Evaluation of Light Cementitious Matrix with Composite Textile Reinforcement from Garment Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Materials

2.2. Matrix Design

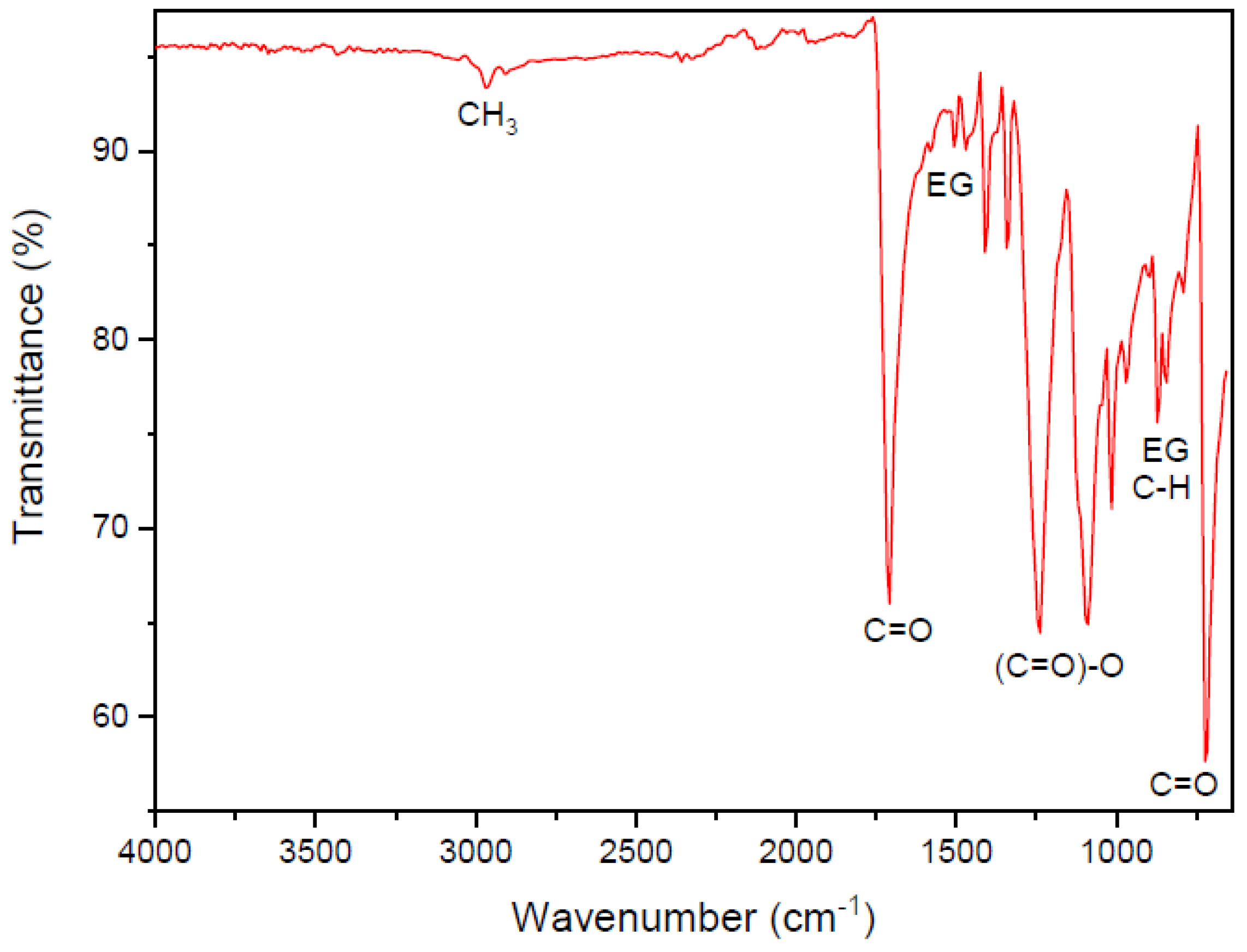

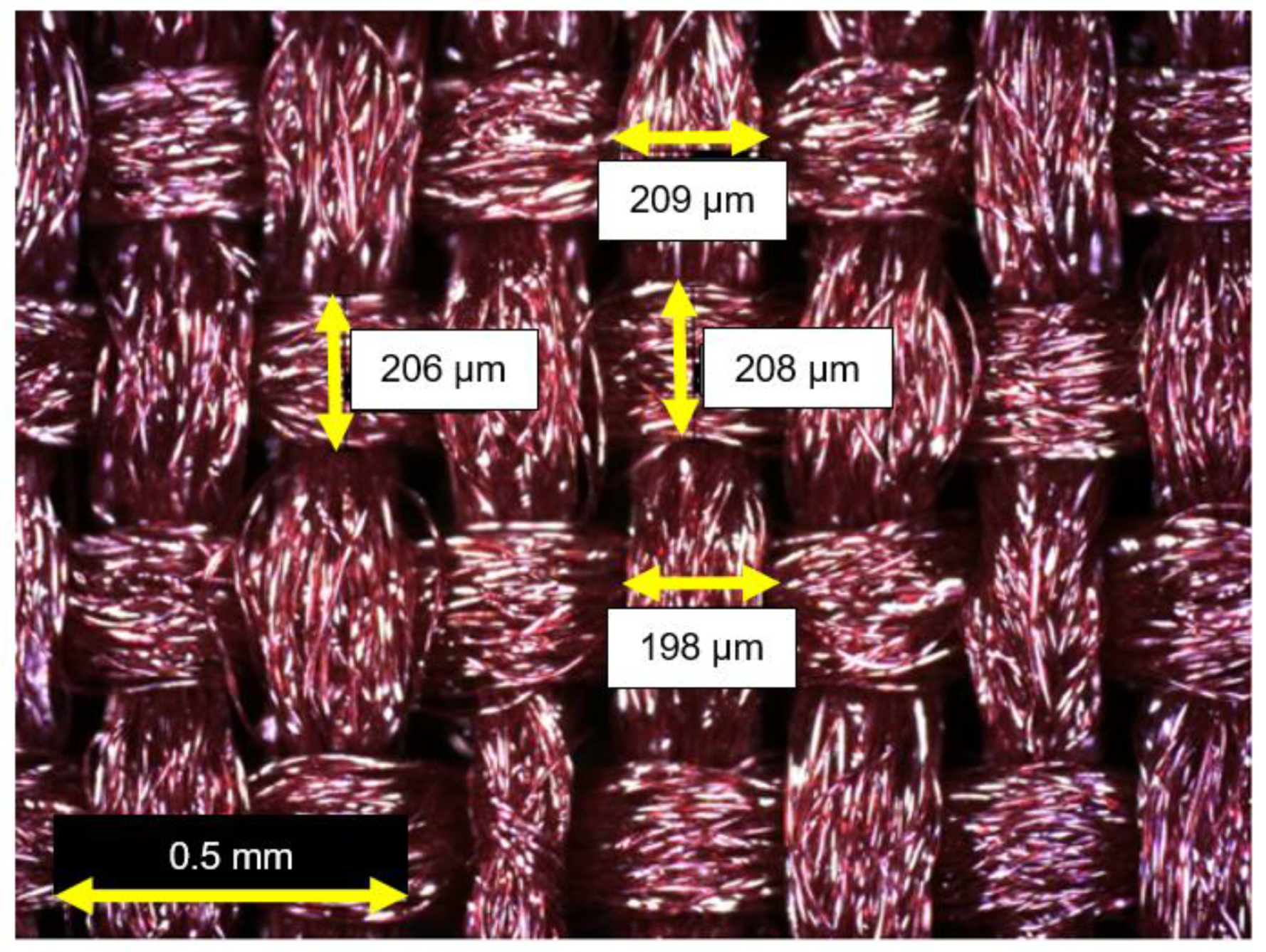

2.3. Polyester Textile Waste

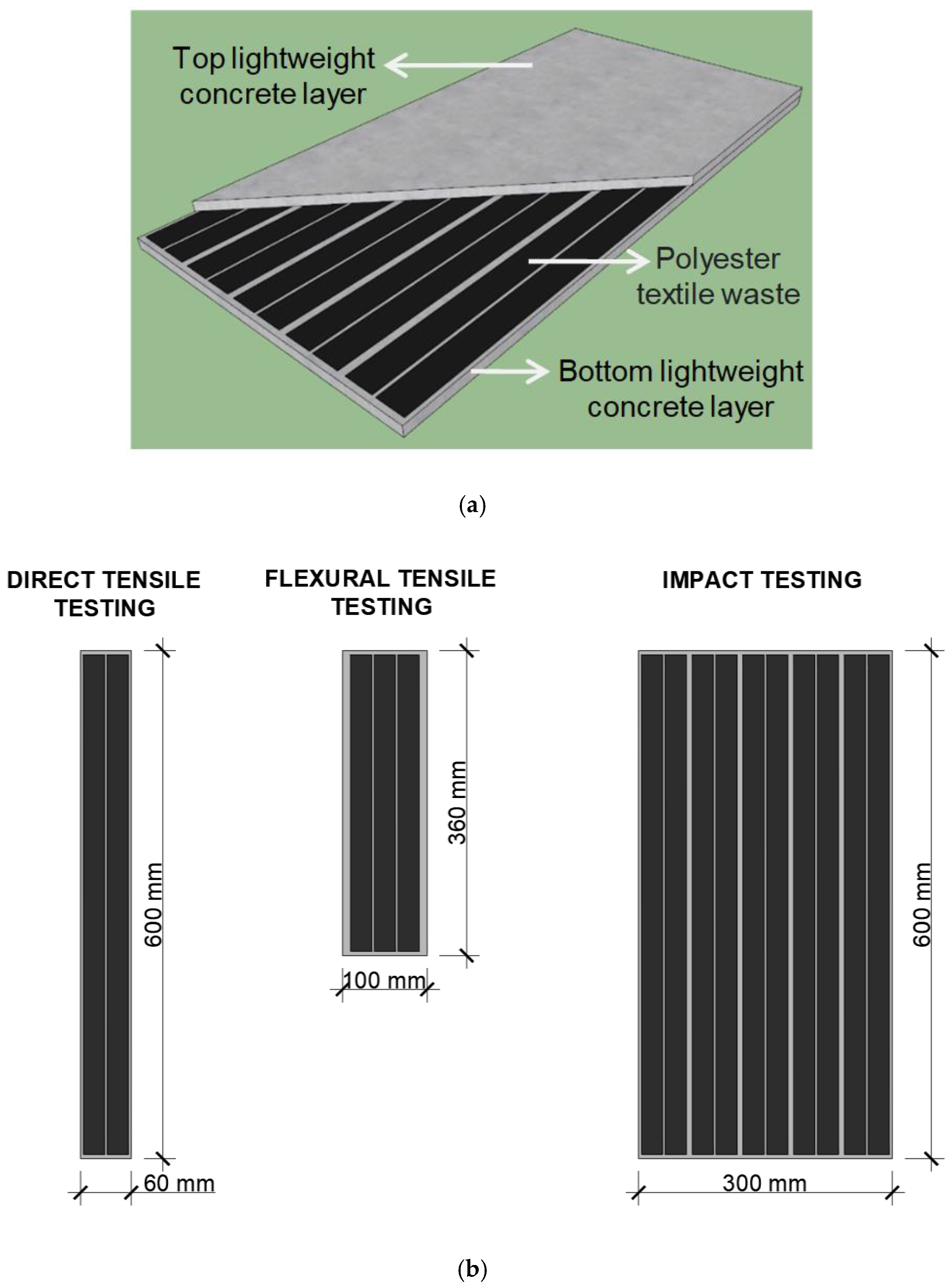

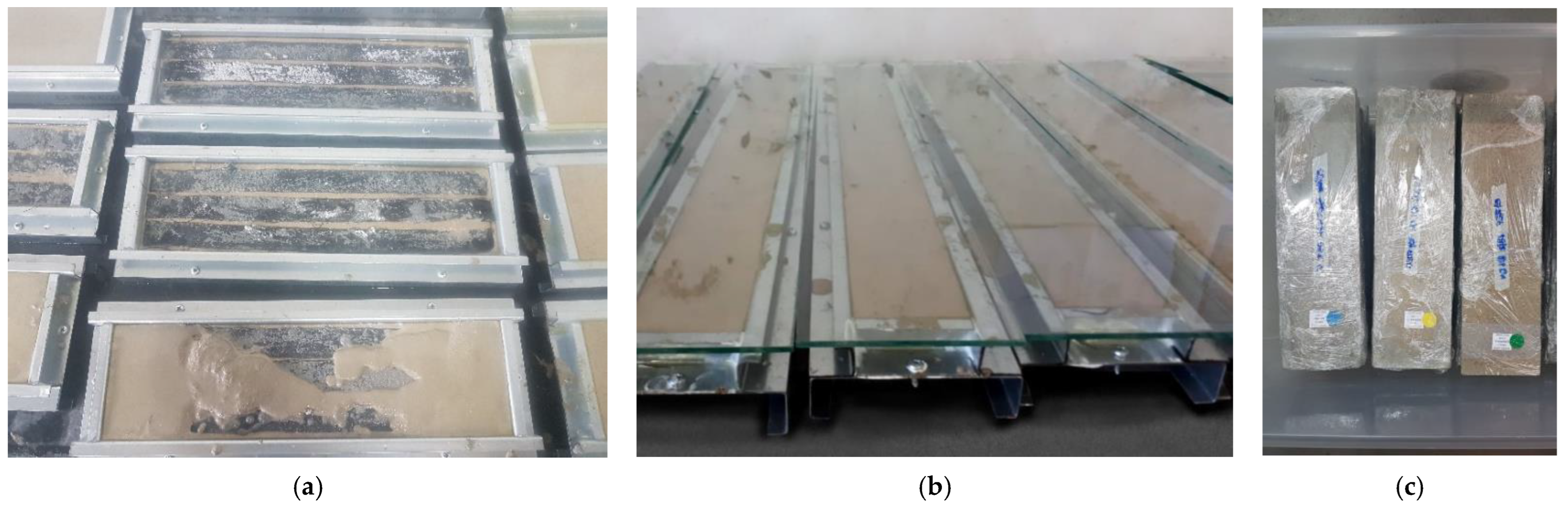

2.4. Composite Production and Analysis

3. Results and Discussion

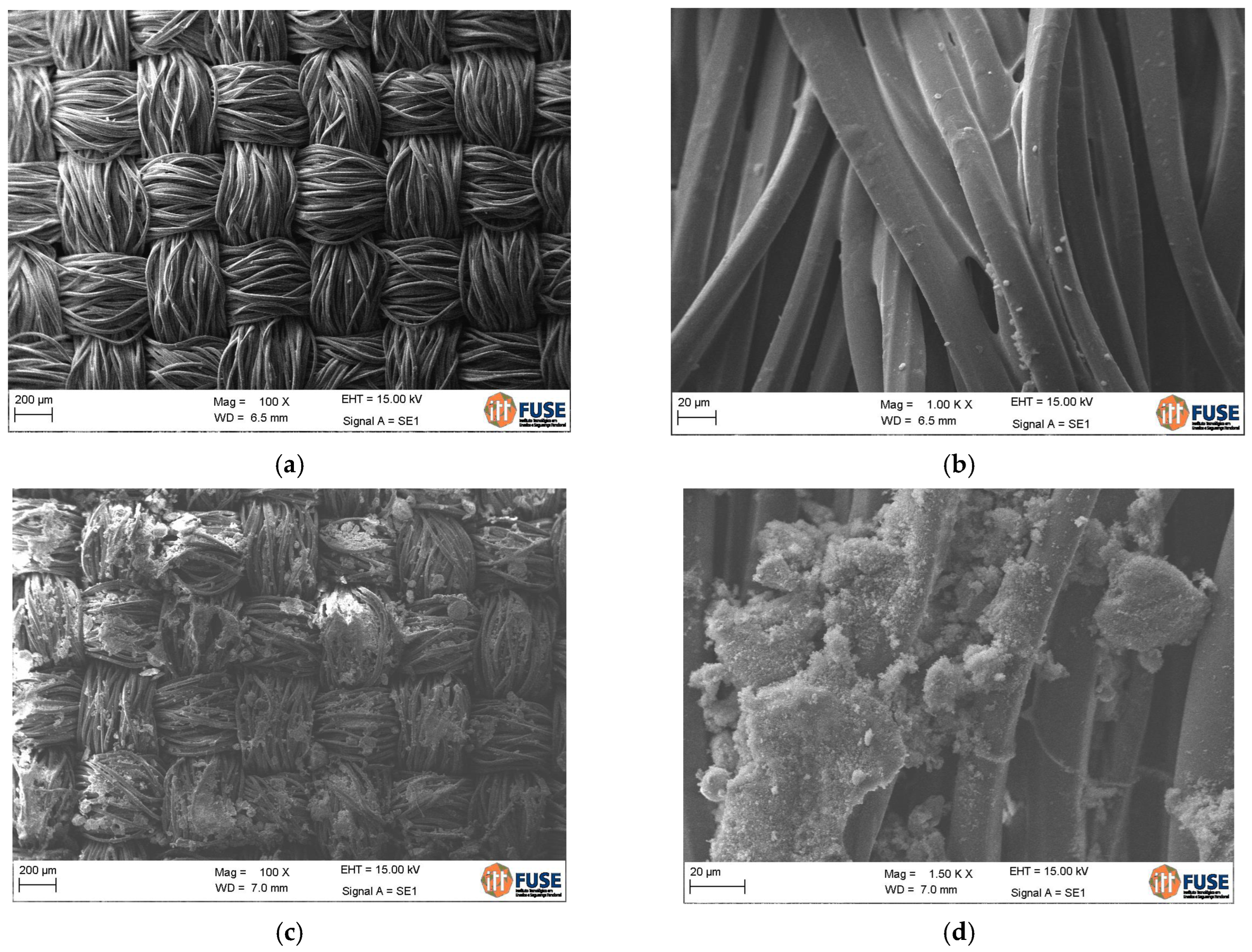

3.1. Textile Reinforcement Characterization

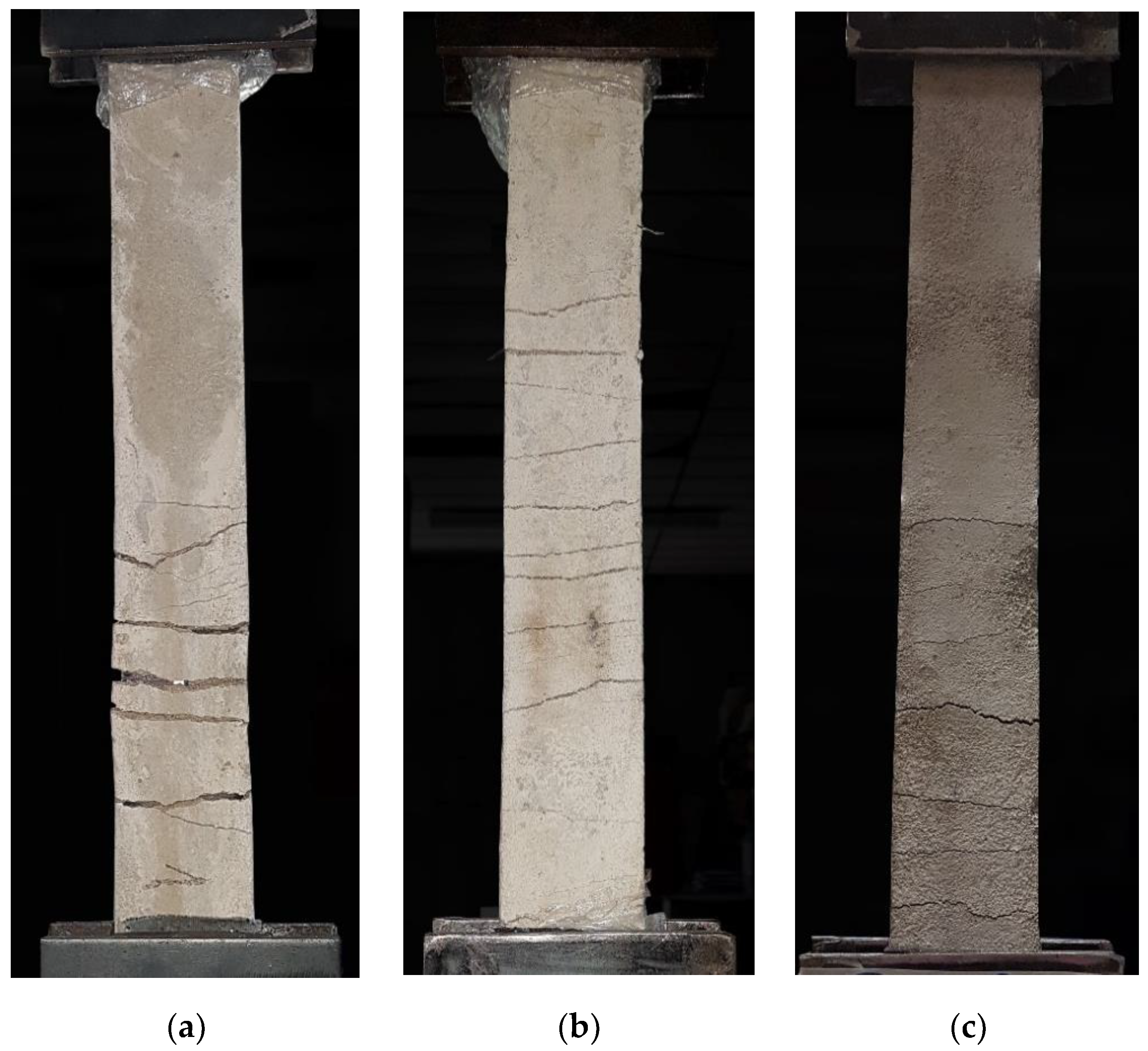

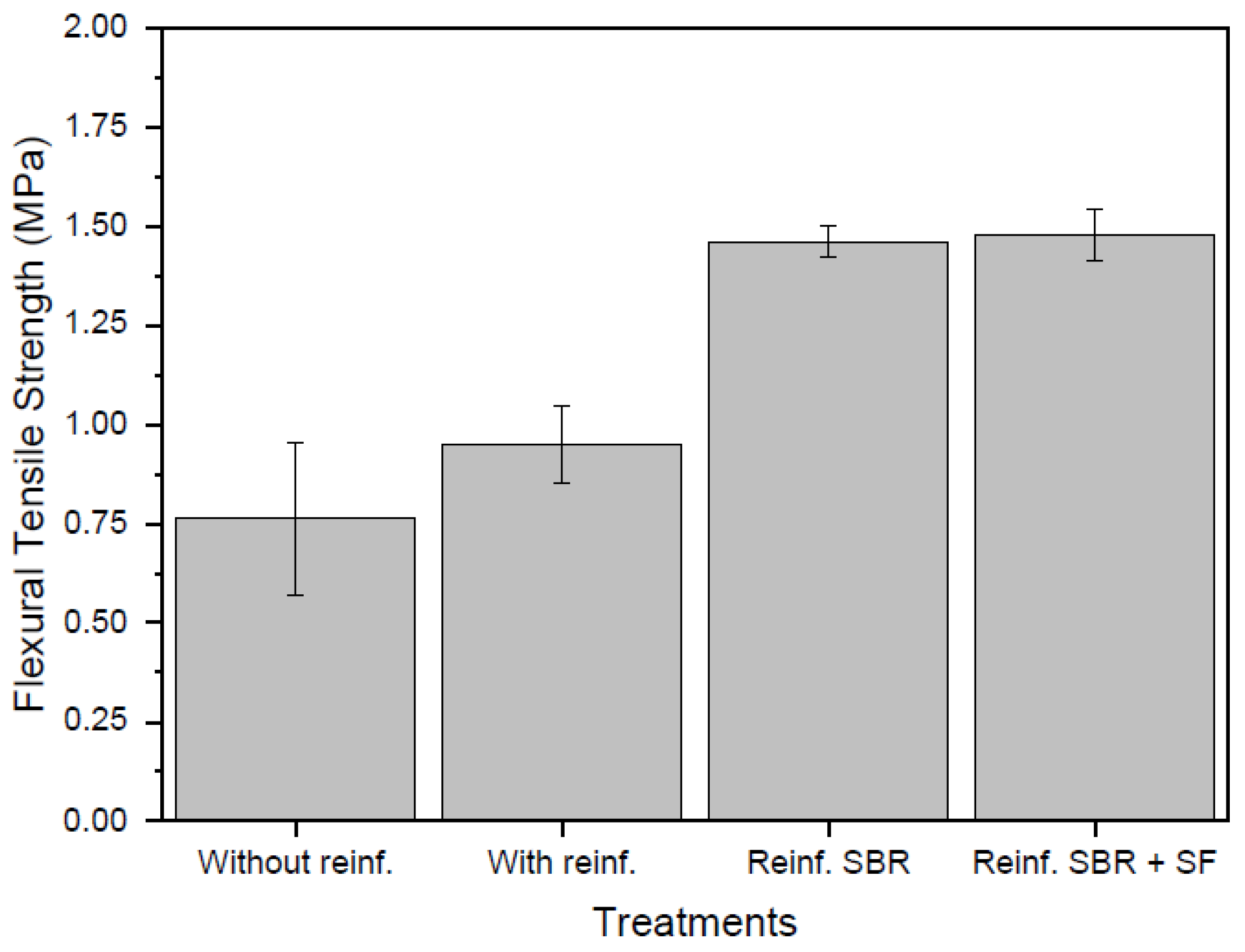

3.2. Analysis of the Composites

4. Conclusions

- The polyester used as reinforcement was a planar 2-D textile manufactured from two filaments weaved perpendicular to each other (0°/90°) with alternating over/under crossing.

