Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection

Abstract

1. Introduction

2. Application of Geopolymers in Biomedical Areas

2.1. Drug Delivery Systems

2.2. Bone Regeneration

2.3. Dental Implantology

3. Potential of Geopolymers in Water Purification

4. Geopolymers in the Energy Industry

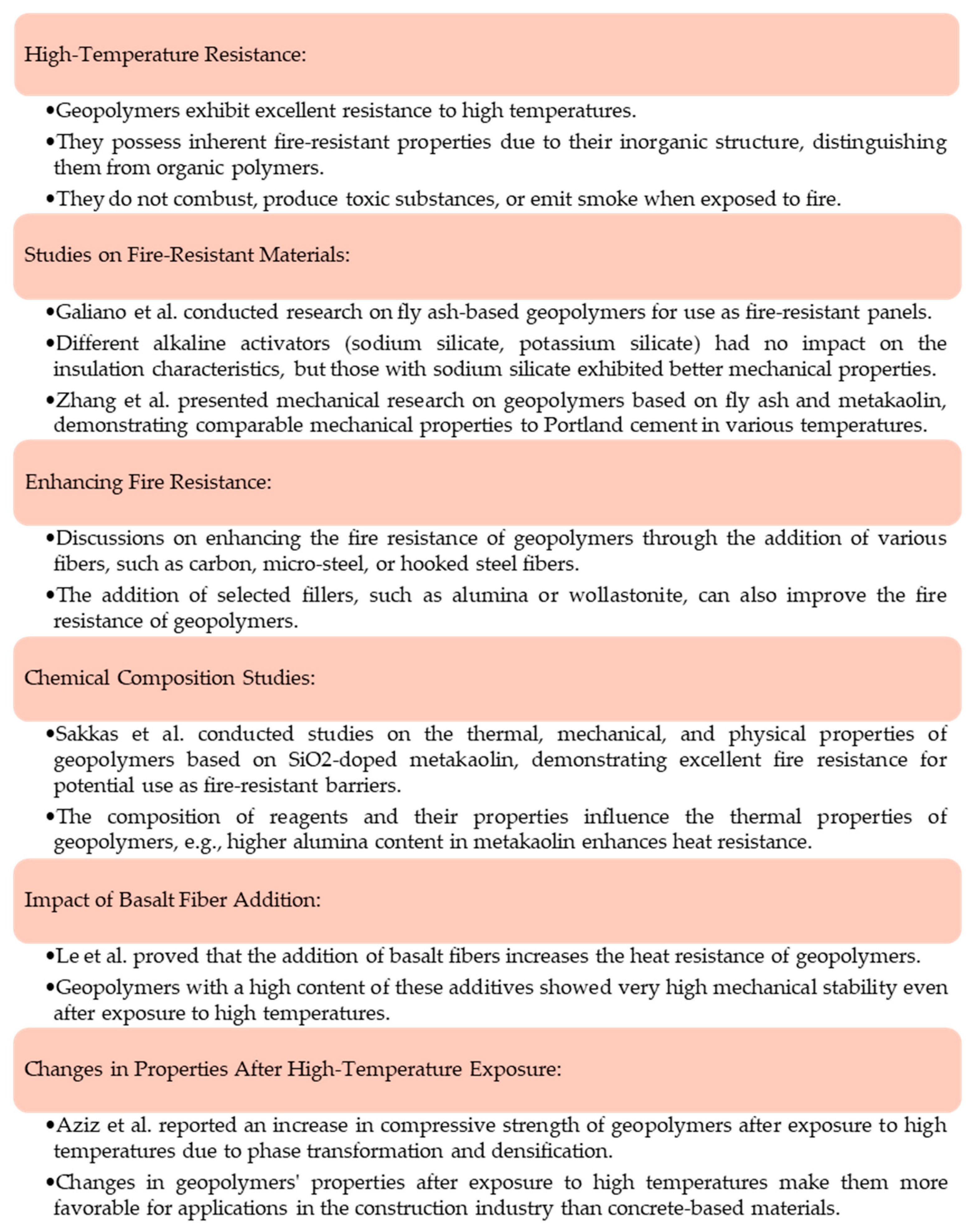

4.1. Role in the Development of Fire-Resistant Materials

4.2. Thermal Insulation

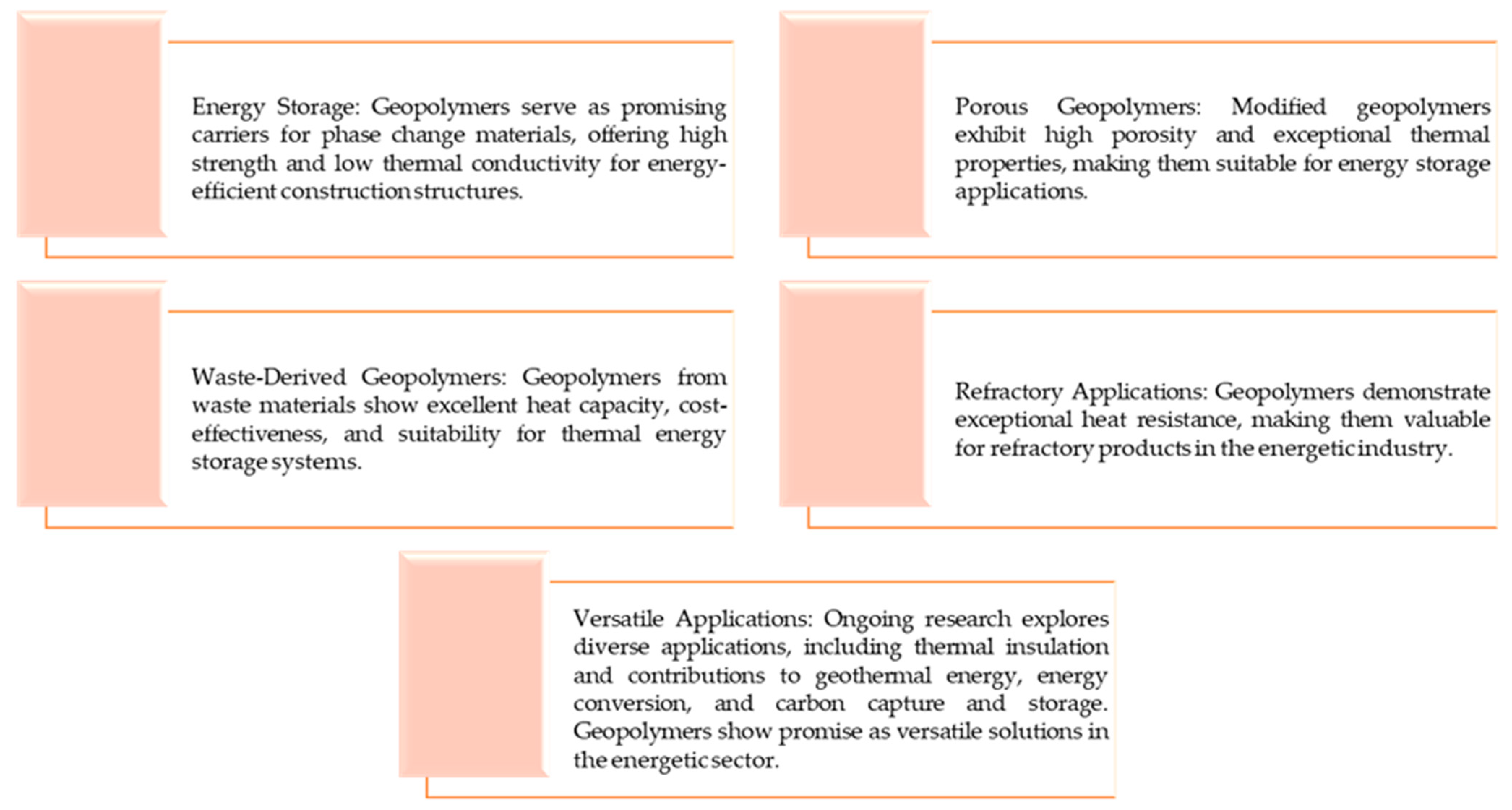

4.3. Further Possible Applications in the Energy Industry

5. Geopolymer Applications in Microbial Protection

6. Geopolymers as Anticorrosive Solutions in Industry

7. Summary

7.1. Conclusions

- Geopolymer materials, initially investigated mainly for the construction industry, have shown wide application potential in fields such as medicine, environmental protection and the energy industry. Importantly, they play an important role in the design of materials with antimicrobial and anticorrosive properties.

- Geopolymers are gaining attention in medicine due to their excellent mechanical properties, controlled porosity and biocompatibility. In the field of drug delivery, their strength allows for the formation of safe release systems for active substances, especially opioids. In bone regeneration and dental implantology, geopolymers show the ability to promote bone tissue formation.

- Geopolymers may be applicable for the removal of a variety of contaminants, including heavy metals, dyes, pharmaceuticals and surfactants from wastewater. Their chemical stability, porosity and large surface area make these materials a versatile tool for effective removal of contaminants through adsorption processes, making them a promising material in the field of water purification.

- Geopolymers show excellent resistance to high temperatures, which makes them promising for the fabrication of fire-resistant materials. Improving the high-temperature resistance of geopolymers, while improving their mechanical properties, may be achieved by introducing modifiers such as carbon fibers into the geopolymer matrix. Geopolymers, due to their thermal properties, are also being considered as effective materials for thermal insulation. Research into their use as insulation materials confirms their potential to reduce thermal conductivity, making them an attractive choice in the energy industry. Moreover, studies on the potential of geopolymers as energy storage materials are opening up new prospects for their use in the energy field.

