Investigation of the Relationship between Permanent Deformation and Dynamic Modulus Performance for Bearing-Layer Asphalt Mixture

Abstract

:1. Introduction

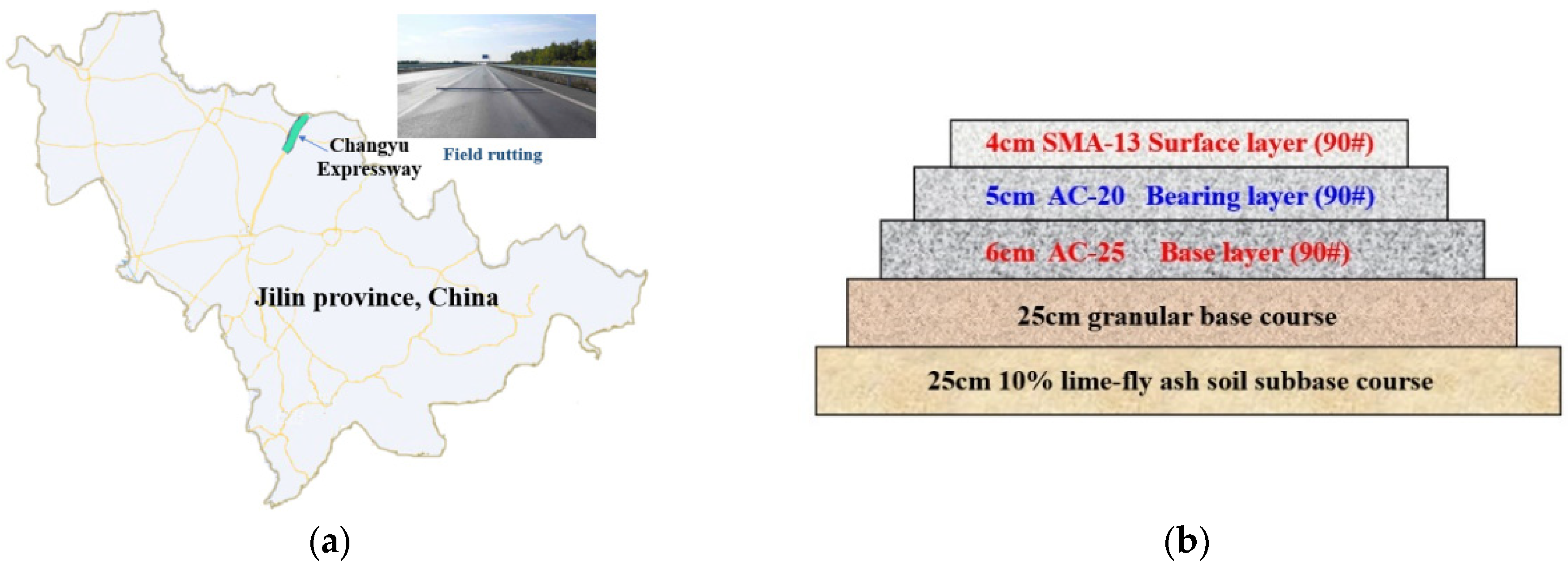

2. Investigation of Permanent Deformation of Asphalt Pavement in Northeast China

2.1. Road Section Information

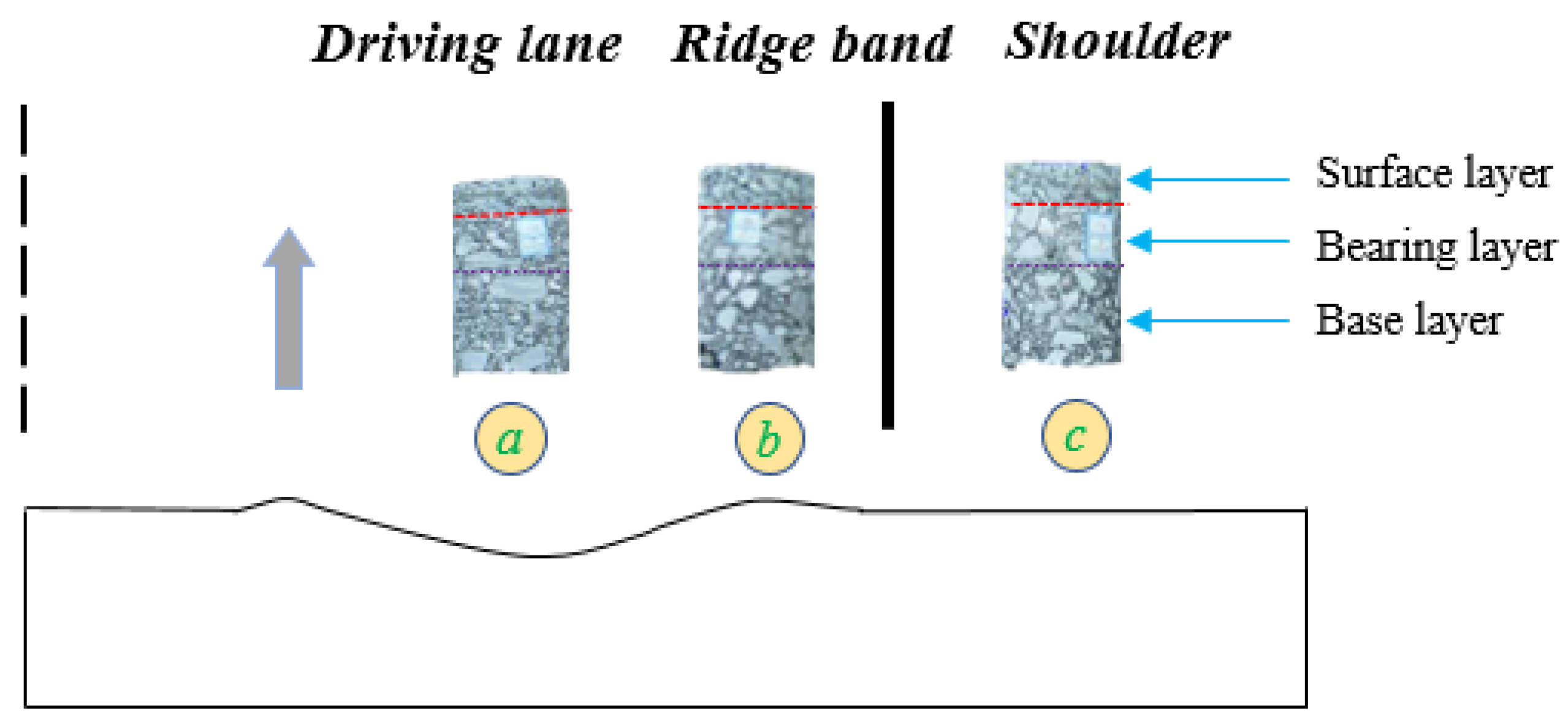

2.2. Field Cores Information

3. Materials and Methods

