Enhanced Room-Temperature Thermoelectric Performance of 2D-SnSe Alloys via Electric-Current-Assisted Sintering

Abstract

1. Introduction

2. Experimental

2.1. Bridgman Crystal Growth

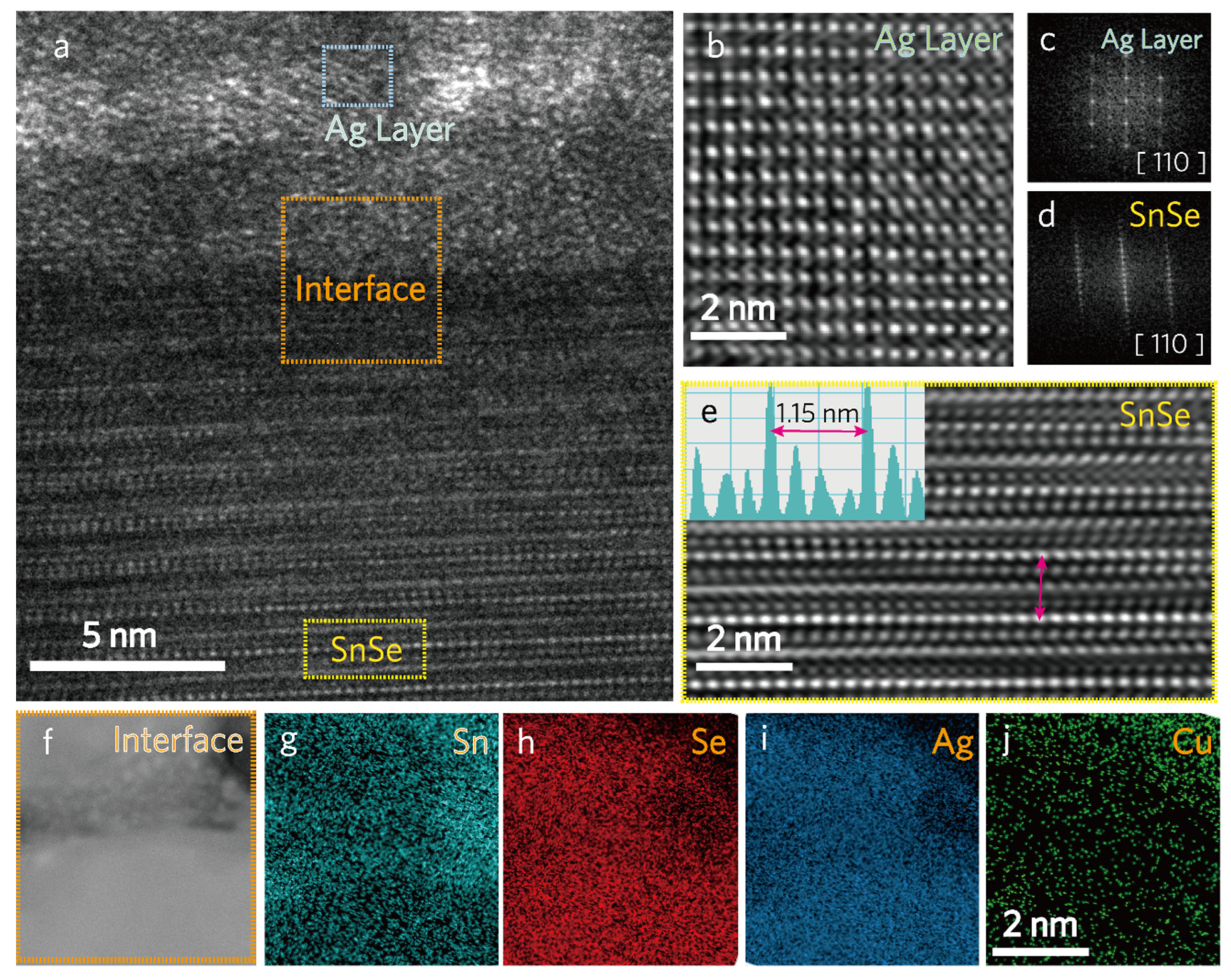

2.2. Ag Sputtering

2.3. Characterization

2.4. TE Measurement

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Seebeck, T.J. Magnetische Polarisation der Metalle und Erze durch Temperatur-Differenz; Abhandlungen der Koniglichen Akademie der Wissenschaften zu Berlin; Leopold Classic Library: South Yarra, Australia, 1822; pp. 265–373. (In German) [Google Scholar]

