Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

2.1.1. Portland Cement

2.1.2. Water

2.1.3. Quarry Dust (QD)

2.1.4. Coarse Aggregates

2.1.5. Sawdust Ash (SDA)

2.2. Methods

Experimental Investigation and Setup

2.3. Mixture Components Formulation

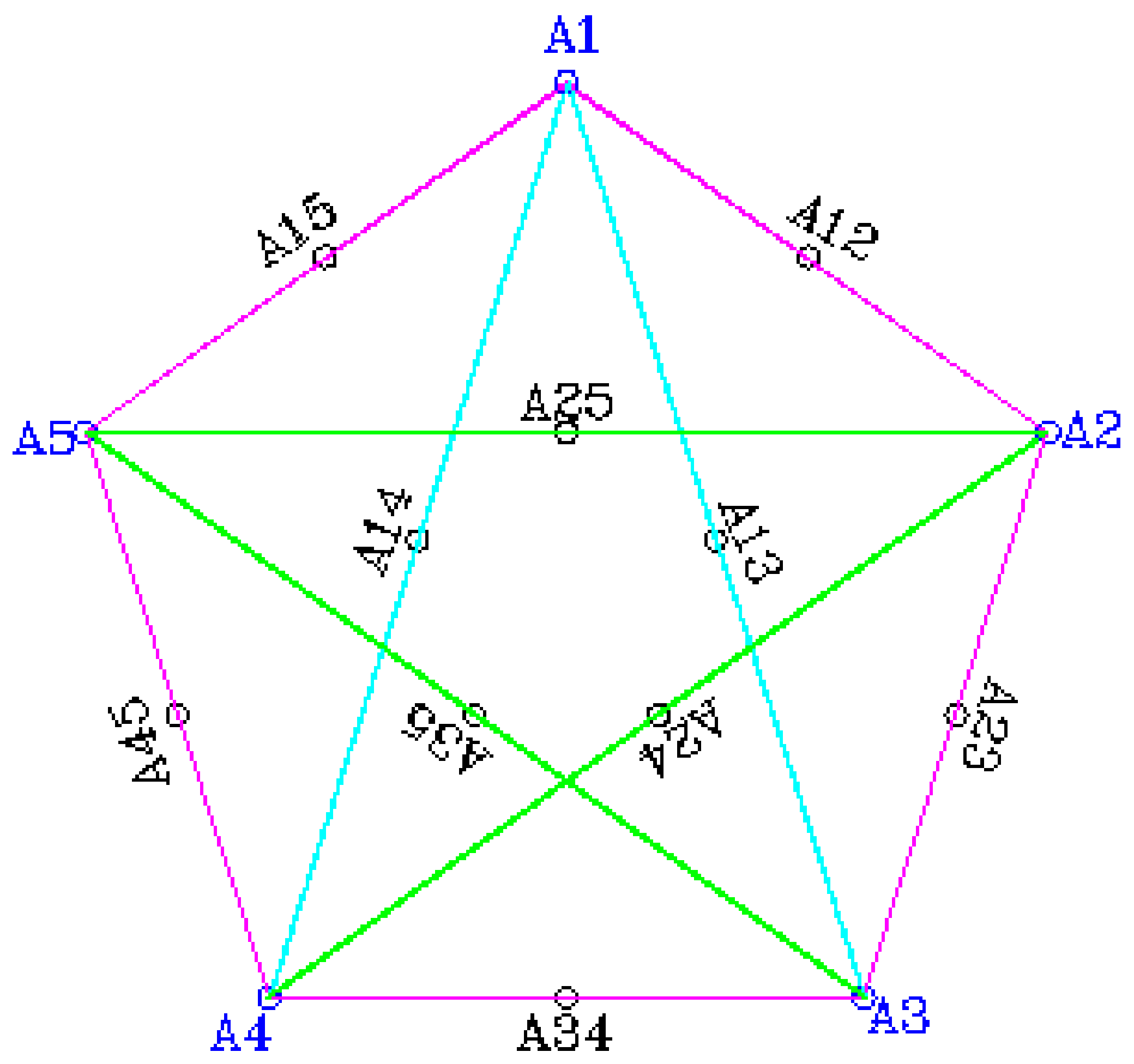

2.3.1. Design of Experiments

2.3.2. Scheffe’s Simplex Lattice Design

2.3.3. Derivation of Scheffe’s Second Order Response Function

2.3.4. Actual Components and Pseudo-Components

2.4. Mix Ratio Development

Mixture Formulation Computation

- For second-order control points

2.5. Chemical Characterization

- X-ray fluorescence (XRF) is a secondary characteristic emission from a substance fraught by being barraged with high-energy gamma or X-rays. The trend is broadly adapted for the assessment of chemical and elemental oxides, for the proper characterization of the test materials’ chemical constituents and for research in geochemistry and forensic science [51]. High-energy photons are used in XRF spectroscopy to bombard an atom so as to excite the electrons around it. Several photons are created with enough energy to expel an electron attached to the atom’s nucleus. When an electron from an atom’s inner orbital is evicted, an electron from a higher energy orbital is moved to the lower energy orbital, causing the atom to produce X-rays or photons in a process known as fluorescence [52].

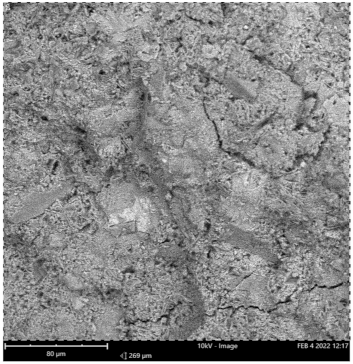

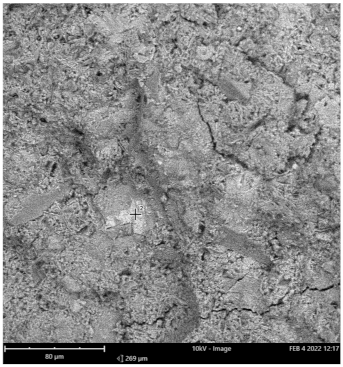

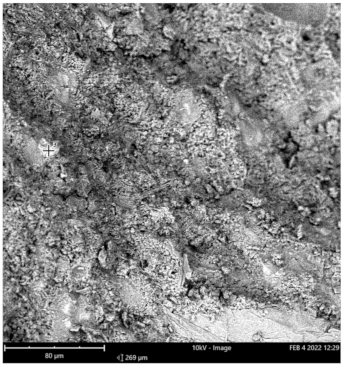

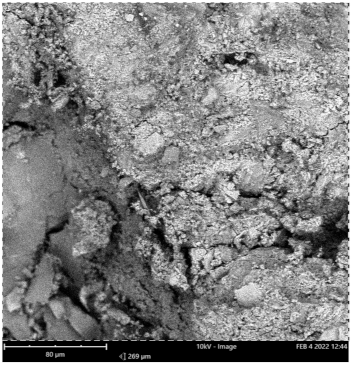

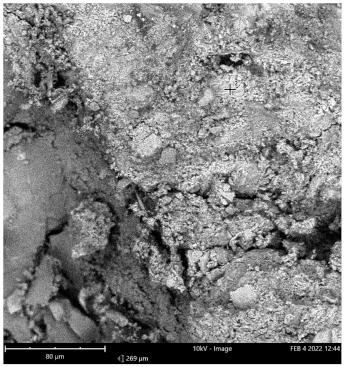

- Scanning electron microscopy (SEM) uses a kind of electron microscope to directly study the surfaces of solid objects or materials through the utilization of a beam of the directed electrons of relatively low energy scanned in a regular manner over the surface of the specimen. Large, hardened and bulky specimen can be taken for investigation in the SEM as no specific sample preparation technique is required. For clear imaging to be obtained, the specimen to be tested needs to be electrically conducting. To achieve this level of conductivity, a film of a metal such as gold of 50–100 Angstroms thick is evaporated on the surface of the specimen in a vacuum [53].

- In EDXRF spectrometers, a sample is directly irradiated by an X-ray tube functioning as a source, and the fluorescence emitted by the sample is detected with an energy dispersive detector. All spectrometers have three basic components: a radiation source, sample substance and detection mechanism. The varied energy of the characteristic radiation coming straight from the sample can be measured using this detector. The detector can distinguish between the radiation emitted by the sample and the radiation emitted by the various elements present in the sample. Dispersion is the term for this separation [50]. The sample is produced, mounted on a stud and inserted into the chamber of a machine with an SEM capability to obtain such an image. As needed, the technician can move the observation lens around and focus on different places. Under various magnifications, a variety of images can be created. The elements that predominate in the sample can also be determined using energy-dispersive X-ray spectroscopy (EDS). Comparing the attributes of known specimens can help determine the sample’s elemental and microstructural composition [54].

