Data-Driven Prediction and Uncertainty Quantification of Process Parameters for Directed Energy Deposition

Abstract

:1. Introduction

2. Prediction Workflow

- Regression models

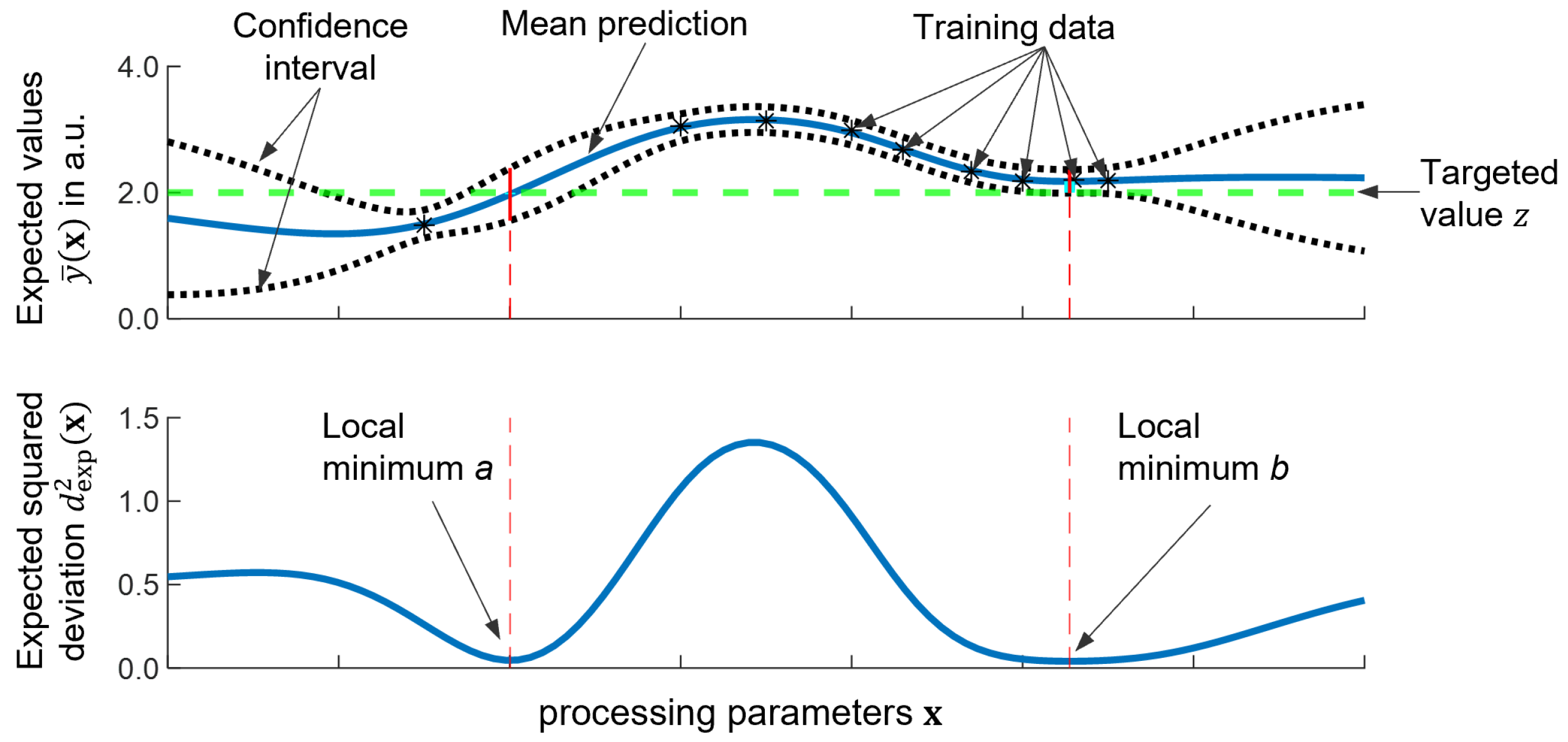

- Identification of optimal process parameters

- Application

3. Materials and Methods

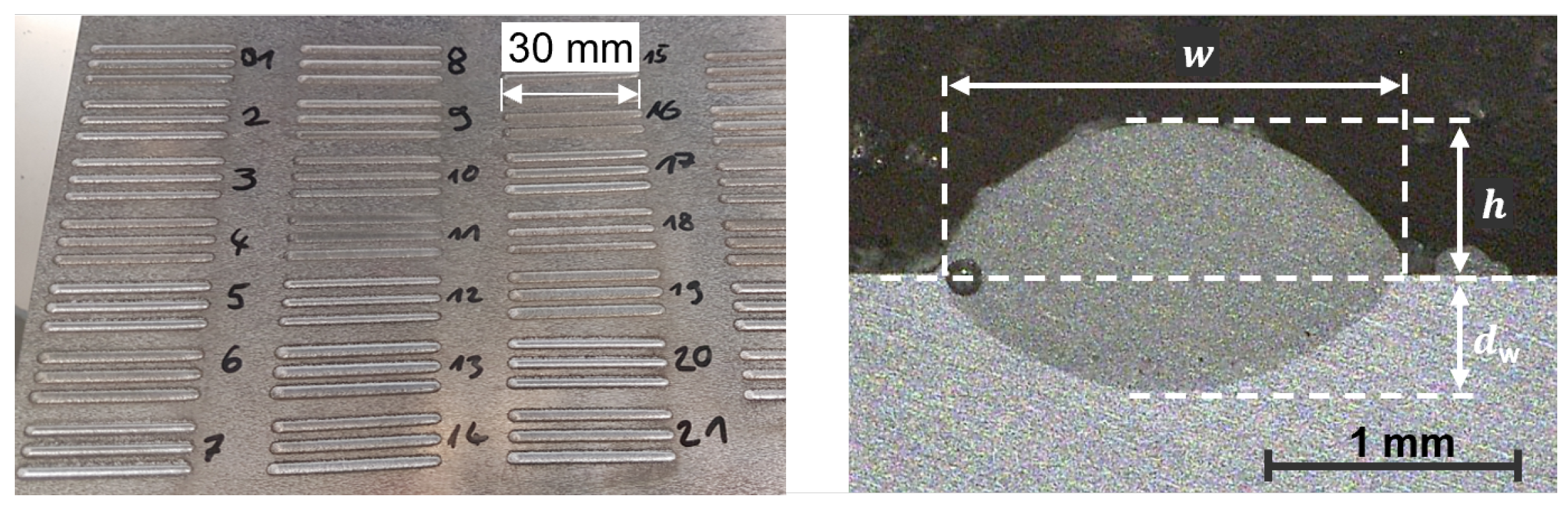

3.1. Experimental Data

3.2. Training of Regression Models

4. Results and Discussion

4.1. Analysis of Regression Models

4.2. Identification of Optimal Process Parameters

4.2.1. Multiple Local Minima

4.2.2. Optimal Process Parameters at Different Velocities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GPR | Gaussian Process Regression |

| RT | Regression tree |

| UQ | Uncertainty quantification |

| DED | Directed energy deposition |

| DED-LB/M | Laser-based directed energy deposition using metal powder |

| LPBF | Laser powder bed fusion |

| FFF | Fused filament fabrication |

| EBM | Electron beam melting |

| CAD | Computer aided design |

| ARD | Automatic relevance determination |

| MAE | Mean absolute error |

| v | Velocity |

| P | Laser power |

| Powder flow rate | |

| Laser beam diameter on the surface of the substrate | |

| Expected squared deviation between prediction and target value | |

| z | Target value of geometry characteristic |

| Prediction performed with the GPR model | |

| Depth of of a single DED track | |

| w | Depth of a single DED track |

| h | Height of a single DED track |

| Coefficient of determination | |

| Vector with linear basis functions | |

| Coefficients of linear basis | |

| k | Kernel of GPR model |

| Length scale | |

| Signal variance | |

| Kronecker delta | |

| Measured values in the test data set | |

| Mean value of |

References

- Schuh, G.; Rudolf, S.; Riesener, M. Design for industrie 4.0. In Proceedings of the 14th International Design Conference, Cavtat, Dubrovnik, 16–19 May 2016. [Google Scholar]

