | 0.078 | 0.007 | 0.143 | 0.061 | Bal. |

| Samples | Ecorr (V) | Icorr (μA/cm2) |

|---|---|---|

| Casting | −1.000 | 11.72 |

| SLM | −1.020 | 15.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, Z.; Sui, Q.; Xu, S.; Yuan, Q.; Zhang, D.; Liu, J. A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting. Materials 2023, 16, 1331. https://doi.org/10.3390/ma16041331

Wang J, Wang Z, Sui Q, Xu S, Yuan Q, Zhang D, Liu J. A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting. Materials. 2023; 16(4):1331. https://doi.org/10.3390/ma16041331

Chicago/Turabian StyleWang, Jiang, Zhen Wang, Qingxuan Sui, Shurong Xu, Quan Yuan, Dong Zhang, and Jun Liu. 2023. "A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting" Materials 16, no. 4: 1331. https://doi.org/10.3390/ma16041331

APA StyleWang, J., Wang, Z., Sui, Q., Xu, S., Yuan, Q., Zhang, D., & Liu, J. (2023). A Comparison of the Microstructure, Mechanical Properties, and Corrosion Resistance of the K213 Superalloy after Conventional Casting and Selective Laser Melting. Materials, 16(4), 1331. https://doi.org/10.3390/ma16041331