Effect of Modified Cow Dung Fibers on Strength and Autogenous Shrinkage of Alkali-Activated Slag Mortar

Abstract

:1. Introduction

2. Experimental Section

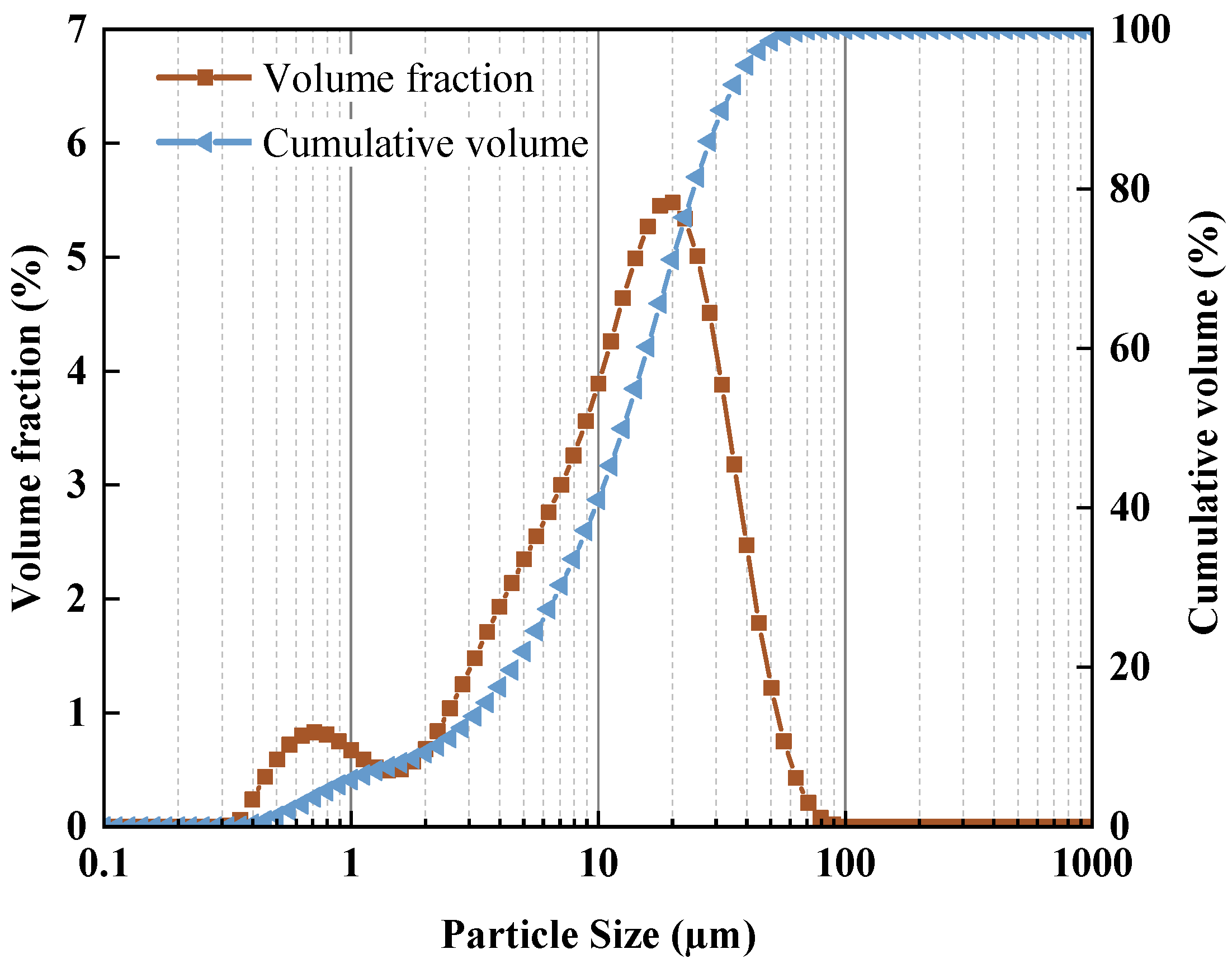

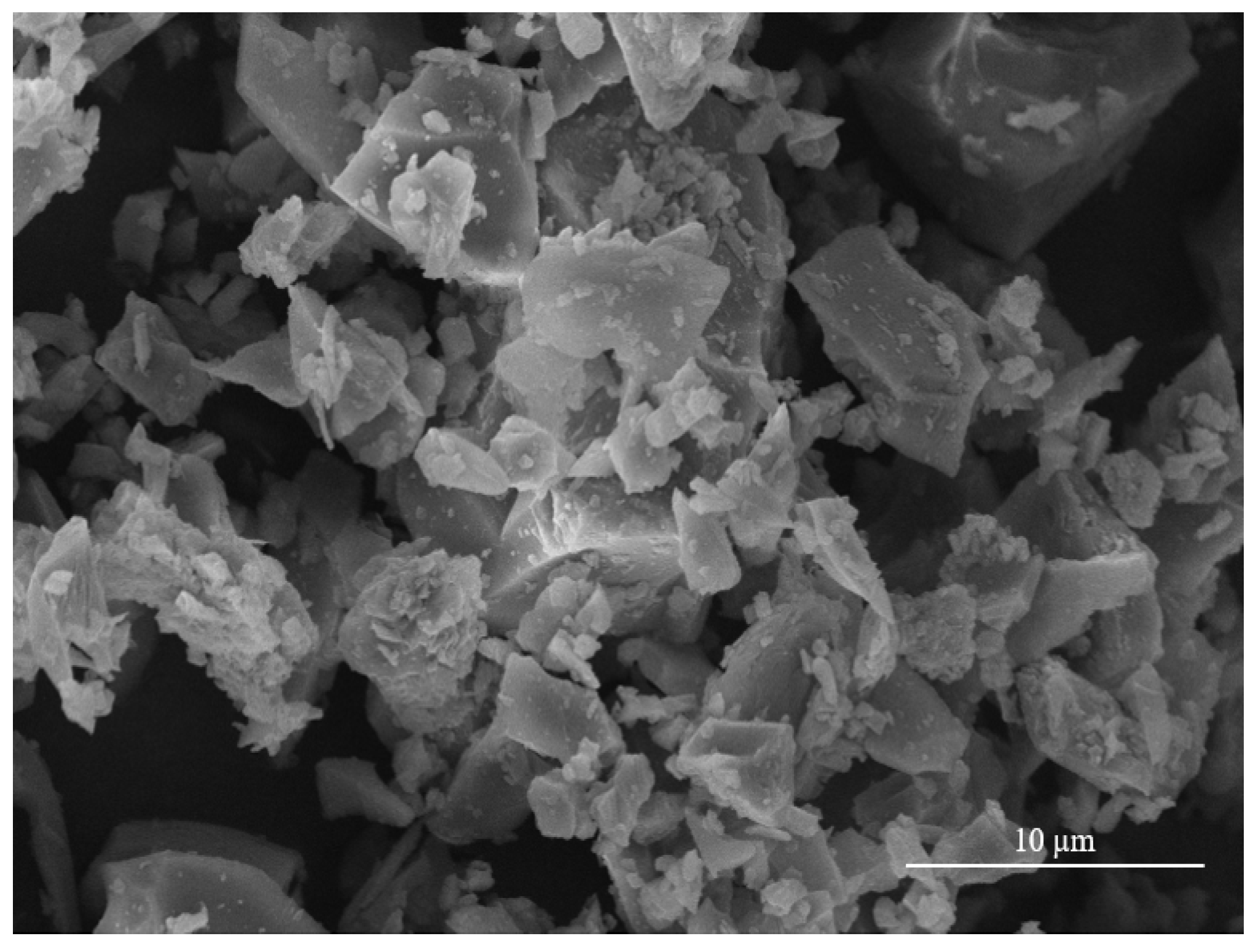

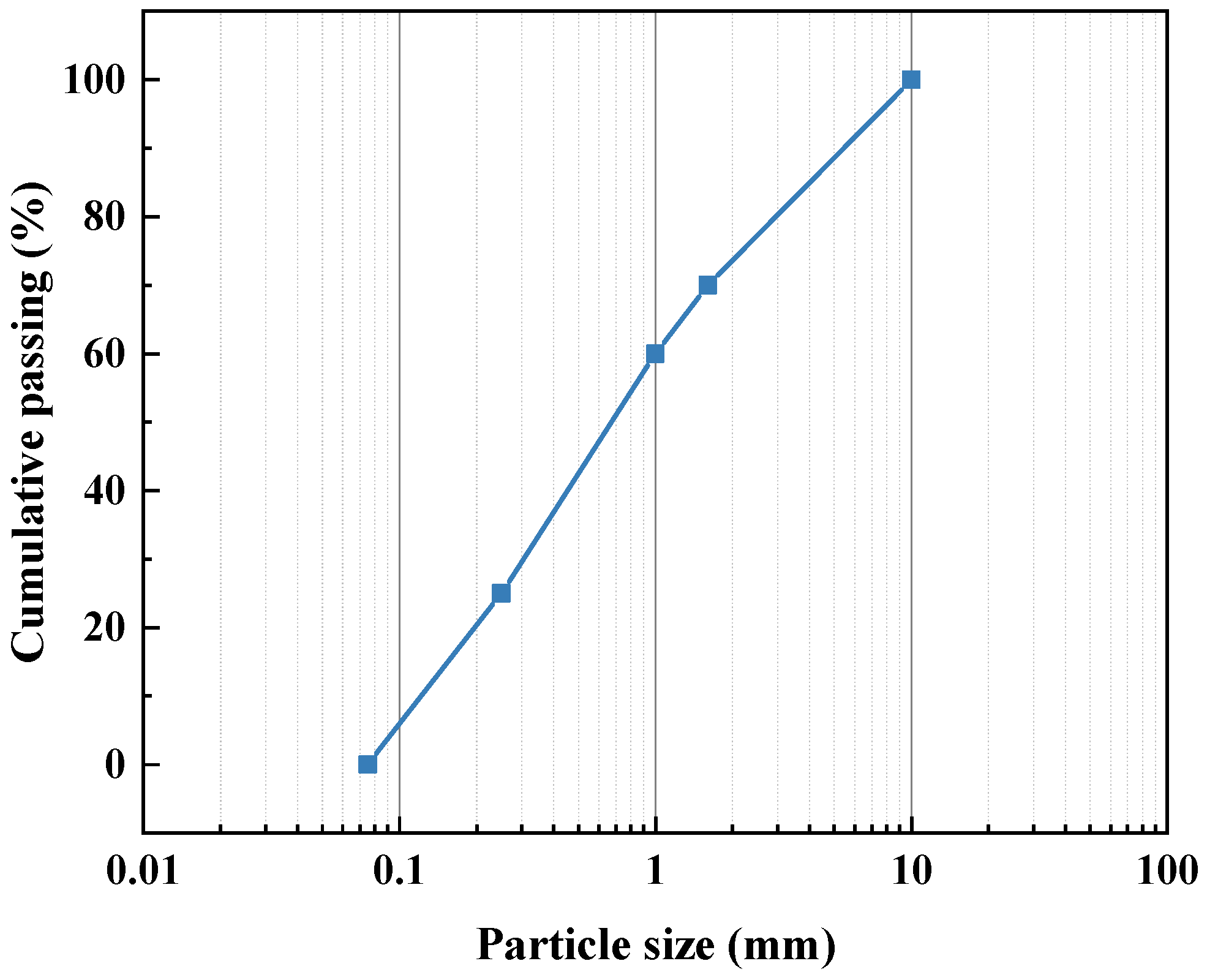

2.1. Materials

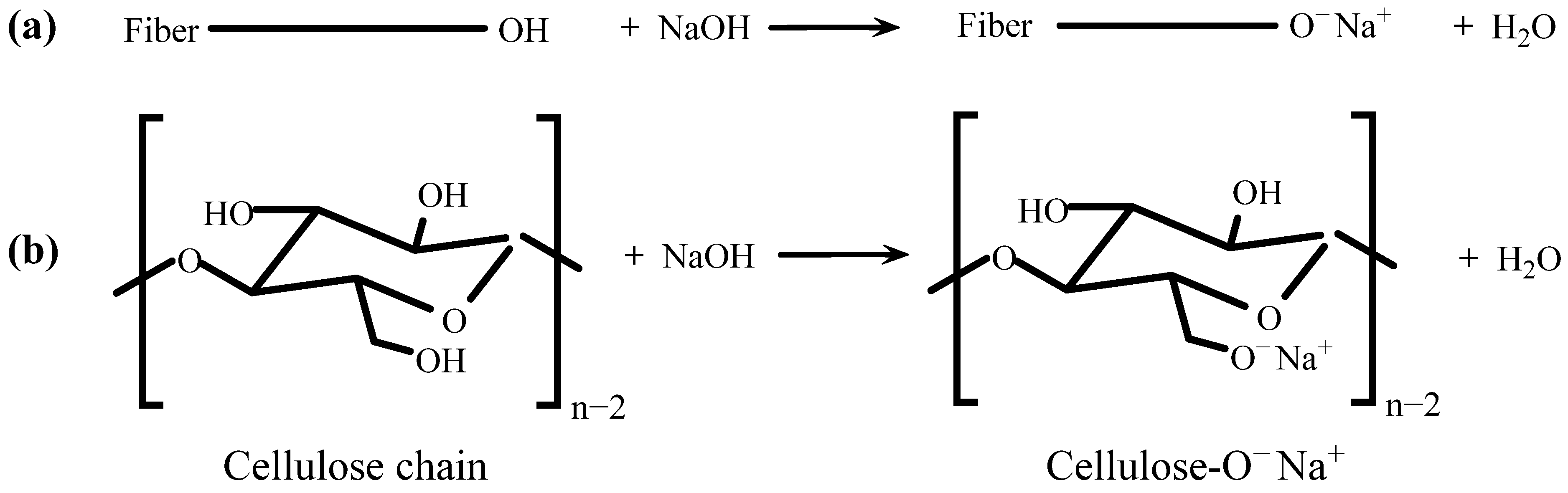

2.2. Modification of Cow Dung Fibers

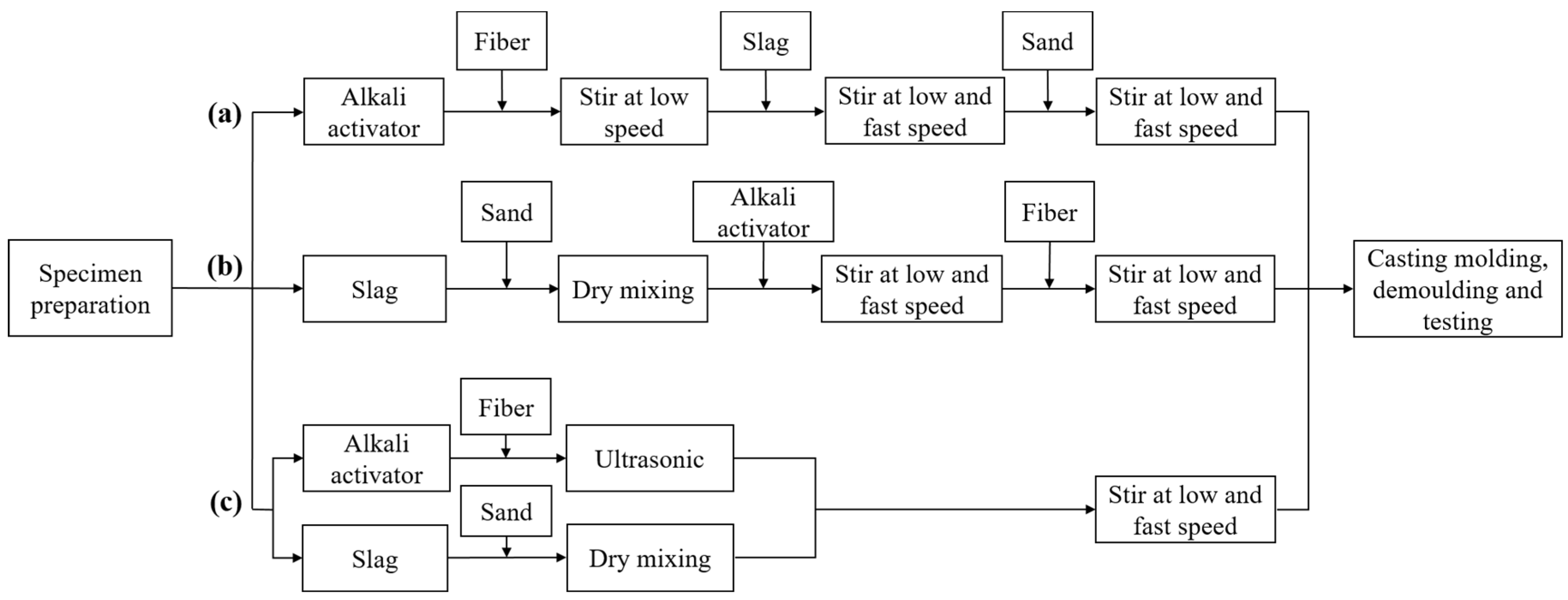

2.3. Mortar Preparation

2.4. Testing and Analysis

2.4.1. Fourier Transform Infrared (FTIR) Spectroscopy Analysis

2.4.2. X-ray Diffraction (XRD) Analysis

2.4.3. Water Absorption

2.4.4. Dispersion

2.4.5. Flowability

2.4.6. Mechanical Properties

2.4.7. Autogenous Shrinkage

2.4.8. Morphological Analysis

3. Results and Discussion

3.1. Modification of Cow Dung Fibers

3.2. Chemical Characterization of Cow Dung Fibers

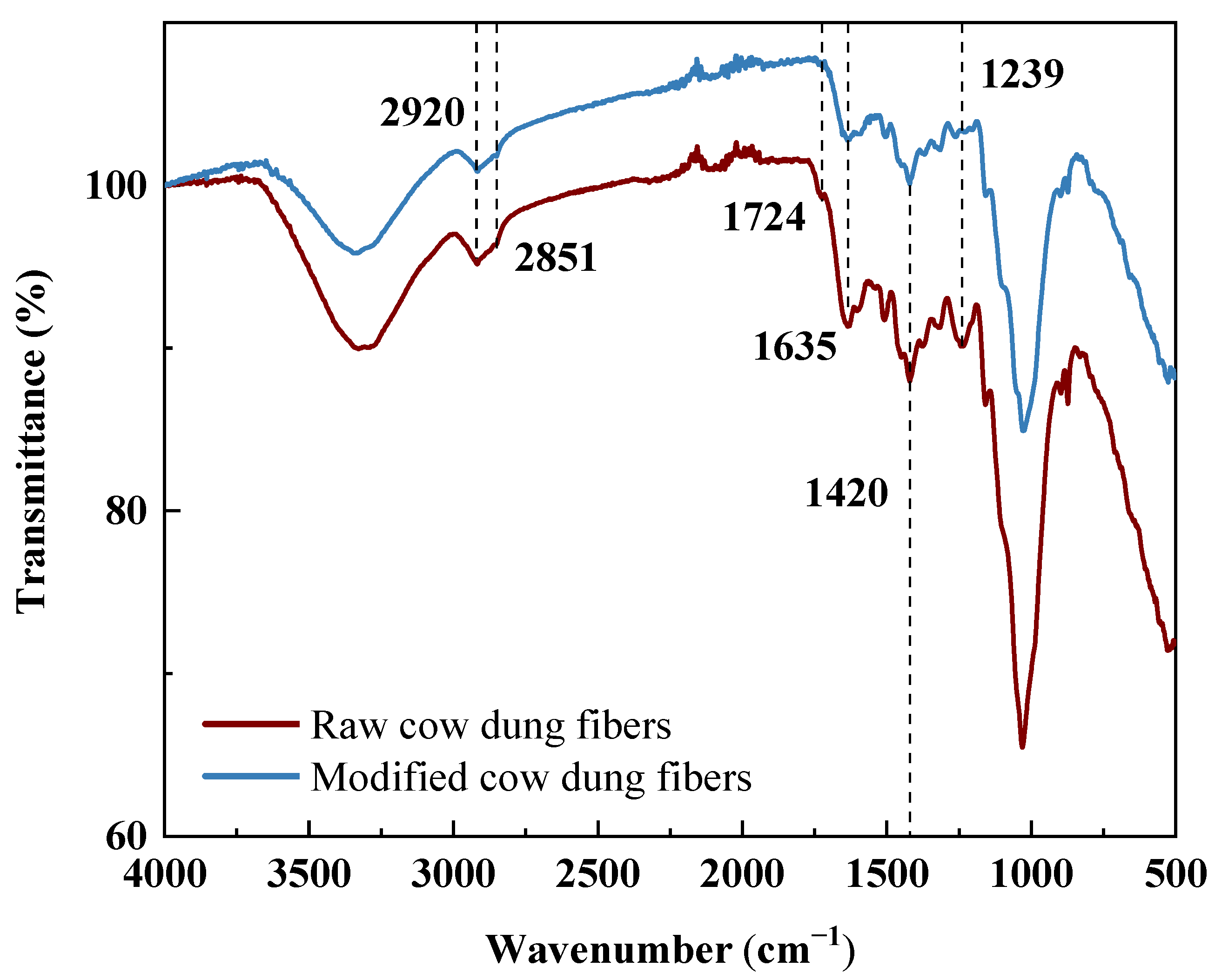

3.2.1. Fourier Transform Infrared (FTIR) Spectroscopy Analysis

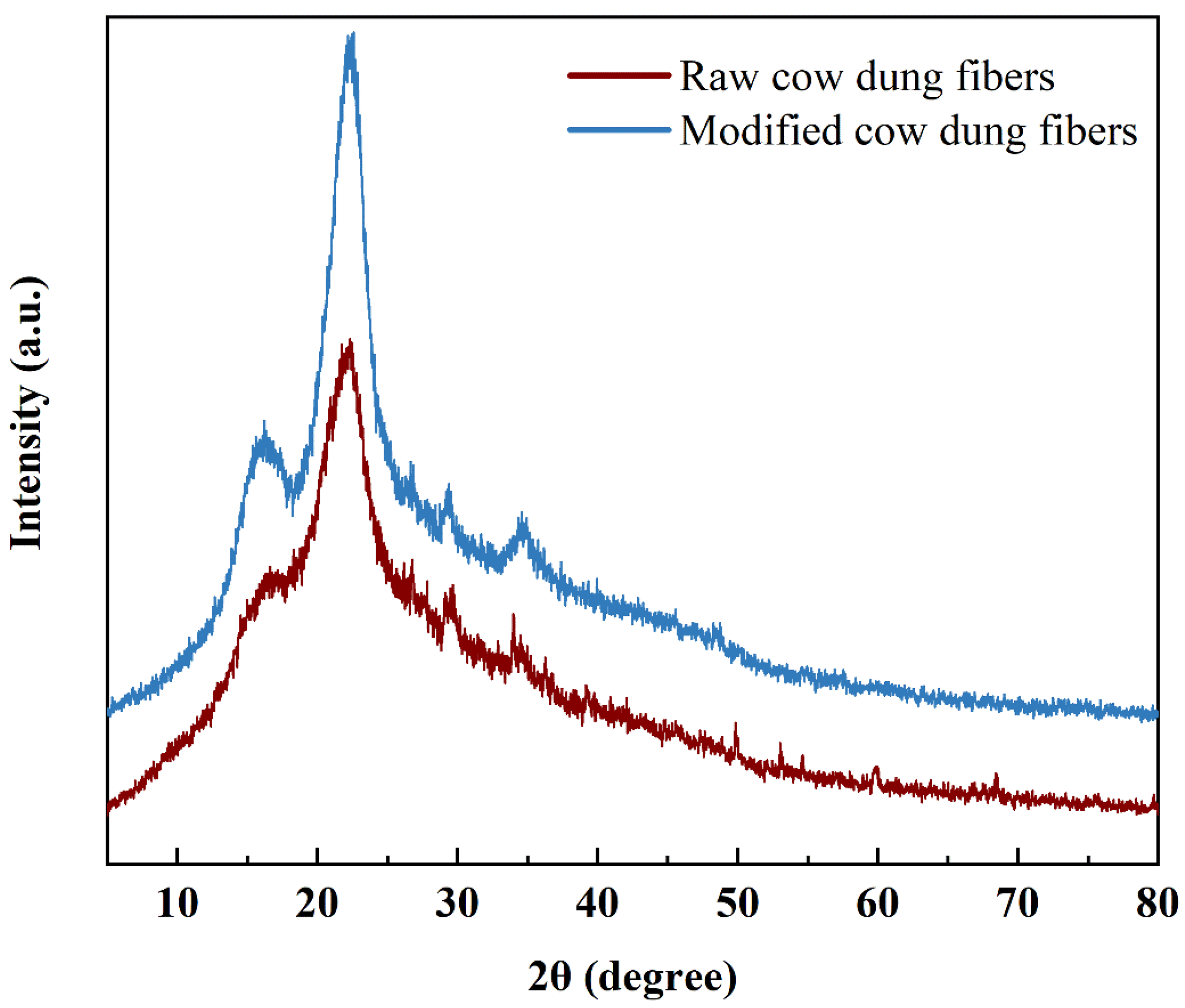

3.2.2. X-ray Diffraction (XRD) Analysis

3.3. Physical Characterization of Cow Dung Fibers

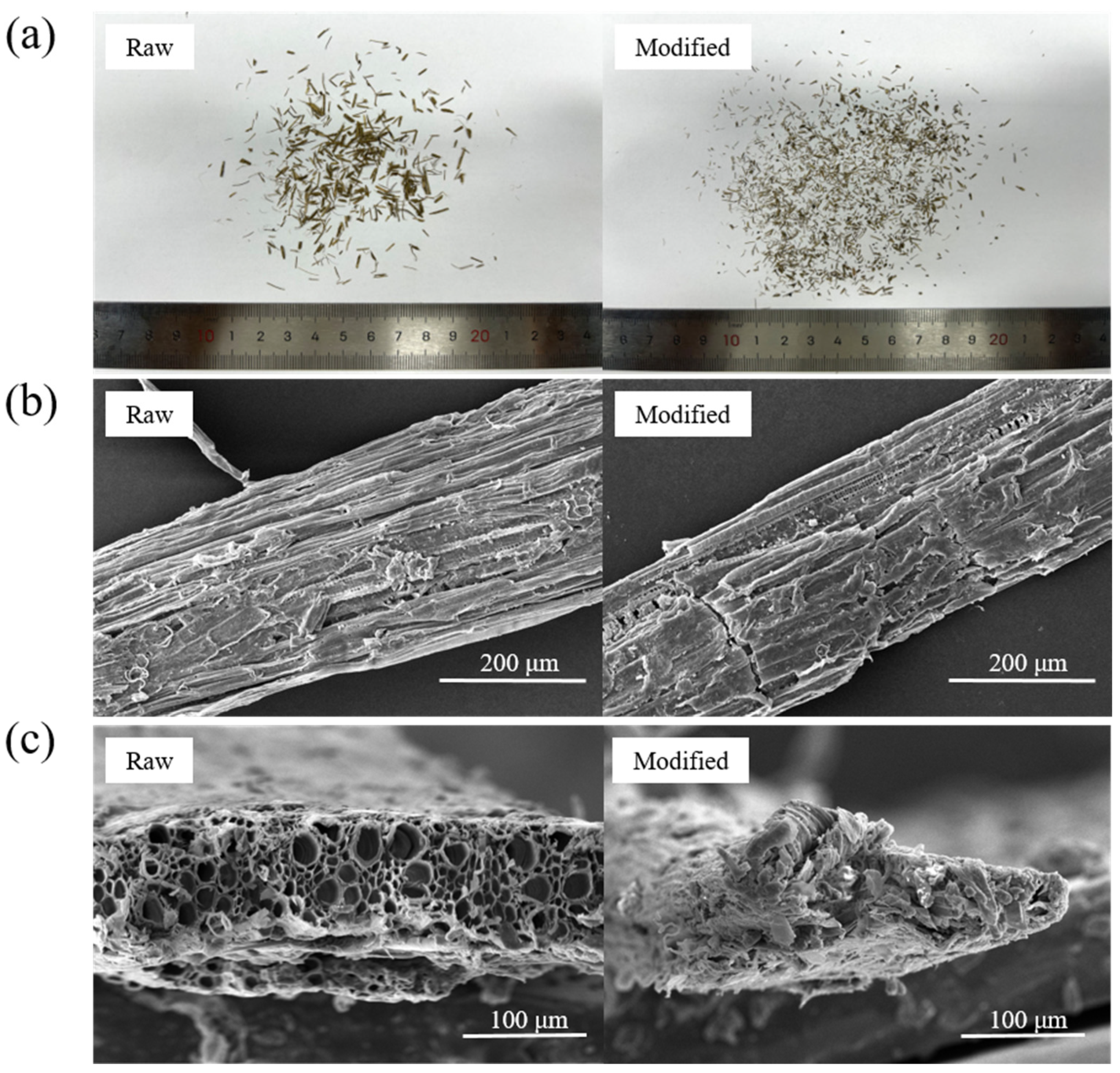

3.3.1. Images of Cow Dung Fibers

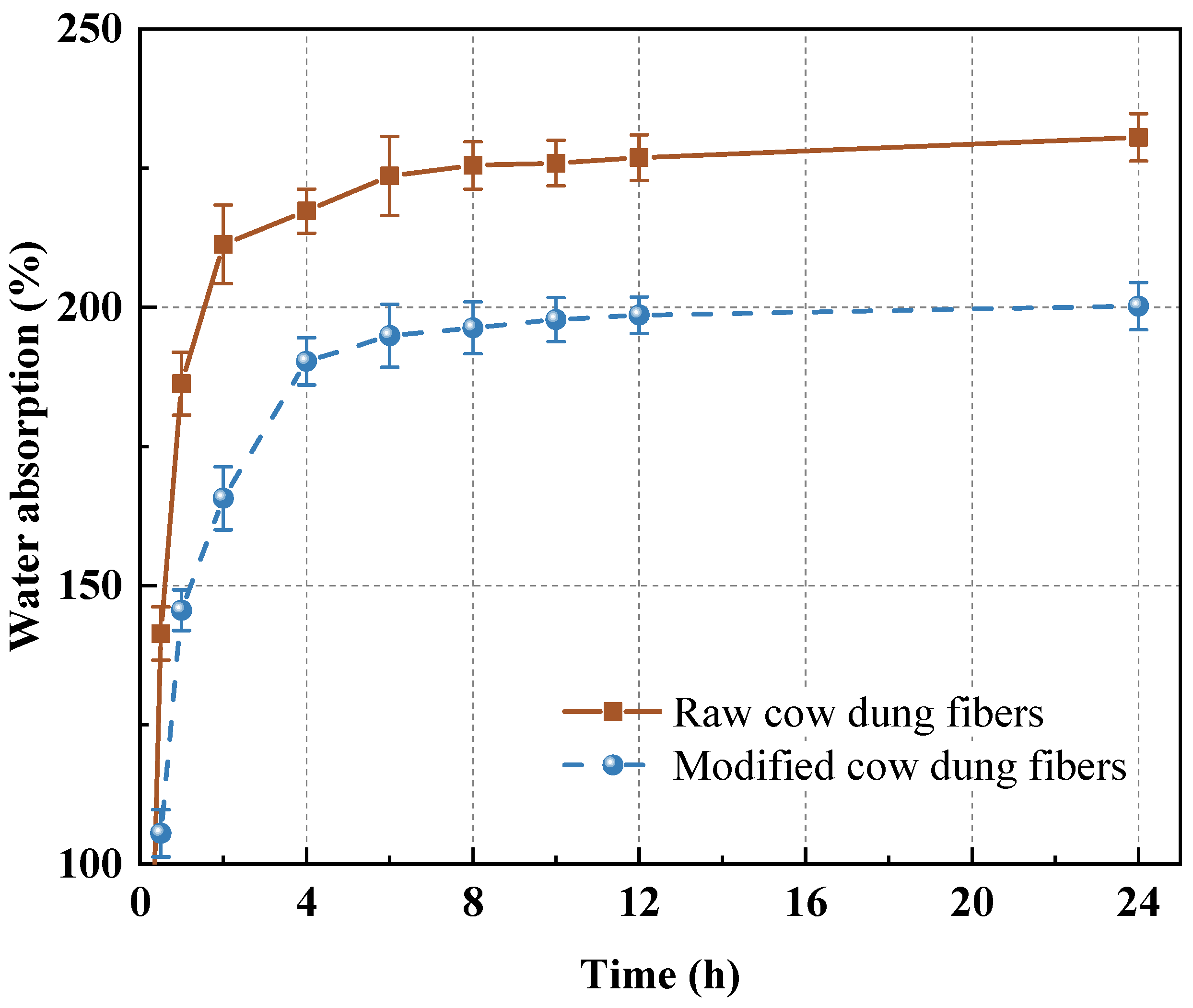

3.3.2. Water Absorption of Cow Dung Fibers

3.4. Dispersion of Cow Dung Fibers

