Experimental Characterisation of Lime-Based Textile-Reinforced Mortar Systems Made of Either Jute or Flax Fabrics

Abstract

1. Introduction

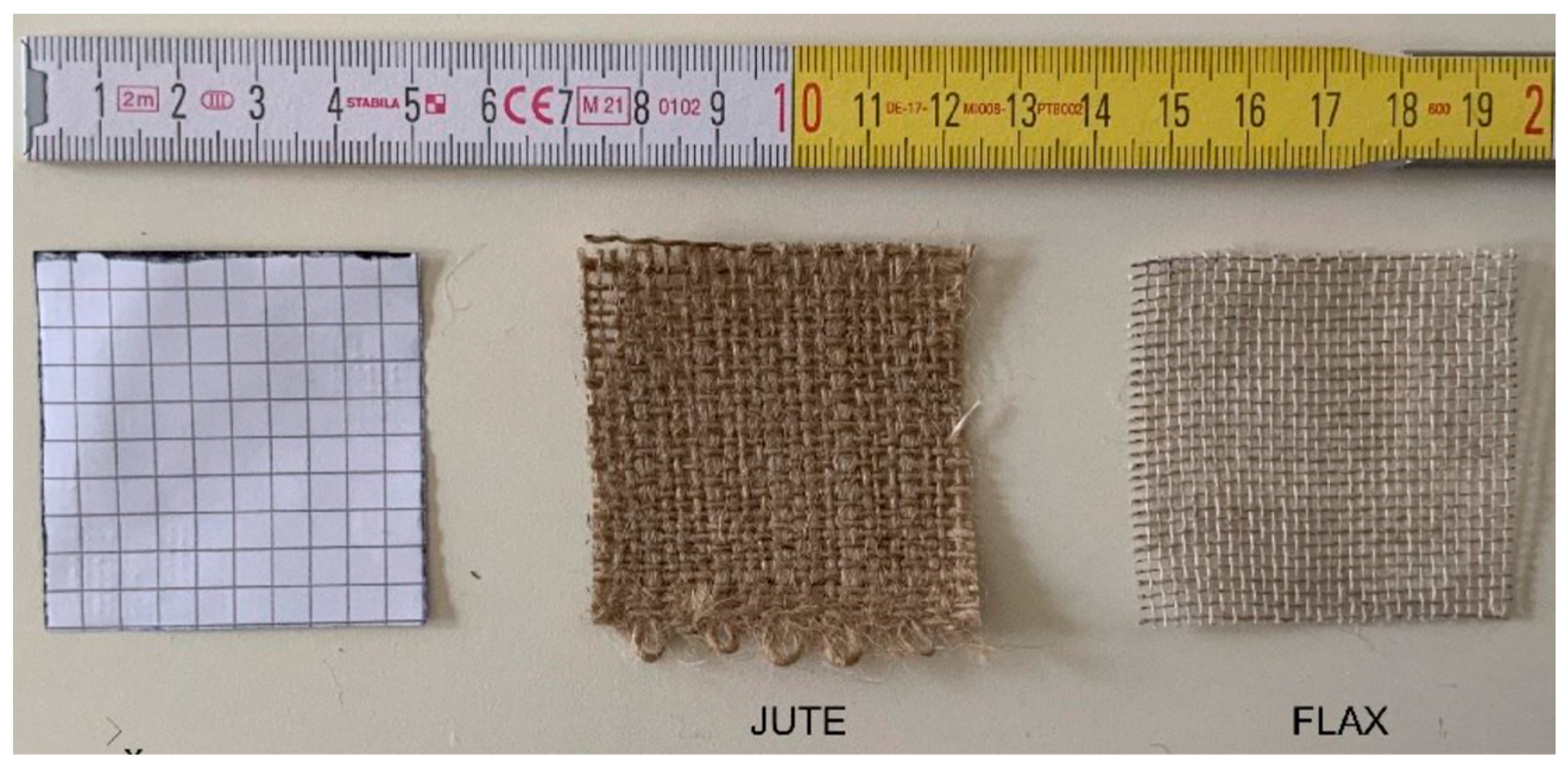

2. Materials and Methods

2.1. Geometric Characterisation of Natural Yarns

2.2. Physical Characterisation of Natural Yarns

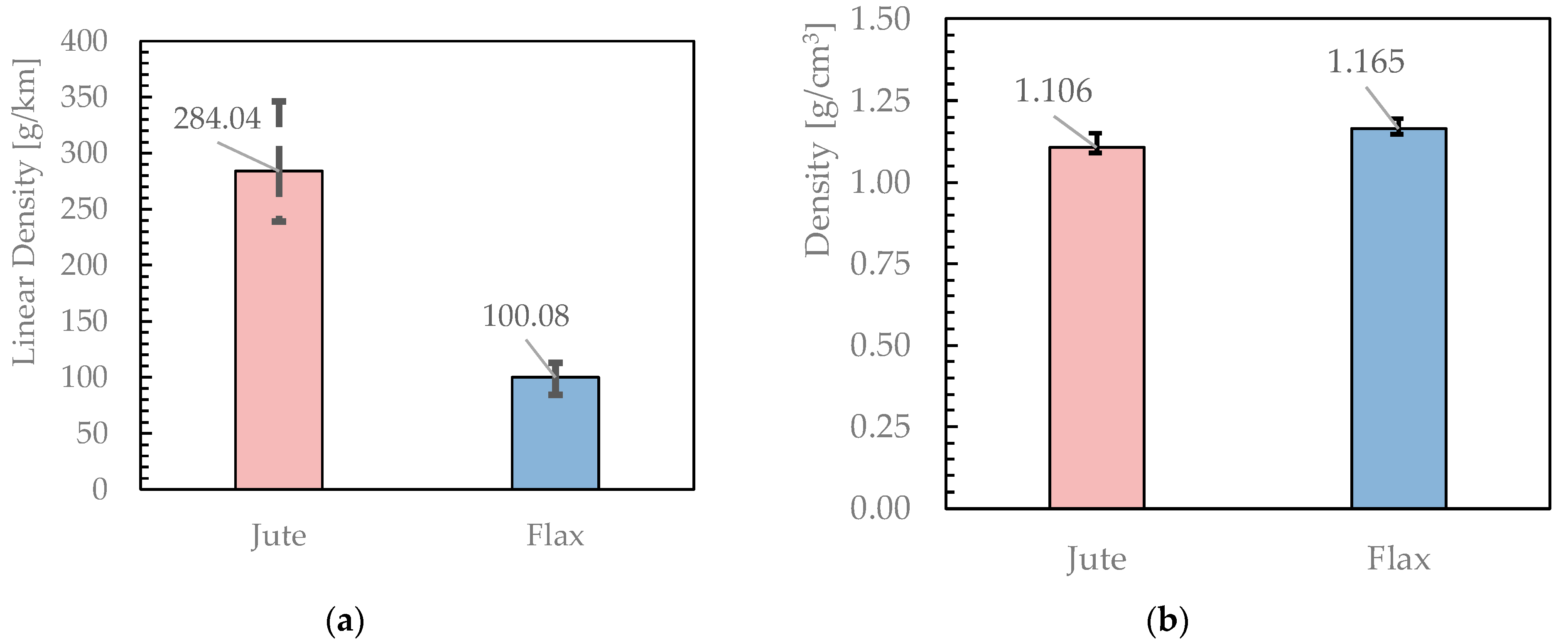

2.2.1. Linear Density

- m is the mass, in gram, of the specimen;

- L is the length, in meters, of the specimen.

2.2.2. Density

- ρ is the solid specimen density;

- ρ(fl) is the fluid density;

- ρ(a) = 0.0012 g/cm3 is the air density measured at 20 °C and 101.325 kPa;

- W(a) is the weight of the solid specimen, in air;

- W(fl) is the weight of the solid specimen, in fluid;

- 0.99983 is the geometrical correction factor.

2.2.3. Other Properties

- Linear Density in dry conditionswhere:

- TEX is the linear density of the specimen in dry condition [27];

- Wdry is the weight of the solid specimen, in dry condition;

- L is the length of the solid specimen, equal to 75 cm.

- Densitywhere:

- Vdry is the volume of the specimen in dry condition, in cm3;

- ρdry is the density of the specimen in dry condition, in g/cm3.

- Cross section and diameter of the yarnwhere:

- Ayarn is the area of the yarn, in mm2;

- Ddry is the equivalent diameter assessed assuming a circular cross section of the specimen in dry condition, in mm.

