The Dissolution Behavior of Feldspar Minerals in Various Low-Molecular-Weight Organic Acids

Abstract

:1. Introduction

2. Materials and Methods

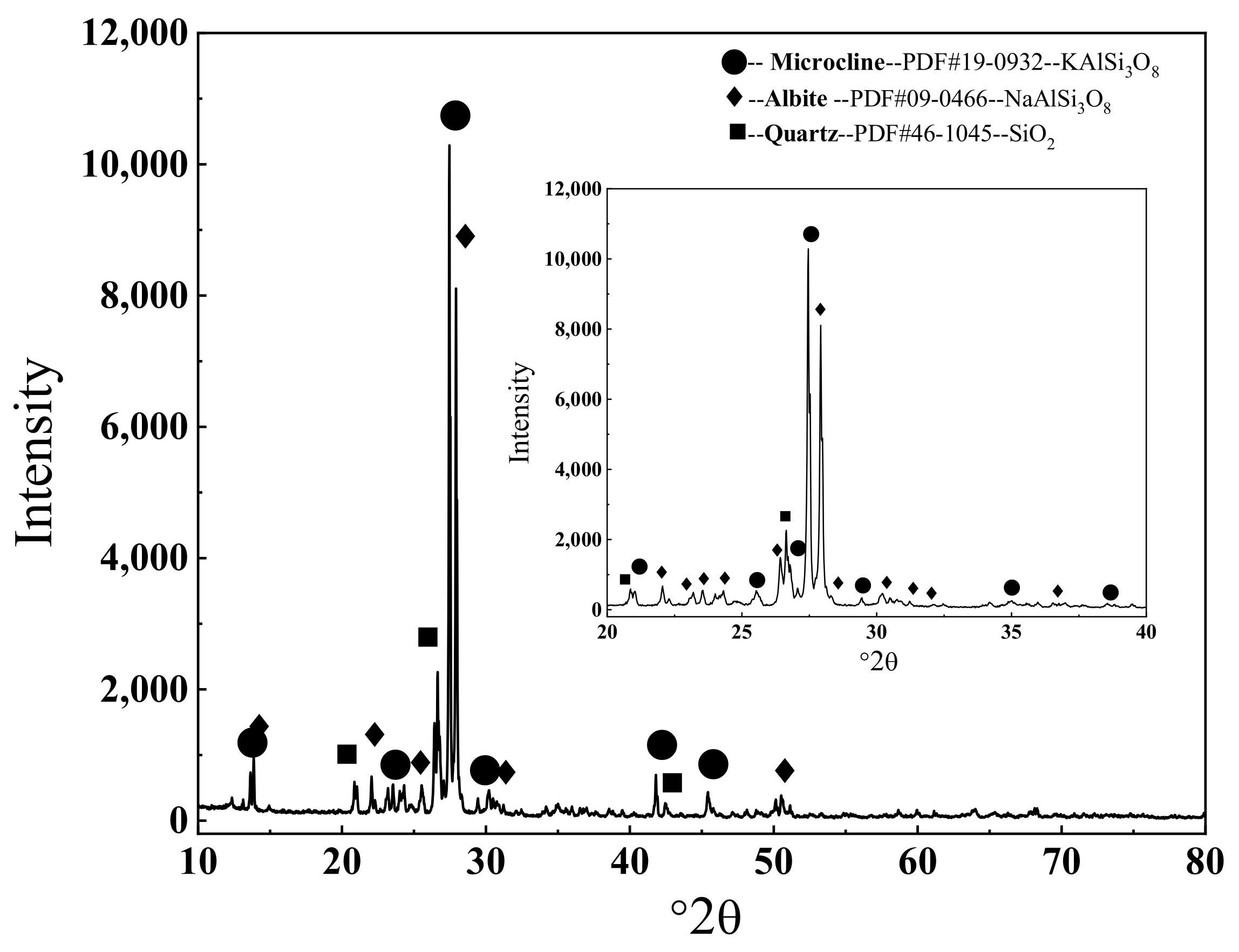

