The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds

Abstract

:1. Introduction

2. Materials and Methods

Methodology

3. Results

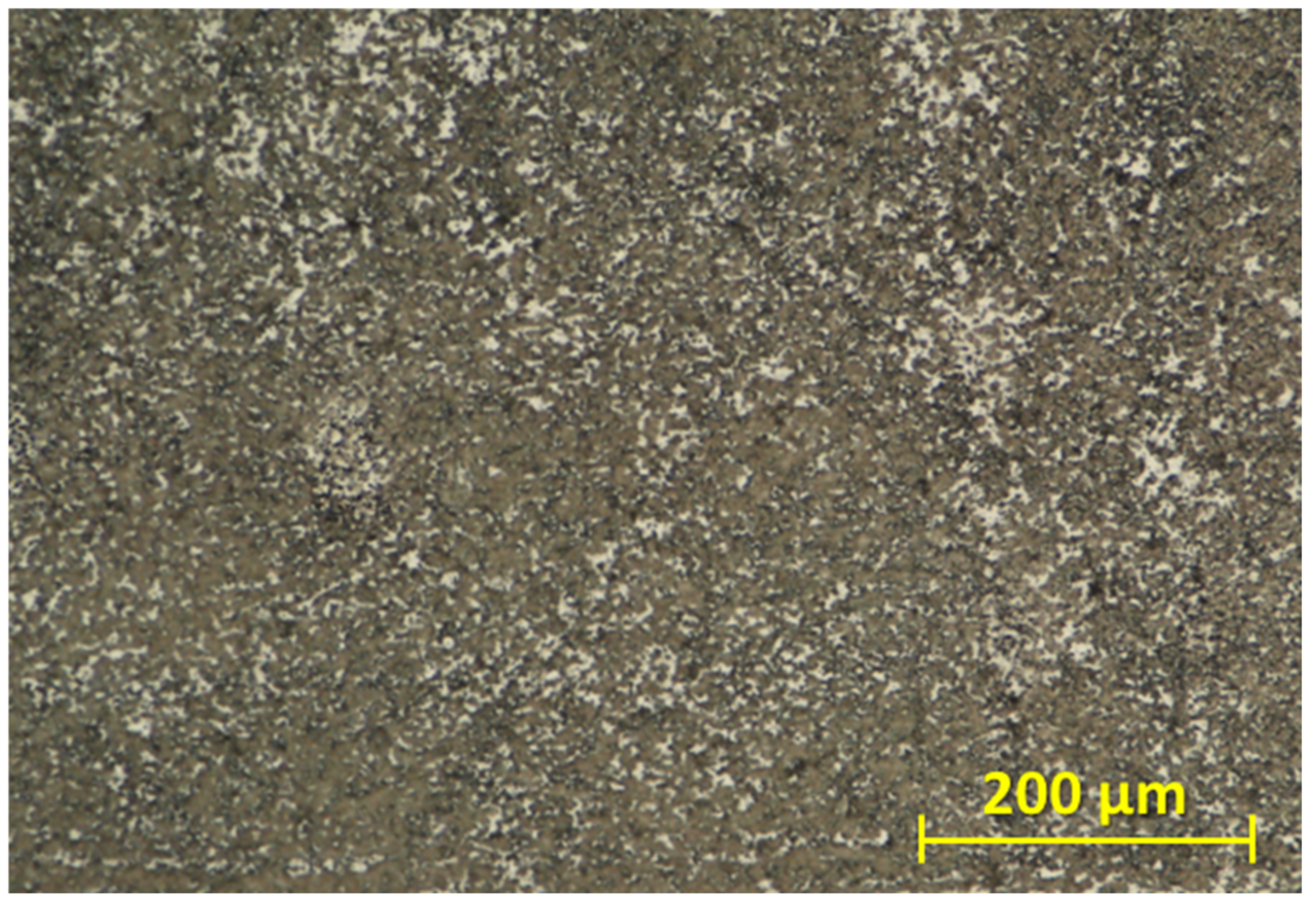

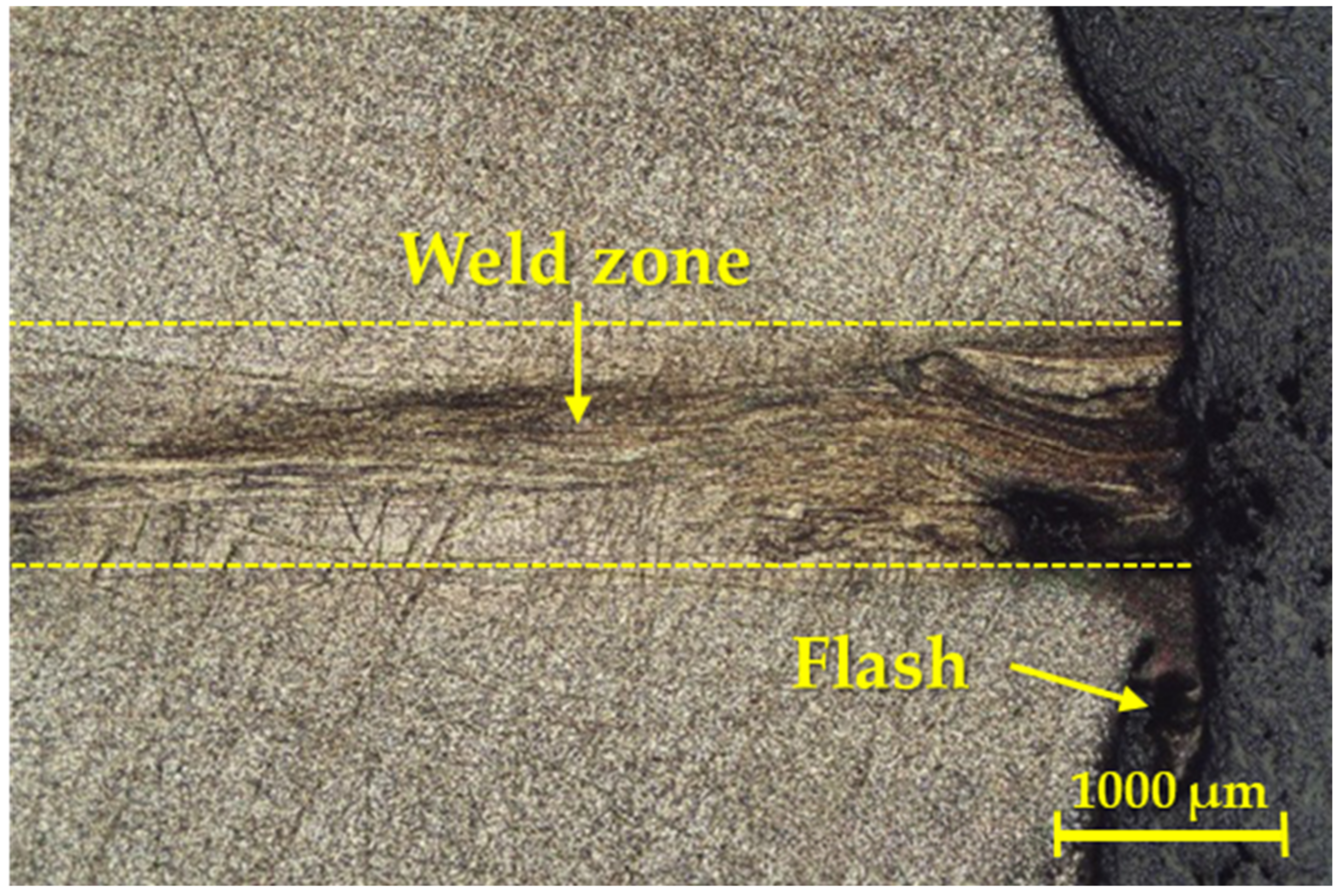

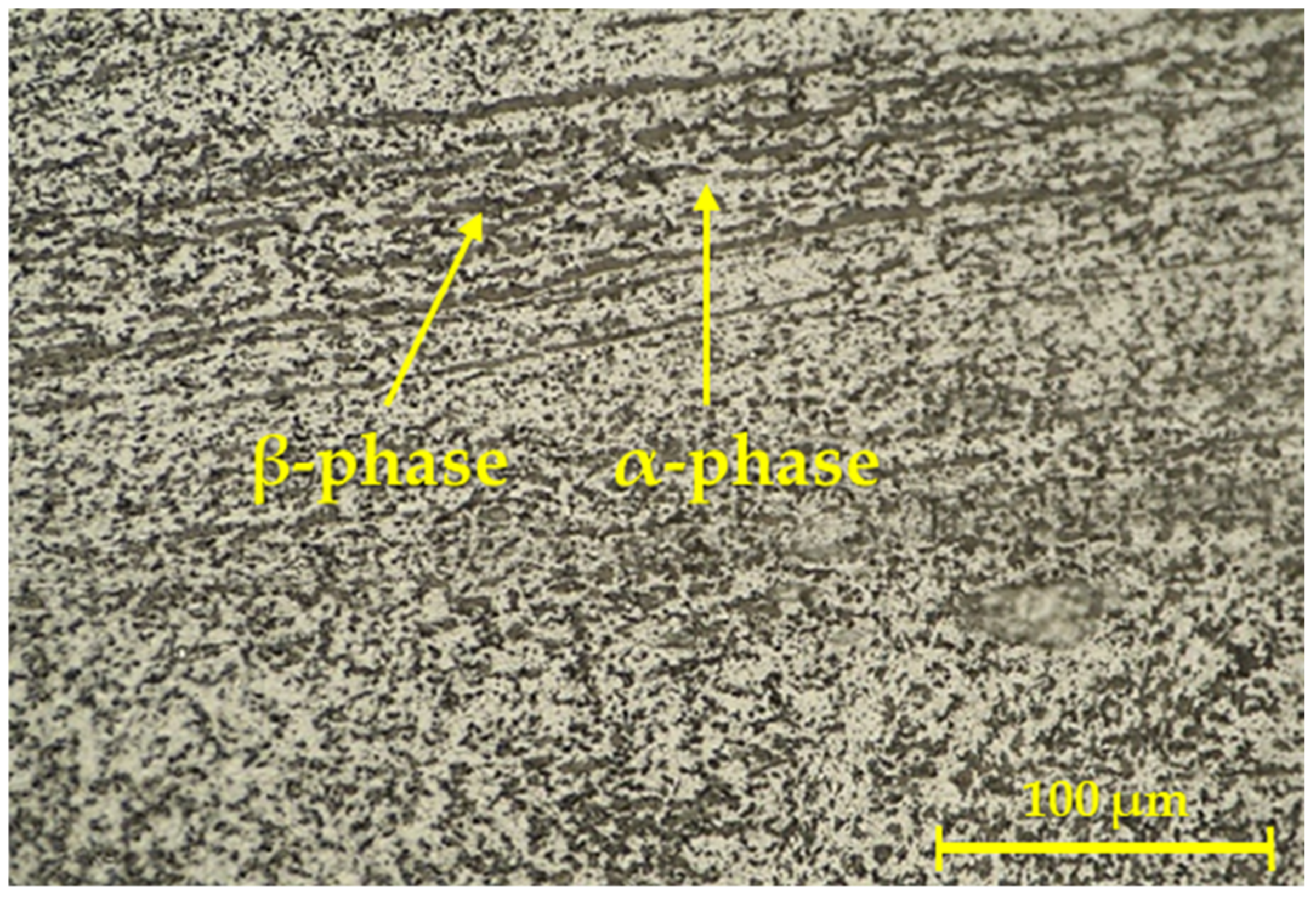

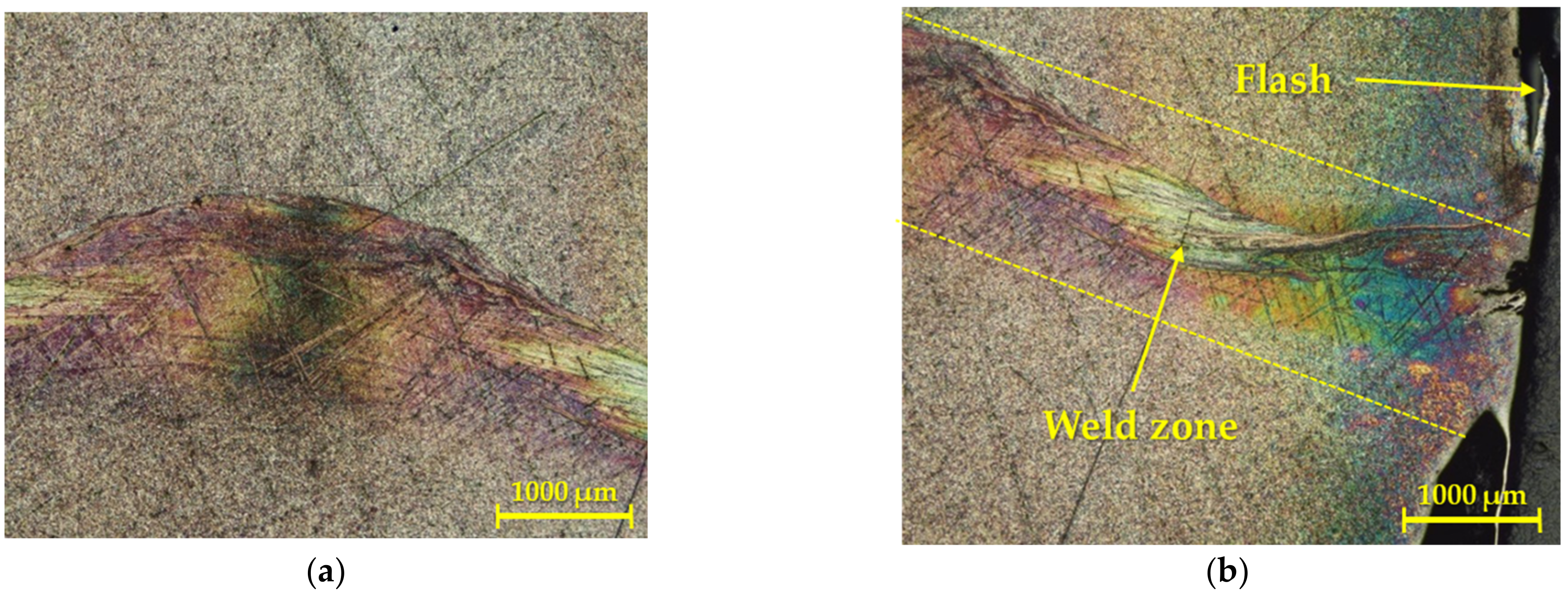