- Maximum direct tensile strength of the isolated textile was within expected values for polyester. However, the high variability of results produced a caveat with respect to improvements in mechanical performance of both untreated and impregnated textiles.

- Average maximum stress in the warp direction had more satisfactory performance for both untreated and SBR impregnated textiles. In the case of SBR + SF impregnated textiles, the maximum stresses in the warp and weft directions were equivalent. This was considered to be a positive result which would allow the use of textile waste with difficult identification of weave direction.

- Characterization of the composites confirmed improvements with the use of impregnated textile reinforcement. Direct tensile tests demonstrated that the composite with SBR impregnated reinforcement had a larger number of cracks with smaller widths when compared to composites with untreated reinforcement. Measured maximum direct tensile stress increased up to 53.57% and 64.28% for composites with SBR and SBR + SF impregnated reinforcement, respectively, when compared to composites with no reinforcement.

- Flexural tensile strength presented increases of 92.10% and 94.73% for composites with SBR and SBR + SF impregnated reinforcement, respectively, when compared to unreinforced composites. Comparison of the same two impregnated reinforcement composites with untreated reinforced samples yielded increases in strength of 53.68% and 55.78%, respectively.

- Impact testing determined that, in general, reinforced composites had increased tenacity. In particular, the composite with reinforcement impregnated with SBR + SF presented the highest tenacity both with 2.5 J and 5.0 J impacts, which further confirmed the advantages of impregnated textiles.

- Microstructural analysis of the composites with impregnated reinforcement confirmed improved adhesiveness between the textile and the cementitious matrix. Impregnation strengthened the transition zone between the textile and cementitious matrix, thus increasing tenacity and resistance to fissuring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Year, T.F. The Fiber Year. Available online: https://thefiberyear.com/ (accessed on 14 January 2022).