- Maalouf, E.; Daaboul, J.; Le Duigou, J.; Hussein, B. Production management for mass customization and smart cellular manufacturing system: NSGAII and SMPSO for factory-level planning. Int. J. Adv. Manuf. Technol. 2022, 120, 6833–6854. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Vandera, C. Smart mobile apps for supporting product design and decision-making in the era of mass customisation. Int. J. Comput. Integr. Manuf. 2017, 30, 690–707. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Software-defined Cloud Manufacturing for Industry 4.0. Procedia CIRP 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Xu, L.; Chen, L.; Gao, Z.; Moya, H.; Shi, W. Reshaping the Landscape of the Future: Software-Defined Manufacturing. Computer 2021, 54, 27–36. [Google Scholar] [CrossRef]

- Lechler, A.; Riedel, O.; Coupek, D. Virtual representation of physical objects for software defined manufacturing. In Proceedings of the 24th International Conference on Production Research (ICPR 2017), Posnan, Poland, 30 July–3August 2017. [Google Scholar] [CrossRef]

- Barwasser, A.; Lentes, J.; Riedel, O.; Zimmermann, N.; Dangelmaier, M.; Zhang, J. Method for the development of Software-Defined Manufacturing equipment. Int. J. Prod. Res. 2023, 61, 6467–6484. [Google Scholar] [CrossRef]

- Poprawe, R. Lasertechnik für die Fertigung; VDI-Buch, Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Cavaliere, P. Laser Cladding of Metals; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Mahamood, R.M. Laser Metal Deposition Process of Metals, Alloys, and Composite Materials; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Moeller, M. Prozessmanagement fuer das Laser-Pulver-Auftragschweissen; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Huegel, H.; Graf, T. (Eds.) Additive Verfahren. In Materialbearbeitung mit Laser; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2022; pp. 415–454. [Google Scholar]

- Ahsan, M.N.; Pinkerton, A.J. An analytical–numerical model of laser direct metal deposition track and microstructure formation. Model. Simul. Mater. Sci. Eng. 2011, 19, 055003. [Google Scholar] [CrossRef]

- El Cheikh, H.; Courant, B.; Hascoët, J.Y.; Guillén, R. Prediction and analytical description of the single laser track geometry in direct laser fabrication from process parameters and energy balance reasoning. J. Mater. Process. Technol. 2012, 212, 1832–1839. [Google Scholar] [CrossRef]

- Gao, J.; Wu, C.; Hao, Y.; Xu, X.; Guo, L. Numerical simulation and experimental investigation on three-dimensional modelling of single-track geometry and temperature evolution by laser cladding. Opt. Laser Technol. 2020, 129, 106287. [Google Scholar] [CrossRef]

- Huang, Y.; Khamesee, M.B.; Toyserkani, E. A new physics-based model for laser directed energy deposition (powder-fed additive manufacturing): From single-track to multi-track and multi-layer. Opt. Laser Technol. 2019, 109, 584–599. [Google Scholar] [CrossRef]

- Zhang, D.; Feng, Z.; Wang, C.; Liu, Z.; Dong, D.; Zhou, Y.; Wu, R. Modeling of Temperature Field Evolution During Multilayered Direct Laser Metal Deposition. J. Therm. Spray Technol. 2017, 26, 831–845. [Google Scholar] [CrossRef]

- Chadha, U.; Selvaraj, S.K.; Lamsal, A.S.; Maddini, Y.; Ravinuthala, A.K.; Choudhary, B.; Mishra, A.; Padala, D.; M, S.; Lahoti, V.; et al. Directed Energy Deposition via Artificial Intelligence-Enabled Approaches. Complexity 2022, 2022, 2767371. [Google Scholar] [CrossRef]

- Sideris, I.; Crivelli, F.; Bambach, M. GPyro: Uncertainty-aware temperature predictions for additive manufacturing. J. Intell. Manuf. 2023, 34, 243–259. [Google Scholar] [CrossRef]

- Caiazzo, F.; Caggiano, A. Laser Direct Metal Deposition of 2024 Al Alloy: Trace Geometry Prediction via Machine Learning. Materials 2018, 11, 444. [Google Scholar] [CrossRef] [PubMed]

