Inter-Critically Reheated CGHAZ of Ultra-High-Strength Martensitic Steel with Different Cooling Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

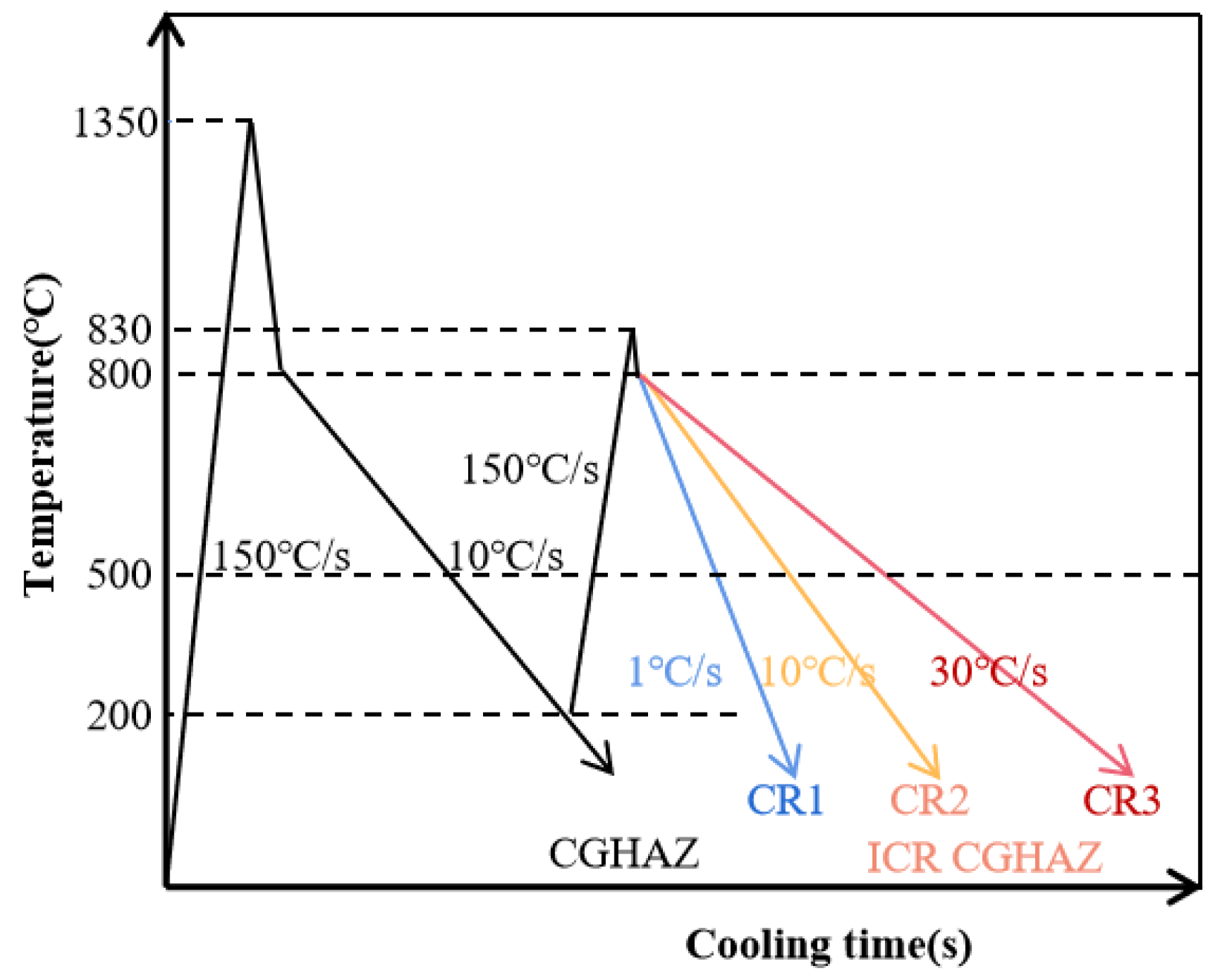

2.2. Welding Thermal Simulation

2.3. Microstructure and Mechanical Properties

3. Results

3.1. Microstructure

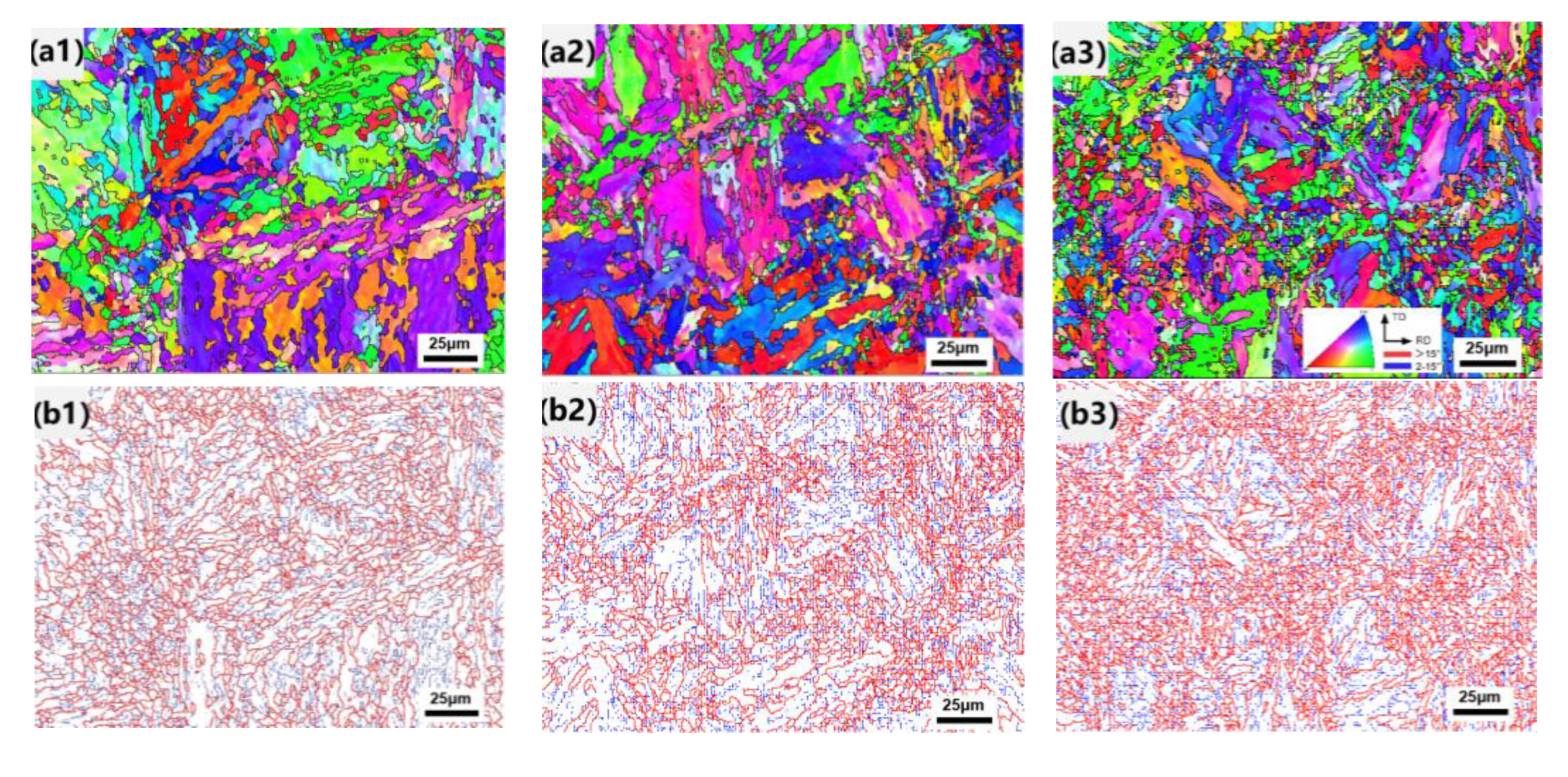

3.2. Electron Backscatter Diffraction (EBSD)

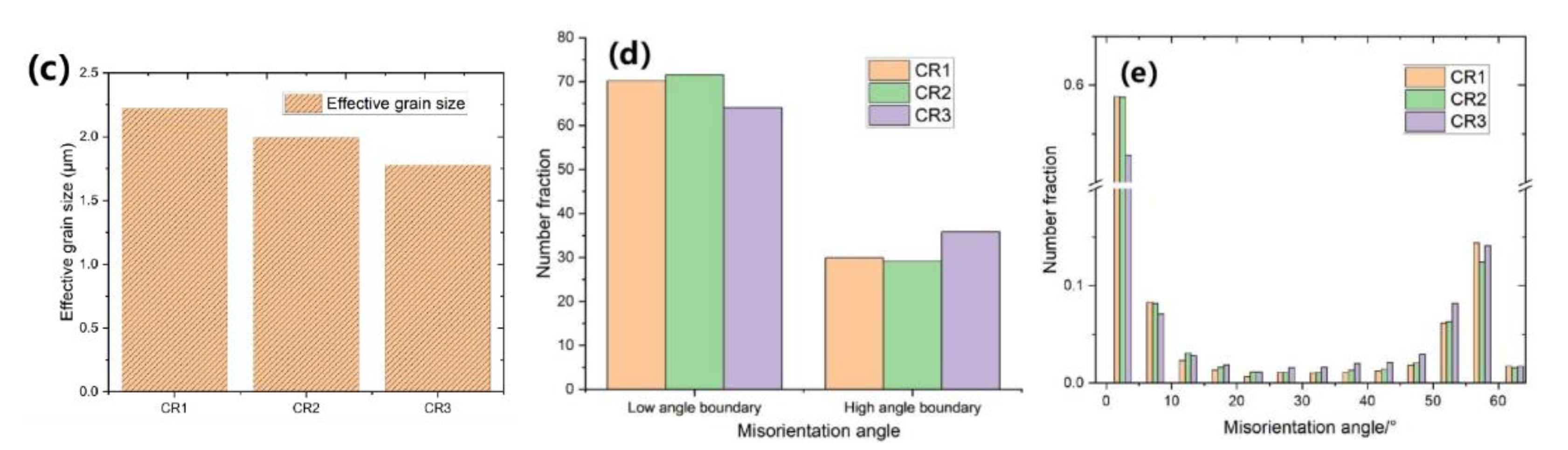

3.3. Mechanical Properties

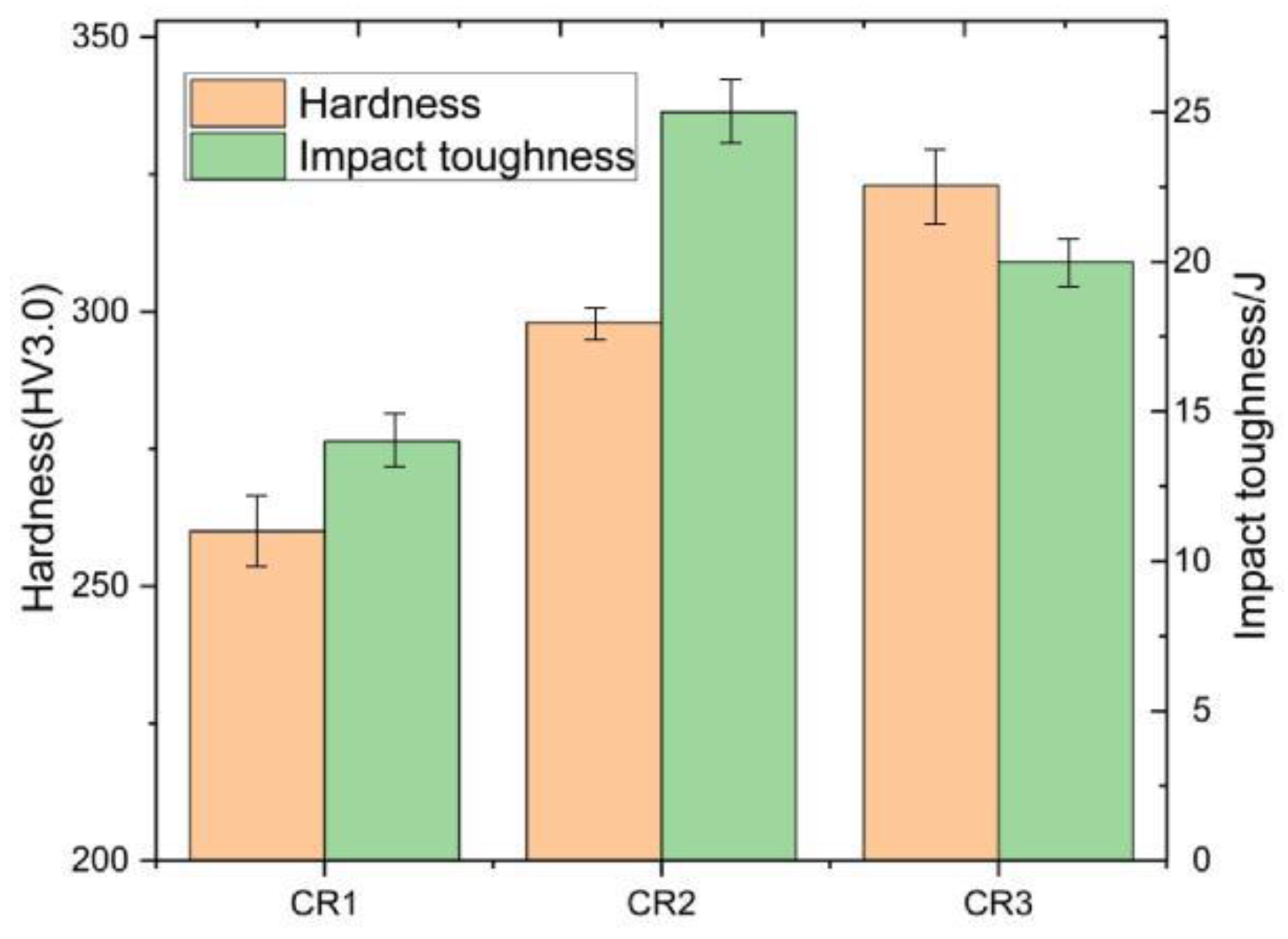

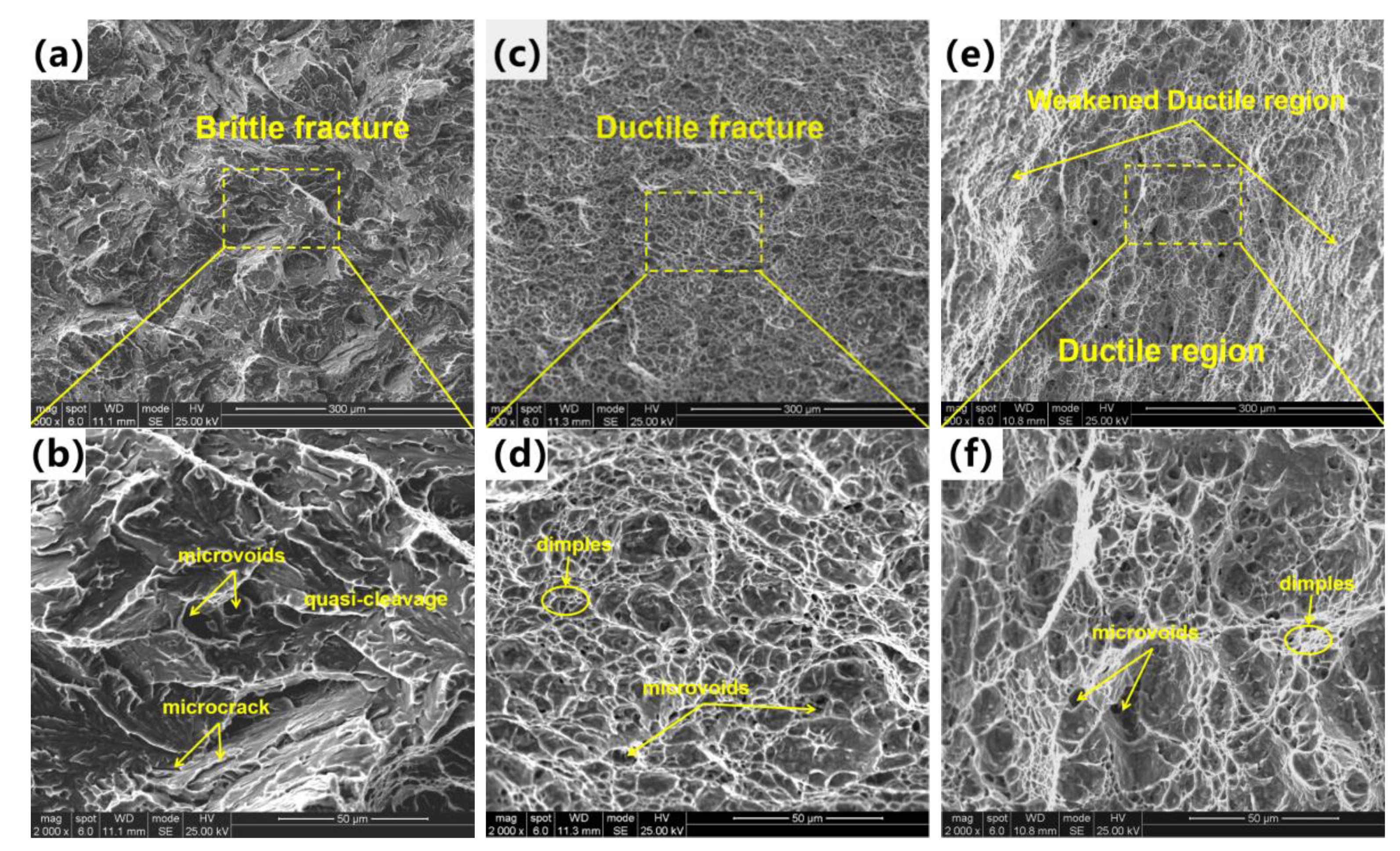

3.4. Fracture Characteristics

4. Discussion