- Geopolymers are gaining recognition in terms of protection against microorganisms. The possibility of incorporating additives such as silver nanoparticles or other antimicrobial substances into the geopolymer matrix allows geopolymers to be tailored to specific applications. In addition, they demonstrate the capability of maintaining antimicrobial activity even at high temperatures, which makes them useful in fields where protection against various microorganisms while maintaining heat resilience is critical.

- Geopolymers, as anticorrosion materials, are gaining the attention of researchers. Current studies are focusing on developing effective anticorrosion coatings based on geopolymers. Moreover, other experiments have confirmed the excellent durability of geopolymer coatings on metal, suggesting their promising application in corrosion protection.

7.2. Future Directions and Limitations

- Sustainable Geopolymer Production:

- Adapting Geopolymers to Specific Applications:

- Advances in Nanotechnology:

- Biomedical Applications and Drug Delivery Systems:

- Standardization and Regulation:

- Life Cycle Assessment:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castillo, H.; Collado, H.; Droguett, T.; Vesely, F.; Garrido, P.; Palma, S. State of the art of geopolymers: A review. e-Polymers 2022, 22, 108–124. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications, and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Shehata, N.; Sayed, E.T.; Ali Abdelkareem, M. Recent progress in environmentally friendly geopolymers: A review. Sci. Total Environ. 2021, 762, 143166. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Ceramic-Like Inorganic Polymers. J. Ceram. Sci. Technol. 2017, 8, 335–350. [Google Scholar]

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A review and prospects for the minerals industry. Miner. Eng. 2007, 20, 1261–1277. [Google Scholar] [CrossRef]

- Nguyen, V.V.; Le, V.S.; Louda, P.; Szczypiński, M.M.; Ercoli, R.; Růžek, V.; Łoś, P.; Prałat, K.; Plaskota, P.; Pacyniak, T.; et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers 2022, 14, 304. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y. A sustainable roadmap for additive manufacturing using geopolymers in construction industry. Resour. Conserv. Recycl. 2022, 186, 106592. [Google Scholar] [CrossRef]

