Effect of High-Pressure Torsion on Phase Formation and Mechanical Properties of a High-Entropy TiZrHfMoCrCo Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

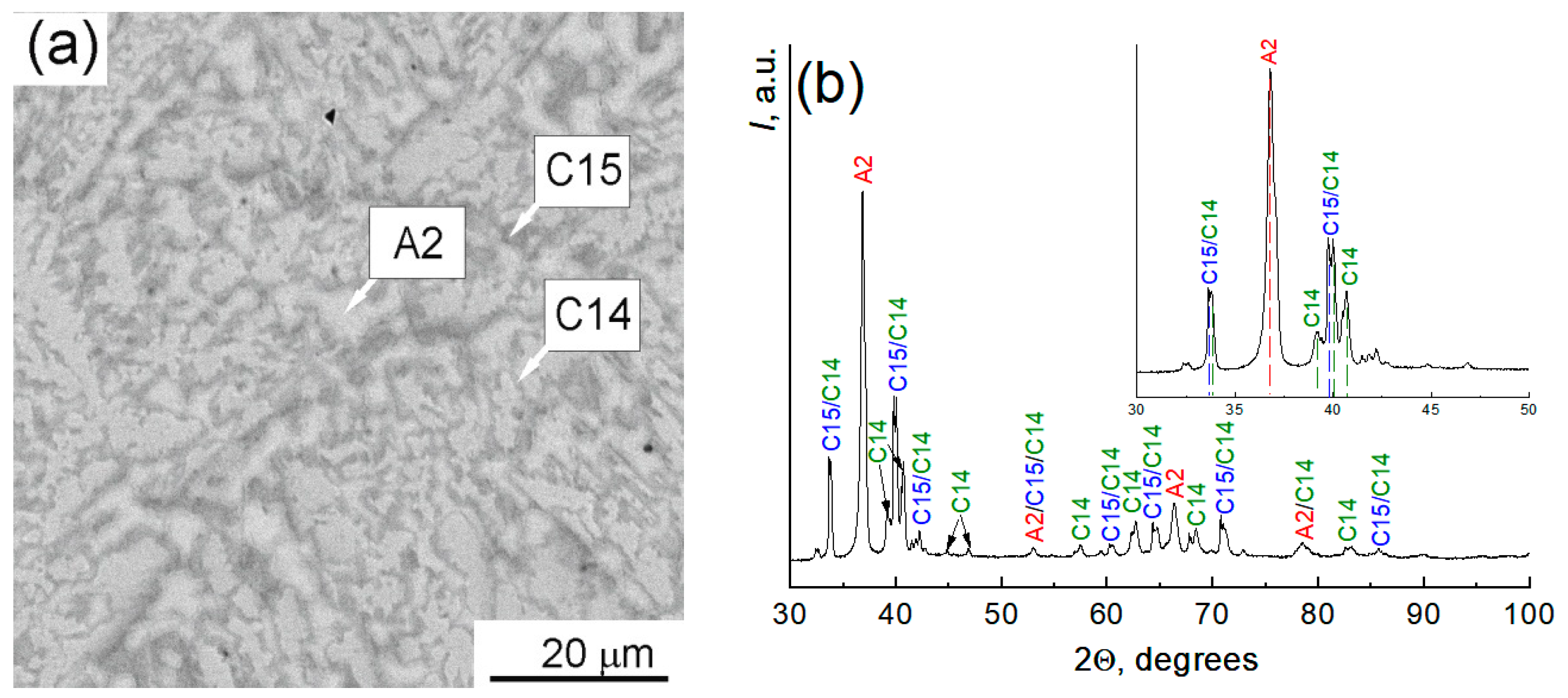

3.1. HEA Microstructure in the Initial State

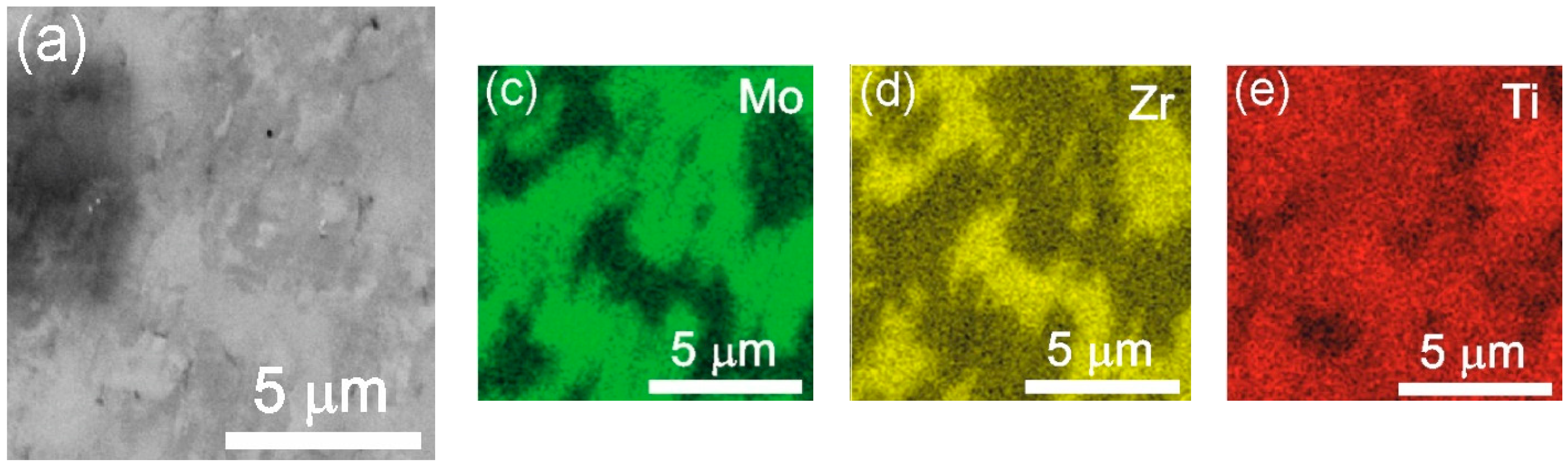