3.1. Materials and Sample Preparation

3.2. Test Methods

3.2.1. Dynamic Modulus Test

3.2.2. Uniaxial Compression Test

3.2.3. Uniaxial Penetration Test

3.2.4. Splitting Test

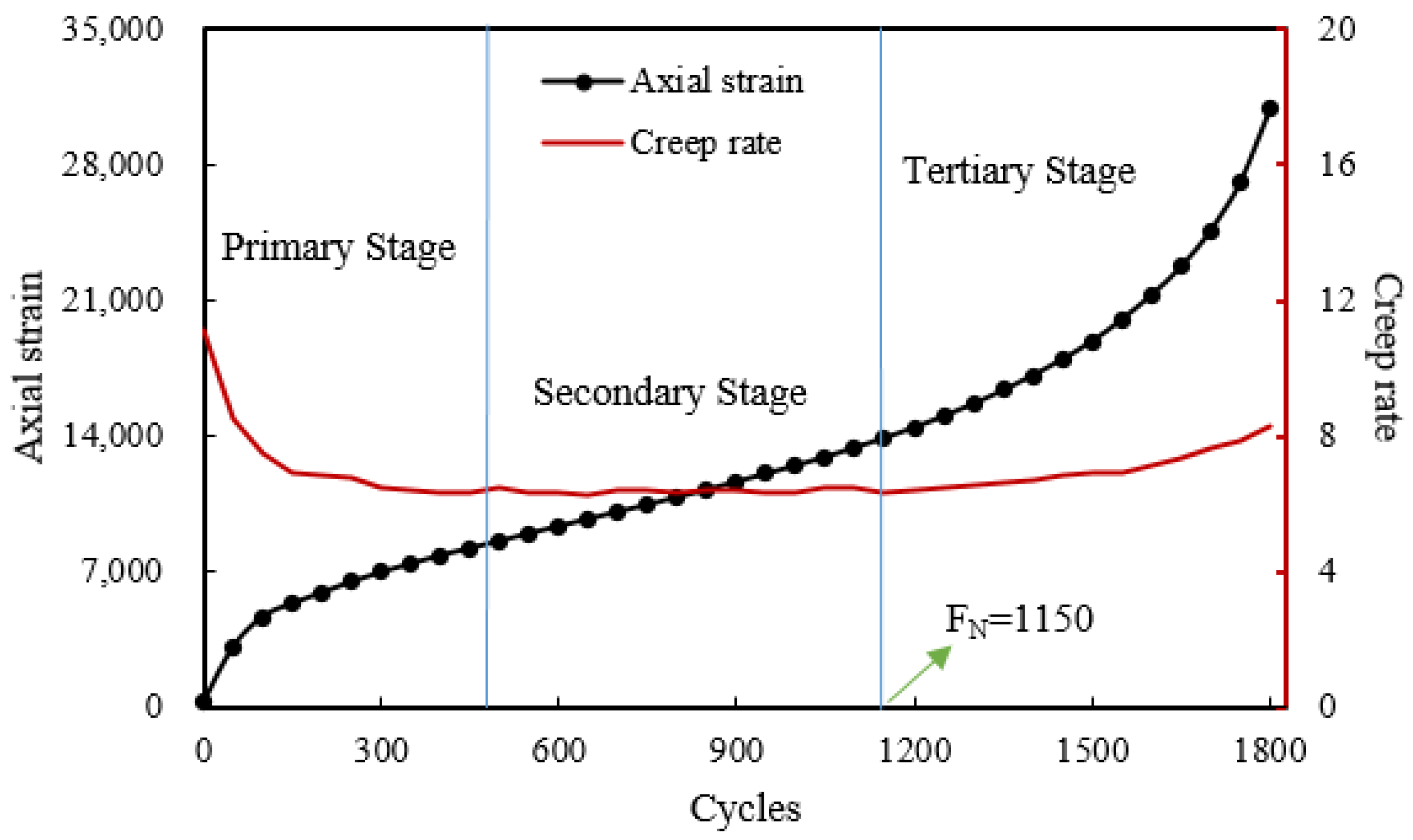

3.2.5. Dynamic Creep Test

4. Results and Discussion

4.1. Thickness Changes in Each Layer of the Field Cores

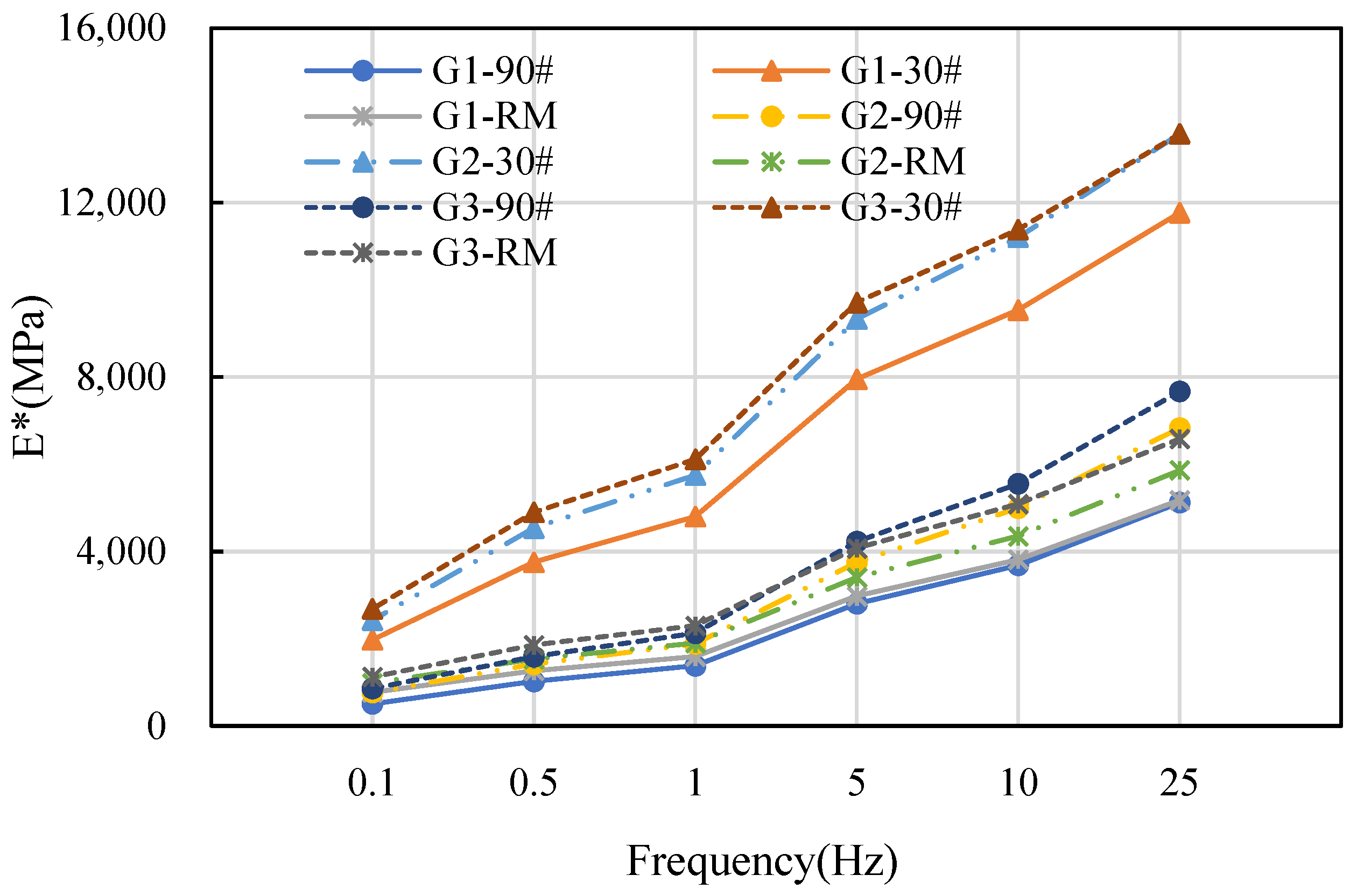