- Asghar, R.; Khan, M.A.; Alyousef, R.; Javed, M.F.; Ali, M. Promoting the green Construction: Scientometric review on the mechanical and structural performance of geopolymer concrete. Constr. Build. Mater. 2023, 368, 130502. [Google Scholar] [CrossRef]

- Ansari, M.A.; Shariq, M.; Mahdi, F. Geopolymer concrete for clean and sustainable construction—A state-of-the-art review on the mix design approaches. Structures 2023, 55, 1045–1070. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction-recent developments. Constr. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Wang, M. Structure, Reactivity, and Mechanical Properties of Sustainable Geopolymer Material: A Reactive Molecular Dynamics Study. Front. Mater. 2020, 7, 69. [Google Scholar] [CrossRef]

- Matsimbe, J.; Dinka, M.; Olukanni, D.; Musonda, I. Geopolymer: A Systematic Review of Methodologies. Materials 2022, 15, 6852. [Google Scholar] [CrossRef]

- Lingyu, T.; Dongpo, H.; Jianing, Z.; Hongguang, W. Durability of geopolymers and geopolymer concretes: A review. Rev. Adv. Mat. Sci. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- Petermann, J.C.; Saeed, A.; Hammons, M.I. Alkali-Activated Geopolymers: A Literature Review; Applied Research Associates Inc.: Panama City, FL, USA, 2010. [Google Scholar]

- Castillo, H.; Collado, H.; Droguett, T.; Sánchez, S.; Vesely, M.; Garrido, P.; Palma, S. Factors affecting the compressive strength of geopolymers: A review. Minerals 2021, 11, 1317. [Google Scholar] [CrossRef]

- Bai, C.; Colombo, P. Processing, properties and applications of highly porous geopolymers: A review. Ceram. Int. 2018, 44, 16103–16118. [Google Scholar] [CrossRef]

- Alhawat, M.; Ashour, A.; Yildirim, G.; Aldemir, A.; Sahmaran, M. Properties of geopolymers sourced from construction and demolition waste: A review. J. Build. Eng. 2022, 50, 104104. [Google Scholar] [CrossRef]

- Kumar, A.S.; Muthukannan, M.; Krishna, I.S. Optimisation of bio medical waste ash in GGBS based of geopolymer concrete. Mater. Sci. Eng. 2020, 872, 012163. [Google Scholar]

- Liu, C.; Huang, X.; Wu, Y.Y.; Deng, X.; Liu, J.; Zheng, Z.; Hui, D. Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnol. Rev. 2020, 9, 155–169. [Google Scholar] [CrossRef]

- Mohd Mortar, N.A.; Abdullah, M.M.A.B.; Abdul Razak, R.; Abd Rahim, S.Z.; Aziz, I.H.; Nabiałek, M.; Ghazali, M.F. Geopolymer ceramic application: A review on mix design, properties and reinforcement enhancement. Materials 2022, 15, 7567. [Google Scholar] [CrossRef]

- Suresh Kumar, A.; Muthukannan, M.; Arun Kumar, K.; Chithambar Ganesh, A.; Kanniga Devi, R. Development of environmental-friendly geopolymer concrete using incinerated biomedical waste ash. In Recent Advances in Structural Engineering and Construction Management: Select Proceedings of ICSMC 2021; Springer Nature Singapore: Singapore, 2022; pp. 709–726. [Google Scholar]

- Wang, Y.S.; Alrefaei, Y.; Dai, J.G. Silico-aluminophosphate and alkali-aluminosilicate geopolymers: A comparative review. Front. Mater. 2019, 6, 106. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Maged, A.; Eloffy, M.G.; Zahran, M.; Kharbish, S.; Elwakeel, K.Z.; Bhatnagar, A. Geopolymers as sustainable eco-friendly materials: Classification, synthesis routes, and applications in wastewater treatment. Sep. Purif. Technol. 2023, 324, 124631. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Bone Tissue Applications: Recent Advances and Future Perspectives. Polymers 2023, 15, 1087. [Google Scholar] [CrossRef]

- Pangdaeng, S.; Sata, V.; Aguiar, J.B.; Pacheco-Torgal, F.; Chindaprasirt, J.; Chindaprasirt, P. Bioactivity enhancement of calcined kaolin geopolymer with CaCl2 treatment. Sci. Asia 2016, 42, 407–414. [Google Scholar] [CrossRef][Green Version]

- Ogun, B.S.; Derun, E.M. Investigation of nanoparticle use in geopolymer production. Eurasian J. Biol. Chem. Sci. 2019, 2, 79–83. [Google Scholar]

- Tippayasam, C.; Sutikulsombat, S.; Kamseu, E.; Rosa, R.; Thavorniti, P.; Chindaprasirt, P.; Leonelli, C.; Heness, G.; Chaysuwan, D. In vitro surface reaction in SBF of a non-crystalline aluminosilicate(geopolymer) material. J. Aust. Ceram. Soc. 2019, 55, 11–17. [Google Scholar] [CrossRef]

- Poolkwan, K.; Asavapisit, S.; Piyapanuwat, R. Properties of hydroxyapatite-based geopolymer synthesized from calcined kaolin. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2022; Volume 1234, p. 012027. [Google Scholar]

- Cai, B.; Engqvist, H.; Bredenberg, S. Evaluation of the resistance of a geopolymer-based drug delivery system to tampering. Int. J. Pharm. 2014, 465, 169–174. [Google Scholar] [CrossRef]

- Forsgren, J.; Pedersen, C.; Strømme, M.; Engqvist, H. Synthetic Geopolymers for Controlled Delivery of Oxycodone: Adjustable and Nanostructured Porosity Enables Tunable and Sustained Drug Release. PLoS ONE 2011, 6, e17759. [Google Scholar] [CrossRef]

- Jämstorp, E.; Strømme, M.; Frenning, G. Modeling structure–function relationships for diffusive drug transport in inert porous geopolymer matrices. J. Pharm. Sci. 2011, 100, 4338–4348. [Google Scholar] [CrossRef]