3.1.1. Element Distribution

3.1.2. Component Analysis along a Given Line

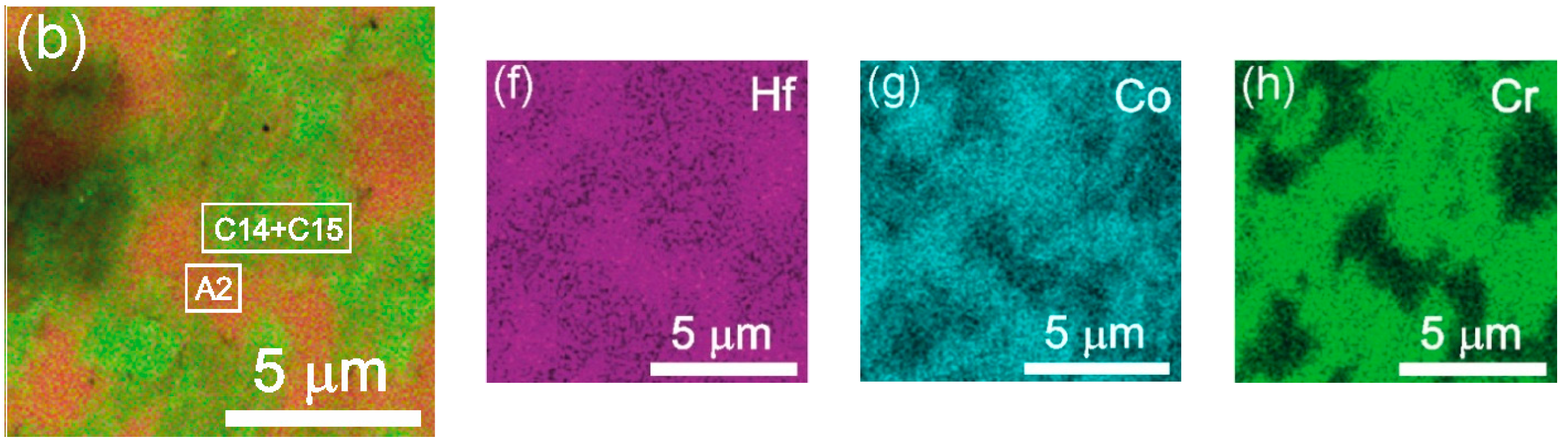

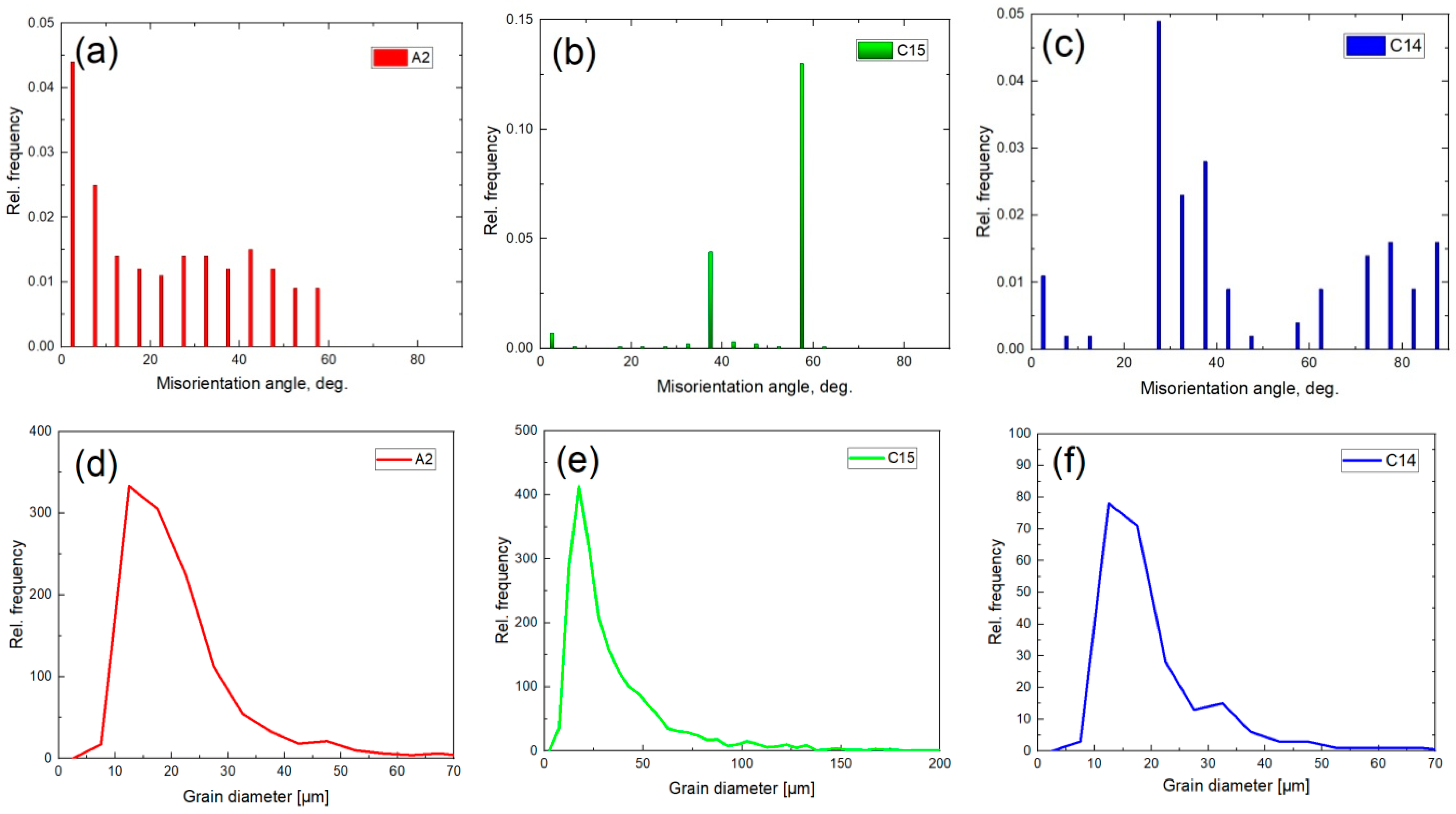

3.1.3. EBSD Measurements

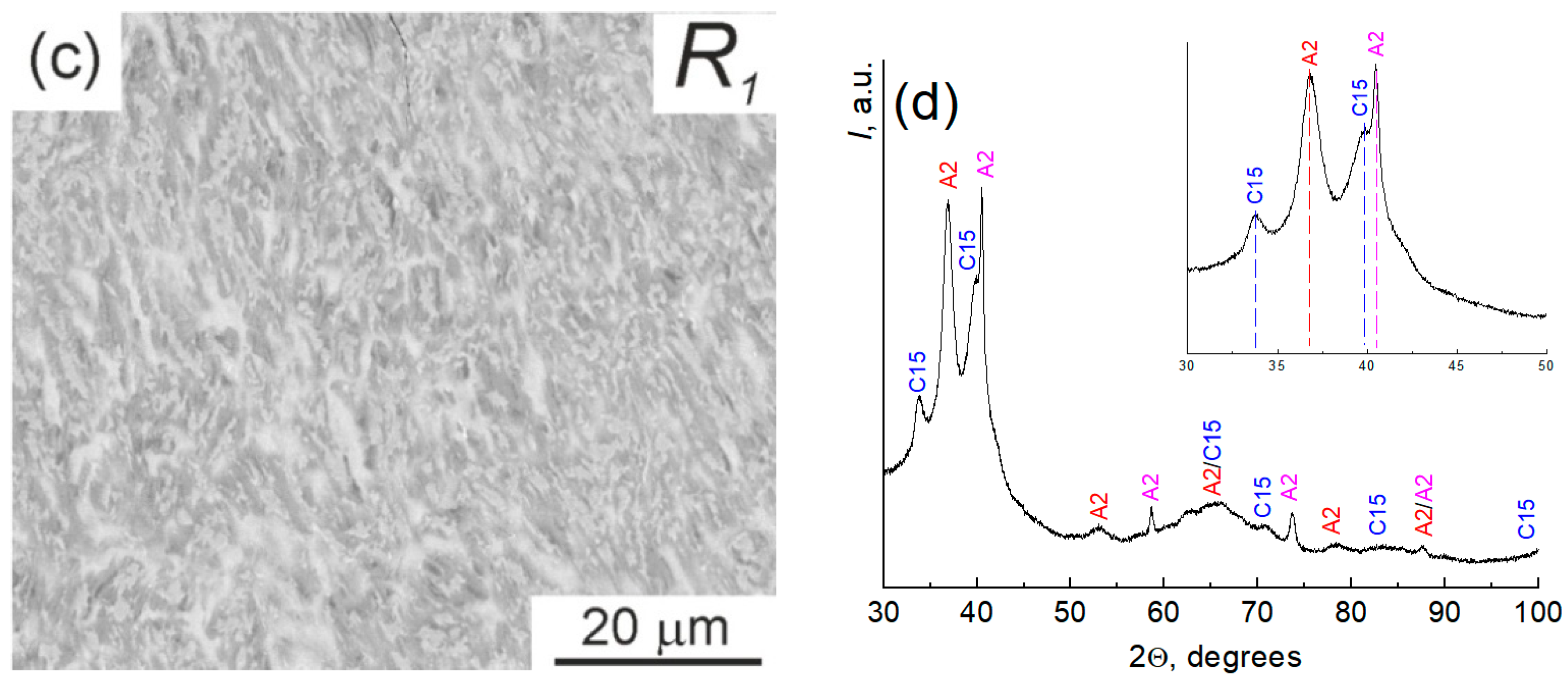

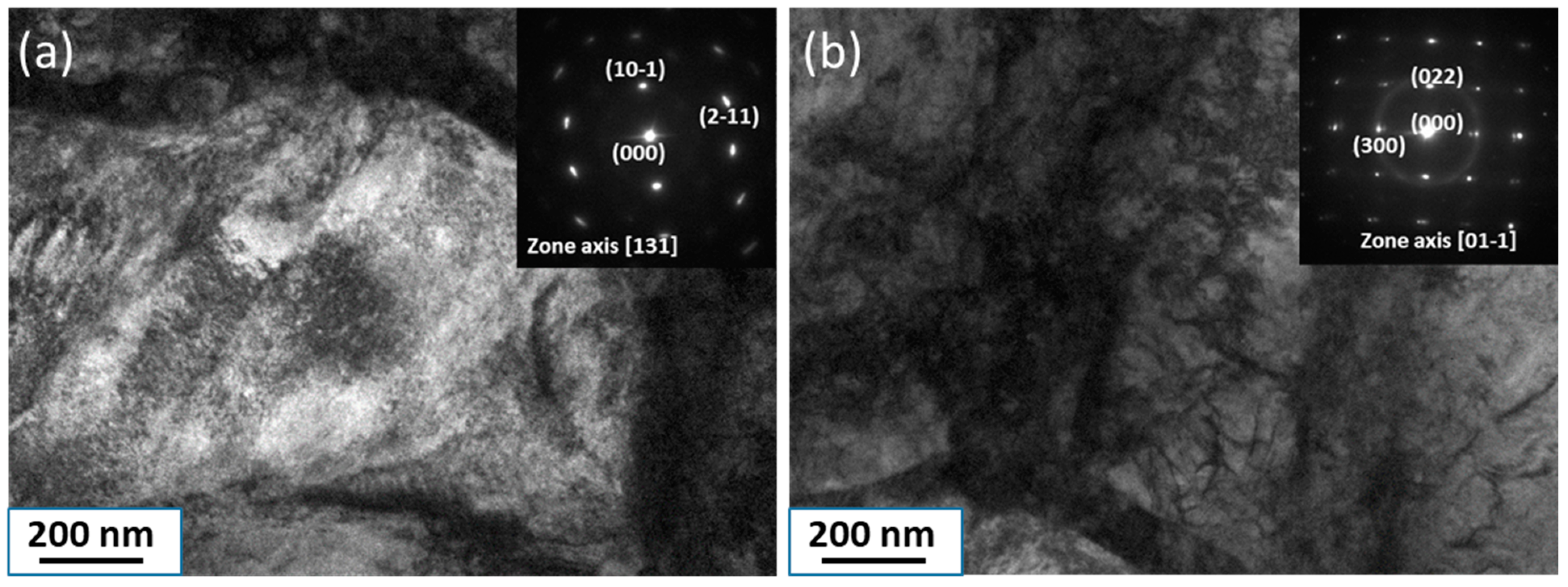