2.1. Materials

2.2. Experimental Procedure

2.3. Characterization of the Sample

3. Results and Discussion

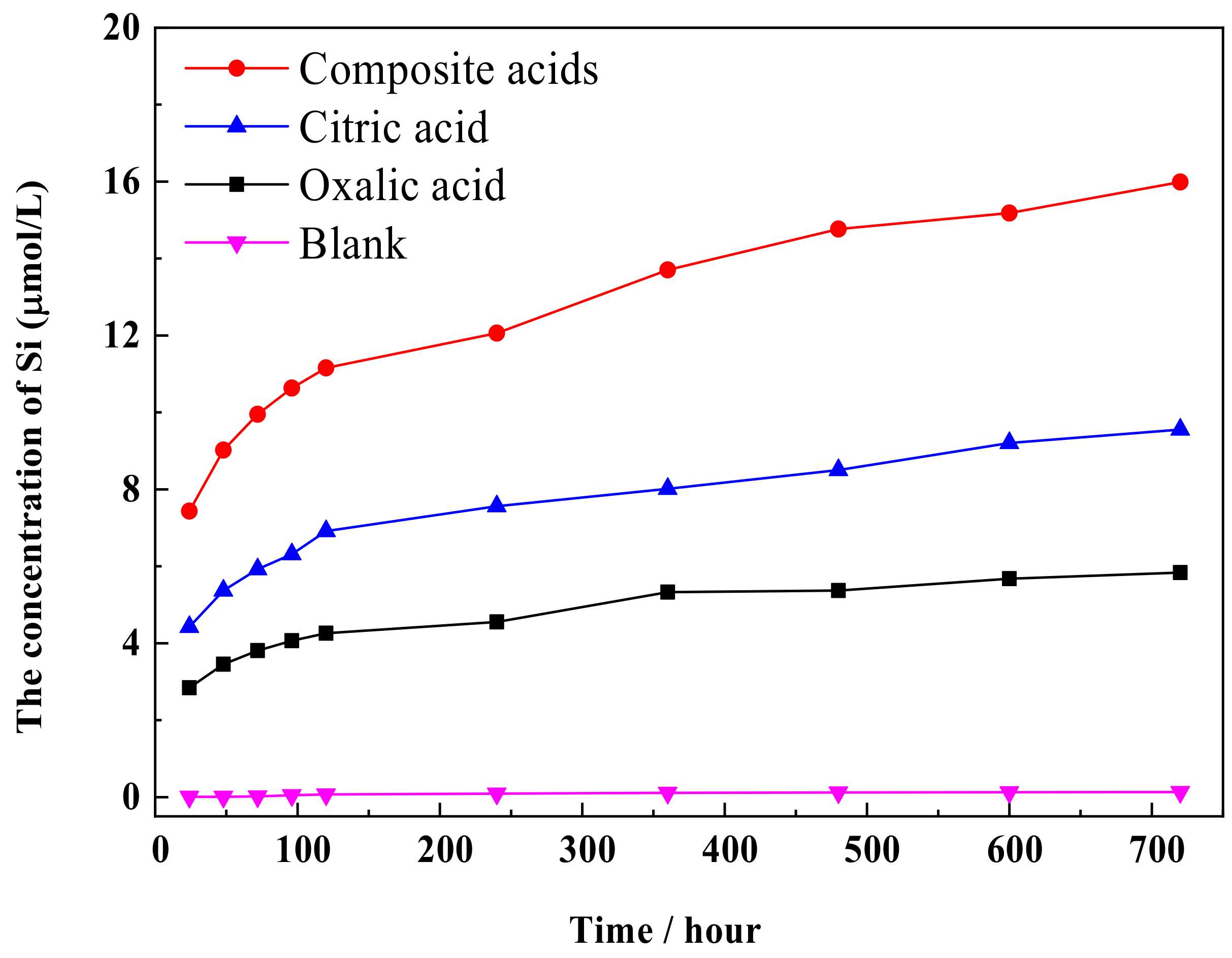

