Microstructure, Mechanical Properties and Fatigue Crack Growth Behavior of Gas Tungsten Arc Welding Welded Joint of the Hastelloy N Alloy

Abstract

:1. Introduction

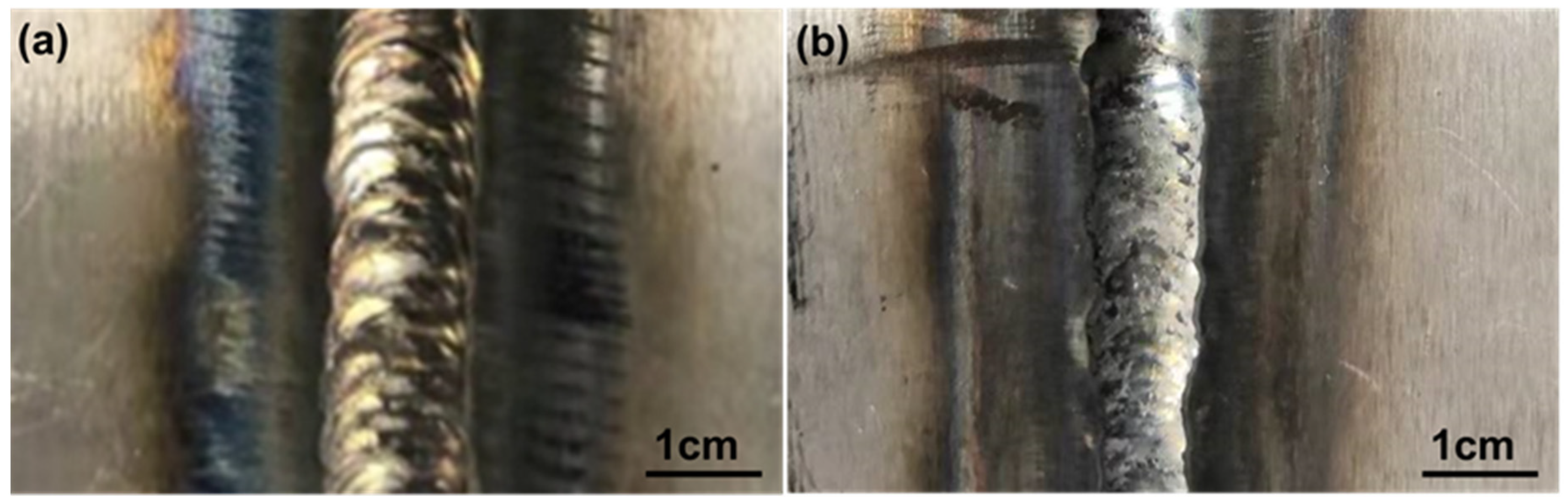

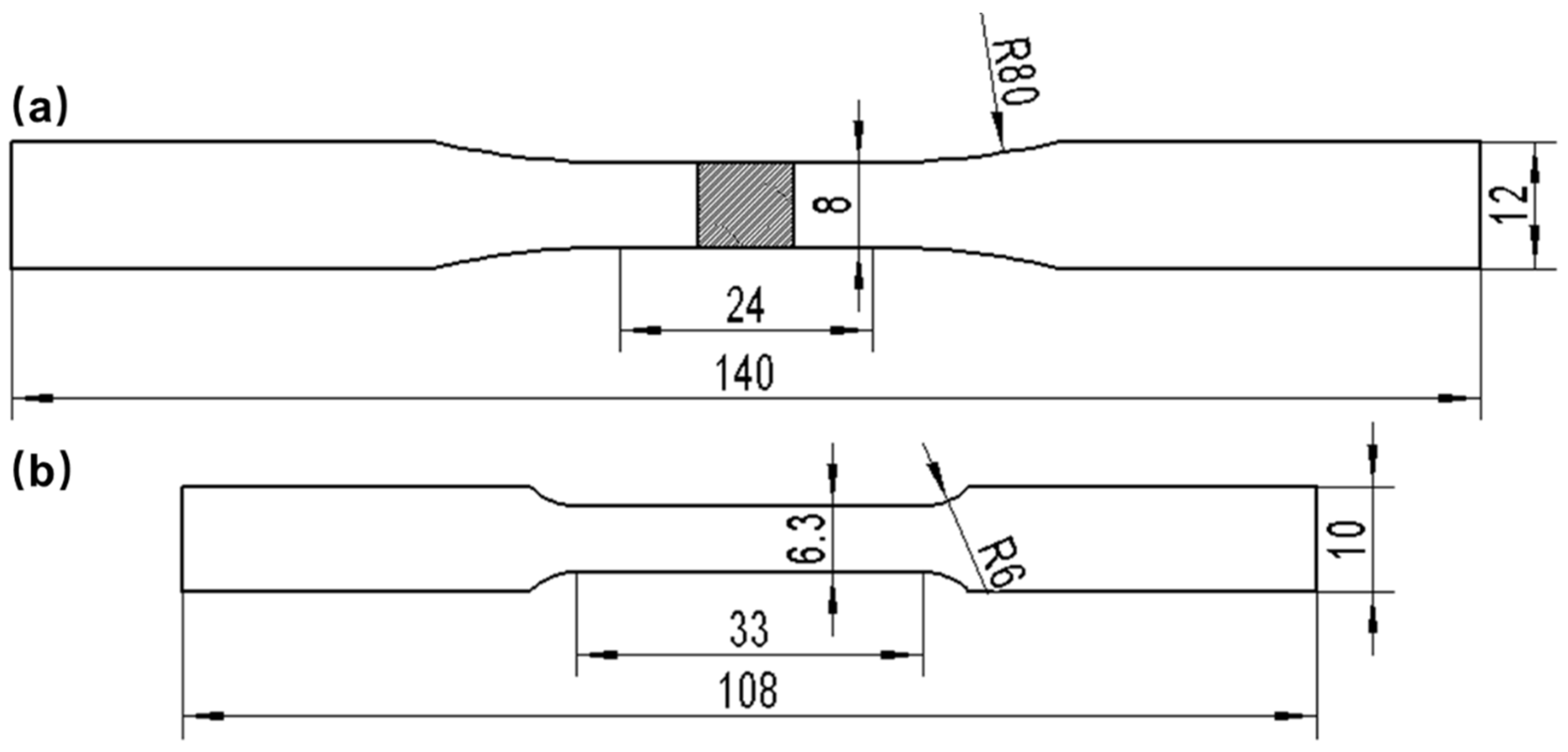

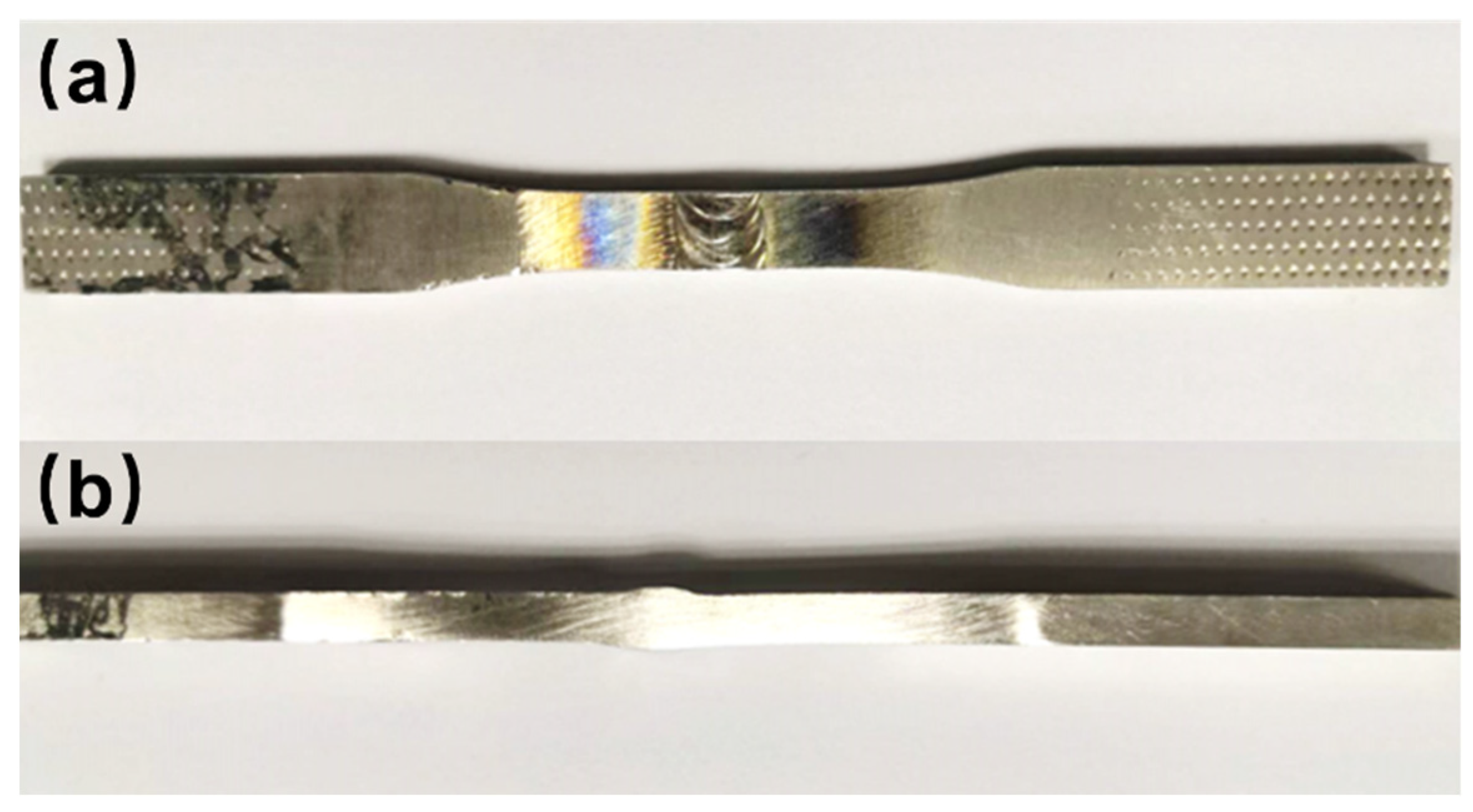

2. Materials and Methods

3. Results and Discussion

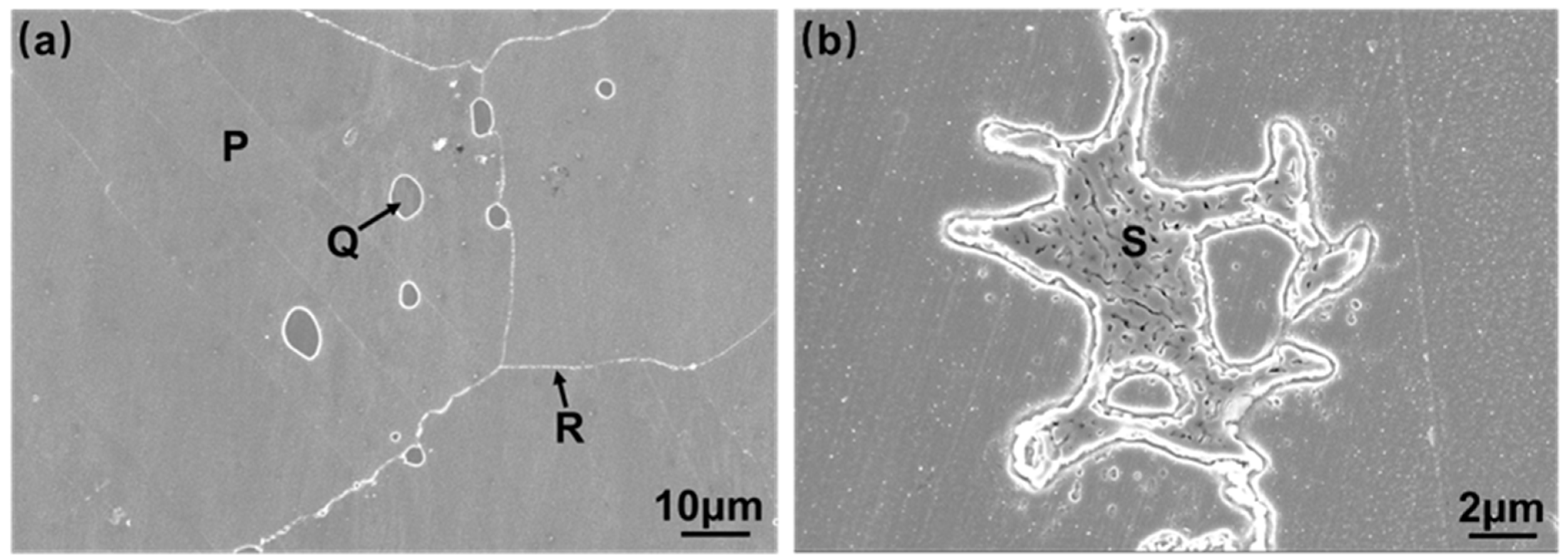

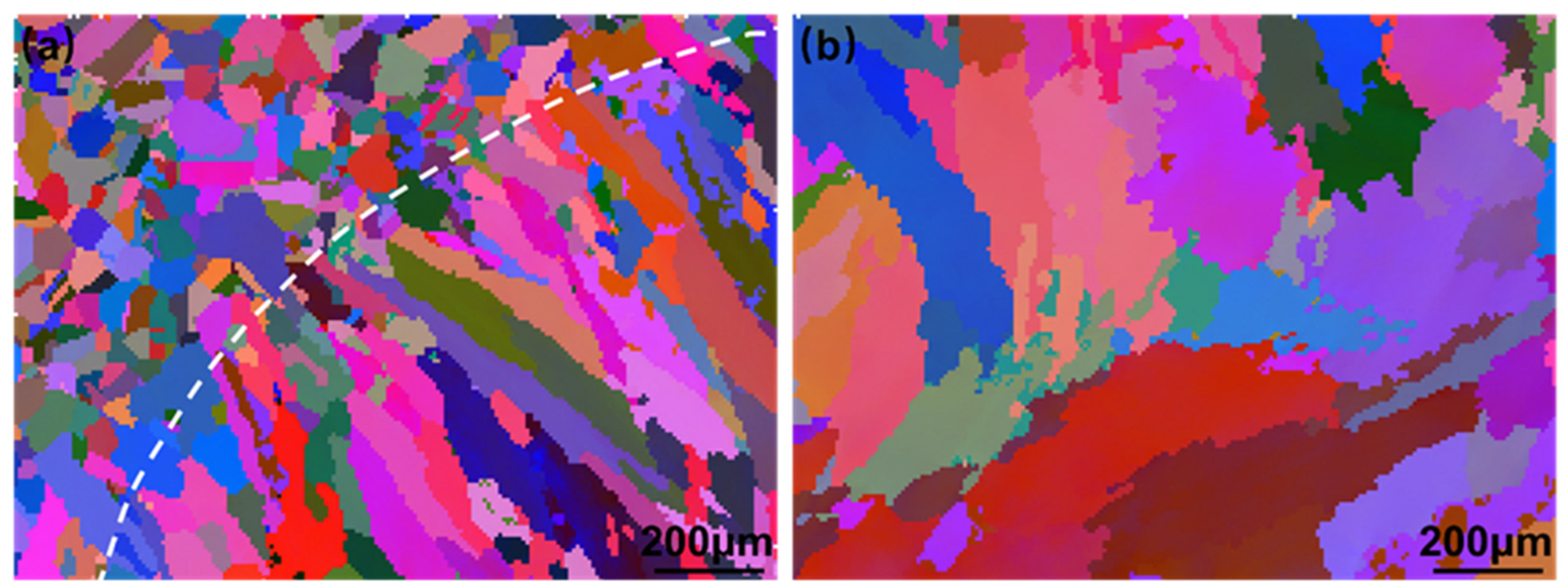

3.1. Microstructure

3.2. Hardness Distribution

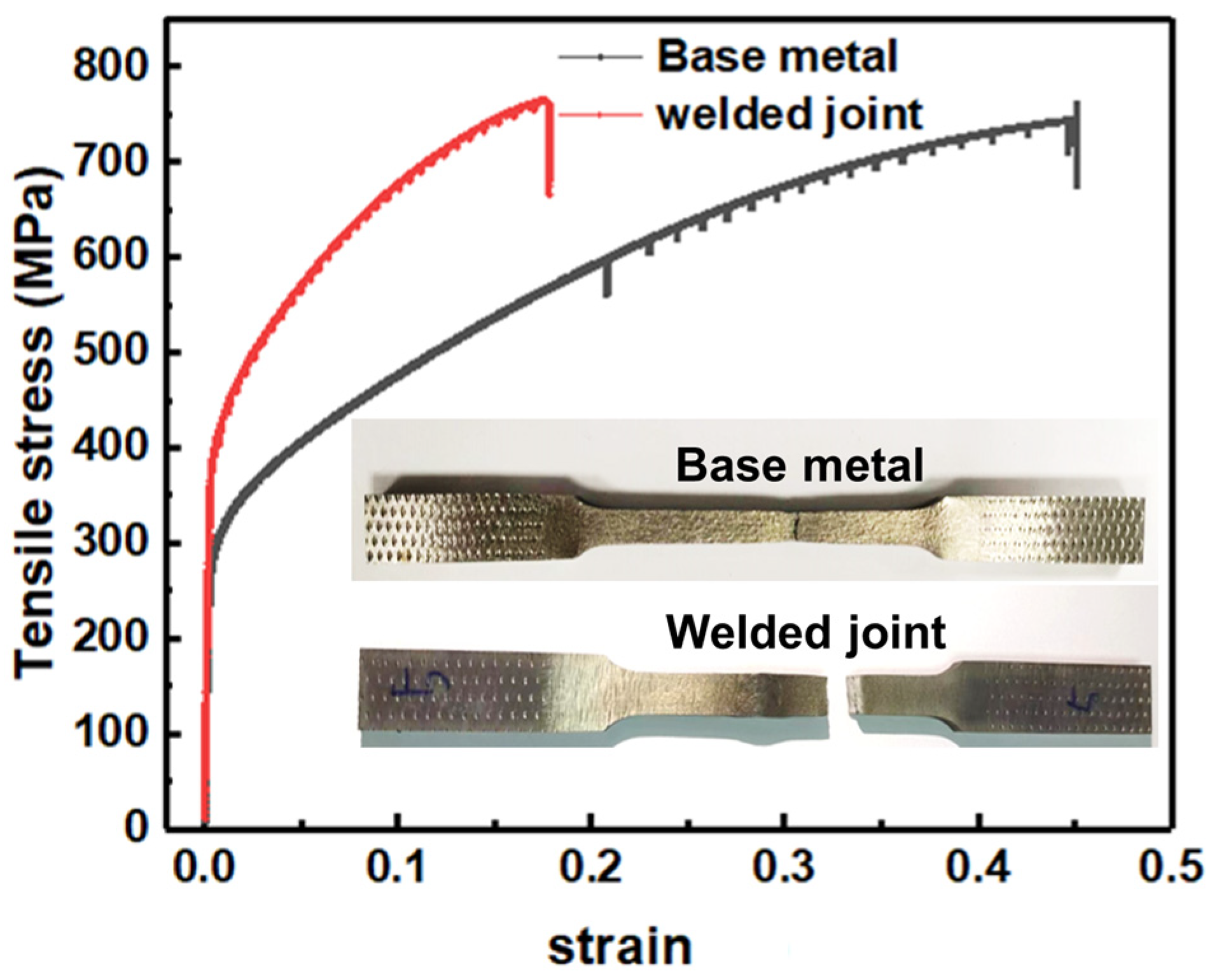

3.3. Tensile Properties

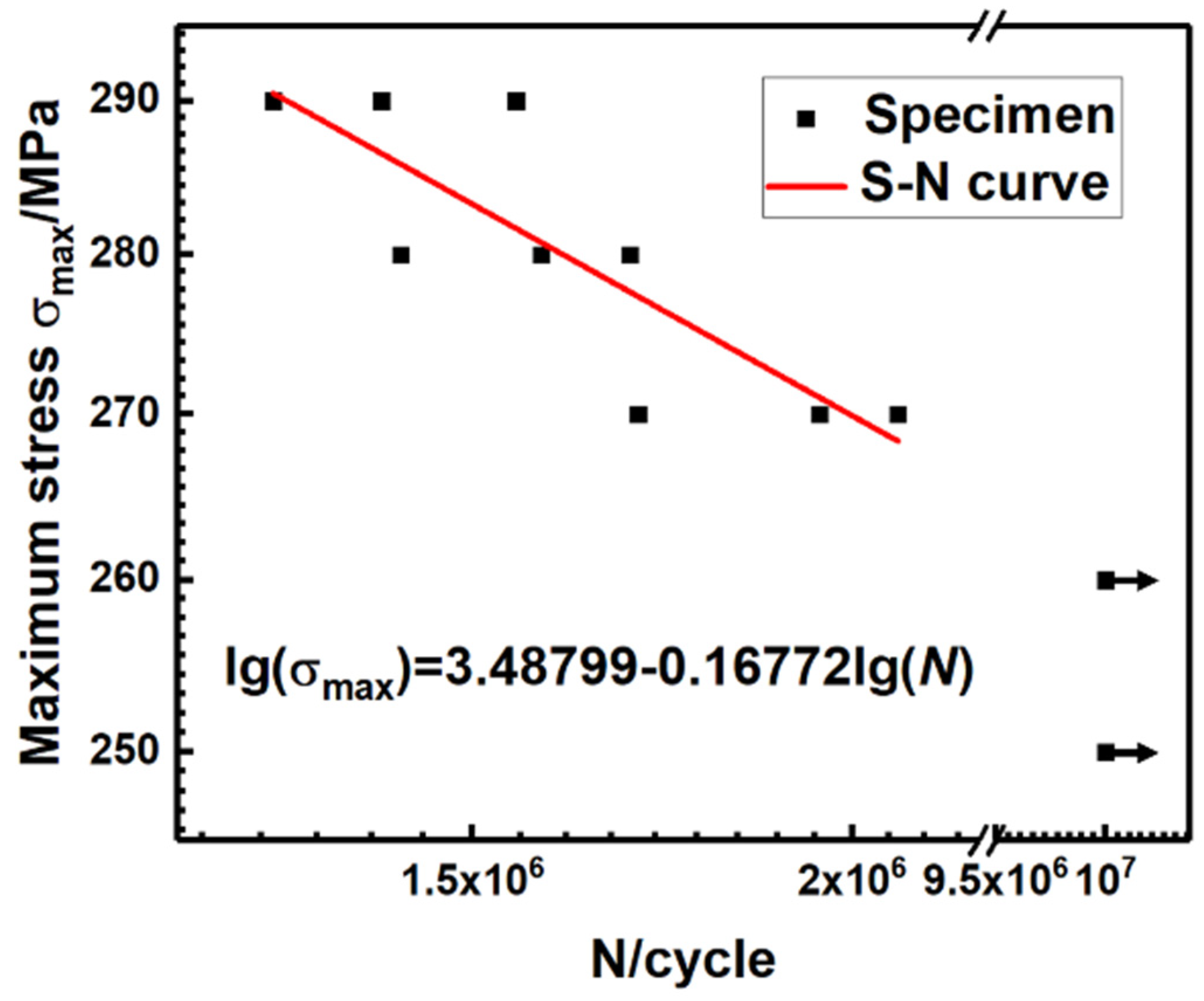

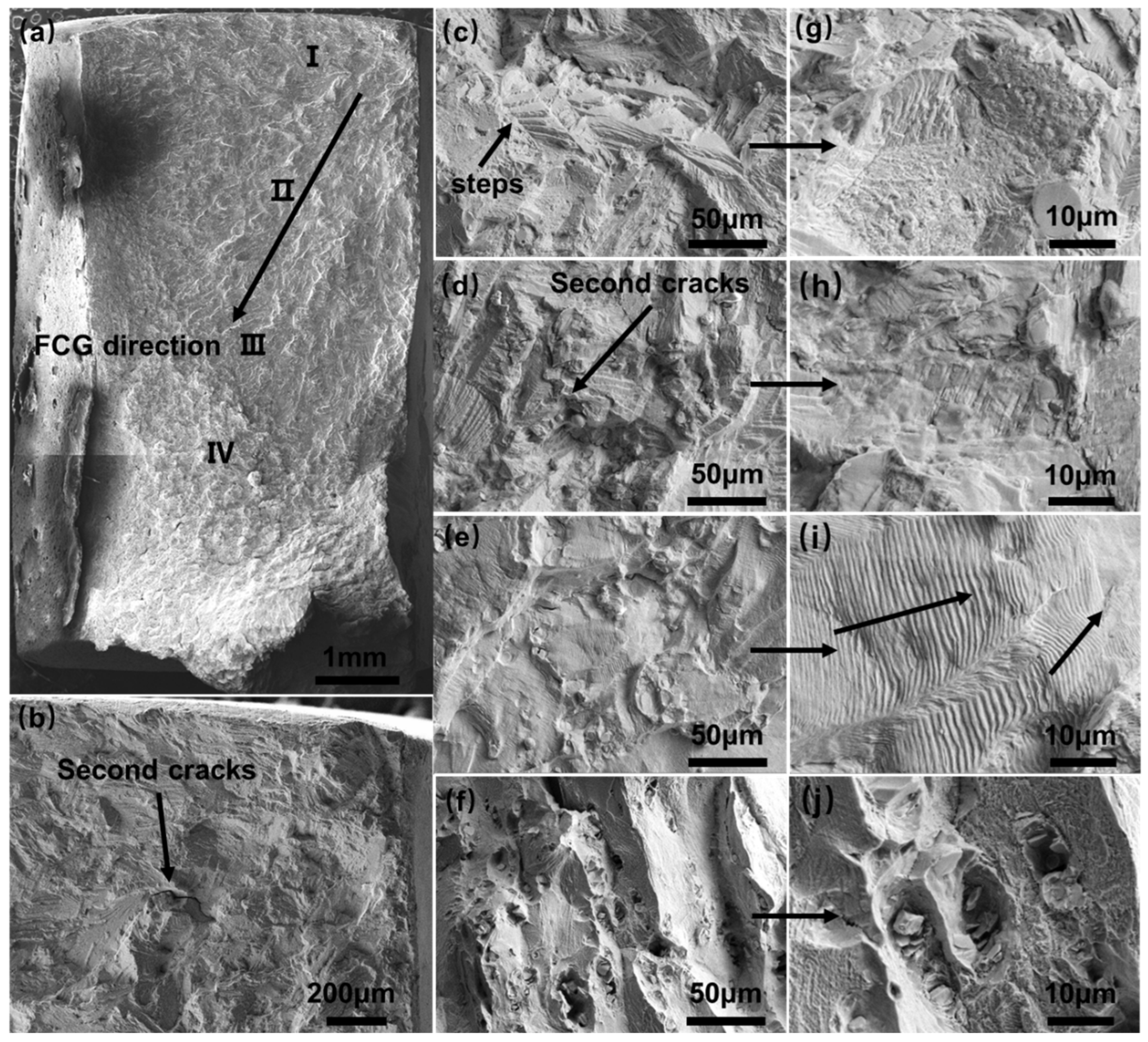

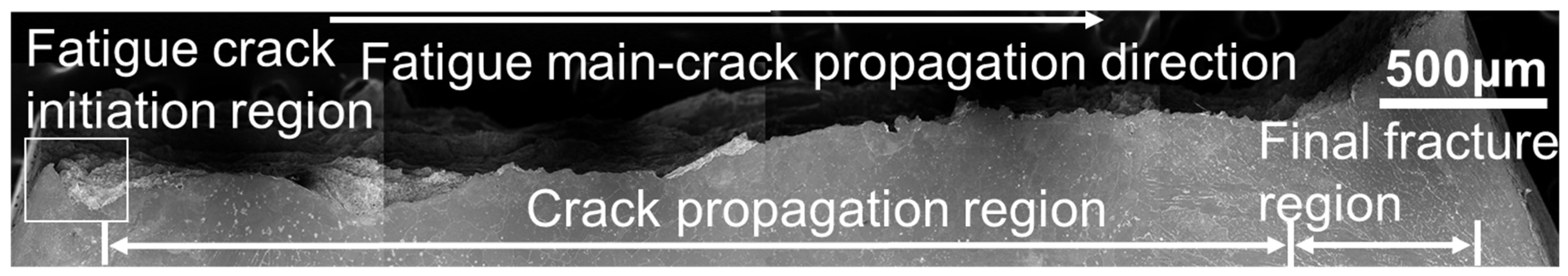

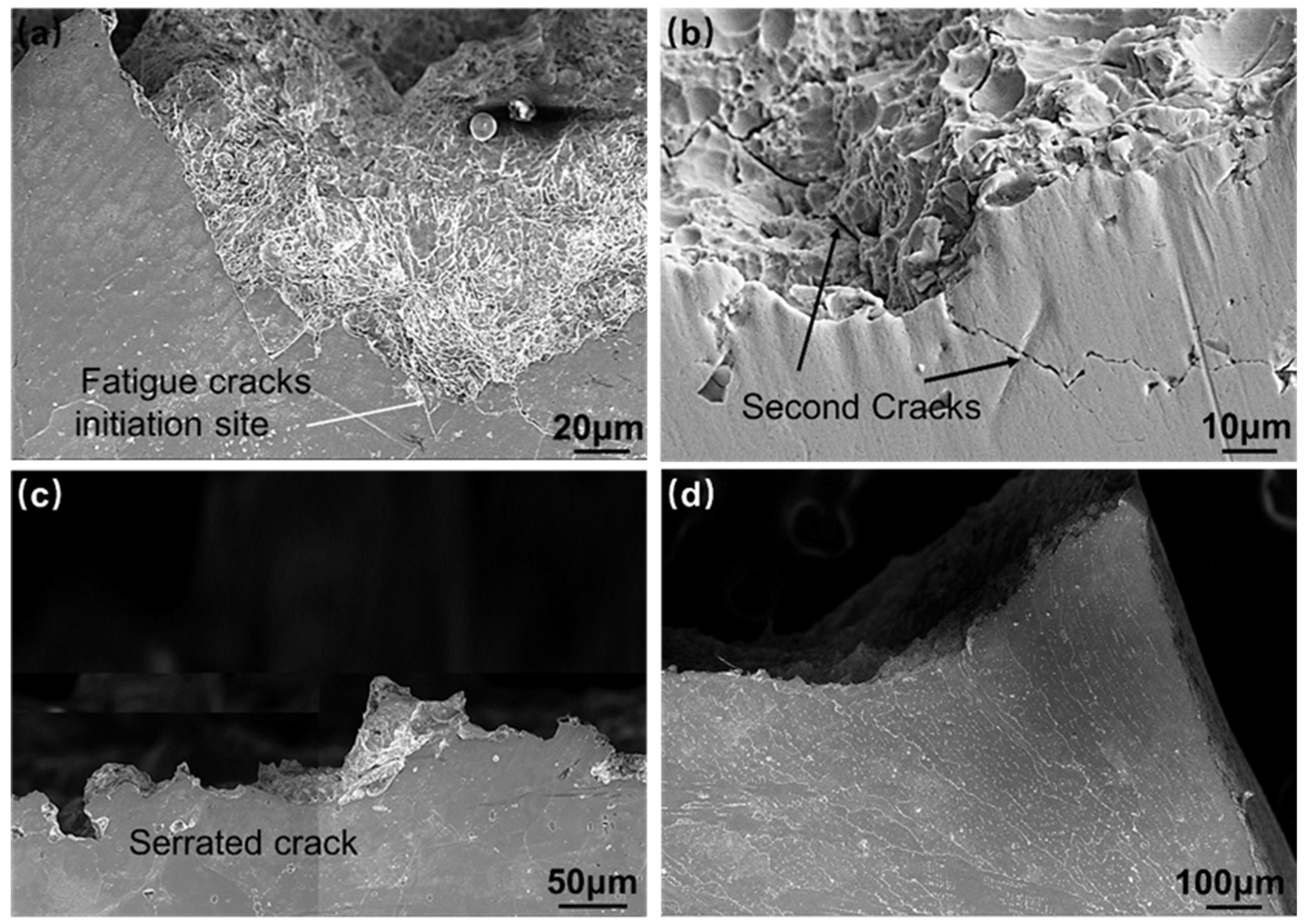