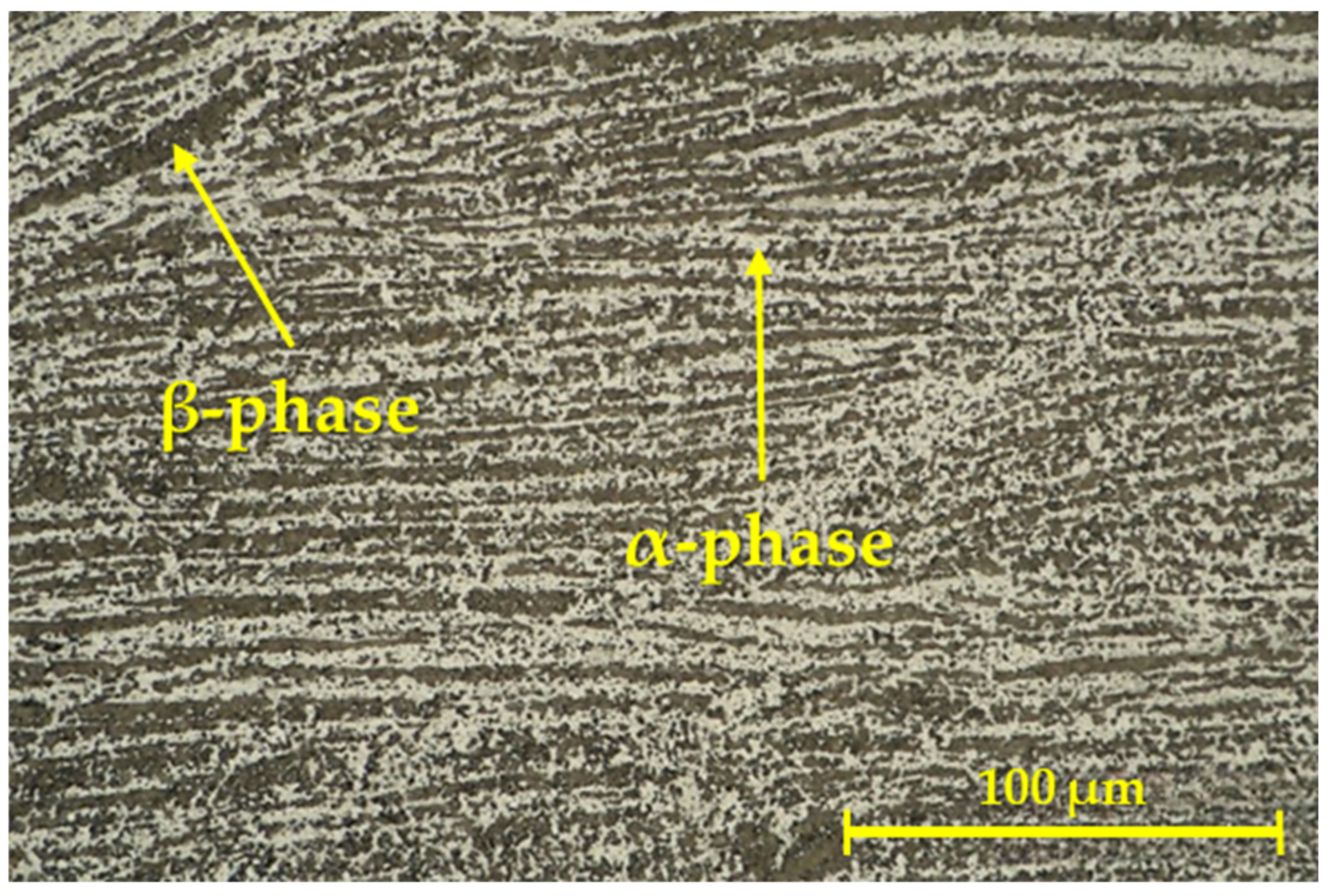

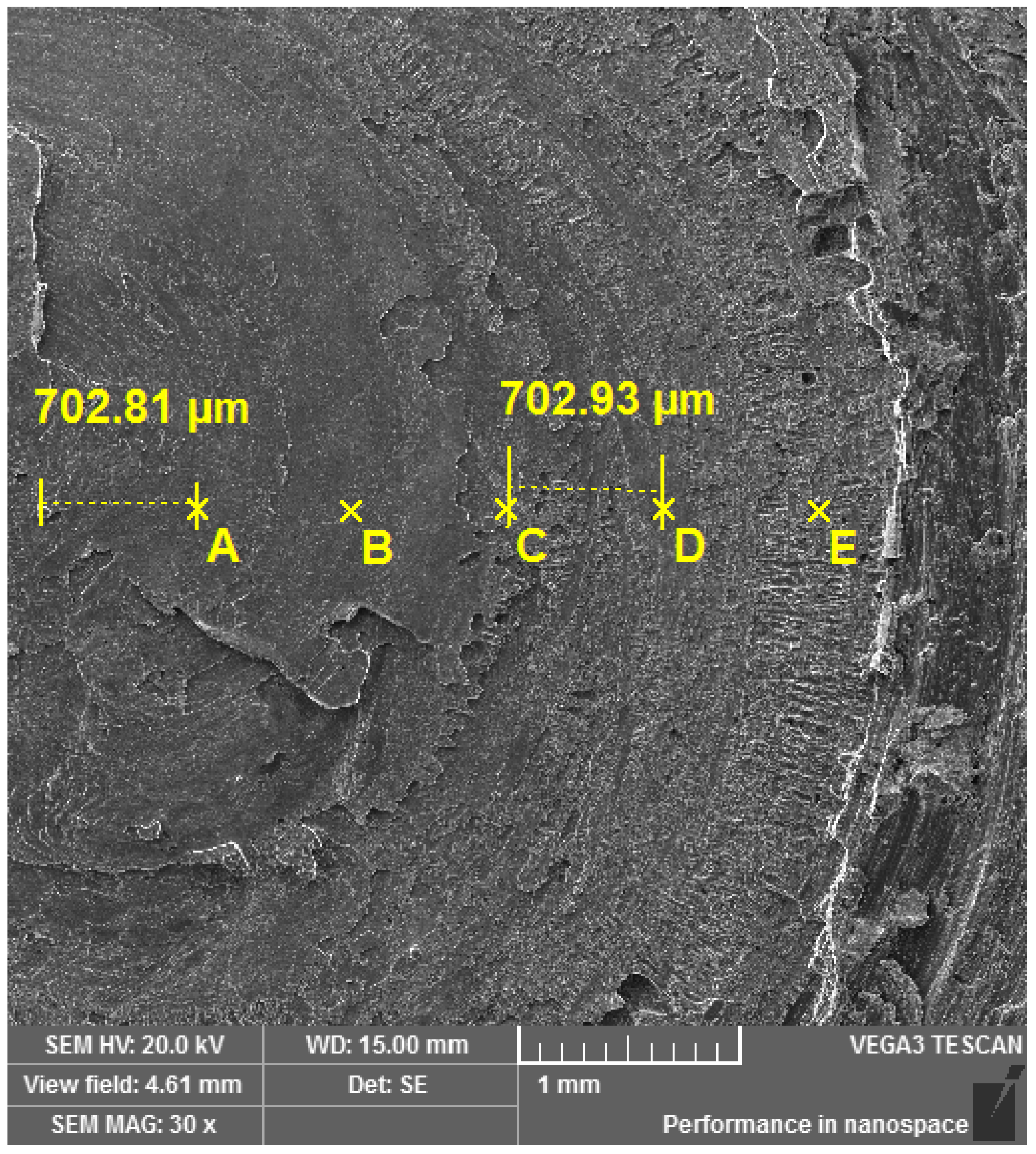

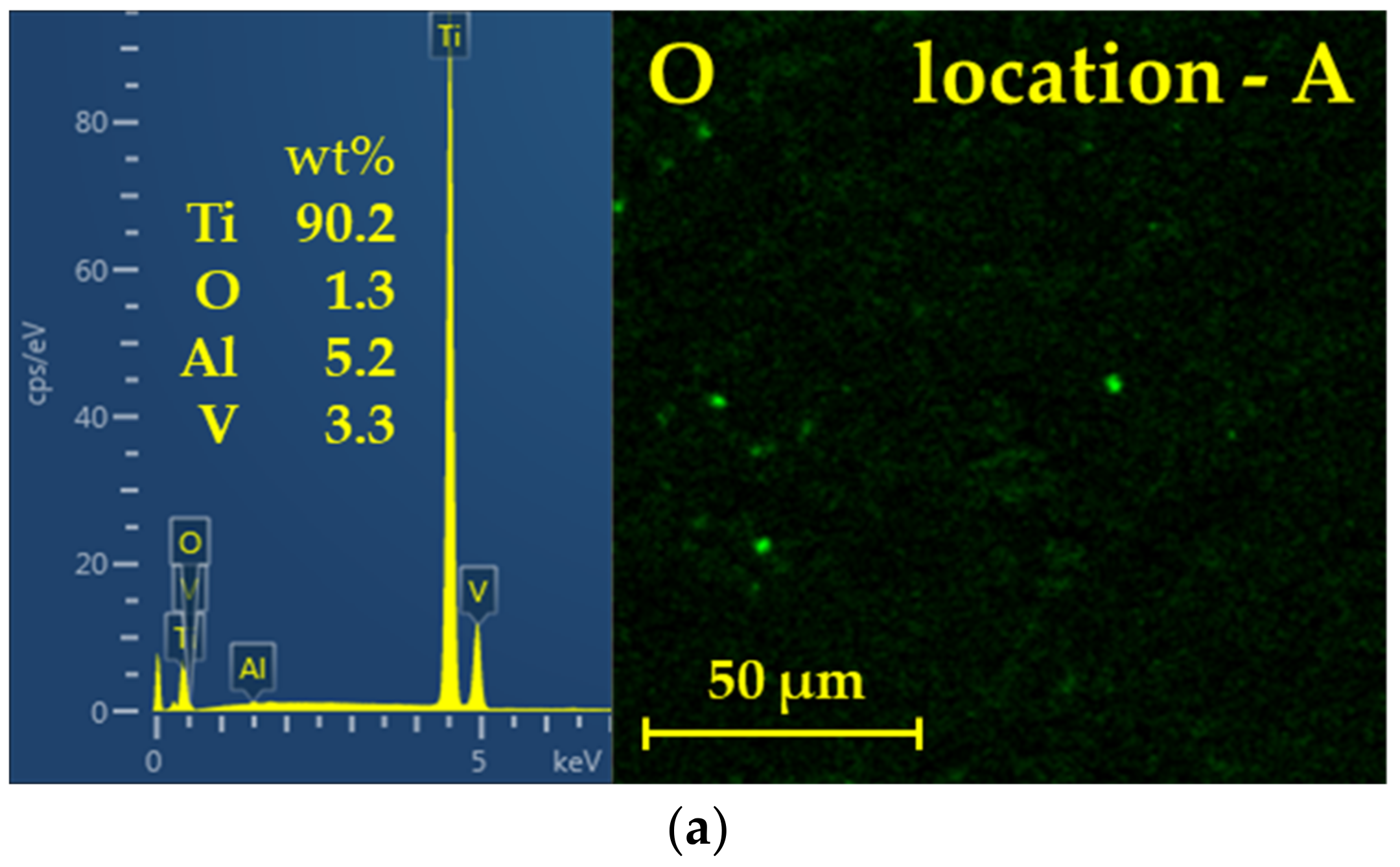

3.1. Macrostructure and Microstructure of the RFW Joints