- Li, L.; Han, W.; Pi, L.; Niu, P.; Han, J.; Wang, C.; Su, B.; Li, H.; Xiong, J.; Bando, Y.; et al. Emerging in-plane anisotropic two-dimensional materials. InfoMat 2019, 1, 54–73. [Google Scholar] [CrossRef]

- Mori, H.; Usui, H.; Ochi, M.; Kuroki, K. Temperature-and doping-dependent roles of valleys in the thermoelectric performance of SnSe: A first-principles study. Phys. Rev. B 2017, 96, 085113. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef] [PubMed]

- Hou, S.; Li, Z.; Xue, Y.; Ning, X.; Wang, J.; Wang, S. Surprisingly high in-plane thermoelectric performance in a-axisoriented epitaxial SnSe thin films. Mater. Today Phys. 2021, 18, 100399. [Google Scholar] [CrossRef]

- Kutorasinski, K.; Wiendlocha, B.; Kaprzyk, S.; Tobola, J. Electronic structure and thermoelectric properties of n- and p-type SnSe from first-principles calculations. Phys. Rev. B 2015, 91, 205201. [Google Scholar] [CrossRef]

- Li, F.; Wang, H.; Huang, R.; Chen, W.; Zhang, H. Recent Advances in SnSe Nanostructures beyond Thermoelectricity. Adv. Funct. Mater. 2022, 32, 2200516. [Google Scholar] [CrossRef]

- Wei, T.R.; Tan, G.; Zhang, X.; Wu, C.F.; Li, J.F.; Dravid, V.P.; Snyder, G.J.; Kanatzidis, M.G. Distinct Impact of Alkali-Ion Doping on Electrical Transport Properties of Thermoelectric p-Type Polycrystalline SnSe. J. Am. Chem. Soc. 2016, 138, 8875–8882. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Chen, K.; Zhang, Z.; Li, Y.; Lu, Y.; Chen, X.; Yang, D.; Shan, C. Revealing the Anisotropic Structural and Electrical Stabilities of 2D SnSe under Harsh Environments: Alkaline Environment and Mechanical Strain. ACS Appl. Mater. Interfaces 2022, 14, 9824–9832. [Google Scholar] [CrossRef]

- Cho, J.Y.; Siyar, M.; Jin, W.C.; Hwang, E.; Bae, S.H.; Hong, S.H.; Kim, M.; Park, C. Electrical Transport and Thermoelectric Properties of SnSe–SnTe Solid Solution. Materials 2019, 12, 3854. [Google Scholar] [CrossRef]

- Wei, W.; Chang, C.; Yang, T.; Liu, J.; Tang, H.; Zhang, J.; Li, Y.; Xu, F.; Zhang, Z.; Li, J.F.; et al. Achieving High Thermoelectric Figure of Merit in Polycrystalline SnSe via Introducing Sn Vacancies. J. Am. Chem. Soc. 2018, 140, 499–505. [Google Scholar] [CrossRef]

- Sheng, Z.; Guo, C.; Hu, S.; Xiao, Z.; Guo, L. Routes to High-Carrier-Density Doping in Thermoelectric SnSe. J. Phys. Chem. C 2022, 126, 1230–1241. [Google Scholar] [CrossRef]

- Singh, N.K.; Bathula, S.; Gahtori, B.; Tyagi, K.; Haranath, D.; Dhar, A. The effect of doping on thermoelectric performance of p-type SnSe: Promising thermoelectric material. J. Alloys Compd. 2016, 668, 152–158. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Liu, G.Q.; Tan, X.; Li, D.; Shao, H.; Tan, T.; Jiang, J. Texturing degree boosts thermoelectric performance of silver-doped polycrystalline SnSe. NPG Asia Mater. 2017, 9, 426. [Google Scholar] [CrossRef]

- Chen, C.L.; Wang, H.; Chen, Y.Y.; Daya, T.; Snyder, G.J. Thermoelectric properties of p-type polycrystalline SnSe doped with Ag. J. Mater. Chem. A 2014, 2, 11171. [Google Scholar] [CrossRef]

- Xin, N.; Li, Y.; Shen, H.; Shen, L.; Tang, G. Realizing high thermoelectric performance in hot-pressed polycrystalline AlxSn1−xSe through band engineering tuning. J. Mater. 2022, 8, 475–488. [Google Scholar] [CrossRef]

- Tang, G.; Wei, W.; Zhang, J.; Li, Y.; Wang, X.; Xu, G.; Chang, C.; Wang, Z.; Du, Y.; Zhao, L.D. Realizing High Figure of Merit in Phase-Separated Polycrystalline Sn1−xPbxSe. J. Am. Chem. Soc. 2016, 138, 13647–13654. [Google Scholar] [CrossRef]