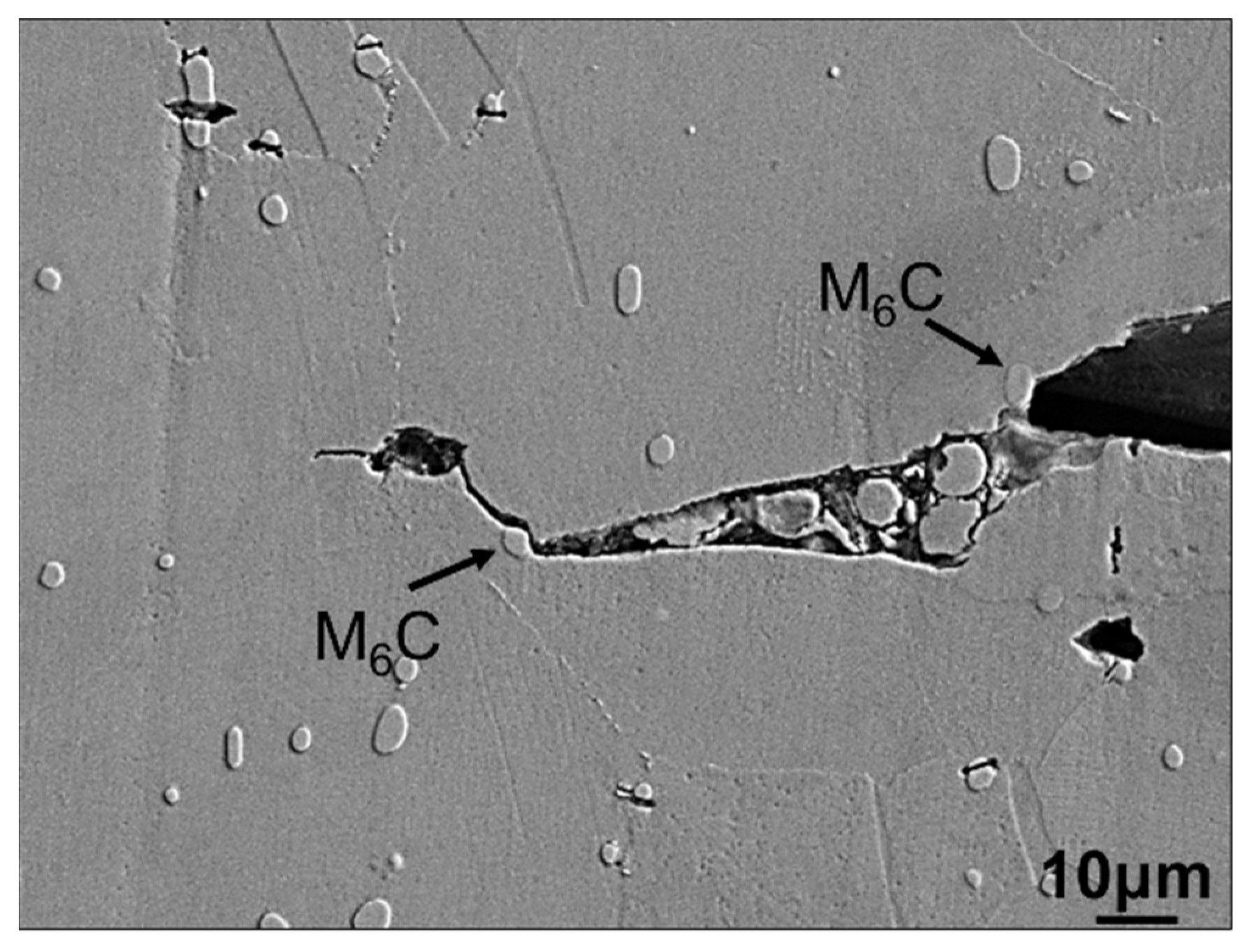

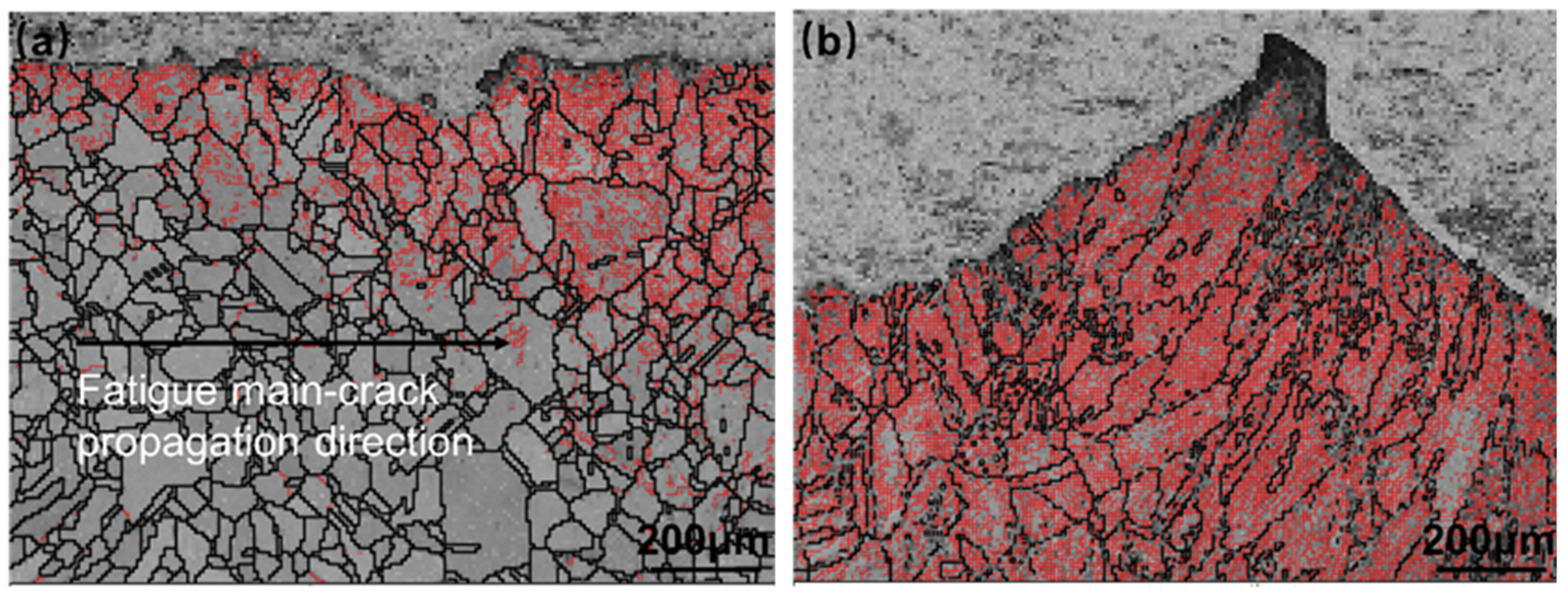

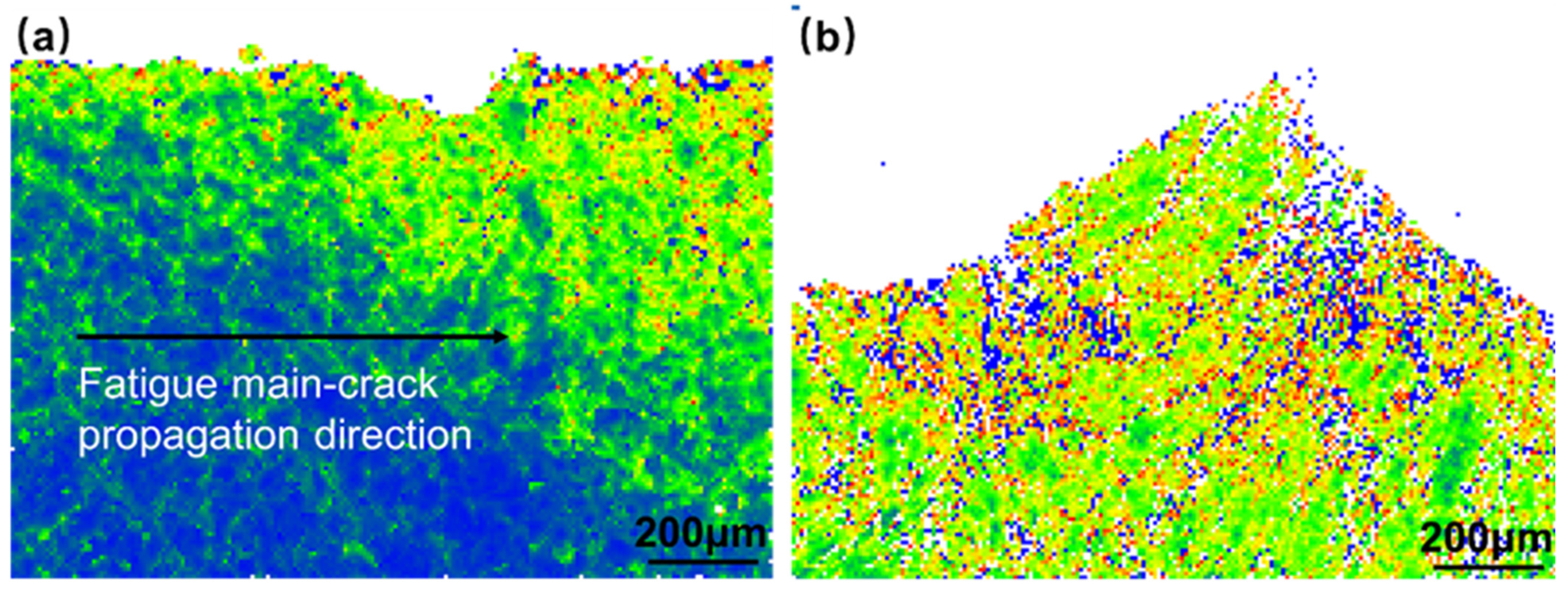

3.4. Fatigue

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fukasawa, M.; Umeda, M.; Akiyama, T. Worry about Radiation and Its Risk Factors Five to Ten Years after the Fukushima Nuclear Power Plant Disaster. Int. J. Environ. Res. Public. Health 2022, 19, 16943. [Google Scholar] [CrossRef] [PubMed]

- Serp, J.; Allibert, M.; Beneš, O.; Delpech, S.; Feynberg, O.; Ghetta, V.; Heuer, D.; Holcomb, D.; Ignatiev, V.; Kloosterman, J.L.; et al. The Molten Salt Reactor in Generation IV: Overview and Perspectives. Prog. Nucl. Energy 2014, 77, 308–319. [Google Scholar] [CrossRef]