3.2. HEA Microstructure after HPT Treatment

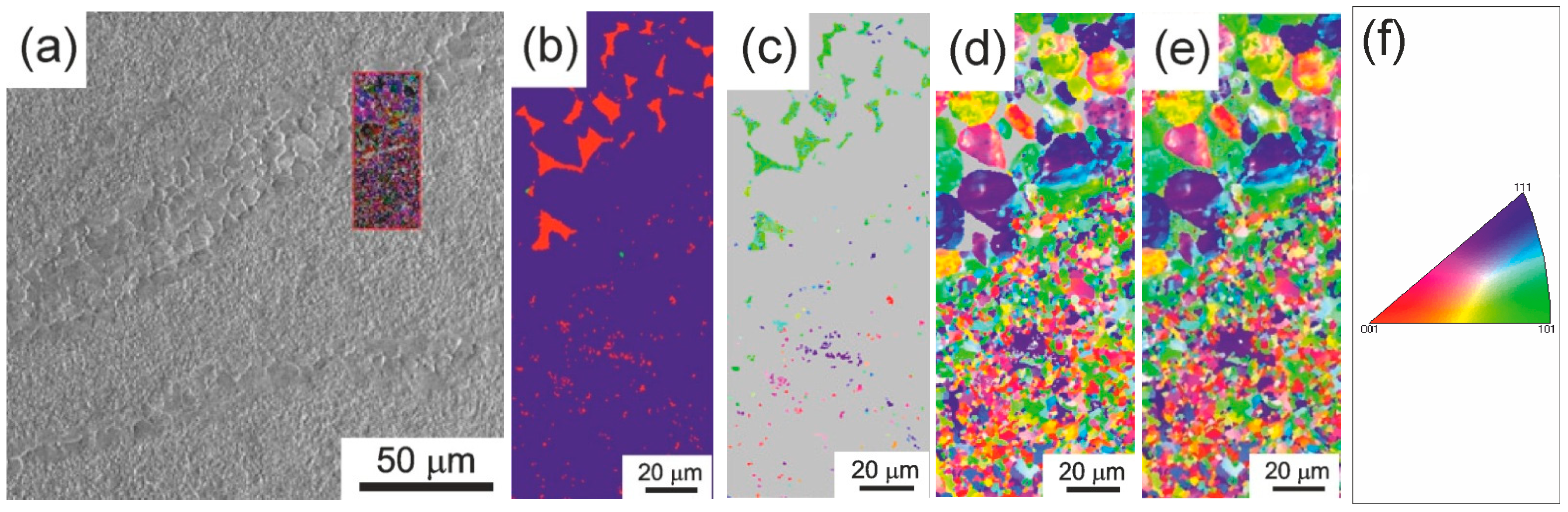

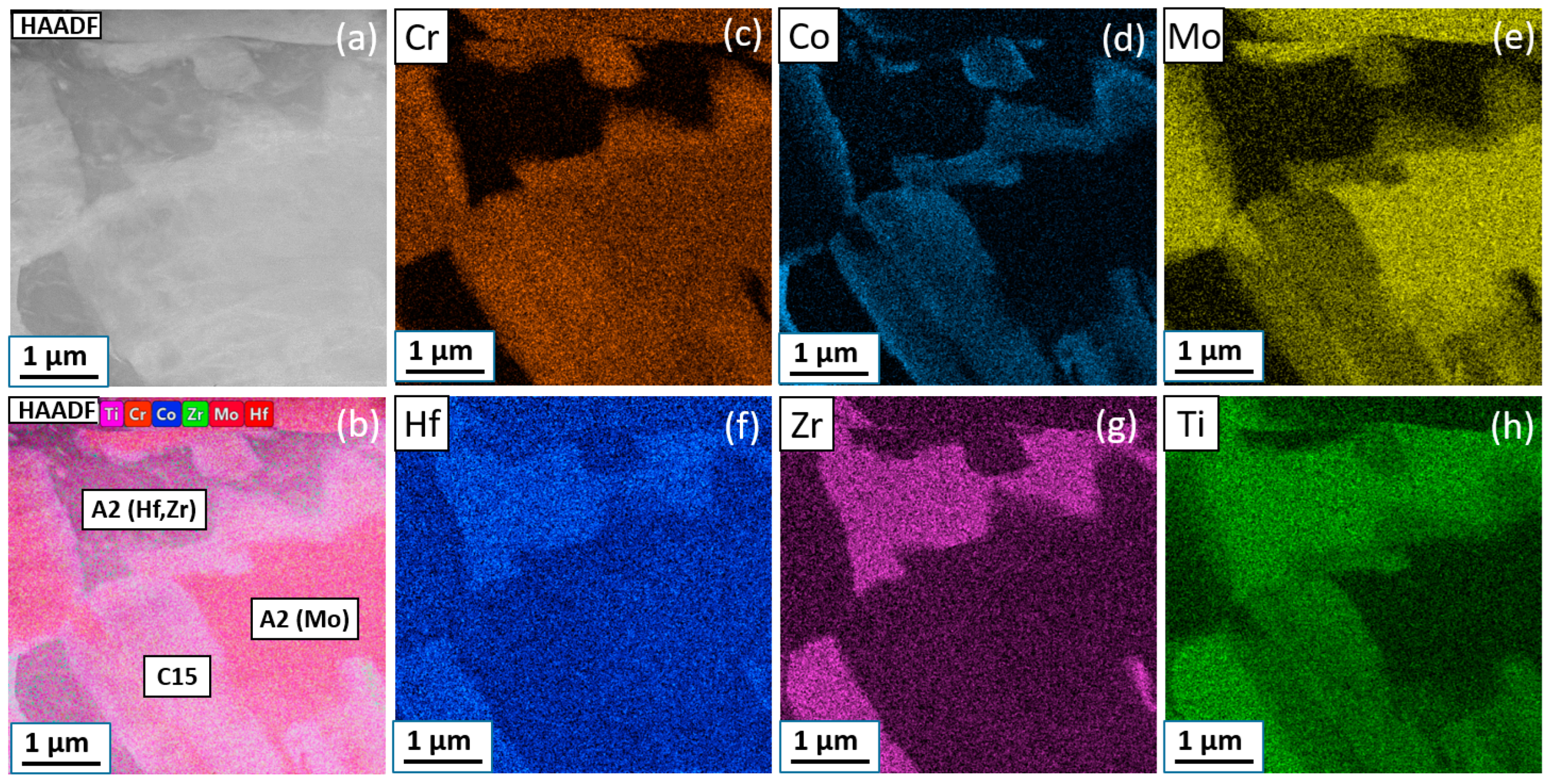

Distribution of Elements in the HEA Sample after HPT Treatment

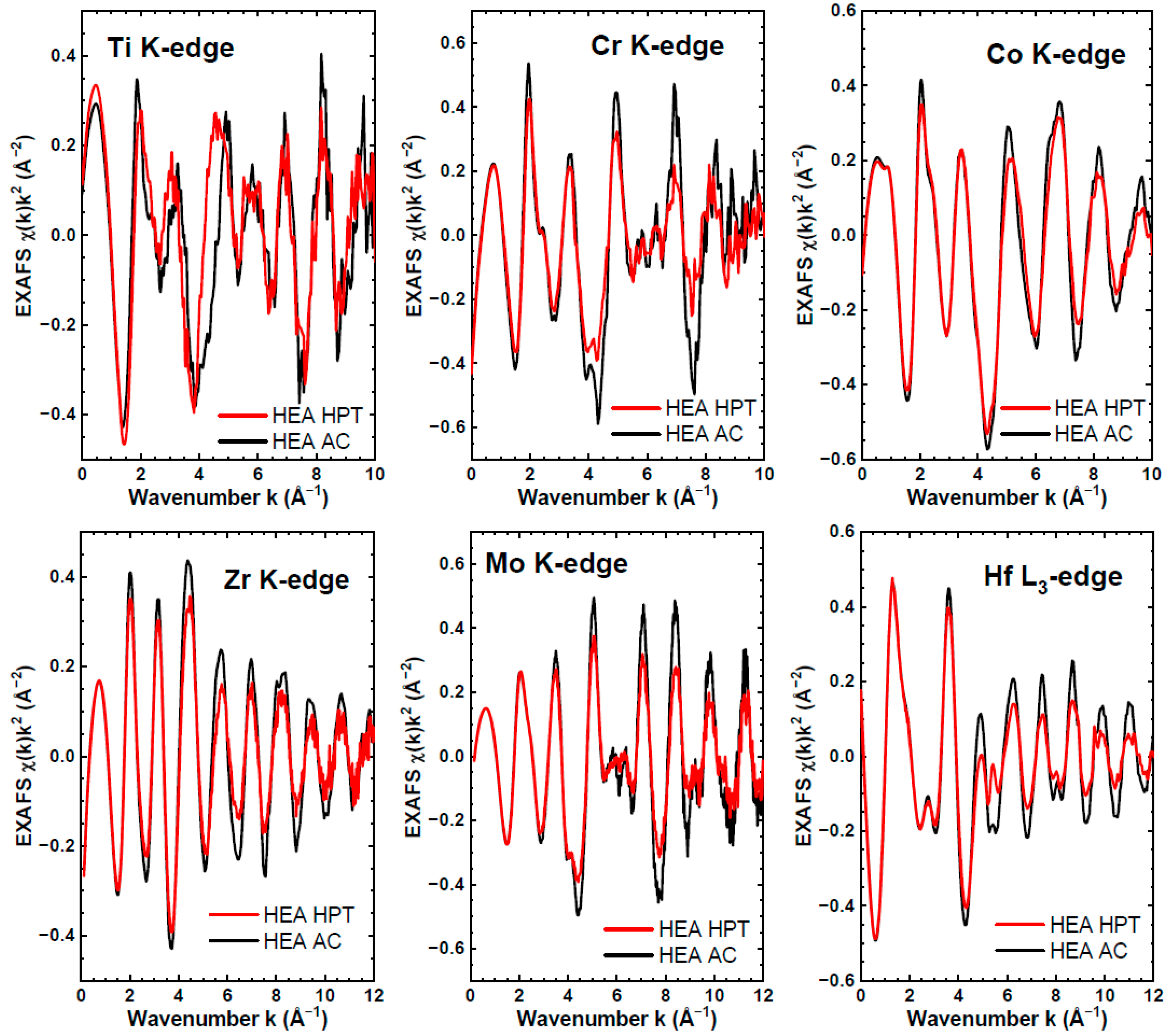

3.3. X-ray Absorption Spectroscopy

3.4. Mechanical Tests

