Constitutive Modeling of Annealed OFHC with Wide Strain-Rate and Temperature Effects: Incorporating Dislocation Dynamics and Normalized Microstructural Size Evolution

Abstract

:1. Introduction

2. Constitutive Modelling

2.1. Thermal Stress

2.1.1. Thermal Activation Effect in Fixed Structures

2.1.2. Microstructural Evolution

2.1.3. Threshold Stress and Thermal Stress

2.2. Athermal Stress

2.3. Flow Stress and Hardening Rate

2.4. Shear Modulus

2.5. Adiabatic Temperature Rise

3. Application

3.1. Parameter Calibration

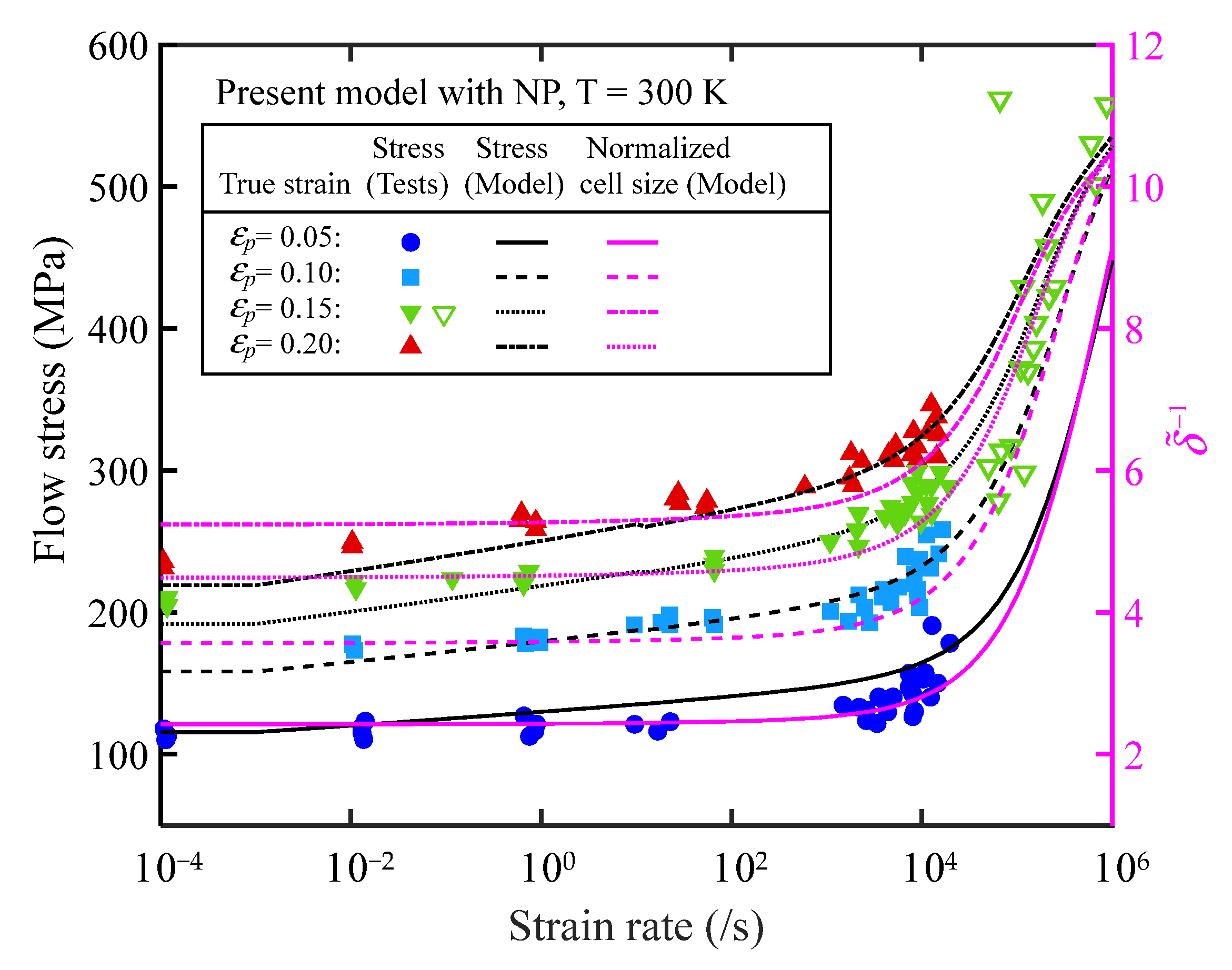