- Allibert, M.; Delpech, S.; Gerardin, D.; Heuer, D.; Laureau, A.; Merle, E. Homogeneous Molten Salt Reactors (MSRs): The Molten Salt Fast Reactor (MSFR) concept. In Handbook of Generation IV Nuclear Reactors, 2nd ed.; Pioro, I.L., Ed.; Woodhead Publishing Series in Energy: Cambridge, Britain, 2023; Volume 7, pp. 231–257. [Google Scholar]

- Tsvetkov, P. Generation IV: United States. In Handbook of Generation IV Nuclear Reactors, 2nd ed.; Pioro, I.L., Ed.; Woodhead Publishing Series in Energy: Cambridge, Britain, 2023; Volume 9, pp. 287–301. [Google Scholar]

- Swindeman, R.W.; Ren, W.; Katcher, M.; Holcmb, D.E. Hastelloy N for Molten Salt Reactors Used for Power Generation. In Proceedings of the ASME 2014 Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries, Seattle, DC, USA, 25–27 March 2014. [Google Scholar]

- Wright, R.N.; Sham, S. Status of Metallic Structural Materials for Molten Salt Reactors; INL/EXT-18-45171; Idaho National Laboratory: Idaho Falls, ID, USA, 2018. [Google Scholar]

- Wang, Y.; Wang, C.; Wu, J. The effect of graphite on the corrosion of Hastelloy N in molten fluorides. J. Nucl. Mater. 2021, 557, 153277. [Google Scholar] [CrossRef]

- Zhu, H.; Muránsky, O.; Wei, T.; Davis, J.; Budzakoska, E.; Huang, H.; Drew, M. The effect of applied stress on the high-temperature creep behaviour and microstructure of NiMoCr Hastelloy-N alloy. Materialia 2021, 16, 101069. [Google Scholar] [CrossRef]