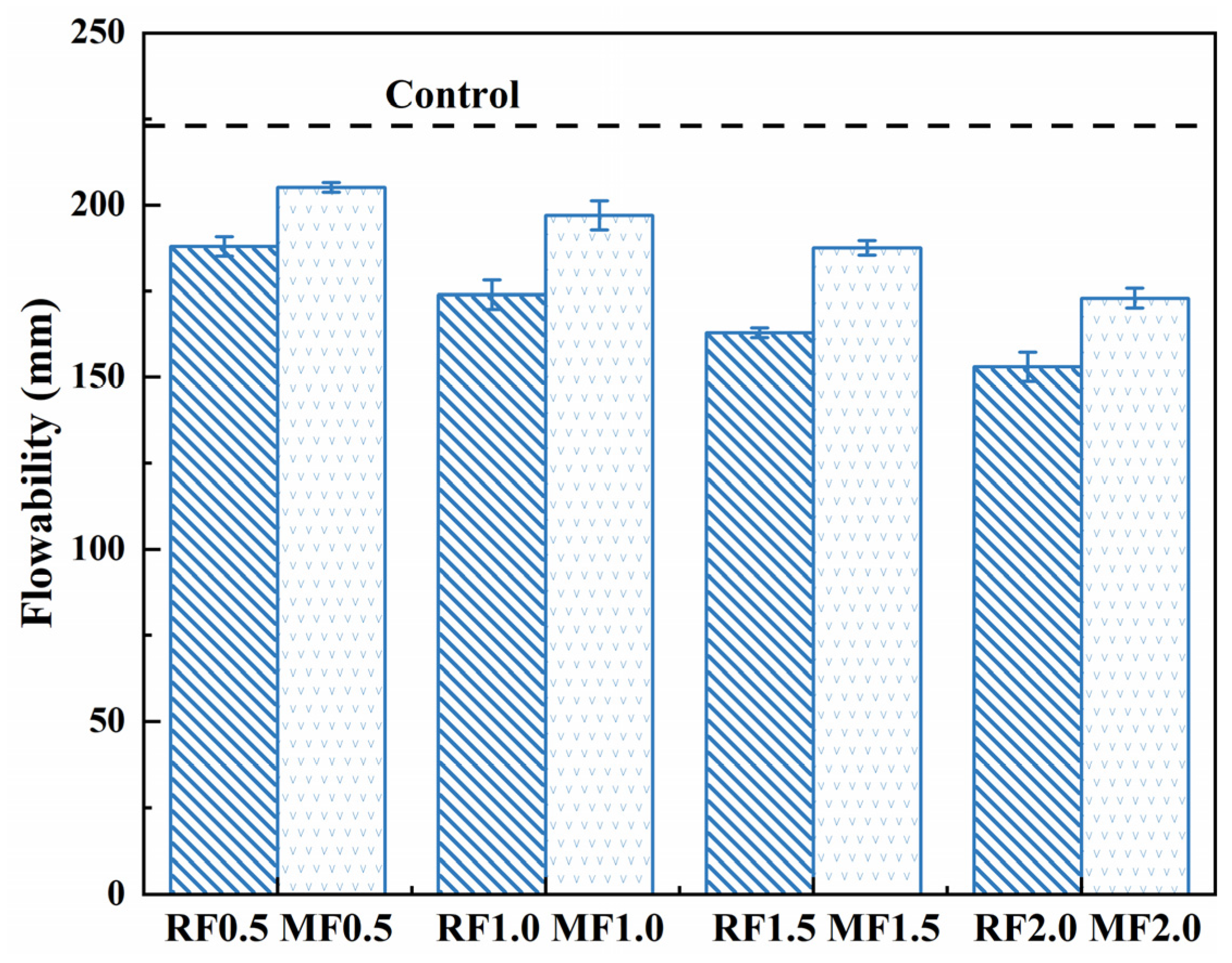

3.5. Flowability of AAS Mortar

3.6. Mechanical Properties of AAS Mortar

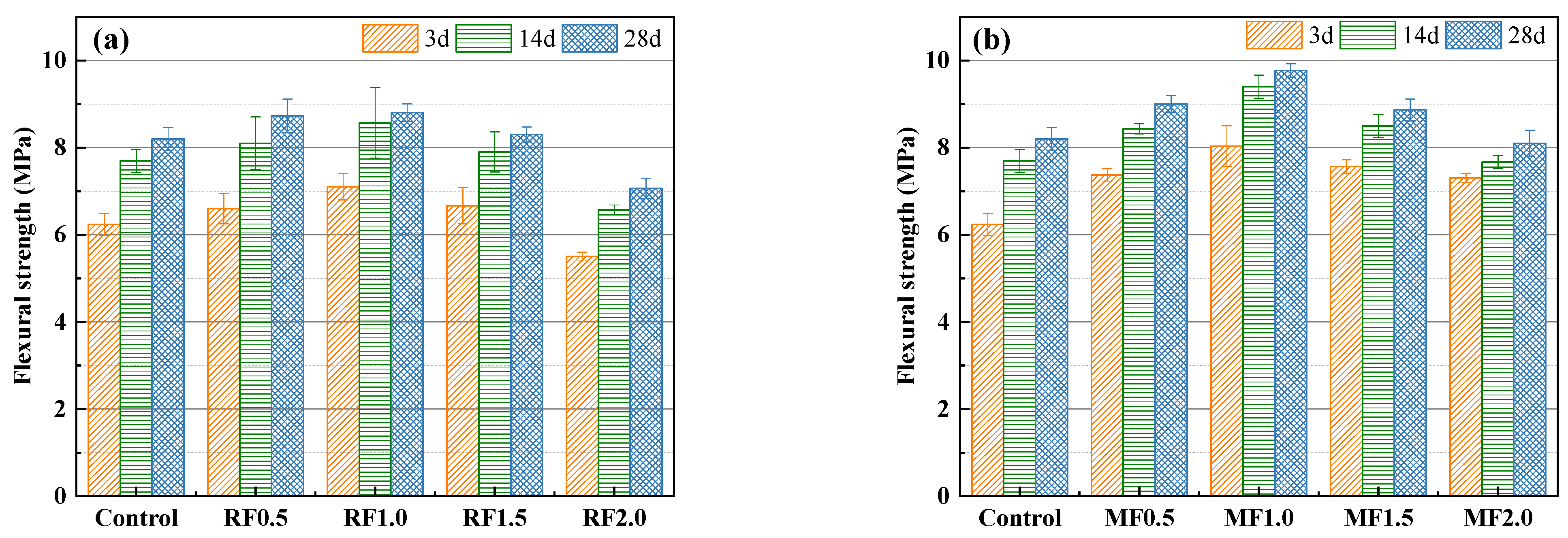

3.6.1. Flexural Strength

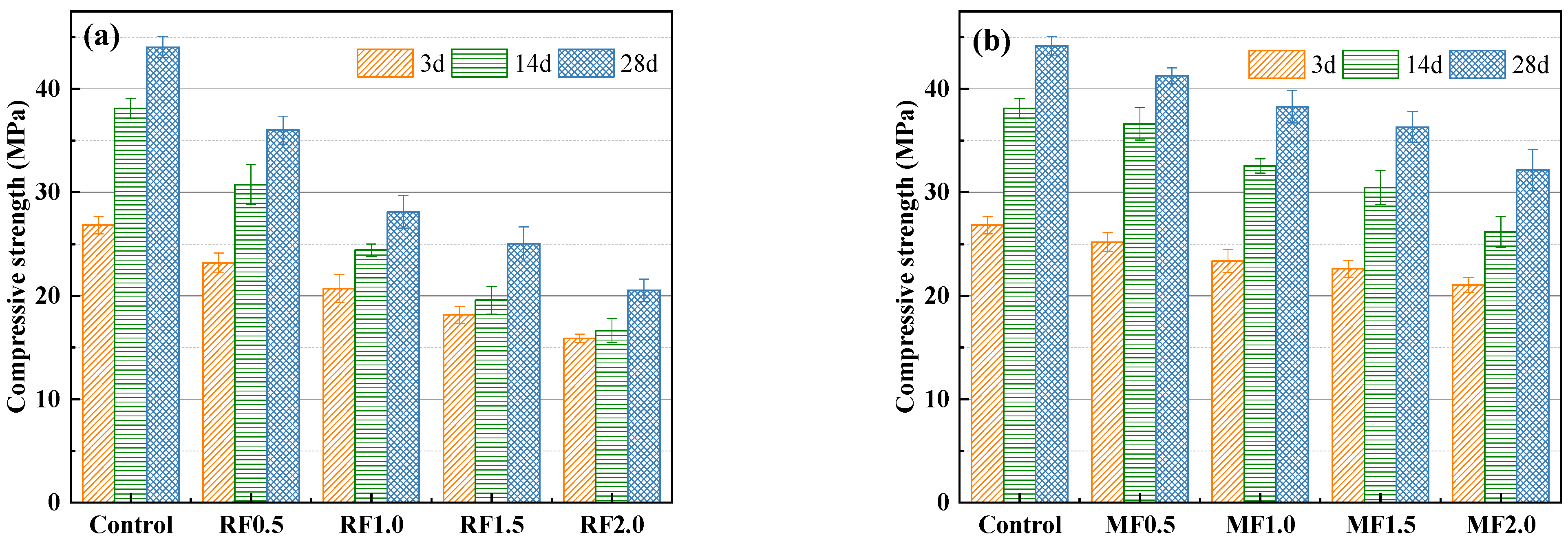

3.6.2. Compressive Strength

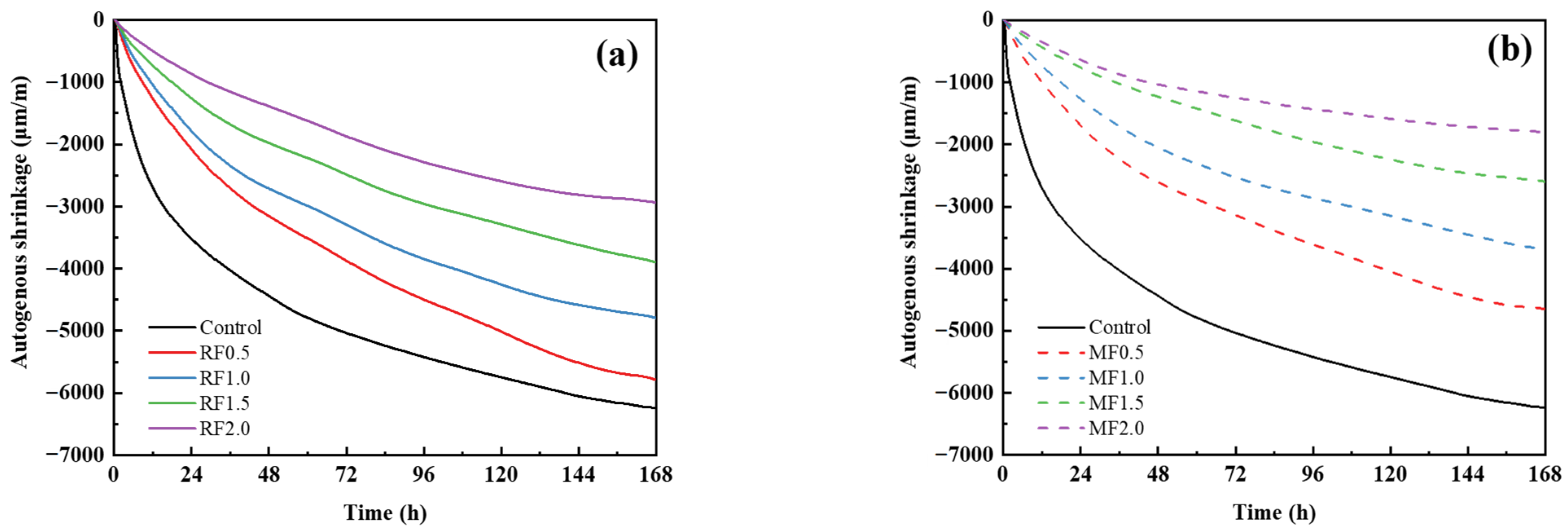

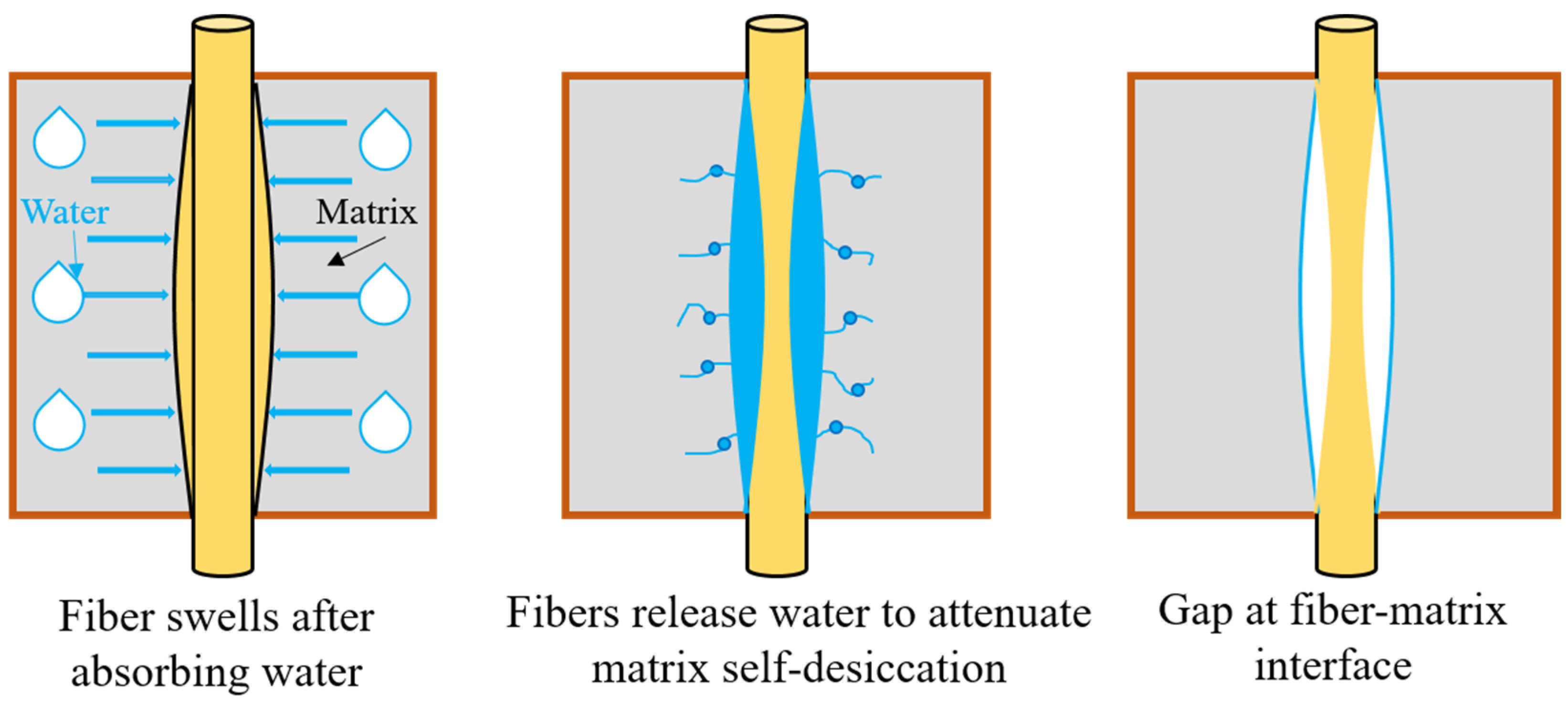

3.7. Autogenous Shrinkage of AAS Paste

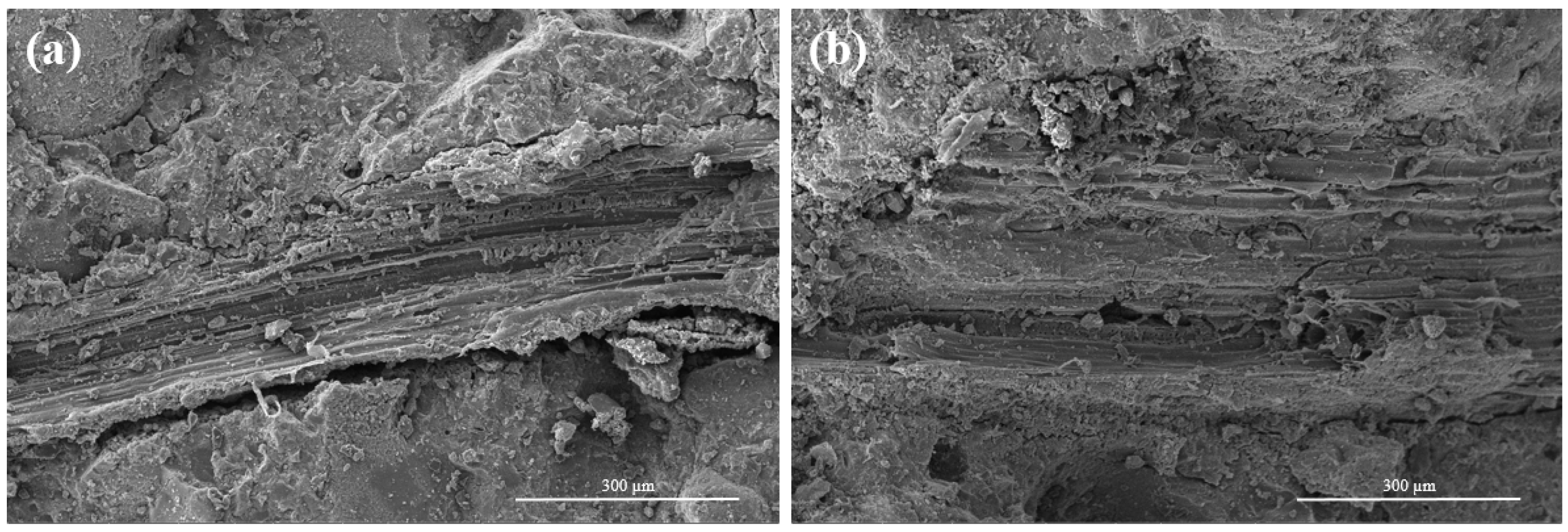

3.8. Morphological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Puertas, F.; García-Díaz, I.; Barba, A.; Gazulla, M.F.; Palacios, M.; Gómez, M.P.; Martínez-Ramírez, S. Ceramic wastes as alternative raw materials for Portland cement clinker production. Cem. Concr. Compos. 2008, 30, 798–805. [Google Scholar] [CrossRef]

- Sun, G.; Ye, G.; De Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, Z.; Shi, C.; Li, N.; Jiao, D.; Yuan, Q. Rheology of alkali-activated materials: A review. Cem. Concr. Compos. 2021, 121, 104061. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Shrinkage mechanisms of alkali-activated slag. Cem. Concr. Res. 2016, 88, 126–135. [Google Scholar] [CrossRef]

- de Azevedo, A.R.; Cruz, A.S.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Daironas, M. Natural fibers as an alternative to synthetic fibers in reinforcement of geopolymer matrices: A comparative review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef]