- Water Absorption ratio

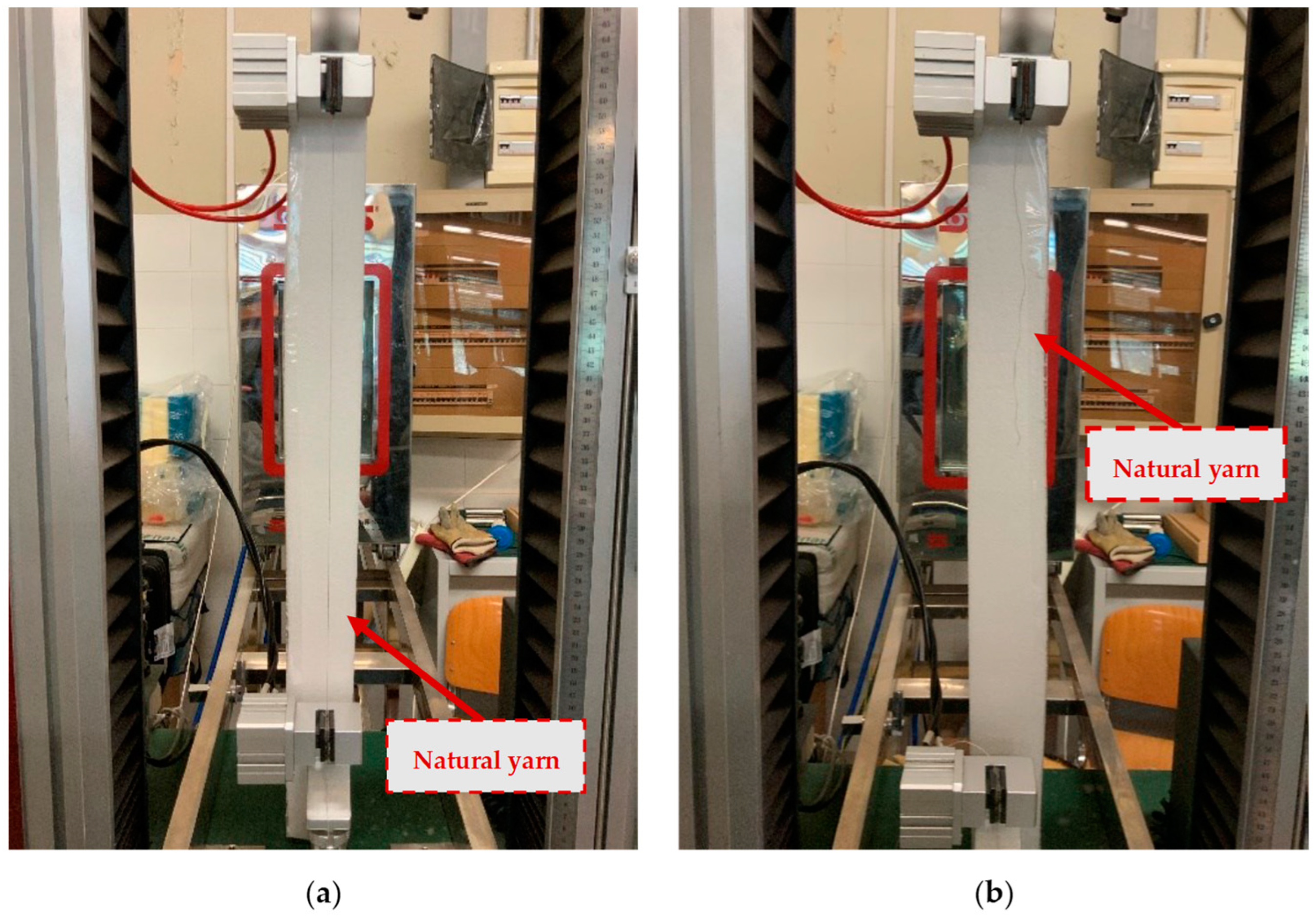

2.3. Mechanical Characterisation of Natural Yarns

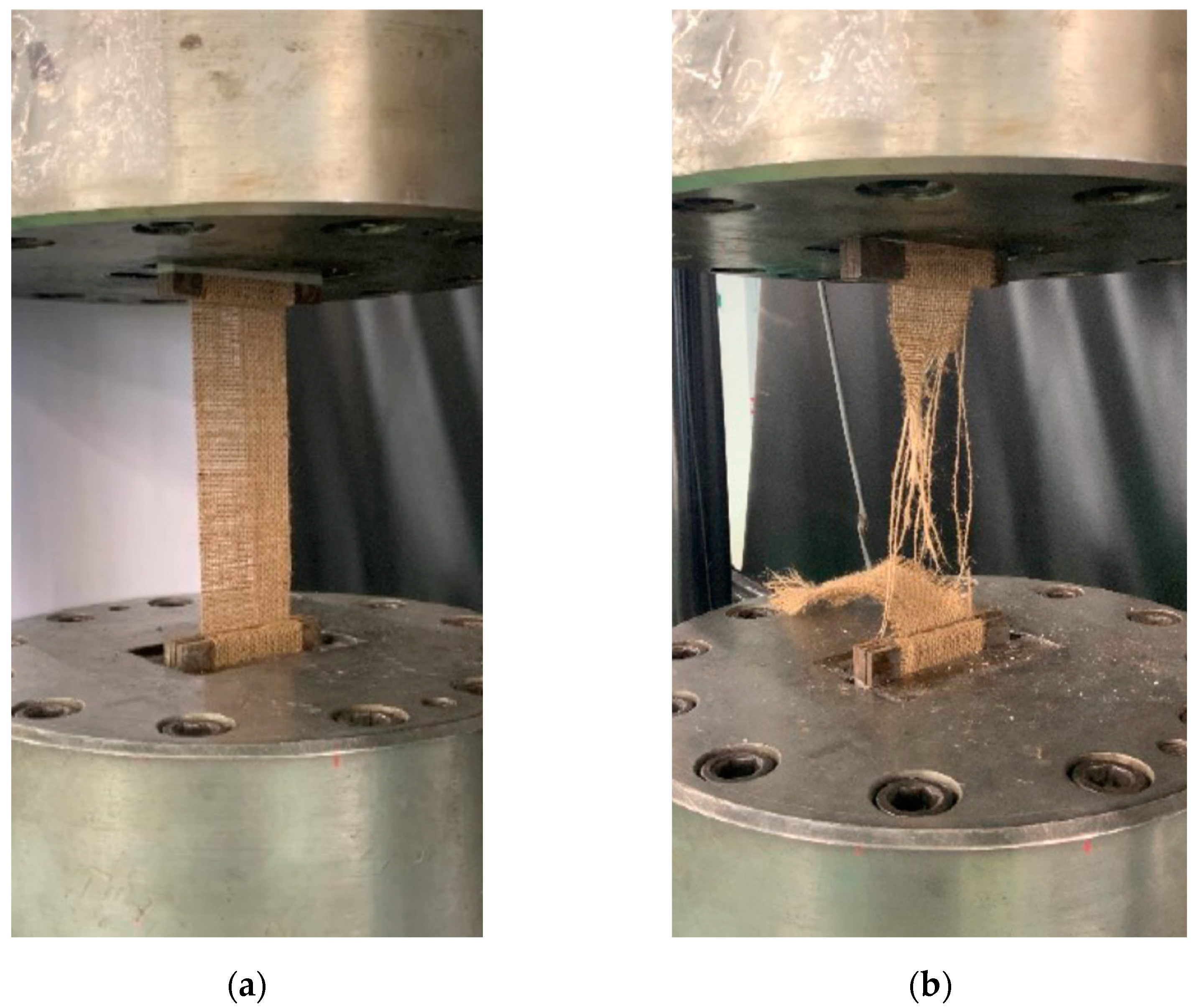

2.4. Mechanical Characterisation of Natural Textiles

2.5. Mechanical Characterisation of Lime-Based Mortars

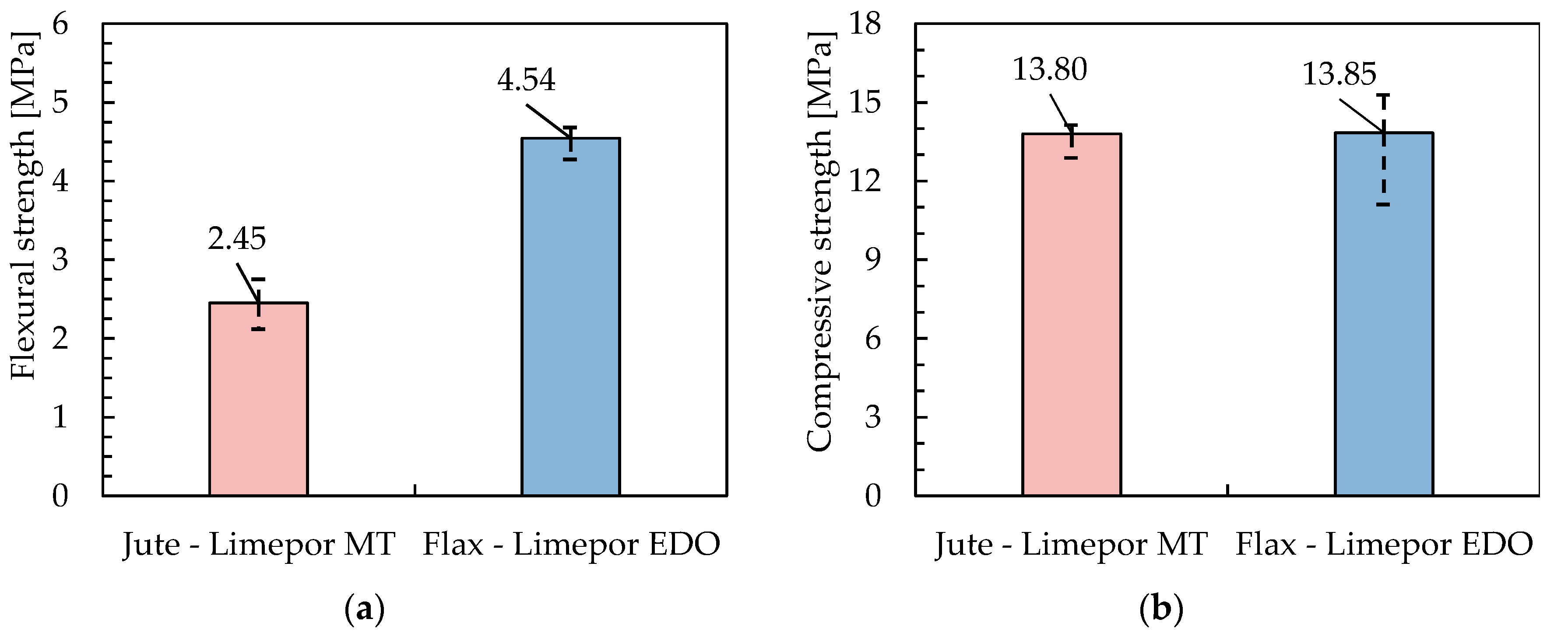

2.5.1. Flexural Strength

- f is the flexural strength;

- F is the maximum load applied to the specimen, in N;

- l is the distance between the axes of the support rollers, in mm;

- b is the width of the specimen, in mm;

- d is the depth of the specimen, in mm.

2.5.2. Compressive Strength

2.6. Mechanical Characterisation of Natural TRM Systems

- Limepor MT matrix with jute fabric reinforcement;

- Limepor EDO matrix with flax fabric reinforcement.

- Assembly of the formwork necessary for the implementation of the samples;

- Preparation of the two types of premixed mortar;

- The laying of a thin layer of release agent, in order to allow the easier removal of the samples, and then of the first layer of mortar;

- The laying of the fabric band;

- The laying of the last layer of mortar;

- After setting, the specimens were extracted from the formwork.