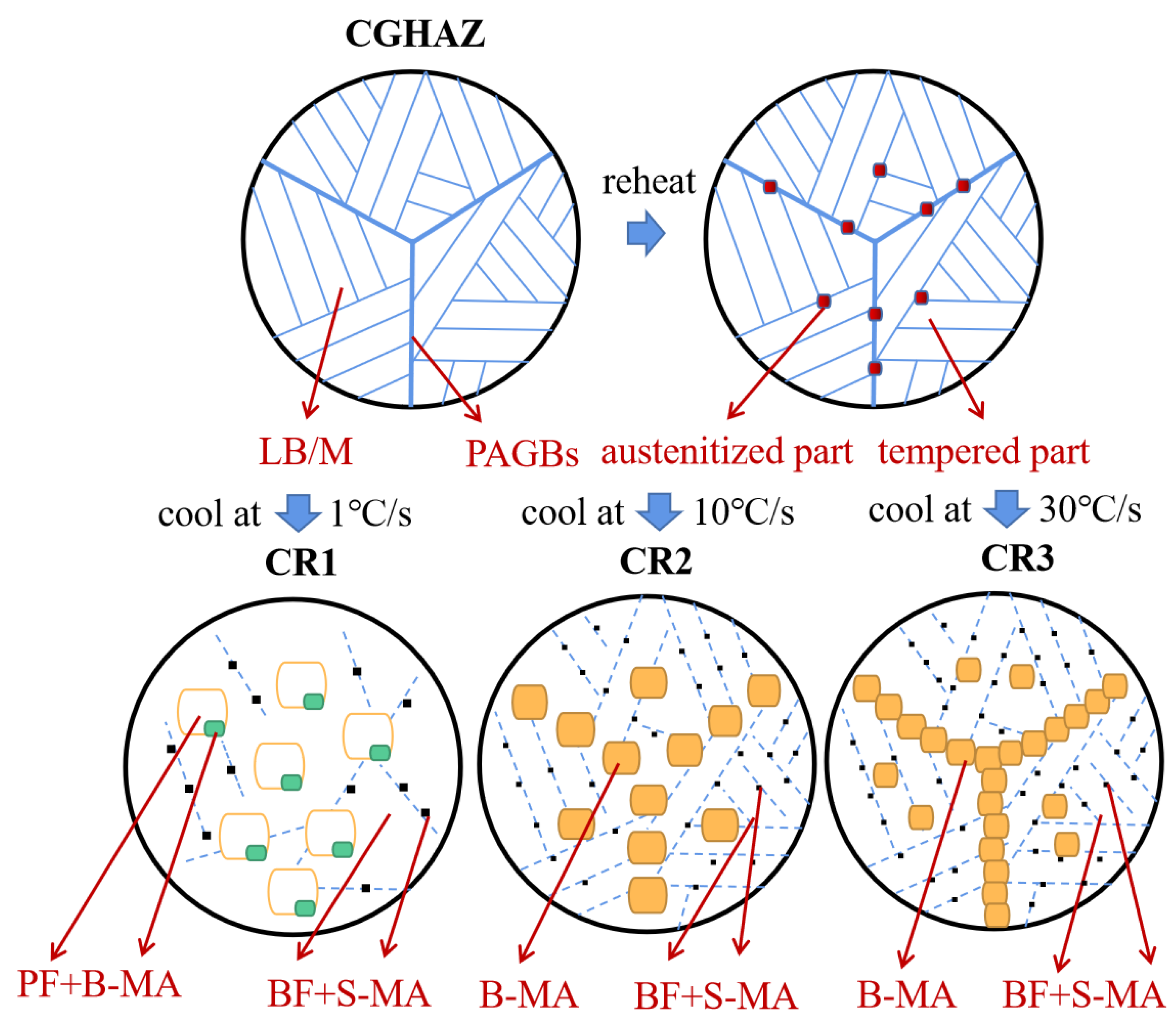

4.1. Effect of Cooling Rate on the Microstructure of ICR CGHAZ

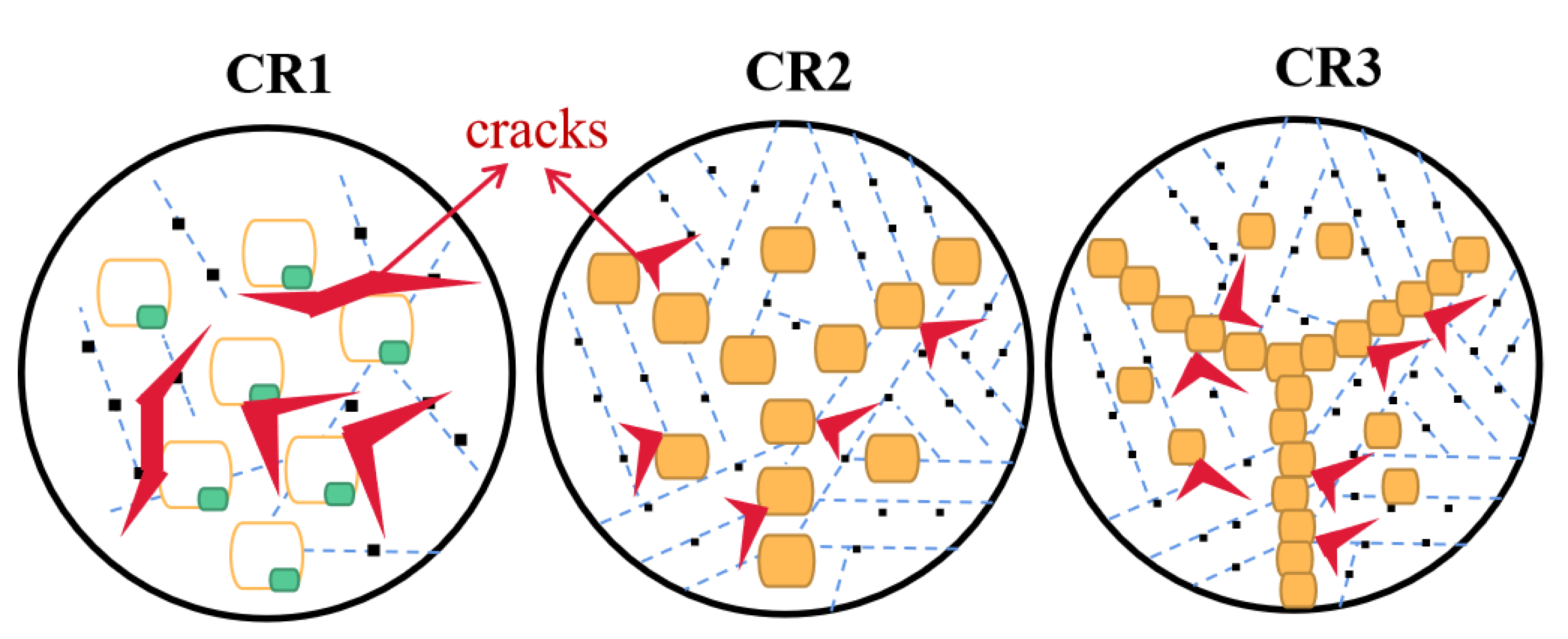

4.2. Effect of Microstructure on the Mechanical Properties of ICR CGHAZ

5. Conclusions

- In the preparation of ICR CGHAZ, cooling at 1 °C/s(CR1) created a microstructure of GB, BF and MA, while cooling at 10 °C/s(CR2) and 30 °C/s(CR3) created a microstructure of BF and MA.

- From CR1 to CR3, the effective grain size decreased and the number of hard phases increased, resulting in the monotonic increase of hardness.