2.6. Permeability Tests

2.7. Cantabro Test (ASTM C1747)

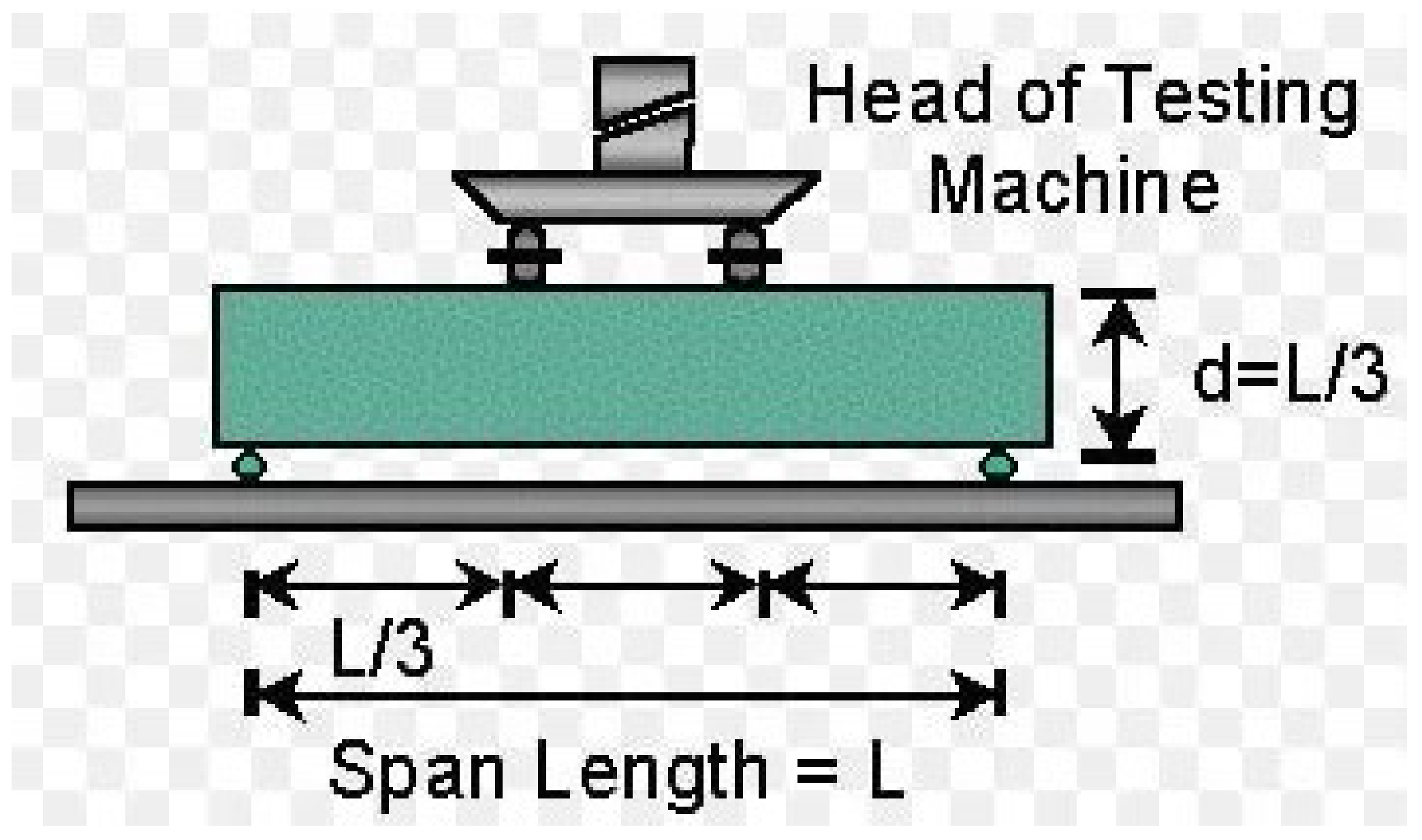

2.8. Flexural Strength Test

2.9. Model Statistical Test of Adequacy

- Null Hypothesis

- Alternative Hypothesis

3. Results Discussion and Analysis

3.1. Physicochemical Properties of the Test Materials

3.2. Chemical Characterization of the Test Cement, SDA and QD

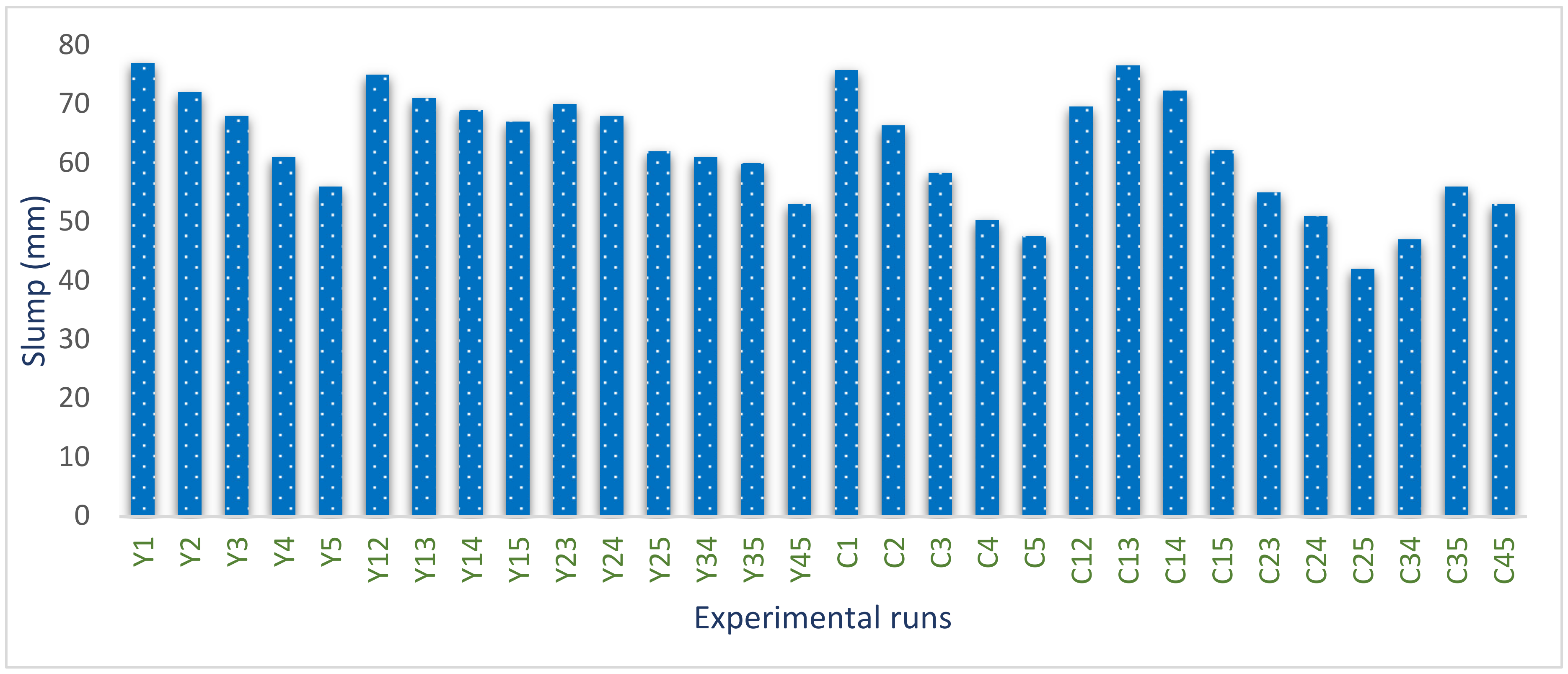

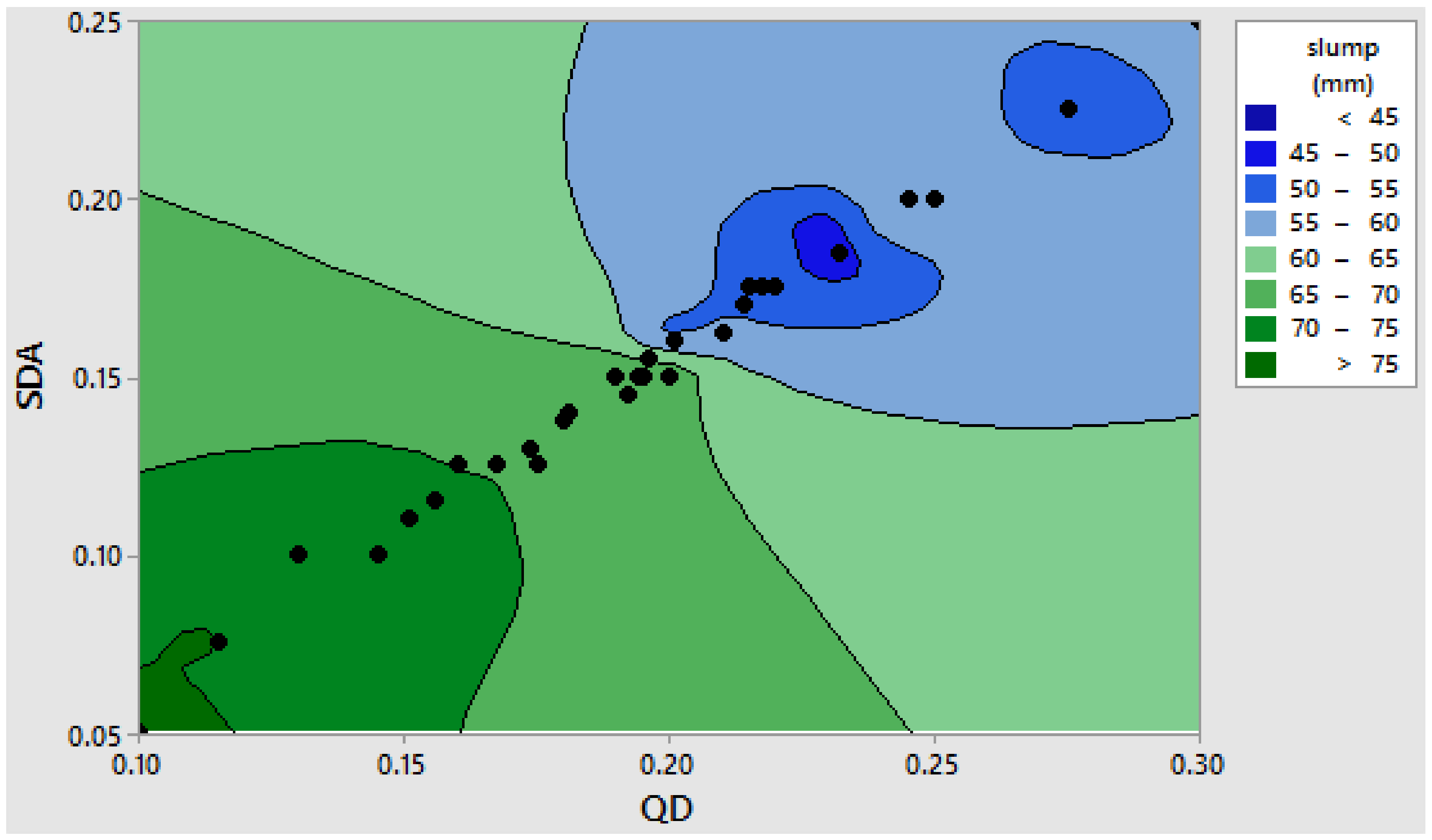

3.3. Slump Test Results

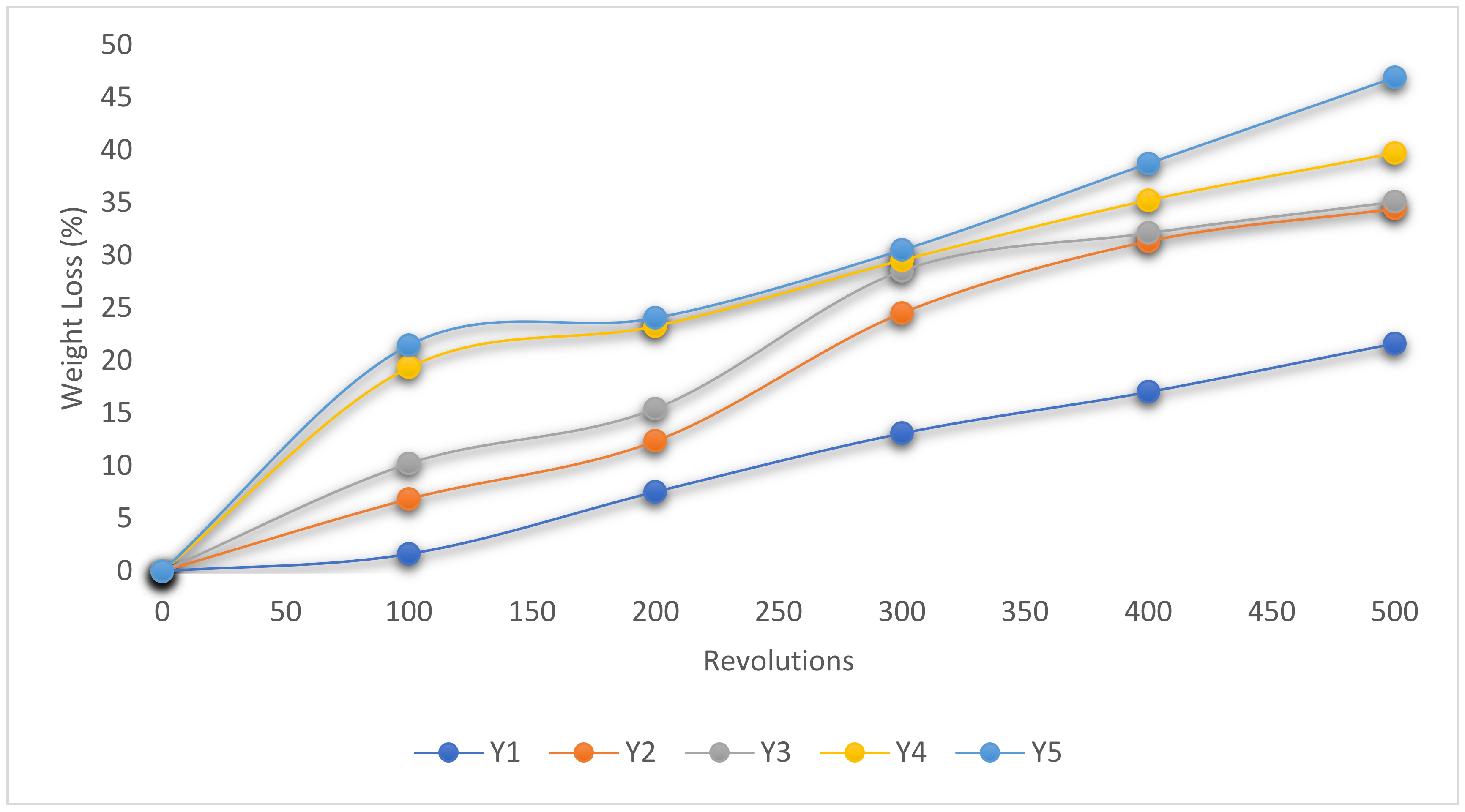

3.4. Abrasion Resistance Test

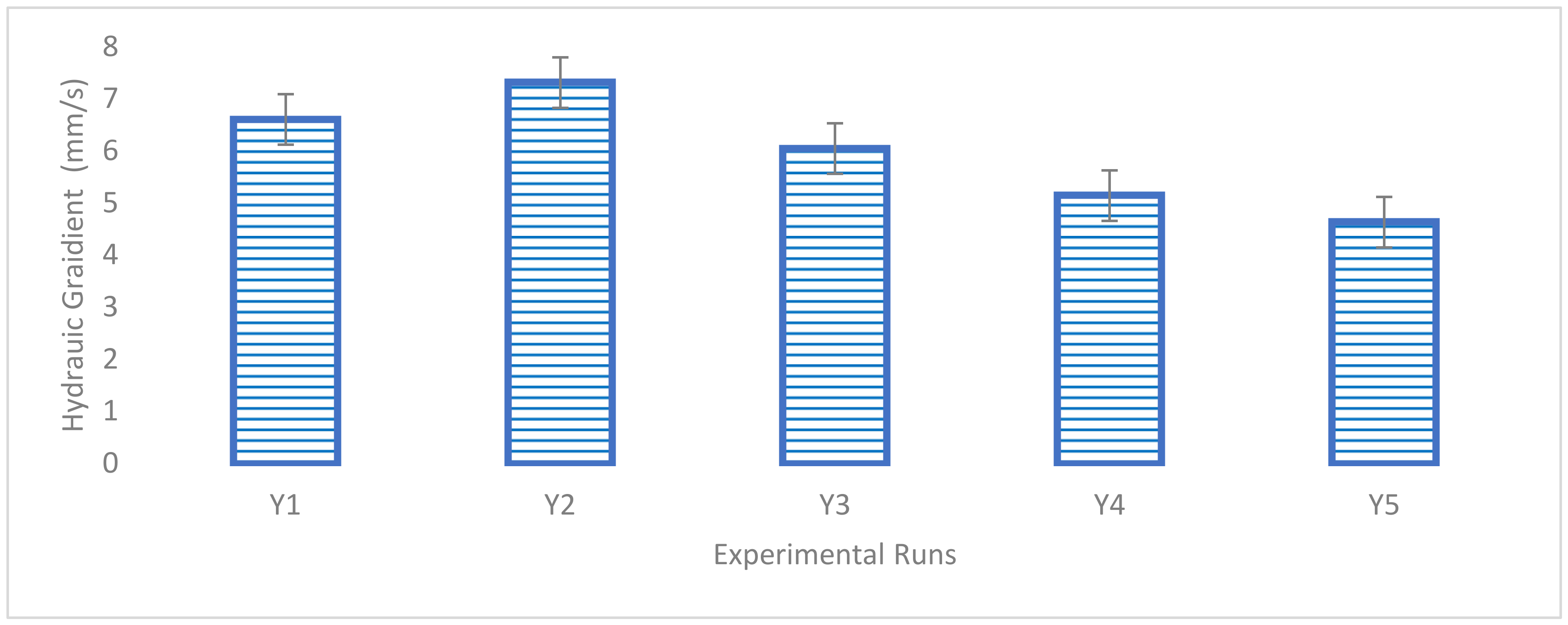

3.5. Hydraulic Conductivity

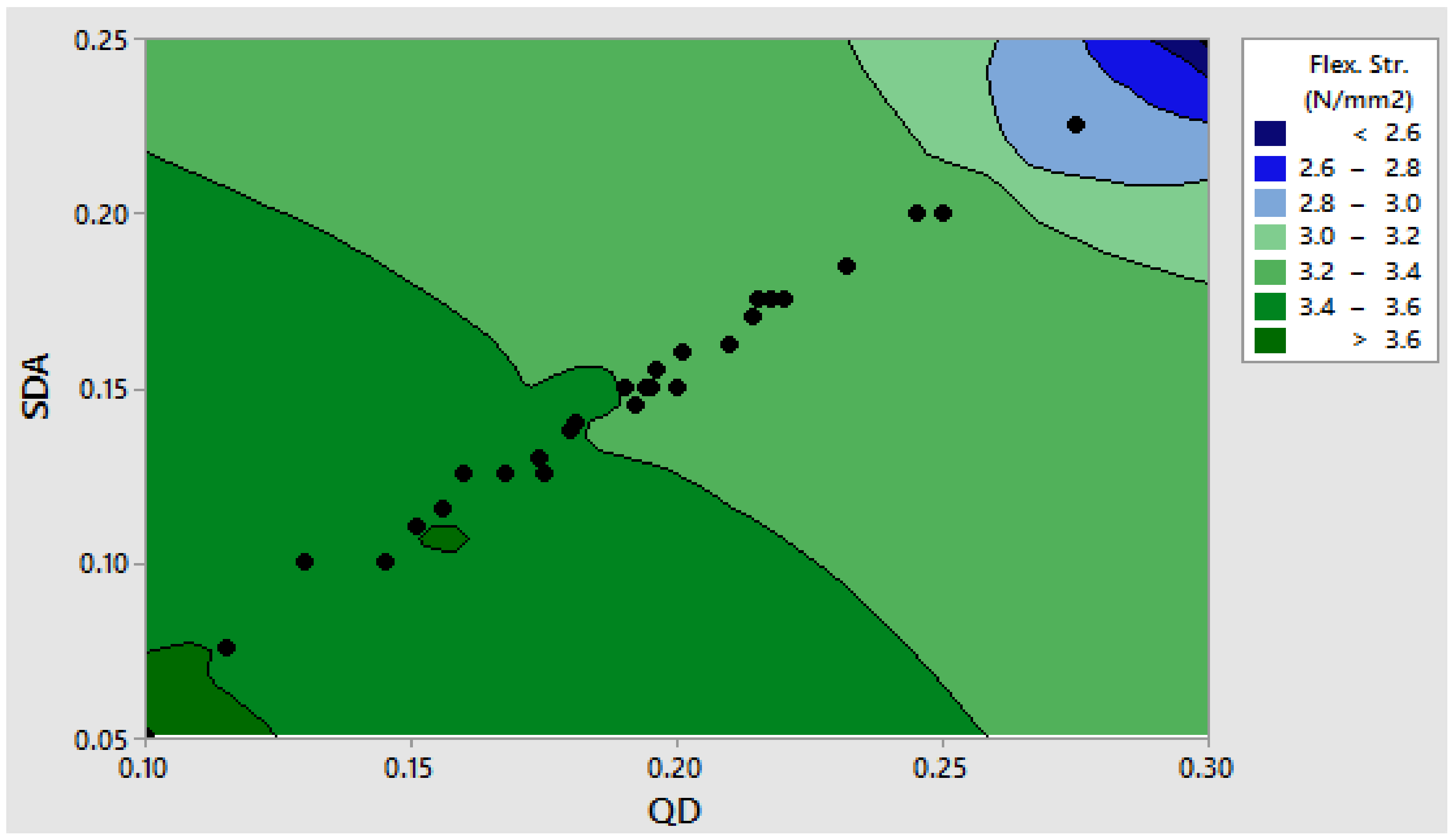

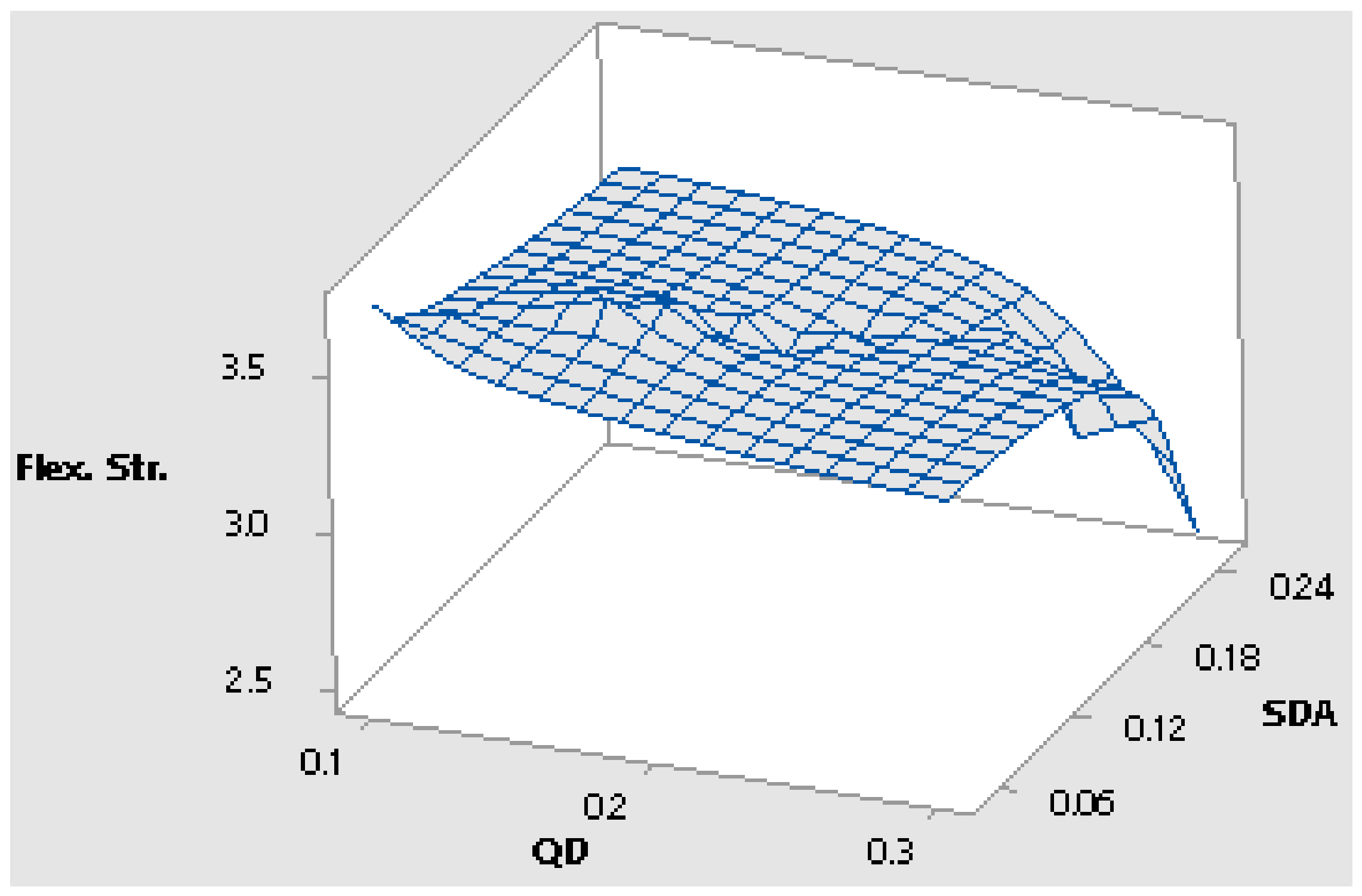

3.6. Flexural Strength Result

Scheffe’s Regression Equation

3.7. Test of Adequacy and Validation of Scheffe’s Model

Evaluation of Scheffe’s Model for Flexural Strength Property

3.8. Sensitivity Analysis

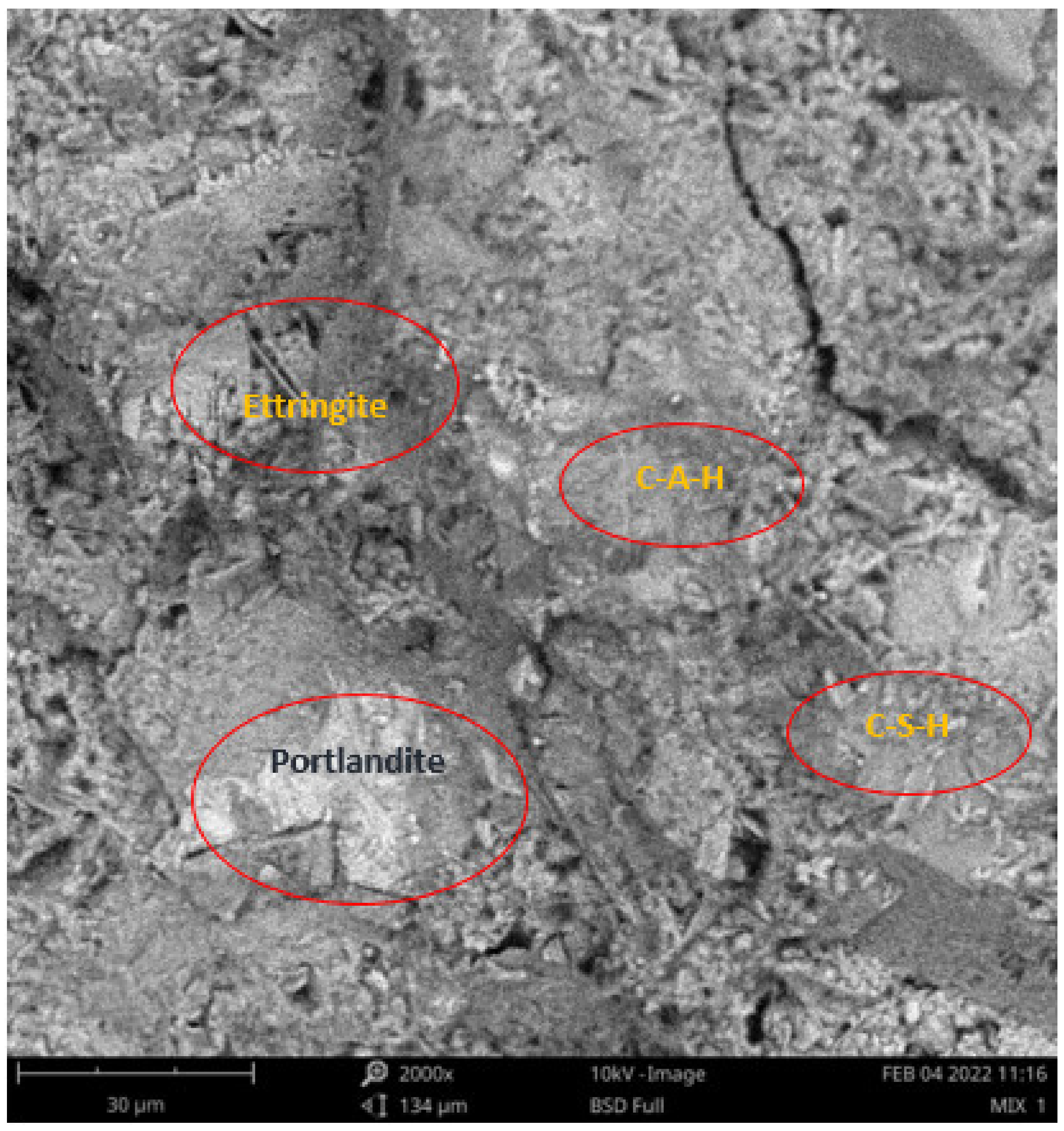

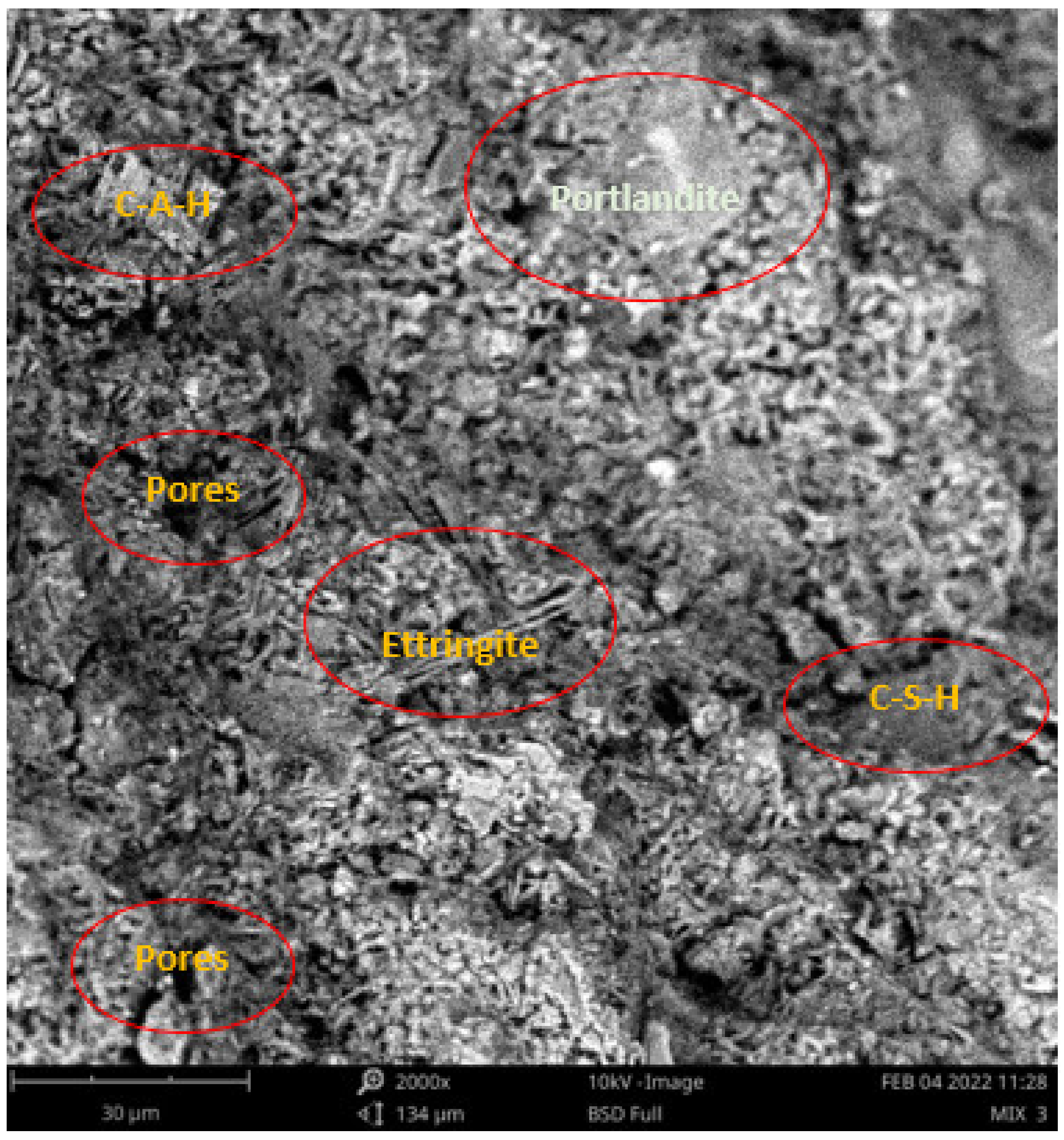

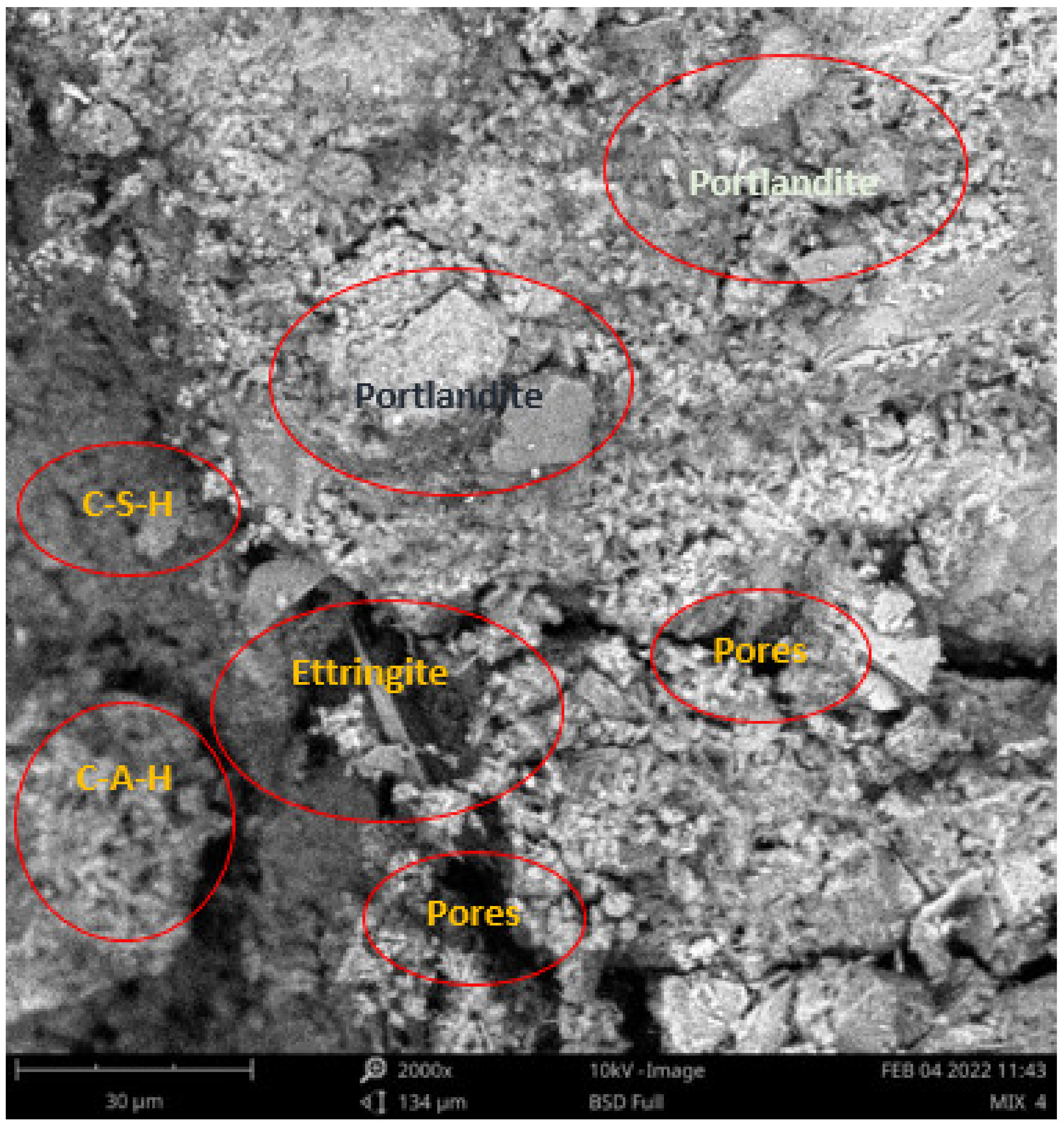

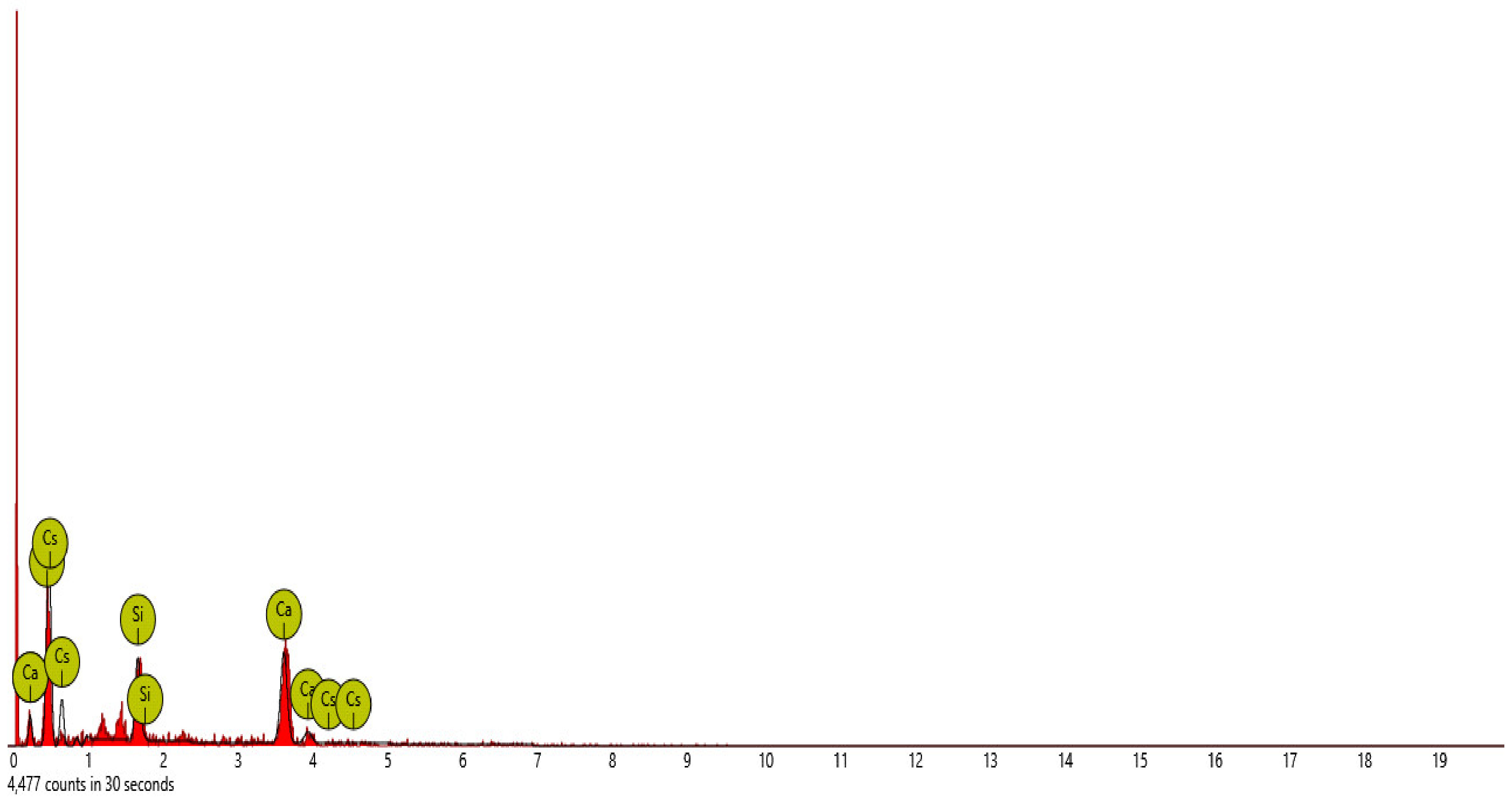

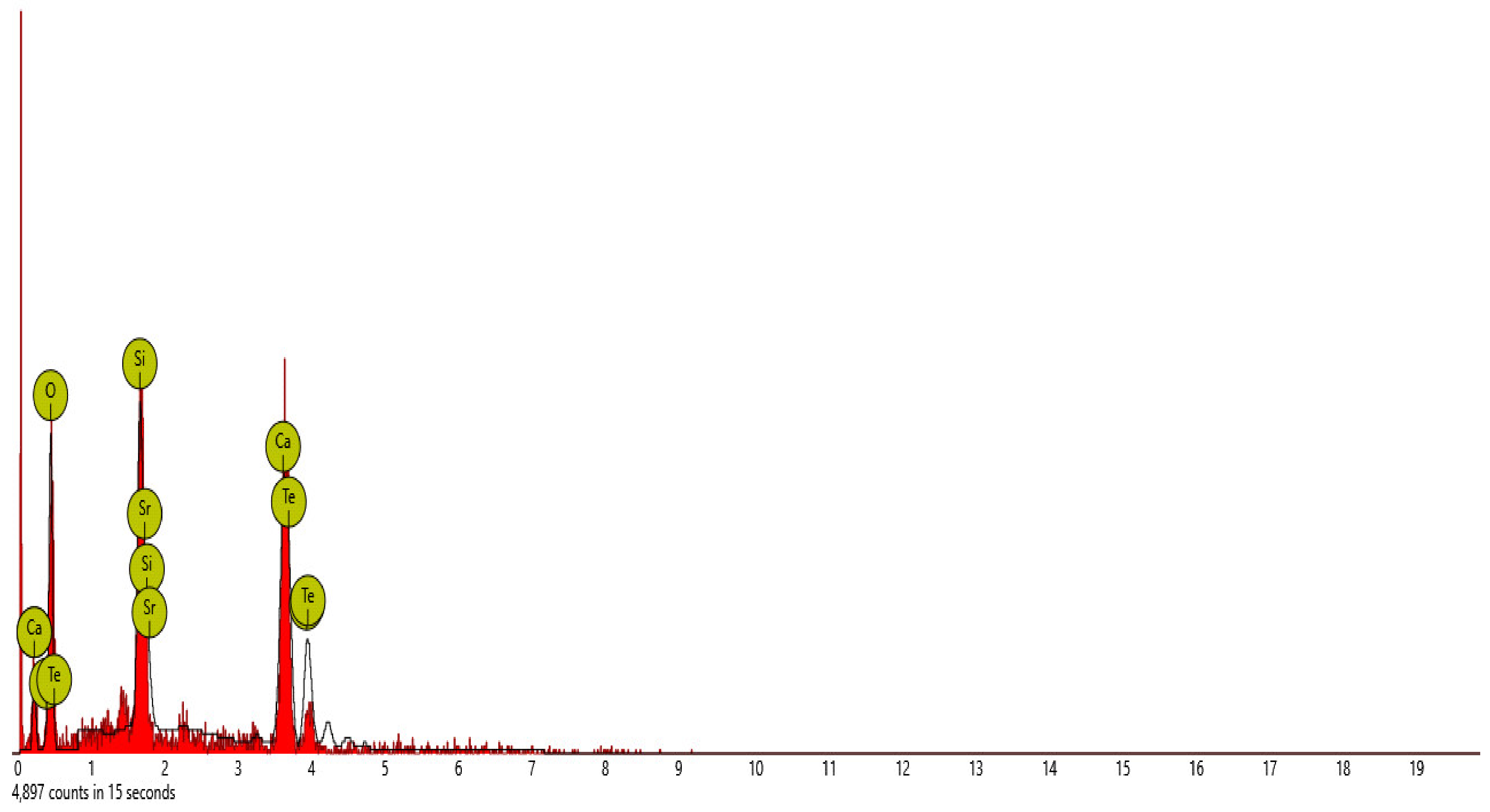

3.9. Microstructural Characterization

SEM-EDS Analysis

4. Conclusions

