The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Film Characterization and Testing

3. Results

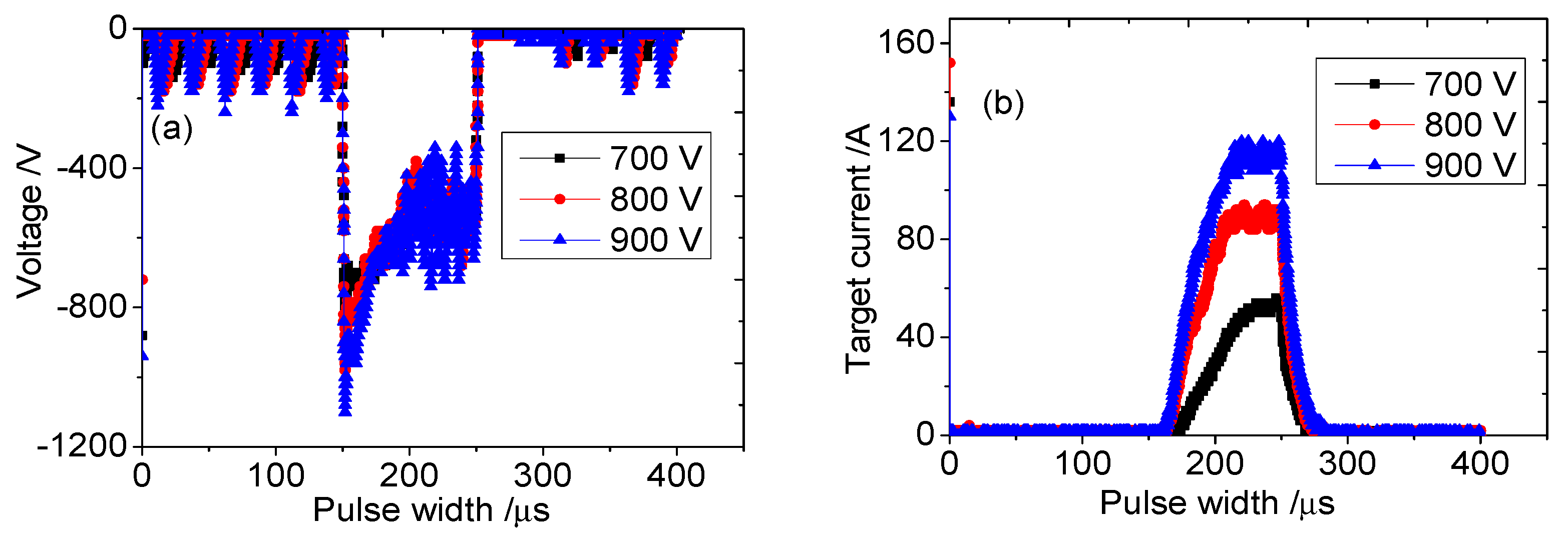

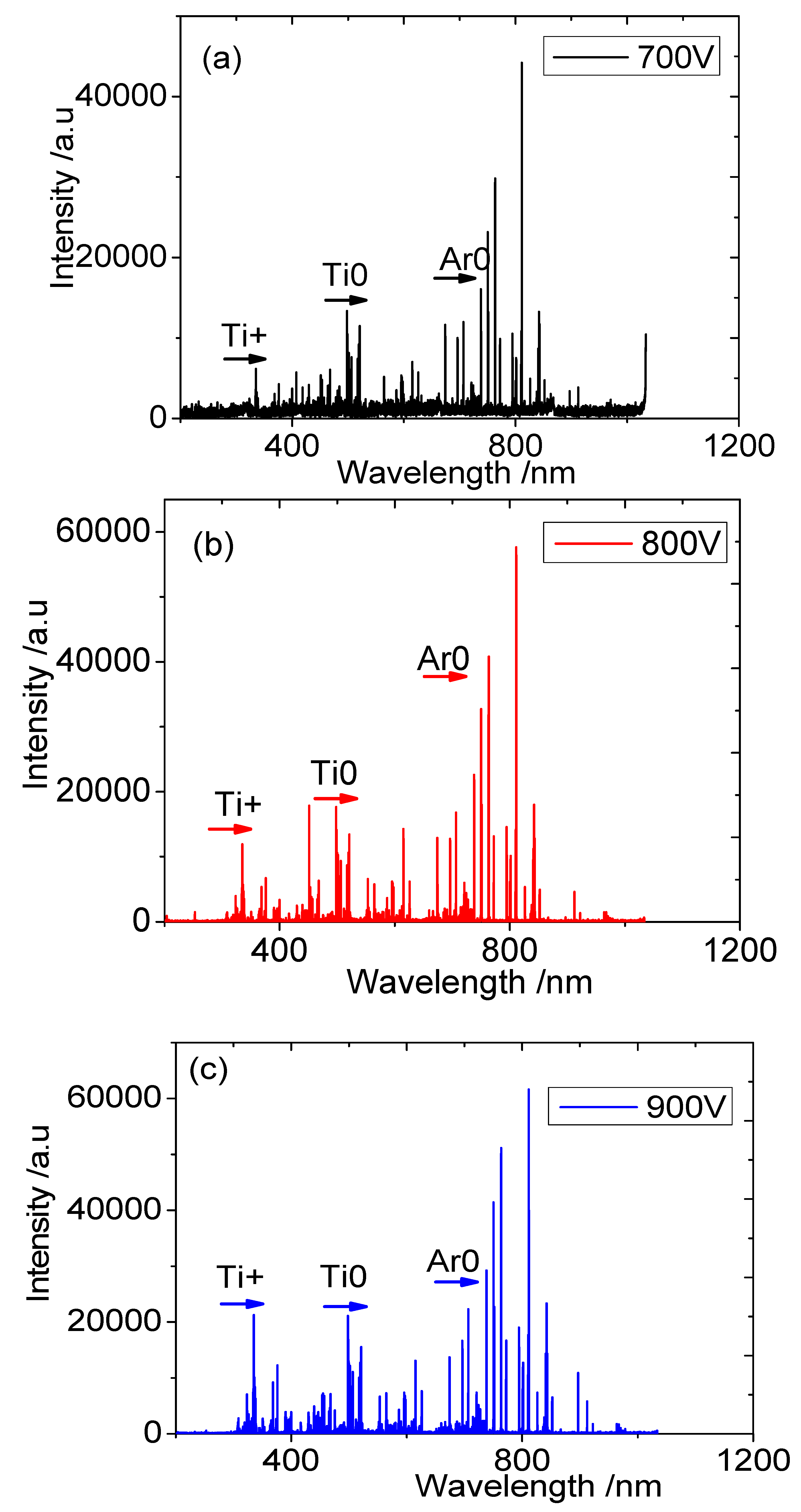

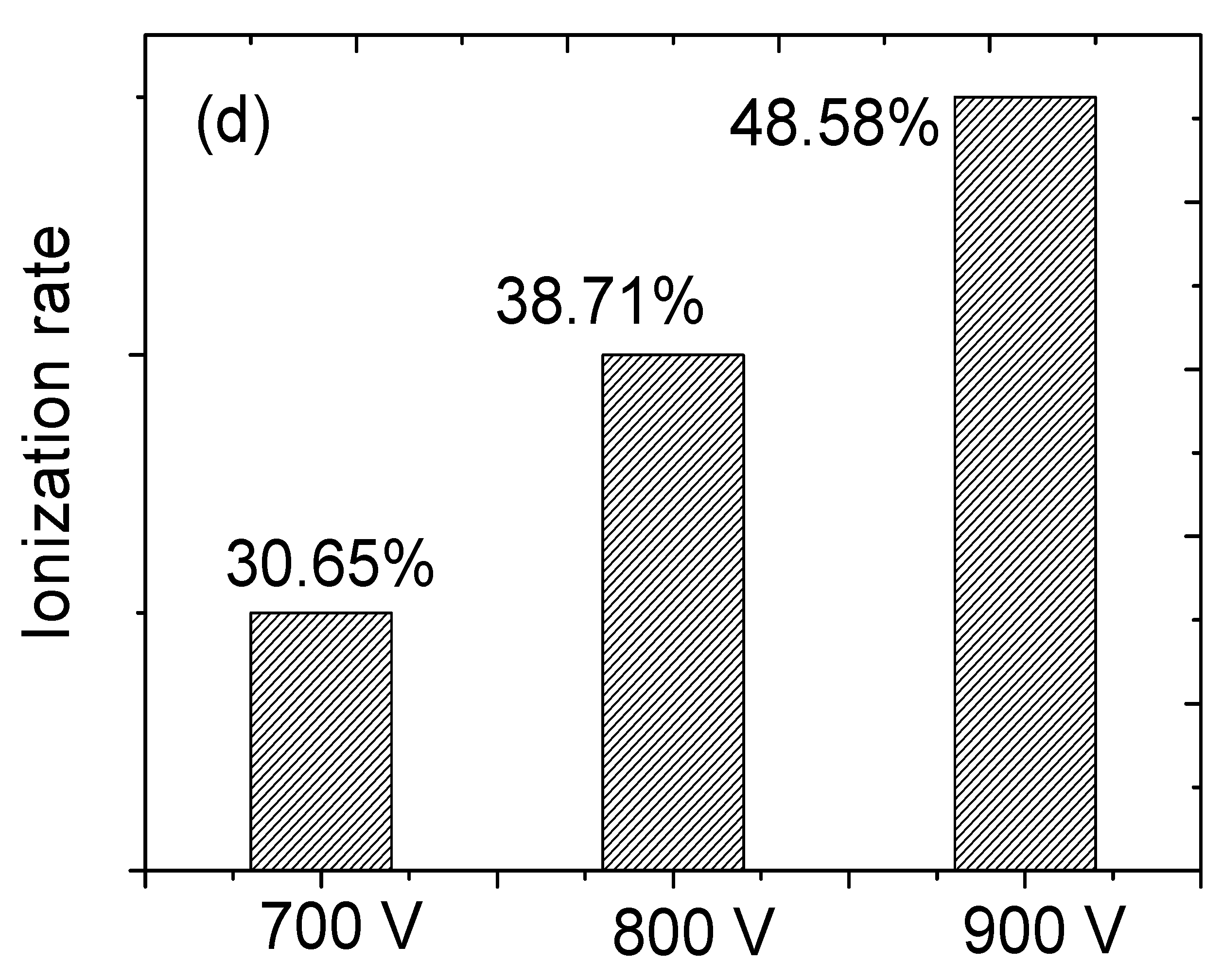

3.1. Target Discharge and Plasma Characteristics

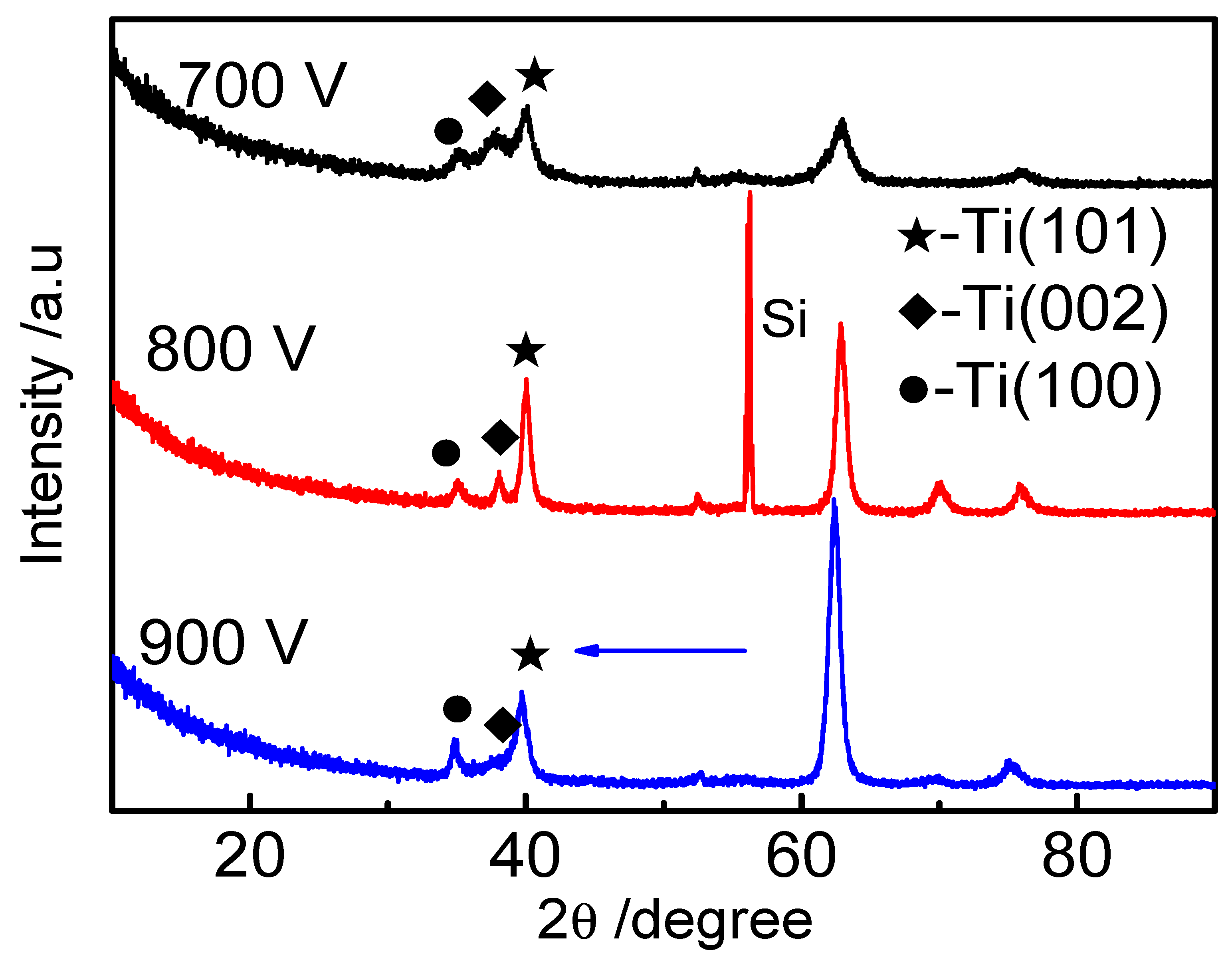

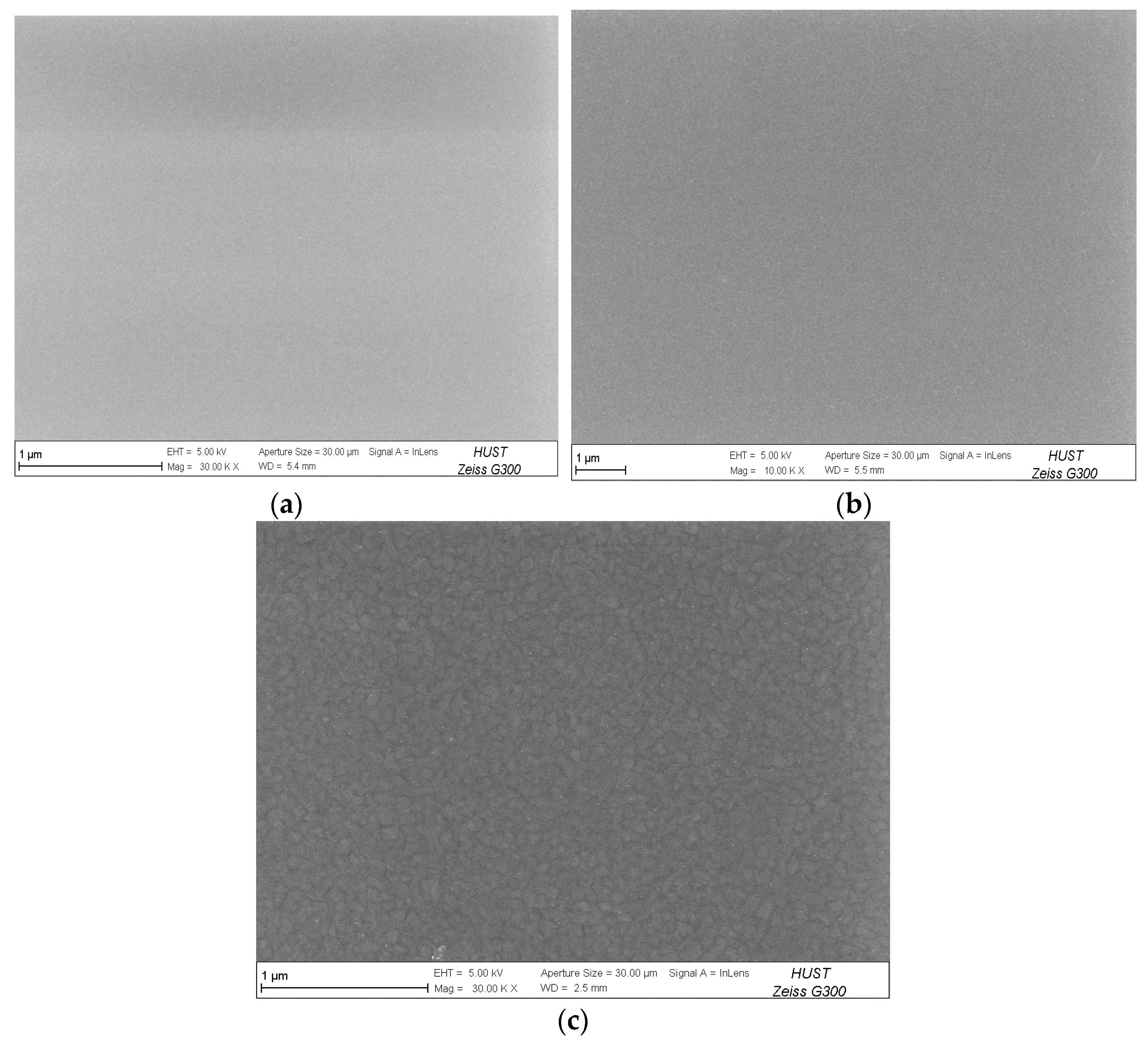

3.2. Microstructure and Composition