3.1. The Dissolution Kinetics of Al and Si from Alkali Feldspar in LMWOAs

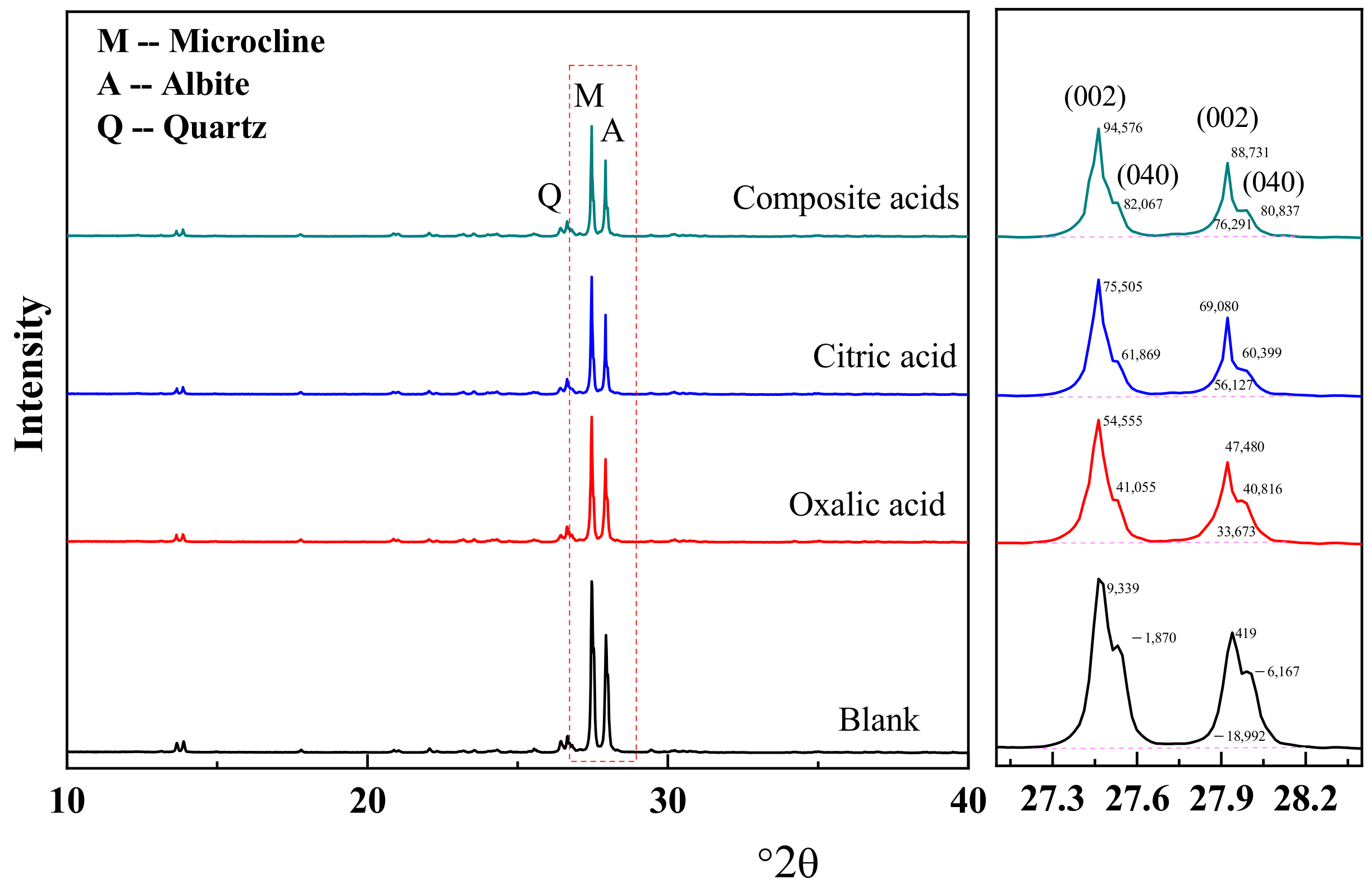

3.2. The Changes of Alkali Feldspar after Treatment with LWMOAs

- (1)