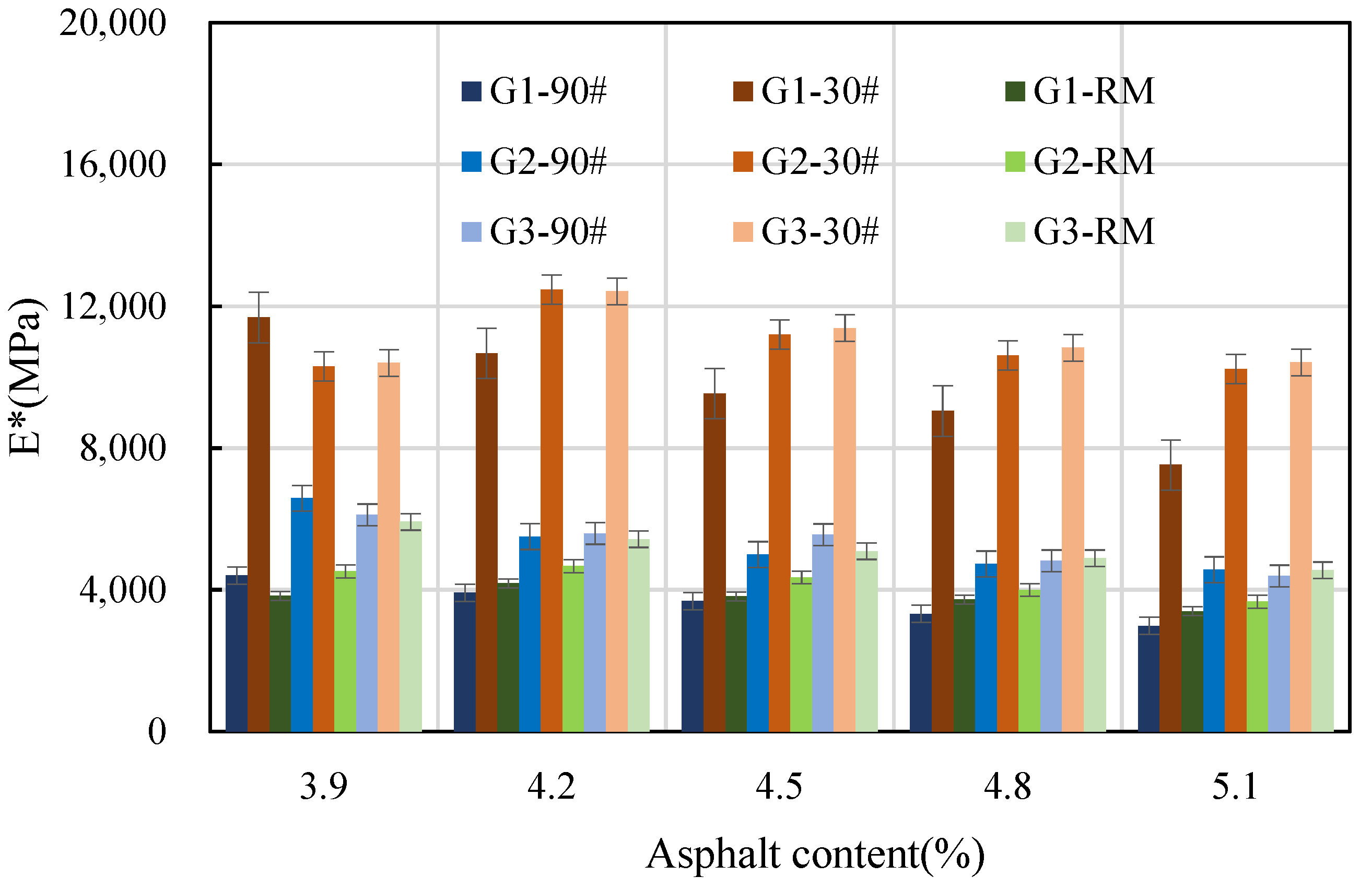

4.2. Design Parameters of Asphalt Mixture in the Bearing Layer

4.2.1. Analysis of Factors Influencing Design Parameter

4.2.2. Sensitivity Analysis

4.3. Control Standard for Asphalt Mixture in the Bearing Layer

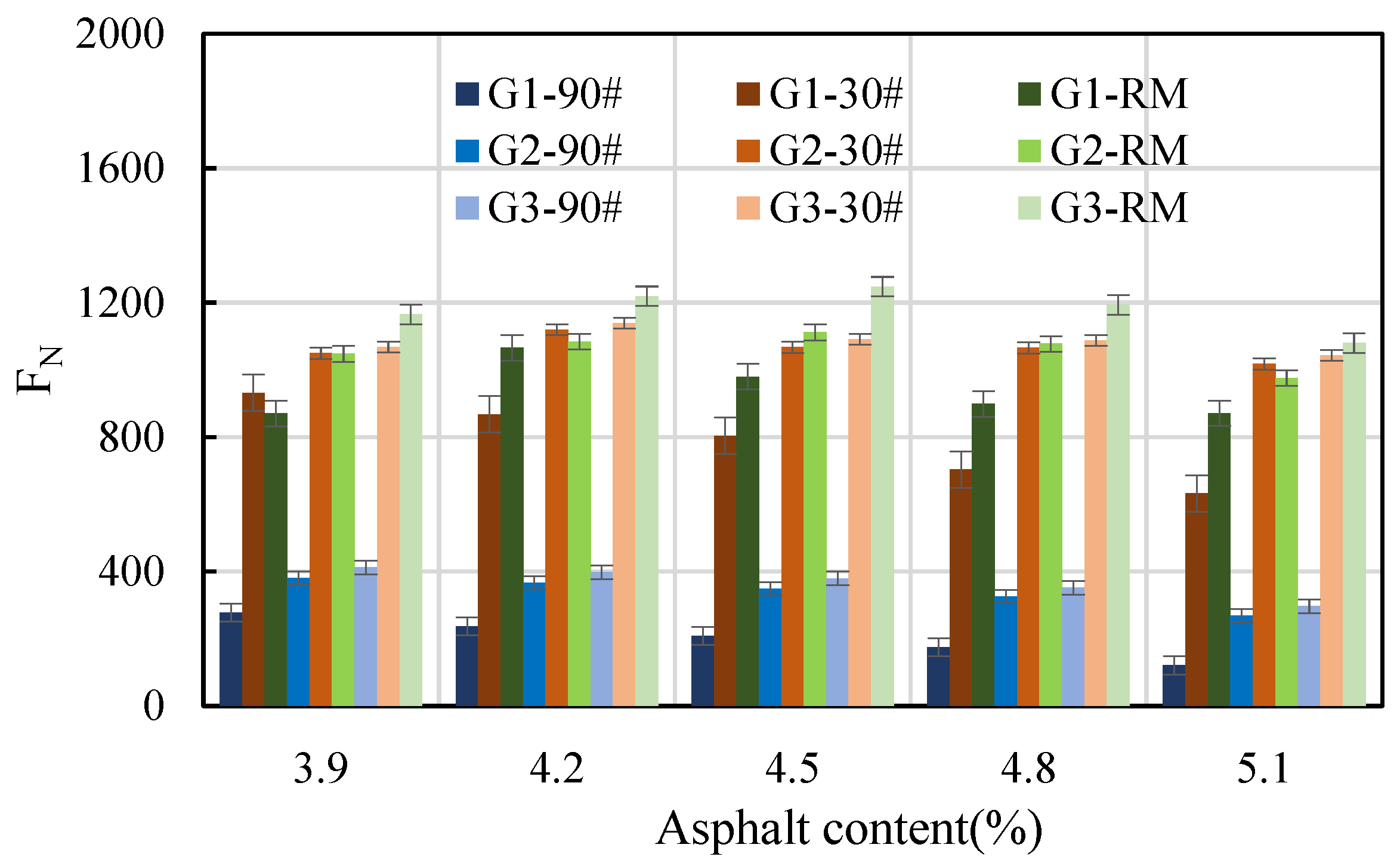

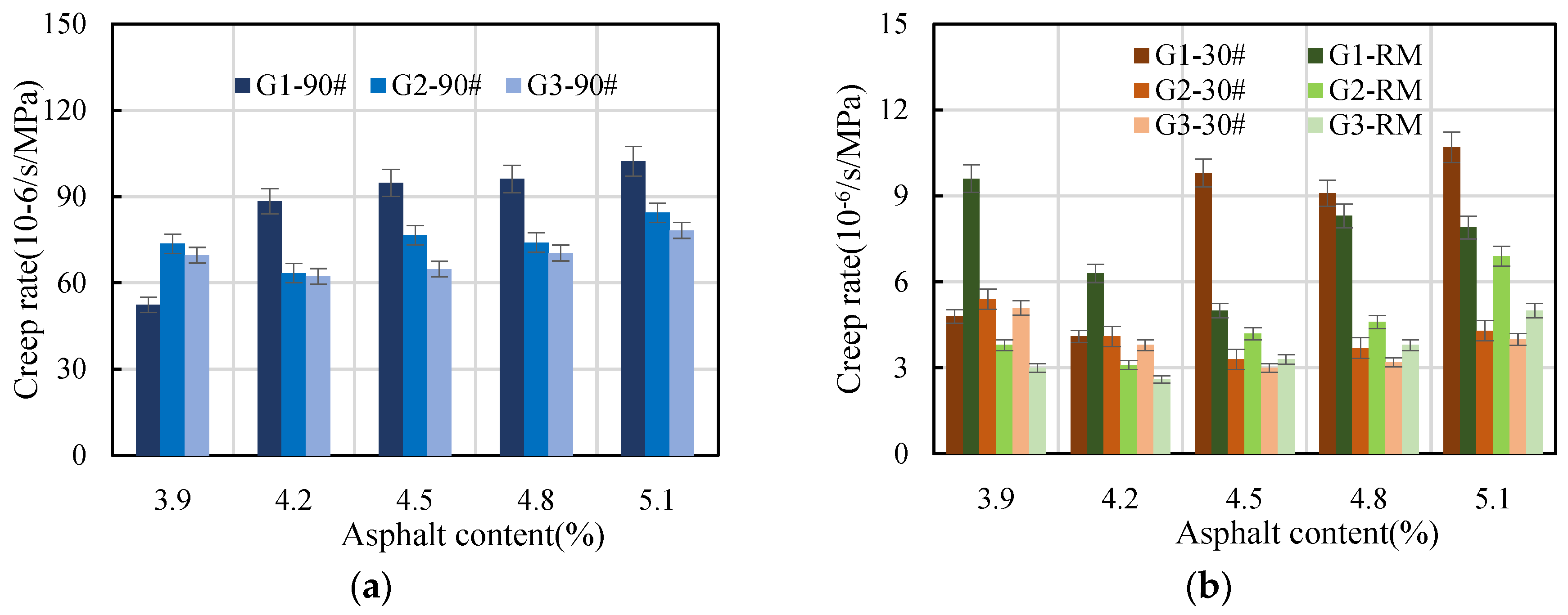

4.3.1. Analysis of Factors Influencing Dynamic Creep

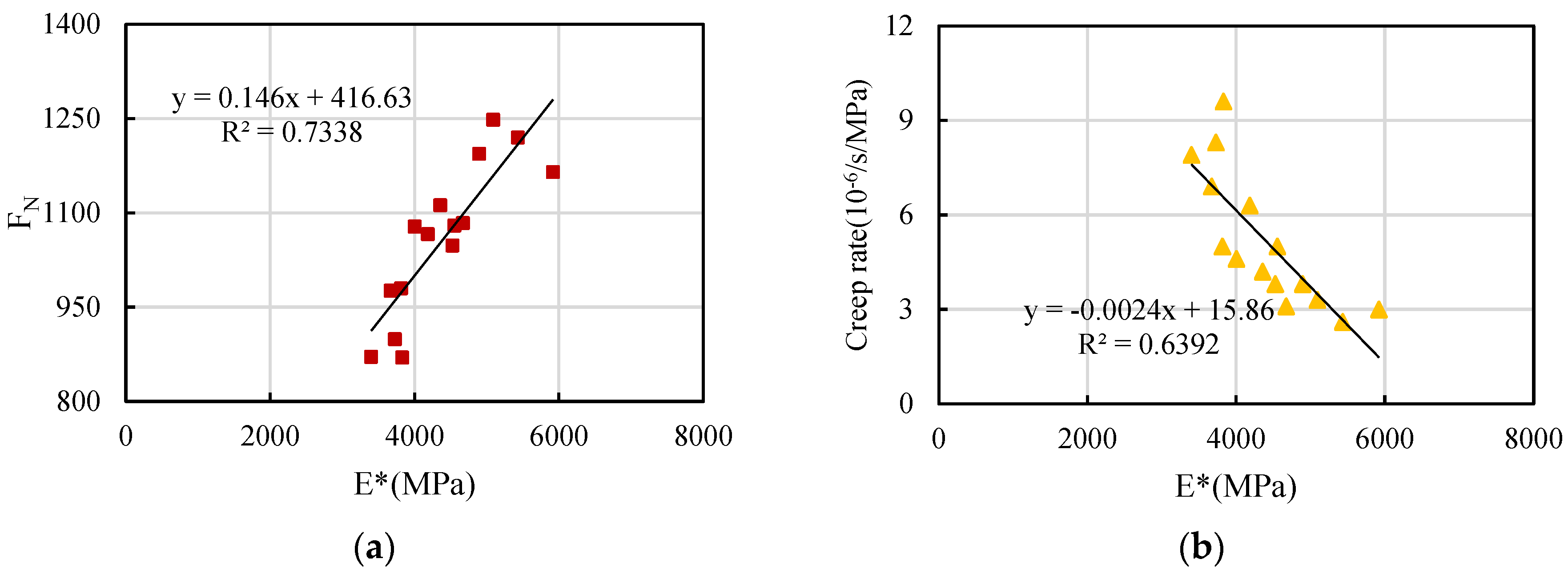

