Dynamic Responses of Sandwich Beams with Polymethacrylimide (PMI) Foam Cores When Subjected to Impact Loading

Abstract

1. Introduction

2. Experimental Procedures

2.1. Materials and Specimens

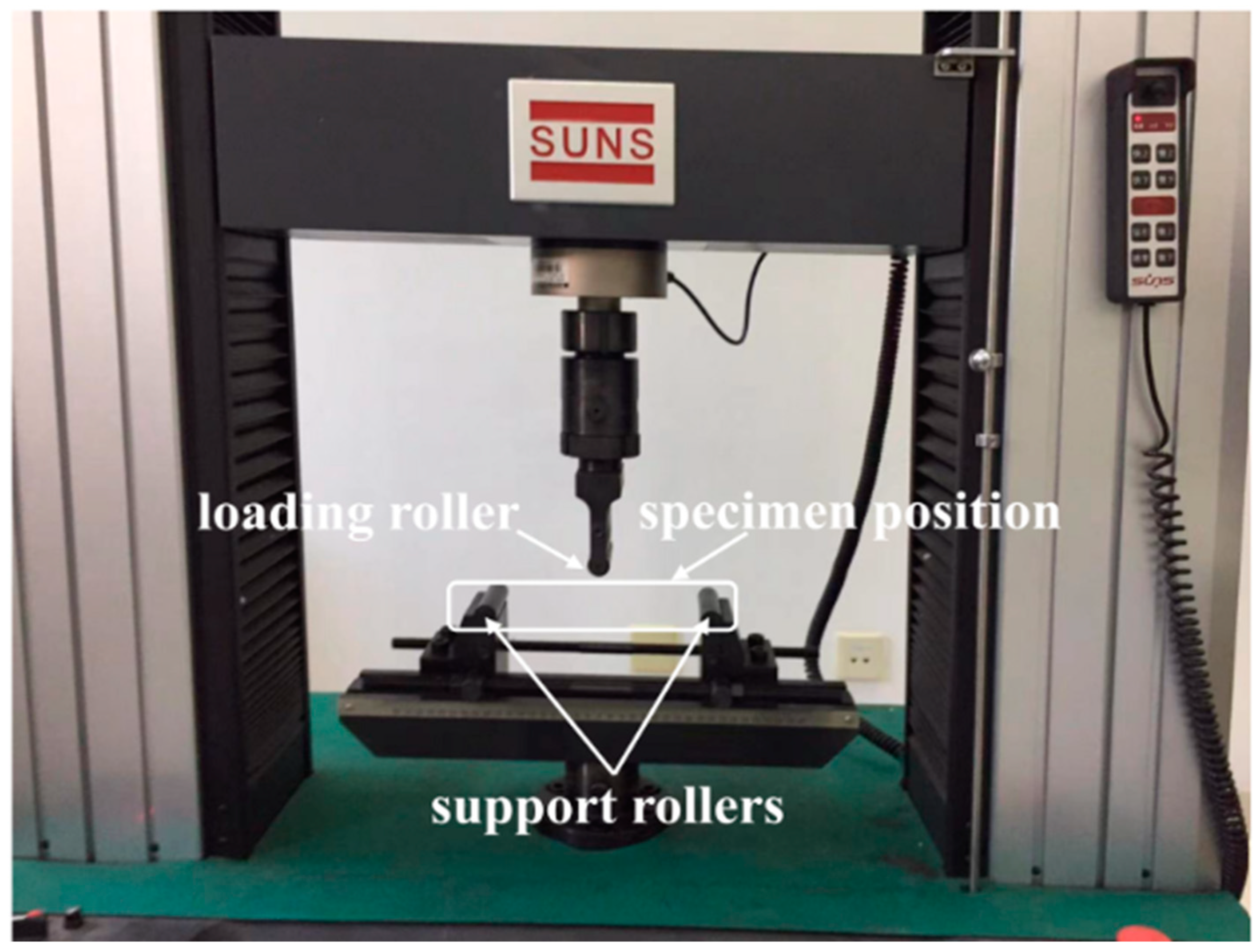

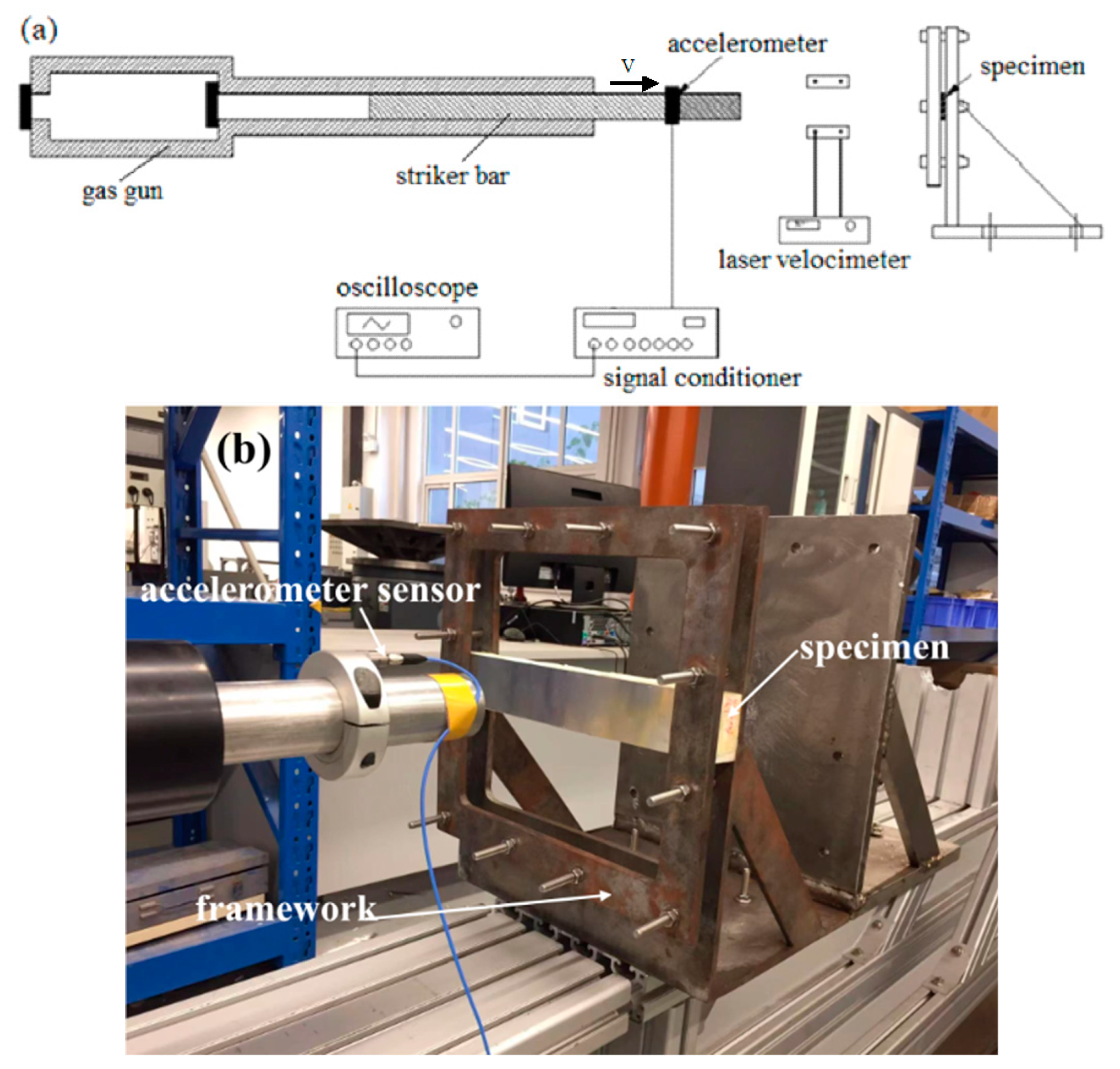

2.2. Experimental Apparatus

3. Results and Discussion

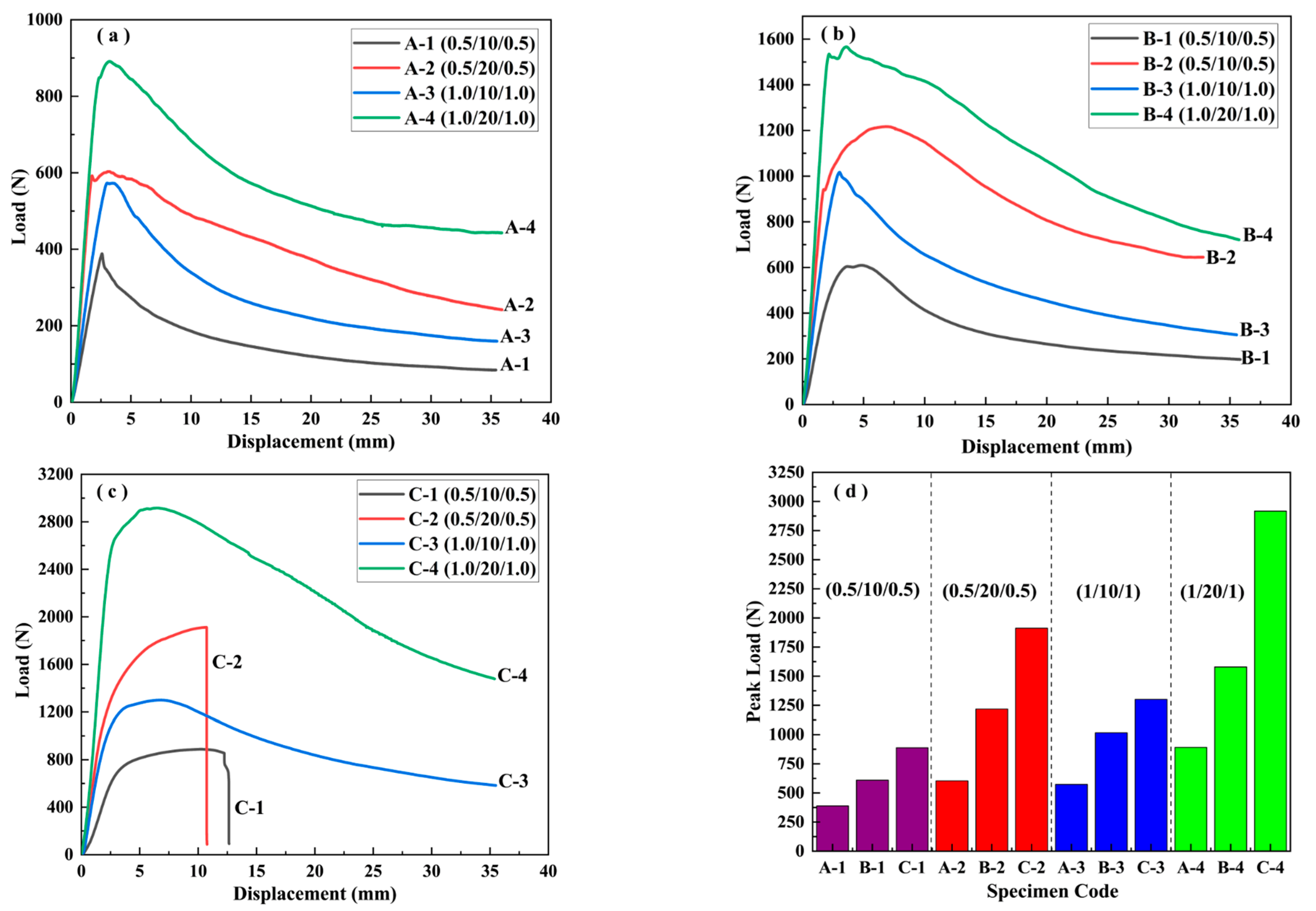

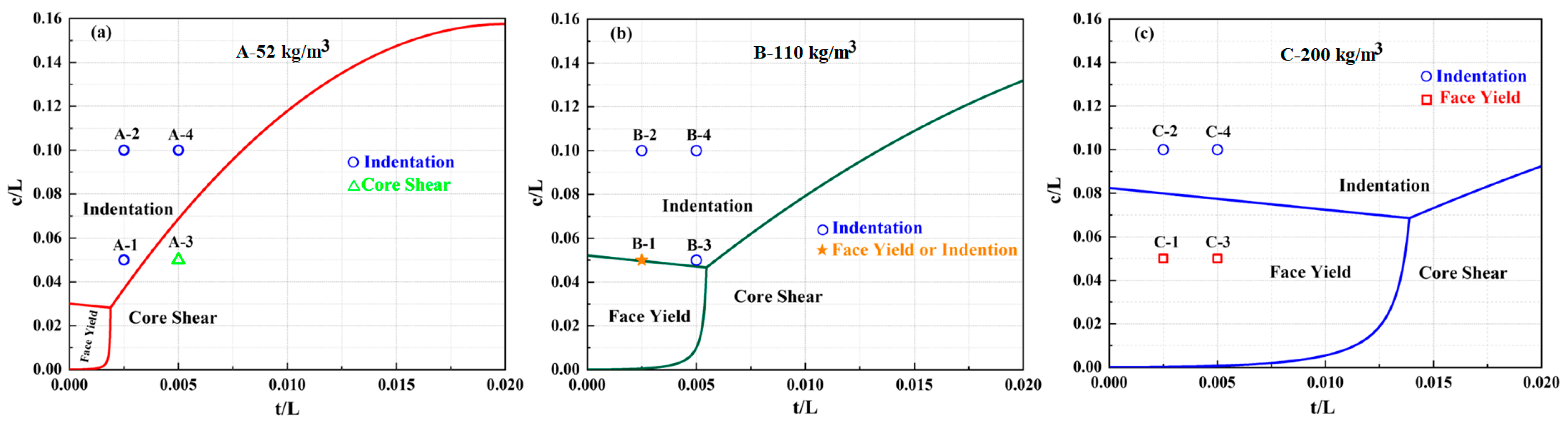

3.1. Quai-Static Load Cases

3.1.1. Load–Displacement Curves

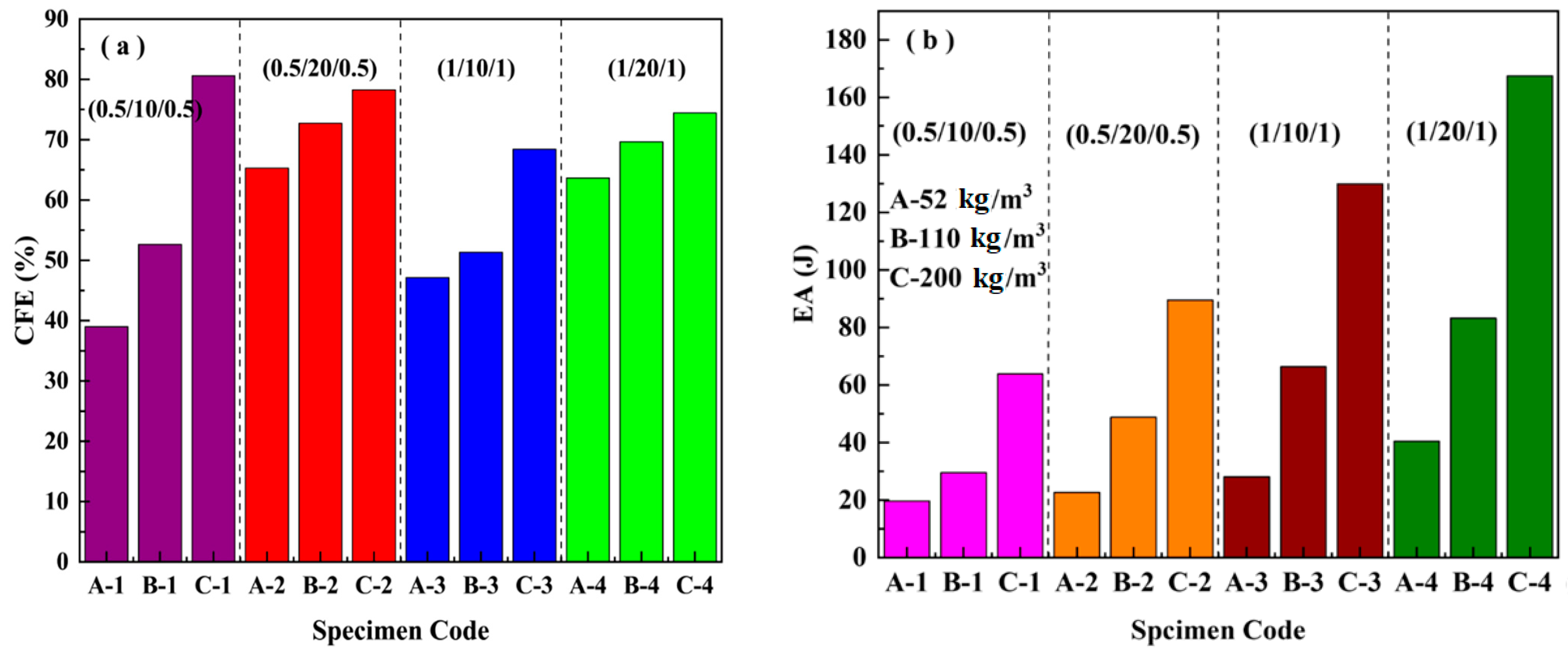

3.1.2. Energy Absorption under the Three-Point Bending Load

3.2. Dynamic Load Case

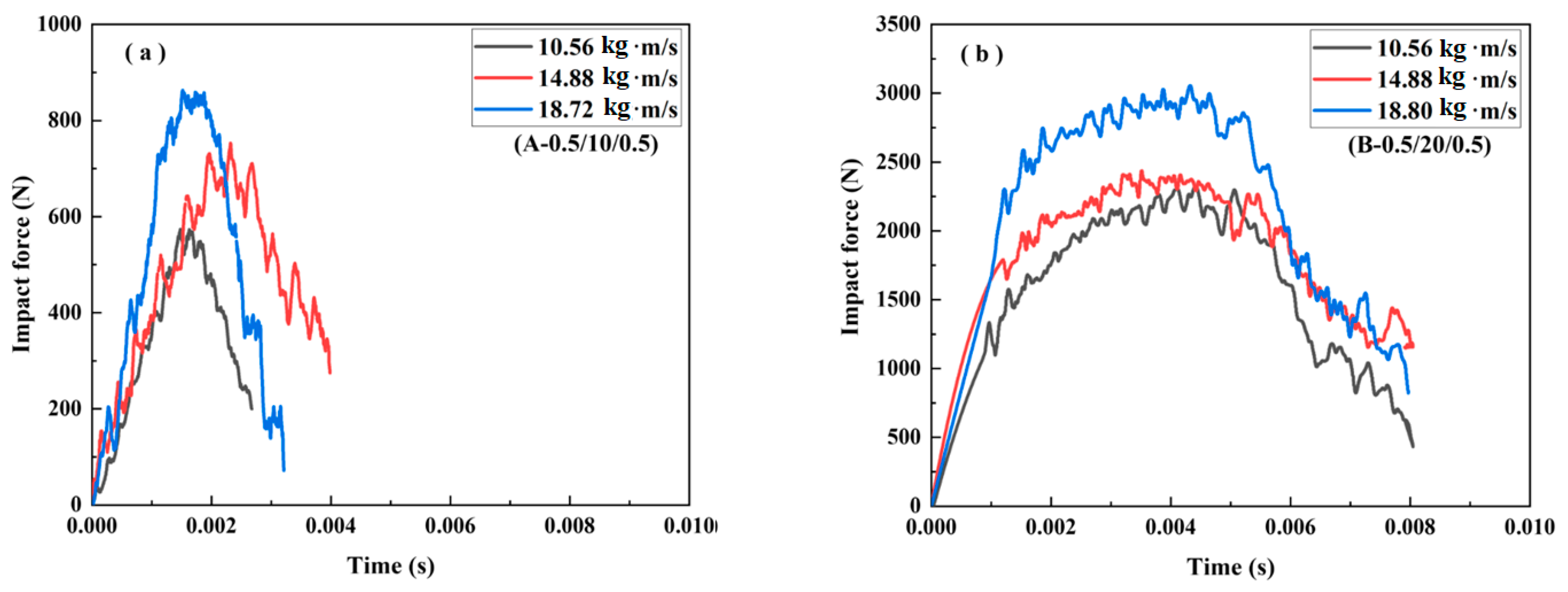

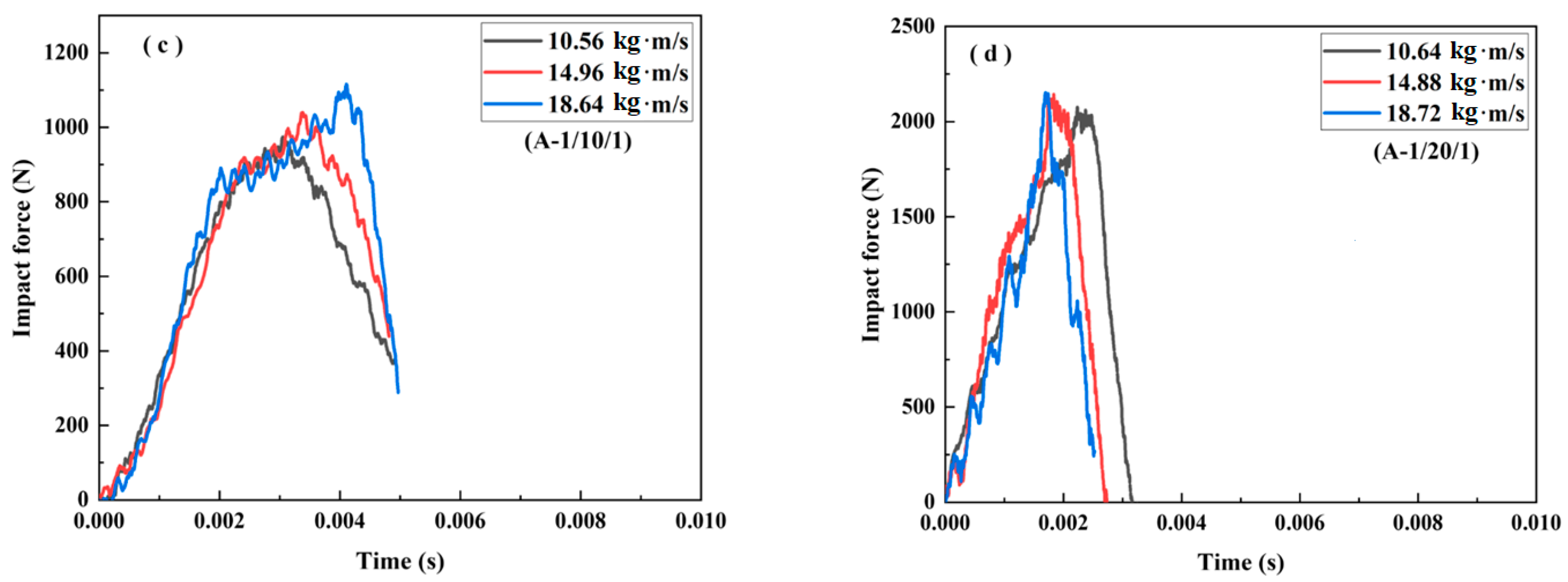

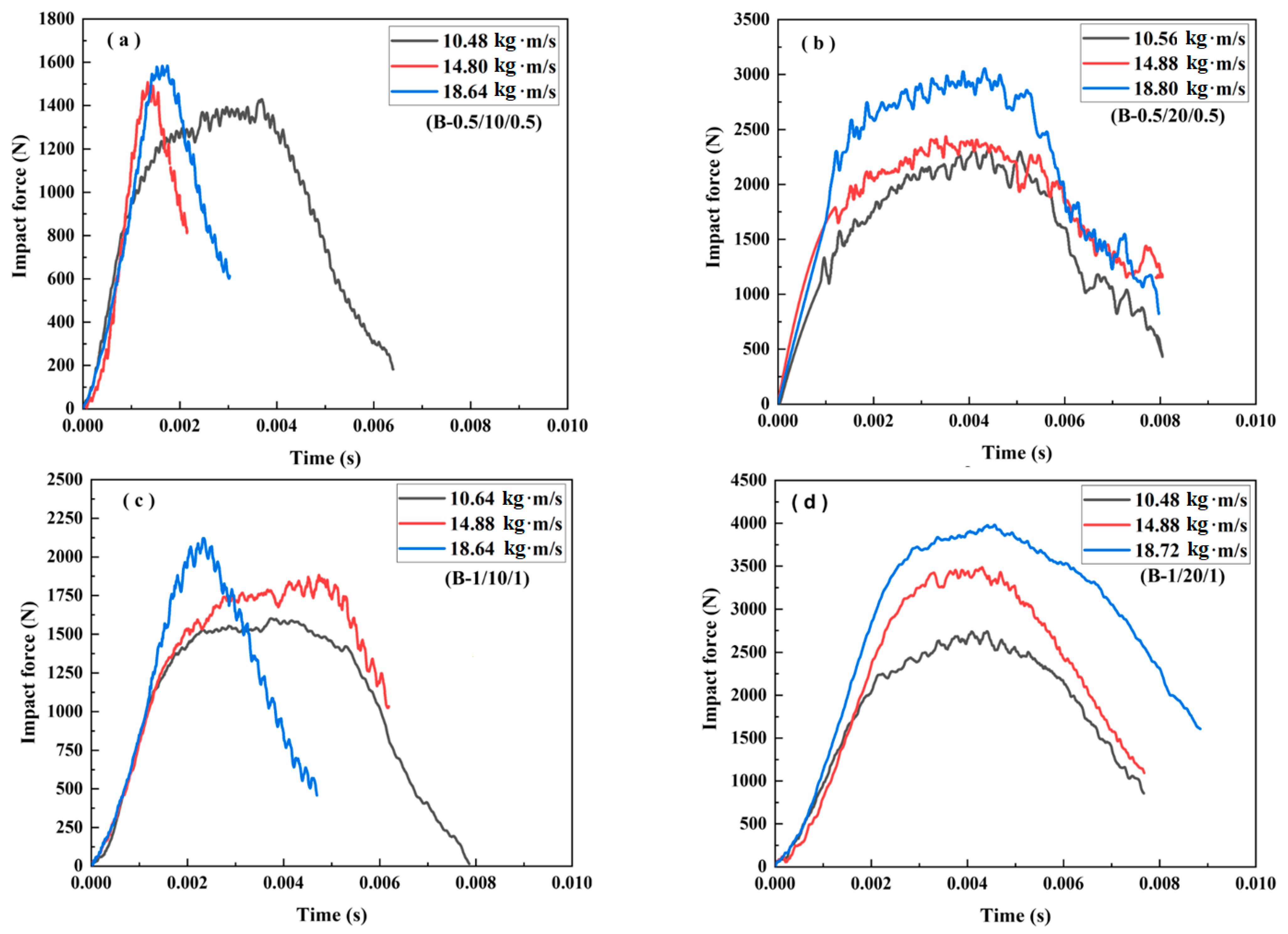

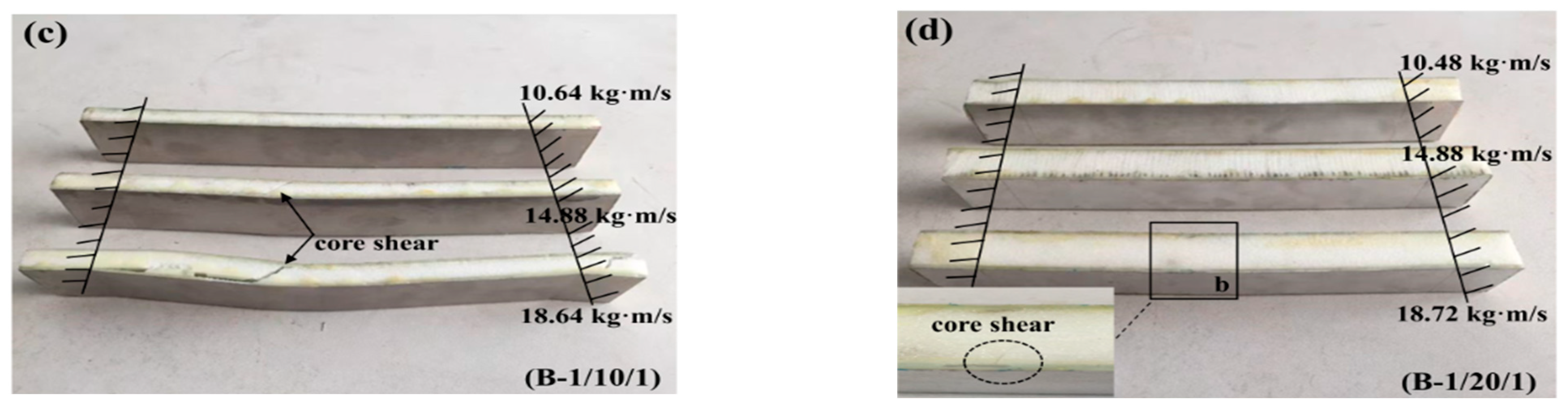

3.2.1. Impact Force–Time Curves

- Case 1: Core density of 52 kg/m3

- Case 2: Core density of 110 kg/m3

- Case 3: Core density of 200 kg/m3

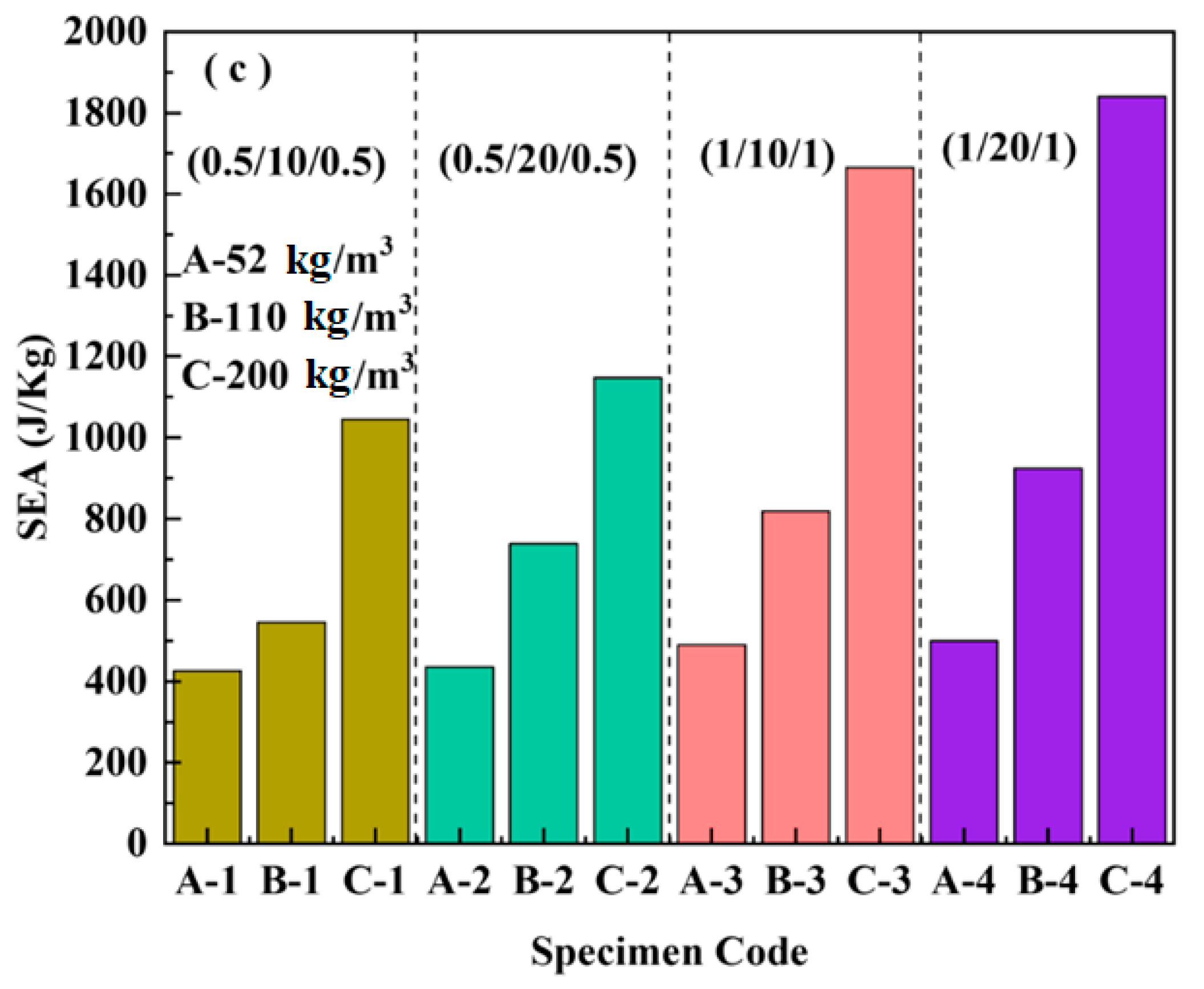