3.4.1. Microhardness Measurements

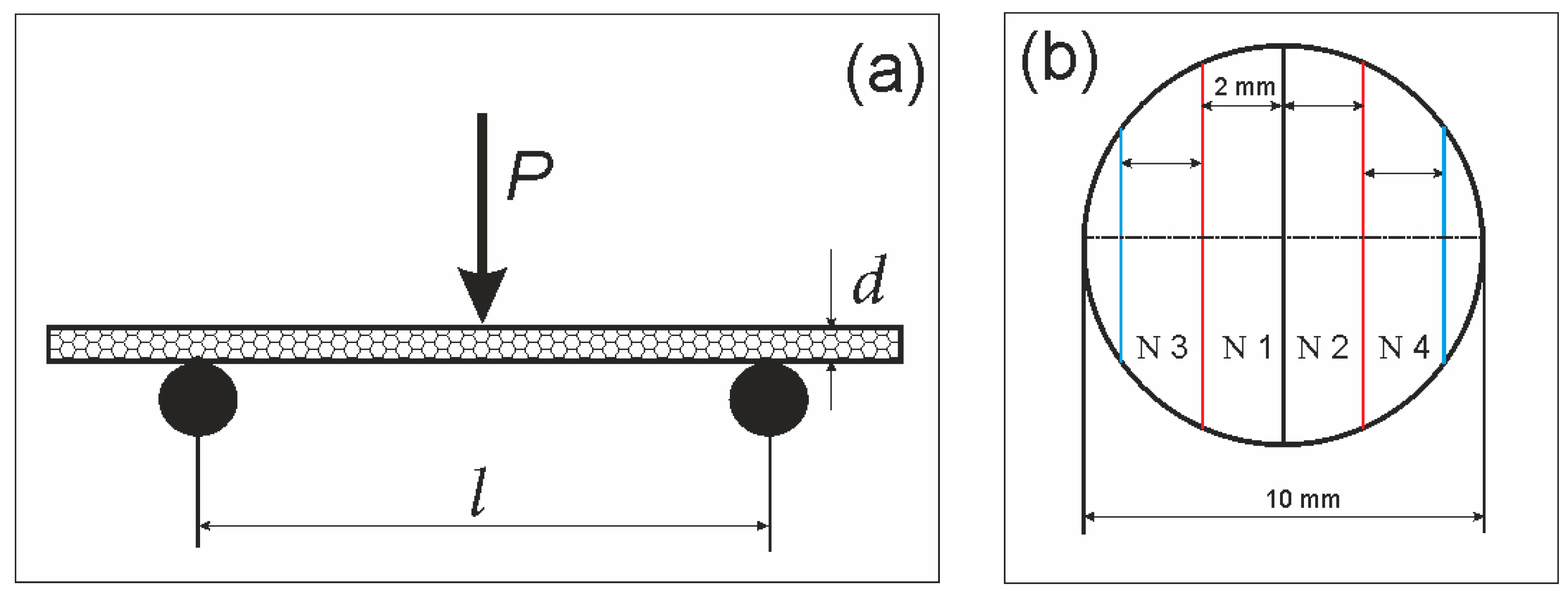

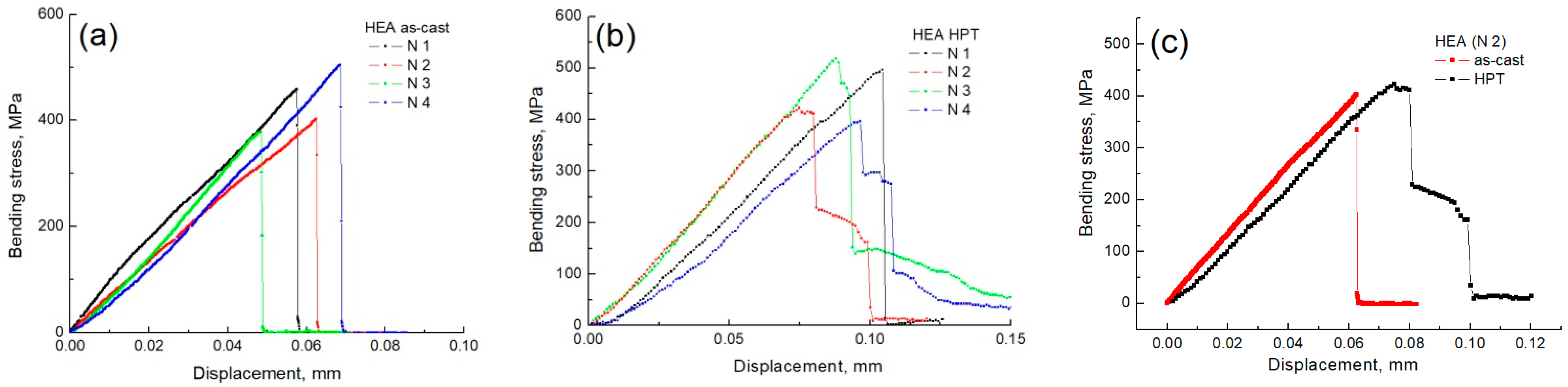

3.4.2. Three-Point Bending

4. Conclusions

- (1)

- The HPT treatment induced significant phase alterations and caused the disappearance of the hcp Laves phase C14 and the decomposition of the bcc phase A2 into two separate bcc A2 phases with distinct lattice parameters and compositions. One phase, enriched in hafnium, exhibited a lattice parameter of 3.445 nm, while the other, enriched in molybdenum, displayed a lattice parameter of 3.150 nm.