- Jämstorp, E.; Strømme, M.; Bredenberg, S. Influence of Drug Distribution and Solubility on Release from Geopolymer Pellets—A Finite element Method Study. J. Pharm. Sci. 2012, 101, 1803–1810. [Google Scholar] [CrossRef]

- Radhi, H.A.A.; Ahmad, M.A. Biological Test of Porous Geopolymer as a Bone Substitute. J. Med. Chem. Sci. 2023, 6, 710–719. [Google Scholar]

- de Andrade, R.; Paim, T.C.; Bertaco, I.; Naasani, L.S.; Buchner, S.; Kovářík, T.; Hájek, J.; Wink, M.R. Hierarchically porous bioceramics based on geopolymer-hydroxyapatite composite as a novel biomaterial: Structure, mechanical properties, and biocompatibility evaluation. Appl. Mater. Today 2023, 33, 101875. [Google Scholar] [CrossRef]

- Murphy, C.M.; O’Brien, F.J. Understanding the effect of mean pore size on cell activity in collagen-glycosaminoglycan scaffolds. Cell Adh. Migr. 2010, 4, 377–381. [Google Scholar] [CrossRef]

- Faza, Y.; Harmaji, A.; Takarini, V.; Hasratiningsih, Z.; Cahyanto, A. Synthesis of Porous Metakaolin Geopolymer as Bone Substitute Materials. Key Eng. Mater. 2019, 829, 182–187. [Google Scholar] [CrossRef]

- Sutanto, D.; Satari, M.H.; Hernowo, B.S.; Priosoeryanto, B.P.; Septawendar, R.; Asri, L.A.T.W.; Purwasasmita, B.S. Geopolymer–carbonated apatite nanocomposites with magnesium and strontium trace elements for dental restorative materials. J. Korean Ceram. Soc. 2020, 57, 546–556. [Google Scholar] [CrossRef]

- Sunendar, B.; Fathina, A.; Harmaji, A.; Mardhian, D.F.; Asri, L.; Widodo, H.B. The effect of CHA-doped Sr addition to the mechanical strength of metakaolin dental implant geopolymer composite. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; Volume 1887, p. 020020. [Google Scholar]

- Sutanto, D.; Satari, M.H.; Hernowo, B.S.; Priosoeryanto, B.P.; Septawendar, R.; Asri, L.A.T.A.; Purwasasmita, B.S. In vivo histomorphological evaluation of geopolymer-carbonated apatite nanocomposites implanted on rabbit tibia at early bone healing. Padjadjaran J. Dent. 2021, 33, 63–73. [Google Scholar] [CrossRef]

- Grba, N.; Baldermann, A.; Dietzel, M. Novel green technology for wastewater treatment: Geo-material/geopolymer applications for heavy metal removal from aquatic media. Int. J. Sediment Res. 2023, 38, 33–48. [Google Scholar] [CrossRef]

- Maleki, A.; Mohammad, M.; Emdadi, Z.; Asim, N.; Azizi, M.; Safaei, J. Adsorbent materials based on a geopolymer paste for dye removal from aqueous solutions. Arab. J. Chem. 2020, 13, 3017–3025. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Ge, Y. Oleic acid-tailored geopolymer microspheres with tunable porous structure for enhanced removal from tetracycline in saline water. Sustainability 2022, 14, 6705. [Google Scholar] [CrossRef]

- Song, Y.; Li, Z.; Zhang, J.; Tang, Y.; Ge, Y.; Cui, X. A Low-Cost Biomimetic Heterostructured Multilayer Membrane with Geopolymer Microparticles for Broad-Spectrum Water Purification. ACS Appl. Mater. Interfaces 2020, 12, 12133–12142. [Google Scholar] [CrossRef]

- Siyal, A.A.; Shamsuddin, M.R.; Rabat, N.E.; Zulfiqar, M.; Man, Z.; Low, A. Fly ash based geopolymer for the adsorption of anionic surfactant from aqueous solution. J. Clean. Prod. 2019, 229, 232–243. [Google Scholar] [CrossRef]

- Maged, A.; El-Fattah, H.A.; Kamel, R.M.; Kharbish, S.; Elgarahy, A.M. A comprehensive review on sustainable clay-based geopolymers for wastewater treatment: Circular economy and future outlook. Environ. Monit. Assess. 2023, 195, 693. [Google Scholar] [CrossRef] [PubMed]

- Tan, T.H.; Mo, K.H.; Ling, T.C.; Lai, S.H. Current development of geopolymer as alternative adsorbent for heavy metal removal. Environ. Technol. Innov. 2020, 18, 100684. [Google Scholar] [CrossRef]

- Latorrata, S.; Balzarotti, R.; Adami, M.I.; Marino, B.; Mostoni, S.; Scotti, R.; Bellotto, M.; Cristiani, C. Wastewater Treatment Using Alkali-Activated-Based Sorbents Produced from Blast Furnace Slag. Appl. Sci. 2021, 11, 2985. [Google Scholar] [CrossRef]

- Lan, T.; Guo, S.; Li, X.; Guo, J.; Bai, T.; Zhao, Q.; Yang, W.; Li, P. Mixed precursor geopolymer synthesis for removal of Pb(II) and Cd(II). Mater. Lett. 2020, 274, 127977. [Google Scholar] [CrossRef]

- Wei, E.; Wang, K.; Muhammad, Y.; Chen, S.; Dong, D.; Wei, Y.; Fujita, T. Preparation and conversion mechanism of different geopolymer-based zeolite microspheres and their adsorption properties for Pb2+. Sep. Purif. Technol. 2022, 282, 119971. [Google Scholar] [CrossRef]

- Novais, R.M.; Buruberri, L.H.; Seabra, M.P.; Labrincha, J.A. Novel porous fly-ash containing geopolymer monoliths for lead adsorption from wastewaters. J. Hazard. Mater. 2016, 318, 631–640. [Google Scholar] [CrossRef]