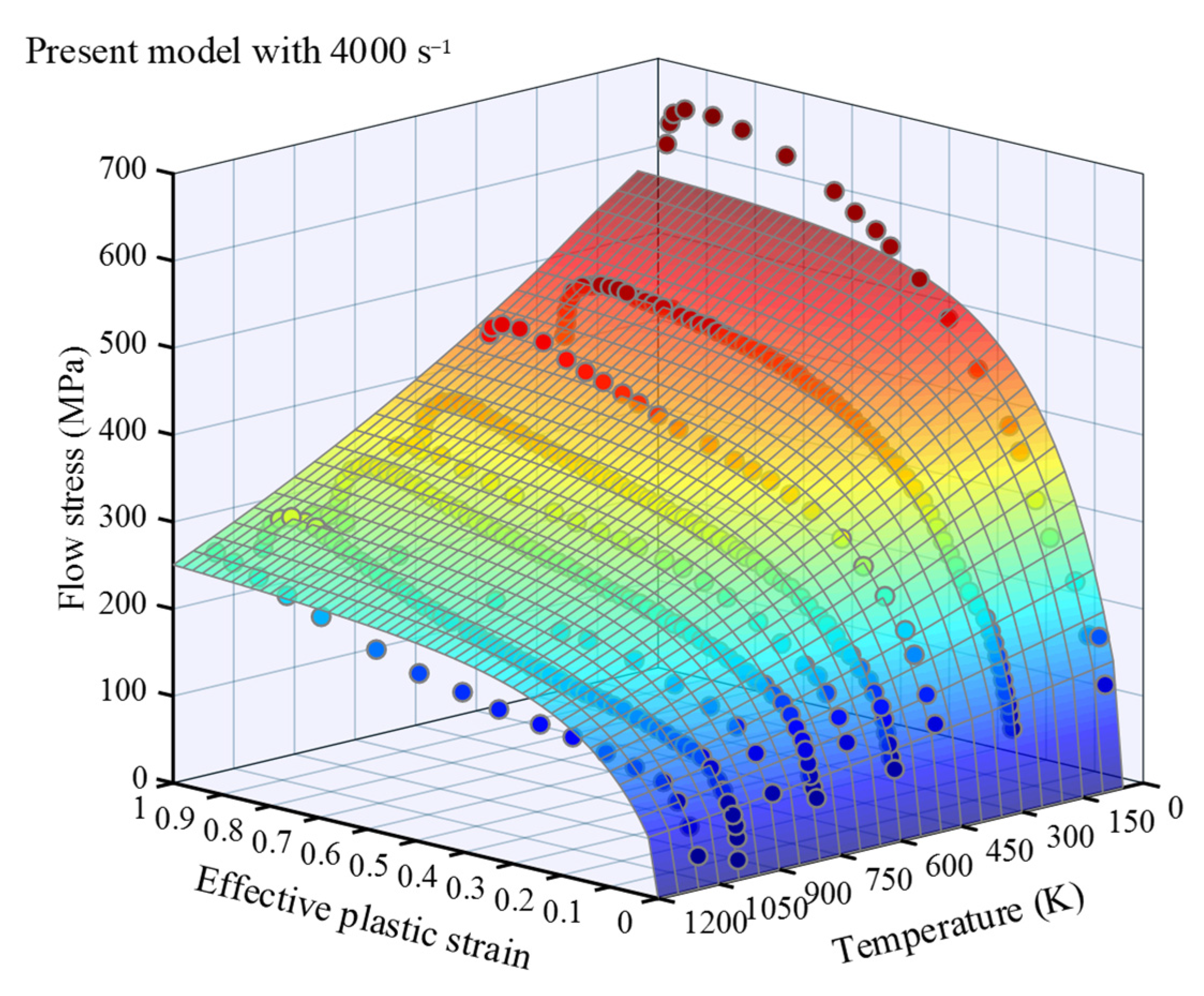

3.2. Simulation Results

4. Result Analysis and Discussion

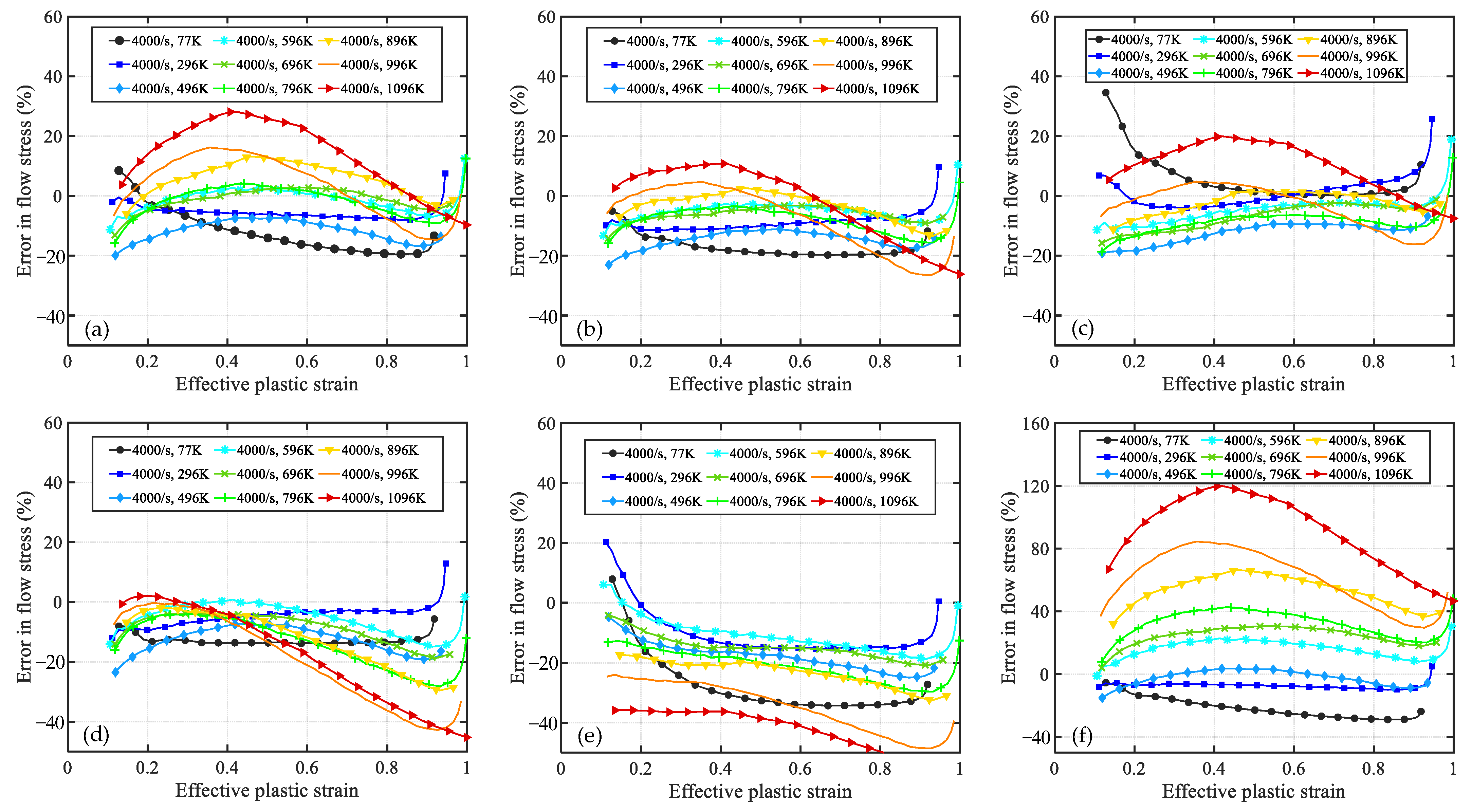

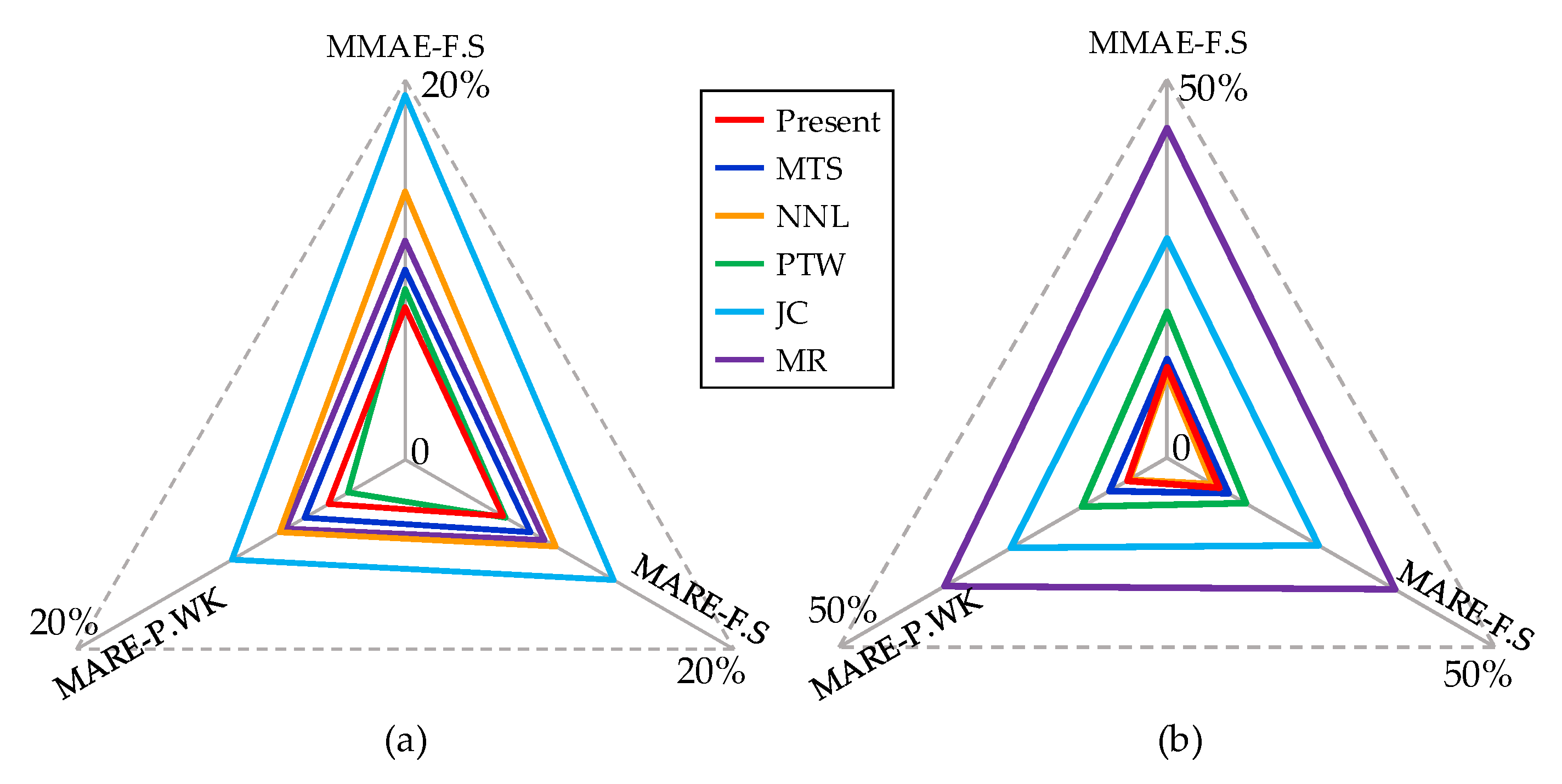

4.1. Relative Error Analysis

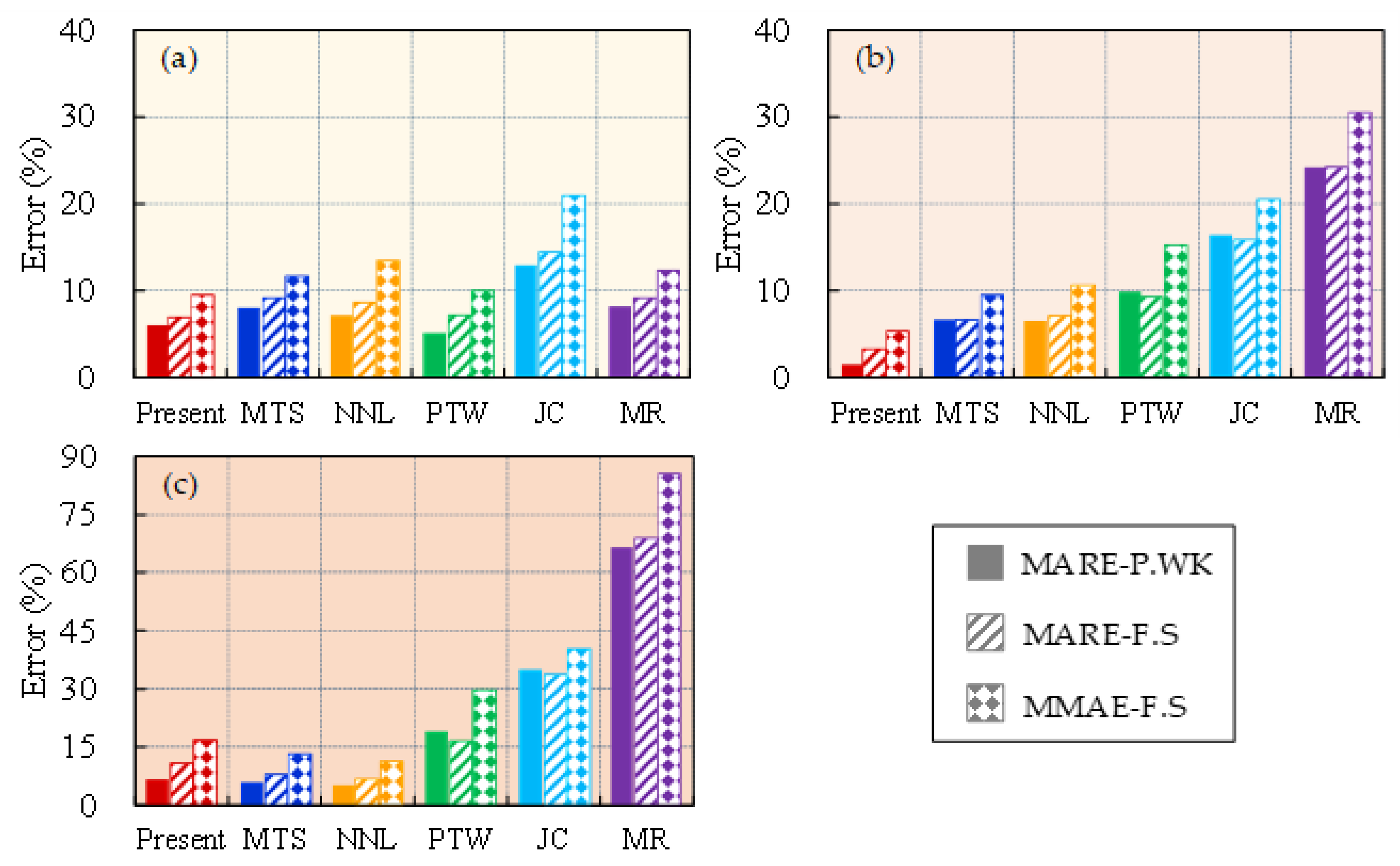

4.2. Comprehensive Error Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Source of Experimental Data

| Condition | (s−1) | T (K) | References | Purity (%) | |

|---|---|---|---|---|---|

| Fixed strain and room temperature | 0.15 | 6 × (104, 105) | 300 | Tong and Clifton (1992) [51] | 99.99 |