- (2)

- Employing EBSD enabled the determination of the average grain size and the misorientation distribution of grain boundaries within each phase. The observation of the wetting of A2/A2 grain boundaries by layers of the C15 phase was also noted.

- (3)

- The findings from the X-ray absorption spectroscopy analysis at the Ti, Cr, Co, Zr, and Mo K-edges, along with the Hf L3-edge, confirmed the retention of the local atomic structure of the metal atoms post-HPT treatment. A marginal increase in static disorder was detected, highlighting distinct local environments around Mo/Cr, Zr/Hf, and Ti atoms.

- (4)

- Despite the fairly high microhardness value of 600 HV for the material, HPT exhibited a minimal impact on this property, although the microhardness of individual phases underwent significant changes, surpassing a two-fold difference.

- (5)

- Pioneering tests were conducted and utilized the three-point bending method for the investigated alloy. The initial material exhibited greater brittleness compared to its post-HPT state. Additionally, the initial HEAs showcased a higher Young’s modulus of 135 GPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Nagase, T.; Iijima, Y.; Matsugaki, A.; Ameyama, K.; Nakano, T. Design and fabrication of Ti–Zr-Hf-Cr-Mo and Ti–Zr-Hf-Co-Cr-Mo highentropy alloys as metallic biomaterials. Mater. Sci. Eng. C 2020, 107, 110322. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Progr. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Gubicza, J.; Heczel, A.; Kawasaki, M.; Han, J.-K.; Zhao, Y.; Xue, Y.; Huang, S.; Labar, J.L. Evolution of microstructure and hardness in Hf25Nb25Ti25Zr25 high-entropy alloy during high-pressure torsion. J. Alloys Compd. 2019, 788, 318–328. [Google Scholar] [CrossRef]

- Gubicza, J.; El-Tahawy, M.; Huang, Y.; Choi, H.; Choe, H.; Lábár, J.L.; Langdon, T.G. Microstructure, phase composition and hardness evolution in 316L stainless steel processed by high-pressure torsion. Mater. Sci. Eng. A 2016, 657, 215–223. [Google Scholar] [CrossRef]

- Fu, Y.; Huang, C.; Du, C.; Li, J.; Dai, C.; Luo, H.; Liu, Z.; Li, X. Evolution in microstructure, wear, corrosion, and tribocorrosion behavior of Mo-containing high-entropy alloy coatings fabricated by laser cladding. Corr. Sci. 2021, 191, 109727. [Google Scholar] [CrossRef]

- Fan, Q.; Chen, C.; Fan, C.; Liu, Z.; Cai, X.; Lin, S.; Yang, C. Ultrasonic suppression of element segregation in gas tungsten arc cladding AlCoCuFeNi high-entropy alloy coatings. Surf. Coat. Technol. 2021, 420, 127364. [Google Scholar] [CrossRef]

- de Assumpção Pereira-da-Silva, M.; Ferri, F.A. Scanning Electron Microscopy. In Nanocharacterization Techniques; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 1–35. ISBN 978-0-323-49778-7. [Google Scholar]

- Wang, M.; Cui, H.; Zhao, Y.; Wang, C.; Wei, N.; Zhao, Y.; Zhang, X.; Song, Q. A simple strategy for fabrication of an FCC-based complex concentrated alloy coating with hierarchical nanoprecipitates and enhanced mechanical properties. Mater. Des. 2019, 180, 107893. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, G.; Cui, H.; Lu, Y.; Zhao, Y.; Wei, N.; Li, T. Effect of plasma remelting on microstructure and properties of a CoCrCuNiAl0.5 high-entropy alloy prepared by spark plasma sintering. J. Mater. Sci. 2021, 56, 5878–5898. [Google Scholar] [CrossRef]

- Löbel, M.; Lindner, T.; Clauß, S.; Pippig, R.; Dietrich, D.; Lampke, T. Microstructure and Wear Behavior of the High-Velocity-Oxygen-Fuel Sprayed and Spark Plasma Sintered High-Entropy Alloy AlCrFeCoNi. Adv. Eng. Mater. 2021, 23, 2001253. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Wang, C.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Jägle, E.A.; Zaefferer, S.; Raabe, D. Reducing hot tearing by grain boundary segregation engineering in additive manufacturing: Example of an AlxCoCrFeNi high-entropy alloy. Acta Mater. 2021, 204, 116505. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, N.; Shi, M.; Xing, B.; Zuo, X.; Yin, S. Microstructure and Tribological Properties of Plasma Cladding FeCoNiCr-x(TiC) Composite Coatings. J. Therm. Spray Technol. 2022, 31, 1649–1661. [Google Scholar] [CrossRef]

- You, D.; Yang, G.; Choa, Y.-H.; Kim, J.-K. Crack-resistant σ/FCC interfaces in the Fe40Mn40Co10Cr10 high entropy alloy with the dispersed σ-phase. Mater. Sci. Eng. A 2022, 831, 142039. [Google Scholar] [CrossRef]

- Shahmira, H.; Nili-Ahmadabadi, M.; Shafieea, A.; Andrzejczuk, M.; Lewandowska, M.; Langdon, T.G. Effect of Ti on phase stability and strengthening mechanisms of a nanocrystalline CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 725, 196–206. [Google Scholar] [CrossRef]

- Gnesin, B.A.; Gnesin, I.B.; Nekrasov, A.N. The interaction of carbon with Mo5Si3 and W5Si3 silicides. Nowotny phase synthesis. Intermetallics 2013, 41, 82–95. [Google Scholar] [CrossRef]

- Welter, E.; Chernikov, R.; Herrmann, M.; Nemausat, R. A beamline for bulk sample X-ray absorption spectroscopy at the high brilliance storage ring PETRA III. AIP Conf. Proc. 2019, 2054, 040002. [Google Scholar] [CrossRef]

- Kalinko, A. XAESA v.0.07. 2023. Available online: https://gitlab.desy.de/aleksandr.kalinko/xaesa (accessed on 5 December 2023).