- Exchange, T. Welcome to the 2020 Preferred Fiber & Materials Market Report. 103. 2020. Available online: https://textileexchange.org/app/uploads/2021/04/Textile-Exchange_Preferred-Fiber-Material-Market-Report_2020.pdf (accessed on 10 December 2022).

- Foundation, T.E.M. The Ellen Macarthur Foundation. Available online: www.ellenmacarthurfoundation.org/publications/a-new-textiles-economy-redesigning-fashions-future (accessed on 14 January 2022).

- Dissanayake, D.G.K.; Weerasinghe, D.U.; Wijesinghe, K.A.P.; Kalpage, K.M.D.M.P. Developing a compression moulded thermal insulation panel using postindustrial textile waste. Waste Manag. 2018, 79, 356–361. [Google Scholar] [CrossRef]

- Tomovska, E.; Jordeva, S.; Trajković, D.; Zafirova, K. Attitudes towards managing post-industrial apparel cuttings waste. J. Text. Inst. 2017, 108, 172–177. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Binici, H.; Eken, M.; Dolaz, M.; Aksogan, O.; Kara, M. An environmentally friendly thermal insulation material from sunflower stalk, textile waste and stubble fibres. Constr. Build. Mater. 2014, 51, 24–33. [Google Scholar] [CrossRef]

- Rubino, C.; Liuzzi, S.; Martellotta, F.; Stefanizzi, P. Textile wastes in building sector: A review. Model. Meas. Control B 2018, 87, 172–179. [Google Scholar] [CrossRef]

- Paiva, A.; Varum, H.; Caldeira, F.; Sá, A.; Nascimento, D.; Teixeira, N. Textile subwaste as a thermal insulation building material. ICPSD 2011 Int. Conf. Pet. Sustain. Dev. 2011, 26, 78–82. [Google Scholar]