- Pant, P.; Chatterjee, D. Prediction of clad characteristics using ANN and combined PSO-ANN algorithms in laser metal deposition process. Surfaces Interfaces 2020, 21, 100699. [Google Scholar] [CrossRef]

- Feenstra, D.R.; Molotnikov, A.; Birbilis, N. Utilisation of artificial neural networks to rationalise processing windows in directed energy deposition applications. Mater. Des. 2021, 198, 109342. [Google Scholar] [CrossRef]

- Gao, J.; Wang, C.; Hao, Y.; Liang, X.; Zhao, K. Prediction of TC11 single-track geometry in laser metal deposition based on back propagation neural network and random forest. J. Mech. Sci. Technol. 2022, 36, 1417–1425. [Google Scholar] [CrossRef]

- Bhardwaj, T.; Shukla, M. Laser Additive Manufacturing- Direct Energy Deposition of Ti-15Mo Biomedical Alloy: Artificial Neural Network Based Modeling of Track Dilution. Lasers Manuf. Mater. Process. 2020, 7, 245–258. [Google Scholar] [CrossRef]

- Liu, H.; Qin, X.; Huang, S.; Jin, L.; Wang, Y.; Lei, K. Geometry Characteristics Prediction of Single Track Cladding Deposited by High Power Diode Laser Based on Genetic Algorithm and Neural Network. Int. J. Precis. Eng. Manuf. 2018, 19, 1061–1070. [Google Scholar] [CrossRef]

- Saqib, S.; Urbanic, R.J.; Aggarwal, K. Analysis of Laser Cladding Bead Morphology for Developing Additive Manufacturing Travel Paths. Procedia CIRP 2014, 17, 824–829. [Google Scholar] [CrossRef]

- Narayana, P.L.; Kim, J.H.; Lee, J.; Choi, S.W.; Lee, S.; Park, C.H.; Yeom, J.T.; Reddy, N.G.S.; Hong, J.K. Optimization of process parameters for direct energy deposited Ti-6Al-4V alloy using neural networks. Int. J. Adv. Manuf. Technol. 2021, 114, 3269–3283. [Google Scholar] [CrossRef]

- Lee, S.; Peng, J.; Shin, D.; Choi, Y.S. Data analytics approach for melt-pool geometries in metal additive manufacturing. Sci. Technol. Adv. Mater. 2019, 20, 972–978. [Google Scholar] [CrossRef] [PubMed]

- Pham, T.Q.D.; Hoang, T.V.; van Tran, X.; Fetni, S.; Duchêne, L.; Tran, H.S.; Habraken, A.M. Uncertainty Quantification in the Directed Energy Deposition Process Using Deep Learning-Based Probabilistic Approach. Key Eng. Mater. 2022, 926, 323–330. [Google Scholar] [CrossRef]

- Hu, Z.; Mahadevan, S. Uncertainty quantification and management in additive manufacturing: Current status, needs, and opportunities. Int. J. Adv. Manuf. Technol. 2017, 93, 2855–2874. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Ji, Y.; Mahadevan, S.; Horstemeyer, M.F.; Hu, Z.; Chen, L.; Chen, L.Q. Uncertainty Quantification in Metallic Additive Manufacturing through Physics-Informed Data-Driven Modeling. JOM 2019, 71, 2625–2634. [Google Scholar] [CrossRef]

- Gholaminezhad, I.; Assimi, H.; Jamali, A.; Vajari, D.A. Uncertainty quantification and robust modeling of selective laser melting process using stochastic multi-objective approach. Int. J. Adv. Manuf. Technol. 2016, 86, 1425–1441. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; Adaptive computation and machine learning; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Bishop, C.M. Pattern Recognition and Machine Learning; Information science and statistics; Springer: New York, NY, USA, 2006. [Google Scholar]

- Meng, L.; Zhang, J. Process Design of Laser Powder Bed Fusion of Stainless Steel Using a Gaussian Process-Based Machine Learning Model. JOM 2020, 72, 420–428. [Google Scholar] [CrossRef]