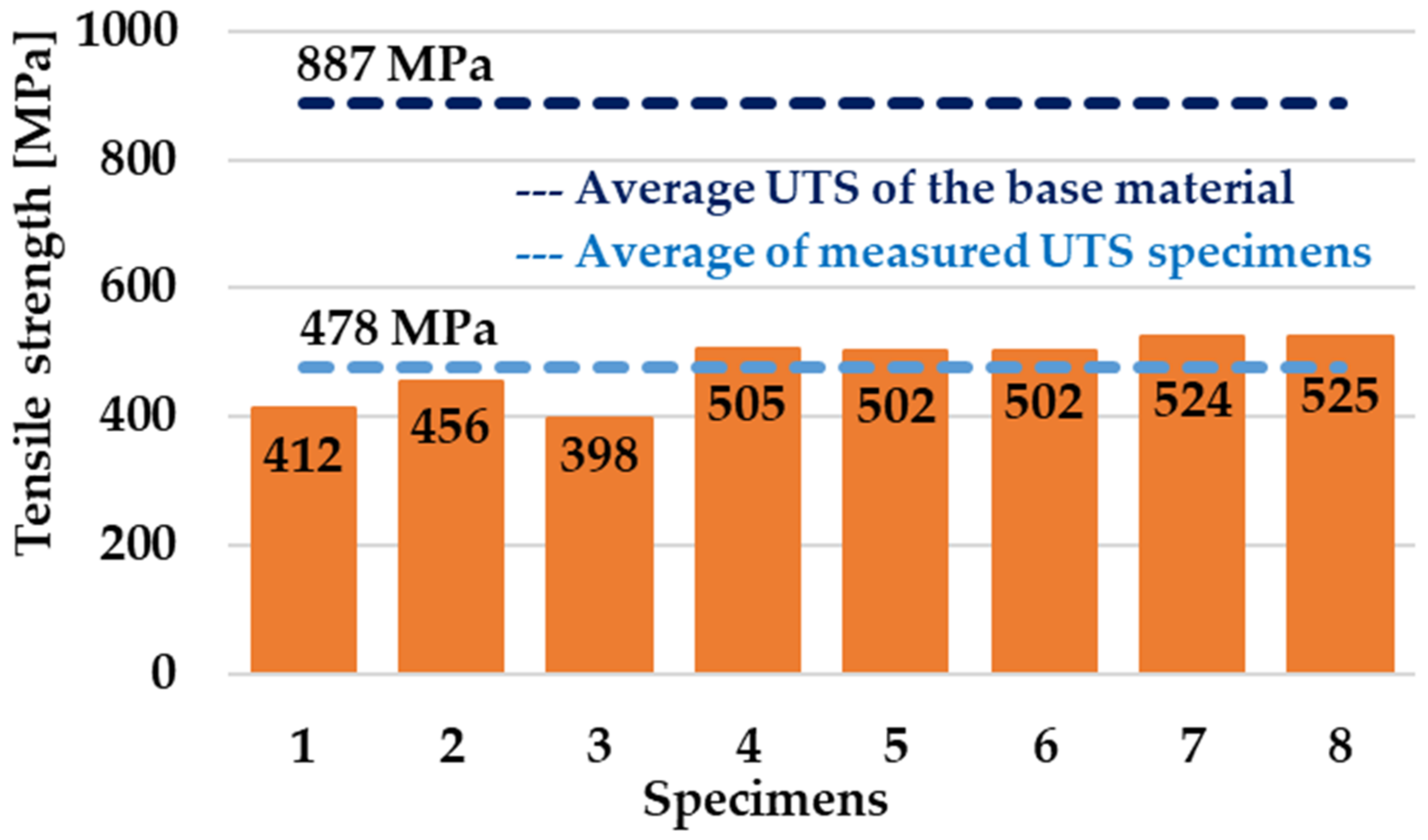

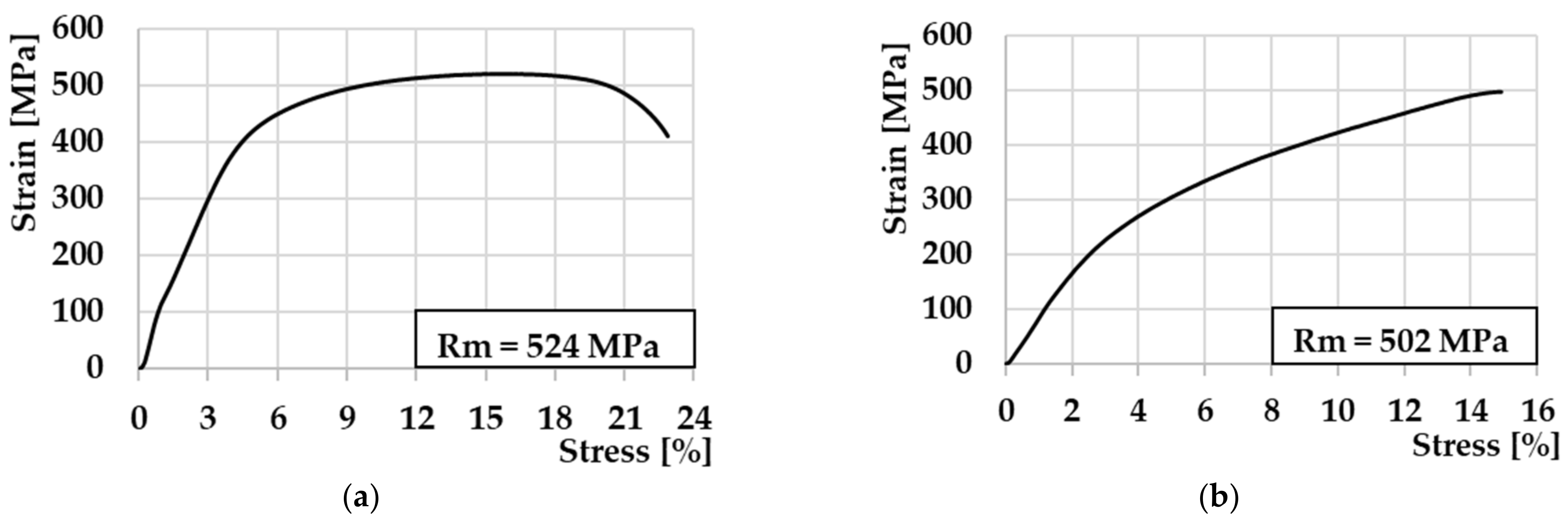

3.2. Tensile Test

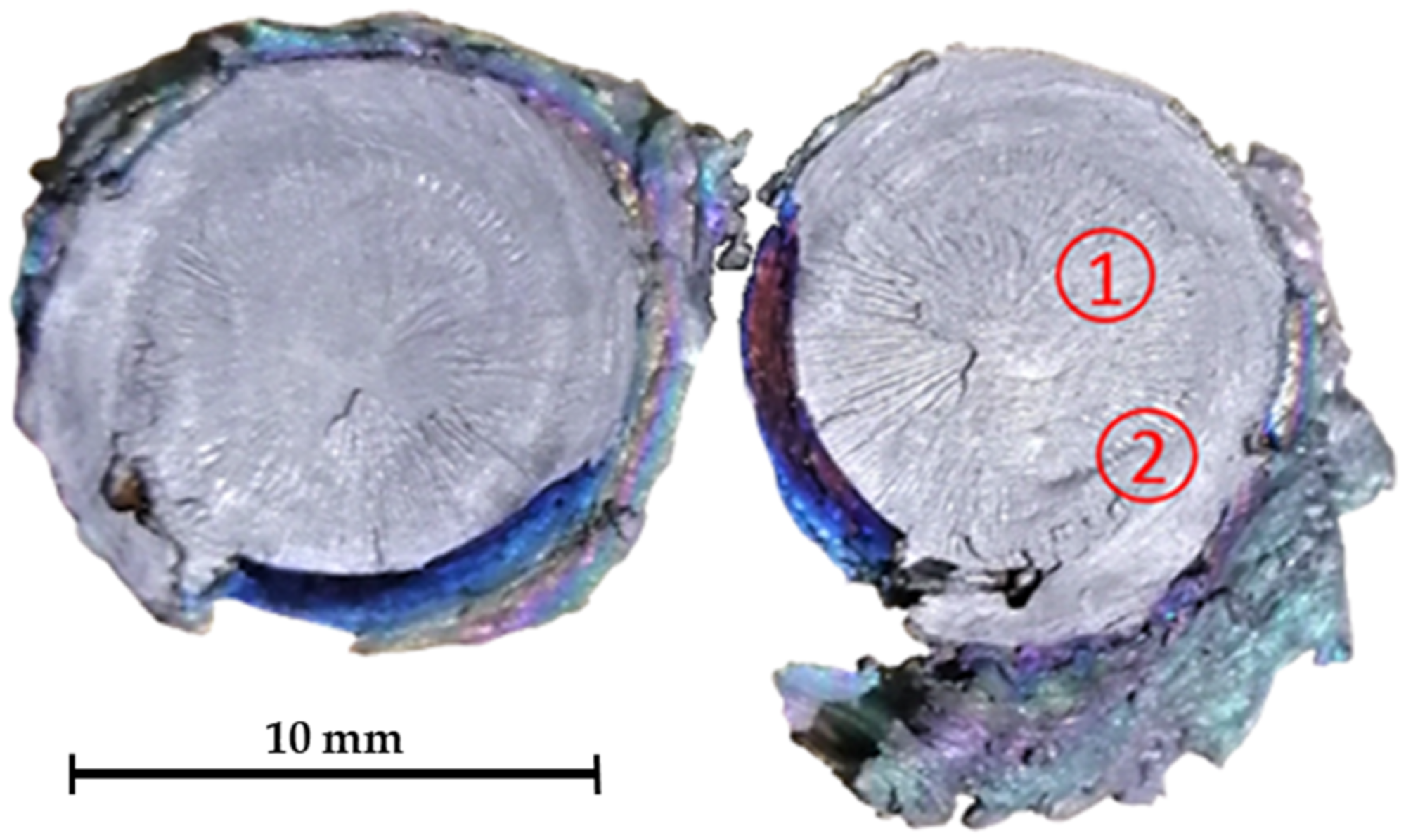