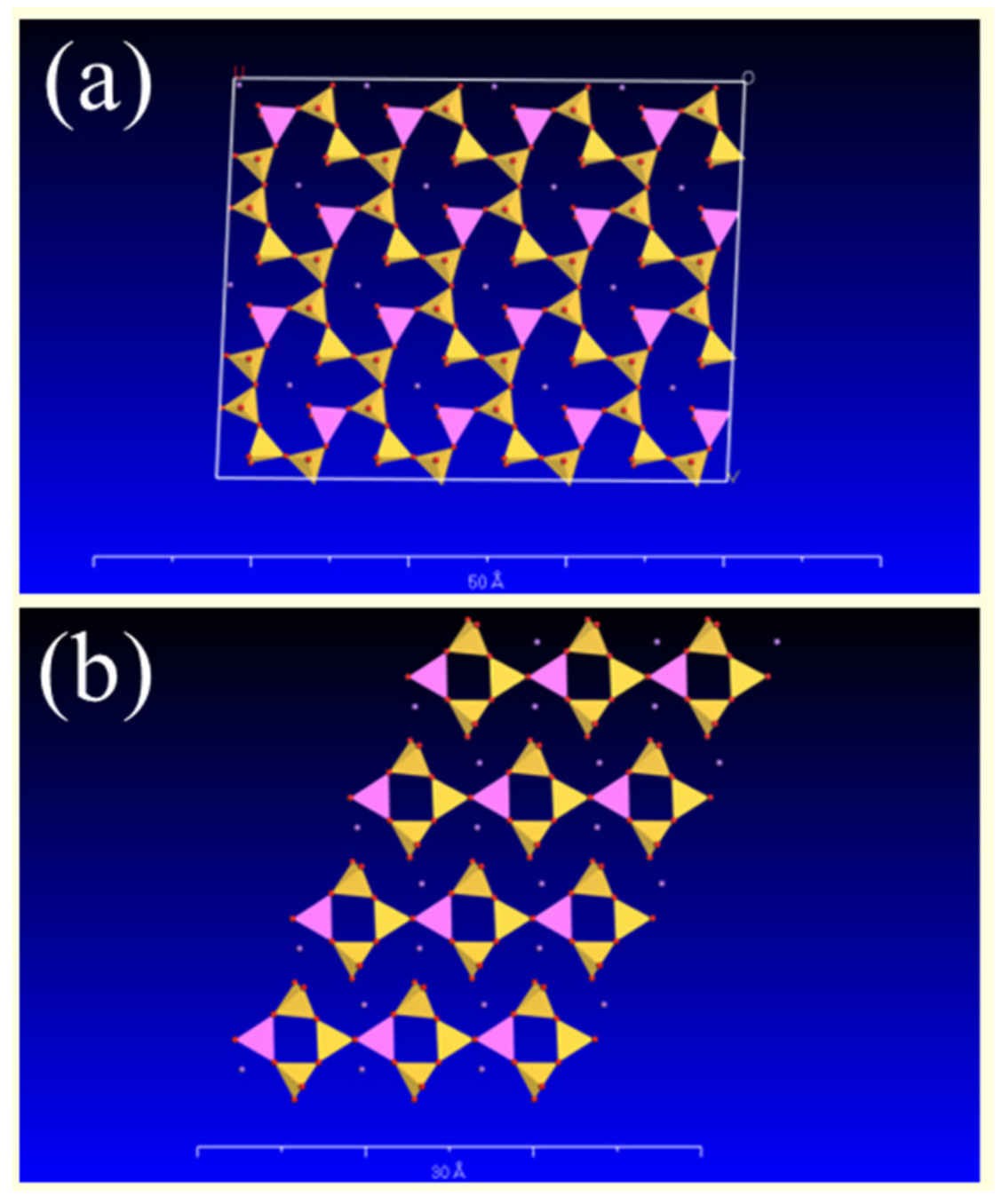

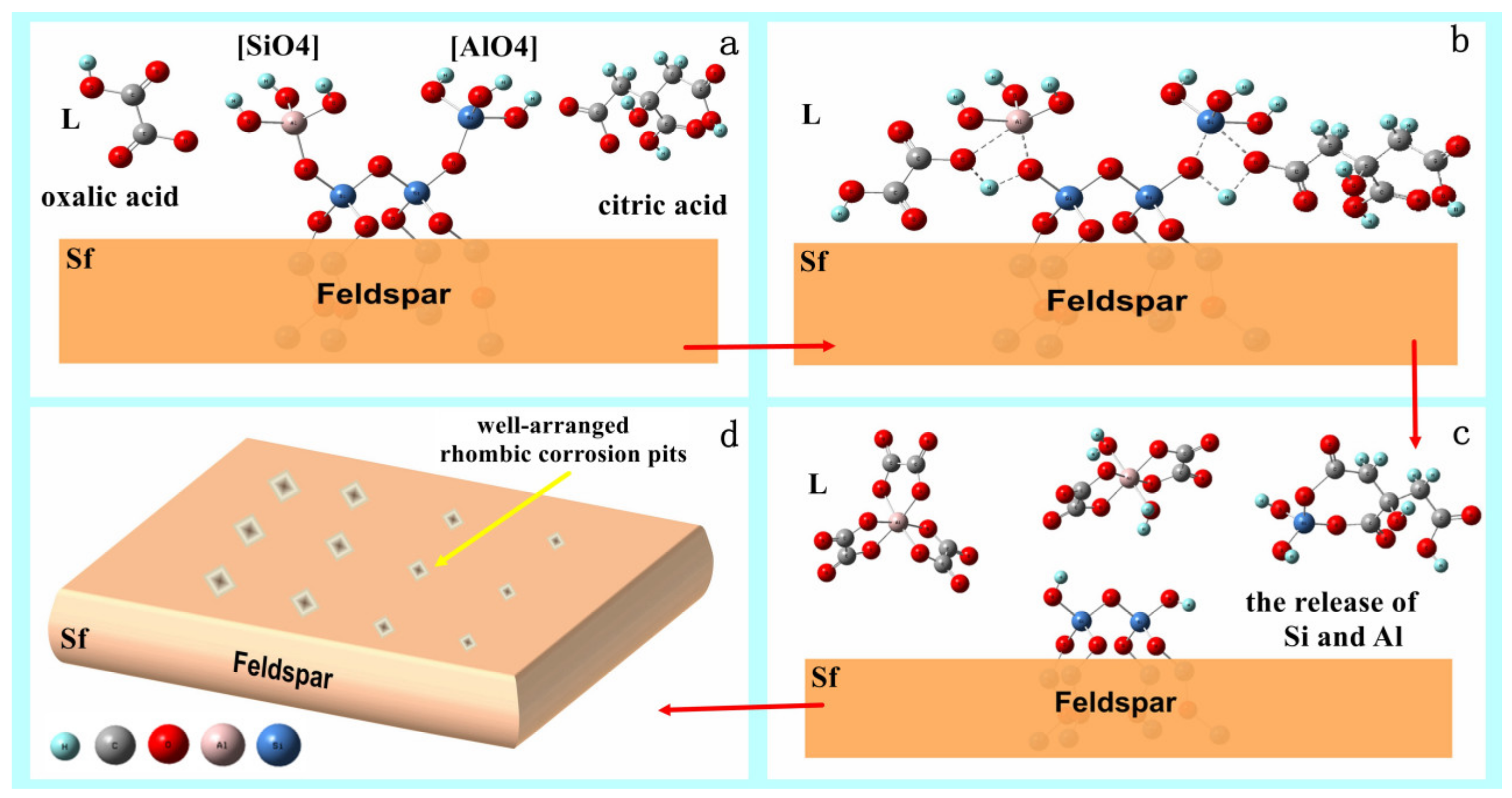

- At the beginning of the reaction, the organic acid ionizes in the aqueous solution, producing hydrogen ions and carboxylate organic acid anions (R-COO-) (Figure 10a). These ions then diffuse and adsorb to the Si and Al sites on the feldspar surface (Figure 10b), forming surface complexes denoted as Sf-Si (Al) -Lx (Sf represents the mineral solid phase, L represents the organic acid molecule, and x represents the number of organic acid molecules adsorbed to the same Si (Al) site).