4.3.2. Relationship between Dynamic Modulus and Permanent Deformation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, G.; Chen, L.; Qian, Z.; Zhang, Y.; Ren, H. Rutting Prediction Models for Asphalt Pavements with Different Base Types Based on Riohtrack Full-Scale Track. Constr. Build. Mater. 2021, 305, 124793. [Google Scholar] [CrossRef]

- Li, H.; Xu, H.; Chen, F.; Liu, K.; Tan, Y.; Leng, B. Evolution of water migration in porous asphalt due to clogging. J. Clean. Prod. 2022, 330, 129823. [Google Scholar] [CrossRef]

- Liu, Y.; Su, P.; Li, M.; You, Z.; Zhao, M. Review on evolution and evaluation of asphalt pavement structures and materials. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 573–599. [Google Scholar] [CrossRef]

- Garbowski, T.; Pożarycki, A. Multi-level backcalculation algorithm for robust determination of pavement layers parameters. Inverse Probl. Sci. Eng. 2017, 25, 674–693. [Google Scholar] [CrossRef]

- Mataei, B.; Nejad, F.M.; Zahedi, M.; Zakeri, H. Evaluation of pavement surface drainage using an automated image acquisition and processing system. Automat. Constr. 2018, 86, 240–255. [Google Scholar] [CrossRef]

- Wang, S.; Sui, X.; Leng, Z.; Jiang, J.; Lu, G. Asphalt pavement density measurement using non-destructive testing methods: Current practices, challenges, and future vision. Constr. Build. Mater. 2022, 344, 128154. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T. Semi-automatic inspection tool of pavement condition from three-dimensional profile scans. Procedia Eng. 2017, 172, 310–318. [Google Scholar] [CrossRef]