- Bellum, R.R. Influence of steel and PP fibers on mechanical and microstructural properties of fly ash-GGBFS based geopolymer composites. Ceram. Int. 2022, 48, 6808–6818. [Google Scholar] [CrossRef]

- Song, W.; Yi, J.; Wu, H.; He, X.; Song, Q.; Yin, J. Effect of carbon fiber on mechanical properties and dimensional stability of concrete incorporated with granulated-blast furnace slag. J. Clean. Prod. 2019, 238, 117819. [Google Scholar] [CrossRef]

- Sun, P.; Wu, H. Transition from brittle to ductile behavior of fly ash using PVA fibers. Cem. Concr. Compos. 2008, 30, 29–36. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R.K.; Raza, A.; Hussain, U.; Rahman, M.L.; Nazari, S.; Choteborsky, R. Natural cellulosic fiber reinforced concrete: Influence of fiber type and loading percentage on mechanical and water absorption performance. Materials 2022, 15, 874. [Google Scholar] [CrossRef]

- Seki, Y.; Selli, F.; Erdoğan, Ü.H.; Atagür, M.; Seydibeyoğlu, M.Ö. A review on alternative raw materials for sustainable production: Novel plant fibers. Cellulose 2022, 29, 4877–4918. [Google Scholar] [CrossRef]