- Jiang, Z.; Tao, W.; Yu, K.; Tan, C.; Chen, Y.; Li, L.; Li, Z. Comparative study on fiber laser welding of GH3535 superalloy in continuous and pulsed waves. Mater. Des. 2016, 110, 728–739. [Google Scholar] [CrossRef]

- Fan, G.; Wang, W.; Shi, W.; Wang, S.; Lu, Y. Creep crack growth of GH3535 alloy at elevated temperatures. Mat. Charact. 2021, 181, 111412. [Google Scholar] [CrossRef]

- Xiao, X.; Li, M.; Liang, J.; Jiang, L.; Wang, D.; Ye, X.; Chen, Z.; Wang, N.; Li, Z. Fine structure characterization of an explosive-ly-welded GH3535/316H bimetallic plate interface. Int. J. Min. Met. Mater. 2021, 28, 1811–1820. [Google Scholar] [CrossRef]

- Danon, A.; Muránsky, O.; Zhu, H.; Wei, T.; Flores-Johnson, E.; Li, Z.; Kruzic, J. The effect of microstructure and welding-induced plasticity on the strength of Ni–Mo–Cr alloy welds. Materialia 2021, 17, 101126. [Google Scholar] [CrossRef]

- Wang, X.; Gong, W.; Wang, X.; Yu, K. Numerical investigation of creep crack growth behavior of UNS N10003 alloy based on the creep damage model. Int. J. Pres. Ves. Pip. 2022, 200, 104838. [Google Scholar] [CrossRef]

- Fan, J.; Li, P.; Liang, J.; Ye, X.; Zhou, X. Intermediate-temperature heat treatment of UNS N10003 alloy during cold working. J. Mater. Eng. Perform. 2021, 30, 2355–2364. [Google Scholar] [CrossRef]

- Xu, Z.; Jiang, L.; Dong, J.; Li, Z.; Zhou, X. The effect of silicon on precipitation and decomposition behaviors of m6c carbide in a Ni–Mo–Cr superalloy. J. Alloys Compd. 2015, 620, 197–203. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Jiang, L.; Ye, X.; Yu, K.; Chen, S.; Li, Z.; Zhou, X. Evolution of Carbide Precipitates in Hastelloy-N Joints during Welding and Post Weld Heat Treatment. Mat. Charact. 2018, 135, 311–316. [Google Scholar] [CrossRef]

- Chen, S.; Ye, X.; Yu, K.; Li, C.; Li, Z. Microstructure and mechanical properties of UNS N10003 alloy welded joints. Mater. Sci. Eng. A 2017, 682, 168–177. [Google Scholar] [CrossRef]

- Chen, S.; Tsang, D.; Li, J.; Yu, K.; Li, Z.; Zhong, L.; Li, Z.; Zhou, X.; Yang, J. Microstructure and local strains in GH3535 alloy heat affected zone and their influence on the mechanical properties. Mater. Sci. Eng. A 2017, 699, 48–54. [Google Scholar] [CrossRef]