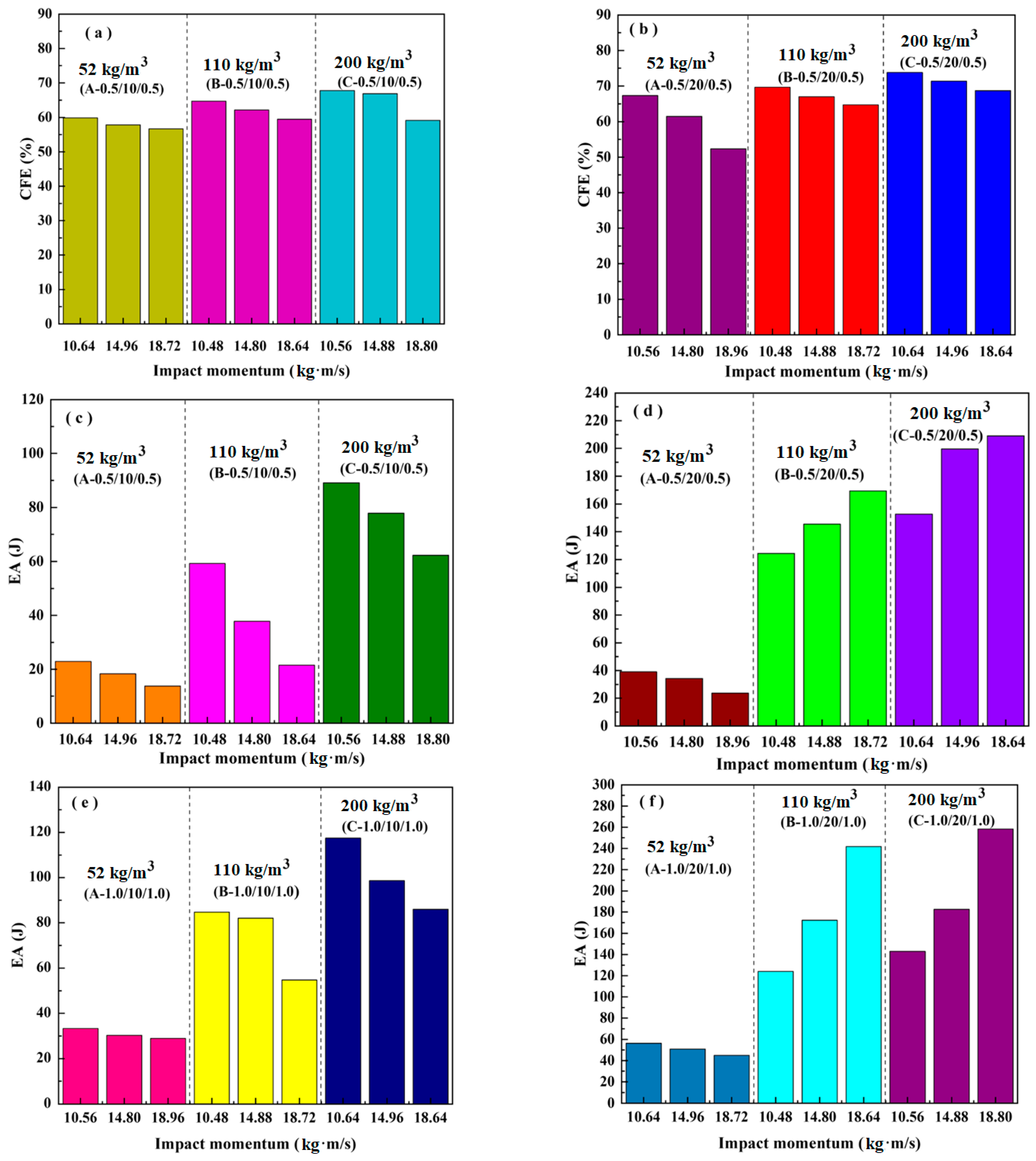

3.2.2. Energy Absorption under Impact Loading

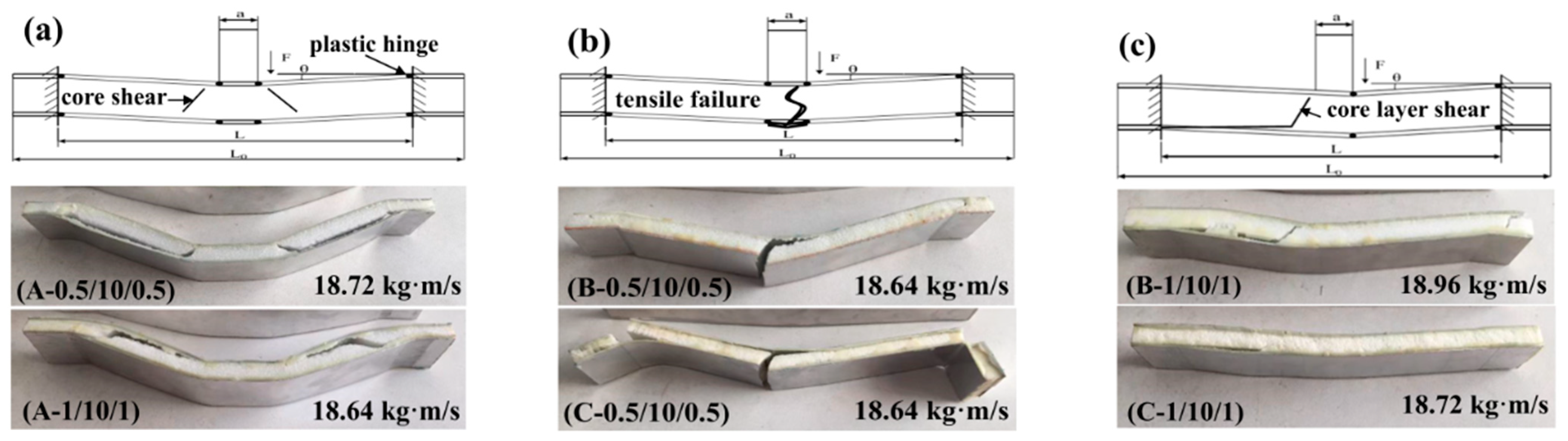

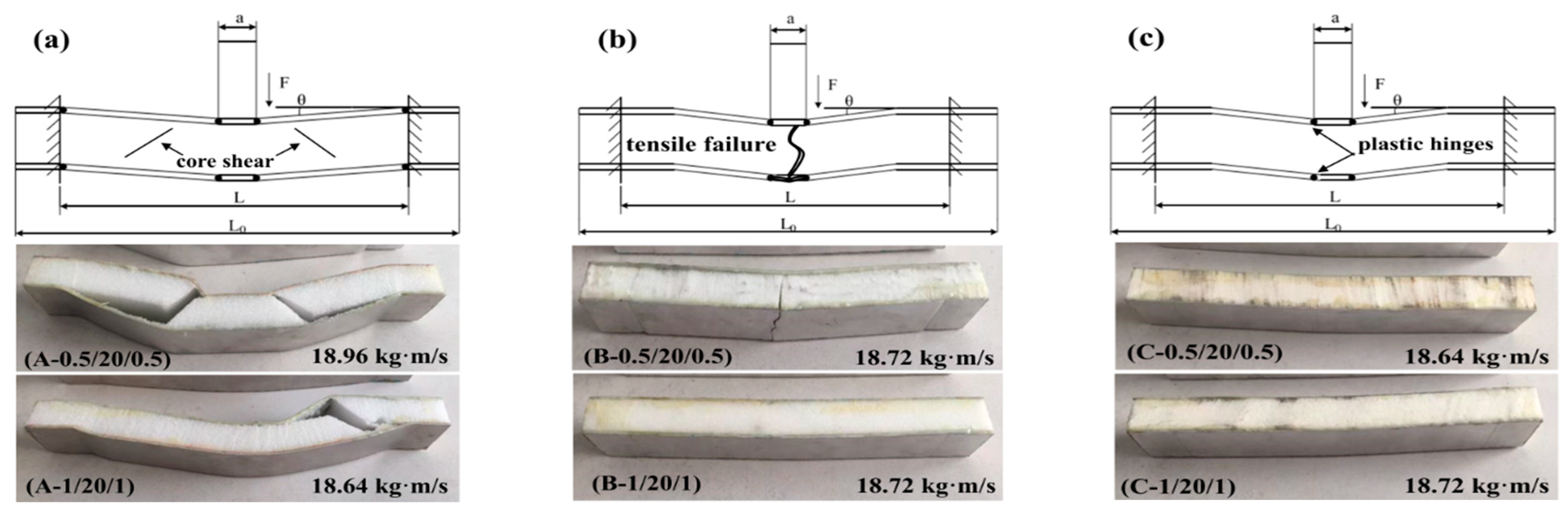

3.3. Failure Modes and Deformation Mechanisms

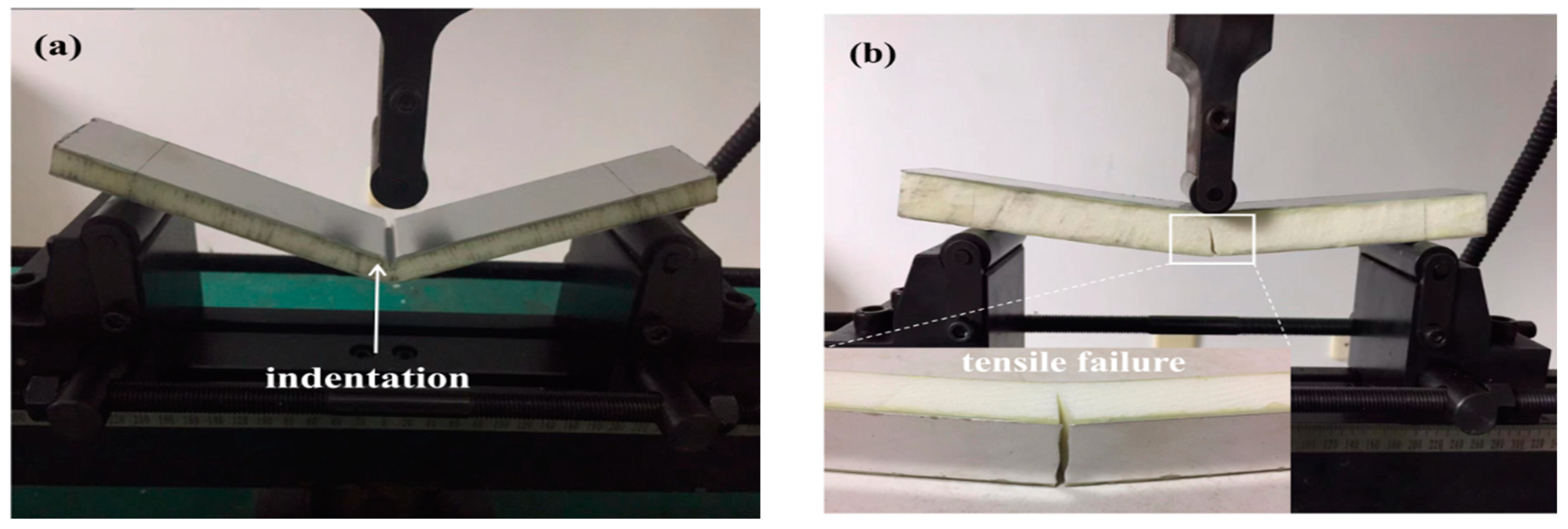

3.3.1. Quasi-Static Load Case: Failure Modes and Deformation Mechanisms

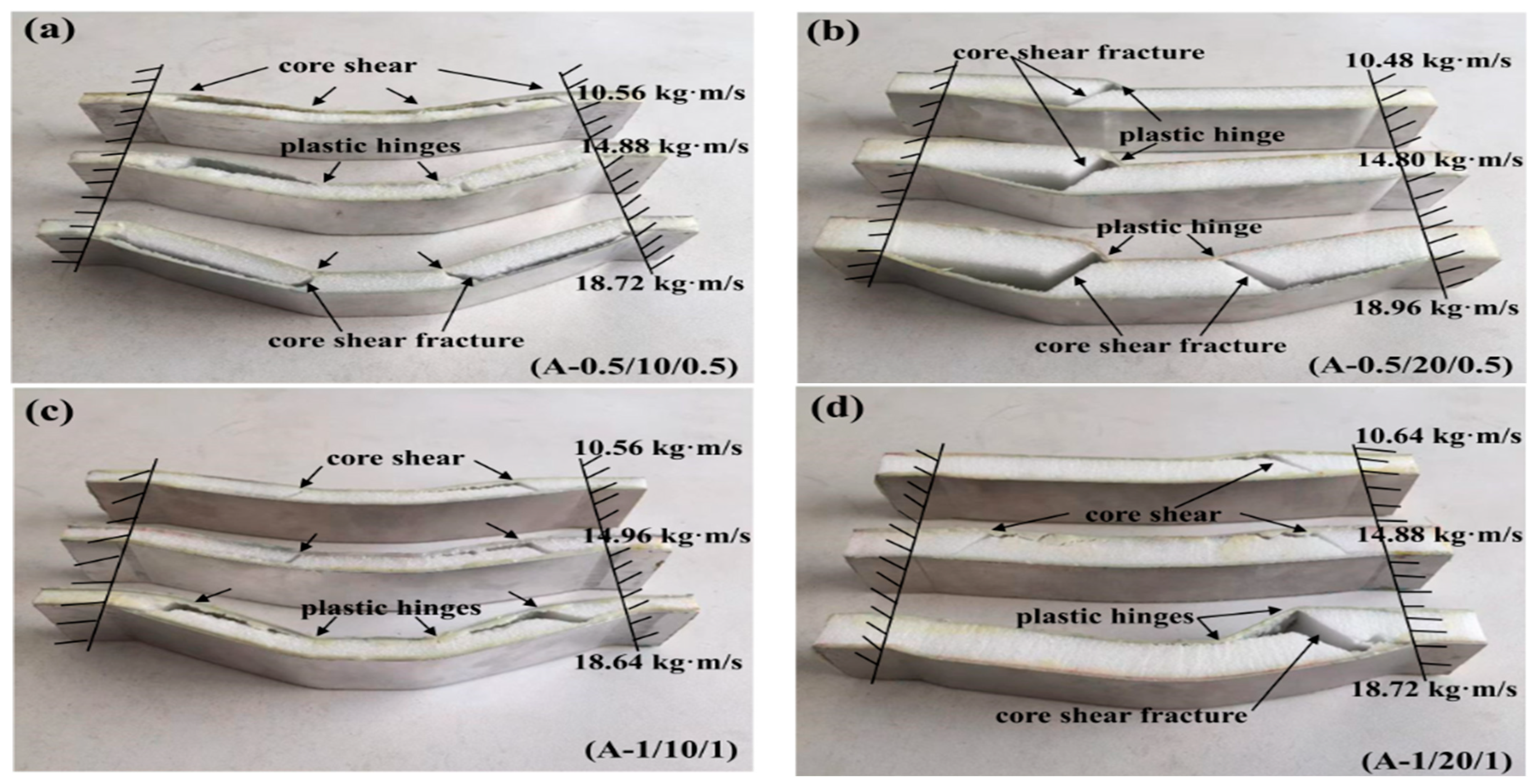

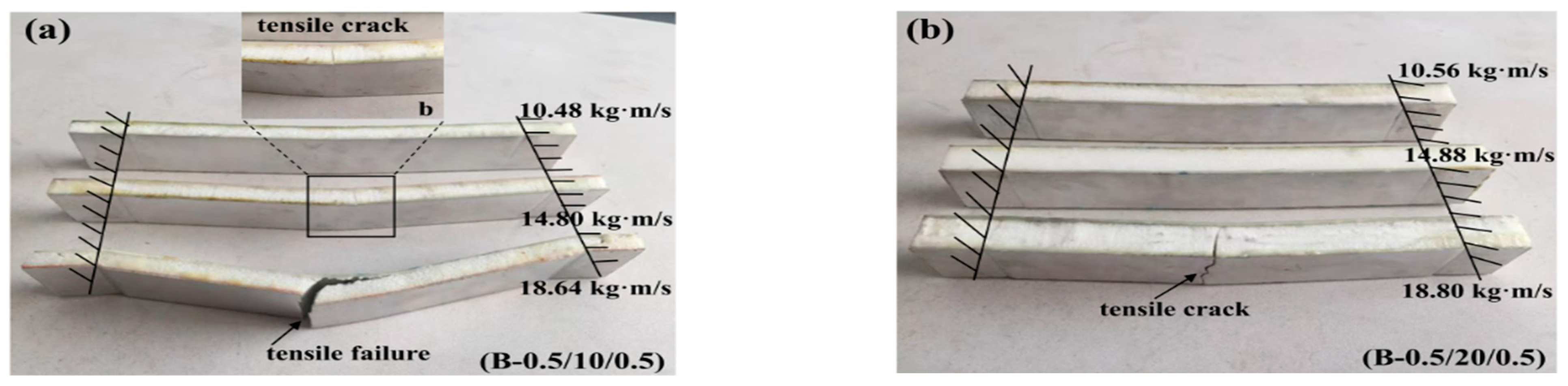

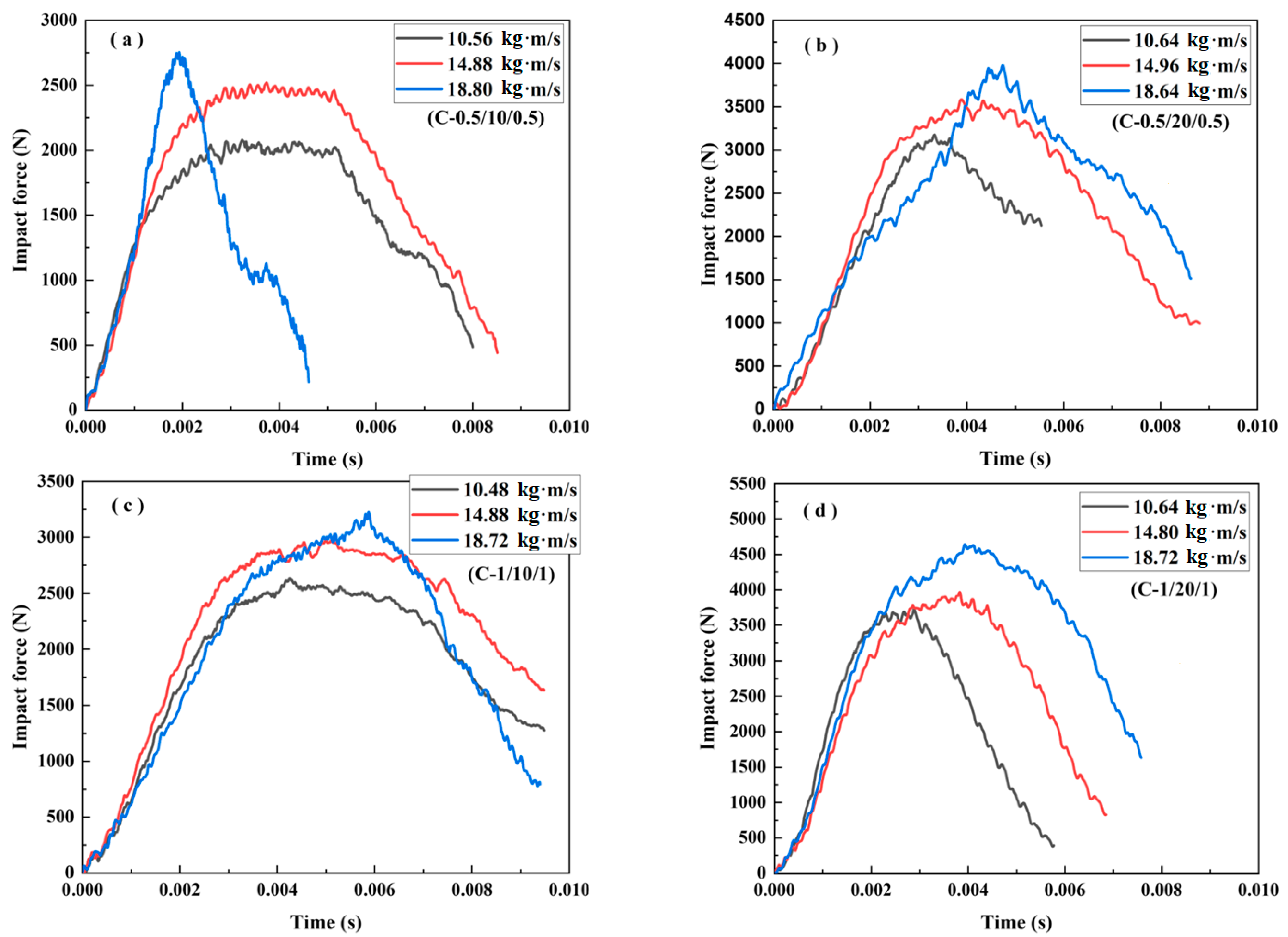

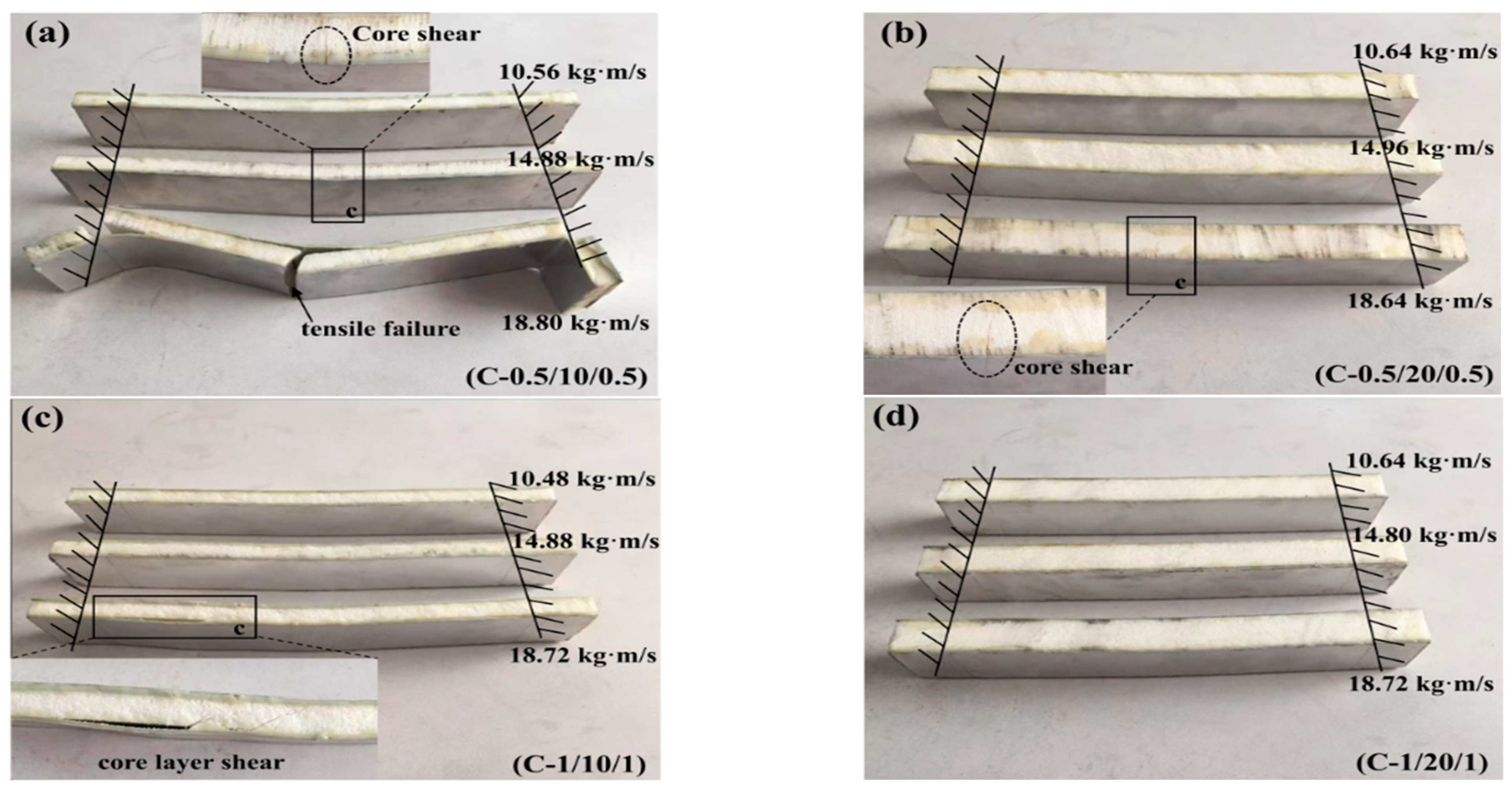

3.3.2. Impact Load Case: Failure Mode and Deformation Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, D.; Aymerich, F. Effect of core density on the low-velocity impact response of foam-based sandwich composites. Compos. Struct. 2020, 239, 112040. [Google Scholar] [CrossRef]

- Kazemi, M. Experimental analysis of sandwich composite beams under three-point bending with an emphasis on the layering effects of foam core. Structures 2021, 29, 383–391. [Google Scholar] [CrossRef]