- With the increase of cooling rate, the density of HAGBs increased, the MA types changed from coarse slender shape to fine island and the MA distribution changed from sparse to dense, which was beneficial to toughness. In CR3, the formed tail-head connected MA was detrimental to toughness. Therefore, the toughness of samples first increased and then decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aksel, H.; Eren, Ö. A discussion on the advantages of steel structures in the context of sustainable construction. New Arch.-Int. J. Contemp. Archit. 2015, 2, 46–53. [Google Scholar]

- e Sousa, A.C.; Nussbaumer, A. Multiaxial ultra low cycle fatigue in welded high strength steel structural components. J. Constr. Steel Res. 2019, 153, 473–482. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Chen, Z.Z.; Kou, D.X.; Li, Y.Q.; Ma, Y.L.; Li, Y.M. Evolution of microstructure in reheated coarse-grained zone of G115 novel martensitic heat-resistant steel. J. Iron Steel Res. Int. 2022, 29, 327–338. [Google Scholar] [CrossRef]

- Kumar, S.; Sharma, A.; Pandey, C.; Basu, B.; Nath, S.K. Impact of Subsequent Pass Weld Thermal Cycles on First-Pass Coarse Grain Heat-Affected Zone’s Microstructure and Mechanical Properties of Naval Bainitic Steel. J. Mater. Eng. Perform. 2021, 31, 390–399. [Google Scholar] [CrossRef]

- Qi, X.; Huan, P.; Wang, X.; Liu, Z.; Shen, X.; Gao, Y.; Di, H. Effect of root welding heat input on microstructure evolution and fracture mechanism in intercritically reheat-coarse grained heat-affected zone of X80 pipeline steel. Mater. Today Commun. 2022, 31, 103413. [Google Scholar] [CrossRef]

- Davis, C.L.; King, J.E. Cleavage initiation in the intercritically reheated coarse-grained heat affected zone: Part II. Failure criteria and statistical effects. Metall. Mater. Trans. A 1996, 27, 3019–3029. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Xi, X.; Wang, G.; Chen, L. The role of copper in microstructure and toughness of intercritically reheated coarse grained heat affected zone in a high strength low alloy steel. Mater. Charact. 2021, 181, 111511. [Google Scholar] [CrossRef]

- Cui, J.; Zhu, W.; Chen, Z.; Chen, L. Microstructural Characteristics and Impact Fracture Behaviors of a Novel High-Strength Low-Carbon Bainitic Steel with Different Reheated Coarse-Grained Heat-Affected Zones. Met. Mater. Trans. A 2020, 51, 6258–6268. [Google Scholar] [CrossRef]