- Tiuc, A.E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved Sound Absorption Properties of Polyurethane Foam Mixed with Textile Waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Lee, Y.; Joo, C. Sound absorption properties of recycled polyester fibrous assembly absorbers. Autex Res. J. 2003, 3, 78–84. [Google Scholar]

- Binici, H.; Aksogan, O. Engineering properties of insulation material made with cotton waste and fly ash. J. Mater. Cycles Waste Manag. 2015, 17, 157–162. [Google Scholar] [CrossRef]

- Rajput, D.; Bhagade, S.S.; Raut, S.P.; Ralegaonkar, R.V.; Mandavgane, S.A. Reuse of cotton and recycle paper mill waste as building material. Constr. Build. Mater. 2012, 34, 470–475. [Google Scholar] [CrossRef]

- Nakrani, H.M.; Nathani, B.B. Performance evaluation of textile reinforced concrete. Int. Res. J. Eng. Technol. 2016, 3, 2281–2284. [Google Scholar]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Mechanical and durability characterization of a new textile waste micro-fiber reinforced cement composite for building applications. Case Stud. Constr. Mater. 2021, 14, e00492. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.C.; Li, V.C. Concrete reinforcement with recycled fibers. J. Mater. Civ. Eng. 2000, 12, 314–319. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Claramunt, J.; Ventura, H.; Fernández-Carrasco, L.J.; Ardanuy, M. Tensile and flexural properties of cement composites reinforced with flax nonwoven fabrics. Materials 2017, 10, 215. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Mobasher, B.; Filho, R.D.T. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Zhu, D.; Mobasher, B.; Soranakom, C.; Toledo Filho, R.D. High speed tensile behavior of sisal fiber cement composites. Mater. Sci. Eng. A 2010, 527, 544–552. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; de Andrade Silva, F.; Fairbairn, E.M.R.; de Almeida MeloFilho, J. Durability of compression molded sisal fiber reinforced mortar laminates. Constr. Build. Mater. 2009, 23, 2409–2420. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Tensile behavior of flax textile reinforced lime-mortar: Influence of reinforcement amount and textile impregnation. Cem. Concr. Compos. 2021, 119, 103984. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Filho, R.D.T.; Martinelli, E. Mechanical response and analysis of cracking process in hybrid TRM composites with flax textile and Curauá fibres. Polymers 2021, 13, 715. [Google Scholar] [CrossRef] [PubMed]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Toledo Filho, R.D.; de Andrade Silva, F.; Mechtcherine, V.; Butler, M.; Hempel, S. The effect of accelerated aging on the interface of jute textile reinforced concrete. Cem. Concr. Compos. 2016, 74, 7–15. [Google Scholar] [CrossRef]

- Claramunt, J.; Fernández-Carrasco, L.J.; Ventura, H.; Ardanuy, M. Natural fiber nonwoven reinforced cement composites as sustainable materials for building envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Characterization of a textile waste nonwoven fabric reinforced cement composite for non-structural building components. Constr. Build. Mater. 2021, 276, 122179. [Google Scholar] [CrossRef]

- NBR 16697; Cimento Portland—Requisitos. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2018.

- NBR 11355; Vermiculita Expandida—Análise Granulométrica—Método de Ensaio. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2015.

- NBR 7211; Agregados Para Concreto—Especificação. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2019.

- NBR 15823-2; Concreto Autoadensável, Parte 2: Determinação do Espalhamento, do Tempo de Escoamento e do Índice de Estabilidade Visual—Método do Cone de Abrams. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2017.

- NBR 13278; Argamassa Para Assentamento e Revestimento de Paredes e Tetos—Determinação da Densidade de Massa e do Teor de ar Incorporado. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2005.

- NBR 8953; Concreto Para Fins Estruturais—Classificação Pela Massa Específica, por Grupos de Resistência e Consistência. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2015.

- NBR 7215; Cimento Portland—Determinação da Resistência. À Compressão de Corpos de Prova Cilíndricos. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2019.

- NBR ISO 13934-1; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2016.

- C947-03; Standard Test Method for Flexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam with Third-Point Loading). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2016.

- Vlach, T.; Laiblová, L.; Ženíšek, M.; Řepka, J.; Hájek, P. Soft insert for support modeling of slightly textile reinforced concrete. Key Eng. Mater. 2018, 760, 158–163. [Google Scholar] [CrossRef]

- NBR 11675; Divisórias Leves Internas Moduladas—Verificação da Resistência aos Impactos. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2016.