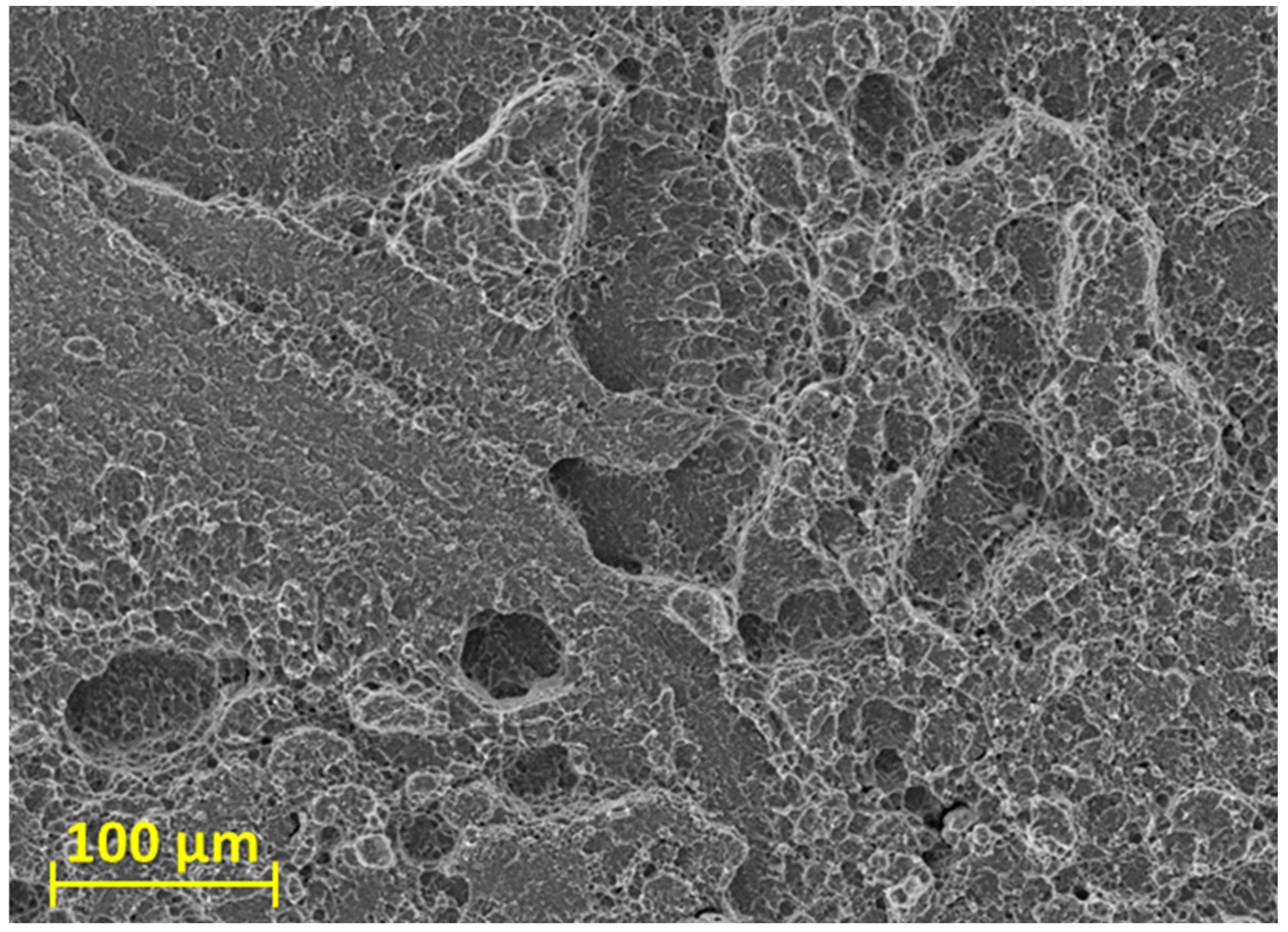

3.3. Fractography

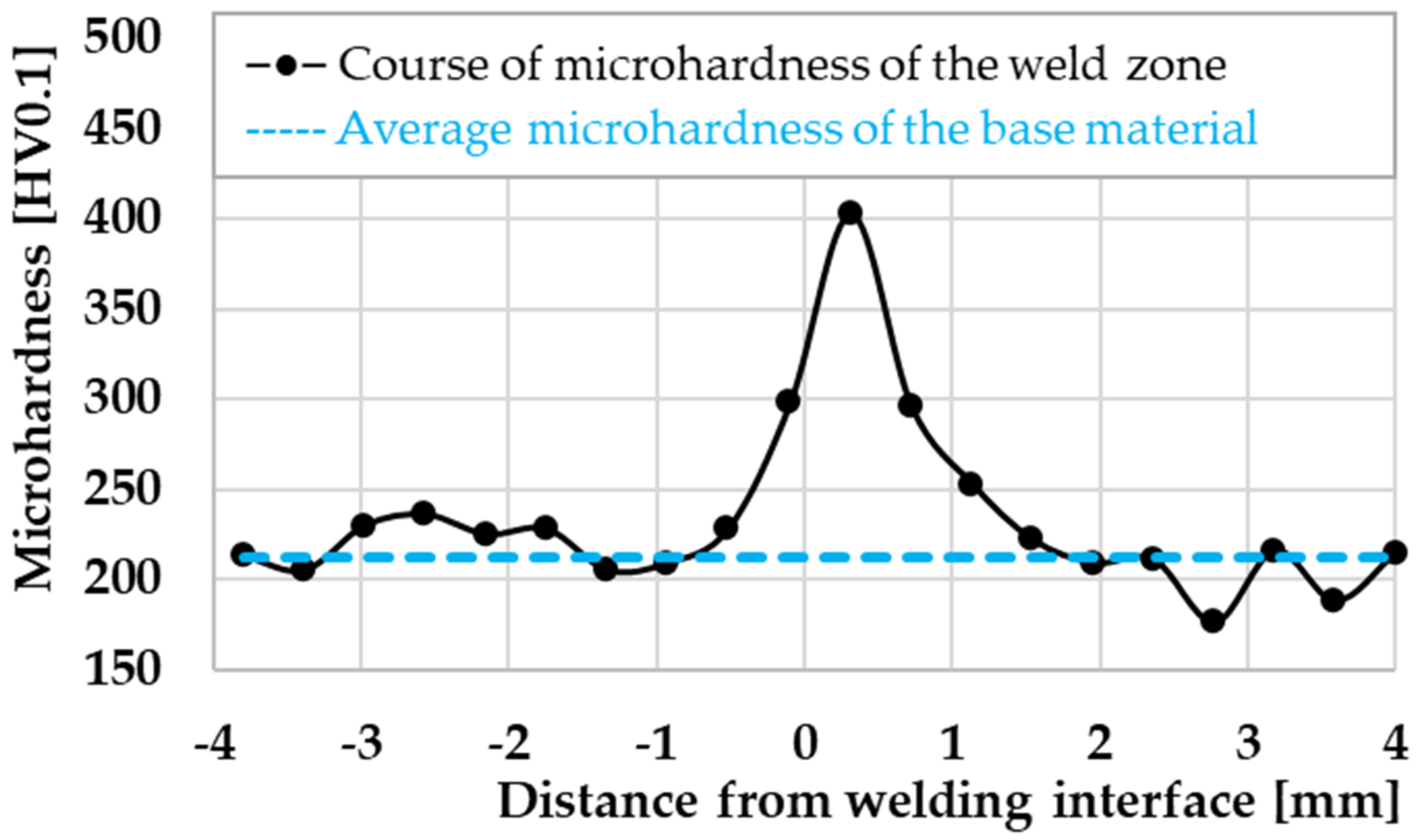

3.4. Microhardness

4. Discussion

5. Conclusions

- The most reliable geometry of the contact surfaces was proven to be geometry number one—the geometry without any special modification of the contact surfaces.

