Effect of Weld Length on Strength, Fatigue Behaviour and Microstructure of Intersecting Stitch-Friction Stir Welded AA 6016-T4 Sheets

Abstract

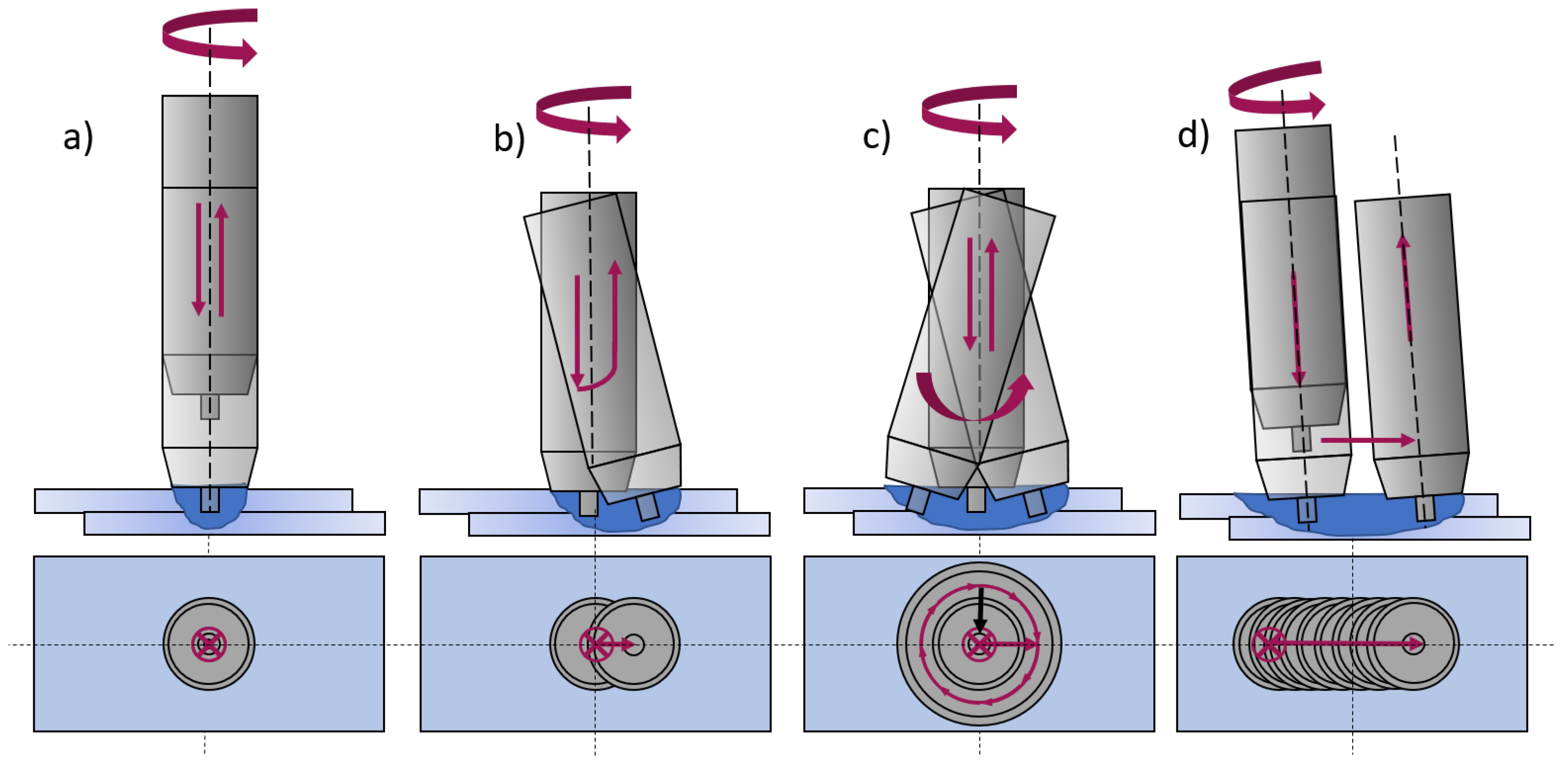

1. Introduction

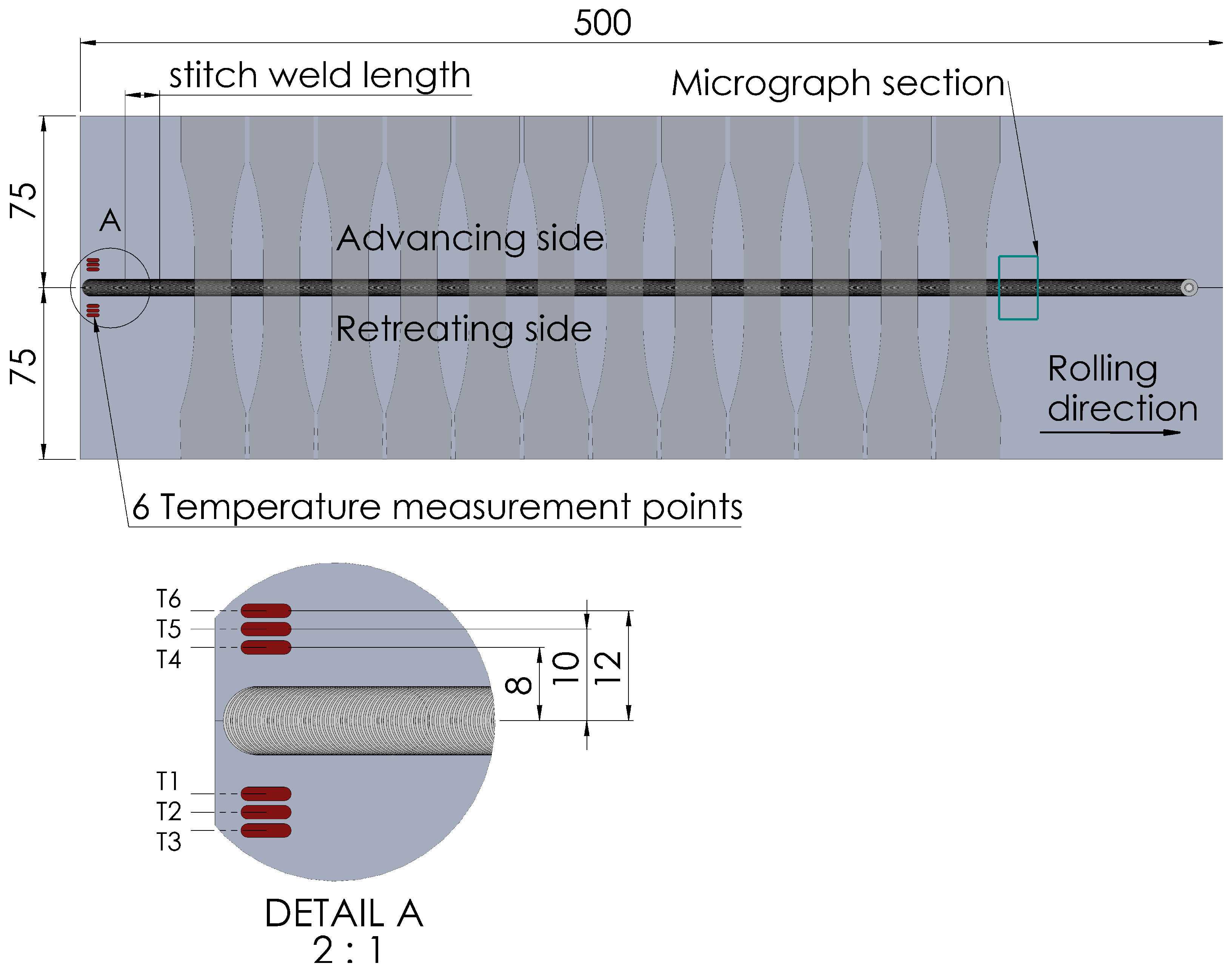

2. Materials and Methods

3. Results and Discussion

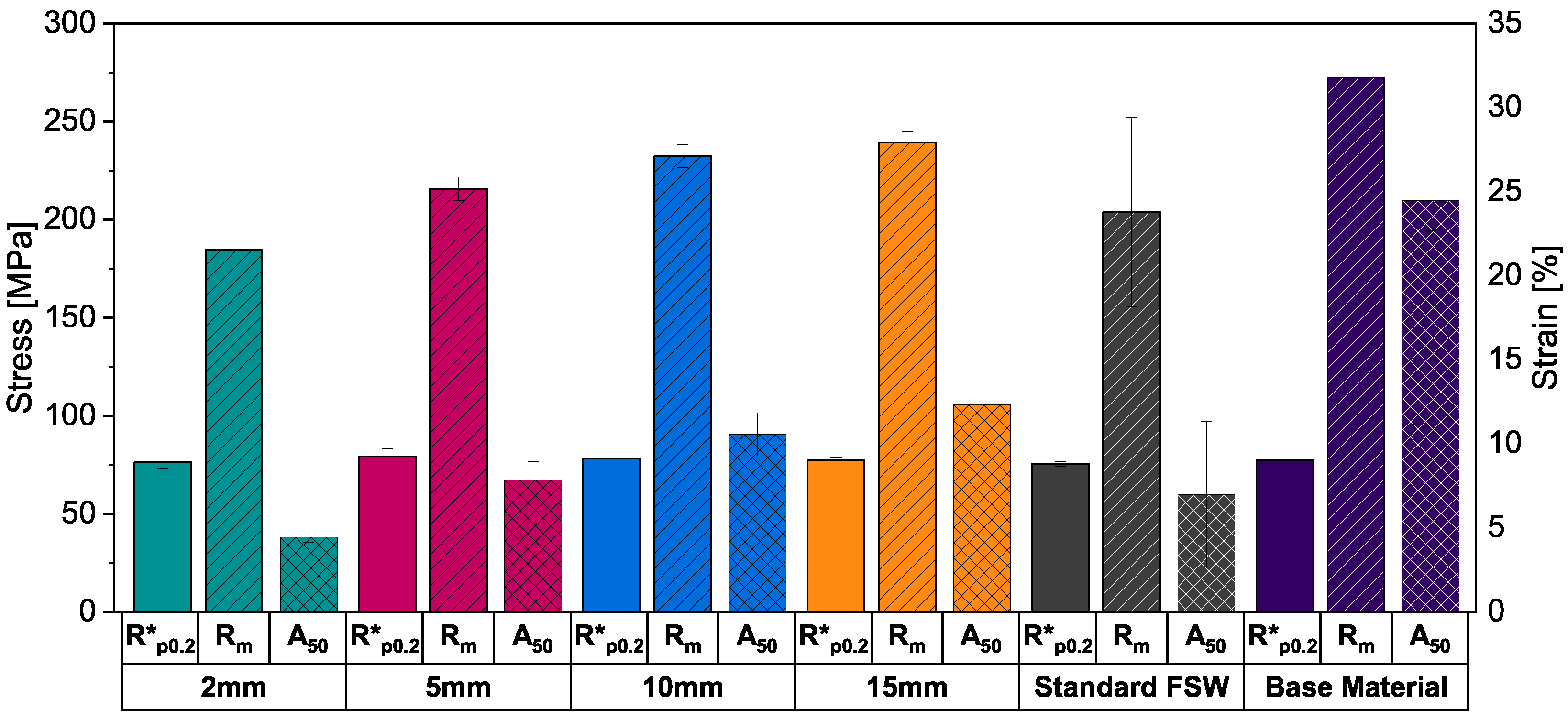

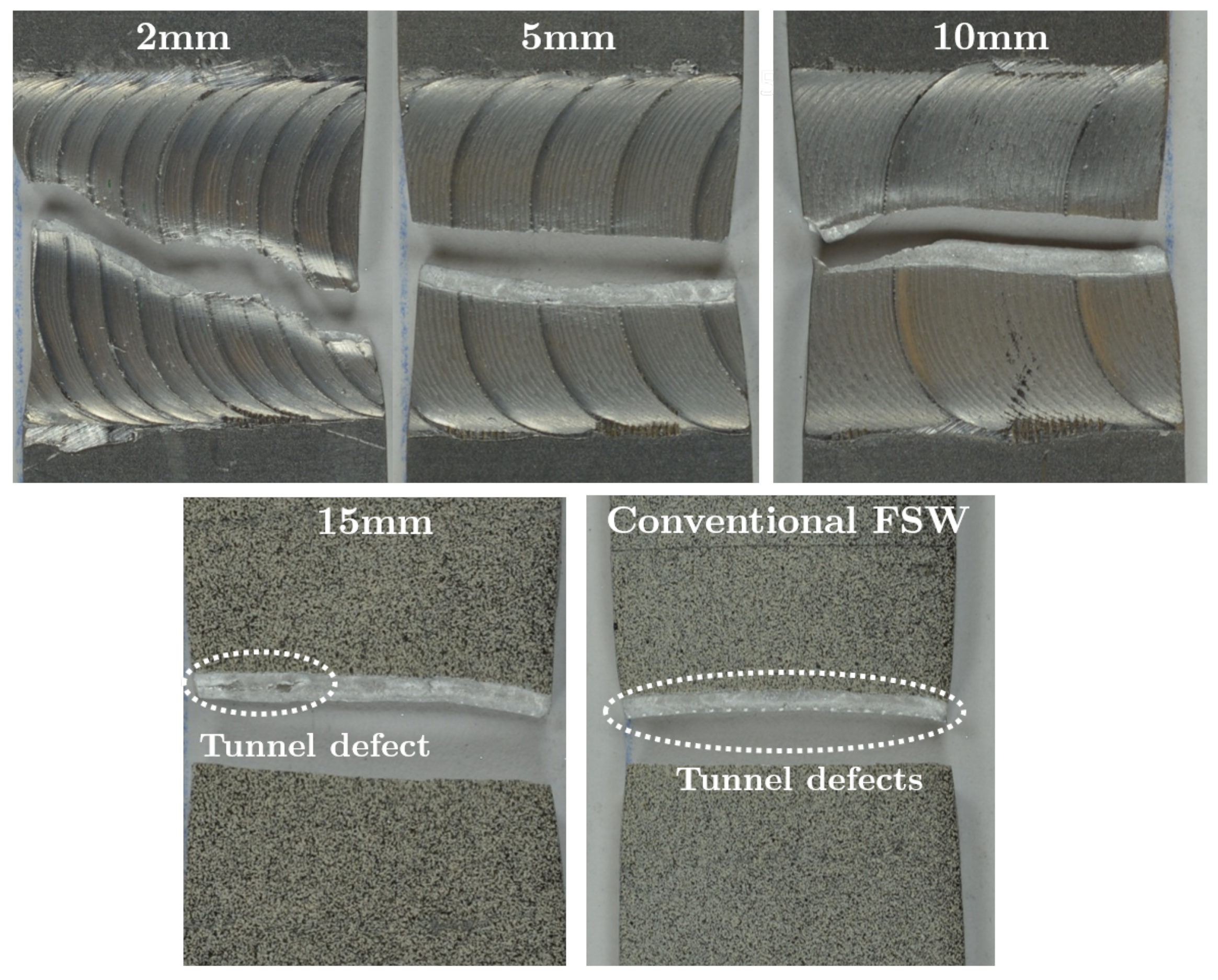

3.1. Mechanical Properties

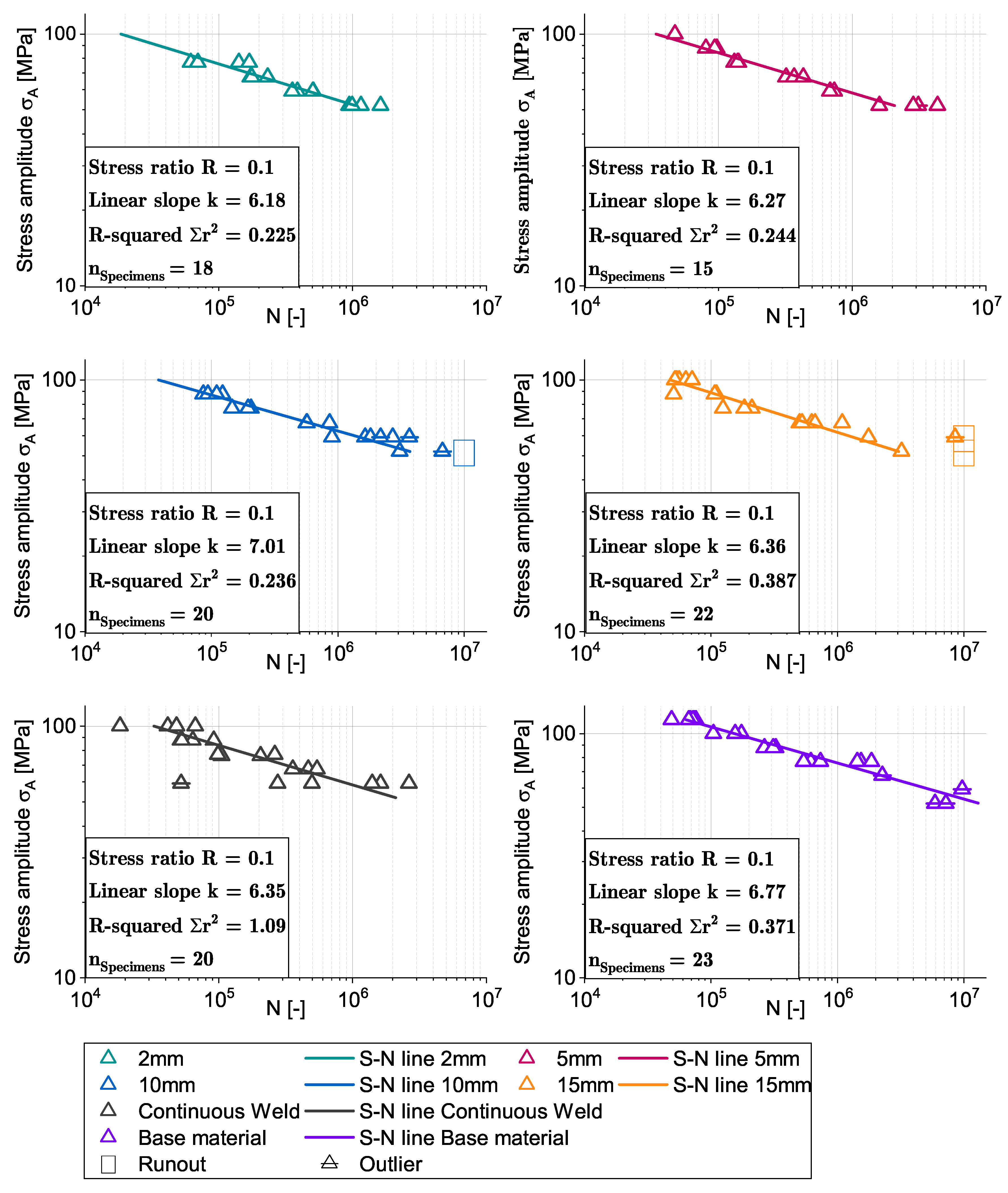

3.1.1. Fatigue Testing

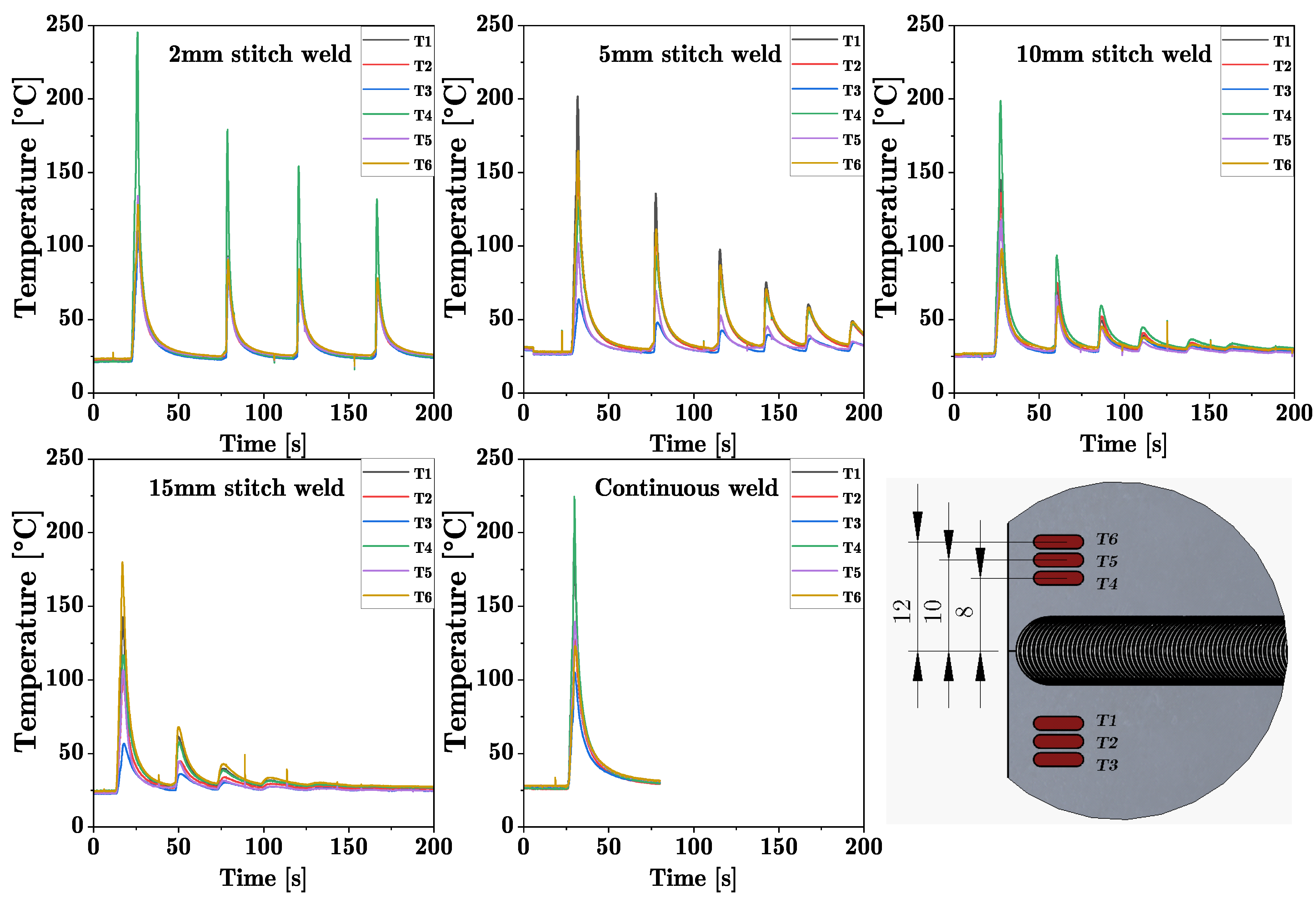

3.1.2. Microhardness and Thermal Analysis

4. Conclusions