- Saunders, R.; Rawlings, A.; Birnbaum, A.; Iliopoulos, A.; Michopoulos, J.; Lagoudas, D.; Elwany, A. Additive Manufacturing Melt Pool Prediction and Classification via Multifidelity Gaussian Process Surrogates. Integr. Mater. Manuf. Innov. 2022, 11, 497–515. [Google Scholar] [CrossRef]

- Tapia, G.; Khairallah, S.; Matthews, M.; King, W.E.; Elwany, A. Gaussian process-based surrogate modeling framework for process planning in laser powder-bed fusion additive manufacturing of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2018, 94, 3591–3603. [Google Scholar] [CrossRef]

- Olleak, A.; Xi, Z. Calibration and Validation Framework for Selective Laser Melting Process Based on Multi-Fidelity Models and Limited Experiment Data. J. Mech. Des. 2020, 142, 081701. [Google Scholar] [CrossRef]

- Moges, T.; Yang, Z.; Jones, K.; Feng, S.; Witherell, P.; Lu, Y. Hybrid Modeling Approach for Melt-Pool Prediction in Laser Powder Bed Fusion Additive Manufacturing. J. Comput. Inf. Sci. Eng. 2021, 21, 050902. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Q.; Michaleris, P. A Physics-Informed Two-Level Machine-Learning Model for Predicting Melt-Pool Size in Laser Powder Bed Fusion. J. Dyn. Syst. Meas. Control 2021, 143, 121006. [Google Scholar] [CrossRef]

- Yan, F.; Chan, Y.C.; Saboo, A.; Shah, J.; Olson, G.B.; Chen, W. Data-Driven Prediction of Mechanical Properties in Support of Rapid Certification of Additively Manufactured Alloys. Comput. Model. Eng. Sci. 2018, 117, 343–366. [Google Scholar] [CrossRef]

- Lee, J.A.; Sagong, M.J.; Jung, J.; Kim, E.S.; Kim, H.S. Explainable machine learning for understanding and predicting geometry and defect types in Fe-Ni alloys fabricated by laser metal deposition additive manufacturing. J. Mater. Res. Technol. 2023, 22, 413–423. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, L.; Fuh, J.Y.H.; Zhang, H.; Yan, W. Multi-physics modeling and Gaussian process regression analysis of cladding track geometry for direct energy deposition. Opt. Lasers Eng. 2020, 127, 105950. [Google Scholar] [CrossRef]

- Hermann, F.; Chen, B.; Ghasemi, G.; Stegmaier, V.; Ackermann, T.; Reimann, P.; Vogt, S.; Graf, T.; Weyrich, M. A Digital Twin Approach for the Prediction of the Geometry of Single Tracks Produced by Laser Metal Deposition. Procedia CIRP 2022, 107, 83–88. [Google Scholar] [CrossRef]

- Menon, N.; Mondal, S.; Basak, A. Multi-Fidelity Surrogate-Based Process Mapping with Uncertainty Quantification in Laser Directed Energy Deposition. Materials 2022, 15, 2902. [Google Scholar] [CrossRef] [PubMed]

- Menon, N.; Mondal, S.; Basak, A. Linking processing parameters with melt pool properties of multiple nickel-based superalloys via high-dimensional Gaussian process regression. J. Mater. Inform. 2023, 3, 7. [Google Scholar] [CrossRef]

- Nath, P.; Olson, J.D.; Mahadevan, S.; Lee, Y.T.T. Optimization of fused filament fabrication process parameters under uncertainty to maximize part geometry accuracy. Addit. Manuf. 2020, 35, 101331. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Karnati, S.; Nag, S.; Johnson, N.; Khan, G.; Ribic, B. Accelerating Additive Design with Probabilistic Machine Learning. ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2022, 8, 011109. [Google Scholar] [CrossRef]

- Mondal, S.; Gwynn, D.; Ray, A.; Basak, A. Investigation of Melt Pool Geometry Control in Additive Manufacturing Using Hybrid Modeling. Metals 2020, 10, 683. [Google Scholar] [CrossRef]