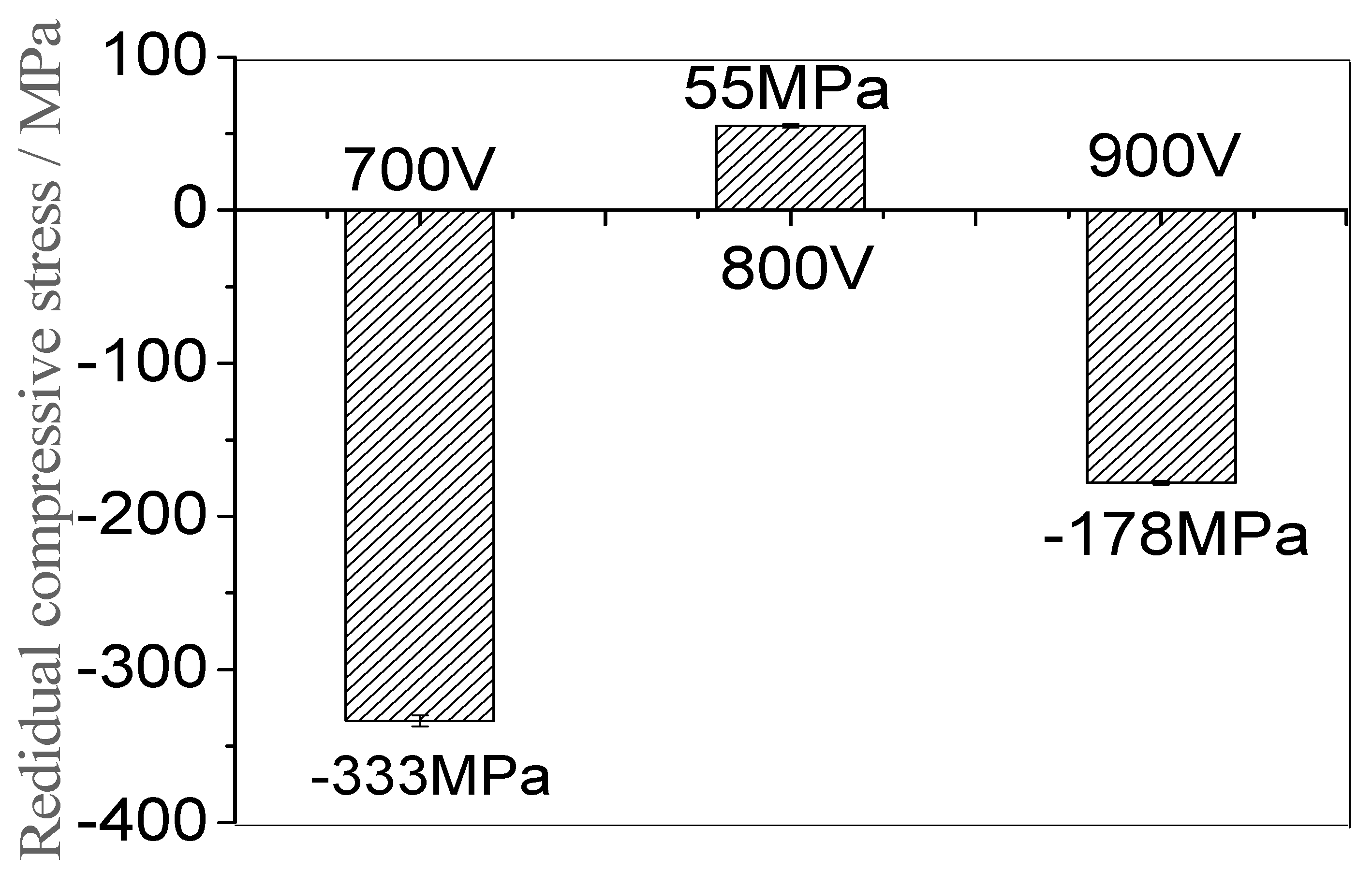

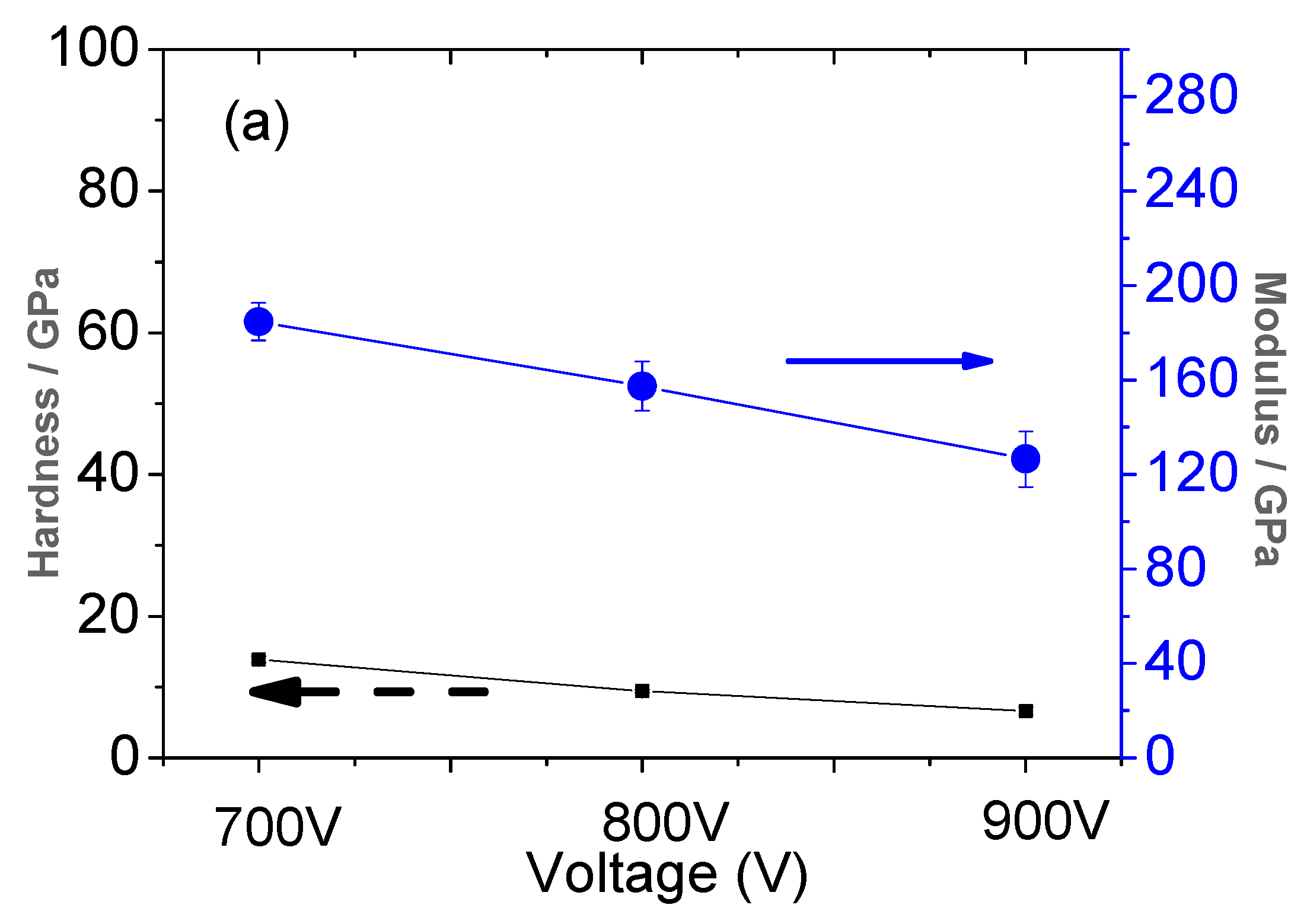

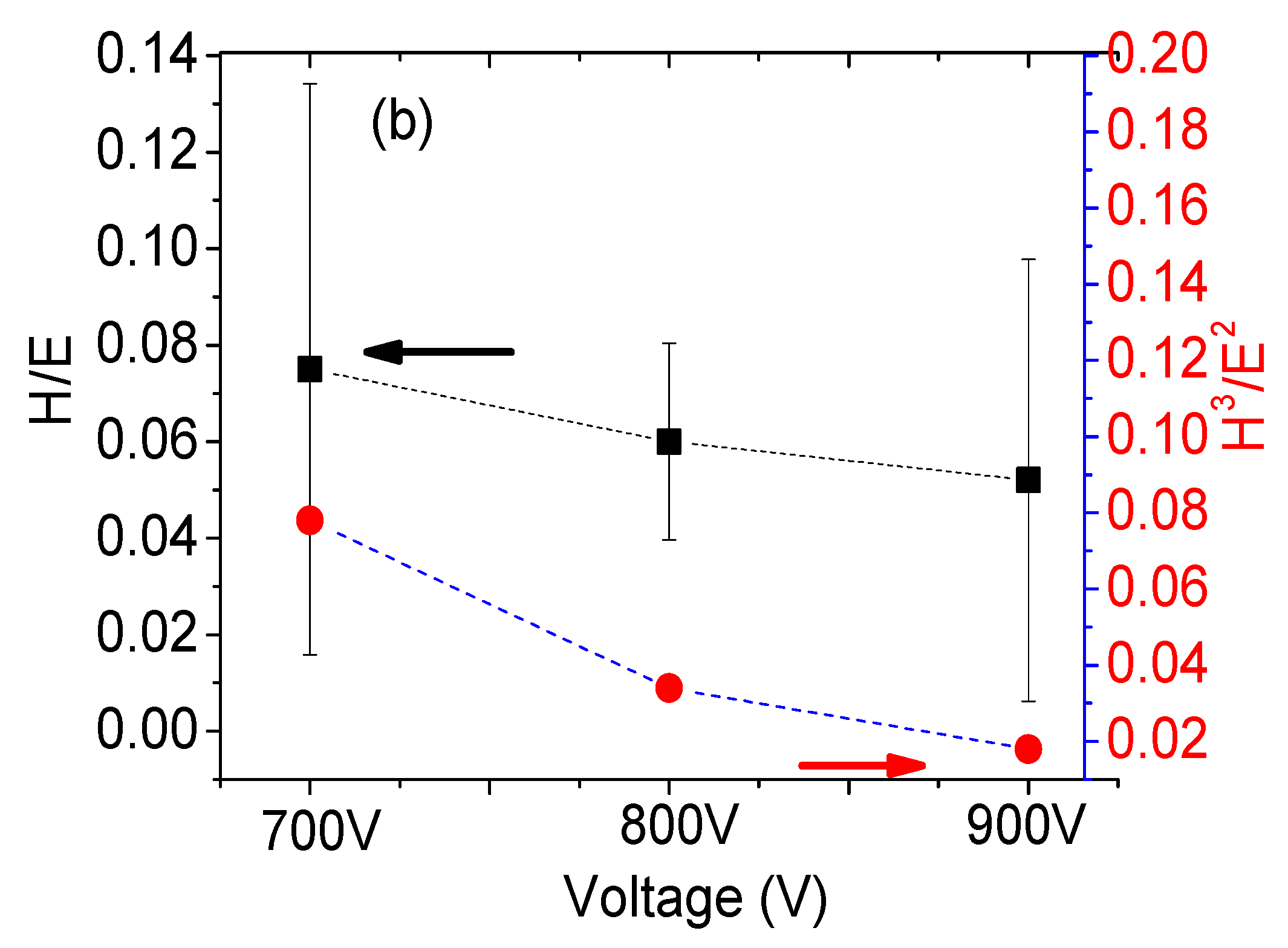

3.3. Mechanical Properties of the Film

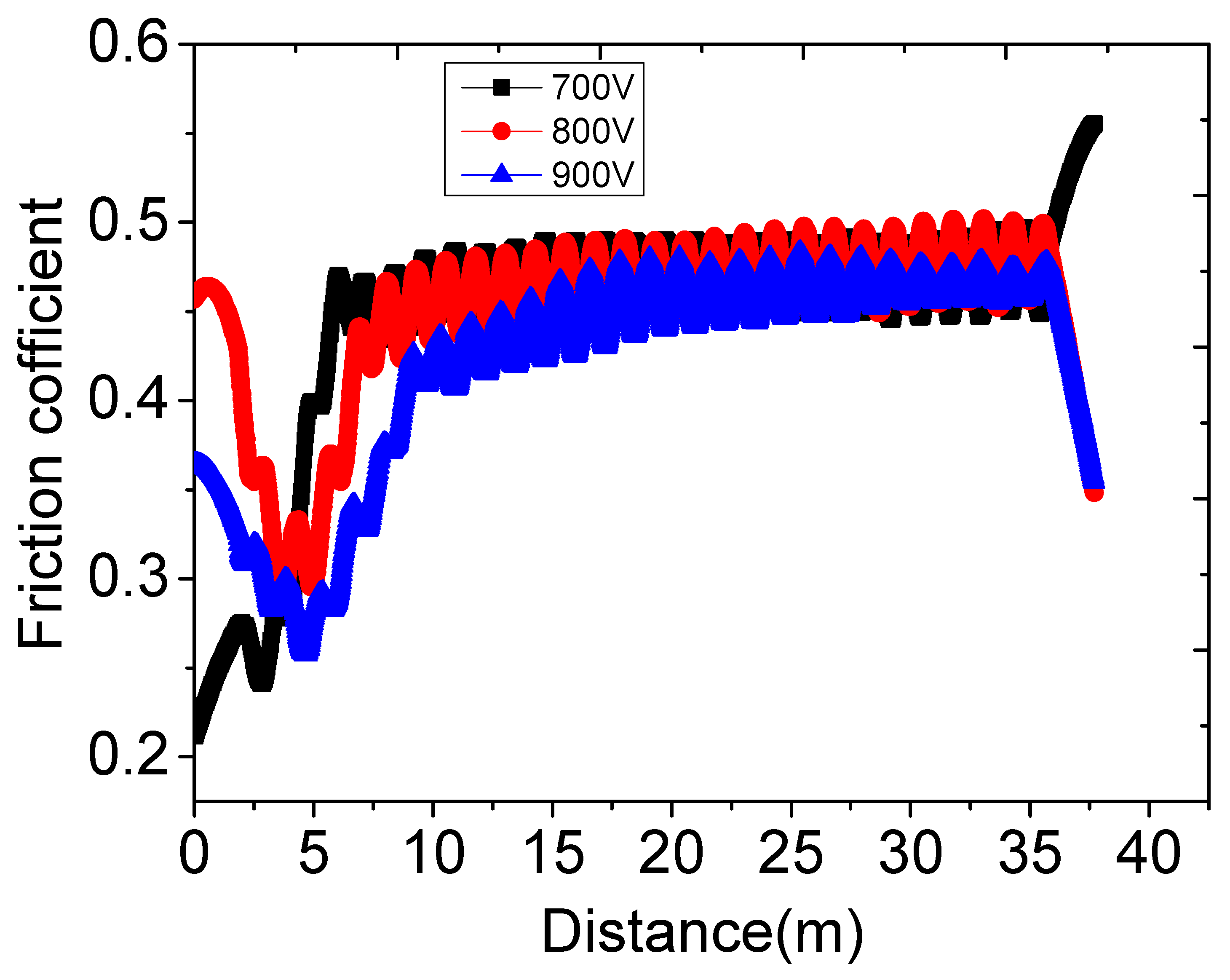

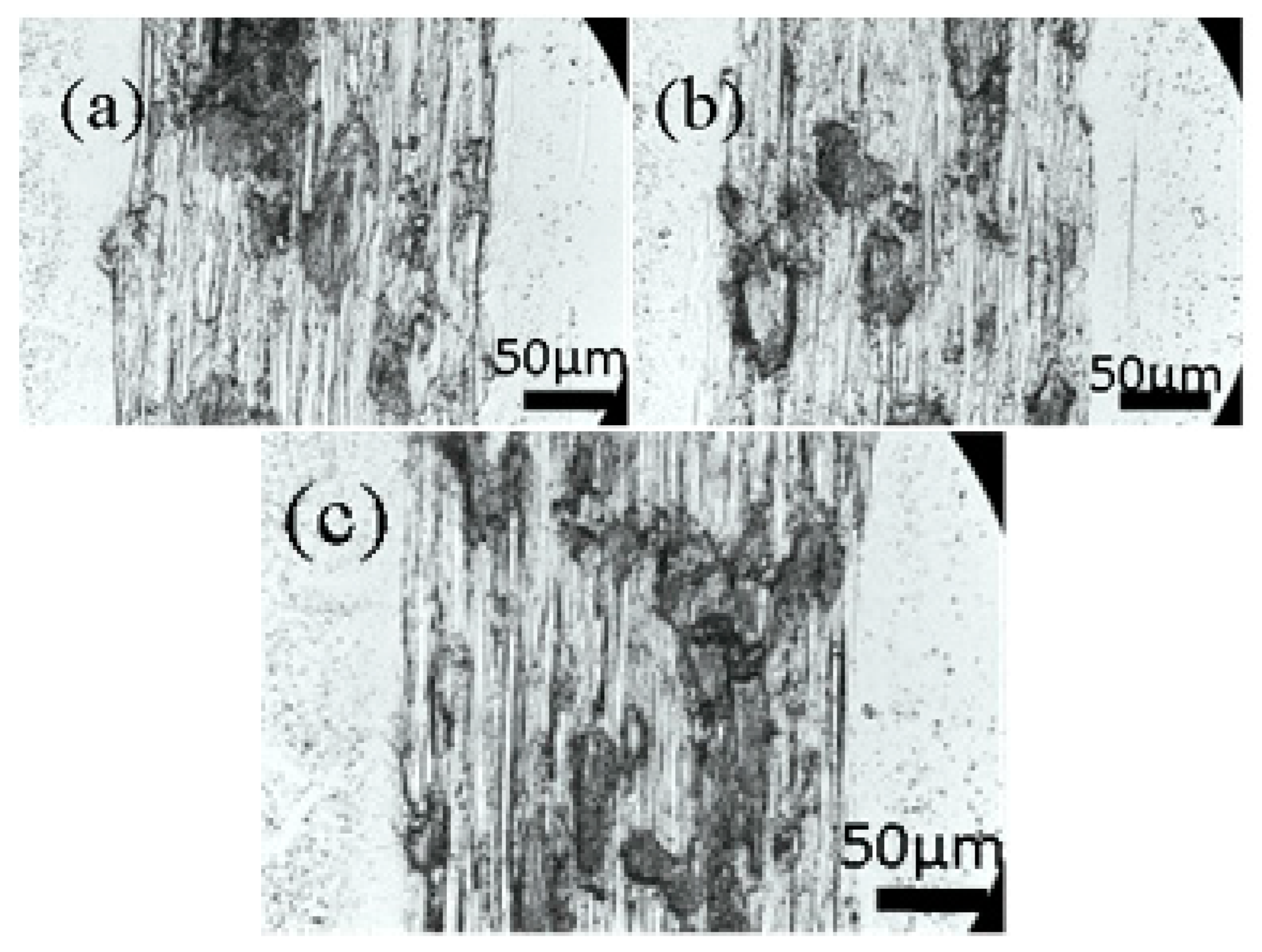

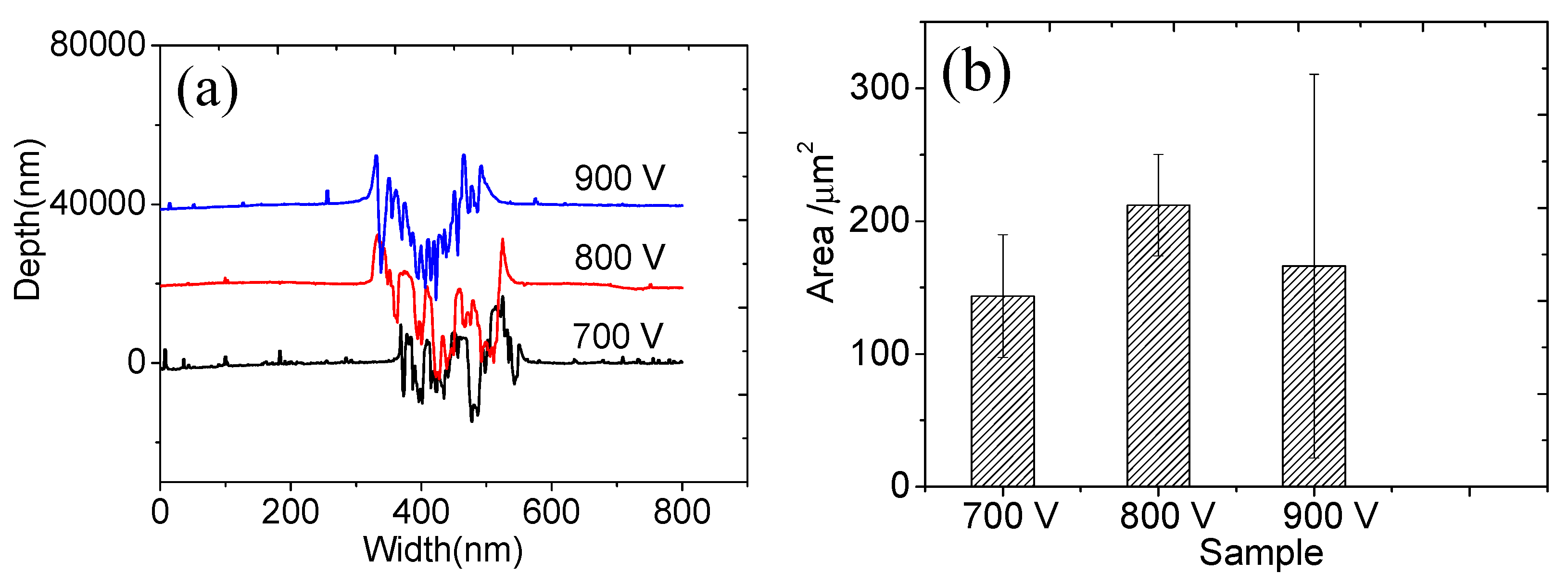

3.4. Tribological Properties of Thin Films

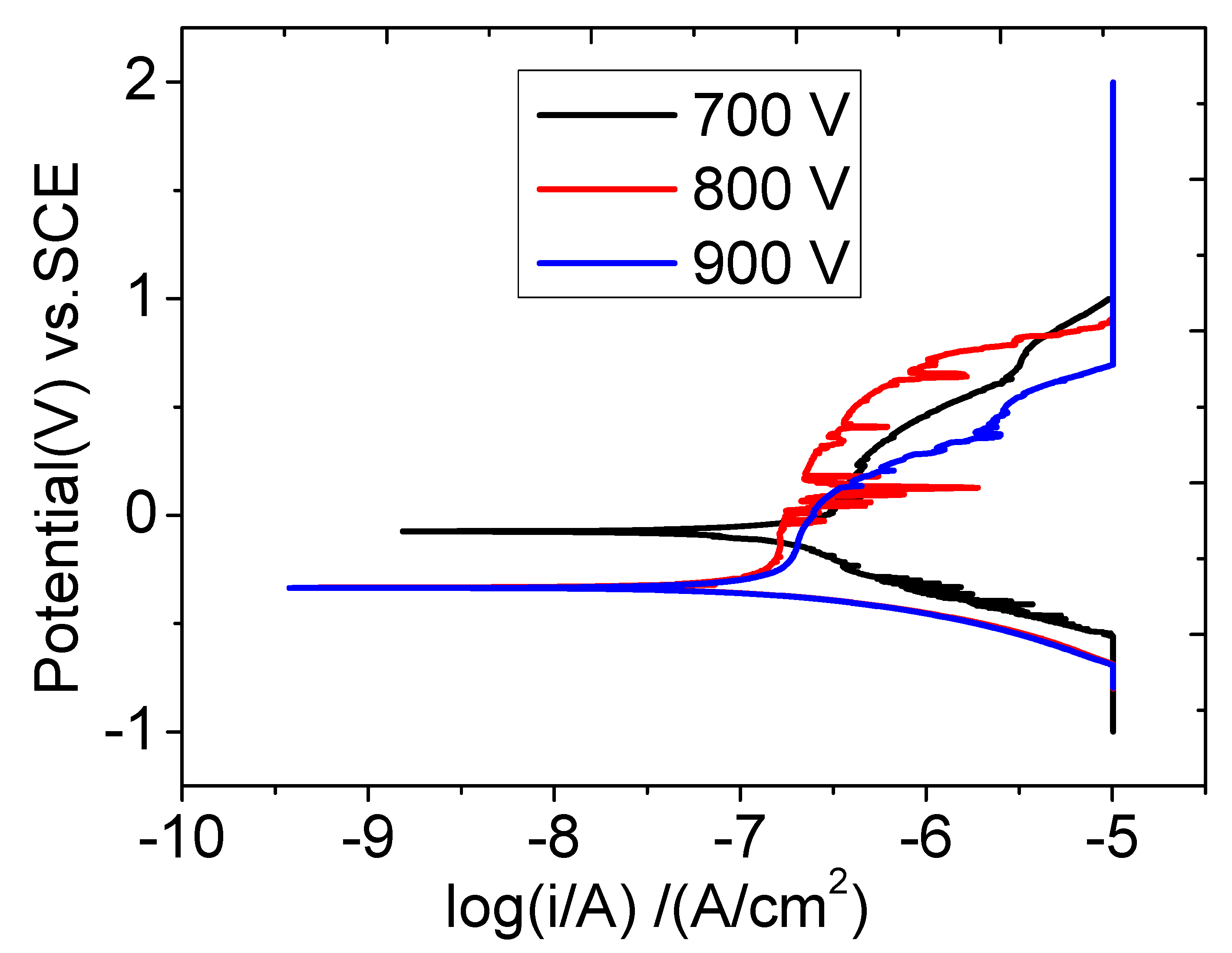

3.5. Film Corrosion Resistance

4. Discussion and Conclusions