- Zhu, Z.; Kuzmikova, L.; Li, H.; Barbaro, F. Effect of inter-critically reheating temperature on microstructure and properties of simulated inter-critically reheated coarse grained heat affected zone in X70 steel. Mater. Sci. Eng. A 2014, 605, 8–13. [Google Scholar] [CrossRef]

- Kumar, S.; Kasyap, P.; Pandey, C.; Basu, B.; Nath, S. Role of heat inputs on microstructure and mechanical properties in coarse-grained heat-affected zone of bainitic steel. CIRP J. Manuf. Sci. Technol. 2021, 35, 724–734. [Google Scholar] [CrossRef]

- Zhu, Z.; Han, J.; Li, H. Influence of Heat Input on Microstructure and Toughness Properties in Simulated CGHAZ of X80 Steel Manufactured Using High-Temperature Processing. Met. Mater. Trans. A 2015, 46, 5467–5475. [Google Scholar] [CrossRef]

- Guo, X.; Liu, S.; Xu, J.; Wang, S.; Fu, L.; Chai, Z.; Lu, H. Effect of step cooling process on microstructures and mechanical properties in thermal simulated CGHAZ of an ultra-high strength steel. Mater. Sci. Eng. A 2021, 824, 141827. [Google Scholar] [CrossRef]

- Yang, X.; Di, X.; Liu, X.; Wang, D.; Li, C. Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels. Mater. Charact. 2019, 155, 109818. [Google Scholar] [CrossRef]

- Davis, C.L.; King, J.E. Effect of cooling rate on intercritically reheated microstructure and toughness in high strength low alloy steel. Mater. Sci. Technol. 1993, 9, 8–15. [Google Scholar] [CrossRef]

- Huda, N.; Wang, Y.; Li, L.; Gerlich, A.P. Effect of martensite-austenite (MA) distribution on mechanical properties of inter-critical Reheated Coarse Grain heat affected zone in X80 linepipe steel. Mater. Sci. Eng. A 2019, 765, 138301. [Google Scholar] [CrossRef]

- Li, X.; Ma, X.; Subramanian, S.V.; Misra, R.D.K.; Shang, C. Structure–property–fracture mechanism correlation in heat-affected zone of X100 ferrite− bainite pipeline steel. Metall. Mater. Trans. E 2015, 2, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Li, H.Y.; Wang, X.; Tang, W.; Luo, D.; Liu, D.; Li, Y.H.; Peng, N.Q.; Xiong, X.J. Determination and analysis of CCT curve of a high strength steel. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 1090–1098. [Google Scholar]

- Li, X.; Fan, Y.; Ma, X.; Subramanian, S.; Shang, C. Influence of Martensite–Austenite constituents formed at different intercritical temperatures on toughness. Mater. Des. 2015, 67, 457–463. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Wang, X. Improvement of stress-relief cracking resistance in coarse-grained heat-affected zone of T23 steel by refining sub-structure through second thermal cycle. J. Mater. Res. Technol. 2020, 9, 8568–8579. [Google Scholar] [CrossRef]

- Zhu, Z.; Kuzmikova, L.; Li, H.; Barbaro, F. The Effect of Chemical Composition on Microstructure and Properties of Intercritically Reheated Coarse-Grained Heat-Affected Zone in X70 Steels. Met. Mater. Trans. A 2013, 45, 229–235. [Google Scholar] [CrossRef]

- Nakao, Y.; Oshige, H.; Noi, S. Distribution of microstructure in HAZ of multi-pass welded high strength steel—Study on distribution of microstructure and toughness in multi-pass weld HAZ (Report 1). Q. J. Jpn. Weld. Soc. 1985, 3, 766–773. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Kang, J.; Yuan, G.; Misra, R.; Wang, G. Improved toughness of double-pass welding heat affected zone by fine Ti–Ca oxide inclusions for high-strength low-alloy steel. Mater. Sci. Eng. A 2020, 780, 139198. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Cao, N.; Lin, X.; Sun, J. Crystallography of Reverted Austenite in the Intercritically Reheated Coarse-Grained Heat-Affected Zone of High Strength Pipeline Steel. Acta Metall. Sin. 2021, 57, 967–976. [Google Scholar]

- Zhang, X.; Miyamoto, G.; Toji, Y.; Nambu, S.; Koseki, T.; Furuhara, T. Orientation of austenite reverted from martensite in Fe-2Mn-1.5Si-0.3C alloy. Acta Mater. 2018, 144, 601–612. [Google Scholar] [CrossRef]

- Qi, X.; Huan, P.; Wang, X.; Di, H.; Shen, X.; Sun, Q.; Liu, Z.; He, J. Study on the mechanism of heat input on the grain boundary distribution and impact toughness in CGHAZ of X100 pipeline steel from the aspect of variant. Mater. Charact. 2021, 179, 111344. [Google Scholar] [CrossRef]