- With the mentioned geometry, there was the least saturation with interstitial elements of the atmosphere. The remaining two tested geometries of the contact surfaces were not suitable for the RFW of the titanium alloy Ti6Al4V, precisely due to their tendency to be saturated with interstitial elements from the atmosphere.

- The static tensile test confirmed the brittle fracture with a certain proportion of plastic deformation. These specimens were fractured in the RFW area. The ductile fracture mechanism was observed in two specimens, but the difference in the UTS value compared to the specimens broken by the brittle fracture mechanism was not significant. The specimens in which a ductile fracture mechanism was observed were fractured outside the weld interface, in the HAZ.

- The average value of the ultimate tensile strength reached approximately half of the UTS limit of the base material. On the basis of the experimental results, it was possible to determine the appropriate tested geometry of the contact surfaces and also to understand the effect of saturating the weld joint with interstitial elements from the atmosphere, in a process in which no protective atmosphere or filler material was used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dang, Z.; Qin, G.; Wang, J. Bonding mechanism and fracture behavior of inertia friction welded joint of 2219 aluminum alloy to 304 stainless steel. Mater. Sci. Eng. A 2023, 866, 144641. [Google Scholar] [CrossRef]

- Banerjee, A.; Ntovas, M.; Silva, D.L.; Rahimi, S. Microstructure and mechanical properties of dissimilar inertia friction welded 316L stainless steel to A516 ferritic steel for potential applications in nuclear reactors. Manuf. Lett. 2022, 33, 33–37. [Google Scholar] [CrossRef]

- Balasubramanian, M.; Murali, S.; Hemadri, C.; Kumar, C. A new method of dissimilar friction welding of titanium to stainless steel. Mater. Today Proc. 2021, 46, 3644–3647. [Google Scholar] [CrossRef]

- Meisnar, M.; Baker, S.; Bennett, J.M.; Bernard, A.; Mostafa, A.; Resch, S.; Fernandes, N.; Norman, A. Microstructural characterisation of rotary friction welded AA6082 and Ti-6Al-4V dissimilar joints. Mater. Des. 2017, 132, 188–197. [Google Scholar] [CrossRef]

- Mishra, N.K.; Shrivastava, A. Improvement in strength and ductility of rotary friction welded Inconel 600 and stainless steel 316L with Cu interlayer. CIRP J. Manuf. Sci. Technol. 2023, 41, 19–29. [Google Scholar] [CrossRef]

- Rehman, A.U.; Usmani, Y.; Al-Samhan, A.M.; Anwar, S. Rotary friction welding of Inconel 718 to Inconel 600. Metals 2021, 11, 244. [Google Scholar] [CrossRef]

- Selvaraj, R.; Shanmugam, K.; Selvaraj, P.; Prasanna Nagasai, B.; Balasubramanian, V. Optimization of process parameters of rotary friction welding of low alloy steel tubes using response surface methodology. Forces Mech. 2023, 10, 100175. [Google Scholar]

- Gotawala, N.; Shrivastava, A. Investigation of interface microstructure and mechanical properties of rotatory friction welded dissimilar aluminum-steel joints. Mater. Sci. Eng. A 2021, 825, 141900. [Google Scholar] [CrossRef]

- Celik, S.; Karaoglan, A.D.; Ersozlu, I. An effective approach based on response surface methodology for predicting friction welding parameters. High Temp. Mater. Process. 2015, 35, 235–241. [Google Scholar] [CrossRef]

- Dawood, A.B.; Butt, S.I.; Hassain, G.; Siddigui, M.A.; Magsood, A.; Zhang, F. Thermal model of rotary friction welding for similar and dissimilar metals. Metals 2017, 7, 224. [Google Scholar] [CrossRef]

- Kumar, S.A.; Khadeer, A.S.; Rajinikanth, V.; Pahari, S.; Kumar, R.B. Evaluation of bond interface characteristics of rotary friction welded carbon steel to low alloy steel pipe joints. Mater. Sci. Eng. A 2021, 824, 141844. [Google Scholar] [CrossRef]

- Rangasamy, S.; Kamalamurthy, S.; Ponnusamy, S.; Bellamkonda, P.N.; Visvalingam, B. Optimization of mechanical properties of rotary friction welding parameters of low alloy steel tubes using design of experiments concept. Int. J. Interact. Des. Manuf. 2023, 17, 1–15. [Google Scholar] [CrossRef]

- Özdemir, N. Investigation of the mechanical properties of friction–welded joints between AISI 304L and AISI 4340 steel as a function rotational speed. Mater. Lett. 2005, 59, 2504–2509. [Google Scholar] [CrossRef]

- Vyas, H.D.; Metha, K.P.; Badheka, V.; Doshi, B. Friction welding of dissimilar joints copper-stainless steel pipe consist of 0.06 wall thickness to pipe diameter ratio. J. Manuf. Process. 2021, 68, 1176–1190. [Google Scholar] [CrossRef]

- Kumar, D.M.; Palani, P.K.; Karthik, V. Effect of welding parameters on joint strength of rotary friction welded UNS S31803 tubes. Mater. Today Proc. 2021, 39, 1265–1269. [Google Scholar] [CrossRef]

- Li, W.; Vairis, A.; Preuss, M.; Ma, T. Linear and rotary friction welding review. Int. Mater. Rev. 2016, 61, 71–100. [Google Scholar] [CrossRef]

- Akbarimousavi, S.A.; Goharikia, M. Investigations on the mechanical properties and microstructure of dissimilar cp-titanium and AISI 316L austenitic stainless steel continuous friction welds. Mater. Des. 2011, 32, 3066–3075. [Google Scholar] [CrossRef]

- Dey, H.C.; Ashfaq, M.; Bhaduri, A.K.; Rao, K.P. Joining of titanium to 304L stainless steel by friction welding. J. Mater. Process. Technol. 2009, 209, 5862–5870. [Google Scholar] [CrossRef]

- Lee, W.B.; Kim, Y.J.; Jung, S.B. Effects of copper insert layer on the properties of friction welded joints between TiAl and AISI 4140 structural steel. Intermetallics 2004, 12, 671–678. [Google Scholar] [CrossRef]

- Jin, F.; Rao, H.; Wang, Q.; Wen, G.; Liu, P.; Liu, J.; Shen, J.; Li, J.; Xiong, J.; Ma, N. Heat-pattern induced non-uniform radial microstructure and properties of Ti-6Al-4V joint prepared by rotary friction welding. Mater. Charact. 2023, 195, 112536. [Google Scholar] [CrossRef]

- Gavalec, M.; Barényi, I. The effect of rotary friction welding conditions on the properties and microstructure of selected materials. In Collection of Lectures from 3rd Edition of the Quality in Welding 2022 Conference, 1st ed.; Welding Research Institute: Bratislava, Slovakia, 2022; p. 134. [Google Scholar]