- Hegger, J.; Voss, S. Investigations on the bearing behaviour and application potential of textile reinforced concrete. Eng. Struct. 2008, 30, 2050–2056. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Ciência e Engenharia de Materiais: Uma Introdução; Grupo Gen-LTC: Rio de Janeiro, Brazil, 2016; ISBN 978-1-118-32457-8. [Google Scholar]

- Riande, E.; Diaz-Calleja, R.; Prolongo, M.; Masegosa, R.; Salom, C. Polymer Viscoelasticity: Stress Strain Practice; CRC Press: Boca Raton, FL, USA, 2000; ISBN 9780429175534. [Google Scholar]

- Triantafillou, T.C. Strengthening of Existing Masonry Structures: Concepts and Structural Behavior; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; ISBN 9781782424697. [Google Scholar]

- Haik, R.; Adiel Sasi, E.; Peled, A. Influence of three-dimensional (3D) fabric orientation on flexural properties of cement-based composites. Cem. Concr. Compos. 2017, 80, 1–9. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Zhou, M.; Fang, D.; Jiang, D. Research on the Fracture Properties and Modification Mechanism of Polyester Fiber and SBR Latex Modified Cement Concrete. Adv. Mater. Sci. Eng. 2016, 2016, 5163702. [Google Scholar] [CrossRef]

| Characteristic | Chemical Compound and Properties | Cement | Silica Fume | |

|---|---|---|---|---|

| Chemical (% wt.) | SiO2 | 20.16 | 91.42 | |

| Al2O3 | 4.78 | 1.96 | ||

| Fe2O3 | 2.52 | 0.13 | ||

| CaO | 60.76 | 0.53 | ||

| Na2O | 0.38 | - | ||

| TiO2 | 0.24 | - | ||

| K2O | 0.86 | 2.72 | ||

| MgO | 1.51 | - | ||

| P2O5 | 0.12 | - | ||

| SO3 | 2.75 | 1.34 | ||

| Cr2O3 | - | - | ||

| MnO | 0.04 | - | ||

| SrO | 0.25 | - | ||

| ZnO | - | - | ||

| LOI | 5.63 | 1.90 | ||

| Physical | Specific mass (g/cm3) | 2.99 | 2.21 | |

| Specific surface (m2/g) | 1.55 | 17.77 | ||

| Laser granulometry (wet measurement) | D10 (µm) | 5.91 | 1.73 | |

| D50 (µm) | 13.59 | 6.35 | ||

| D95 (µm) | 34.80 | 14.66 | ||

| Dave (µm) | 15.13 | 6.70 | ||

| Composite | Width (mm) | Fissured Area (mm2) | Fissure Content (%) |

|---|---|---|---|

| unreinforced | - | - | - |

| untreated reinforcement | 2.86 | 1322.00 | 3.67 |

| SBR impregnated reinforcement | 1.09 | 811.00 | 2.25 |

| SBR + SF impregnated reinforcement | 0.59 | 371.00 | 1.03 |

| Sample | Stress 1st Crack (MPa) | Deformation 1st Crack (%) | Maximum Tensile Force (MPa) | Maximum Deformation(%) |

|---|---|---|---|---|

| Unreinforced | 0.26 (0.03) | 0.04 | 0.28 (0.02) | 0.07 (0.03) |

| Untreated | 0.22 (0.02) | 0.04 | 0.31 (0.13) | 0.26 (0.15) |

| SBR | 0.37 (0.10) | 0.06 | 0.43 (0.06) | 1.03 (1.49) |

| SBR + SF | 0.42 (0.04) | 0.10 | 0.46 (0.02) | 0.20 (0.13) |

| Composite | Depth (mm) | Diameter (mm) | Fissured Area (mm2) | Fissure Content (%) | |

|---|---|---|---|---|---|

| 2.5 J | unreinforced | - | - | - | - |

| untreated reinforcement | 2.98 | 16.54 | 601.82 | 0.33 | |

| SBR impregnated reinforcement | 1.10 | 14.02 | 341.72 | 0.19 | |

| SBR + SF impregnated reinforcement | 1.36 | 15.65 | 11.86 | 0.007 | |

| 5.0 J | SBR + SF impregnated reinforcement | 3.55 | 21.26 | 1658.54 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grings, K.J.O.; Carneiro Ribeiro, F.R.; Junior, D.V.A.; de Azevedo, A.R.G.; Kulakowski, M.P. Evaluation of Light Cementitious Matrix with Composite Textile Reinforcement from Garment Waste. Materials 2023, 16, 733. https://doi.org/10.3390/ma16020733

Grings KJO, Carneiro Ribeiro FR, Junior DVA, de Azevedo ARG, Kulakowski MP. Evaluation of Light Cementitious Matrix with Composite Textile Reinforcement from Garment Waste. Materials. 2023; 16(2):733. https://doi.org/10.3390/ma16020733

Chicago/Turabian StyleGrings, Kátia Jocasta Ortiz, Francisco Roger Carneiro Ribeiro, Davi Vaz André Junior, Afonso Rangel Garcez de Azevedo, and Marlova Piva Kulakowski. 2023. "Evaluation of Light Cementitious Matrix with Composite Textile Reinforcement from Garment Waste" Materials 16, no. 2: 733. https://doi.org/10.3390/ma16020733

APA StyleGrings, K. J. O., Carneiro Ribeiro, F. R., Junior, D. V. A., de Azevedo, A. R. G., & Kulakowski, M. P. (2023). Evaluation of Light Cementitious Matrix with Composite Textile Reinforcement from Garment Waste. Materials, 16(2), 733. https://doi.org/10.3390/ma16020733