- Tagarielli, V.; Fleck, N. A comparison of the structural response of clamped and simply supported sandwich beams with aluminium faces and a metal foam core. J. Appl. Mech. 2004, 72, 408–417. [Google Scholar] [CrossRef]

- Zhang, Y.; Zong, Z.; Liu, Q.; Ma, J.; Wu, Y.; Li, Q. Static and dynamic crushing responses of CFRP sandwich panels filled with different reinforced materials. Mater. Des. 2017, 117, 396–408. [Google Scholar] [CrossRef]

- Jiang, B.; Li, Z.; Lu, F. Failure mechanism of sandwich beams subjected to three-point bending. Compos. Struct. 2015, 133, 739–745. [Google Scholar]

- Zhang, J.; Huang, W.; Yuan, H.; Wu, X. Failure behavior of a sandwich beam with GLARE face-sheets and aluminum foam core under three-point bending. Thin-Walled Struct. 2023, 183, 110438. [Google Scholar] [CrossRef]

- Hamed, Y.; Shehry, A.; Sayed, M. Nonlinear modified positive position feedback control of cantilever beam system carrying an intermediate lumped mass. Alex. Eng. J. 2020, 59, 3847–3862. [Google Scholar] [CrossRef]

- Sayed, M.; Mousa, A.; Mustafa, I. Stability and bifurcation analysis of a buckled beam via active control. Appl. Math. Model. 2020, 82, 649–665. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Z.; Yu, J.; Qian, C.; Lu, F. Deformation and failure mechanisms of sandwich beams under three-point bending at elevated temperatures. Compos. Struct. 2014, 111, 285–290. [Google Scholar] [CrossRef]

- Zhang, W.; Qin, Q.; Li, J.; Li, K.; Poh, L.; Li, Y.; Zhang, J.; Xie, S.; Chen, H.; Zhao, J. Deformation and failure of hybrid composite sandwich beams with a metal foam core under quasi-static load and low-velocity impact. Compos. Struct. 2020, 242, 112175. [Google Scholar] [CrossRef]