- Chu, Q.L.; Zhang, M.; Li, J.H.; Yan, C.; Qin, Z.L. Influence of vanadium filler on the properties of titanium and steel TIG welded joints. J. Mater. Process. Technol. 2017, 240, 293–304. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Andrzejewski, H.; Grevey, D. The formation of intermetallics in dissimilar Ti6Al4V/copper/AISI 316 L electron beam and Nd:YAG laser joints. Intermetallics 2011, 19, 1466–1473. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.G.; Feng, J.C. Influences of different filler metals on electron beam welding of titanium alloy to stainless steel. Trans. Nonferrous Met. Soc. China 2014, 24, 108–114. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.; Chen, G.; Feng, J. High strength electron beam welded titanium stainless steel joint with V/Cu based composite filler metals. Vacuum 2013, 94, 41–47. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.G.; Chen, G.Q.; Feng, J.C.; Tang, Q. Electron beam welding of Ti-15-3 titanium alloy to 304 stainless steel with copper interlayer sheet. Trans. Nonferrous Met. Soc. China 2010, 20, 1829–1834. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Liu, Y.L.; Gou, G.Q.; Gao, W.; Chen, J. Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci. Rep. 2021, 11, 10020. [Google Scholar] [CrossRef]

- Kundu, S.; Ghosh, M.; Laik, A.; Bhanumurthy, K.; Kale, G.B.; Chatterjee, S. Diffusion bonding of commercially pure titanium to 304 stainless steel using copper interlayer. Mater. Sci. Eng. A 2005, 407, 154–160. [Google Scholar] [CrossRef]

- Cetima. Inspection Certificate 3.1 According to EN 10204:2004; Cetima: Trapani, Italy, 2004. [Google Scholar]

- Campanella, D.; Buffa, G.; Barcellona, A.; Fratini, L. Friction Stir Welding of Ti6Al4V complex geometries for aeronautical applications: A feasibility study. Procedia Manuf. 2020, 50, 93–97. [Google Scholar] [CrossRef]

- Squillance, A.; Prisco, U.; Ciliberto, S.; Astarita, A.J. Effect of welding parameters on morphology and mechanical properties of Ti–6Al–4V laser beam welded butt joints. Mater. Process. Technol. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Mouritz, A.P. Introduction to Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 202–223. ISBN 978-1-85573-946-8. [Google Scholar]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Almere, The Netherlands, 2000; ISBN 9781615030620. [Google Scholar]

- Rominiyi, A.L.; Mashinini, P.M. Continuous wave laser welding of Ti6Al4V alloy joints: Microstructure and mechanical properties. Mater. Lett. 2023, 336, 133934. [Google Scholar] [CrossRef]

- Carpenter Technology. Technical Data Sheet Titanium Alloy Ti 6Al-4V; Carpenter Technology: Philadelphia, PA, USA, 2020. [Google Scholar]

- Ptáček, L.; Cihlář, J.; Foret, R.; Kořínek, Z.; Pacal, B.; Penkava, J.; Steidl, J.; Šemberger, J.; Švejcar, J.; Ustohal, V.; et al. Material Science II; Academic Publishing House CERM: Brno, Czech Republic, 2002; ISBN 80-7204-248-3. [Google Scholar]

- Hrivňák, I. Welding and Weldability of Materials; STU Publishing House: Bratislava, Slovakia, 2009; 486p. [Google Scholar]

- Zhao, J.; Zhang, J.; Gao, Q.; Yan, T.; Zhan, X. Research on microstructure evolution and tensile characteristics of Ti6Al4V double lap-fillet joints fabricated by dual laser-beam bilateral synchrnous welding. Opt. Laser Technol. 2022, 145, 107472. [Google Scholar] [CrossRef]

- Fu, Z.H.; Yang, B.J.; Shan, M.L.; Li, T.; Zhu, Z.Y.; Ma, C.P.; Zhang, X.; Gou, G.Q.; Wang, Z.R.; Gao, W. Hydrogen embrittlement behavior of SUS301L-MT stainless steel laser-arc hybrid welded joint localized zones. Corros. Sci. 2020, 164, 108337. [Google Scholar] [CrossRef]

- Omoniyi, P.; Mahamood, M.; Jen, T.C.; Akinlabi, E. TIG welding of Ti6Al4V alloy: Microstructure, fractography, tensile and microhardness data. Data Br. 2021, 38, 107274. [Google Scholar] [CrossRef]

- EN ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- Dubec, A.; Kováčiková, P.; Krmela, J.; Krmelová, V.; Artyukhov, A. Fracture Analysis of High-Strength Screw for Highway Construction. Materials 2021, 14, 1599. [Google Scholar] [CrossRef]

- Krbata, M.; Ciger, R.; Kohutiar, M.; Eckert, M.; Barenyi, I.; Trembach, B.; Dubec, A.; Escherova, J.; Gavalec, M.; Beronská, N. Microstructural Changes and Determination of a Continuous Cooling Transformation (CCT) Diagram Using Dilatometric Analysis of M398 High-Alloy Tool Steel Produced by Microclean Powder Metallurgy. Materials 2023, 16, 4473. [Google Scholar] [CrossRef]

- Gavalec, M.; Barényi, I.; Chochlíková, H. Properties and microstructure of joints created by the method of rotary friction welding. In Proceedings of the 31st International Conference on Metallurgy and Materials METAL 2022, Brno, Czech Republic, 18–19 May 2022. [Google Scholar]

- Steuwer, A.; Hattingh, D.G.; James, M.N.; Singh, U.; Buslaps, T. Residual stresses, microstructure and tensile properties in Ti-6Al-4V friction stir welds. Sci.Technol. Join. 2012, 17, 525–533. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, F.; Wu, X.; Luo, J.; Li, W.; Yan, X. The Microstructure Evolution and Mechanical Properties of Rotary Friction Welded Duplex Stainless Steel Pipe. Materials 2023, 16, 3569. [Google Scholar] [CrossRef]

- Seiatin, S.L. An overview of the thermomechanical processing of α/β titanium alloys: Current status and future research opportunities. Metall. Mater. Trans. 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

| Element | Al | V | H | O | N | C | Fe | Ti |

|---|---|---|---|---|---|---|---|---|

| (wt.%) | 5.95 | 4.00 | 0.00 | 0.20 | 0.01 | 0.03 | 0.04 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavalec, M.; Barenyi, I.; Krbata, M.; Kohutiar, M.; Balos, S.; Pecanac, M. The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds. Materials 2023, 16, 6492. https://doi.org/10.3390/ma16196492

Gavalec M, Barenyi I, Krbata M, Kohutiar M, Balos S, Pecanac M. The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds. Materials. 2023; 16(19):6492. https://doi.org/10.3390/ma16196492

Chicago/Turabian StyleGavalec, Matúš, Igor Barenyi, Michal Krbata, Marcel Kohutiar, Sebastian Balos, and Milan Pecanac. 2023. "The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds" Materials 16, no. 19: 6492. https://doi.org/10.3390/ma16196492

APA StyleGavalec, M., Barenyi, I., Krbata, M., Kohutiar, M., Balos, S., & Pecanac, M. (2023). The Effect of Rotary Friction Welding Conditions on the Microstructure and Mechanical Properties of Ti6Al4V Titanium Alloy Welds. Materials, 16(19), 6492. https://doi.org/10.3390/ma16196492