- It is possible to perform intersecting stitch welds with excellent strength properties and without flaws such as pores, kissing bond defects or tunnel defects.

- With the parameter set used in this study, visually defect-free intersecting welds up to a stitch length of 15 mm can be welded. For longer stitch welds or conventional friction stir welds, the welding parameters (dwelling time, plunging speed, rotational speed, feed speed) have to be adapted with regard to the time between the stitch welds.

- The tensile strength, ultimate plastic elongation and fatigue strength can be scaled with the stitch weld length. Specimens with a stitch weld length of 15 mm achieve 87% tensile strength and 50% ultimate plastic elongation of the base materials’ values. The shortest examined weld specimens reach 67% of the tensile strength of the base material due to the high cyclic heat input and the associated decrease in hardness. It should be highlighted that no influence of the weld stitch length on the substitute proof strength of the specimens could be investigated.

- The temperature cycles in intersecting stitched welds have a significant effect on the microstructure and hardness distribution of the welds. With decreasing stitch weld length, the cyclic heat input into the previous welds increases, resulting in an increased softened zone in the welds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emadi, P.; Andilab, B.; Ravindran, C. Engineering Lightweight Aluminum and Magnesium Alloys for a Sustainable Future. J. Indian Inst. Sci. 2022, 102, 405–420. [Google Scholar] [CrossRef]

- Fuchslocher, G. Wie sich Aluminium im Fahrzeugbau einen Platz erobert, Automobil Produktion. Available online: https://www.automobil-produktion.de/produktion/wie-sich-aluminium-im-fahrzeugbau-einen-platz-erobert-27-173.html (accessed on 29 March 2022).

- Engler, O.; Schäfer, C.; Myhr, O.R. Effect of natural ageing and pre-straining on strength and anisotropy in aluminium alloy AA 6016. Mater. Sci. Eng. A 2015, 639, 65–74. [Google Scholar] [CrossRef]