- Yu, Z.; Song, W.; Li, J.; Li, Q. Improved simultaneous adsorption of Cu(II) and Cr(VI) of organic modified metakaolin-based geopolymer. Arab. J. Chem. 2020, 13, 4811–4823. [Google Scholar] [CrossRef]

- He, P.Y.; Zhang, Y.J.; Chen, H.; Han, Z.C.; Liu, L.C. Low-cost and facile synthesis of geopolymer-zeolite composite membrane for chromium (VI) separation from aqueous solution. J. Hazard. Mater. 2020, 392, 122359. [Google Scholar] [CrossRef]

- Ghani, U.; Hussain, S.; Noor-ul-Amin; Imtiaz, M.; Khan, S.A. Laterite clay-based geopolymer as a potential adsorbent for the heavy metals removal from aqueous solutions. J. Saudi Chem. Soc. 2020, 24, 874–884. [Google Scholar] [CrossRef]

- Pachana, P.K.; Rattanasak, U.; Nuithitikul, K.; Jitsangiam, P.; Chindaprasirt, P. Sustainable utilization of water treatment residue as a porous geopolymer for iron removal from groundwater. J. Environ. Manag. 2022, 302, 114036. [Google Scholar] [CrossRef]

- Franchin, G.; Pesonen, J.; Luukkonen, T.; Bai, C.; Scanferla, P.; Botti, R.; Carturan, S.; Innocentini, M.; Colombo, P. Removal of ammonium from wastewater with geopolymer sorbents fabricated via additive manufacturing. Mater. Des. 2020, 195, 109006. [Google Scholar] [CrossRef]

- Salam, M.A.; Mokhtar, M.; Albukhari, S.M.; Baamer, D.F.; Palmisano, L.; AlHammadi, A.A.; Abukhadra, M.R. Synthesis of zeolite/geopolymer composite for enhanced sequestration of phosphate (PO43−) and ammonium (NH4+) ions; equilibrium properties and realistic study. J. Environ. Manag. 2021, 300, 113723. [Google Scholar] [CrossRef] [PubMed]

- Hua, P.; Sellaoui, L.; Franco, D.; Netto, M.S.; Dotto, G.; Bajahzar, A.; Belmabrouk, H.; Bonilla-Petriciolet, A.; Li, Z. Adsorption of acid green and procion red on a magnetic geopolymer based adsorbent: Experiments, characterization and theoretical treatment. Chem. Eng. J. 2020, 383, 123113. [Google Scholar] [CrossRef]

- El Alouani, M.; Alehyen, S.; EL Achouri, M.; Taibi, M. Removal of Cationic Dye-Methylene Blue-from Aqueous Solution by Adsorption on Fly Ash-based Geopolymer. J. Mater. Environ. Sci. 2018, 9, 32–46. [Google Scholar]

- Pimraksa, K.; Setthaya, N.; Thala, M.; Chindaprasirt, P.; Murayama, M. Geopolymer/Zeolite composite materials with adsorptive and photocatalytic properties for dye removal. PLoS ONE 2020, 15, e0241603. [Google Scholar] [CrossRef] [PubMed]

- Li, C.J.; Zhang, Y.J.; Chen, H.; He, P.Y.; Meng, Q. Development of porous and reusable geopolymer adsorbents for dye wastewater treatment. J. Clean. Prod. 2022, 348, 131278. [Google Scholar] [CrossRef]

- Shikuku, V.O.; Tome, S.; Hermann, D.T.; Tompsett, G.A.; Timko, M.T. Rapid Adsorption of Cationic Methylene Blue Dye onto Volcanic Ash-metakaolin Based Geopolymers. Silicon 2022, 14, 9349–9359. [Google Scholar] [CrossRef]

- Papa, E.; Mor, M.; Natali Murri, A.; Landi, E.; Medri, V. Ice-templated geopolymer beads for dye removal. J. Colloid Interface Sci. 2020, 572, 364–373. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Biomass fly ash geopolymer monoliths for effective methylene blue removal from wastewaters. J. Clean. Prod. 2018, 171, 783–794. [Google Scholar] [CrossRef]

- Purbasari, A.; Ariyanti, D.; Fitriani, E. Adsorption of Methyl Orange Dye by Modified Fly Ash-Based Geopolymer–Characterization, Performance, Kinetics and Isotherm Studies. J. Ecol. Eng. 2023, 24, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Ebrahim, A.A.M.; El-Apasery, M.A. A Facile Route for Removal of Reactive Dye Red 195 by Using Geopolymer Based on Bentonite. Egypt. J. Chem. 2023, 321–327. [Google Scholar] [CrossRef]

- Fitriani, E.; Purbasari, A. Application of low-cost mesoporous geopolymer for dye waste removal. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1053, p. 012002. [Google Scholar]

- Al-Mashaqbeh, A.; El-Eswed, B.; Banat, R.; Khalili, F.I. Immobilization of organic dyes in geopolymeric cementing material. Environ. Nanotechnol. Monit. Manag. 2018, 10, 351–359. [Google Scholar] [CrossRef]

- Luhar, I.; Luhar, S.; Abdullah, M.M.A.B.; Razak, R.A.; Vizureanu, P.; Sandu, A.V.; Matasaru, P.-D. A State-of-the-Art Review on Innovative Geopolymer Composites Designed for Water and Wastewater Treatment. Materials 2021, 14, 7456. [Google Scholar] [CrossRef] [PubMed]

- He, R.; Dai, N.; Wang, Z. Thermal and Mechanical Properties of Geopolymers Exposed to High Temperature: A Literature Review. Adv. Civ. Eng. 2020, 2020, 7532703. [Google Scholar] [CrossRef]

- Azimi, E.A.; Al Bakri Abdullah, M.M.; Ming, L.; Yong, H.C.; Hussin, K.; Aziz, I.H. Processing, and properties of geopolymers as thermal insulating materials: A review. Rev. Adv. Mater. Sci. 2016, 44, 273–285. [Google Scholar]

- Lahoti, M.; Tan, K.H.; Yang, E.-H. A critical review of geopolymer properties for structural fire-resistance applications. Constr. Build. Mater. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Galiano, Y.L.; Leiva, C.; Arenas, C.; Arroyo, F.; Vilches, L.; Pereira, C.F.; Villegas, R. Behavior of Fly Ash-Based Geopolymer Panels Under Fire. Waste Biomass 2017, 8, 2485–2494. [Google Scholar] [CrossRef]

- NEN 7345:1995 nl; Leaching Characteristics of Solid Earthy and Stony Building and Waste Materials—Leaching Tests—Determination of the Leaching of Inorganic Components from Buildings and Monolitic Waste Materials with the Diffusion Test. NEN: Delft, The Netherlands, 1995.