3. Results

3.1. Physical Properties of Natural Yarns

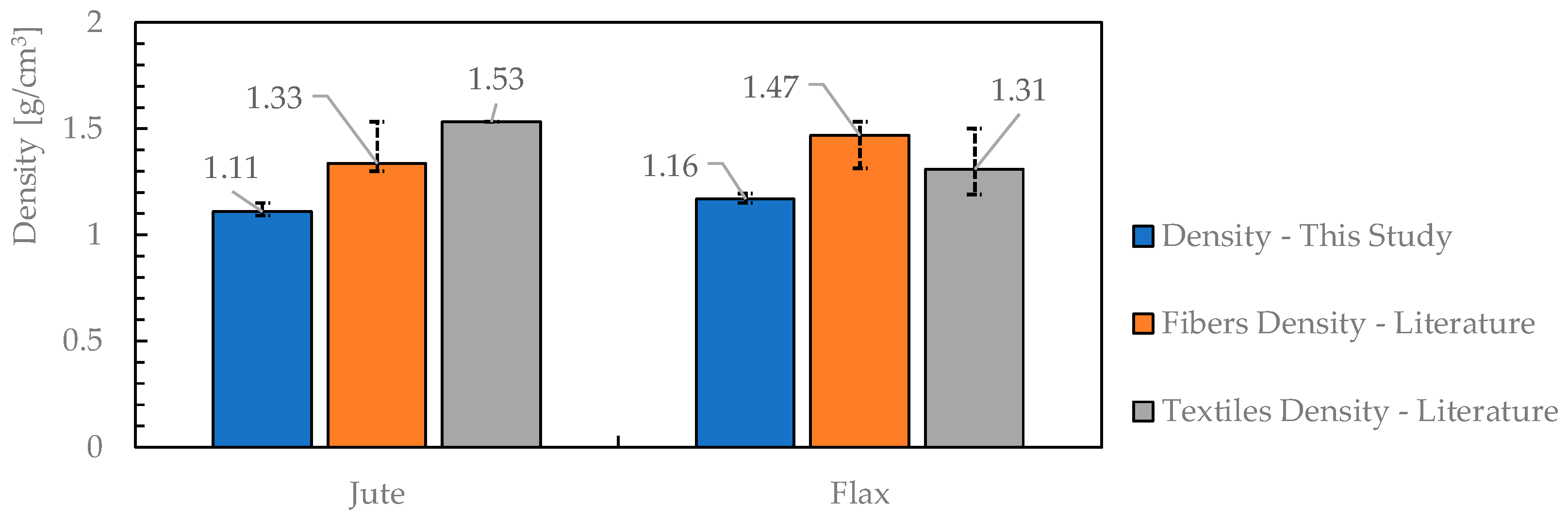

3.1.1. Linear Density and Density

3.1.2. Other properties: Cross Section and Absorption

3.2. Mechanical Properties of Natural Yarns