- Kuzmin, A.; Chaboy, J. EXAFS and XANES analysis of oxides at the nanoscale. IUCrJ 2014, 1, 571–589. [Google Scholar] [CrossRef]

- Ankudinov, A.L.; Ravel, B.; Rehr, J.J.; Conradson, S.D. Real-space multiple-scattering calculation and interpretation of X-ray-absorption near-edge structure. Phys. Rev. B 1998, 58, 7565–7576. [Google Scholar] [CrossRef]

- Rehr, J.J.; Albers, R.C. Theoretical approaches to X-ray absorption fine structure. Rev. Mod. Phys. 2000, 72, 621–654. [Google Scholar] [CrossRef]

- Murdock, J.E.; Lundy, T.S.; Stansbury, E.E. Diffusion of Ti44 and V48 in titanium. Acta Metall. 1964, 12, 1033–1039. [Google Scholar] [CrossRef]

- Köler, U.; Herzig, C. On the anomalous self-diffusion in b.c.c. titanium. Phys. Stat. Sol. 1987, 144, 243. [Google Scholar] [CrossRef]

- Kidson, G.V.; McGurn, I. Self-diffusion in body-centered cubic zirconium. Can. J. Phys. 1961, 39, 1146–1157. [Google Scholar] [CrossRef]

- Federer, J.I.; Lundy, I.S. Diffusion of Zr95 and Cb95 in BCC Zirconium. Trans. Metall. Soc. AIME 1963, 227, 592–598. [Google Scholar]

- Herzig, C.; Eckseler, H. On the anomalous in β-zirconium. Int. J. Mater. Res. 1979, 70, 215–223. [Google Scholar] [CrossRef]

- Pruthi, D.D.; Agarwala, R.P. Solute and solvent diffusion in Zr-V alloys. Philos. Mag. A 1982, 46, 841–848. [Google Scholar] [CrossRef]

- Dyment, F.; Libanati, C.M. Self-diffusion of Ti, Zr, and Hf in their hcp phases, and diffusion of Nb95 in hcp Zr. J. Mater. Sci. 1968, 3, 349–359. [Google Scholar] [CrossRef]

- Bronfin, M.B.; Bokshtein, S.Z.; Zhukhovitsky, A.A. Determination of diffusion coefficient using the shift of activity curve. Zavod. Lab. 1960, 26, 828–830. [Google Scholar]

- Maier, K.; Mehrer, H.; Rein, G. Self-diffusion in molybdenum. Int. J. Mater. Res. 1979, 70, 271–276. [Google Scholar] [CrossRef]

- Mundy, J.N.; Tse, C.W.; McFall, W.D. Isotope effect in chromium self-diffusion. Phys. Rev. B 1976, 13, 2349–2357. [Google Scholar] [CrossRef]

- Mundy, J.N.; Hoff, H.A.; Pelleg, J.; Rothman, S.J.; Nowicki, L.J.; Schmidt, E.A. Self-diffusion in chromium. Phys. Rev. B 1981, 24, 658–665. [Google Scholar] [CrossRef]

- Hirano, K.I.; Agarwala, R.P.; Averback, B.L.; Cohen, M. Diffusion in cobalt-nickel alloys. J. Appl. Phys. 1962, 33, 3049–3054. [Google Scholar] [CrossRef]

- Bussmann, W.; Herzig, C.; Rempp, W.; Maier, K.; Mehrer, H. Isotope effect and self-diffusion in face-centred cubic cobalt. Phys. Stat. Sol. A 1979, 56, 87–97. [Google Scholar] [CrossRef]

- Straumal, B.B.; Klinger, L.M.; Shvindlerman, L.S. The influence of pressure on indium diffusion along single tin–germanium interphase boundaries. Scripta Metall. 1983, 17, 275–279. [Google Scholar] [CrossRef]

- Molodov, D.A.; Straumal, B.B.; Shvindlerman, L.S. The effect of pressure on migration of the [001] tilt grain boundaries in the tin bicrystals. Scripta Metall. 1984, 18, 207–211. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Murashkin, M.Y.; Straumal, B.B. Enhanced ductility in ultrafine-grained Al alloys produced by SPD techniques. Mater. Sci. Forum 2009, 633–634, 321–332. [Google Scholar] [CrossRef]

- Chinh, N.Q.; Csanádi, T.; Gubicza, J.; Valiev, R.Z.; Straumal, B.B.; Langdon, T.G. The effect of grain-boundary sliding and strain rate sensitivity on the ductility of ultrafine-grained materials. Mater. Sci. Forum 2011, 667–669, 677–682. [Google Scholar] [CrossRef]

- Straumal, B.B.; Protasova, S.G.; Mazilkin, A.A.; Rabkin, E.; Goll, D.; Schütz, G.; Baretzky, B.; Valiev, R. Deformation-driven formation of equilibrium phases in the Cu–Ni alloys. J. Mater. Sci. 2012, 47, 360–367. [Google Scholar] [CrossRef]

- Straumal, B.B.; Gornakova, A.S.; Mazilkin, A.A.; Fabrichnaya, O.B.; Kriegel, M.J.; Baretzky, B.; Jiang, J.-Z.; Dobatkin, S.V. Phase transformations in the severely plastically deformed Zr–Nb alloys. Mater. Lett. 2012, 81, 225–228. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Kucheev, Y.O.; Kurmanaeva, L.; Ivanisenko, Y.; Baretzky, B.; Korneva, A.; Zięba, P.; Molodov, D.A. Phase transitions during high pressure torsion of Cu–Co alloys. Mater. Lett. 2014, 118, 111–114. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Ivanisenko, Y.; Mazilkin, A.A.; Kogtenkova, O.A.; Kurmanaeva, L.; Korneva, A.; Zięba, P.; Baretzky, B. Phase transitions induced by severe plastic deformation: Steady-state and equifinality. Int. J. Mater. Res. 2015, 106, 657–664. [Google Scholar] [CrossRef]

- Straumal, B.B.; Pontikis, V.; Kilmametov, A.R.; Mazilkin, A.A.; Dobatkin, S.V.; Baretzky, B. Competition between precipitation and dissolution in Cu–Ag alloys under high pressure torsion. Acta Mater. 2017, 122, 60–71. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; Korneva, A.; Mazilkin, A.A.; Straumal, P.B.; Zięba, P.; Baretzky, B. Phase transitions in Cu-based alloys under high pressure torsion. J. Alloys Compd. 2017, 707, 20–26. [Google Scholar] [CrossRef]

- Straumal, B.B.; Kilmametov, A.R.; López, G.A.; López-Ferreño, I.; Nó, M.L.; San Juan, J.; Hahn, H.; Baretzky, B. High-pressure torsion driven phase transformations in Cu–Al–Ni shape memory alloys. Acta Mater. 2017, 125, 274–285. [Google Scholar] [CrossRef]

- Mazilkin, A.; Straumal, B.; Kilmametov, A.; Straumal, P.; Baretzky, B. Phase transformations induced by severe plastic deformation. Mater. Trans. 2019, 60, 1489–1499. [Google Scholar] [CrossRef]

- Muller, J.E.; Jepsen, O.; Andersen, O.K.; Wilkins, J.W. Systematic structure in the K-edge photoabsorption spectra of the 4d transition metals: Theory. Phys. Rev. Lett. 1978, 40, 720–722. [Google Scholar] [CrossRef]

- Müller, J.E.; Jepsen, O.; Wilkins, J.W. X-ray absorption spectra: K-edges of 3d transition metals, L-edges of 3d and 4d metals, and M-edges of palladium. Solid State Commun. 1982, 42, 365–368. [Google Scholar] [CrossRef]

- Keski-Rahkonen, O.; Krause, M.O. Total and partial atomic-level widths. At. Data Nucl. Data Tables 1974, 14, 139–146. [Google Scholar] [CrossRef]