- Zhang, H.Y.; Kodur, V.; Qi, S.L.; Cao, L.; Wu, B. Development of metakaolin–fly ash based geopolymers for fire resistance applications. Constr. Build. Mater. 2014, 55, 38–45. [Google Scholar] [CrossRef]

- Zhang, H.; Kodur, V.; Cao, L.; Qi, S. Fiber Reinforced Geopolymers for Fire Resistance Applications. Procedia Eng. 2014, 71, 153–158. [Google Scholar] [CrossRef]

- Alzeebaree, R.; Mawlod, A.O.; Amen, D.K.; Younis, K.H.; Mohammedameen, A. Fire Resistance Performance of Fiber Reinforced Geopolymer Concrete: Review. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 318, p. 03003. [Google Scholar]

- Luhar, S.; Nicolaides, D.; Luhar, I. Fire Resistance Behaviour of Geopolymer Concrete: An Overview. Buildings 2021, 11, 82. [Google Scholar] [CrossRef]

- Li, H.; Peng, X.; Li, J.; Li, L.; Hu, D.; Xiang, Y.; Han, L.; Xu, Z. Preparation and fireproofing performance of the wollastonite-metakaolin-based geopolymer foams. Mater. Lett. 2022, 307, 131020. [Google Scholar] [CrossRef]

- Sakkas, K.; Kapelari, S.; Panias, D.; Nomikos, P.P.; Sofianos, A. Fire Resistant K-Based Metakaolin Geopolymer for Passive Fire Protection of Concrete Tunnel Linings. Open Access Libr. J. 2014, 1, 1–9. [Google Scholar] [CrossRef]

- Abbass, A.M.; Firdous, R.; Yankwa Djobo, J.N.Y.; Stephan, D.; Elrahman, M.A. The role of chemistry and fineness of metakaolin on the fresh properties and heat resistance of blended fly ash-based geopolymer. SN Appl. Sci. 2023, 5, 136. [Google Scholar] [CrossRef]

- Le, V.S.; Louda, P.; Tran, H.N.; Nguyen, P.D.; Bakalova, T.; Ewa Buczkowska, K.; Dufkova, I. Study on Temperature-Dependent Properties and Fire Resistance of Metakaolin-Based Geopolymer Foams. Polymers 2020, 12, 2994. [Google Scholar] [CrossRef] [PubMed]

- Aziz, I.H.; Abdullah, M.M.A.B.; Yong, H.C.; Ming, L.Y.; Hussin, K.; Kadir, A.A.; Azimi, E.A. Manufacturing of Fire Resistance Geopolymer: A Review. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 78, p. 01023. [Google Scholar]

- Hassan, A.; Arif, M.; Shariq, M.; Alomayri, T.; Pereira, S. Fire resistance characteristics of geopolymer concrete for environmental sustainability: A review of thermal, mechanical and microstructure properties. Environ. Dev. Sustain. 2023, 25, 8975–9010. [Google Scholar] [CrossRef]

- Islam, S.; Bhat, G. Environmentally-friendly thermal and acoustic insulation materials from recycled textiles. J. Environ. Manag. 2019, 251, 109536. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Mechanical, thermal insulation, thermal resistance, and acoustic absorption properties of geopolymer foam concrete. Cem. Concr. Compos. 2015, 62, 97–105. [Google Scholar] [CrossRef]

- Soe, P.S.; Sornlar, W.; Wannagon, A.; Chaysuwan, D. Mechanical and thermal properties of bottom ash-based porous geopolymer as thermal insulation material for construction. J. Mater. Cycles Waste Manag. 2023, 25, 2964–2975. [Google Scholar] [CrossRef]

- Ahmed, M.M.; El-Naggar, K.A.M.; Tarek, D.; Ragab, A.; Sameh, H.; Zeyad, A.M.; Tayeh, B.A.; Maafa, I.M.; Yousef, A. Fabrication of thermal insulation geopolymer bricks using ferrosilicon slag and alumina waste. Case Stud. Constr. Mater. 2021, 15, e00737. [Google Scholar] [CrossRef]

- Bai, C.; Franchin, G.; Elsayed, H.; Zaggia, A.; Conte, L.; Li, H.; Colombo, P. High-porosity geopolymer foams with tailored porosity for thermal insulation and wastewater treatment. J. Mater. Res. 2017, 32, 3251–3259. [Google Scholar] [CrossRef]

- Ekiz Bariş, K.; Tanaçan, L. Natural pozzolan–based green geopolymer foam for thermal insulation. J. Sustain. Constr. Mater. Technol. 2022, 7, 128–144. [Google Scholar] [CrossRef]

- Łach, M.; Korniejenko, K.; Mikuła, J. Thermal insulation and thermally resistant materials made of geopolymer foams. Procedia Eng. 2016, 151, 410–416. [Google Scholar] [CrossRef]