| 0.05, 0.10, 0.15, 0.20 | (10−4, 2 × 104) | Preston, Tonks, and Wallace (2003) [24] | 99.99 |

| Condition | (s−1) | T (K) | References | Purity (%) |

|---|---|---|---|---|

| Room temperature and wide range of strain rates | 0.015, 8500, 6.4 × 105 | 295 | Follansbee and Kocks (1988) [13] | 99.99 |

| 0.001, 0.1, 4000, 8000 | 296 | Nemat-Nasser and Li (1998) [20] | 99.98 | |

| 0.0004, 6000 | 298 | Tanner and McGinty (1999) [52] | 99.99 | |

| 1.3 × 104 | 296 | Jing and Wang (2022) [53] | Not mentioned |

| Condition | T (K) | References | Purity (%) | |

|---|---|---|---|---|

| Fixed strain rate and wide range of temperatures | 4000 | 77, 296, 496, 596, 696, 796, 896, 996, 1096 | Nemat-Nasser and Li (1998) [20] | 99.98 |

References

- Salvado, F.; Teixeira-Dias, F.; Walley, S.M.; Lea, L.; Cardoso, J. A Review on the Strain Rate Dependency of the Dynamic Viscoplastic Response of FCC Metals. Prog. Mater. Sci. 2017, 88, 186–231. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Walley, S.M. High Strain Rate Properties of Metals and Alloys. Int. Mater. Rev. 2008, 53, 105–128. [Google Scholar] [CrossRef]

- Gao, C.Y.; Zhang, L.C. Constitutive Modelling of Plasticity of Fcc Metals under Extremely High Strain Rates. Int. J. Plast. 2012, 32–33, 121–133. [Google Scholar] [CrossRef]

- Jia, X.; Hao, K.; Luo, Z.; Fan, Z. Plastic Deformation Behavior of Metal Materials: A Review of Constitutive Models. Metals 2022, 12, 2077. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Materials Subjected to Large Strains. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Malvern, L.E. The Propagation of Longitudinal Waves of Plastic Deformation in a Bar of Material Exhibiting a Strain-Rate Effect. J. Appl. Mech. 1951, 18, 203–208. [Google Scholar] [CrossRef]