- Yu, K.; Jiang, Z.; Leng, B.; Li, C.; Li, Z. Effects of post-weld heat treatment on microstructure and mechanical properties of laser welds in GH3535 superalloy. Opt. Laser Technol. 2016, 81, 18–25. [Google Scholar] [CrossRef]

- Yu, K.; Jiang, Z.; Li, C.; Chen, S.; Tao, W.; Zhou, X.; Li, Z. Microstructure and mechanical properties of fiber laser welded GH3535 superalloy. Mater. Sci. Technol. 2017, 33, 1189–1299. [Google Scholar] [CrossRef]

- He, Y.; Xiao, F.; Sun, Y.; Lu, C.; Gao, Z. Tailoring microstructure and mechanical performance of Hastelloy N-Hastelloy N superalloy joint through modifying brazing processing parameters and post thermal exposure. Mat. Charact. 2021, 173, 110947. [Google Scholar] [CrossRef]

- Liu, J.; Huang, H.; Liu, A.; Li, Y. The effects of post-irradiation isochronous annealing on defects evolution and hardening in Hastelloy N alloy. J. Nucl. Mater. 2021, 548, 152855. [Google Scholar] [CrossRef]

- Hu, C.; Huang, H.; Zhu, Z.; Liu, A.; Li, Y. Effect of post-irradiation annealing on microstructure evolution and hardening in GH3535 alloy irradiated by Au ions. Acta Metall. Sin. 2022, 35, 9. [Google Scholar] [CrossRef]

- Zhu, Y.; Qiu, J.; Hou, J.; Liu, W.; Chen, H.; Ai, H.; Yu, G.; Wang, J.; Zhou, X. Effects of SO42− Ions on the corrosion of GH3535 weld joint in FLiNaK molten salt. J. Nucl. Mater. 2017, 492, 122–127. [Google Scholar] [CrossRef]

- Ramu, A.; Pavlik, V.; Sillikova, V.; Matselko, O.; Boca, M. Corrosion of Hastelloy N and hastelloy-G35 from vapors generated from flinak salt with addition of 5% oxygen in argon atmosphere. Mater. Corros. 2023, 74, 670–682. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, X.; Li, C.; Gao, J.; Wei, T.; Lei, G.; Li, J.; Ye, L.; Huang, Q.; Zhou, Z. Temperature dependence of nickel ion irradiation damage in GH3535 alloy weld metal. J. Nucl. Mater. 2017, 497, 108–116. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, L.; Li, C.; Leng, B.; Zhou, X. Effects of post-weld heat treatment on microstructure and mechanical properties of Hastelloy N superalloy welds. Mater. Today Commun. 2019, 19, 230–237. [Google Scholar] [CrossRef]

- Jiang, L.; Ye, X.; Wang, Z.; Yu, C.; Dong, J.; Xie, R.; Li, Z.; Yan, L.; Sham, T.; Zhou, X.; et al. The critical role of Si doping in enhancing the stability of M6C carbides. J. Alloys Compd. 2017, 728, 917–926. [Google Scholar] [CrossRef]

- Yadav, A.; Kumar, A.; Gupta, P.; Sinha, D. Numerical Study of Temperature Distributions and Solidification Pattern in the Weld Pool of Arc Welded Plate. Defect Diffus. Forum 2019, 392, 218–227. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.; Kumar, P.; Kumar, P.; Saini, S.; Thakare, J.; Kumar, S. Study on effect of double austenitiza-tion treatment on fracture morphology tensile tested nuclear grade P92 steel. Eng. Fail. Anal. 2019, 96, 158–167. [Google Scholar] [CrossRef]

- Wojciech, J.; Jacek, G.; Tomasz, K. Temperature-Based prediction of joint hardness in TIG welding of inconel 600, 625 and 718 nickel superalloys. Materials 2021, 14, 442. [Google Scholar]

- Cui, Z.; Tan, Y. Metallography and Heat Treatment, 3rd ed.; China Machine Press: Beijing, China, 2011. [Google Scholar]

- He, Y.; Yang, J.; Zheng, S. Microstructure dependent fatigue crack growth characteristics in the Ni-17Mo-7Cr base superalloy before and after thermal exposure. J. Mater. Res. 2016, 31, 3880–3890. [Google Scholar] [CrossRef]

| Welding Stick | Welding Current (A) | Arc Voltage (V) | Welding Speed (mm/min) | Front Gas Flow (L/min) | Back Gas Flow (L/min) |

|---|---|---|---|---|---|

| ERNiMo-2 | 90 | 12 | 40 | 14 | 12 |

| Elements | Ni | Mo | Cr | Fe | Cu | Ti | Si |

|---|---|---|---|---|---|---|---|

| P | 68.59 | 15.43 | 8.25 | 4.93 | 2.01 | 0.46 | 0.34 |

| Q | 30.09 | 54.44 | 8.12 | 2.25 | 1.91 | 0.13 | 2.46 |

| R | 39.68 | 47.12 | 6.63 | 1.38 | 1.68 | 0.39 | 2.59 |

| S | 31.36 | 55.88 | 8.50 | 1.30 | 0.38 | 0.48 | 2.09 |

| Tensile Stress Rm (MPa) | Yield Stress R0.2 (MPa) | Elongation ζ | |

|---|---|---|---|

| Base metal | 760 | 290 | 46 |

| Welded joint | 764 | 380 | 19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Ma, B.; Feng, D.; Chen, S.; Ma, Y.; Li, H.; Lv, C.; Zheng, W.; Yang, J. Microstructure, Mechanical Properties and Fatigue Crack Growth Behavior of Gas Tungsten Arc Welding Welded Joint of the Hastelloy N Alloy. Materials 2023, 16, 6510. https://doi.org/10.3390/ma16196510

Wang S, Ma B, Feng D, Chen S, Ma Y, Li H, Lv C, Zheng W, Yang J. Microstructure, Mechanical Properties and Fatigue Crack Growth Behavior of Gas Tungsten Arc Welding Welded Joint of the Hastelloy N Alloy. Materials. 2023; 16(19):6510. https://doi.org/10.3390/ma16196510

Chicago/Turabian StyleWang, Sai, Baoyun Ma, Daochen Feng, Shuangjian Chen, Yinghe Ma, Huaxin Li, Chuanyang Lv, Wenjian Zheng, and Jianguo Yang. 2023. "Microstructure, Mechanical Properties and Fatigue Crack Growth Behavior of Gas Tungsten Arc Welding Welded Joint of the Hastelloy N Alloy" Materials 16, no. 19: 6510. https://doi.org/10.3390/ma16196510

APA StyleWang, S., Ma, B., Feng, D., Chen, S., Ma, Y., Li, H., Lv, C., Zheng, W., & Yang, J. (2023). Microstructure, Mechanical Properties and Fatigue Crack Growth Behavior of Gas Tungsten Arc Welding Welded Joint of the Hastelloy N Alloy. Materials, 16(19), 6510. https://doi.org/10.3390/ma16196510