- Shahedan, N.F.; Al Bakri Abdullah, M.M.; Mahmed, N.; Ming, L.Y.; Abd Rahim, S.Z.; Aziz, I.H.A.; Kadir, A.A.; Sandu, A.V.; Ghazali, M.F. Thermal Insulation and Mechanical Properties in the Presence of Glass Bubble in Fly Ash Geopolymer Paste. Arch. Metall. Mater. 2022, 67, 221–226. [Google Scholar]

- Rashad, A.M. Insulating and fire-resistant behaviour of metakaolin and fly ash geopolymer mortars. Constr. Mater. 2019, 172, 37–44. [Google Scholar] [CrossRef]

- Fang, Y.; Ahmad, M.R.; Lao, J.C.; Qian, L.P.; Dai, J.G. Development of artificial geopolymer aggregates with thermal energy storage capacity. Cem. Concr. Compos. 2023, 135, 104834. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, H.; Bernardo, E.; Lei, S.; Wang, L. Thermal energy storage performance of hierarchical porous kaolinite geopolymer based shape-stabilized composite phase change materials. Ceram. Int. 2023, 49, 29808–29819. [Google Scholar] [CrossRef]

- Jacob, R.; Trout, N.; Solé, A.; Clarke, S.; Fernández, A.I.; Cabeza, L.F.; Saman, W.; Bruno, F. Novel geopolymer for use as a sensible storage option in high temperature thermal energy storage systems. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020; Volume 2303, p. 190019. [Google Scholar]

- Jacob, R.; Trout, N.; Raud, R.; Clarke, S.; Steinberg, T.A.; Saman, W.; Bruno, F. Geopolymer encapsulation of a chloride salt phase change material for high temperature thermal energy storage. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016; Volume 1734, p. 050021. [Google Scholar]

- Yang, J.L.; Zhang, W.B.; Chai, S.S.; Theint, M.M.; Yin, Y.; Yang, Z.Q.; Li, J.J.; Yi, Y.H.; Ma, X.J. A geopolymer membrane for application in a structural mechanics and energy storage difunctional supercapacitor. Phys. Chem. Chem. Phys. 2023, 25, 24448–24458. [Google Scholar] [CrossRef]

- Rahjoo, M.; Goracci, G.; Gaitero, J.J.; Martauz, P.; Rojas, E.; Dolado, J.S. Thermal Energy Storage (TES) Prototype Based on Geopolymer Concrete for High-Temperature Applications. Materials 2022, 15, 7086. [Google Scholar] [CrossRef]

- Rahjoo, M.; Goracci, G.; Martauz, P.; Rojas, E.; Dolado, J.S. Geopolymer Concrete Performance Study for High-Temperature Thermal Energy Storage (TES) Applications. Sustainability 2022, 14, 1937. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Ding, B.; Gu, J.; Cai, J. Study on the mechanical and thermal properties of one-part geopolymer composite for high performance in energy piles. Case Stud. Constr. Mater. 2023, 19, e02230. [Google Scholar] [CrossRef]

- Díaz, E.E.S.; Barrios, V.A.E. Development, and use of geopolymers for energy conversion: An overview. Constr. Build. Mater. 2022, 315, 125774. [Google Scholar] [CrossRef]

- Freire, A.L.; José, H.J.; Moreira, R.F.P.M. Potential applications for geopolymers in carbon capture and storage. Int. J. Greenh. Gas Control 2022, 118, 103687. [Google Scholar] [CrossRef]

- Sarkar, M.; Maiti, M.; Maiti, S.; Xu, S.; Li, Q. ZnO-SiO2 nanohybrid decorated sustainable geopolymer retaining anti-biodeterioration activity with improved durability. Mater. Sci. Eng. C 2018, 92, 663–672. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.; Ye, H. Structural composition of antibacterial zinc-doped geopolymers. Dalton Trans. 2023, 52, 8065–8076. [Google Scholar] [CrossRef] [PubMed]

- Rondinella, A.; Furlani, E.; Dell’Antone, L.; Marin, E.; Boschetto, F.; Sordetti, F.; Lanzutti, A.; Andreatta, F.; Fedrizzi, L.; Maschio, S. Mechanical and antibacterial behavior of multilayered geopolymer coatings on Ti6Al4V alloys. J. Mater. Sci. 2022, 57, 18578–18588. [Google Scholar] [CrossRef]

- Hashimoto, S.; Machino, T.; Takeda, H.; Daiko, Y.; Honda, S.; Iwamoto, Y. Antimicrobial activity of geopolymers ion-exchanged with copper ions. Ceram. Int. 2015, 41, 13788–13792. [Google Scholar] [CrossRef]

- Růžek, V.; Novosád, J.; Buczkowska, K.E. Geopolymer Antimicrobial and Hydrophobic Modifications: A Review. Ceramics 2023, 6, 1749–1764. [Google Scholar] [CrossRef]

- Armayani, M.; Pratama, M.A. The Properties of Nano Silver (Ag)-Geopolymer as Antibacterial Composite for Functional Surface Materials. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 97, p. 01010. [Google Scholar]

- Lira, B.C.S.; Dellosa, S.B.A.; Toh, C.I.L.; Quintero, A.P.A.; Nidoy, A.L.S.; Cerna, K.D.; Yu, D.E.C.; Janairo, J.I.B.; Promentilla, M.A.B. Coal Fly Ash-based Geopolymer Spheres Coated with Amoxicillin and Nanosilver for Potential Antibacterial Applications. ASEAN J. Chem. Eng. 2019, 19, 25–37. [Google Scholar] [CrossRef]

- Cerna, K.D.; Janairo, J.I.; Promentilla, M.A. Development of nanosilver-coated geopolymer beads (AgGP) from fly ash and baluko shells for antimicrobial applications. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 268, p. 05003. [Google Scholar]