- Perzyna, P. Fundamental Problems in Viscoplasticity. In Advances in Applied Mechanics; Chernyi, G.G., Dryden, H.L., Germain, P., Howarth, L., Olszak, W., Prager, W., Probstein, R.F., Ziegler, H., Eds.; Elsevier: Amsterdam, The Netherlands, 1966; Volume 9, pp. 243–377. [Google Scholar]

- Campbell, J.D. Dynamic Plasticity: Macroscopic and Microscopic Aspects. Mater. Sci. Eng. 1973, 12, 3–21. [Google Scholar] [CrossRef]

- Rule, W.K.; Jones, S.E. A Revised Form for the Johnson–Cook Strength Model. Int. J. Impact Eng. 1998, 21, 609–624. [Google Scholar] [CrossRef]

- Wang, J.; Guo, W.-G.; Li, P.; Zhou, P. Modified Johnson-Cook Description of Wide Temperature and Strain Rate Measurements Made on a Nickel-Base Superalloy. Mater. High Temp. 2017, 34, 157–165. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, X.; Chen, H.; Yang, X.; Wang, F.; Zeng, L. Modified Johnson-Cook Constitutive Model of Metallic Materials under a Wide Range of Temperatures and Strain Rates. Results Phys. 2021, 27, 104498. [Google Scholar] [CrossRef]

- Kumar Reddy Sirigiri, V.; Yadav Gudiga, V.; Shankar Gattu, U.; Suneesh, G.; Mohan Buddaraju, K. A Review on Johnson Cook Material Model. Mater. Today Proc. 2022, 62, 3450–3456. [Google Scholar] [CrossRef]

- Follansbee, P.S.; Kocks, U.F. A Constitutive Description of the Deformation of Copper Based on the Use of the Mechanical Threshold Stress as an Internal State Variable. Acta Metall. 1988, 36, 81–93. [Google Scholar] [CrossRef]

- Mecking, H.; Kocks, U.F. Kinetics of Flow and Strain-Hardening. Acta Metall. 1981, 29, 1865–1875. [Google Scholar] [CrossRef]

- Klepaczko, J.R. Physical-State Variables—The Key to Constitutive Modeling in Dynamic Plasticity. Nucl. Eng. Des. 1991, 127, 103–115. [Google Scholar] [CrossRef]

- Mohamadnejad, S.; Basti, A.; Ansari, R. Analyses of Dislocation Effects on Plastic Deformation. Multiscale Sci. Eng. 2020, 2, 69–89. [Google Scholar] [CrossRef]

- Lea, L.J.; Jardine, A.P. Characterisation of High Rate Plasticity in the Uniaxial Deformation of High Purity Copper at Elevated Temperatures. Int. J. Plast. 2018, 102, 41–52. [Google Scholar] [CrossRef]

- Lea, L.; Brown, L.; Jardine, A. Time Limited Self-Organised Criticality in the High Rate Deformation of Face Centred Cubic Metals. Commun. Mater. 2020, 1, 93. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based Constitutive Relations for Material Dynamics Calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Li, Y. Flow Stress of fcc Polycrystals with Application to OFHC Cu. Acta Mater. 1998, 46, 565–577. [Google Scholar] [CrossRef]

- Gao, C.Y.; Zhang, L.C. A Constitutive Model for Dynamic Plasticity of FCC Metals. Mater. Sci. Eng. A 2010, 527, 3138–3143. [Google Scholar] [CrossRef]

- Austin, R.A.; McDowell, D. A Dislocation-Based Constitutive Model for Viscoplastic Deformation of Fcc Metals at Very High Strain Rates. Int. J. Plast. 2011, 27, 1–24. [Google Scholar] [CrossRef]

- Austin, R.A.; McDowell, D.L. Parameterization of a Rate-Dependent Model of Shock-Induced Plasticity for Copper, Nickel, and Aluminum. Int. J. Plast. 2012, 32–33, 134–154. [Google Scholar] [CrossRef]

- Preston, D.; Tonks, D.; Wallace, D. Model of Plastic Deformation for Extreme Loading Conditions. J. Appl. Phys. 2003, 93, 211–220. [Google Scholar] [CrossRef]

- Molinari, A.; Ravichandran, G. Constitutive Modeling of High-Strain-Rate Deformation in Metals Based on the Evolution of an Effective Microstructural Length. Mech. Mater. 2005, 37, 737–752. [Google Scholar] [CrossRef]

