Micron- and Nanosized Alloy Particles Made by Electric Explosion of W/Cu-Zn and W/Cu/Ni-Cr Intertwined Wires for 3D Extrusion Feedstock

Abstract

1. Introduction

2. Experimental Procedure

2.1. Electric Explosion Synthesis of Multimetallic Particles

2.2. Characterization of Powders

3. Results and Discussion

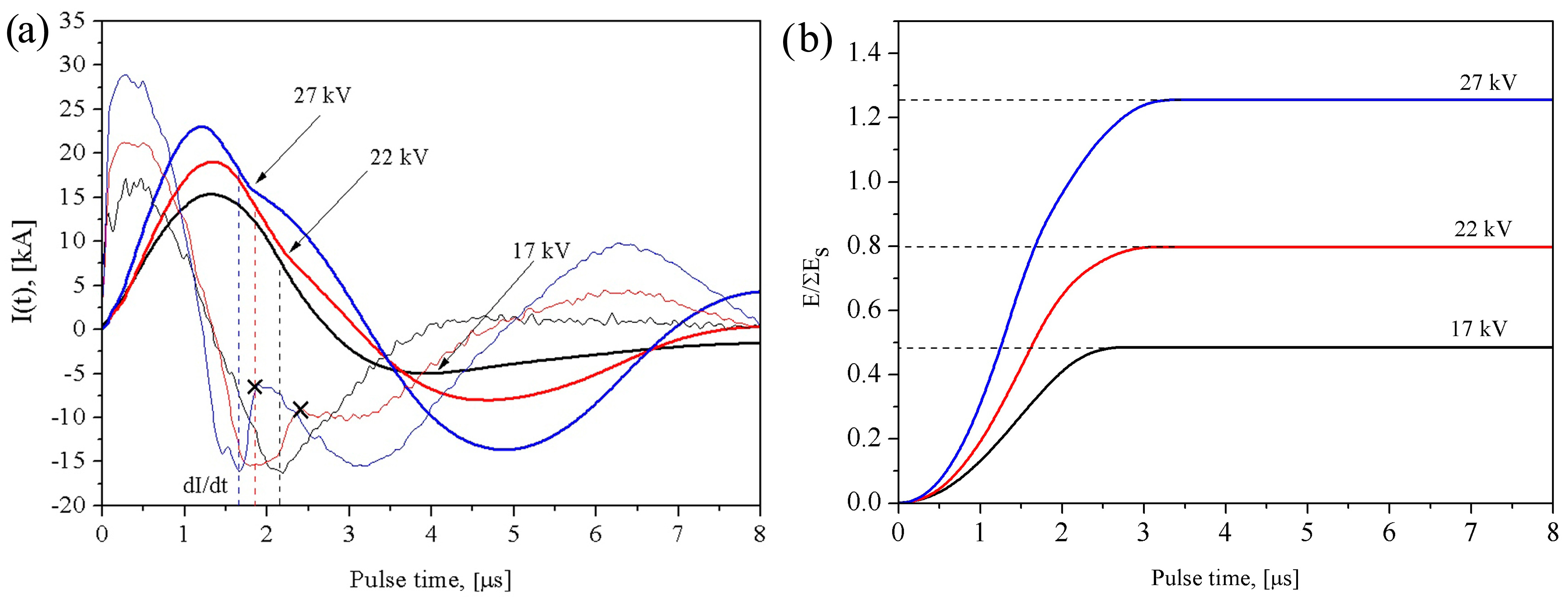

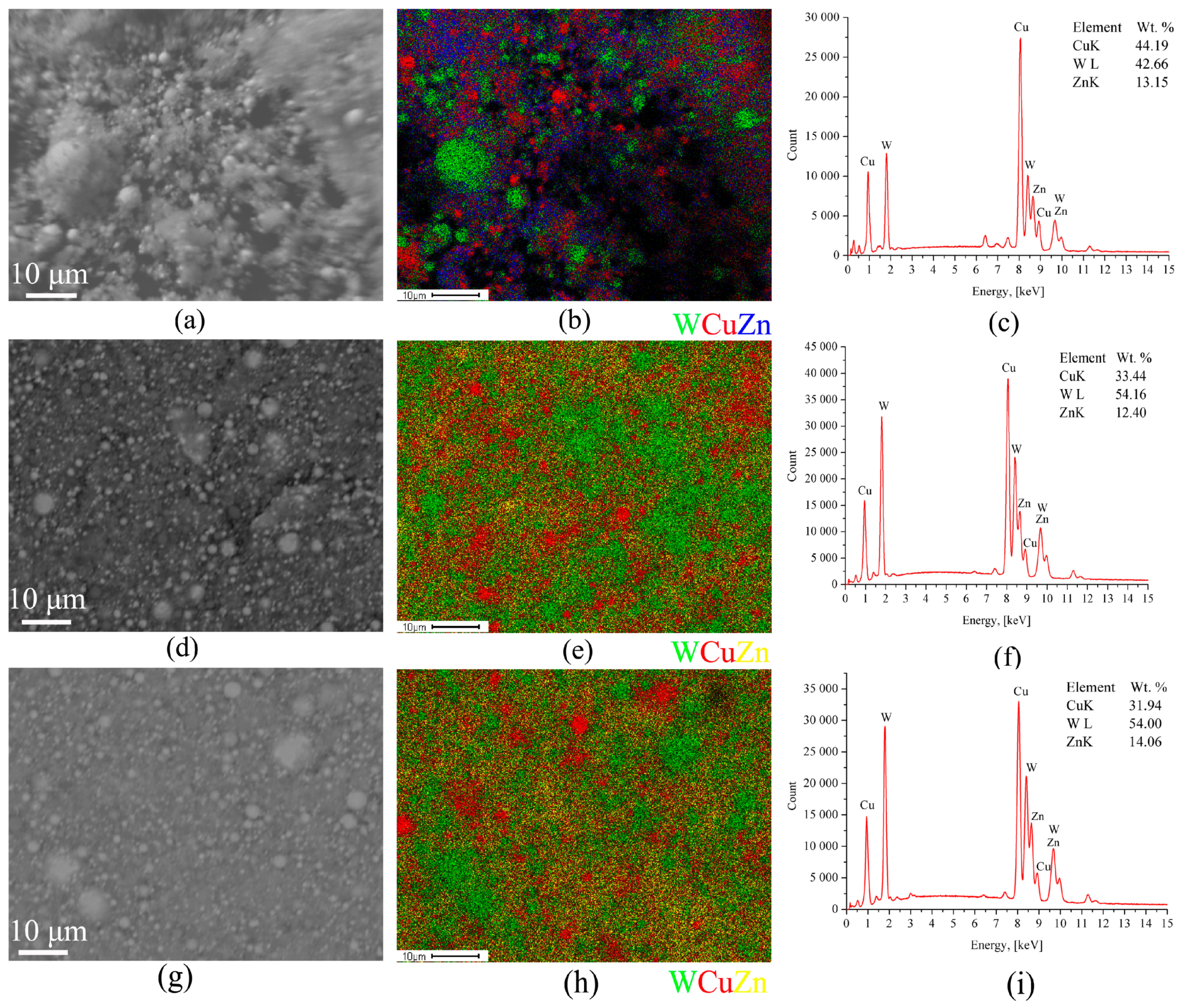

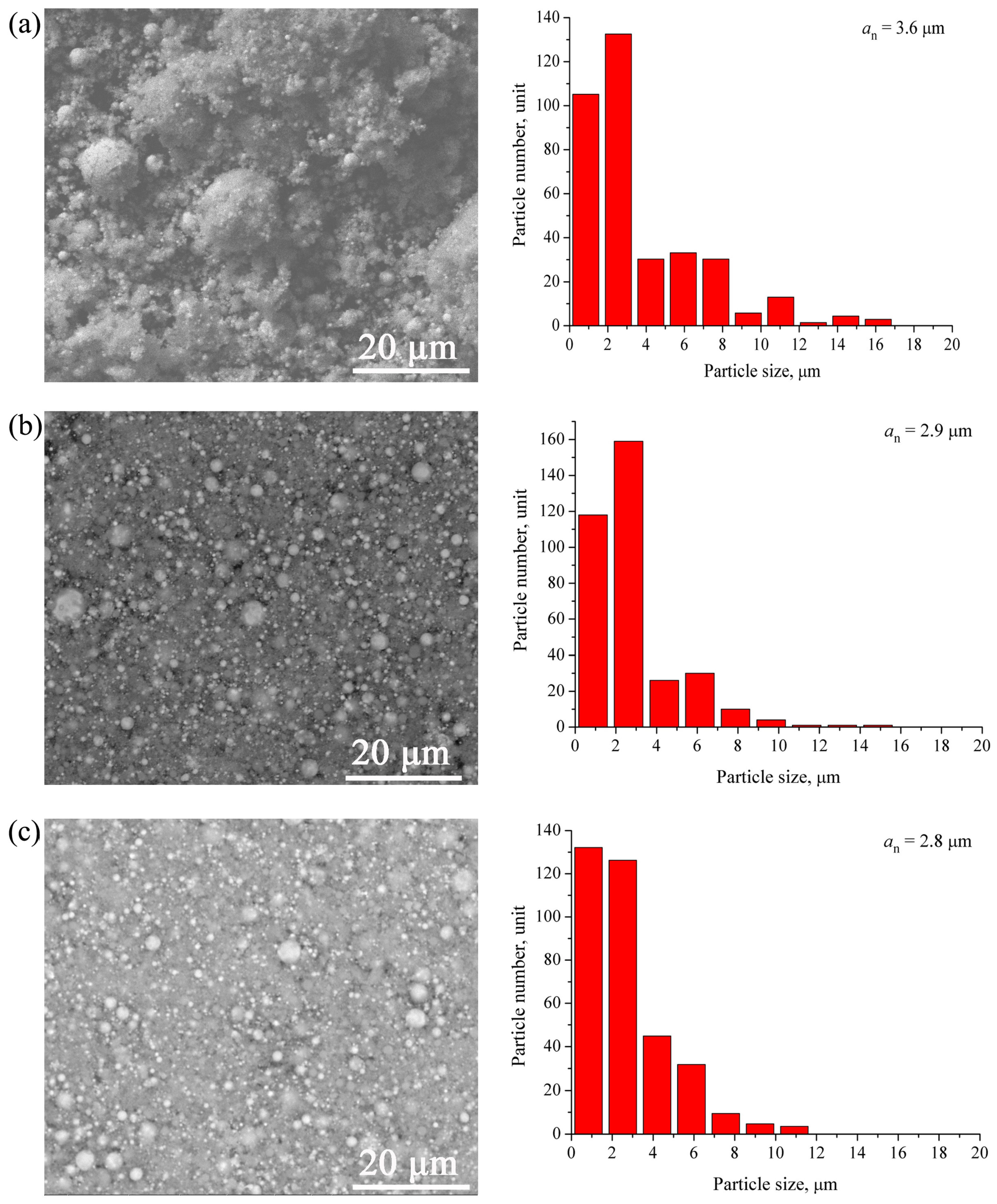

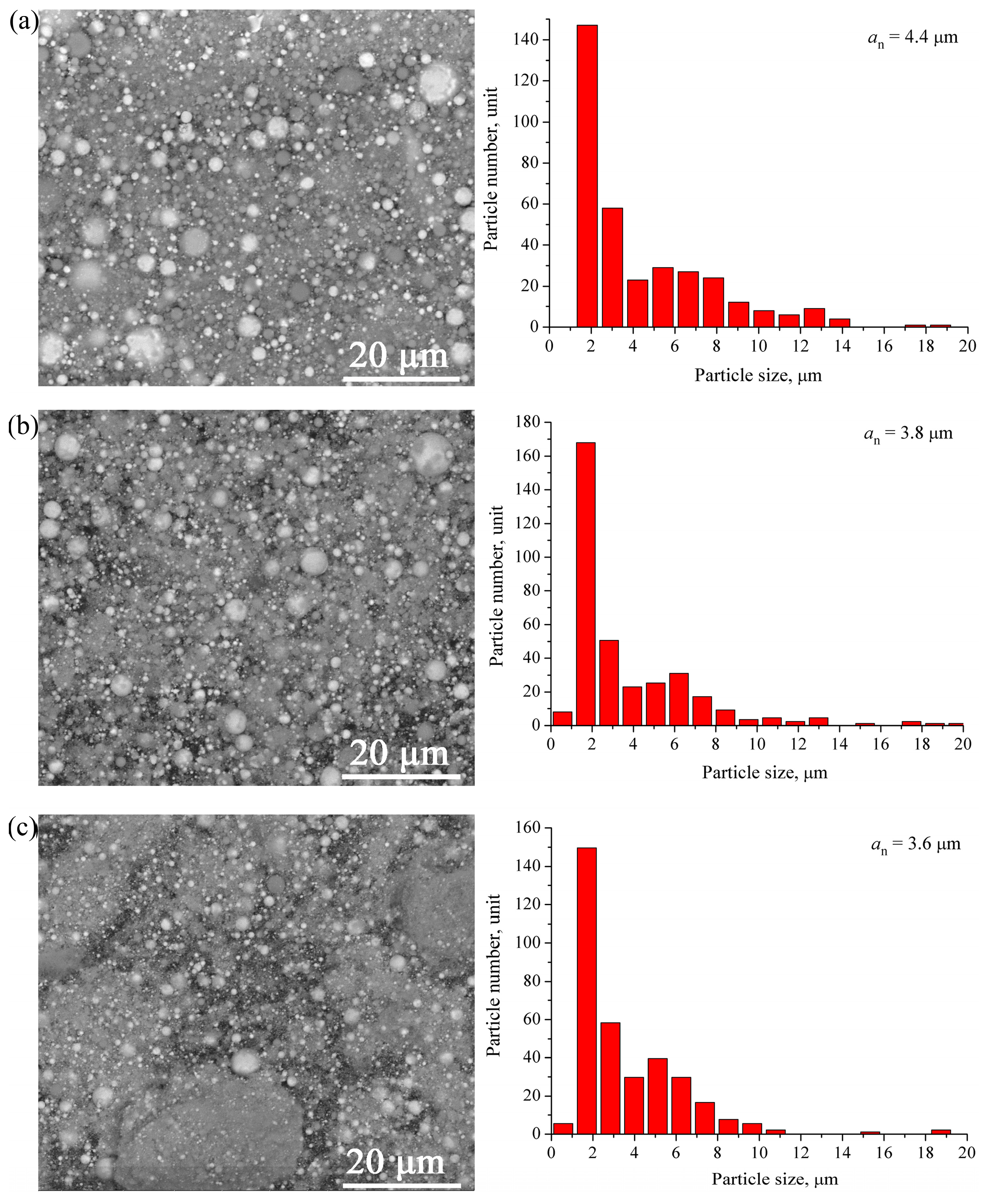

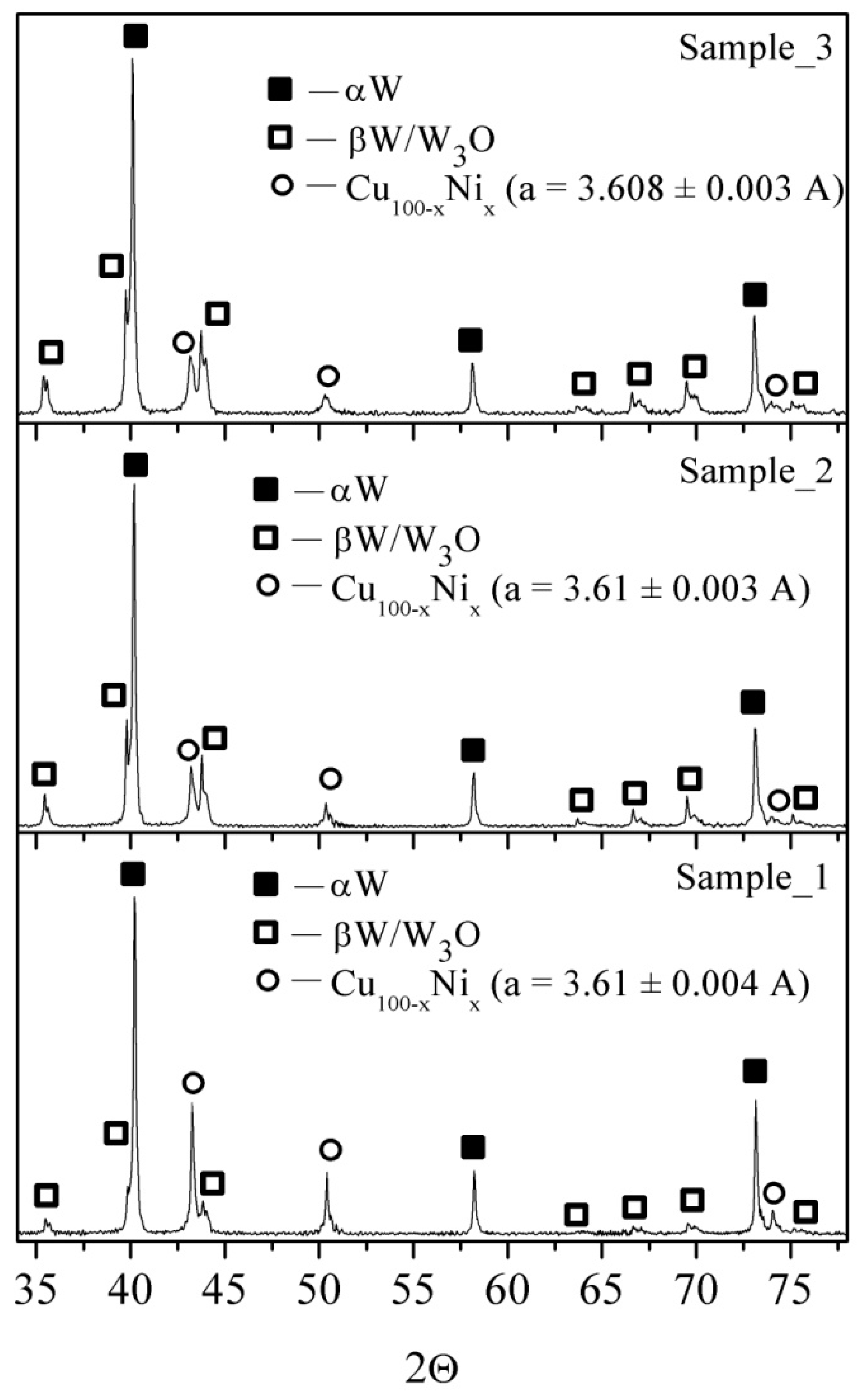

3.1. Electric Explosion Synthesis of W/Cu-Zn Powders

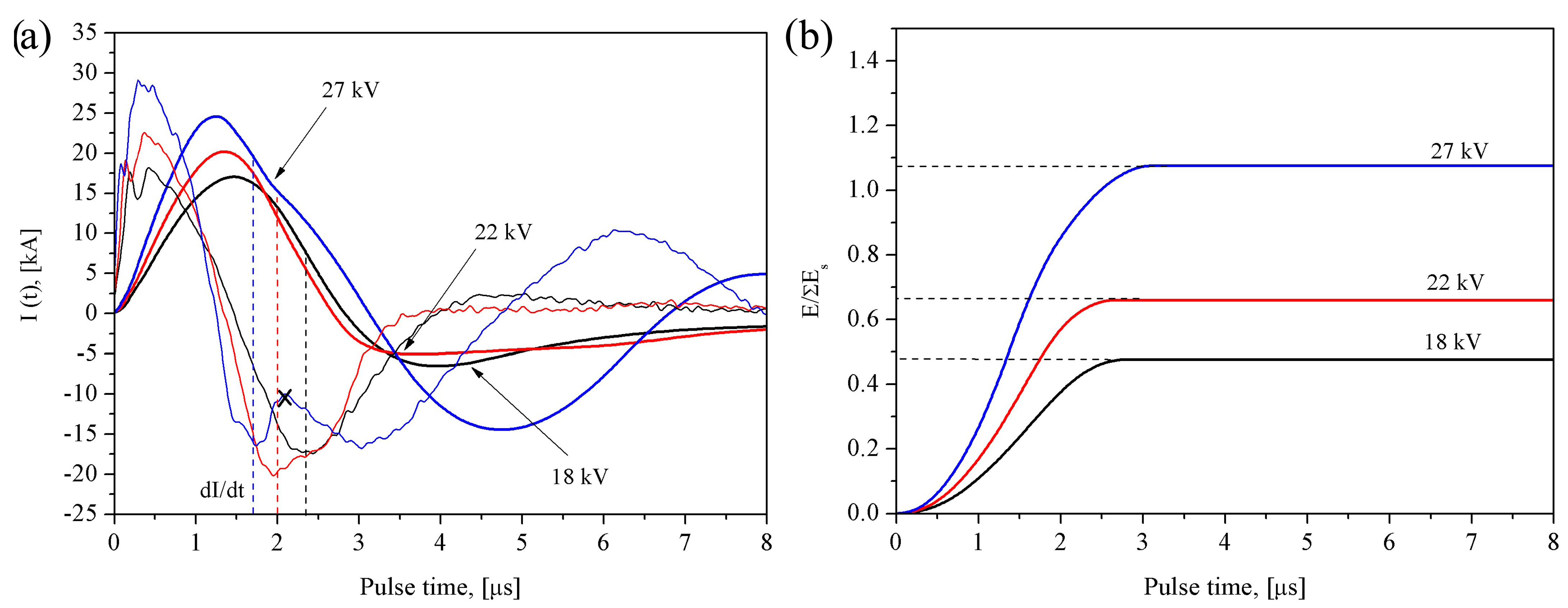

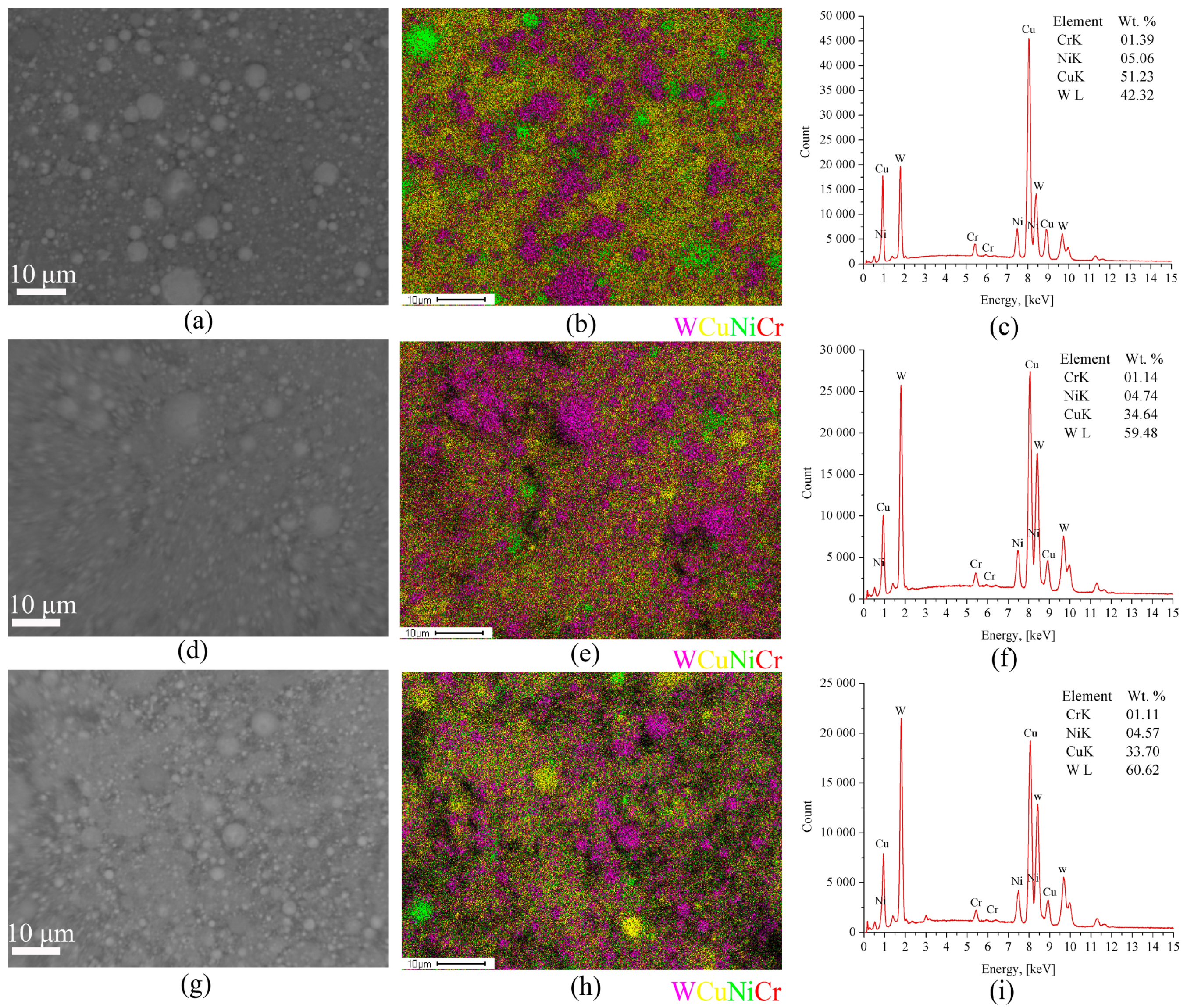

3.2. Electric Explosion Synthesis of W/Cu/Ni-Cr Powders