- (2)

- At the solid-liquid interface, the organic acid molecules polarize the Si(Al) in the adsorption site, causing a rearrangement of the Si(Al)-O bond electron cloud, leading to elongation and breakage of the Si(Al)-O bond (Figure 10c).

- (3)

- The dissolution process is influenced by the variable density of Si and Al arrangement in the individual crystal faces of feldspar, as well as by the selective orientation of citric acid and oxalic acid to dissolve Si and Al. As a result, the (040) faces of microline and albite in feldspar are preferentially dissolved under the influence of the organic acids, followed by (002).

- (4)

- The synergistic effect of the composite acids leads to the rapid formation of well-arranged rhombic corrosion pits on the feldspar surface (Figure 10d). These corrosion pits increase in number with reaction time, resulting in an increase in the specific surface area of the feldspar.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, M.; Wu, F. A review of environmental characteristics and effects of low-molecular-weight organic acids in the surface ecosystem. J. Environ. Sci. 2014, 26, 935–954. [Google Scholar] [CrossRef] [PubMed]

- Lawrence, C.; Harden, J.; Maher, K. Modeling the influence of organic acids on soil weathering. Geochim. Cosmochim. Acta 2014, 139, 487–507. [Google Scholar] [CrossRef]

- Julien, A.A. The effect of organic acids on mineral dissolution rates and stoichiometry. Proc. Am. Assoc. Adv. Sci. 1897, 28, 311–344. [Google Scholar]

- Sprengel, G.K. The role of organic acids on mineral dissolution. Soil Sci. 1926, 8, 145–151. [Google Scholar]

- Keller, W.D.; Huang, W.D. Dissolution of rock-forming silicate minerals in organic acids; simulated first-stage weathering of fresh mineral surfaces. Am. Mineral. 1970, 55, 2076–2094. [Google Scholar]

- Drever, J.I.; Stillings, L.L. The role of organic acids in mineral weathering. Colloids Surf. A Physicochem. Eng. Asp. 1997, 120, 167–181. [Google Scholar] [CrossRef]

- Sun, C.; Yao, Z.; Wang, Q.; Guo, L.; Shen, X. Theoretical study on the organic acid promoted dissolution mechanism of forsterite mineral. Appl. Surf. Sci. 2023, 614, 156063. [Google Scholar] [CrossRef]

- Welch, S.A.; Ullman, W.J. Feldspar dissolution in acidic and organic solutions: Composition and pH dependence of dissolution rate. Geochim. Cosmochim. Acta 1996, 60, 2939–2948. [Google Scholar] [CrossRef]

- Schott, E.H.; Oelkers, J. Does organic acid adsorption affect alkali-feldspar dissolution rate. Chem. Geol. 1998, 151, 235–245. [Google Scholar]

- Blake, R.E.; Walter, L.M. Kinetics of feldspar and quartz dissolution at 70–80 °C and near-neutral pH: Effect of organic acids and NaCl. Geochim. Cosmochim. Acta 1999, 63, 2043–2059. [Google Scholar] [CrossRef]

- Huertas, F.J.; Chou, L.; Wollast, R. Mechanism of kaolinite dissolution at room temperature and pressure Part II: Kinetic study. Geochim. Cosmochim. Acta 1999, 63, 3261–3275. [Google Scholar] [CrossRef]

- Blake, R.E.; Walter, L.M. Effects of organic acids on the dissolution of orthoclase at 80 °C and pH 6. Chem. Geol. 1996, 132, 91–102. [Google Scholar] [CrossRef]