- DIN EN 1999-1-1; Eurocode 9: Bemessung und Konstruktion von Aluminiumtragwerken: Teil 1-1: Allgemeine Bemessungsregeln. Beuth Publishing GmbH: Berlin, Germany, 2014.

- Sun, T.; Franciosa, P.; Sokolov, M.; Ceglarek, D. Challenges and opportunities in laser welding of 6xxx high strength aluminium extrusions in automotive battery tray construction. Procedia CIRP 2020, 94, 565–570. [Google Scholar] [CrossRef]

- Bamberg, P.; Seewald, R.; Schiebahn, A.; Reisgen, U.; Precoma, N.; Epperlein, M. Improvement of the resistance spot welding of Al-Mg-Si alloys by using cladding technology: An optical and mechanical characterization study. J. Adv. Join. Process. 2022, 5, 100090. [Google Scholar] [CrossRef]

- Khan, N.Z.; Khan, Z.A.; Siddiquee, A.N. Effect of Shoulder Diameter to Pin Diameter (D/d) Ratio on Tensile Strength of Friction Stir Welded 6063 Aluminium Alloy. Mater. Today Proc. 2015, 2, 1450–1457. [Google Scholar] [CrossRef]

- Saravanan, V.; Rajakumar, S.; Banerjee, N.; Amuthakkannan, R. Effect of shoulder diameter to pin diameter ratio on microstructure and mechanical properties of dissimilar friction stir welded AA2024-T6 and AA7075-T6 aluminum alloy joints. Int. J. Adv. Manuf. Technol. 2016, 87, 3637–3645. [Google Scholar] [CrossRef]