- Brakat, A.; Zhang, Y. Shrinkage mitigation of alkali-activated slag with natural cellulose fibres. Adv. Cem. Res. 2019, 31, 47–57. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural fiber reinforced high calcium fly ash geopolymer mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Mechanical properties of carbon-nanotube-reinforced cementitious materials: Database and statistical analysis. Mag. Concr Res. 2020, 72, 1047–1071. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Z.; Zhang, T.; Zhou, L. Dispersion of carbon fibers in cement-based composites with different mixing methods. Constr. Build. Mater. 2017, 134, 220–227. [Google Scholar] [CrossRef]

- Vedrtnam, A.; Gunwant, D. Improving fatigue behavior of cow-dung fiber reinforced epoxy composite using waste glass powder. Mater. Res. Express 2019, 6, 105408. [Google Scholar] [CrossRef]

- Sharma, D.; Yadav, K.D.; Kumar, S. Role of sawdust and cow dung on compost maturity during rotary drum composting of flower waste. Bioresour. Technol. 2018, 264, 285–289. [Google Scholar] [CrossRef]

- Bamogo, H.; Ouedraogo, M.; Sanou, I.; Ouedraogo, K.M.J.; Dao, K.; Aubert, J.E.; Millogo, Y. Improvement of water resistance and thermal comfort of earth renders by cow dung: An ancestral practice of Burkina Faso. J. Cult. Herit. 2020, 46, 42–51. [Google Scholar] [CrossRef]