- Qi, B.; Perez, I.; Ansari, P.H.; Lu, F.; Croft, M. L2 and L3 measurements of transition-metal 5d orbital occupancy, spin-orbit effects, and chemical bonding. Phys. Rev. B 1987, 36, 2972–2975. [Google Scholar] [CrossRef]

- Gornakova, A.; Straumal, B.; Kuzmin, A.; Tyurin, A.; Chernyaeva, E.; Druzhinin, A.; Afonikova, N.; Davdian, G. Influence of heat treatment and high-pressure torsion on phase transformations in TiZrHfMoCr high-entropy alloy. Metals 2023, 13, 1030. [Google Scholar] [CrossRef]

- Fan, Q.; Chen, C.; Fan, C.; Liu, Z.; Cai, X.; Lin, S.; Yang, C. Effect of high Fe content on the microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy coatings prepared by gas tungsten arc cladding. Surf. Coat. Technol. 2021, 418, 127242. [Google Scholar] [CrossRef]

- Gornakova, A.S.; Straumal, B.B.; Tyurin, A.I.; Afonikova, N.S.; Druzhinin, A.V.; Davdian, G.S.; Kilmametov, A.R. Phase transformations caused by heat treatment and high-pressure torsion in TiZrHfMoCrCo Alloy. Materials 2023, 16, 1354. [Google Scholar] [CrossRef] [PubMed]

| Phase Designation | Phase Description, Spatial Group | Component Composition, wt.% | Type of Crystal Lattice |

|---|---|---|---|

| A2 | BCC lattice (Ti,Zr,Hf)cub Im3m 4/m-32/m | Ti—13.5 ± 0.8 Cr—0.5 ± 0.5 Co—1.2 ± 0.9 Zr—28.4 ± 1.7 Mo—7.1 ± 1.7 Hf—46.4 ± 3.1 |  |

| C15 | The Laves phase | Ti—11.5 ± 0.6 |  |

| FCC lattice | Cr—6.0 ± 0.6 | ||

| Cr2Ti | Co—6.0 ± 0.6 | ||

| Zr—13.8 ± 1.6 | |||

| Fd3m | Mo—20.9 ± 2.4 | ||

| F4_1/d-32/m | Hf—39.6 ± 3.0 | ||

| C14 | The Laves phase | Ti—6.4 ± 0.7 |  |

| HCP lattice | Cr—5.1 ± 0.6 | ||

| Cr2Zr | Co—1.2 ± 0.8 | ||

| Zr—11.3 ± 1.7 | |||

| P63/mmc | Mo—34.9 ± 1.9 | ||

| P6_3/m 2/m 2/c | Hf—41.3 ± 3.1 |

| Phases | Chemical Composition Measured by EDS/SEM | Chemical Composition Measured by EDS/TEM |

|---|---|---|

| A2 enriched in Hf, Zr | Ti—13.6 ± 0.5 | Ti—12.9 ± 1.2 |

| Cr—1.0 ± 0.3 | Cr—0.5 ± 0.1 | |

| Co—1.6 ± 0.2 | Co—1.0 ± 0.2 | |

| Zr—25.8 ± 0.5 | Zr—35.4 ± 5.1 | |

| Mo—6.5 ± 0.3 | Mo—6.5 ± 1.0 | |

| Hf—51.5 ± 1.0 | Hf—43.7 ± 5.5 | |

| A2 enriched in Mo | Ti—6.7 ± 0.3 | Ti—5.0 ± 0.5 |

| Cr—5.4 ± 0.2 | Cr—4.8 ± 0.7 | |

| Co—1.3 ± 0.3 | Co—1.0 ± 0.2 | |

| Zr—10.6 ± 0.4 | Zr—14.1 ± 2.0 | |

| Mo—31.2 ± 0.6 | Mo—38.3 ± 5.5 | |

| Hf—44.8 ± 0.9 | Hf—36.8 ± 4.6 | |

| C15 | Ti—11.8 ± 0.5 | Ti—9.5 ± 0.8 |

| Cr—5.3 ± 0.2 | Cr—6.8 ± 1.0 | |

| Co—7.1 ± 0.3 | Co—5.1 ± 0.9 | |

| Zr—15.4 ± 0.6 | Zr—16.2 ± 2.2 | |

| Mo—15.1 ± 0.6 | Mo—24.0 ± 4.5 | |

| Hf—45.3 ± 0.9 | Hf—38.4 ± 4.6 |

| HEA (As-Cast) | HEA (HPT) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| N 1 | N 2 | N 3 | N 4 | Average Value | N 1 | N 2 | N 3 | N 4 | Average Value | |

| σmax (MPa) | 460 | 402 | 379 | 506 | 436 ± 28 | 498 | 420 | 519 | 396 | 458 ± 29 |

| E (GPa) | 135 | 97 | 113 | 111 | 114 ± 7 | 83 | 105 | 105 | 79 | 93 ± 7 |

| ε (%) | 0.3 | 0.4 | 0.3 | 0.4 | 0.35 ± 0.05 | 0.6 | 0.4 | 0.4 | 0.5 | 0.48 ± 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gornakova, A.S.; Kabirova, D.B.; Korneva, A.; Straumal, B.; Imayev, M.F.; Kuzmin, A.; Czaja, P.; Afonikova, N.S.; Orlov, V.I.; Nekrasov, A.N.; et al. Effect of High-Pressure Torsion on Phase Formation and Mechanical Properties of a High-Entropy TiZrHfMoCrCo Alloy. Materials 2023, 16, 7558. https://doi.org/10.3390/ma16247558

Gornakova AS, Kabirova DB, Korneva A, Straumal B, Imayev MF, Kuzmin A, Czaja P, Afonikova NS, Orlov VI, Nekrasov AN, et al. Effect of High-Pressure Torsion on Phase Formation and Mechanical Properties of a High-Entropy TiZrHfMoCrCo Alloy. Materials. 2023; 16(24):7558. https://doi.org/10.3390/ma16247558

Chicago/Turabian StyleGornakova, Alena S., Dilara B. Kabirova, Anna Korneva, Boris Straumal, Marcel F. Imayev, Alexei Kuzmin, Paweł Czaja, Natalia S. Afonikova, Valeriy I. Orlov, Alexei N. Nekrasov, and et al. 2023. "Effect of High-Pressure Torsion on Phase Formation and Mechanical Properties of a High-Entropy TiZrHfMoCrCo Alloy" Materials 16, no. 24: 7558. https://doi.org/10.3390/ma16247558

APA StyleGornakova, A. S., Kabirova, D. B., Korneva, A., Straumal, B., Imayev, M. F., Kuzmin, A., Czaja, P., Afonikova, N. S., Orlov, V. I., Nekrasov, A. N., Khayretdinov, N. F., & Davdian, G. (2023). Effect of High-Pressure Torsion on Phase Formation and Mechanical Properties of a High-Entropy TiZrHfMoCrCo Alloy. Materials, 16(24), 7558. https://doi.org/10.3390/ma16247558