- Using Scheffe’s optimization method, the flexural strength properties of the pervious concrete mixed with SDA and QD was modeled using a quadratic polynomial order. When the ratios are known, the created model may forecast the flexural strength of pervious concrete made up of five constituents, and vice versa.

- The permeability test, which offers a critical evaluation of the functional behavior of pervious concrete, revealed a maximum response of 7.32 mm/s at SDA and QD contents of 2.833% and 3.683% in the concrete, respectively, allowing surface runoff to permeate through it and be directed towards a safe discharge point to prevent flooding and erosion issues. The calculated findings revealed a decrease in the hydraulic conductivity of the concrete as the SDA and QD fractions increased, indicating the existence of more voids at lower SDA and QD contents of 1.5–3.0% and 3.2–3.7% in the mixture, respectively.

- The examination of the rheological characteristics of freshly mixed concrete shows that the inclusion of pozzolanic materials reduced the slump behavior of the fresh blended pervious concrete while increasing the setting time response to maximum with a cement–SDA blend ratio of 0.75:0.25.

- The maximum compressive strength obtained from the experimental program after 28 days of curing within the factor space was 3.703 N/mm2 with a mix proportion of 0.435:0.95:0.1:1.55:0.05 for water, cement, QD, coarse aggregate and SDA, respectively, and the minimum flexural strength response of 2.504 N/mm2 was obtained with a mix ratio of 0.6:0.75:0.3:4.1:0.25 for water, cement, QD, coarse aggregate and SDA, respectively.

- Using Student’s t-test and an analysis of variance, the model’s prediction ability was statistically evaluated and validated (ANOVA). There is no substantial discrepancy between the model-predicted and actual control results, according to the computed performance evaluation result. The obtained results for flexural strength, abrasion resistance and permeability response showed robust strength applications for road drainage purposes. Additionally, with the aid of scanning electron microscopy and electron diffraction spectroscopy, the pooled effects of SDA and QD in green pervious concrete production were qualitatively inveterate.

- Thus, the combination of QD and SDA aided the concrete matrix to form porous micro structures and enhanced its mechanical and hydraulic gradient properties. Finally, the added SDA and QD were observed to be valuable constituents in the development of the green pervious concrete material with saving costs through the recycling of solid wastes and its derivatives as well as enhanced its mechanical behavior and hydraulic gradient performance for pavement applications to successfully drain storm water.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AlShareedah, O.; Nassiri, S. Methodology for Mechanistic Design of Pervious Concrete Pavements. J. Transp. Eng. Part B Pavements 2019, 145, 4019012. [Google Scholar] [CrossRef]

- Arafa, S.; Milad, A.; Yusoff, N.I.; Al-Ansari, N.; Yaseen, Z.M. Investigation into the permeability and strength of pervious geopolymer concrete containing coated biomass aggregate material. J. Mater. Res. Technol. 2021, 15, 2075–2087. [Google Scholar] [CrossRef]

- Zhong, R.; Leng, Z.; Poon, C.-S. Research and application of pervious concrete as a sustainable pavement material: A state-of-the-art and state-of-the-practice review. Constr. Build. Mater. 2018, 183, 544–553. [Google Scholar] [CrossRef]

- Aoki, Y.; Ravindrarajah, R.S.; Khabbaz, H. Properties of pervious concrete containing fly ash. Road Mater. Pavement Des. 2012, 13, 1–11. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Pervious Concrete Pavement. EPA, Washington, DC. Available online: http://cfpub.epa.gov/npdes/stormwater/menuofbmps/index.cfm?action=browse&Rbutton=detail&bmp=137&minmeas-ure=5 (accessed on 21 August 2021).