- Lwuozor, K.O.; Emenike, E.C.; Aniagor, C.O.; Iwuchukwu, F.U.; Ibitogbe, E.M.; Temitayo, O.B.; Adeniyi, A.G. Removal of pollutants from aqueous media using cow dung-based adsorbents. Curr. Res. Green. Sustain. Chem. 2022, 5, 100300. [Google Scholar]

- Fadmoro, O.F.; Kar, S.S.; Tiwari, D.; Singh, A. Environmental and economic impact of mixed cow dung and husk ashes in subgrade soil stabilization. Int. J. Pavement. Res. Technol. 2022, 15, 835–846. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, X. Pozzolanic activity of feedlot biomass (cattle manure) ash. Constr. Build. Mater. 2012, 28, 493–498. [Google Scholar] [CrossRef]

- Ramachandran, D.; Vishwakarma, V.; Viswanathan, K. Detailed studies of cow dung ash modified concrete exposed in fresh water. J. Build. Eng. 2018, 20, 173–178. [Google Scholar]

- Li, K.; Yang, Z.; Zhang, Y.; Li, Y.; Lu, L.; Niu, D. Effect of pretreated cow dung fiber on mechanical and shrinkage properties of cementitious composites. J. Clean. Prod. 2022, 348, 131374. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- John, V.M.; Cincotto, M.A.; Sjöström, C.; Agopyan, V.; Oliveira, C.T.A. Durability of slag mortar reinforced with coconut fibre. Cem. Concr. Compos. 2005, 27, 565–574. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Marvila, M.T.; Tayeh, B.A.; Cecchin, D.; Pereira, A.C.; Monteiro, S.N. Technological performance of açaí natural fibre reinforced cement-based mortars. J. Build. Eng. 2021, 33, 101675. [Google Scholar] [CrossRef]

- Fadele, O.; Oguocha, I.N.; Odeshi, A.G.; Soleimani, M.; Tabil, L.G. Effect of chemical treatments on properties of raffia palm (Raphia farinifera) fibers. Cellulose 2019, 26, 9463–9482. [Google Scholar] [CrossRef]

- Anand, P.B.; Lakshmikanthan, A.; Gowdru Chandrashekarappa, M.P.; Selvan, C.P.; Pimenov, D.Y.; Giasin, K. Experimental investigation of effect of fiber length on mechanical, wear, and morphological behavior of silane-treated pineapple leaf fiber reinforced polymer composites. Fibers 2022, 10, 56. [Google Scholar] [CrossRef]

- Shang, X.; Yang, J.; Song, Q.; Wang, L. Efficacy of modified rice straw fibre on properties of cementitious composites. J. Clean. Prod. 2020, 276, 124184. [Google Scholar] [CrossRef]

- Malenab, R.A.J.; Ngo, J.P.S.; Promentilla, M.A.B. Chemical treatment of waste abaca for natural fiber-reinforced geopolymer composite. Materials 2017, 10, 579. [Google Scholar] [CrossRef] [PubMed]