- Durrenberger, L.; Molinari, A.; Rusinek, A. Internal Variable Modeling of the High Strain-Rate Behavior of Metals with Applications to Multiphase Steels. Mater. Sci. Eng. A 2008, 478, 297–304. [Google Scholar] [CrossRef]

- Durrenberger, L.; Molinari, A. Modeling of Temperature and Strain-Rate Effects in Metals Using an Internal Variable Model. Exp. Mech. 2009, 49, 247–255. [Google Scholar] [CrossRef]

- Kocks, U.F.; Argon, A.S.; Ashby, M.F. Thermodynamics and Kinetics of Slip. Prog. Mater. Sci. 1975, 19, 141–145. [Google Scholar]

- Wang, Z.Q.; Beyerlein, I.J.; LeSar, R. Slip Band Formation and Mobile Dislocation Density Generation in High Rate Deformation of Single Fcc Crystals. Philos. Mag. 2008, 88, 1321–1343. [Google Scholar] [CrossRef]

- Gil Sevillano, J.; van Houtte, P.; Aernoudt, E. Large Strain Work Hardening and Textures. Prog. Mater. Sci. 1980, 25, 69–134. [Google Scholar] [CrossRef]

- Nes, E. Modelling of Work Hardening and Stress Saturation in FCC Metals. Prog. Mater. Sci. 1997, 41, 129–193. [Google Scholar] [CrossRef]

- Staker, M.R.; Holt, D.L. The Dislocation Cell Size and Dislocation Density in Copper Deformed at Temperatures between 25 and 700 °C. Acta Metall. 1972, 20, 569–579. [Google Scholar] [CrossRef]

- Estrin, Y.; Kubin, L.P. Local Strain Hardening and Nonuniformity of Plastic Deformation. Acta Metall. 1986, 34, 2455–2464. [Google Scholar] [CrossRef]

- Voce, E. The Relationship between Stress and Strain for Homogeneous Deformations. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Armstrong, R.W. The (Cleavage) Strength of Pre-Cracked Polycrystals. Eng. Fract. Mech. 1987, 28, 529–538. [Google Scholar] [CrossRef]

- Meyers, M.A.; Andrade, U.R.; Chokshi, A.H. The Effect of Grain Size on the High-Strain, High-Strain-Rate Behavior of Copper. Met. Mater. Trans. A 1995, 26, 2881–2893. [Google Scholar] [CrossRef]

- Yan, S.; Yang, H.; Li, H.; Yao, X. A Unified Model for Coupling Constitutive Behavior and Micro-Defects Evolution of Aluminum Alloys under High-Strain-Rate Deformation. Int. J. Plast. 2016, 85, 203–229. [Google Scholar] [CrossRef]

- Kocks, F.; Mecking, H. Physics and Phenomenology of Strain Hardening: The FCC Case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Nadal, M.-H.; Le Poac, P. Continuous Model for the Shear Modulus as a Function of Pressure and Temperature up to the Melting Point: Analysis and Ultrasonic Validation. J. Appl. Phys. 2003, 93, 2472–2480. [Google Scholar] [CrossRef]

- Klepaczko, J.; Rusinek, A.; Rodríguez-Martínez, J.A.; Pęcherski, R.; Arias, A. Modelling of Thermo-Viscoplastic Behaviour of DH36 and Weldox 460-E Structural Steels at Wide Ranges of Strain Rates and Temperatures, Comparison of Constitutive Relations for Impact Problems. Mech. Mater. 2009, 41, 599–621. [Google Scholar] [CrossRef]

- Baig, M.; Khan, A.S.; Choi, S.-H.; Jeong, A. Shear and Multiaxial Responses of Oxygen Free High Conductivity (OFHC) Copper over Wide Range of Strain-Rates and Temperatures and Constitutive Modeling. Int. J. Plast. 2013, 40, 65–80. [Google Scholar] [CrossRef]

- Mason, J.J.; Rosakis, A.J.; Ravichandran, G. On the Strain and Strain Rate Dependence of the Fraction of Plastic Work Converted to Heat: An Experimental Study Using High Speed Infrared Detectors and the Kolsky Bar. Mech. Mater. 1994, 17, 135–145. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Abed, F.H. Effect of Dislocation Density Evolution on the Thermomechanical Response of Metals with Different Crystal Structures at Low and High Strain Rates and Temperatures. Arch. Mech. 2005, 57, 299–343. [Google Scholar]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier: Amsterdam, The Netherlands; Boston, MA, USA, 2004; ISBN 978-0-08-044164-1. [Google Scholar]