- Chandrappa, A.K.; Biligiri, K.P. Comprehensive investigation of permeability characteristics of pervious concrete: A hydrodynamic approach. Constr. Build. Mater. 2016, 123, 627–637. [Google Scholar] [CrossRef]

- Gupta, R. Monitoring in situ performance of pervious concrete in British Columbia—A pilot study. Case Stud. Constr. Mater. 2014, 1, 1–9. [Google Scholar] [CrossRef]

- Murao, K.; Yuasu, Y.; Misima, N.; Hatanaka, S. Experimental study on the strength of porous concrete with low quality recycled aggregate. J. Archit. Inst. Jpn. 2002, 8, 823–824. [Google Scholar]

- Arafa, S.; Elmesh, A.; Elbasir, O.M.M.; Yusoff, N.I.; Milad, A. Development of Nomograph Chart for Pervious Concrete Containing Coated Biomass Aggregate. Civ. Eng. Arch. 2021, 9, 47–57. [Google Scholar] [CrossRef]

- Sriravindrarajah, R.; Nguyen, L.D.; Do, H.M.; Aoki, Y. Effect of clogging on the water permeability of pervious concrete. In Proceedings of the 21st Australasian Conference on the Mechanics of Structures and Materials (ACMSM21), Melbourne, Australia, 7–10 December 2010; pp. 873–876. [Google Scholar]

- Barišić, I.; Galić, M.; Grubeša, I.N. Pervious concrete mix optimization for sustainable pavement solution. IOP Conf. Ser. Earth Environ. Sci. 2017, 90, 012091. [Google Scholar] [CrossRef]

- Kováč, M.; Sičáková, A. Pervious Concrete as an Environmental Solution for Pavements: Focus on Key Properties. Environments 2018, 5, 11. [Google Scholar] [CrossRef]

- Tennis, P.D.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Portland Cement Association: Skokie, IL, USA, 2004. [Google Scholar]

- Vaddy, P.; Singh, A.; Sampath, P.V.; Biligiri, K.P. Multi-Scale In Situ Investigation of Infiltration Parameter in Pervious Concrete Pavements. J. Test. Eval. 2020, 49, 5. [Google Scholar] [CrossRef]

- Elahi, M.; Zia, A. Suitability of local wood ash for concrete as a partial replacement of cement. In Proceedings of the 1st Conference on Sustainability in Civil Engineering, Islamabad, Pakistan, 1 August 2019; pp. 1–7. [Google Scholar]

- Uwadiegwu, A.G.; Michael, M.E. Characterization of Bambara Nut Shell Ash (BNSA) in Concrete Production. J. Kejuruter. 2021, 33, 621–634. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Alaneme, G.; Van, D.B.; Van, M.N.; Ezugwu, C.; Amhadi, T.; Sosa, F.; Orji, F.; Ugorji, B. Generalized Review on EVD and Constraints Simplex Method of Materials Properties Optimization for Civil Engineering. Civ. Eng. J. 2019, 5, 729. [Google Scholar] [CrossRef]

- Attah, I.C.; Etim, R.K.; Alaneme, G.U.; Ekpo, D.U.; Usanga, I.N. Scheffe’s approach for single additive optimization in selected soils amelioration studies for cleaner environment and sustainable subgrade materials. Clean. Mater. 2022, 5, 100126. [Google Scholar] [CrossRef]

- Attah, I.C.; Etim, R.K.; Alaneme, G.U.; Bassey, O.B. Optimization of mechanical properties of rice husk ash concrete using Scheffe’s theory. SN Appl. Sci. 2020, 2, 928. [Google Scholar] [CrossRef]

- Mulligan, A.M. Attainable Compressive Strength of Pervious Concrete Paving Systems. Master’s Thesis, University of Central Florida, Orlando, FL, USA, 2005. [Google Scholar]

- Ubachukwu, O.A.; Okafor, F.O. Formulation of predictive model for the compressive strength of oyster shell powdercement concrete using Scheffe’s simplex lattice theory. Epitoanyag—J. Silic. Based Compos. Mater. 2020, 72, 210–218. [Google Scholar] [CrossRef]

- George, U.A.; Elvis, M.M. Optimization of flexural strength of palm nut fibre concrete using Scheffe’s theory. Mater. Sci. Energy Technol. 2019, 2, 272–287. [Google Scholar] [CrossRef]

- Ambrose, E.E.; Okafor, F.O.; Onyia, M.E. Compressive strength and Scheffe’s optimization of mechanical properties of recycled ceramics tile aggregate concrete. Epitoanyag—J. Silic. Based Compos. Mater. 2021, 73, 91–102. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E.M.; Attah, I.C.; Udousoro, I.M. Mechanical behaviour optimization of saw dust ash and quarry dust concrete using adaptive neuro-fuzzy inference system. Innov. Infrastruct. Solutions 2021, 7, 122. [Google Scholar] [CrossRef]

- Iro, U.I.; Alaneme, G.U.; Milad, A.; Olaiya, B.C.; Otu, O.N.; Isu, E.U.; Amuzie, M.N. Optimization and Simulation of Saw Dust Ash Concrete Using Extreme Vertex Design Method. Adv. Mater. Sci. Eng. 2022, 2022, 5082139. [Google Scholar] [CrossRef]

- Otani, T.; Sato, Y.; Kiyohara, C.; Murakami, M.; Mitsui, Y. An equation for predicting the compressive strength of porous concrete. J. Struct. Constr. Eng. 2005, 590, 25–30. [Google Scholar] [CrossRef] [PubMed]

- George, U.A.; Elvis, M.M. Modelling of the mechanical properties of concrete with cement ratio partially replaced by aluminium waste and sawdust ash using artificial neural network. SN Appl. Sci. 2019, 1, 1514. [Google Scholar] [CrossRef]

- Nigerian Industrial Standard (NIS) 444-1; Composition, Specifications and Conformity Criteria for Common Cements. Standard Organization of Nigeria: Wupa, Nigeria, 2003.

- ASTM C1602–12; Standard Specification for Mixing Water Used in the Production Hydraulic Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C 618; Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolanas for Use as Mineral Admixtures in Ordinary Portland Cement Concrete. Annual Book of ASTM Standards: West Conshecken, PA, USA, 2008.

- British Standard (BS) EN 12620; Aggregates for Concrete. British Standard Institution: London, UK, 2002.

- BS 8615–1:2019; Specification for Pozzolanic Materials for Use with Portland Cement. Natural Pozzolana and Natural Calcined Pozzolana. British Standard Institution: London, UK, 2019.

- Ezeokpube, G.C.; Alaneme, G.U.; Attah, I.C.; Udousoro, I.M.; Nwogbo, D. Experimental investigation of crude oil contaminated soil for sustainable concrete production. Arch. Struct. Constr. 2022, 2, 349–364. [Google Scholar] [CrossRef]

- Onyelowe, K.; Alaneme, G.; Igboayaka, C.; Orji, F.; Ugwuanyi, H.; Van, D.B.; Van, M.N. Scheffe optimization of swelling, California bearing ratio, compressive strength, and durability potentials of quarry dust stabilized soft clay soil. Mater. Sci. Energy Technol. 2018, 2, 67–77. [Google Scholar] [CrossRef]

- Oguaghamba, O.; Okafor, F.; Anokwute, V. Application of Scheffe’s Model for stabilization of Amuro-okigwe subgrade using male inflorescence of oil palm ash. Niger. J. Technol. 2019, 38, 60. [Google Scholar] [CrossRef]

- Uwanuakwa, I.D.; Idoko, J.B.; Mbadike, E.; Reşatoğlu, R.; Alaneme, G. Application of deep learning in structural health management of concrete structures. Proc. Inst. Civ. Eng.-Bridg. Eng. 2022, 1–8. [Google Scholar] [CrossRef]

- Ikpa, C.C.; Alaneme, G.U.; Mbadike, E.M.; Nnadi, E.; Chigbo, I.C.; Abel, C.; Udousoro, I.M.; Odum, L.O. Evaluation of Water Quality Impact on the Compressive Strength of Concrete. J. Kejuruter. 2021, 33, 527–538. [Google Scholar]

- Gen, M.; Cheng, R. Genetic Algorithm and Engineering Design; John Wiley & Sons Inc.: New York, NY, USA, 1997. [Google Scholar]

- Scheffe, H. Experiments with Mixtures. J. R. Stat. Soc. Ser. B 1958, 20, 344–360. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E.M. Experimental investigation of Bambara nut shell ash in the production of concrete and mortar. Innov. Infrastruct. Solutions 2021, 6, 66. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E. Modelling of the Compressive Strength of Palm-Nut-Fibre Concrete Using Scheffe’s Theory. Comput. Eng. Phys. Model. 2020, 3, 36–52. [Google Scholar] [CrossRef]

- Claringbold, P.J. Use of the Simplex Design in the Study of Joint Action of Related Hormones. Biometrics 1955, 11, 174. [Google Scholar] [CrossRef]

- Becker, N.G. Models for the Response of a Mixture. J. R. Stat. Soc. Ser. B 1968, 30, 349–358. [Google Scholar] [CrossRef]

- Ezeh, J.C.; Ibearugbulem, O.M. Application of Scheffe’s model in optimization of compressive strength of Rivers stone Aggregate concrete. Int. J. Nat. Appl. Sci. 2009, 5, 303–308. [Google Scholar]

- Gamil, Y.; Zamahri, K.A.; Bakar, I. Application of Scheffe’s Theory to Develop Mathematical Prediction Model to Predict UCS for Hybrid Containing Organic Soil and POFA-OPC Additives. Civ. Eng. Arch. 2018, 6, 54–64. [Google Scholar] [CrossRef]

- Scheffé, H. The Simplex-Centroid Design for Experiments with Mixtures. J. R. Stat. Soc. Ser. B 1963, 25, 235–251. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Attah, I.C.; Etim, R.K.; Dimonyeka, M.U. Mechanical Properties Optimization of Soil—Cement Kiln Dust Mixture Using Extreme Vertex Design. Int. J. Pavement Res. Technol. 2021, 15, 719–750. [Google Scholar] [CrossRef]

- Attah, I.C.; Okafor, F.O.; Ugwu, O.O. Optimization of California bearing ratio of tropical black clay soil treated with cement kiln dust and metakaolin blend. Int. J. Pavement Res. Technol. 2020, 14, 655–667. [Google Scholar] [CrossRef]

- Simon, M.J. Concrete Mixture Optimization Using Statistical Method. Final Report; Federal Highway Administration: Maclean, VA, USA, 2003; pp. 120–127.