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Zhuo, L.; Yi, E. Progress, challenges and potentials/trends of tungsten-copper (W-Cu) composites/pseudo-alloys: Fabrication, regulation and application. Int. J. Refract. Met. Hard Mater. 2021, 100, 105648. [Google Scholar] [CrossRef]

- Hou, C.; Song, X.; Tang, F.; Li, Y.; Cao, L.; Wang, J.; Nie, Z. W–Cu composites with submicron- and nanostructures: Progress and challenges. NPG Asia Mater. 2019, 11, 74. [Google Scholar] [CrossRef]

- Zhang, X.; Hattar, K.; Chen, Y.; Shao, L.; Li, J.; Sun, C.; Yu, K.; Li, N.; Taheri, M.L.; Wang, H.; et al. Radiation damage in nanostructured materials. Prog. Mater. Sci. 2018, 96, 217–321. [Google Scholar] [CrossRef]

- Aboud, T.; Weiss, B.-Z.; Chaim, R. Mechanical alloying of the immiscible system W-Cu. Nano Struct. Mater. 1995, 6, 405–408. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, H.; Gao, B.; Wang, X.; Hu, Y.; Shi, Z. Rapid consolidation of ultrafine grained W-30 wt.% Cu composites by field assisted sintering from the sol-gel prepared nanopowders. J. Alloys Compd. 2017, 724, 155–162. [Google Scholar] [CrossRef]

- Wang, X.; Wei, S.; Xu, L.; Li, J.; Li, X.; Shan, K. Preparation of W–Cu nano-composite powders with high copper content using a chemical co-deposition technique. Adv. Powder Technol. 2018, 29, 1323–1330. [Google Scholar] [CrossRef]