- Stilling, L.L.; Drever, J.I.; Brantley, S.L.; Sun, Y.; Oxburgh, R. Rates of feldspar dissolution at pH 3–7 with 0–8 mM oxalic acid. Chem. Geol. 1996, 132, 79–89. [Google Scholar] [CrossRef]

- Cama, J.; Ganor, J. The effects of organic acids on the dissolution of silicate minerals: A case study of oxalate catalysis of kaolinite dissolution. Geochim. Cosmochim. Acta 2006, 70, 2191–2209. [Google Scholar] [CrossRef]

- Hu, H.; Liu, S.; Jie, X.; Li, Y.; Wang, X.; Li, C. The role of low molecular weight organic acids on mineral dissolution. Chin. Agric. Sci. Bull. 2005, 21, 104–109. [Google Scholar]

- Kong, M.; Huang, L.; Li, L.; Zhang, Z.; Zheng, S.; Wang, M.K. Effects of oxalic and citric acids on three clay minerals after incubation. Appl. Clay Sci. 2014, 99, 207–214. [Google Scholar] [CrossRef]

- Castillo, L.A.; Barbosa, S.E.; Maiza, P.; Capiati, N.J. Surface modifications of talcs: Effects of inorganic and organic acid treatments. J. Mater. Sci. 2011, 46, 2578–2586. [Google Scholar] [CrossRef]

- Poulson, S.R.; Drever, J.I.; Stilling, L.L. Aqueous Si-oxalate complexing, oxalate adsorption onto quartz, and the effect of oxalate upon quartz dissolution rates. Chem. Geol. 1997, 140, 1–7. [Google Scholar] [CrossRef]

- Li, J.; Zhang, W.; Li, S.; Li, X.; Lu, J. Effects of citrate on the dissolution and transformation of biotite, analyzed by chemical and atomic force microscopy. Appl. Geochem. 2014, 51, 101–108. [Google Scholar] [CrossRef]

- Ramos, M.E.; Huertas, F.J. Adsorption of lactate and citrate on montmorillonite in aqueous solutions. Appl. Clay Sci. 2014, 90, 27–34. [Google Scholar] [CrossRef]

- Cawthray, G.R. An improved reversed-phase liquid chromatographic method for the analysis of low-molecular mass organic acids in plant root exudates. J. Chromatogr. A 2003, 1011, 233–240. [Google Scholar] [CrossRef] [PubMed]

- Meng, H.; Yan, Z.; Li, X. Effects of exogenous organic acids and flooding on root exudates, rhizosphere bacterial community structure, and iron plaque formation in Kandelia obovata seedlings. Sci. Total Environ. 2022, 830, 154695. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, X.; Zuo, W.; Li, S.; Sun, G.; Wang, W.; Yu, Y.; Huang, H. Root exuded low-molecular-weight organic acids affected the phenanthrene degrader differently: A multi-omics study. J. Hazar. Mater. 2021, 414, 125367. [Google Scholar] [CrossRef] [PubMed]

- Anithadevi, K.S.; Panneerselvan, L.; Robin, L.; Ravi, N.; Mallavarapu, M. The impact of low molecular weight organic acids from plants with C3 and C4 photosystems on the rhizoremediation of polycyclic aromatic hydrocarbons contaminated soil. Envir. Technol. Innov. 2020, 19, 100957. [Google Scholar]

- Rocha, C.S.; Almeida CM, R.; Basto MC, P.; Vasconcelos MT, S.D. Marsh plant response to metals: Exudation of aliphatic low molecular weight organic acids (ALMWOAs). Estuarine, Coast. Shelf Sci. 2016, 171, 77–84. [Google Scholar] [CrossRef]

- Welch, S.A.; Ullman, W.J. The effect of organic acids on plagioclase dissolution rates and stoichiometry. Geochim. Cosmochim. Acta 1993, 57, 2725–2736. [Google Scholar] [CrossRef]