- As the trigger voltage of the target increased from 700 V to 900 V, the peak current also increased. The ion–atom ratio near the Ti substrate gradually increased with the increase in the sputtering voltage, and the ion–atom ratio of Ti increased from 30% to 48%.

- As the trigger voltage continued to increase to 900 V, it could be seen that the surface of the titanium film had obvious particles, indicating that the grain size of the film continues to increase with the increase in the trigger voltage.

- With the increase in trigger voltage, the Ti ion–atom ratio increased, and the residual compressive stress generated by the Ti film changed to tensile stress and then to low compressive stress. As the voltage increased, the hardness and elastic modulus of the film were reduced, and the film was shown to not be wear-resistant. When the voltage was 700 V, the self-corrosion potential of the film was the largest, as was the corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z. Effect of evaporation rate on properties of Ti film prepared by electron beam evaporation on silicon wafer. Electroplat. Finish. 2023, 42, 4. [Google Scholar]

- Yang, L.; Pan, Y.; Zheng, S.; Zhu, X. Structure and process parameters of titanium films prepared by magnetron sputtering on graphite. Plat. Finish. 2023, 45, 7. [Google Scholar]

- Ma, D.L.; Deng, Q.Y.; Liu, H.Y.; Li, Y.T.; Leng, Y.X. Microstructure and properties of Ti2AlN thin film synthesized by vacuum annealing of high power pulsed magnetron sputtering deposited Ti/AlN multilayers. Surf. Coat. Technol. 2021, 425, 127749. [Google Scholar] [CrossRef]

- Samuelsson, M.; Lundin, D.; Jensen, J.; Raadu, M.A.; Gudmundsson, J.T.; Helmersson, U. On the film density using high power impulse magnetron sputtering. Surf. Coat. Technol. 2010, 205, 591–596. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Bohlmark, J.; Alami, J.; Christou, C.; Ehiasarian, A.P.; Helmersson, U. Ionization of sputtered metals in high power pulsed magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 2005, 23, 18–22. [Google Scholar] [CrossRef]