- Li, X.; Hu, P.; Wang, J.; Chen, S.; Zhou, W. In situ synthesis of core-shell W-Cu nanopowders for fabricating full-densified and fine-grained alloys with dramatically improved performance. J. Alloy. Compd. 2021, 853, 156958. [Google Scholar] [CrossRef]

- Oh, J.-W.; Na, H.; Cho, Y.S.; Choi, H. In Situ Synthesis of Bimetallic Tungsten-Copper Nanoparticles via Reactive RadioFrequency (RF) Thermal Plasma. Nanoscale Res. Lett. 2018, 13, 220. [Google Scholar] [CrossRef]

- Kotov, Y.A. The electrical explosion of wire: A method for the synthesis of weakly aggregated nanopowders. Nanotechnologies Russ. 2009, 4, 415–424. [Google Scholar] [CrossRef]

- Romanova, V.; Ivanenkov, G.; Mingaleev, A.; Ter-Oganesyan, A.; Shelkovenko, T.; Pikuz, S. Electric explosion of fine wires: Three groups of materials. Plasma Phys. Rep. 2015, 41, 617–636. [Google Scholar] [CrossRef]

- Sarkisov, G.S.; Sasorov, P.V.; Struve, K.W.; McDaniel, D.H. State of the metal core in nanosecond exploding wires and related phenomena. J. Appl. Phys. 2004, 96, 1674. [Google Scholar] [CrossRef]

- Lv, F.; Liu, P.; Qi, H.; Liu, J.; Sun, R.; Wang, W. The early stage of the thermal pulse explosions of aluminum nanowires under different energy deposition levels. Comput. Mater. Sci. 2019, 170, 109142. [Google Scholar] [CrossRef]

- Shi, H.; Wu, J.; Li, X.; Murphy, A.; Li, X.; Li, C.; Li, P. Understanding the nanoparticle formation during electrical wire explosion using a modified moment model. Plasma Sources Sci. Technol. 2019, 28, 085010. [Google Scholar] [CrossRef]

- Pervikov; Toropkov, N.; Kazantsev, S.; Bakina, O.; Glazkova, E.; Lerner, M. Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires. Materials 2021, 14, 6602. [Google Scholar] [CrossRef] [PubMed]

- Krinitcyn, M.; Toropkov, N.; Pervikov, A.; Glazkova, E.; Lerner, M. Characterization of nano/micro bimodal 316L SS powder obtained by electrical explosion of wire for feedstock application in powder injection molding. Powder Technol. 2021, 394, 225–233. [Google Scholar] [CrossRef]

- Oh, J.W.; Ryu, S.K.; Lee, W.S.; Park, S.J. Analysis of compaction and sintering behavior of 316L stainless steel nano/micro bimodal powder. Powder Technol. 2017, 322, 1–8. [Google Scholar] [CrossRef]