- Camargo, M.M.; Adefrs Taye, E.; Roether, J.A.; Tilahun Redda, D.; Boccaccini, A.R. A review on natural fiber-reinforced geopolymer and cement-based composites. Materials 2020, 13, 4603. [Google Scholar] [CrossRef] [PubMed]

- Vinod, A.; Gowda, T.G.Y.; Vijay, R.; Sanjay, M.R.; Gupta, M.K.; Jamil, M.; Kushvaha, V.; Siengchin, S. Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: A sustainable and green material for cleaner production. J. Clean. Prod. 2021, 294, 126337. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Ren, M.; Gao, X. Utilization of natural sisal fibers to manufacture eco-friendly ultra-high performance concrete with low autogenous shrinkage. J. Clean. Prod. 2022, 332, 130105. [Google Scholar] [CrossRef]

- Yang, Y. Methods study on dispersion of fibers in CFRC. Cem. Concr. Res. 2002, 32, 747–750. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Modeling the mechanical properties of cementitious materials containing CNTs. Cem. Concr. Compos. 2019, 104, 103347. [Google Scholar] [CrossRef]

- Bordelon, A.C.; Roesler, J.R. Spatial distribution of synthetic fibers in concrete with X-ray computed tomography. Cem. Concr. Compos. 2014, 53, 35–43. [Google Scholar] [CrossRef]

- ASTM C1437-20; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C349-18; Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure). ASTM: West Conshohocken, PA, USA, 2018.