- Othman, N.H.; Ishak, M.; Shah, L.H. Effect of shoulder to pin ratio on magnesium alloy Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2017, 238, 012008. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of Tool Pin Profile and Tool Rotational Speed on Mechanical Properties of Friction Stir Welded AA6061 Aluminium Alloy. Mater. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Bayazid, S.M.; Farhangi, H.; Ghahramani, A. Effect of Pin Profile on Defects of Friction Stir Welded 7075 Aluminum Alloy. Procedia Mater. Sci. 2015, 11, 12–16. [Google Scholar] [CrossRef]

- Hou, W.; Ding, Y.; Huang, G.; Huda, N.; Shah, L.H.A.; Piao, Z.; Shen, Y.; Shen, Z.; Gerlich, A. The role of pin eccentricity in friction stir welding of Al-Mg-Si alloy sheets: Microstructural evolution and mechanical properties. Int. J. Adv. Manuf. Technol. 2022, 121, 7661–7675. [Google Scholar] [CrossRef]

- Ahmad Shah, L.H.; Hou, W.; Razmpoosh, M.H.; Walbridge, S.; Gerlich, A. Strain rate and microtexture analysis of rapid-quenched AA6061 friction stir welds produced with tool eccentricity. J. Mater. Res. Technol. 2022, 21, 1434–1441. [Google Scholar] [CrossRef]

- Kallee, S.W. Industrial applications of friction stir welding. In Friction Stir Welding; Elsevier: Amsterdam, The Netherlands, 2010; pp. 118–163. [Google Scholar]

- Connolly, C. Friction spot joining in aluminium car bodies. Ind. Robot. Int. J. 2007, 34, 17–20. [Google Scholar] [CrossRef]

- AT 14153 U1 2015-05-15; Gebrauchsmusterschrift: Punktschweißzange: Gebrauchsmuster. Stirtec GmbH: Kalsdorf bei Graz, Austria, 2015.

- Schilling, C.; Dos Santos, J. Method and Device for Joining at Least Two Adjoining Work Pieces by Friction Welding. U.S. Patent 6722556B2, 20 April 2004. [Google Scholar]

- Montag, T.; Wulfsberg, J.P.; Hameister, H.; Marschner, R. Influence of Tool Wear on Quality Criteria for Refill Friction Stir Spot Welding (RFSSW) Process. Procedia CIRP 2014, 24, 108–113. [Google Scholar] [CrossRef]

- Kluz, R.; Kubit, A.; Trzepiecinski, T.; Faes, K.; Bochnowski, W. A Weighting Grade-Based Optimization Method for Determining Refill Friction Stir Spot Welding Process Parameters. J. Mater. Eng. Perform. 2019, 28, 6471–6482. [Google Scholar] [CrossRef]

- Okamoto, K.; Hunt, F.; Hirano, S. Development of Friction Stir Welding Technique and Machine for Aluminum Sheet Metal Assembly- Friction Stir Welding of Aluminum for Automotive Applications (2); SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Hunt, F.; Badarinarayan, H.; Okamoto, K. Design of Experiments for Friction Stir Stitch Welding of Aluminum Alloy 6022-T4—Friction Stir Welding of Aluminum for Automotive Applications (3); SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Tweedy, B.M.; Widener, C.A.; Merry, J.D.; Brown, J.M.; Burford, D.A. Factors Affecting the Properties of Swept Friction Stir Spot Welds; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2008. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E.; Rajesh, S.; Lim, W.H. Evaluating weld properties of conventional and swept friction stir spot welded 6061-T6 aluminium alloy. Mater. Express 2019, 9, 851–860. [Google Scholar] [CrossRef]

- Badarinarayan, H.; Yang, Q.; Okamoto, K. Effect of weld orientation on static strength and failure mode of friction stir stitch welds in lap-shear specimens of aluminium 6022-T4 sheets. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 908–920. [Google Scholar] [CrossRef]

- Walz, D.; Werz, M.; Weihe, S. A New Concept for Producing High Strength Aluminum Line-Joints in Car Body Assembly by a Robot Guided Friction Stir Welding Gun. In Advances in Automotive Production Technology—Theory and Application; ARENA2036; Weißgraeber, P., Heieck, F., Ackermann, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; Volume 50, pp. 361–368. [Google Scholar] [CrossRef]

- DIN EN 573-3; Aluminium and Aluminium Alloys—Chemical Composition and Form of Wrought Products: Part 3: Chemical Composition and Form of Products. Beuth Publishing GmbH: Berlin, Germany, 2022.