- Huang, M.; Rivera-Díaz-del-Castillo, P.E.J.; Bouaziz, O.; van der Zwaag, S. A Constitutive Model for High Strain Rate Deformation in FCC Metals Based on Irreversible Thermodynamics. Mech. Mater. 2009, 41, 982–988. [Google Scholar] [CrossRef]

- Banerjee, B. Taylor Impact Tests: Detailed Report; Technical Report No. C-SAFE-CD-IR-05-001; Department of Mechanical Engineering, University of Utah: Salt Lake City, UT, USA, 2005. [Google Scholar]

- Banerjee, B. An Evaluation of Plastic Flow Stress Models for the Simulation of High-Temperature and High-Strain-Rate Deformation of Metals. arXiv 2005. [CrossRef]

- Steinberg, D.J.; Lund, C.M. A Constitutive Model for Strain Rates from 10−4 to 106 s−1. J. Appl. Phys. 1989, 65, 1528–1533. [Google Scholar] [CrossRef]

- Nix, W.D.; Gibeling, J.C.; Hughes, D.A. Time-Dependent Deformation of Metals. Metall. Trans. A 1985, 16, 2215–2226. [Google Scholar] [CrossRef]

- Tong, W.; Clifton, R.J.; Huang, S. Pressure-Shear Impact Investigation of Strain Rate History Effects in Oxygen-Free High-Conductivity Copper. J. Mech. Phys. Solids 1992, 40, 1251–1294. [Google Scholar] [CrossRef]

- Tanner, A.B.; McDowell, D.L. Deformation, Temperature and Strain Rate Sequence Experiments on OFHC Cu. Int. J. Plast. 1999, 15, 375–399. [Google Scholar] [CrossRef]

- Jing, C.; Wang, J.; Zhang, C.; Sun, Y.; Shi, Z. Influence of Size Effect on the Dynamic Mechanical Properties of OFHC Copper at Micro-/Meso-Scales. Int. J. Adv. Manuf. Technol. 2022, 120, 4775–4789. [Google Scholar] [CrossRef]

| ρm (kg/m3) | Cp (J/kg/K) | β | μ0 (GPa) | Tm (K) | ζm | mu (amu) | |

|---|---|---|---|---|---|---|---|

| 8930 | 382 | 0.9 | 50.7 | 1356 | 0.04 | 0.057 | 63.55 |

| (MPa) | D0 (μm) | B (MPa) | ||

|---|---|---|---|---|

| 20.6 | 158 [19] | 62 | 230 [3] | 0.64 [3] |

| N0 (m−2) | M | b (nm) | (K−1) | p | q | (s−1) | |

|---|---|---|---|---|---|---|---|

| 1013 [44] | 3.06 [45] | 0.4 [46] | 0.256 [31] | 4.9 × 10−5 [20] | 2/3 [13] | 1 [13] | 107 [13] |

| (s−1) | (K) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.12 | 0.377 | 0.24 | 0.5 | 4.3 | 50 | 0.8 | 0 | 107 | 298 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, M.; Xiao, Q.; Zu, X.; Tan, Y.; Huang, Z. Constitutive Modeling of Annealed OFHC with Wide Strain-Rate and Temperature Effects: Incorporating Dislocation Dynamics and Normalized Microstructural Size Evolution. Materials 2023, 16, 6517. https://doi.org/10.3390/ma16196517

Xu M, Xiao Q, Zu X, Tan Y, Huang Z. Constitutive Modeling of Annealed OFHC with Wide Strain-Rate and Temperature Effects: Incorporating Dislocation Dynamics and Normalized Microstructural Size Evolution. Materials. 2023; 16(19):6517. https://doi.org/10.3390/ma16196517

Chicago/Turabian StyleXu, Mengwen, Qiangqiang Xiao, Xudong Zu, Yaping Tan, and Zhengxiang Huang. 2023. "Constitutive Modeling of Annealed OFHC with Wide Strain-Rate and Temperature Effects: Incorporating Dislocation Dynamics and Normalized Microstructural Size Evolution" Materials 16, no. 19: 6517. https://doi.org/10.3390/ma16196517

APA StyleXu, M., Xiao, Q., Zu, X., Tan, Y., & Huang, Z. (2023). Constitutive Modeling of Annealed OFHC with Wide Strain-Rate and Temperature Effects: Incorporating Dislocation Dynamics and Normalized Microstructural Size Evolution. Materials, 16(19), 6517. https://doi.org/10.3390/ma16196517