- Cawley, G.C.; Talbot, N.L. On over-fitting in model selection and subsequent selection bias in performance evaluation. J. Mach. Learn. Res. 2010, 11, 2079–2107. [Google Scholar]

- Hassen, A.A.; Noakes, M.; Nandwana, P.; Kim, S.; Kunc, V.; Vaidya, U.; Love, L.; Nycz, A. Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing. Addit. Manuf. 2020, 32, 101093. [Google Scholar] [CrossRef]

- Hermann, F.; Vogt, S.; Göbel, M.; Möller, M.; Frey, K. Laser Metal Deposition of AlSi10Mg with high build rates. Procedia CIRP 2022, 111, 210–213. [Google Scholar] [CrossRef]

| per Predictor (P///v) | β: Coefficients of Linear Basis (1/P///v) | MAE | |||

|---|---|---|---|---|---|

| w | 0.08 | 1.05/0.03/1.05/0.15 | [2.06/0.31/0.08/0.09/−0.65] | 0.89 | 0.11 mm |

| h | 0.04 | 1.62/0.25/1.95/0.05 | [0.53/0.03/0.45/−0.01/−0.48] | 0.88 | 0.04 mm |

| 0.02 | 1.17/0.04/1.90/0.17 | [0.52/0.13/−0.05/0.04/−0.13] | 0.91 | 0.04 mm |

| No. | P [W] | [g/min] | [mm] | v [m/min] | |

|---|---|---|---|---|---|

| a | 2836 | 3.0 | 1.3 | 1.5 | 0.014 |

| b | 2815 | 3.3 | 1.8 | 2.0 | 0.027 |

| c | 2669 | 1.6 | 1.6 | 1.0 | 0.060 |

| d | 3399 | 3.1 | 1.0 | 2.3 | 0.064 |

| e | 2173 | 2.1 | 2.3 | 1.0 | 0.071 |

| f | 2173 | 2.0 | 1.5 | 1.0 | 0.076 |

| g | 3054 | 7.3 | 2.1 | 4.0 | 0.082 |

| h | 2965 | 7.3 | 2.3 | 3.9 | 0.083 |

| v [m/min] | P [W] | [g/min] | [mm] | |

|---|---|---|---|---|

| 2 | 1856 | 3.2 | 2.0 | 0.018 |

| 4 | 2188 | 8.4 | 2.0 | 0.014 |

| 6 | 2684 | 12.6 | 2.0 | 0.028 |

| 8 | 3329 | 16.8 | 1.1 | 0.020 |

| 10 | 3867 | 21.0 | 2.0 | 0.025 |

| 12 | 3647 | 25.1 | 2.8 | 0.087 |

| 14 | 4000 | 29.2 | 2.7 | 0.095 |

| 16 | 4000 | 33.6 | 3.0 | 0.130 |

| 18 | 4000 | 37.7 | 3.0 | 0.251 |

| 20 | 4000 | 42 | 3.0 | 0.457 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hermann, F.; Michalowski, A.; Brünnette, T.; Reimann, P.; Vogt, S.; Graf, T. Data-Driven Prediction and Uncertainty Quantification of Process Parameters for Directed Energy Deposition. Materials 2023, 16, 7308. https://doi.org/10.3390/ma16237308

Hermann F, Michalowski A, Brünnette T, Reimann P, Vogt S, Graf T. Data-Driven Prediction and Uncertainty Quantification of Process Parameters for Directed Energy Deposition. Materials. 2023; 16(23):7308. https://doi.org/10.3390/ma16237308

Chicago/Turabian StyleHermann, Florian, Andreas Michalowski, Tim Brünnette, Peter Reimann, Sabrina Vogt, and Thomas Graf. 2023. "Data-Driven Prediction and Uncertainty Quantification of Process Parameters for Directed Energy Deposition" Materials 16, no. 23: 7308. https://doi.org/10.3390/ma16237308

APA StyleHermann, F., Michalowski, A., Brünnette, T., Reimann, P., Vogt, S., & Graf, T. (2023). Data-Driven Prediction and Uncertainty Quantification of Process Parameters for Directed Energy Deposition. Materials, 16(23), 7308. https://doi.org/10.3390/ma16237308