- Ezeokpube, G.C.; Ahaneku, I.E.; Alaneme, G.U.; Attah, I.C.; Etim, R.K.; Olaiya, B.C.; Udousoro, I.M. Assessment of Mechanical Properties of Soil-Lime-Crude Oil-Contaminated Soil Blend Using Regression Model for Sustainable Pavement Foundation Construction. Adv. Mater. Sci. Eng. 2022, 2022, 7207842. [Google Scholar] [CrossRef]

- Pessanha, S.; Queralt, I.; Carvalho, M.L.; Sampaio, J.M. Determination of gold leaf thickness using X-ray fluorescence spectrometry: Accuracy comparison using analytical methodology and Monte Carlo Simulations. Appl. Radiat. Isot. 2019, 152, 6–10. [Google Scholar] [CrossRef]

- De Viguerie, L.; Sole, V.A.; Walter, P. Multilayers quantitative X-ray fluorescence analysis applied to easel paintings. Anal. Bioanal. Chem. 2009, 395, 2015–2020. [Google Scholar] [CrossRef]

- Joy, D.C.; Bradbury, S.; Ford, B.J. Scanning Electron Microscope—Encyclopedia Britannica. Available online: https://www.britannica.com/technology/scanning-electron-microscope (accessed on 21 August 2021).

- Etim, R.K.; Attah, I.C.; Ekpo, D.U.; Usanga, I.N. Evaluation on Stabilization Role of Lime and Cement in Expansive Black Clay-Oyster Shell Ash Composite. Transp. Infrastruct. Geotechnol. 2021, 9, 729–763. [Google Scholar] [CrossRef]

- Wanielista, M.; Chopra, M.; Spence, J.; Ballock, C. Hydraulic Performance Assessment of Pervious Concrete Pavements for Stormwater Management Credit. Final Report; Florida Department of Transportation: Tallahassee, FL, USA, 2007.

- Lederle, R.; Shepard, T.; Meza, V.D.L.V. Comparison of methods for measuring infiltration rate of pervious concrete. Constr. Build. Mater. 2020, 244, 118339. [Google Scholar] [CrossRef]

- Wu, H.; Huang, B.; Shu, X.; Dong, Q. Laboratory Evaluation of Abrasion Resistance of Portland Cement Pervious Concrete. J. Mater. Civ. Eng. 2011, 23, 697–702. [Google Scholar] [CrossRef]

- Ndububa, E.E.; Osadebe, N.N. An optimization of the flexural strength of fibre cement mixtures using Scheffe’s simplex lattice. Niger. Soc. Eng. Tech. Trans. 2007, 42, 1–5. [Google Scholar]

- ASTM C1161-02c(2008)e1; Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature. ASTM International: West Conshohocken, PA, USA, 2013.

- Alaneme, G.U.; Mbadike, E.M. Optimisation of strength development of bentonite and palm bunch ash concrete using fuzzy logic. Int. J. Sustain. Eng. 2021, 14, 835–851. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Mbadike, E.M.; Iro, U.I.; Udousoro, I.M.; Ifejimalu, W.C. Adaptive neuro-fuzzy inference system prediction model for the mechanical behaviour of rice husk ash and periwinkle shell concrete blend for sustainable construction. Asian J. Civ. Eng. 2021, 22, 959–974. [Google Scholar] [CrossRef]

- Etim, R.K.; Attah, I.C.; Yohanna, P. Experimental study on potential of oyster shell ash in structural strength improvement of lateritic soil for road construction. Int. J. Pavement Res. Technol. 2020, 13, 341–351. [Google Scholar] [CrossRef]

- Sofi, A.; Saxena, A.; Agrawal, P.; Sharma, A.R.; Sharma, K. Strength predictions of saw dust and steel fibers in concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 12473–12477. [Google Scholar]

- Elinwa, A.U.; Mamuda, A.M. Sawdust ash as powder material for self-compacting concrete containing naphthalene sulfonate. Adv. Civil. Eng. 2014, 2014, 129276. [Google Scholar] [CrossRef]

- Ogbonna, C.; Mbadike, E.M.; Alaneme, G.U. Effects of Cassava-Peel-Ash on Mechanical Properties of Concrete. Umudike J. Eng. Technol. 2021, 6, 61–75. [Google Scholar] [CrossRef]

- Ma, W. Behavior of Aged Reinforced Concrete Columns under High Sustained Concentric and Eccentric Loads. Ph.D. Thesis, University of Nevada, Las Vegas, NV, USA, 2021. [Google Scholar]

- Vancura, M.; MacDonald, K.; Khazanovich, L. Structural Analysis of Pervious Concrete Pavement. Transp. Res. Rec. J. Transp. Res. Board 2011, 2226, 13–20. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Sebaibi, N.; Boutouil, M.; Leleyter, L.; Baraud, F. A modified method for the design of pervious concrete mix. Constr. Build. Mater. 2014, 73, 271–282. [Google Scholar] [CrossRef]

- Schaefer, V.R.; Wang, K.; Suleiman, M.T.; Kevern, J.T. Mix Design Development for Pervious Concrete in Cold Weather Climates; Reports from National Concrete Pavement Technology Center; Iowa Department of Transportation: Ames, IA, USA, 2006.

- Khankhaje, E.; Razman, M.; Mirza, J.; Warid, M. Sustainable pervious concrete incorporating palm oil fuel ash as cement replacement. Chem. Eng. Trans. 2017, 56, 445–450. [Google Scholar]

- American Concrete Institute (ACI). Report on Pervious Concrete. ACI 522R-ACI; 38800 Country Club Drive: Farmington Hills, MI, USA, 2010. [Google Scholar]

- Alaneme, G.U.; Attah, I.C.; Mbadike, E.M.; Dimonyeka, M.U.; Usanga, I.N.; Nwankwo, H.F. Mechanical strength optimization and simulation of cement kiln dust concrete using extreme vertex design method. Nanotechnol. Environ. Eng. 2021, 7, 467–490. [Google Scholar] [CrossRef]

- Ujong, J.A.; Mbadike, E.M.; Alaneme, G.U. Prediction of cost and duration of building construction using artificial neural network. Asian J. Civ. Eng. 2022, 23, 1117–1139. [Google Scholar] [CrossRef]

- Obianyo, J.I.; Okey, O.E.; Alaneme, G.U. Assessment of cost overrun factors in construction projects in Nigeria using fuzzy logic. Innov. Infrastruct. Solut. 2022, 7, 304. [Google Scholar] [CrossRef]

- Iqbal, M.; Onyelowe, K.C.; Jalal, F.E. Smart computing models of California bearing ratio, unconfined compressive strength, and resistance value of activated ash-modified soft clay soil with adaptive neuro-fuzzy inference system and ensemble random forest regression techniques. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 207–225. [Google Scholar] [CrossRef]

- Aju, D.E.; Onyelowe, K.C.; Alaneme, G.U. Constrained vertex optimization and simulation of the unconfined compressive strength of geotextile reinforced soil for flexible pavement foundation construction. Clean. Eng. Technol. 2021, 5, 100287. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artifcial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Alaneme, G.U.; Dimonyeka, M.U.; Ezeokpube, G.C.; Uzoma, I.I.; Udousoro, I.M. Failure assessment of dys-functional flexible pavement drainage facility using fuzzy analytical hierarchical process. Innov. Infrastruct. Solutions 2021, 6, 122. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Jalal, F.E.; Onyia, M.E.; Onuoha, I.C.; Alaneme, G.U. Application of Gene Expression Programming to Evaluate Strength Characteristics of Hydrated-Lime-Activated Rice Husk Ash-Treated Expansive Soil. Appl. Comput. Intell. Soft Comput. 2021, 2021, 6686347. [Google Scholar] [CrossRef]

- Chimmaobi, O.; Mbadike, E.M.; Alaneme, G.U. Experimental Investigation of Cassava Peel Ash in the Production of Concrete and Mortar. Umudike J. Eng. Technol. 2020, 6, 10–21. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

| Actual | Pseudo | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Z5 | Response | X1 | X2 | X3 | X4 | X5 |

| 0.435 | 0.95 | 0.1 | 1.55 | 0.05 | Y1 | 1 | 0 | 0 | 0 | 0 |

| 0.45 | 0.9 | 0.13 | 1.95 | 0.1 | Y2 | 0 | 1 | 0 | 0 | 0 |

| 0.5 | 0.85 | 0.19 | 2.85 | 0.15 | Y3 | 0 | 0 | 1 | 0 | 0 |

| 0.55 | 0.8 | 0.25 | 3.55 | 0.2 | Y4 | 0 | 0 | 0 | 1 | 0 |

| 0.6 | 0.75 | 0.3 | 4.1 | 0.25 | Y5 | 0 | 0 | 0 | 0 | 1 |

| 0.4425 | 0.925 | 0.115 | 1.75 | 0.075 | Y12 | 0.5 | 0.5 | 0 | 0 | 0 |

| 0.4675 | 0.9 | 0.145 | 2.2 | 0.1 | Y13 | 0.5 | 0 | 0.5 | 0 | 0 |

| 0.4925 | 0.875 | 0.175 | 2.55 | 0.125 | Y14 | 0.5 | 0 | 0 | 0.5 | 0 |

| 0.5175 | 0.85 | 0.2 | 2.825 | 0.15 | Y15 | 0.5 | 0 | 0 | 0 | 0.5 |

| 0.475 | 0.875 | 0.16 | 2.4 | 0.125 | Y23 | 0 | 0.5 | 0.5 | 0 | 0 |

| 0.5 | 0.85 | 0.19 | 2.75 | 0.15 | Y24 | 0 | 0.5 | 0 | 0.5 | 0 |

| 0.525 | 0.825 | 0.215 | 3.025 | 0.175 | Y25 | 0 | 0.5 | 0 | 0 | 0.5 |

| 0.525 | 0.825 | 0.22 | 3.2 | 0.175 | Y34 | 0 | 0 | 0.5 | 0.5 | 0 |

| 0.55 | 0.8 | 0.245 | 3.475 | 0.2 | Y35 | 0 | 0 | 0.5 | 0 | 0.5 |

| 0.575 | 0.775 | 0.275 | 3.825 | 0.225 | Y45 | 0 | 0 | 0 | 0.5 | 0.5 |

| Actual | Pseudo | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Z1 | Z2 | Z3 | Z4 | Z5 | Response | X1 | X2 | X3 | X4 | X5 |

| 0.48375 | 0.875 | 0.1675 | 2.475 | 0.125 | C1 | 0.25 | 0.25 | 0.25 | 0.25 | 0 |

| 0.49625 | 0.8625 | 0.18 | 2.6125 | 0.1375 | C2 | 0.25 | 0.25 | 0.25 | 0 | 0.25 |

| 0.50875 | 0.85 | 0.195 | 2.7875 | 0.15 | C3 | 0.25 | 0.25 | 0 | 0.25 | 0.25 |

| 0.52125 | 0.8375 | 0.21 | 3.0125 | 0.1625 | C4 | 0.25 | 0 | 0.25 | 0.25 | 0.25 |

| 0.525 | 0.825 | 0.2175 | 3.1125 | 0.175 | C5 | 0 | 0.25 | 0.25 | 0.25 | 0.25 |

| 0.507 | 0.85 | 0.194 | 2.8 | 0.15 | C12 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| 0.4705 | 0.89 | 0.151 | 2.26 | 0.11 | C13 | 0.3 | 0.3 | 0.3 | 0.1 | 0 |