- Bobzin, K.; Kalscheuer, C.; Carlet, M.; Schulze, C. Influence of the etching process on the coating performance in dry tribological contacts. J. Vac. Sci. Technol. A 2023, 41, 33104. [Google Scholar] [CrossRef]

- Cedeño-Vente, M.L.; Mondragón-Rodríguez, G.C.; Camacho, N.; Gómez-Ovalle, A.E.; Gonzalez-Carmona, J.M.; Alvarado-Orozco, J.M.; Espinosa-Arbelaez, D.G. Tailoring the chemical composition and microstructure of CrxN deposited by HiPIMS through duty-cycle modifications. Surf. Coat. Technol. 2021, 422, 127502. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, T.F.; Wu, B.H.; Yu, Y.; Wu, Y.P.; Zhu, S.F.; Jing, F.J.; Huang, N.; Leng, Y.X. Structure, mechanical and corrosion properties of TiN films deposited on stainless steel substrates with different inclination angles by DCMS and HPPMS. Surf. Coat. Technol. 2016, 292, 54–62. [Google Scholar] [CrossRef]

- Chang, C.L.; Luo, G.J.; Yang, F.C.; Tang, J.F. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS. Vacuum 2021, 192, 110449. [Google Scholar] [CrossRef]

- Zanáška, M.; Lundin, D.; Brenning, N.; Du, H.; Dvořák, P.; Vašina, P.; Helmersson, U. Dynamics of bipolar HiPIMS discharges by plasma potential probe measurements. Plasma Sour. Sci. Technol. 2022, 31, 25007. [Google Scholar] [CrossRef]

- Rudolph, M.; Brenning, N.; Hajihoseini, H.; Raadu, M.A.; Fischer, J.; Gudmundsson, J.T.; Lundin, D. Operating modes and target erosion in high power impulse magnetron sputtering. J. Vacuum Sci. Technol. A 2022, 40, 43005. [Google Scholar] [CrossRef]

- Zheng, B.C.; Meng, D.; Che, H.L.; Lei, M.K. On the pressure effect in energetic deposition of Cu thin films by modulated pulsed power magnetron sputtering: A global plasma model and experiments. J. Appl. Phys. 2015, 117, 290. [Google Scholar] [CrossRef]

- Gudmundsson, J.T. Ionization mechanism in the high power impulse magnetron sputtering (HiPIMS) discharge. J. Phys. Conf. Ser. 2008, 100, 82013. [Google Scholar] [CrossRef]

- Chang-Zi, C.; Dong-Lin, M.; Yan-Tao, L.; Yong-Xiang, L. Discharge model and plasma characteristics of high-powerpulsed magnetron sputtering titanium target. Acta Phys. Sin. 2021, 70, 180701. [Google Scholar]

- Wu, B.; Yu, Y.; Wu, J.; Shchelkanov, I.; Ruzic, D.N.; Huang, N.; Leng, Y.X. Tailoring of titanium thin film properties in high power pulsed magnetron sputtering. Vacuum 2018, 150, 144–154. [Google Scholar] [CrossRef]

- Jing, F.J.; Yin, T.L.; Yukimura, K.; Sun, H.; Leng, Y.X.; Huang, N. Titanium film deposition by high-power impulse magnetron sputtering: Influence of pulse duration. Vacuum 2012, 86, 2114–2119. [Google Scholar] [CrossRef]

- Chen, C.-Z.; Li, Y.-T.; Zeng, X.; Leng, Y.-X. Study on plasma characteristics of TiNb target by high power pulsed magnetron sputtering and its effect on properties of thin films. China Surf. Eng. 2022, 35, 1–10. [Google Scholar]

- Ross, A.E.; Ganesan, R.; Bilek, M.M.M.; McKenzie, D.R. A feedback model of magnetron sputtering plasmas in HIPIMS. Plasma Sour. Sci. Technol. 2015, 24, 25018. [Google Scholar] [CrossRef]

- Lennon, M.A.; Bell, K.L.; Gilbody, H.B.; Hughes, J.G.; Kingston, A.E.; Murray, M.J.; Smith, F.J. Recommended Data on the Electron Impact Ionization of Atoms and Ions: Fluorine to Nickel. J. Phys. Chem. Ref. Data 1988, 17, 1285–1363. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of substrate temperature and deposition rate on structure of thick sputtered Cu coatings. J. Vac. Sci. Technol. 1975, 12, 830. [Google Scholar] [CrossRef]

- Janssen, G.C.; Abdalla, M.M.; Van Keulen, F.; Pujada, B.R.; Van Venrooy, B. Celebrating the 100th anniversary of the Stoney equation for film stress: Developments from polycrystalline steel strips to single crystal silicon wafers. Thin Solid Film. 2009, 517, 1858–1867. [Google Scholar] [CrossRef]

- Jiang, F.; Chen, S.; Leng, Y.; Huang, N. Effect of wafer size on the film internal stress measurement by wafer curvature method. J. Wuhan Univ. Technol. Mater. Sci. 2016, 31, 93–99. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Ma, D.; Zeng, X.; Liu, M.; Jiang, X.; Leng, Y.X. Nano dual-phase CuNiTiNbCr high entropy alloy films produced by high-power pulsed magnetron sputtering. Surf. Coat. Technol. 2021, 420, 127325. [Google Scholar] [CrossRef]

| Sample | Trigger Voltage/V | Peak Current/A | Average Power/w | Peak Power/kW | Frequency/Hz | Pulse Width/μs | Argon Flow/ (sccm) | Working Pressure/ Pa | Deposition Time/ min | Thickness/ nm |

|---|---|---|---|---|---|---|---|---|---|---|

| Ti-700 | 700 | 60 | 496 | 24 | 50 | 20 | 386.4 ± 16 | |||

| Ti-800 | 800 | 100 | 1037 | 40 | 400 | 100 | 0.4 | 418.2 ± 20 | ||

| Ti-900 | 900 | 120 | 1346 | 48 | 712.4 ± 59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Ma, D.; Li, Y.; Chen, C. The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering. Materials 2023, 16, 7294. https://doi.org/10.3390/ma16237294

Jiang Q, Ma D, Li Y, Chen C. The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering. Materials. 2023; 16(23):7294. https://doi.org/10.3390/ma16237294

Chicago/Turabian StyleJiang, Quanxin, Donglin Ma, Yantao Li, and Changzi Chen. 2023. "The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering" Materials 16, no. 23: 7294. https://doi.org/10.3390/ma16237294

APA StyleJiang, Q., Ma, D., Li, Y., & Chen, C. (2023). The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering. Materials, 16(23), 7294. https://doi.org/10.3390/ma16237294