- Fathi, A.; Wolff-Fabris, F.; Altstädt, V.; Gätzi, R. An investigation on the flexural properties of balsa and polymer foam core sandwich structures: Influence of core type and contour finishing options. J. Sandw. Struct. Mater. 2013, 15, 487–508. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, L.; Wang, T.; Yao, L.; Sun, X. Bending strength and failure of single-layer and double-layer sandwich structure with graded truss core. Compos. Struct. 2019, 226, 111204. [Google Scholar] [CrossRef]

- Tan, Z.; Luo, H.; Long, W.; Han, X. Dynamic response of clamped sandwich beam with aluminium alloy foam core subjected to impact loading. Compos. Part B Eng. 2013, 46, 39–45. [Google Scholar] [CrossRef]

- Wang, B.; Hu, J.; Li, Y.; Yao, Y.; Wang, S.; Ma, L. Mechanical properties and failure behavior of the sandwich structures with carbon fiber-reinforced X-type lattice truss core. Compos. Struct. 2018, 185, 619–633. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Zhang, D.; Li, Y.; Jin, F.; Fang, D. Enhanced mechanical performance of brazed sandwich panels with high density square honeycomb-corrugation hybrid cores. Thin-Walled Struct. 2020, 151, 106757. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Chen, X.; Yu, Y. Experimental and numerical study of the elastic properties of PMI foams. J. Mater. Sci. 2010, 45, 2688–2695. [Google Scholar] [CrossRef]

- Arezoo, S.; Tagarielli, V.; Petrinic, N.; Reed, J. The mechanical response of Rohacell foams at different length scales. J. Mater. Sci. 2011, 46, 6863–6870. [Google Scholar] [CrossRef]

- Grace, I.; Pilipchuk, V.; Ibrahim, R.; Ayorinde, E. Temperature effect on non-stationary compressive loading response of polymethacrylimide solid foam. Compos. Struct. 2012, 94, 3052–3063. [Google Scholar] [CrossRef]

- Siivola, J.; Minakuchi, S.; Takeda, N. Effect of temperature and humidity conditions on polymethacrylimide (PMI) foam core material and indentation response of its sandwich structures. J. Sandw. Struct. Mater. 2015, 17, 335–358. [Google Scholar] [CrossRef]

- Arezoo, S.; Tagarielli, V.; Siviour, C.; Petrinic, N. Compressive deformation of Rohacell foams: Effects of strain rate and temperature. Int. J. Impact Eng. 2013, 51, 50–57. [Google Scholar] [CrossRef]

- Huo, X.; Jiang, Z.; Luo, Q.; Li, Q.; Sun, G. Mechanical characterization and numerical modeling on the yield and fracture behaviors of polymethacrylimide (PMI) foam materials. Int. J. Mech. Sci. 2022, 218, 107033. [Google Scholar] [CrossRef]

- Qu, J.; Ju, D.; Gao, S.; Chen, J. Research on the dynamic mechanical properties of polymethacrylimide foam sandwich structure. Compos. Struct. 2018, 204, 22–30. [Google Scholar] [CrossRef]

- Schartel, B.; Humphrey, J.; Gibson, A.; Hörold, A.; Trappe, V.; Gettwert, V. Assessing the structural integrity of carbon-fibre sandwich panels in fire: Bench-scale approach. Compos. Part B Eng. 2019, 164, 82–89. [Google Scholar] [CrossRef]