- Pervikov, A.; Pustovalov, A.; Afonnikova, S.; Bauman, Y.; Mishakov, I.; Vedyagin, A. Synthesis and structure of NiCu and NiAl electroexplosive nanoparticles for production of carbon nanofibers. Powder Technol. 2023, 415, 118164. [Google Scholar] [CrossRef]

- Pervikov, A.; Suliz, K.; Kazantsev, S.; Rodkevich, N.; Tarasov, S.; Lerner, M. Preparation of nano/micro-bimodal Ti/Al/(Mo, W, Cu) powders by simultaneous electrical explosion of dissimilar metal wires. Powder Technol. 2022, 397, 117093. [Google Scholar] [CrossRef]

- Khrustalev, A.; Pervikov, A.; Chumaevskii, A.; Suliz, K.; Vorozhtsov, A.; Lerner, M. Physical and mechanical properties of Cu-20wt.%W composites synthesized by explosive compaction of bimetallic nanoparticles. Russ. Phys. J. 2020, 62, 1822–1830. [Google Scholar] [CrossRef]

- Pervikov, A.; Filippov, A.; Mironov, Y.; Kalashnikov, M.; Krinitcyn, M.; Eskin, D.; Lerner, M.; Tarasov, S. Microstructure and properties of a nanostructured W-31 wt% Cu composite produced by magnetic pulse compaction of bimetallic nanoparticles. Int. J. Refract. Met. Hard Mater. 2022, 103, 105735. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Svarovskaya, N.; Lerner, M. The effect of low-temperature auto-ignition of W–Cu2O nanopowders with core-shell structure. Vacuum 2022, 197, 110837. [Google Scholar] [CrossRef]

- Yabuki, A.; Tanaka, S. Oxidation behavior of copper nanoparticles at low temperature. Mater. Res. Bull. 2011, 46, 2323–2327. [Google Scholar] [CrossRef]

- Kawamura, G.; Alvarez, S.; Stewart, I.; Catenacci, M.; Chen, Z.; Ha, Y.-C. Production of oxidation-resistant Cu-based nanoparticles by wire explosion. Sci. Rep. 2015, 5, 18333. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Hou, C.; Tang, F.; Han, T.; Huang, X.; Li, Y.; Wu, G.; Liu, C.; Liang, S.; Luan, J.; et al. Wear-resistance enhancement of nanostructured W-Cu-Cr composites. Int. J. Refract. Met. Hard Mater. 2021, 101, 105673. [Google Scholar] [CrossRef]

- Lozhkomoev, A.S.; Pervikov, A.V.; Kazantsev, S.O.; Sharipova, A.F.; Rodkevich, N.G.; Toropkov, N.E.; Suliz, K.V.; Svarovskaya, N.V.; Kondranova, A.M.; Lerner, M.I. Synthesis of Fe/Fe3O4 core-shell nanoparticles by electrical explosion of the iron wire in an oxygen-containing atmosphere. J. Nanopart. Res. 2021, 23, 73. [Google Scholar] [CrossRef]

- Romanova, V.; Ivanenkov, G.; Mingaleev, A.; Ter-Oganesyan, A.; Tilikin, I.; Shelkovenko, T.; Pikuz, S.A. On the phase state of thin silver wire cores during a fast electric explosion. Phys. Plasmas 2018, 25, 112704. [Google Scholar] [CrossRef]

- Kvartskhava, I.; Bondarenko, V.; Pliutto, A.; Chernov, A. Oscillographic determination of energy of electric explosion of wires. J. Exp. Theor. Phys. 1956, 31, 745–775. Available online: http://jetp.ras.ru/cgi-bin/dn/e_004_05_0623.pdf (accessed on 13 January 2023).

- Haynes, W.M. CRC Handbook of Chemistry and Physics, 97th ed.; CRC Press: Boca Raton, FL, USA, 2017; p. 2643. [Google Scholar]

- Ishihara, S.; Koishi, T.; Orikawa, T.; Suematsu, H.; Nakayama, T.; Suzuki, T.; Niihara, K. Synthesis of intermetallic NiAl compound nanoparticles by pulsed wire discharge of twisted Ni and Al wires. Intermetallics 2012, 23, 134–142. [Google Scholar] [CrossRef]

- Dinnebier, R.; Billinge, S. Powder Diffraction Theory and Practice; RSC Publishing: Oxfordshire, UK, 2008; p. 582. [Google Scholar]

- Wang, Q.; Yang, H.; Shi, J.; Zou, G. Preparation and characterization of nanocrystalline powders of Cu–Zn alloy by wire electrical explosion method. Mater. Sci. Eng. A 2001, 307, 190–194. [Google Scholar] [CrossRef]

- Sarkisov, G.S. Anomalous transparency at 1064 nm of a freely expanding gas cylinder in vacuum during fast electric explosion of thin metal wires. J. Appl. Phys. 2022, 131, 105904. [Google Scholar] [CrossRef]