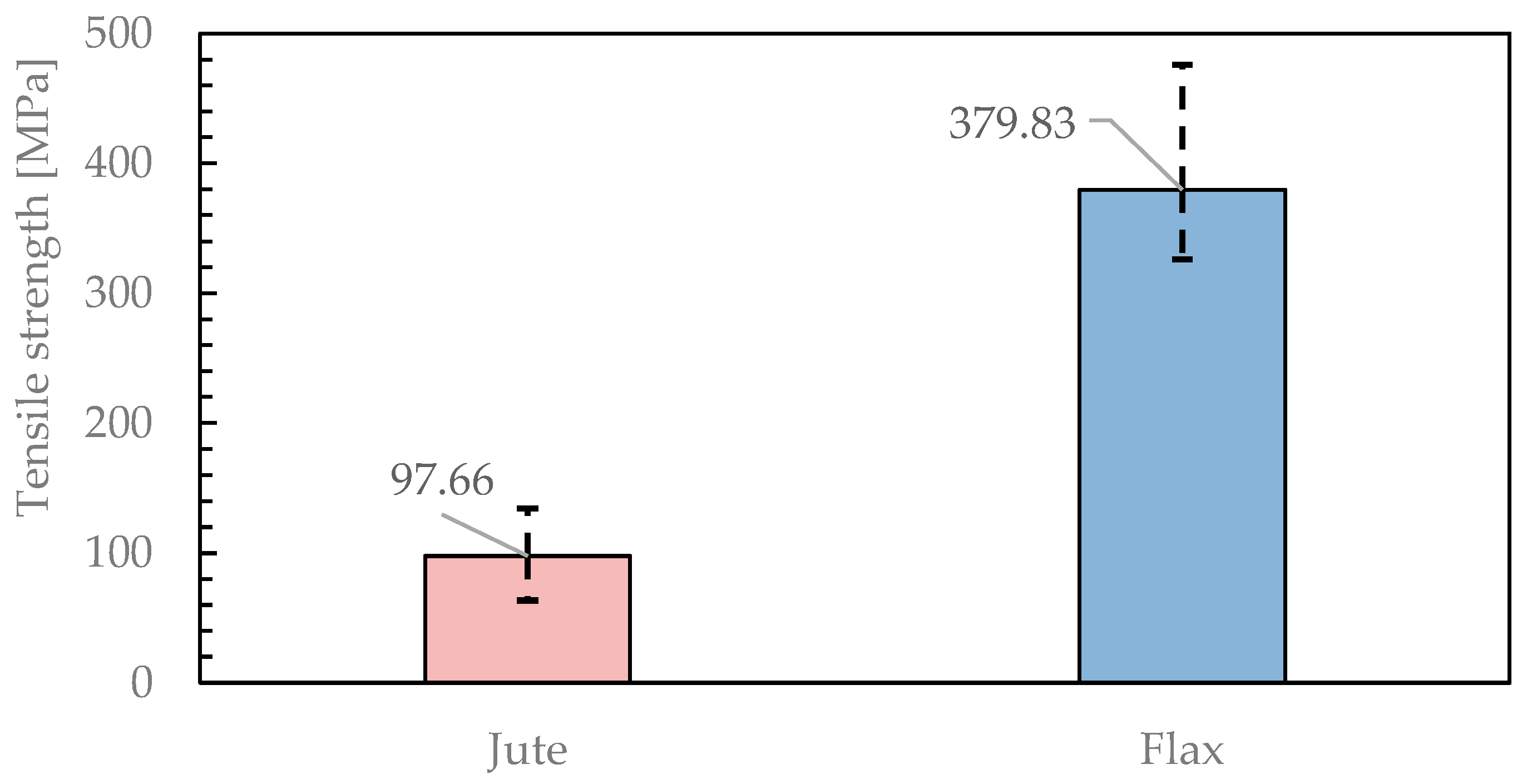

3.2.1. Tensile Strength

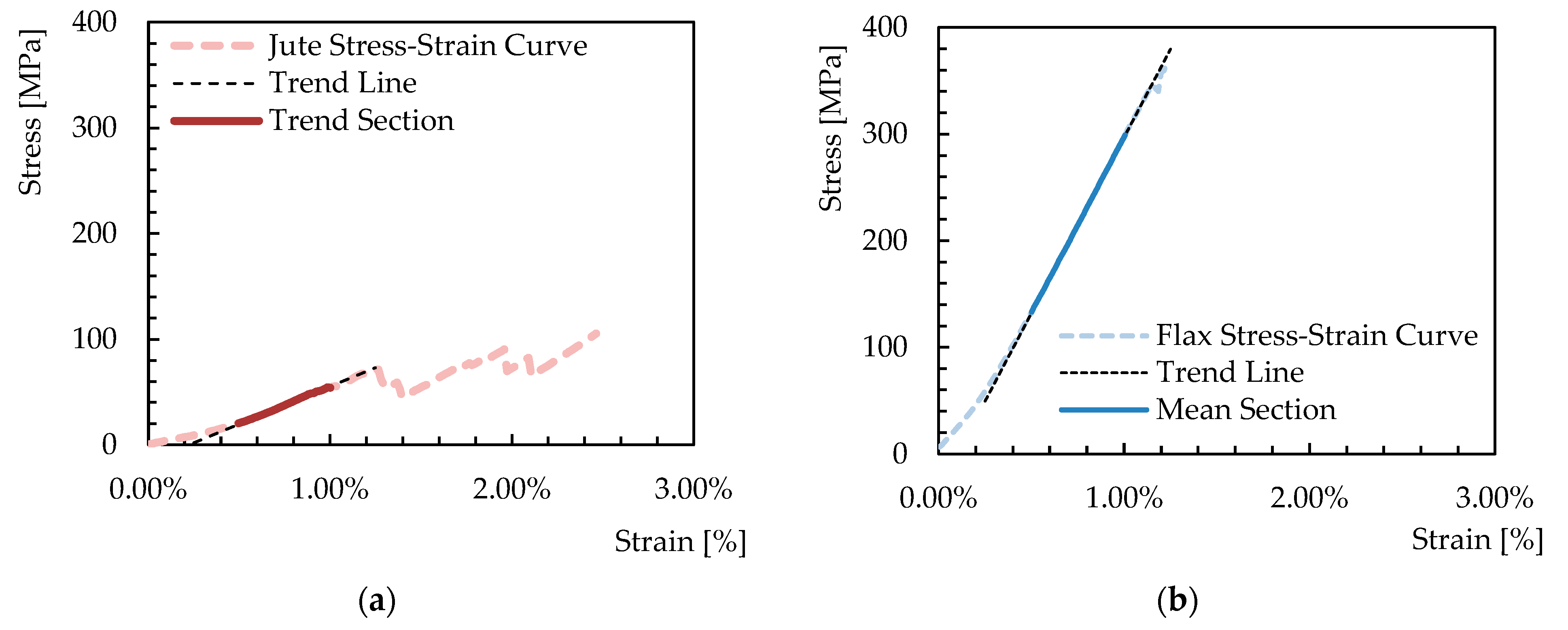

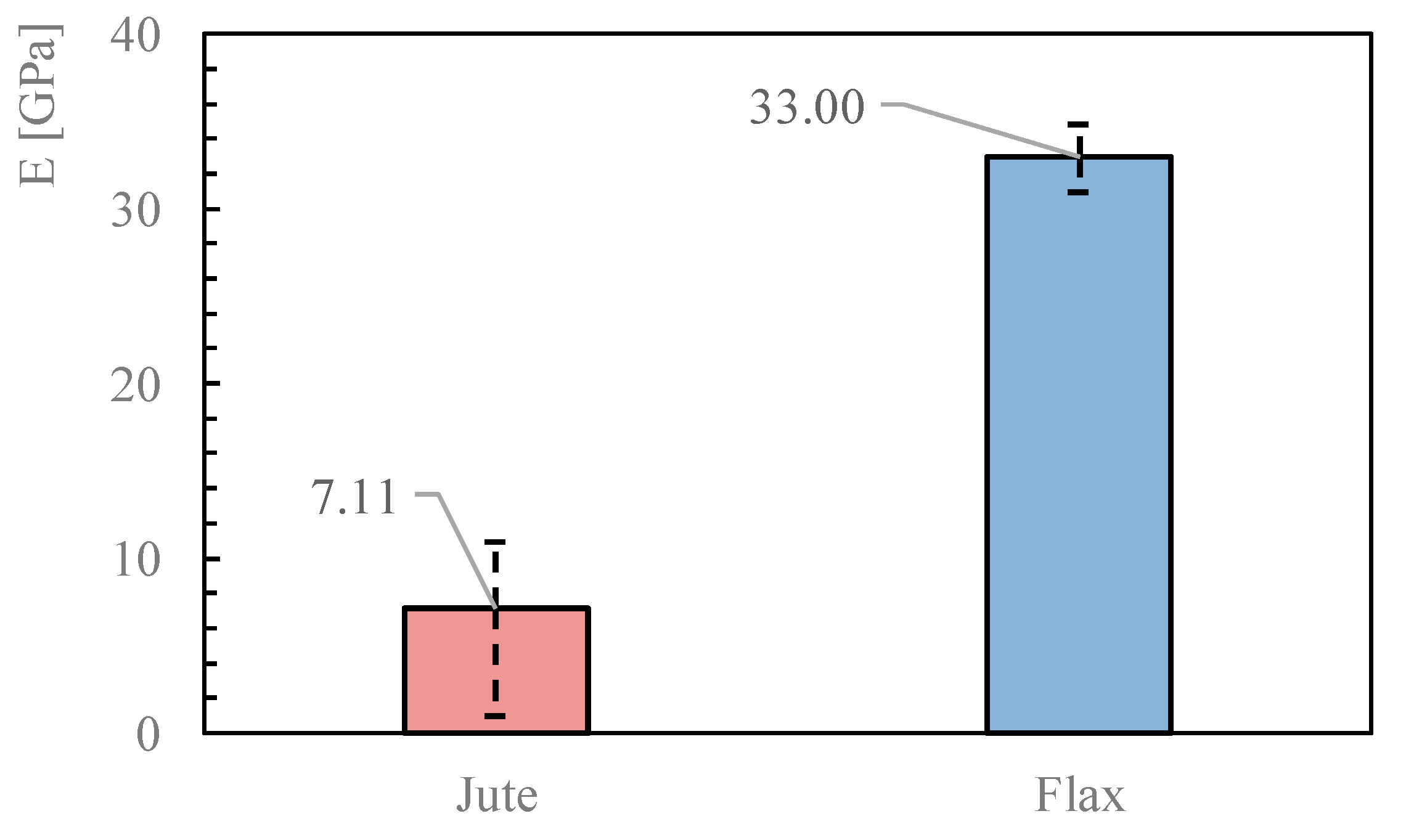

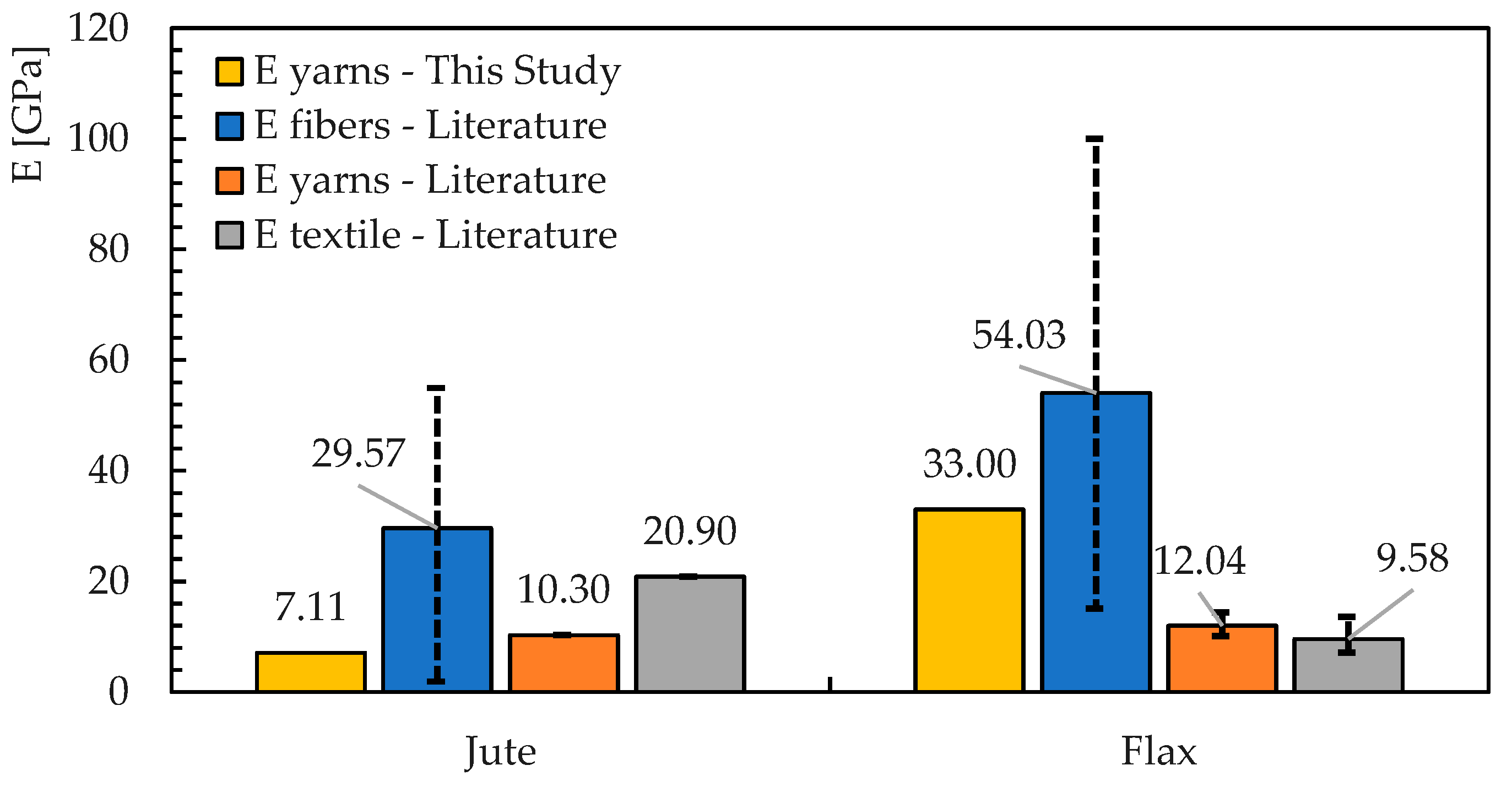

3.2.2. Elastic Modulus

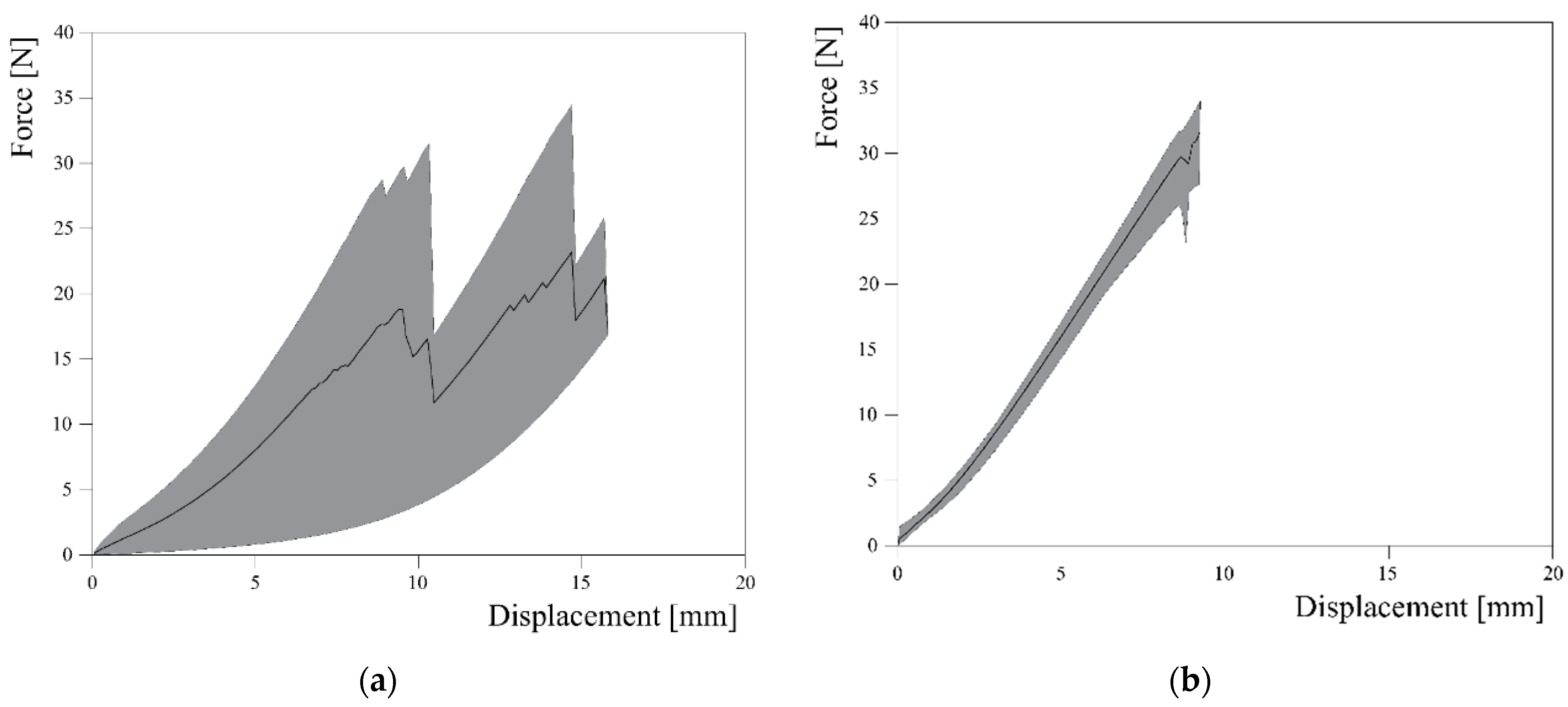