- ASTM C1698-19; Standard Test Methods for Autogenous Strain of Cement Paste and Mortar. ASTM: West Conshohocken, PA, USA, 2019.

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Qi, H. Tribological and physio-mechanical characterization of cow dung fibers reinforced friction composites: An effective utilization of cow dung waste. Tribol. Int. 2019, 131, 200–211. [Google Scholar] [CrossRef]

- Borchani, K.E.; Carrot, C.; Jaziri, M. Untreated and alkali treated fibers from Alfa stem: Effect of alkali treatment on structural, morphological and thermal features. Cellulose 2015, 22, 1577–1589. [Google Scholar] [CrossRef]

- Le Troëdec, M.; Dalmay, P.; Patapy, C.C.; Smith, A.; Chotard, T. Mechanical properties of hemp-lime reinforced mortars: Influence of the chemical treatment of fibers. J. Compos. Mater. 2011, 45, 2347–2357. [Google Scholar] [CrossRef]

- Li, Q.; Ibrahim, L.; Zhou, W.; Zhang, M.; Fernando, G.F.; Wang, L.; Yuan, Z. Holistic solution to natural fiber deterioration in cement composite using hybrid treatments. Cellulose 2020, 27, 981–989. [Google Scholar] [CrossRef]

- Sawsen, C.; Fouzia, K.; Mohamed, B.; Moussa, G. Effect of flax fibers treatments on the rheological and the mechanical behavior of a cement composite. Constr. Build. Mater. 2015, 79, 229–235. [Google Scholar] [CrossRef]

- Ren, G.; Yao, B.; Huang, H.; Gao, X. Influence of sisal fibers on the mechanical performance of ultra-high performance concretes. Constr. Build. Mater. 2021, 286, 122958. [Google Scholar] [CrossRef]

- Rahimi, M.; Hisseine, O.A.; Tagnit-Hamou, A. Effectiveness of treated flax fibers in improving the early age behavior of high-performance concrete. J. Build. Eng. 2022, 45, 103448. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Huang, L.; Kasal, B. Effect of alkali treatment on microstructure and mechanical properties of coir fibres, coir fibre reinforced-polymer composites and reinforced-cementitious composites. Constr. Build. Mater. 2016, 112, 168–182. [Google Scholar] [CrossRef]

- Li, Z.; Lu, T.; Liang, X.; Dong, H.; Ye, H. Mechanisms of autogenous shrinkage of alkali-activated slag and fly ash pastes. Cem. Concr. Res. 2020, 135, 106107. [Google Scholar] [CrossRef]

- Lee, G.W.; Choi, Y.C. Effect of abaca natural fiber on the setting behavior and autogenous shrinkage of cement composite. J. Build. Eng. 2022, 56, 104719. [Google Scholar] [CrossRef]

- Yin, V.; Jiang, Y.; He, H.; Ren, J.; Li, Z. Characterization of one-part alkali-activated slag with rice straw ash. Constr. Build. Mater. 2022, 345, 128403. [Google Scholar] [CrossRef]

- Jo, B.W.; Chakraborty, S. A mild alkali treated jute fibre controlling the hydration behaviour of greener cement paste. Sci. Rep. 2015, 5, 7837. [Google Scholar] [CrossRef] [PubMed]

- Bilba, K.; Arsène, M.A.; Ouensanga, A. Sugar cane bagasse fibre reinforced cement composites. Part I. Influence of the botanical components of bagasse on the setting of bagasse/cement composite. Cem. Concr. Compos. 2003, 25, 91–96. [Google Scholar] [CrossRef]

- Guo, A.; Sun, Z.; Satyavolu, J. Impact of modified kenaf fibers on shrinkage and cracking of cement pastes. Constr. Build. Mater. 2020, 264, 120230. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

| Materials | Chemical Composition (wt%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 | TiO2 | LoI * | |

| Slag | 47.00 | 21.90 | 13.00 | 0.74 | 8.07 | 0.33 | 0.36 | 2.50 | 0.89 | 2.28 |

| Properties | Cow Dung Fiber |

|---|---|

| Density (g/cm3) | 1.37 |

| Length (mm) | 0.075–10 |

| Average diameter (μm) | 220.54 |

| Tensile strength (MPa) | 64.24 |

| Sample | Slag (kg/m3) | Sand (kg/m3) | NaOH (kg/m3) | Water (kg/m3) | PCS (kg/m3) | Cow Dung Fiber | |

|---|---|---|---|---|---|---|---|

| Content (% of Binder Weight) | Type | ||||||

| Control | 558.1 | 1758 | 27.9 | 293 | 0.88 | - | - |

| RF0.5 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 0.5 | Raw |

| RF1.0 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 1.0 | Raw |

| RF1.5 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 1.5 | Raw |

| RF2.0 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 2.0 | Raw |

| MF0.5 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 0.5 | Modified |

| MF1.0 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 1.0 | Modified |

| MF1.5 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 1.5 | Modified |

| MF2.0 | 558.1 | 1758 | 27.9 | 293 | 0.88 | 2.0 | Modified |

| Cow Dung Fibers | Iam (2θ = 18.24) | I200 (2θ = 22.40) | CI (%) |

|---|---|---|---|

| Raw | 657 | 1240 | 47.0 |

| Modified | 623 | 1764 | 64.7 |

| Number | S | φ | β | |

|---|---|---|---|---|

| Pm1 | 7 | 2.66 | 0.38 | 0.68 |

| Pm2 | 7 | 2.65 | 0.38 | 0.68 |

| Pm3 | 6 | 2.18 | 0.36 | 0.70 |

| Am1 | 7 | 2.80 | 0.40 | 0.67 |

| Am2 | 7 | 3.13 | 0.45 | 0.64 |

| Am3 | 7 | 2.89 | 0.41 | 0.66 |

| Um1 | 7 | 2.13 | 0.30 | 0.74 |

| Um2 | 7 | 1.92 | 0.27 | 0.76 |

| Um3 | 7 | 1.95 | 0.28 | 0.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Yang, Z.; Yan, X.; Xu, L.; Briseghella, B.; Marano, G.C. Effect of Modified Cow Dung Fibers on Strength and Autogenous Shrinkage of Alkali-Activated Slag Mortar. Materials 2023, 16, 6808. https://doi.org/10.3390/ma16206808

Li K, Yang Z, Yan X, Xu L, Briseghella B, Marano GC. Effect of Modified Cow Dung Fibers on Strength and Autogenous Shrinkage of Alkali-Activated Slag Mortar. Materials. 2023; 16(20):6808. https://doi.org/10.3390/ma16206808

Chicago/Turabian StyleLi, Kang, Zhengxian Yang, Xueyuan Yan, Liying Xu, Bruno Briseghella, and Giuseppe Carlo Marano. 2023. "Effect of Modified Cow Dung Fibers on Strength and Autogenous Shrinkage of Alkali-Activated Slag Mortar" Materials 16, no. 20: 6808. https://doi.org/10.3390/ma16206808

APA StyleLi, K., Yang, Z., Yan, X., Xu, L., Briseghella, B., & Marano, G. C. (2023). Effect of Modified Cow Dung Fibers on Strength and Autogenous Shrinkage of Alkali-Activated Slag Mortar. Materials, 16(20), 6808. https://doi.org/10.3390/ma16206808