- Gutiérrez, R.M.-d.; Villaquirán-Caicedo, M.; Ramírez-Benavides, S.; Astudillo, M.; Mejía, D. Evaluation of the Antibacterial Activity of a Geopolymer Mortar Based on Metakaolin Supplemented with TiO2 and CuO Particles Using Glass Waste as Fine Aggregate. Coatings 2020, 10, 157. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, X.; Zhu, H. Potential application of geopolymers as protection coatings for marine concrete: I. Basic properties. Appl. Clay Sci. 2010, 49, 1–6. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, A.; Bao, X.; Ni, T.; Ling, J. A review on geopolymer in potential coating application: Materials, preparation and basic properties. J. Build. Eng. 2020, 32, 101734. [Google Scholar] [CrossRef]

- Aguirre-Guerrero, A.M.; Robayo-Salazar, R.A.; de Gutiérrez, R.M. A novel geopolymer application: Coatings to protect reinforced concrete against corrosion. Appl. Clay Sci. 2017, 135, 437–446. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, X.; Zhu, H. Potential application of geopolymers as protection coatings for marine concrete: II. Microstructure and anticorrosion mechanism. Appl. Clay Sci. 2010, 49, 7–12. [Google Scholar] [CrossRef]

- Yang, N.; Das, C.S.; Xue, X.; Li, W.; Dai, J.-G. Geopolymer coating modified with reduced graphene oxide for improving steel corrosion resistance. Constr. Build. Mater. 2022, 342, 127942. [Google Scholar] [CrossRef]

- Tomar, A.S.; Gupta, R.; Singh, A.; Salammal, S.T.; Khan, M.A.; Mishra, D. Evaluation of corrosion protective properties of fly ash-red mud based geopolymer coating material for mild steel. Mater. Today Proc. 2022, 68, 181–186. [Google Scholar] [CrossRef]

- Gupta, R.; Tomar, A.S.; Mishra, D.; Sanghi, S.K. Multifaceted geopolymer coating: Material development, characterization, and study of long term anti-corrosive properties. Microporous Mesoporous Mater. 2021, 317, 110995. [Google Scholar] [CrossRef]

- Tomar, A.S.; Gupta, R.; Bijanu, A.; Tanwar, D.; Singh, A.; Salammal, S.T.; Dhand, C.; Mishra, D. TiO2- geopolymer based novel corrosion protective micro-coatings to emaciate mild steel oxidation in severe environments. Constr. Build. Mater. 2023, 395, 132252. [Google Scholar] [CrossRef]

- Zainal, F.F.; Fazill, M.F.; Kamarudin, H.; Rahmat, A.; Al Bakri Abdullah, M.M.; Wazien, W. Effect of Geopolymer Coating on Mild Steel. Solid State Phenom. 2018, 273, 175–180. [Google Scholar] [CrossRef]

- Morla, P.; Gupta, R.; Azarsa, P.; Sharma, A. Corrosion Evaluation of Geopolymer Concrete Made with Fly Ash and Bottom Ash. Sustainability 2021, 13, 398. [Google Scholar] [CrossRef]

- Omer, L.M.; Gomaa, M.S.; Sufe, W.H.; Elsayed, A.A.; Elghazaly, H.A. Enhancing corrosion resistance of RC pipes using geopolymer mixes when subjected to aggressive environment. J. Eng. Appl. Sci. 2022, 69, 3. [Google Scholar] [CrossRef]

- Sobhan, K.; Martinez, F.J.; Reddy, D.V. Corrosion resistance of fiber-reinforced geopolymer structural concrete in a simulated marine environment. Can. J. Civ. Eng. 2021, 49, 310–317. [Google Scholar] [CrossRef]

| Application of Geopolymers in Biomedical Areas | ||

|---|---|---|

| Drug delivery systems | Excellent mechanical properties | Geopolymers show promise in extended drug release systems, especially for opioids, due to heat resistance and high compressive strength. Geopolymers are more resistant to tampering than traditional drug formulations, requiring increased effort for manipulation. Geopolymers facilitate controlled drug release, potentially reducing opioid abuse. Experiments on the geopolymer matrix reveal a correlation between mesoporosity and drug release kinetics. Geopolymers’ effectiveness as drug carriers depends on optimal component ratios for porosity and compressive strength. |

| Controlled drug release | ||

| Bone regeneration | Development of porous geopolymers as bone substitutes | Metakaolin geopolymers are biocompatible, promoting dense trabecular bone formation. Geopolymers with hydroxyapatite were tested for safety, showing favorable properties for mesenchymal stem cells. Porosity studies of bone regeneration scaffolds focused on optimal component ratios (M/AA) during geopolymerization. An M/AA ratio of 1:1.0 generates a porous geopolymer matrix resembling human cancellous bone, indicating potential as a tissue regeneration substitute. |

| Biocompatibility and bioactivity | ||

| Dental implantology | Use of geopolymers in dental restorative materials | Study on metakaolin geopolymers promoting non-cytotoxic bone regeneration. Investigation of metakaolin geopolymers with optimal mechanical properties for dental implants. Study on geopolymer–carbonate apatite nanocomposites and early bone healing. Geopolymers promising in extended drug release systems, particularly in opioid safety, due to resistance to manipulation and controlled release of active substances. |

| Mechanical properties and biocompatibility | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kudłacik-Kramarczyk, S.; Drabczyk, A.; Figiela, B.; Korniejenko, K. Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection. Materials 2023, 16, 7416. https://doi.org/10.3390/ma16237416

Kudłacik-Kramarczyk S, Drabczyk A, Figiela B, Korniejenko K. Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection. Materials. 2023; 16(23):7416. https://doi.org/10.3390/ma16237416

Chicago/Turabian StyleKudłacik-Kramarczyk, Sonia, Anna Drabczyk, Beata Figiela, and Kinga Korniejenko. 2023. "Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection" Materials 16, no. 23: 7416. https://doi.org/10.3390/ma16237416

APA StyleKudłacik-Kramarczyk, S., Drabczyk, A., Figiela, B., & Korniejenko, K. (2023). Geopolymers: Advanced Materials in Medicine, Energy, Anticorrosion and Environmental Protection. Materials, 16(23), 7416. https://doi.org/10.3390/ma16237416