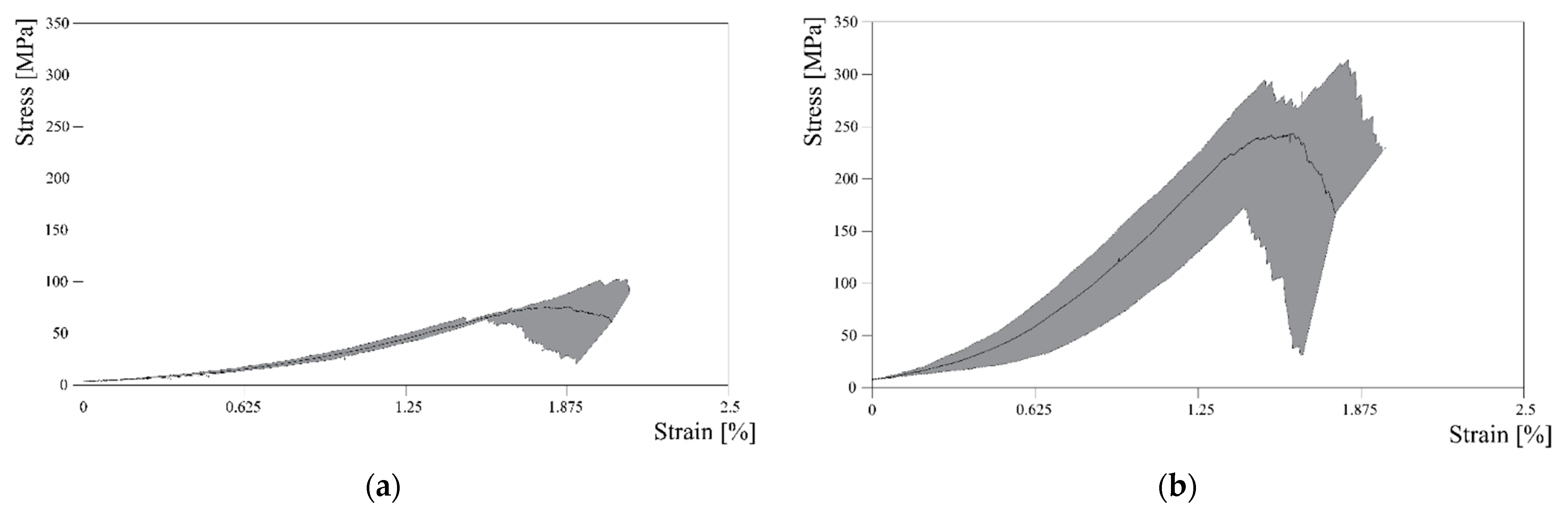

3.3. Mechanical Properties of Natural Textile

- σmax: Maximum tension reached during the test;

- εσmax: Deformation reached when maximum tension occurs;

- εu: Ultimate deformation reached before failure.