- Liu, H.; Shi, X.; Xu, F.; Zhang, L.; Zhang, W.; Chen, L.; Li, Q.; Uher, C.; Day, T.; Snyder, G.J. Copper ion liquid-like thermoelectrics. Nat. Mater. 2012, 11, 422–425. [Google Scholar] [CrossRef]

- Yua, J.; Zhao, K.; Qiua, P.; Shia, X.; Chen, L. Thermoelectric properties of copper-deficient Cu2-xSe (0.05 ≤ x ≤ 0.25) binary compounds. Ceram. Int. 2017, 43, 11142–11148. [Google Scholar] [CrossRef]

- Yunos, M.A.S.M.; Talib, Z.A.; Yunus, W.M.M.Y.; Chyi, J.L.Y.; Paulus, W.S. X-Ray Diffraction analysis of thermally evaporated copper tin selenide thin films at different annealing temperature. J. Mater. Sci. Eng. 2010, 4, 28–33. [Google Scholar]

- Wang, S.; Hui, S.; Peng, K.L.; Bailey, T.P.; Zhou, X.Y.; Tang, X.F.; Uher, C. Grain boundary scattering effects on mobilities in p-type polycrystalline SnSe. J. Mater. Chem. C 2017, 5, 10191–10200. [Google Scholar] [CrossRef]

- Lu, D.L.; Yue, C.; Luo, S.W.; Li, Z.Q.; Xue, W.M.; Qi, X.; Zhon, J. Phase controllable synthesis of SnSe and SnSe2 films with tunable photo response properties. App. Surf. Sci. 2021, 541, 148615. [Google Scholar] [CrossRef]

- Huo, H.J.; Zhang, Y.; Guo, K.; Yang, X.X.; Xing, J.J.; Lie, S.; Zhang, J.; Luo, J. Improvement of anisotropic thermoelectric performance in polycrystalline SnSe by metallic AgSnSe2 compositing. J. Alloys Compd. 2022, 908, 164649. [Google Scholar] [CrossRef]

- Gainza, J.; Molto, S.; Dura, F.S.; Fernandez-Diaz, M.T.; Biskup, N.; Martinez, J.L.; Alonso, J.A.; Nemes, N.M. SnSe:Kx intermetallic thermoelectric polycrystals prepared by arc-melting. J. Mater. Sci. 2022, 57, 8489–8503. [Google Scholar] [CrossRef]

- Tang, G.; Liu, J.; Zhang, J.; Li, D.; Rara, K.H.; Xu, R.; Lu, W.; Liu, J.; Zhang, Y.S.; Feng, Z.Z. Realizing High Thermoelectric Performance below Phase Transition Temperature in Polycrystalline SnSe via Lattice Anharmonicity Strengthening and Strain Engineering. ACS Appl. Mater. Interfaces 2018, 10, 30558–30565. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Biswas, K. Realization of High Thermoelectric Figure of Merit in Solution Synthesized 2D SnSe Nanoplates via Ge Alloying. J. Am. Chem. Soc. 2019, 57, 8489–8503. [Google Scholar] [CrossRef] [PubMed]

- Shu, Y.; Su, X.; Xie, H.; Zheng, G.; Liu, W.; Yan, Y.; Luo, T.T.; Yang, X.; Yang, D.W.; Uher, C.; et al. Modification of Bulk Heterojunction and Cl Doping for High-Performance Thermoelectric SnSe2/SnSe Nanocomposites. ACS Appl. Mater. Interfaces 2018, 10, 15793–15802. [Google Scholar] [CrossRef]

- Wang, S.; Su, X.; Bailey, T.P.; Hu, T.Z.; Zhang, Z.; Tan, G.; Yan, Y.; Liu, W.; Uher, C.; Tang, X.F. Optimizing the average power factor of p-type (Na, Ag) co-doped polycrystalline SnSe. RSC Adv. 2019, 9, 7115–7122. [Google Scholar] [CrossRef]