- DIN EN 485-2; Aluminium und Aluminiumlegierungen—Bänder, Bleche und Platten: Teil 2: Mechanische Eigenschaften. Beuth Publishing GmbH: Berlin, Germany, 2018.

- DIN EN ISO 6892-1; Metallic Materials—Tensile Testing: Part 1: Method of Test at Room Temperature. Beuth Publishing GmbH: Berlin, Germany, 2020.

- ASTM E466-15; Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Haibach, E. Betriebsfestigkeit: Verfahren und Daten zur Bauteilberechnung; 3., korrigierte und erg. aufl. ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- DIN EN ISO 6507-1; Metallic Materials-Vickers Hardness Test: Part 1: Test Method. Beuth Publishing GmbH: Berlin, Germany, 2022.

- Radaj, D. Ermüdungsfestigkeit: Grundlagen für Leichtbau, Maschinen- und Stahlbau; zweite, neubearbeitete und erweiterte auflage; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Ostermann, F. Anwendungstechnologie Aluminium; 3., neu bearb. aufl. 2014 ed.; VDI-Buch; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Maggiolini, E.; Benasciutti, D.; Susmel, L.; Hattingh, D.G.; James, M.N.; Tovo, R. Friction stir welds in aluminium: Design S-N curves from statistical analysis of literature data. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2212–2230. [Google Scholar] [CrossRef]

- Sato, Y.S.; Urata, M.; Kokawa, H. Parameters controlling microstructure and hardness during friction-stir welding of precipitation-hardenable aluminum alloy 6063. Metall. Mater. Trans. A 2002, 33, 625–635. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Loureiro, A.; Leitao, C.; Leal, R.M.; Chaparro, B.M.; Vilaça, P. Influence of friction stir welding parameters on the microstructural and mechanical properties of AA 6016-T4 thin welds. Mater. Des. 2009, 30, 1913–1921. [Google Scholar] [CrossRef]

| EN AW-6016 (AlSi1.2Mg0.4) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | [wt.%] | |

| Chemical composition | 1.0–1.5 | 0.5 | 0.2 | 0.2 | 0.25–0.6 | 0.1 | 0.2 | 0.15 | Balance |

| Ultimate Tensile Strength [MPa] | Proof Strength [MPa] | Total Strain at Maximum Load [%] | Hardness [HBW] | ||||||

| Mechanical properties | 170–250 | 80–140 | 24 | 55 | |||||

| Rotational Speed | Forging Force | Feed Speed | Heel Plunge Depth | Tool Tilt Angle | |

|---|---|---|---|---|---|

| [N] | [mm] | [°] | |||

| Process parameters | 1250 | 4850 | 1300 | 0.15 | 1 |

| Shoulder Diameter | Pin Diameter | Pin Length | Shoulder Angle | Pin Structure | |

| [mm] | [mm] | [mm] | [°] | [-] | |

| Tool dimensions | 14 | 5 | 1.8 | 10 | No |

| Stitch weld length | 2 mm | 5 mm | 10 mm | 15 mm | Continuous weld | Base material |

|---|---|---|---|---|---|---|

| Fatigue strength [MPa] | 46.88 | 52.28 | 56.84 | 55.55 | 52.38 | 68.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walz, D.; Göbel, R.; Werz, M.; Weihe, S. Effect of Weld Length on Strength, Fatigue Behaviour and Microstructure of Intersecting Stitch-Friction Stir Welded AA 6016-T4 Sheets. Materials 2023, 16, 533. https://doi.org/10.3390/ma16020533

Walz D, Göbel R, Werz M, Weihe S. Effect of Weld Length on Strength, Fatigue Behaviour and Microstructure of Intersecting Stitch-Friction Stir Welded AA 6016-T4 Sheets. Materials. 2023; 16(2):533. https://doi.org/10.3390/ma16020533

Chicago/Turabian StyleWalz, Dominik, Robin Göbel, Martin Werz, and Stefan Weihe. 2023. "Effect of Weld Length on Strength, Fatigue Behaviour and Microstructure of Intersecting Stitch-Friction Stir Welded AA 6016-T4 Sheets" Materials 16, no. 2: 533. https://doi.org/10.3390/ma16020533

APA StyleWalz, D., Göbel, R., Werz, M., & Weihe, S. (2023). Effect of Weld Length on Strength, Fatigue Behaviour and Microstructure of Intersecting Stitch-Friction Stir Welded AA 6016-T4 Sheets. Materials, 16(2), 533. https://doi.org/10.3390/ma16020533