3.4. Mechanical Properties of Lime-Based Mortar

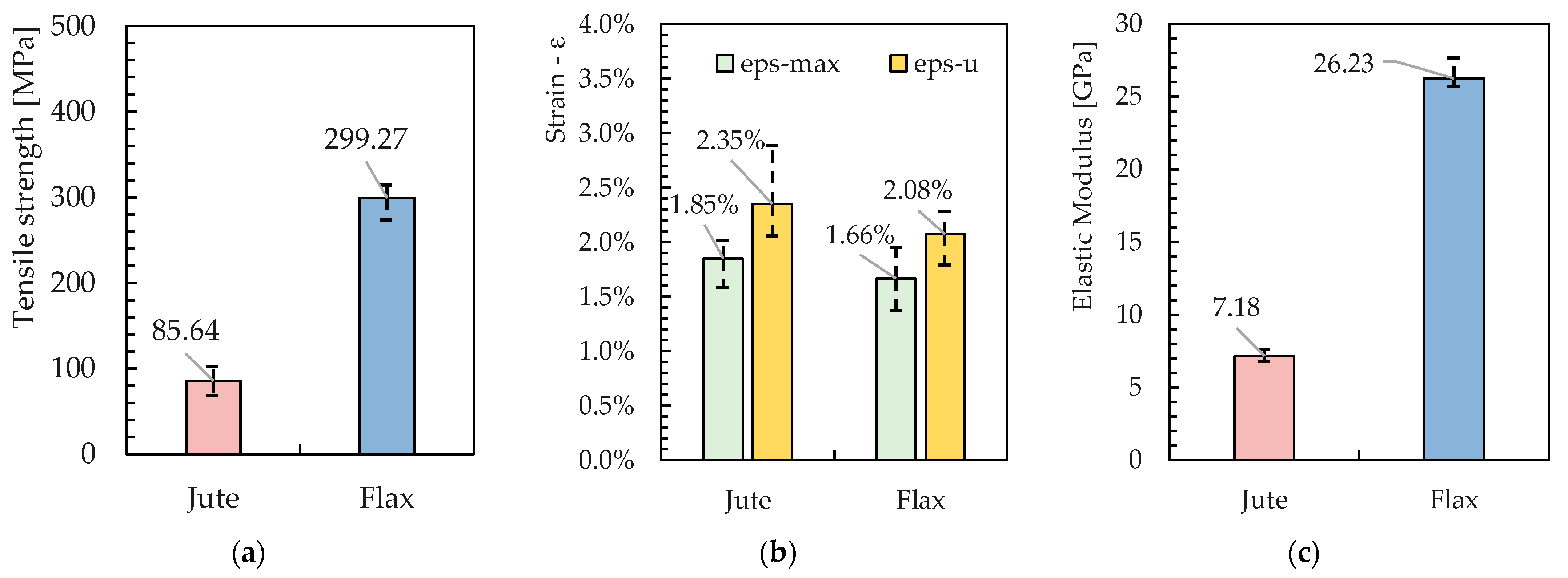

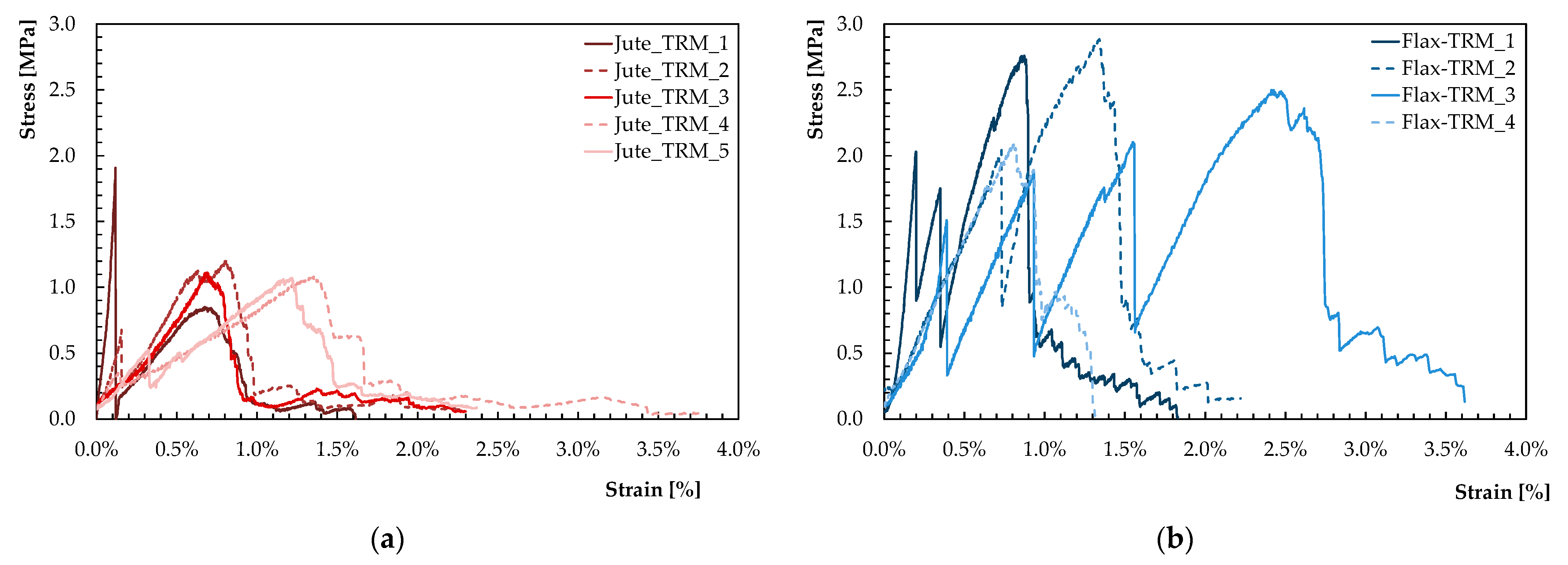

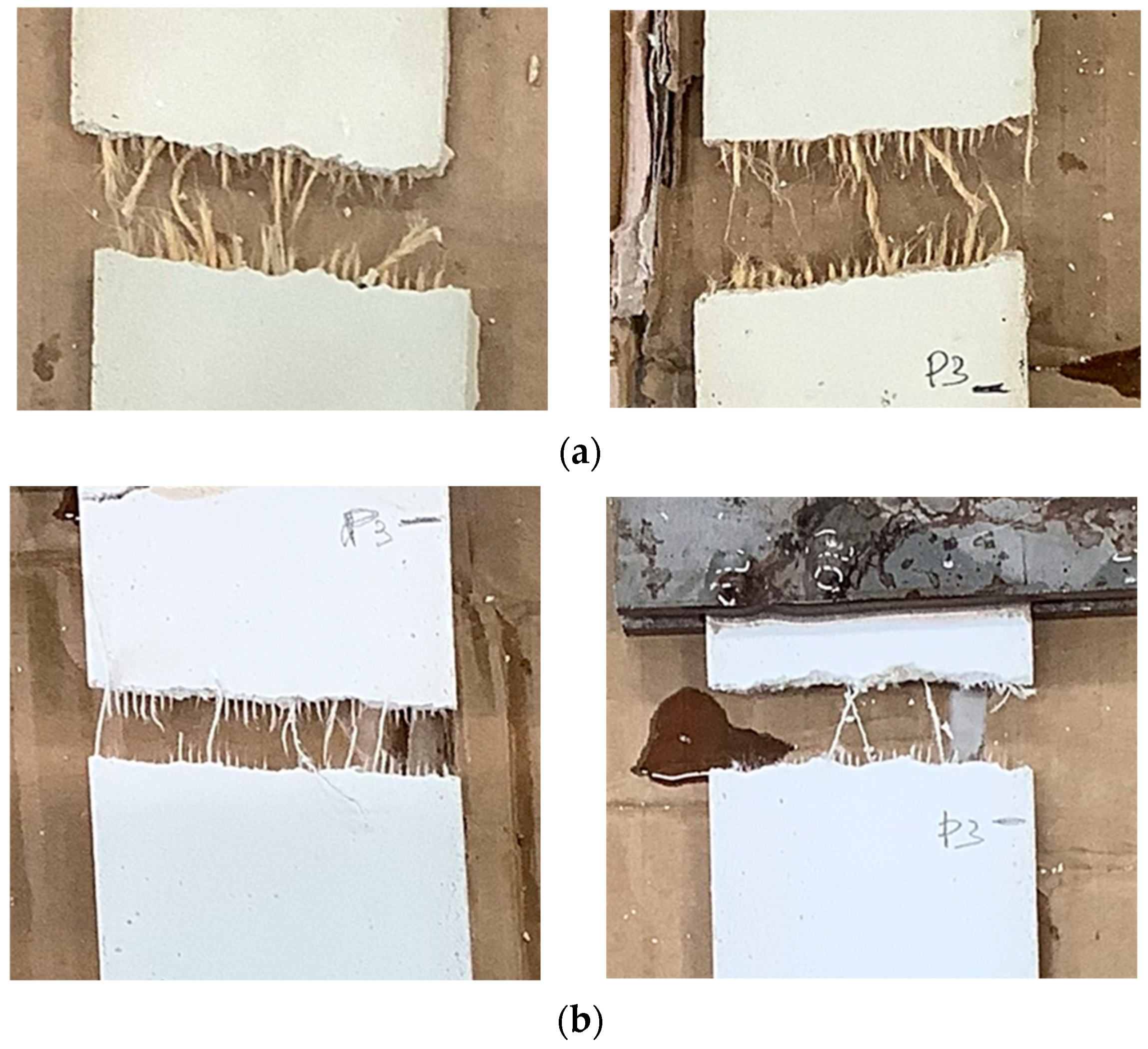

3.5. Mechanical Properties of NTRM

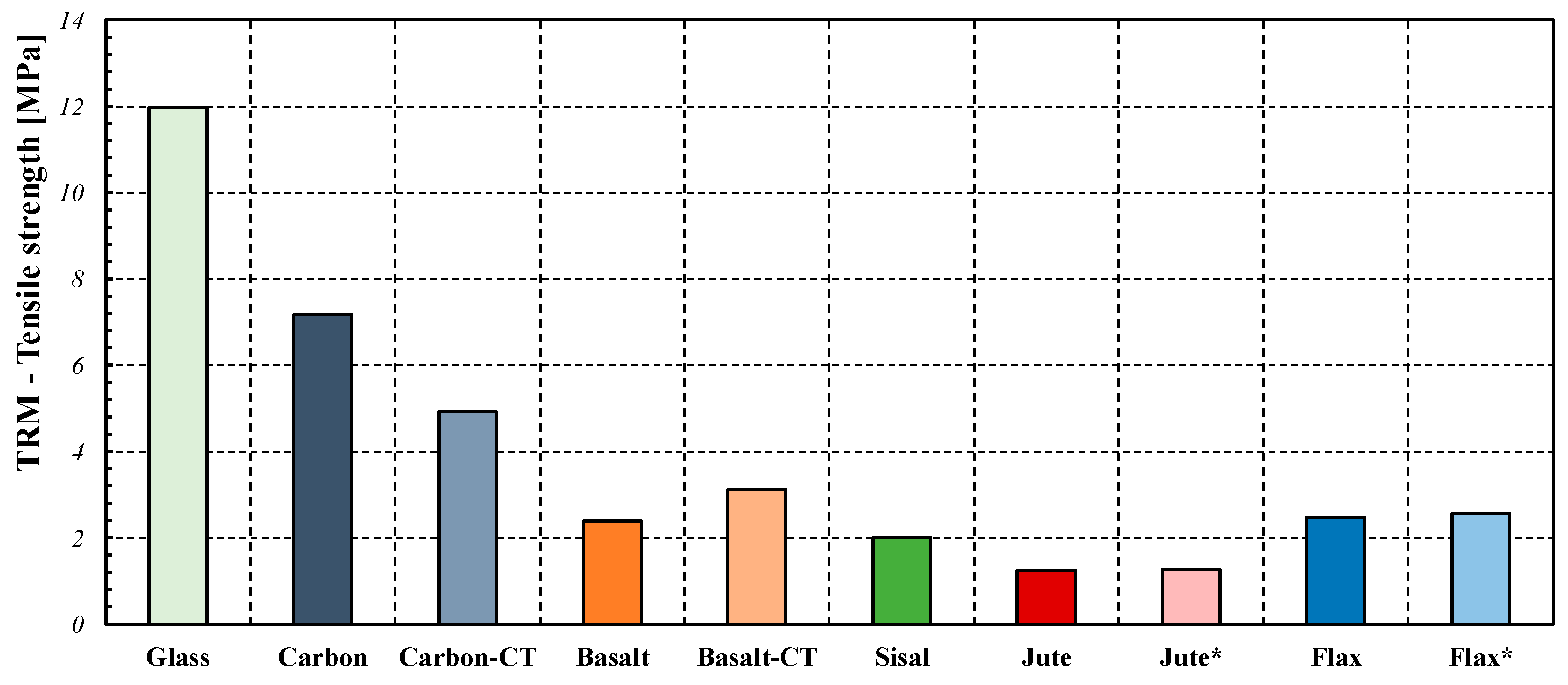

Comparisons in Terms of TRM Strength

4. Conclusions

- -

- The Jute fibre yarns have a transverse section bigger than the Flax yarns; specifically, the area of the former is almost three times bigger than the latter, yet it is affected by significant variability;

- -

- The bigger section area also leads to both higher (almost double) absorption capacity and (almost three times) lower tensile strength of the Jute fibres with respect to the Flax fibres;

- -

- Moreover, flax yarns are significantly stiffer in tension than jute fibres, as the Young modulus ratio is in the order of five between them;

- -

- The tensile response of NTRM is greatly affected by the aforementioned properties of the yarns and textile, as the tested Flax-TRM tends to outperform Jute-TRM in terms of both maximum bending strength and overall post-cracking toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferrara, G.; Caggegi, C.; Martinelli, E.; Gabor, A. Shear capacity of masonry walls externally strengthened using Flax-TRM composite systems: Experimental tests and comparative assessment. Constr. Build. Mater. 2020, 261, 120490. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, R.D. Tensile behavior of flax textile reinforced lime-mortar: Influence of reinforcement amount and textile impregnation. Cem. Concr. Compos. 