- Mohammadijoo, M.; Valloton, J.; Collins, L.; Henein, H.; Ivey, D. Characterization of martensite-austenite constituents and micro-hardness in intercritical reheated and coarse-grained heat affected zones of API X70 HSLA steel. Mater. Charact. 2018, 142, 321–331. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Y.; Wang, J.; Qin, S.; Wu, X.; Yuan, F. Tensile Behaviors and Strain Hardening Mechanisms in a High-Mn Steel with Heterogeneous Microstructure. Materials 2022, 15, 3542. [Google Scholar] [CrossRef]

- Lan, L.; Kong, X.; Qiu, C. Characterization of coarse bainite transformation in low carbon steel during simulated welding thermal cycles. Mater. Charact. 2015, 105, 95–103. [Google Scholar] [CrossRef]

- Zhou, P.; Wang, B.; Wang, L.; Hu, Y.; Zhou, L. Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater. Sci. Eng. A 2018, 722, 112–121. [Google Scholar] [CrossRef]

- Duan, R.H.; Xie, G.M.; Xue, P.; Ma, Z.Y.; Luo, Z.A.; Wang, C.; Misra, R.D.K.; Wang, G.D. Microstructural refinement mechanism and its effect on toughness in the nugget zone of high-strength pipeline steel by friction stir welding. J. Mater. Sci. Technol. 2021, 93, 221–231. [Google Scholar] [CrossRef]

- Luo, X.; Chen, X.; Wang, T.; Pan, S.; Wang, Z. Effect of morphologies of martensite–austenite constituents on impact toughness in intercritically reheated coarse-grained heat-affected zone of HSLA steel. Mater. Sci. Eng. A 2018, 710, 192–199. [Google Scholar] [CrossRef]

- Lambert-Perlade, A.; Sturel, T.; Gourgues, A.F.; Besson, J.; Pineau, A. Mechanisms and modeling of cleavage fracture in simulated heat-affected zone microstructures of a high-strength low alloy steel. Metall. Mater. Trans. A 2004, 35, 1039–1053. [Google Scholar] [CrossRef]

- Niu, Y.; Jia, S.; Liu, Q.; Tong, S.; Li, B.; Ren, Y.; Wang, B. Influence of Effective Grain Size on Low Temperature Toughness of High-Strength Pipeline Steel. Materials 2019, 12, 3672. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, D.C.; Moon, J.; Lee, C.H.; Kim, S.D.; Chung, J.H.; Biro, E.; Park, Y.D. Role of bainitic microstructures with MA constituent on the toughness of an HSLA steel for seismic resistant structural applications. Mater. Sci. Eng. A 2021, 801, 140390. [Google Scholar] [CrossRef]

- Kim, B.C.; Lee, S.; Kim, N.J.; Lee, D.Y. Microstructure and local brittle zone phenomena in high-strength low-alloy steel welds. Metall. Trans. A 1991, 22, 139–149. [Google Scholar] [CrossRef]

| C | Si | Mn | Nb | Ti | Cr + Mo + V | B | Al | Ni | P | S |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.3 | 1.12 | 0.022 | 0.02 | 0.803 | 0.0018 | 0.03 | 0.32 | ≤0.009 | ≤0.009 |

| RP0.2/MPa | UTS/MPa | Elongation/% | AK-40 °C/J |

|---|---|---|---|

| 1260 | 1388 | 13 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Li, H.-Y.; Zhou, W.-H.; Luo, D.; Liu, D.; Liang, L.; Xiao, A.-D. Inter-Critically Reheated CGHAZ of Ultra-High-Strength Martensitic Steel with Different Cooling Rates. Materials 2023, 16, 581. https://doi.org/10.3390/ma16020581

Liu W-J, Li H-Y, Zhou W-H, Luo D, Liu D, Liang L, Xiao A-D. Inter-Critically Reheated CGHAZ of Ultra-High-Strength Martensitic Steel with Different Cooling Rates. Materials. 2023; 16(2):581. https://doi.org/10.3390/ma16020581

Chicago/Turabian StyleLiu, Wen-Jian, Hong-Ying Li, Wen-Hao Zhou, Deng Luo, Dan Liu, Liang Liang, and Ai-Da Xiao. 2023. "Inter-Critically Reheated CGHAZ of Ultra-High-Strength Martensitic Steel with Different Cooling Rates" Materials 16, no. 2: 581. https://doi.org/10.3390/ma16020581

APA StyleLiu, W.-J., Li, H.-Y., Zhou, W.-H., Luo, D., Liu, D., Liang, L., & Xiao, A.-D. (2023). Inter-Critically Reheated CGHAZ of Ultra-High-Strength Martensitic Steel with Different Cooling Rates. Materials, 16(2), 581. https://doi.org/10.3390/ma16020581