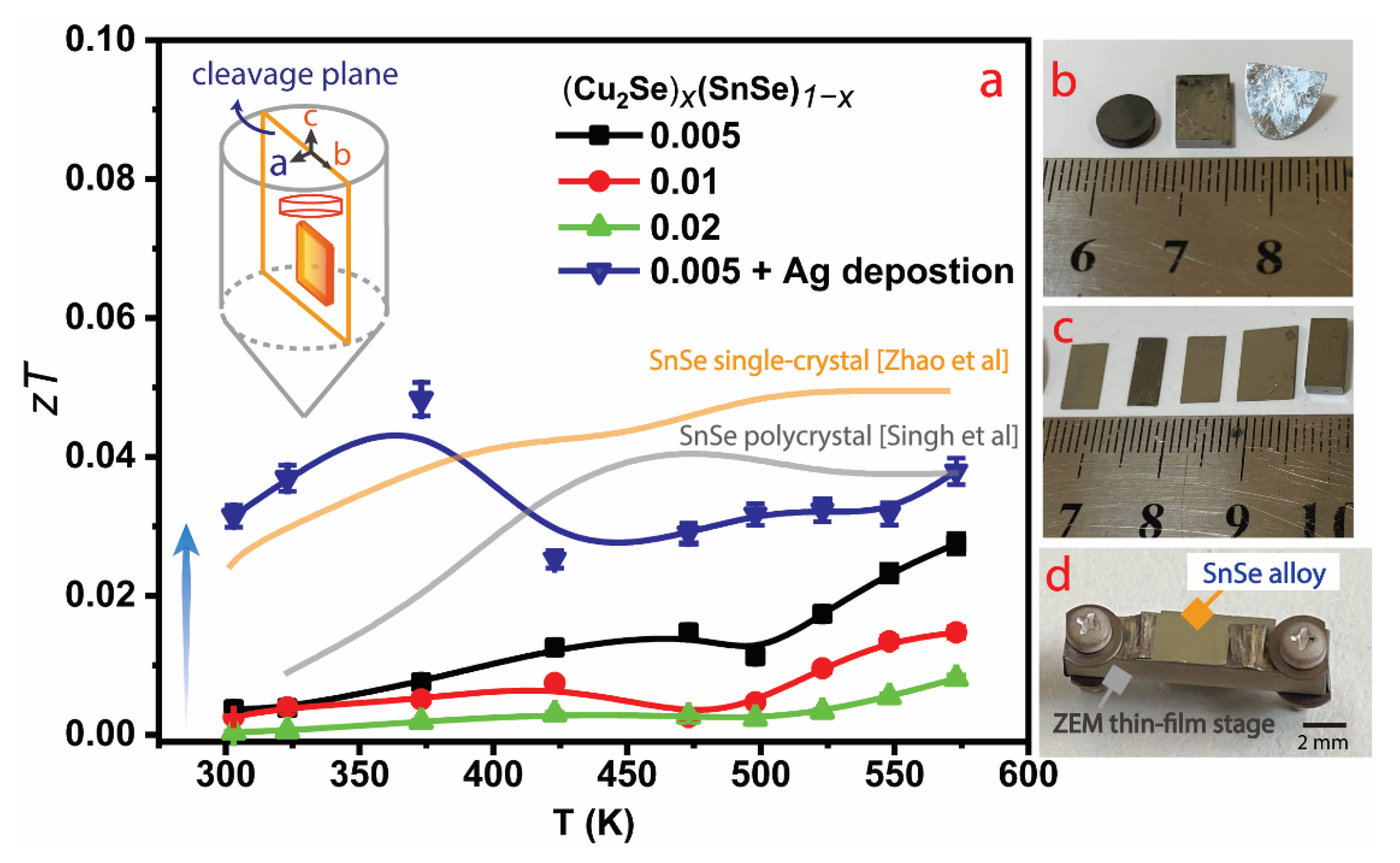

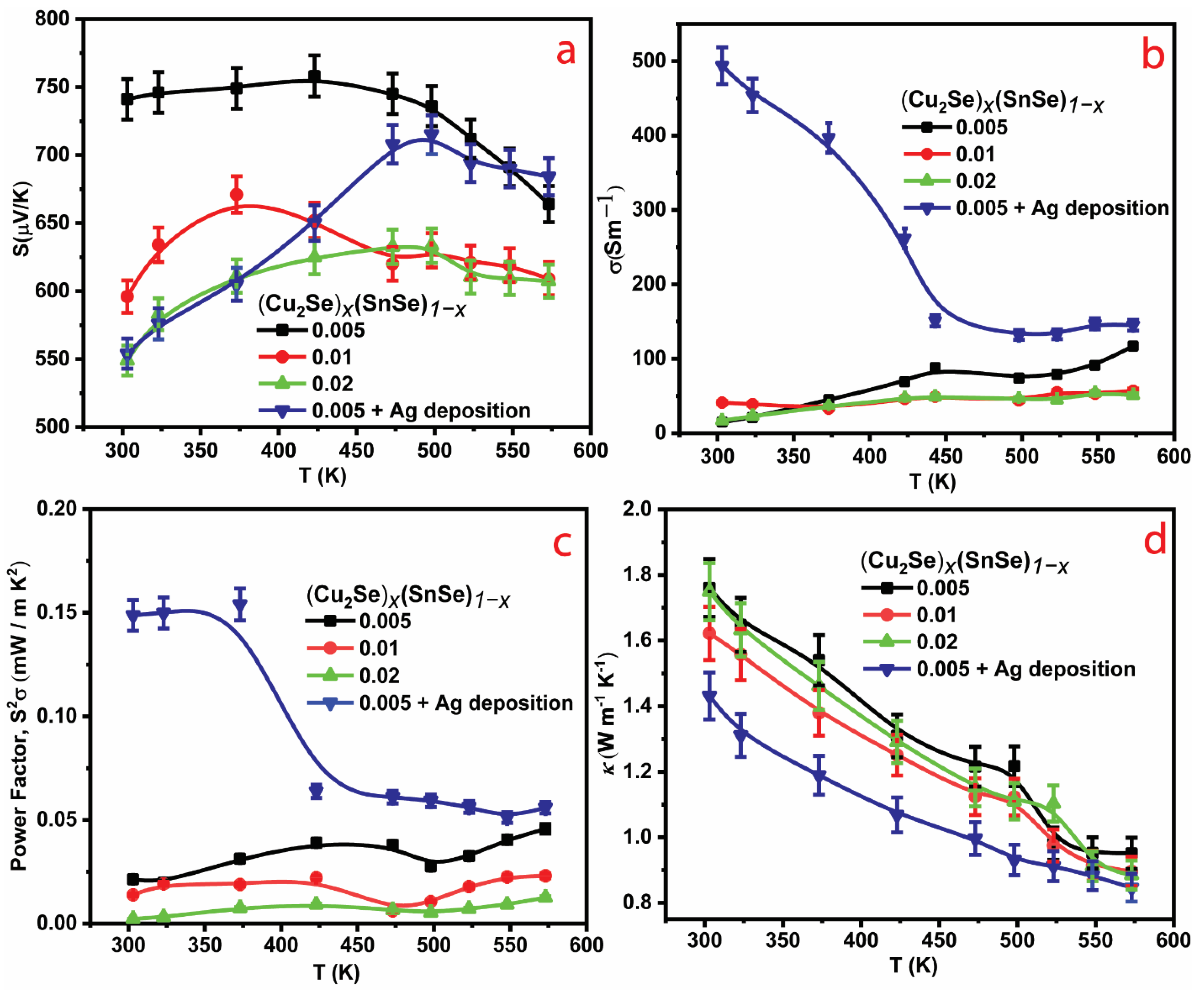

| (Cu2Se)x(SnSe)1−x | S (μV K−1) | σ (S m−1) | PF (mW m−1 K−2) | κ (W m−1 K−1) | n (cm−3) | μ (cm2 V−1 s−1) |

|---|---|---|---|---|---|---|

| x = 0.005 | 741 | 15 | 0.0231 | 1.76 | 9.31 × 1015 | 91.6 |

| x = 0.01 | 596 | 41 | 0.01384 | 1.62 | 1.31 × 1016 | 77.6 |

| x = 0.02 | 549 | 17 | 0.00224 | 1.74 | 1.11 × 1016 | 102.2 |

| Ag-coated x = 0.005 | 554 | 494 | 0.1487 | 1.43 | 3.65 × 1017 | 149 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manibalan, K.; Ho, M.-Y.; Du, Y.-C.; Chen, H.-W.; Wu, H.-J. Enhanced Room-Temperature Thermoelectric Performance of 2D-SnSe Alloys via Electric-Current-Assisted Sintering. Materials 2023, 16, 509. https://doi.org/10.3390/ma16020509

Manibalan K, Ho M-Y, Du Y-C, Chen H-W, Wu H-J. Enhanced Room-Temperature Thermoelectric Performance of 2D-SnSe Alloys via Electric-Current-Assisted Sintering. Materials. 2023; 16(2):509. https://doi.org/10.3390/ma16020509

Chicago/Turabian StyleManibalan, Kesavan, Meng-Yuan Ho, You-Cheng Du, Hung-Wei Chen, and Hsin-Jay Wu. 2023. "Enhanced Room-Temperature Thermoelectric Performance of 2D-SnSe Alloys via Electric-Current-Assisted Sintering" Materials 16, no. 2: 509. https://doi.org/10.3390/ma16020509

APA StyleManibalan, K., Ho, M.-Y., Du, Y.-C., Chen, H.-W., & Wu, H.-J. (2023). Enhanced Room-Temperature Thermoelectric Performance of 2D-SnSe Alloys via Electric-Current-Assisted Sintering. Materials, 16(2), 509. https://doi.org/10.3390/ma16020509