2021, 119, 103984. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Toledo Filho, R.D.; Martinelli, E. Mechanical response and analysis of cracking process in hybrid TRM composites with flax textile and curauá fibres. Polymers 2021, 13, 715. [Google Scholar] [CrossRef]

- Marques, A.I.; Ferreira, J.G.; Candeias, P.; Veiga, M.D.R. Experimental evaluation of brick masonry walls strengthened with TRM (textile reinforced mortar) renders. Buildings 2022, 12, 840. [Google Scholar] [CrossRef]

- Kimia Catalog. Limepor EDO. Technical Sheet. Available online: www.kimia.it/it/prodotti/limepor-edo (accessed on 19 December 2022).

- Kimia Catalog. Limepor MT. Technical Sheet. Available online: www.kimia.it/it/prodotti/limepor-MT (accessed on 19 December 2022).

- CNR DT 215/2018; Istruzioni per la Progettazione, L’esecuzione ed il Controllo di Interventi di Consolidamento Statico Mediante L’utilizzo di Compositi Fibrorinforzati a Matrice Inorganica. Consiglio Nazionale delle Ricerche: Roma, Italy, 2018.

- Amato, G.; Chen, J.F.; D’Anna, J.; La Mendola, L.; Minafò, G. FRCM systems for strengthening masonry structures. Adv. Compos. Constr. ACIC 2017, 244–249. [Google Scholar]

- ACI Committee 549, ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitous Matrix (FRCM) Systems for Repair and Strengthening Concrete Structures. ACI Committee: Farmington Hills, MI, USA, 2013.