- Pikuz, S.; Shelkovenko, T.; Sinars, D.; Greenly, J.; Dimant, Y.; Hammer, D. Multiphase Foamlike Structure of Exploding Wire Cores. Phys. Rev. Lett. 1999, 83, 4313. [Google Scholar] [CrossRef]

- Han, R.; Wu, J.; Zhou, H.; Ding, W.; Qiu, A.; Clayson, T.; Wang, Y.; Ren, H. Characteristics of exploding metal wires in water with three discharge types. J. Appl. Phys. 2017, 122, 033302. [Google Scholar] [CrossRef]

- Apollonov, V.V.; Pletnev, N.V. Formation of Extended Directional Breakdown Channels Produced by a Copper Wire Exploding in the Atmosphere. Tech.Phys. 2013, 58, 1770–1782. [Google Scholar] [CrossRef]

- Han, R.; Zhu, W.; Wu, J.; Li, C.; Zhang, C.; Cui, R.; He, F.; Ouyang, J.; Wang, Y.; Ding, W. Spatial–temporal evolution of plasma radiation in electrical wire explosion: A morphological observation. J. Phys. D Appl. Phys. 2020, 53, 345201. [Google Scholar] [CrossRef]

- Lee, G.-J.; Lee, J.-H.; Lee, D.; Park, K.-I.; Jeong, C.K.; Park, J.-J.; Lee, M.-K. Synthesis and characterization of carbon-coated Cu-Ni alloy nanoparticles and their application in conductive films. Appl. Surf. Sci. 2021, 566, 150672. [Google Scholar] [CrossRef]

| Composition | Wire Diameter, mm | Wire Length, mm | C, μF | U0, kV | ΣEs, J | P, MPa | ||

|---|---|---|---|---|---|---|---|---|

| W | Cu63Zn37 | - | ||||||

| W/Cu/Zn | 0.24 | 0.22 | - | 70 | 1.26 | 17 | 261 | 0.3 |

| 22 | ||||||||

| 27 | ||||||||

| W/Cu/Ni/Cr | W | Cu | Ni79Cr21 | |||||

| 0.24 | 0.20 | 0.1 | 70 | 1.26 | 18 | 310 | 0.3 | |

| Phase | Sample_1 | Sample_2 | Sample_3 | |||

|---|---|---|---|---|---|---|

| dcsr, nm | Δd/d | dcsr, nm | Δd/d | dcsr, nm | Δd/d | |

| α-Cu(Zn) | 58 ± 14 | 0.129 ± 0.018 | 27 ± 5 | 0.069 ± 0.024 | 34 ± 5 | 0.026 ± 0.020 |

| α-W | 174 ± 53 | 0.083 ± 0.021 | 48 ± 2 | 0.012 ± 0.005 | 46 ± 2 | 0.012 ± 0.006 |

| β-W/W3O | 56 ± 8 | 0.199 ± 0.102 | 48 ± 4 | 0.030 ± 0.008 | 35 ± 6 | 0.042 ± 0.036 |

| Phase | Sample_1 | Sample_2 | Sample_3 | |||

|---|---|---|---|---|---|---|

| dcsr, nm | Δd/d | dcsr, nm | Δd/d | dcsr, nm | Δd/d | |

| α-Cu(Ni) | 4721 | 0.089 ± 0.022 | 22 ± 9 | 0.084 ± 0.018 | 20 ± 15 | 0.055 ± 0.034 |

| α-W | 237 ± 22 | 0.048 ± 0.023 | 123 ± 31 | 0.037 ± 0.012 | 69 ± 12 | 0.032 ± 0.011 |

| β-W/W3O | 35 ± 12 | 0.137 ± 0.072 | 26 ± 11 | 0.077 ± 0.038 | 27 ± 13 | 0.068 ± 0.041 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lerner, M.; Suliz, K.; Pervikov, A.; Tarasov, S. Micron- and Nanosized Alloy Particles Made by Electric Explosion of W/Cu-Zn and W/Cu/Ni-Cr Intertwined Wires for 3D Extrusion Feedstock. Materials 2023, 16, 955. https://doi.org/10.3390/ma16030955

Lerner M, Suliz K, Pervikov A, Tarasov S. Micron- and Nanosized Alloy Particles Made by Electric Explosion of W/Cu-Zn and W/Cu/Ni-Cr Intertwined Wires for 3D Extrusion Feedstock. Materials. 2023; 16(3):955. https://doi.org/10.3390/ma16030955

Chicago/Turabian StyleLerner, Marat, Konstantin Suliz, Aleksandr Pervikov, and Sergei Tarasov. 2023. "Micron- and Nanosized Alloy Particles Made by Electric Explosion of W/Cu-Zn and W/Cu/Ni-Cr Intertwined Wires for 3D Extrusion Feedstock" Materials 16, no. 3: 955. https://doi.org/10.3390/ma16030955

APA StyleLerner, M., Suliz, K., Pervikov, A., & Tarasov, S. (2023). Micron- and Nanosized Alloy Particles Made by Electric Explosion of W/Cu-Zn and W/Cu/Ni-Cr Intertwined Wires for 3D Extrusion Feedstock. Materials, 16(3), 955. https://doi.org/10.3390/ma16030955