- Zhou, L.L.; Guo, J.G.; Yang, N.H.; Li, L.Y. Solid-state nuclear magnetic spectrum and infrared spectral characteristics of various alkaline feldspar. Chin. Sci. Earth Sci. 1996, 6, 561–566. [Google Scholar]

- Zhang, M.; Salje, E.K.H.; Carpenter, M.A.; Parsons, I.; Kroll, H.; Reed, S.J.B.; Graeme-Barber, A. Exsolution and Al-Si disorder in alkali feldspars; their analysis by infrared spectroscopy. Am. Mineral. 1997, 82, 849–857. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | K2O | Na2O | Fe2O3 | CaO | TiO | Fe2O3 | LOI 1 |

|---|---|---|---|---|---|---|---|---|---|

| the minerals | 65.75 | 17.32 | 6.40 | 4.38 | 0.32 | 0.11 | 0.06 | 0.32 | 5.34 |

| The Solution | ||||||

|---|---|---|---|---|---|---|

| b | R2 | b | R2 | b | R2 | |

| Composite acid | 31.67 | 0.986 | 202.41 | 0.893 | 1.96 × 10−3 | 0.992 |

| Citric acid | 13.83 | 0.985 | 90.61 | 0.925 | 1.21 × 10−3 | 0.992 |

| Oxalic acid | 8.83 | 0.988 | 57.07 | 0.898 | 1.08 × 10−3 | 0.997 |

| Blank | 0.61 | 0.959 | 4.05 | 0.963 | 8.60 × 10−4 | 0.972 |

| The Solution | ||||||

|---|---|---|---|---|---|---|

| b | R2 | b | R2 | b | R2 | |

| Composite acid | 16.28 | 0.985 | 104.80 | 0.889 | 9.55 × 10−4 | 0.997 |

| Citric acid | 5.91 | 0.969 | 37.66 | 0.855 | 4.58 × 10−4 | 0.993 |

| Oxalic acid | 5.20 | 0.977 | 33.29 | 0.869 | 5.84 × 10−4 | 0.996 |

| Blank | 0.24 | 0.992 | 1.59 | 0.946 | 2.21 × 10−4 | 0.993 |

| Cystal | Raw Materials | Oxalic Acid | Citric Acid | Composite Organic Acids |

|---|---|---|---|---|

| Microcline | 1.65 | 2.83 | 3.37 | 3.66 |

| Albite | 1.51 | 2.08 | 3.03 | 3.39 |

| Treatment Time (h) | 0 | 72 | 120 | 240 | 720 |

|---|---|---|---|---|---|

| SSA (m2/g) | 1.91 | 2.38 | 2.57 | 2.83 | 3.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.-M.; Yu, Y.-L.; Zhong, M.-F.; Yang, H.; Zhang, C.-Y.; Zhang, Z.-J.; Wu, Y.-Y. The Dissolution Behavior of Feldspar Minerals in Various Low-Molecular-Weight Organic Acids. Materials 2023, 16, 6704. https://doi.org/10.3390/ma16206704

Lin S-M, Yu Y-L, Zhong M-F, Yang H, Zhang C-Y, Zhang Z-J, Wu Y-Y. The Dissolution Behavior of Feldspar Minerals in Various Low-Molecular-Weight Organic Acids. Materials. 2023; 16(20):6704. https://doi.org/10.3390/ma16206704

Chicago/Turabian StyleLin, Shao-Min, Ya-Ling Yu, Ming-Feng Zhong, Huan Yang, Chen-Yang Zhang, Zhi-Jie Zhang, and Yun-Ying Wu. 2023. "The Dissolution Behavior of Feldspar Minerals in Various Low-Molecular-Weight Organic Acids" Materials 16, no. 20: 6704. https://doi.org/10.3390/ma16206704

APA StyleLin, S.-M., Yu, Y.-L., Zhong, M.-F., Yang, H., Zhang, C.-Y., Zhang, Z.-J., & Wu, Y.-Y. (2023). The Dissolution Behavior of Feldspar Minerals in Various Low-Molecular-Weight Organic Acids. Materials, 16(20), 6704. https://doi.org/10.3390/ma16206704