- Consiglio Superiore dei Lavori Pubblici. Linea Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti; Consiglio Superiore dei Lavori Pubblici: Rome, Italy, 2018; p. 41.

- AC434. Acceptance Criteria for Concrete and Masonry Strengthening Using Fabric-Reinforced Cementitious Matrix (FRCM) Composite Systems; ICC Evaluation Service: Whittier, CA, USA, 2018. [Google Scholar]

- European Organisation for Technical Assessment EOTA. Externally-Bonded Composite Systems with Inorganic Matrix for Strengthening of Concrete and Masonry Structures; European Assessment Document EAD 340275-00-0104, January 2018; EOTA: Brussels, Belgium, 2020. [Google Scholar]

- Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete: Uniaxial tensile test: Test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [CrossRef]

- de Carvalho Bello, C.B.; Boem, I.; Cecchi, A.; Gattesco, N.; Oliveira, D.V. Experimental tests for the characterization of sisal fiber reinforced cementitious matrix for strengthening masonry structures. Constr. Build. Mater. 2019, 219, 44–55. [Google Scholar] [CrossRef]

- Ministero delle infrastrutture e dei trasporti. Norme Tecniche per le Costruzioni; DM 17/1/2018; Ministero delle infrastrutture e dei trasporti: Rome, Italy, 2018; pp. 1–372.

- Consiglio Superiore dei Lavori Pubblici. Linea Guida per la Progettazione, L’esecuzione e la Manutenzione di Interventi di Consolidamento Strutturale Mediante L’utilizzo di Sistemi di Rinforzo FRCM; Consiglio Superiore dei Lavori Pubblici: Rome, Italy, 2019; pp. 1–26.

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. Part B-Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Zukowski, B.; dos Santos, E.R.F.; dos Santos Mendonça, Y.G.; de Andrade Silva, F.; Toledo Filho, R.D. The durability of SHCC with alkali treated curauá fiber exposed to natural weathering. Cem. Concr. Compos. 2018, 94, 116–125. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Cevallos, O.A.; Olivito, R.S. Effects of fabric parameters on the tensile behaviour of sustainable cementitious composites. Compos. Part B-Eng. 2015, 69, 256–266. [Google Scholar] [CrossRef]

- Ferrara, G.; Pepe, M.; Martinelli, E.; Tolêdo Filho, D. Influence of an impregnation treatment on the morphology and mechanical behaviour of flax yarns embedded in hydraulic lime mortar. Fibers 2019, 7, 30. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Durante, M.; Zinno, A.; Balsamo, A.; Prota, A. Structural behaviour of masonry panels strengthened with an innovative hemp fibre composite grid. Constr. Build. Mater. 2015, 100, 111–121. [Google Scholar] [CrossRef]

- Olivito, R.S.; Dubois, F.; Venneri, A.; Zuccarello, F.A. Experimental and numerical analysis of masonry macroelements reinforced by natural-fibre-composite materials. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering (CICE2012), Rome, Italy, 13–15 June 2012; pp. 1–8. [Google Scholar]

- Cevallos, O.A.; Olivito, R.S.; Codispoti, R.; Ombres, L. Flax and polyparaphenylene benzobisoxazole cementitious composites for the strengthening of masonry elements subjected to eccentric loading. Compos. B Eng. 2015, 71, 82–95. [Google Scholar] [CrossRef]

- Trochoutsou, N.; Di Benedetti, M.; Pilakoutas, K.; Guadagnini, M. In-Plane Cyclic Performance of Masonry Walls Retrofitted with Flax Textile–Reinforced Mortar Overlays. J. Compos. Constr. 2022, 26, 04022049. [Google Scholar] [CrossRef]

- BS EN ISO 1889:2009; Reinforcement Yarns—Determination of Linear Density. British Standard: London, UK, 2009.

- ASTM D8171-18; Standard Test Methods for Density Determination of Flax Fiber. ASTM: West Conshohocken, PA, USA, 2020; Volume i, pp. 1–8.

- Sartorius YDK 01, YDK 01-0D, YDK 01LP—Density Determination. Kit User’s Manual. Available online: http://www.cma4ch.org/chemo/ftp/YDK01_YDK01-0D_YDK01LP.pdf (accessed on 19 December 2022).

- BS ISO 3341:2000; Textile Glass—Yarns—Determination of Breaking Force and Breaking Elongation. British Standard: London, UK, 2000; p. 7.

- BS EN 1015-11; Methods of Test for Mortar for Masonry. British Standard: London, UK, 2019; pp. 1–15.

- Kimia Catalog. Kimitech EP-IN ST14-0221. Available online: https://www.kimia.it/it/prodotti/kimitech-ep-in (accessed on 19 December 2022).

- Ferrara, G. Flax-TRM Composite Systems for Strengthening of Masonry: From Material Identification to Structural Behavior; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Hasan, K.M.; Horváth, P.G.; Alpár, T. Potential natural fiber polymeric nanobiocomposites: A review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Singh, H.; Singh, J.I.P.; Singh, S.; Dhawan, V.; Tiwari, S.K. A brief review of jute fibre and its composites. Mater. Today Proc. 2018, 5, 28427–28437. [Google Scholar] [CrossRef]

- Trochoutsou, N.; Di Benedetti, M.; Pilakoutas, K.; Guadagnini, M. Mechanical Characterisation of Flax and Jute Textile-Reinforced Mortars. Constr. Build. Mater. 2020, 271, 121564. [Google Scholar] [CrossRef]

- Abbass, A.; Lourenço, P.B.; Oliveira, D.V. The use of natural fibers in repairing and strengthening of cultural heritage buildings. Mater. Today Proc. 2020, 31, S321–S328. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V. Mechanical characterization of different FRCM systems for structural reinforcement. Constr. Build. Mater. 2017, 145, 565–575. [Google Scholar] [CrossRef]

- Hojdys, Ł.; Krajewski, P. Tensile Behaviour of FRCM Composites for Strengthening of Masonry Structures—An Experimental Investigation. Materials 2021, 14, 3626. [Google Scholar] [CrossRef] [PubMed]

- Ferrara, G.; Martinelli, E. Tensile behaviour of Textile Reinforced Mortar composite systems with flax fibres. Proc. 12th Fib Int. PhD Symp. Civ. Eng. 2018, 29, 863–869. [Google Scholar]

| X Direction | Y Direction | |

|---|---|---|

| Sample Dimension | 50 mm | 50 mm |

| Jute | 28 yarns | 28 yarns |

| Flax | 32 yarns | 31 yarns |

| Characteristic | Jute-TRM_1 | Jute-TRM_2 | Jute-TRM_3 | Jute-TRM_4 | Jute-TRM_5 |

|---|---|---|---|---|---|

| Thickness [mm] | 6.50 | 6.33 | 6.83 | 6.33 | 6.33 |

| Length [mm] | 300 | 300 | 300 | 200 | 200 |

| Characteristic | Flax-TRM_1 | Flax-TRM_2 | Flax-TRM_3 | Flax-TRM_4 |

|---|---|---|---|---|

| Thickness [mm] | 5.33 | 5.00 | 5.17 | 5.00 |

| Length [mm] | 300 | 300 | 200 | 300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pepe, M.; Lombardi, R.; Ferrara, G.; Agnetti, S.; Martinelli, E. Experimental Characterisation of Lime-Based Textile-Reinforced Mortar Systems Made of Either Jute or Flax Fabrics. Materials 2023, 16, 709. https://doi.org/10.3390/ma16020709

Pepe M, Lombardi R, Ferrara G, Agnetti S, Martinelli E. Experimental Characterisation of Lime-Based Textile-Reinforced Mortar Systems Made of Either Jute or Flax Fabrics. Materials. 2023; 16(2):709. https://doi.org/10.3390/ma16020709

Chicago/Turabian StylePepe, Marco, Rosario Lombardi, Giuseppe Ferrara, Stefano Agnetti, and Enzo Martinelli. 2023. "Experimental Characterisation of Lime-Based Textile-Reinforced Mortar Systems Made of Either Jute or Flax Fabrics" Materials 16, no. 2: 709. https://doi.org/10.3390/ma16020709

APA StylePepe, M., Lombardi, R., Ferrara, G., Agnetti, S., & Martinelli, E. (2023). Experimental Characterisation of Lime-Based Textile-Reinforced Mortar Systems Made of Either Jute or Flax Fabrics. Materials, 16(2), 709. https://doi.org/10.3390/ma16020709