| 0.4755 | 0.885 | 0.156 | 2.315 | 0.115 | C14 | 0.3 | 0.3 | 0.3 | 0 | 0.1 |

| 0.4905 | 0.87 | 0.174 | 2.525 | 0.13 | C15 | 0.3 | 0.3 | 0 | 0.3 | 0.1 |

| 0.5055 | 0.855 | 0.192 | 2.795 | 0.145 | C23 | 0.3 | 0 | 0.3 | 0.3 | 0.1 |

| 0.51 | 0.84 | 0.201 | 2.915 | 0.16 | C24 | 0 | 0.3 | 0.3 | 0.3 | 0.1 |

| 0.5385 | 0.815 | 0.232 | 3.305 | 0.185 | C25 | 0.1 | 0 | 0.3 | 0.3 | 0.3 |

| 0.5235 | 0.83 | 0.214 | 3.035 | 0.17 | C34 | 0.1 | 0.3 | 0 | 0.3 | 0.3 |

| 0.5085 | 0.845 | 0.196 | 2.825 | 0.155 | C35 | 0.1 | 0.3 | 0.3 | 0 | 0.3 |

| 0.4935 | 0.86 | 0.181 | 2.66 | 0.14 | C45 | 0.1 | 0.3 | 0.3 | 0.3 | 0 |

| Test Materials | D10 | D30 | D60 | Cu | Cc |

|---|---|---|---|---|---|

| SDA | 0.06 | 0.085 | 0.125 | 2.083333 | 0.963333 |

| Coarse Agg. | 1.85 | 3 | 5.1 | 2.756757 | 0.953895 |

| QD | 0.135 | 0.4 | 0.9 | 6.666667 | 1.316872 |

| Oxide | CuO | Na2O | Fe2O3 | MnO | Cr2O3 | TiO2 | CaO | Al2O3 | MgO | ZnO | SO3 | SiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SDA (%) | 0.085 | 1.0 | 4.3 | 0.45 | Nil | 0.07 | 10.4 | 8.35 | 3.01 | Nil | 0.89 | 57.85 | 6.5 |

| QD (%) | Nil | Nil | 6.01 | Nil | 0.2 | 3.612 | 13.52 | 15.93 | 4.78 | 0.005 | Nil | 48.5 | 1.8 |

| Oxide | CaO | MgO | Fe2O3 | Na2O | Al2O3 | SiO2 | MnO | LOI | CUO | TiO2 | CdO | K2O |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement (%) | 11.3 | 0.093 | 6.405 | 2.1 | 20.6 | 52.4 | Trace | 3.9 | Trace | 0.52 | Trace | 2.6 |

| Z1 | Z2 | Z3 | Z4 | Z5 | Flex. Str. (N/mm2) | X1 | X2 | X3 | X4 | X5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Y1 | 0.435 | 0.95 | 0.1 | 1.55 | 0.05 | 3.7028 | 1 | 0 | 0 | 0 | 0 |

| Y2 | 0.45 | 0.9 | 0.13 | 1.95 | 0.1 | 3.5303 | 0 | 1 | 0 | 0 | 0 |

| Y3 | 0.5 | 0.85 | 0.19 | 2.85 | 0.15 | 3.606 | 0 | 0 | 1 | 0 | 0 |

| Y4 | 0.55 | 0.8 | 0.25 | 3.55 | 0.2 | 3.2928 | 0 | 0 | 0 | 1 | 0 |

| Y5 | 0.6 | 0.75 | 0.3 | 4.1 | 0.25 | 2.5036 | 0 | 0 | 0 | 0 | 1 |

| Y12 | 0.4425 | 0.925 | 0.115 | 1.75 | 0.075 | 3.5936 | 0.5 | 0.5 | 0 | 0 | 0 |

| Y13 | 0.4675 | 0.9 | 0.145 | 2.2 | 0.1 | 3.5012 | 0.5 | 0 | 0.5 | 0 | 0 |

| Y14 | 0.4925 | 0.875 | 0.175 | 2.55 | 0.125 | 3.4508 | 0.5 | 0 | 0 | 0.5 | 0 |

| Y15 | 0.5175 | 0.85 | 0.2 | 2.825 | 0.15 | 3.3036 | 0.5 | 0 | 0 | 0 | 0.5 |

| Y23 | 0.475 | 0.875 | 0.16 | 2.4 | 0.125 | 3.4264 | 0 | 0.5 | 0.5 | 0 | 0 |

| Y24 | 0.5 | 0.85 | 0.19 | 2.75 | 0.15 | 3.3252 | 0 | 0.5 | 0 | 0.5 | 0 |

| Y25 | 0.525 | 0.825 | 0.215 | 3.025 | 0.175 | 3.2352 | 0 | 0.5 | 0 | 0 | 0.5 |

| Y34 | 0.525 | 0.825 | 0.22 | 3.2 | 0.175 | 3.2456 | 0 | 0 | 0.5 | 0.5 | 0 |

| Y35 | 0.55 | 0.8 | 0.245 | 3.475 | 0.2 | 3.1948 | 0 | 0 | 0.5 | 0 | 0.5 |

| Y45 | 0.575 | 0.775 | 0.275 | 3.825 | 0.225 | 2.8232 | 0 | 0 | 0 | 0.5 | 0.5 |

| Z1 | Z2 | Z3 | Z4 | Z5 | Flex. Str. (N/mm2) | X1 | X2 | X3 | X4 | X5 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.484 | 0.875 | 0.168 | 2.475 | 0.125 | 3.6808 | 0.25 | 0.25 | 0.25 | 0.25 | 0 |

| C2 | 0.496 | 0.863 | 0.180 | 2.613 | 0.138 | 3.5152 | 0.25 | 0.25 | 0.25 | 0 | 0.25 |

| C3 | 0.509 | 0.850 | 0.195 | 2.788 | 0.150 | 3.4628 | 0.25 | 0.25 | 0 | 0.25 | 0.25 |

| C4 | 0.521 | 0.838 | 0.210 | 3.013 | 0.163 | 3.434 | 0.25 | 0 | 0.25 | 0.25 | 0.25 |

| C5 | 0.525 | 0.825 | 0.218 | 3.113 | 0.175 | 3.2896 | 0 | 0.25 | 0.25 | 0.25 | 0.25 |

| C12 | 0.507 | 0.850 | 0.194 | 2.800 | 0.150 | 3.2528 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| C13 | 0.471 | 0.890 | 0.151 | 2.260 | 0.110 | 3.6504 | 0.3 | 0.3 | 0.3 | 0.1 | 0 |

| C14 | 0.476 | 0.885 | 0.156 | 2.315 | 0.115 | 3.646 | 0.3 | 0.3 | 0.3 | 0 | 0.1 |

| C15 | 0.491 | 0.870 | 0.174 | 2.525 | 0.130 | 3.5956 | 0.3 | 0.3 | 0 | 0.3 | 0.1 |

| C23 | 0.506 | 0.855 | 0.192 | 2.795 | 0.145 | 3.298 | 0.3 | 0 | 0.3 | 0.3 | 0.1 |

| C24 | 0.510 | 0.840 | 0.201 | 2.915 | 0.160 | 3.2636 | 0 | 0.3 | 0.3 | 0.3 | 0.1 |

| C25 | 0.539 | 0.815 | 0.232 | 3.305 | 0.185 | 3.3308 | 0.1 | 0 | 0.3 | 0.3 | 0.3 |

| C34 | 0.524 | 0.830 | 0.214 | 3.035 | 0.170 | 3.2832 | 0.1 | 0.3 | 0 | 0.3 | 0.3 |

| C35 | 0.509 | 0.845 | 0.196 | 2.825 | 0.155 | 3.3656 | 0.1 | 0.3 | 0.3 | 0 | 0.3 |

| C45 | 0.494 | 0.860 | 0.181 | 2.660 | 0.140 | 3.1928 | 0.1 | 0.3 | 0.3 | 0.3 | 0 |

| β1 | β2 | β3 | β4 | β5 | β12 | β13 | β14 | β15 | β23 | β24 | β25 | β34 | β35 | β45 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.70 | 3.53 | 3.61 | 3.29 | 2.50 | −0.09 | −0.61 | −0.19 | 0.80 | −0.57 | −0.35 | 0.87 | −0.82 | 0.56 | −0.30 |

| Summary | ||||||

|---|---|---|---|---|---|---|

| Groups | Count | Sum | Average | Variance | ||

| Exp results | 15 | 50.0348 | 3.335653 | 0.017872 | ||

| Predicted results | 15 | 49.66066 | 3.310711 | 0.008116 | ||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between groups | 0.004666 | 1 | 0.004666 | 0.359077 | 0.553837 | 4.195972 |

| Within groups | 0.363836 | 28 | 0.012994 | |||

| Total | 0.368502 | 29 | ||||

| Exp. Results | Predicted Results | |

|---|---|---|

| Mean | 3.335653 | 3.310711 |

| Variance | 0.017872 | 0.008116 |

| Observations | 15 | 15 |

| Pearson correlation | 0.907144 | |

| Degrees of freedom | 14 | |

| t Stat | 1.50179 | |

| P(T ≤ t) one-tail | 0.077684 | |

| t critical one-tail | 1.76131 | |

| P(T ≤ t) two-tail | 0.155367 | |

| t critical two-tail | 2.144787 |

| S/n | Parameter Removed | MAE | RMSE | Rank |

|---|---|---|---|---|

| 1 | OPC | 3.85 | 4.22 | 2 |

| 2 | SDA | 1.74 | 2.62 | 5 |

| 3 | w/c | 4.17 | 4.51 | 1 |

| 4 | Coarse Agg. | 1.96 | 2.97 | 4 |

| 5 | QD | 3.64 | 3.99 | 3 |

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

| 8 | O | Oxygen | 67.08 | 46.91 | |

| 20 | Ca | Calcium | 24.16 | 42.33 | |

| 14 | Si | Silicon | 8.76 | 10.75 |

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

| 20 | Ca | Calcium | 25.91 | 36.74 | |

| 8 | O | Oxygen | 64.67 | 36.62 | |

| 35 | Br | Bromine | 9.42 | 26.64 |

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

| 52 | Te | Tellurium | 20.17 | 50.83 | |

| 20 | Ca | Calcium | 27.53 | 21.79 | |

| 8 | O | Oxygen | 31.88 | 10.07 | |

| 38 | Sr | Strontium | 5.09 | 8.80 | |

| 14 | Si | Silicon | 15.33 | 8.50 |

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

| 8 | O | Oxygen | 63.26 | 43.57 | |

| 20 | Ca | Calcium | 23.24 | 40.10 | |

| 14 | Si | Silicon | 13.50 | 16.33 |

| Element Number | Element Symbol | Element Name | Atomic Conc. | Weight Conc. |

| 74 | W | Tungsten | 23.71 | 69.43 | |

| 20 | Ca | Calcium | 29.04 | 18.53 | |

| 8 | O | Oxygen | 47.25 | 12.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ewa, D.E.; Ukpata, J.O.; Otu, O.N.; Memon, Z.A.; Alaneme, G.U.; Milad, A. Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction. Materials 2023, 16, 598. https://doi.org/10.3390/ma16020598

Ewa DE, Ukpata JO, Otu ON, Memon ZA, Alaneme GU, Milad A. Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction. Materials. 2023; 16(2):598. https://doi.org/10.3390/ma16020598

Chicago/Turabian StyleEwa, Desmond E., Joseph O. Ukpata, Obeten Nicholas Otu, Zubair Ahmed Memon, George Uwadiegwu Alaneme, and Abdalrhman Milad. 2023. "Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction" Materials 16, no. 2: 598. https://doi.org/10.3390/ma16020598

APA StyleEwa, D. E., Ukpata, J. O., Otu, O. N., Memon, Z. A., Alaneme, G. U., & Milad, A. (2023). Scheffe’s Simplex Optimization of Flexural Strength of Quarry Dust and Sawdust Ash Pervious Concrete for Sustainable Pavement Construction. Materials, 16(2), 598. https://doi.org/10.3390/ma16020598