- Yan, L.; He, Z.; Jiang, W.; Cheng, L.; Ma, H.; Zheng, X. A novel scheme to enhance both electromagnetic wave transmission and compressive properties of PMI foam sandwich structures. Compos. Struct. 2021, 277, 114582. [Google Scholar] [CrossRef]

- Flores-Johnson, E.; Li, Q. Experimental study of the indentation of sandwich panels with carbon fibre-reinforced polymer face sheets and polymeric foam core. Compos. Part B Eng. 2011, 42, 1212–1219. [Google Scholar] [CrossRef]

- McGarva, L.; Astrom, B. Experimental investigation of compression moulding of glass/PA12-PMI foam core sandwich components. Compos. Part A 1999, 30, 1171–1185. [Google Scholar] [CrossRef]

- Pan, Z.; Hu, W.; Wang, M.; Wu, Z.; Ying, Z.; Wang, L.; Li, N. Transverse impact damage and axial compression failure of square braided CFRP/PMI sandwich composite beams. Thin-Walled Struct. 2021, 162, 107547. [Google Scholar] [CrossRef]

- Wang, B.; Shi, Y.; Zhou, C.; Li, T. Failure mechanism of PMI foam core sandwich beam in bending. Int. J. Simul. Multidiscip. Des. 2015, 6, A8. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, J.; Sun, H. The failure behavior of double-layer metal foam sandwich beams under three-point bending. Thin-Walled Struct. 2022, 180, 109801. [Google Scholar] [CrossRef]

- Du, Y.; Keller, T.; Song, C.; Wu, L.; Xiong, J. Origami-inspired carbon fiber-reinforced composite sandwich materials-Fabrication and mechanical behavior. Compos. Sci. Technol. 2021, 205, 108667. [Google Scholar] [CrossRef]

- Song, S.; Xiong, C.; Zheng, J.; Yin, J.; Zou, Y.; Zhu, X. Compression, bending, energy absorption properties, and failure modes of composite Kagome honeycomb sandwich structure reinforced by PMI foams. Compos. Struct. 2021, 277, 114611. [Google Scholar] [CrossRef]

- Song, S.; Xiong, C.; Tao, F.; Yin, J.; Zhang, Y.; Zhang, S. Size effect of composite Kagome honeycomb sandwich structure reinforced with PMI foams under quasi-static bending: Experiment tests and numerical analysis. Compos. Struct. 2022, 296, 115832. [Google Scholar] [CrossRef]

- Zhu, K.; Zheng, X.; Zhang, C.; Chen, N.; Han, Y.; Ya, L.; Quaresimin, M. Compressive response and energy absorption of all-composite sandwich panels with channel cores. Compos. Struct. 2022, 289, 115461. [Google Scholar] [CrossRef]

- John, M.; Geyer, A.; Schäuble, R.; Schlimper, R. Comparing unreinforced and pin reinforced CFRP/PMI foam core sandwich structures regarding their damage tolerance behaviour. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Rinker, M.; John, M.; Zahlen, P.; Schäuble, R. Face sheet debonding in CFRP/PMI sandwich structures under quasi-static and fatigue loading considering residual thermal stress. Eng. Fract. Mech. 2011, 78, 2835–2847. [Google Scholar] [CrossRef]

- Yang, F.; Lin, Q.; Jiang, J. Experimental study on fatigue failure and damage of sandwich structure with PMI foam core. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 456–465. [Google Scholar] [CrossRef]

- Yu, J.; Wang, E.; Li, J.; Zheng, Z. Static and low-velocity impact behavior of sandwich beams with closed-cell aluminum-foam core in three-point bending. Int. J. Impact Eng. 2008, 35, 885–894. [Google Scholar] [CrossRef]

- Yang, F.; Hassan, M.; Cantwell, W.; Jones, N. Scaling effects in the low velocity impact response of sandwich structures. Compos. Struct. 2013, 99, 97–104. [Google Scholar] [CrossRef]

- Zhu, Y.; Sun, Y. Low-velocity impact response of multilayer foam core sandwich panels with composite face sheets. Int. J. Mech. Sci. 2021, 209, 106704. [Google Scholar] [CrossRef]

- Chen, C.; Fang, H.; Zhu, L.; Han, J.; Li, X.; Qian, Z.; Zhang, X. Low-velocity impact properties of foam-filled composite lattice sandwich beams: Experimental study and numerical simulation. Compos. Struct. 2023, 306, 116573. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, L.; Sun, H.; Yao, X.; Fu, C.; Jiang, J. The influence of pin on the low-velocity impact performance of foam sandwich structure. Int. J. Mech. Sci. 2023, 244, 108057. [Google Scholar] [CrossRef]

| Specimen Code | Sandwich Structure (mm) | Face Sheet Size (mm) | Foam Core Size (mm) | Weight of the Specimen (kg) |

|---|---|---|---|---|

| A-1 | 0.5/10/0.5 | 260 × 40 × 0.5 | 260 × 40 × 10 | 0.046 |

| A-2 | 0.5/20/0.5 | 260 × 40 × 0.5 | 260 × 40 × 20 | 0.052 |

| A-3 | 1.0/10/1.0 | 260 × 40 × 1.0 | 260 × 40 × 10 | 0.057 |

| A-4 | 1.0/20/1.0 | 260 × 40 × 1.0 | 260 × 40 × 20 | 0.081 |

| B-1 | 0.5/10/0.5 | 260 × 40 × 0.5 | 260 × 40 × 10 | 0.054 |

| B-2 | 0.5/20/0.5 | 260 × 40 × 0.5 | 260 × 40 × 20 | 0.066 |

| B-3 | 1.0/10/1.0 | 260 × 40 × 1.0 | 260 × 40 × 10 | 0.081 |

| B-4 | 1.0/20/1.0 | 260 × 40 × 1.0 | 260 × 40 × 20 | 0.090 |

| C-1 | 0.5/10/0.5 | 260 × 40 × 0.5 | 260 × 40 × 10 | 0.061 |

| C-2 | 0.5/20/0.5 | 260 × 40 × 0.5 | 260 × 40 × 20 | 0.078 |

| C-3 | 1.0/10/1.0 | 260 × 40 × 1.0 | 260 × 40 × 10 | 0.083 |

| C-4 | 1.0/20/1.0 | 260 × 40 × 1.0 | 260 × 40 × 20 | 0.094 |

| No. | Specimen Code | Sandwich Structure | Peak Load (N) | Deflection (mm) | Theoretical Value of Peak Load (N) | Theoretical Value of Deflection (mm) | Failure Mode |

|---|---|---|---|---|---|---|---|

| 1 | A-1 | 0.5/10/0.5 | 388.50 | 2.59 | 447.21 | 2.82 | Indentation |

| 2 | A-2 | 0.5/20/0.5 | 603.66 | 3.22 | 447.21 | 2.21 | Indentation |

| 3 | A-3 | 1.0/10/1.0 | 573.26 | 3.03 | 894.43 | 4.19 | Indentation |

| 4 | A-4 | 1.0/20/1.0 | 891.29 | 4.73 | 894.43 | 4.07 | Indentation |

| 5 | B-1 | 0.5/10/0.5 | 609.87 | 6.82 | 774.59 | 6.20 | Indentation |

| 6 | B-2 | 0.5/20/0.5 | 1217.52 | 2.75 | 774.59 | 2.21 | Indentation |

| 7 | B-3 | 1.0/10/1.0 | 1016.82 | 3.03 | 1549.19 | 3.16 | Indentation |

| 8 | B-4 | 1.0/20/1.0 | 1579.04 | 3.74 | 1549.19 | 3.0 | Indentation |

| 9 | C-1 | 0.5/10/0.5 | 889.19 | 12.17 | 834.75 | 12.94 | Tensile failure |

| 10 | C-2 | 0.5/20/0.5 | 1912.09 | 10.73 | 2031.25 | 10.27 | Tensile failure |

| 11 | C-3 | 1.0/10/1.0 | 1300.20 | 6.67 | 2449.50 | 6.10 | Indentation |

| 12 | C-4 | 1.0/20/1.0 | 2916.96 | 5.46 | 2449.50 | 5.13 | Indentation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahgoub, M.; Zhang, Y.; Yang, C.; Tan, Z. Dynamic Responses of Sandwich Beams with Polymethacrylimide (PMI) Foam Cores When Subjected to Impact Loading. Materials 2023, 16, 1108. https://doi.org/10.3390/ma16031108

Mahgoub M, Zhang Y, Yang C, Tan Z. Dynamic Responses of Sandwich Beams with Polymethacrylimide (PMI) Foam Cores When Subjected to Impact Loading. Materials. 2023; 16(3):1108. https://doi.org/10.3390/ma16031108

Chicago/Turabian StyleMahgoub, Mousab, Yongqiang Zhang, Chen Yang, and Zhuhua Tan. 2023. "Dynamic Responses of Sandwich Beams with Polymethacrylimide (PMI) Foam Cores When Subjected to Impact Loading" Materials 16, no. 3: 1108. https://doi.org/10.3390/ma16031108

APA StyleMahgoub, M., Zhang, Y., Yang, C., & Tan, Z. (2023). Dynamic Responses of Sandwich Beams with Polymethacrylimide (PMI) Foam Cores When Subjected to Impact Loading. Materials, 16(3), 1108. https://doi.org/10.3390/ma16031108