- De Blasiis, M.R.; Di Benedetto, A.; Fiani, M. Mobile laser scanning data for the evaluation of pavement surface distress. Remote Sens. 2020, 12, 942. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Jiang, J.; Ni, F.; Zhao, Z. Nondestructive Prediction of Rutting Resistance of in-Service Middle Asphalt Layer Based on Gene Expression Programing. Constr. Build. Mater. 2021, 293, 123481. [Google Scholar] [CrossRef]

- Xu, T.; Huang, X. Investigation into Causes of in-Place Rutting in Asphalt Pavement. Constr. Build. Mater. 2012, 28, 525–530. [Google Scholar] [CrossRef]

- Li, N.; Zhan, H.; Yu, X.; Tang, W.; Yu, H.; Dong, F. Research on the High Temperature Performance of Asphalt Pavement Based on Field Cores with Different Rutting Development Levels. Mater. Struct. 2021, 54, 70. [Google Scholar] [CrossRef]

- Azarhoosh, A.; Koohmishi, M. Investigation of the Rutting Potential of Asphalt Binder and Mixture Modified by Styrene-Ethylene/Propylene-Styrene Nanocomposite. Constr. Build. Mater. 2020, 255, 119363. [Google Scholar] [CrossRef]

- Imaninasab, R.; Loria-Salazar, L.; Carter, A. Impact of Aggregate Structure Restoration on Rutting Resistance of Asphalt Mixtures with Very High Percentages of Rap. Road Mater. Pavement Des. 2023, 1–17, ahead-of-print. [Google Scholar] [CrossRef]

- Li, S.; Fan, M.; Xu, L.; Tian, W.; Yu, H.; Xu, K. Rutting Performance of Semi-Rigid Base Pavement in Riohtrack and Laboratory Evaluation. Front. Mater. 2021, 7, 590604. [Google Scholar] [CrossRef]

- Zhao, Z.; Jiang, J.; Ni, F.; Dong, Q.; Ding, J.; Ma, X. Factors Affecting the Rutting Resistance of Asphalt Pavement Based on the Field Cores Using Multi-Sequenced Repeated Loading Test. Constr. Build. Mater. 2020, 253, 118902. [Google Scholar] [CrossRef]

- Zhu, H.; Cai, H.; Ren, Q.; Hong, S.; Cao, R. Experiment and Analysis on the Development Law of High Temperature Performance of Existing Asphalt Pavement. Highway 2020, 65, 17–22. [Google Scholar]

- Baghaee Moghaddam, T.; Baaj, H. The Use of Compressible Packing Model and Modified Asphalt Binders in High-Modulus Asphalt Mix Design. Road Mater. Pavement Des. 2020, 21, 1061–1077. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Chang, M.; Dai, W. Evaluating the Effect of Hydrophobic Nanosilica on the Viscoelasticity Property of Asphalt and Asphalt Mixture. Materials 2018, 11, 2328. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, P.; Jiang, J.; Hu, X. High-Temperature Failure of Porous Asphalt Mixture Under Wheel Loading Based On 2D Air Void Structure Analysis. Constr. Build. Mater. 2020, 252, 119051. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, S.; Lv, R.; Wu, J.; Qi, H. Viscoelastic Mechanical Performance of Dense Polyurethane Mixtures Based on Dynamic and Static Modulus Testing and Creep Testing. Constr. Build. Mater. 2022, 320, 126207. [Google Scholar] [CrossRef]

- NCHRP. Simple Performance Test for Superpave Mix Design; (Project 9-19 Fy’98); NCHRP REPORT 465; Transportation Research Board: Washington, DC, USA, 2002. [Google Scholar]

- Zhang, J.; Alvarez, A.E.; Lee, S.I.; Torres, A.; Walubita, L.F. Comparison of Flow Number, Dynamic Modulus, and Repeated Load Tests for Evaluation of HMA Permanent Deformation. Constr. Build. Mater. 2013, 44, 391–398. [Google Scholar] [CrossRef]

- Chaturabong, P.; Bahia, H.U. Mechanisms of Asphalt Mixture Rutting in the Dry Hamburg Wheel Tracking Test and the Potential to be Alternative Test in Measuring Rutting Resistance. Constr. Build. Mater. 2017, 146, 175–182. [Google Scholar] [CrossRef]

- Witczak, M.W.; Kaloush, K.E.; Von Quintus, H. Pursuit of the Simple Performance Test for Asphalt Mixture Rutting. J. Assoc. Asph. Paving Technol. 2002, 71, 671–691. [Google Scholar]

- Xu, H.; Zhan, H.; Wang, M.; Tan, Y. Microstructural characteristics evolution of asphalt mastics under cyclic environmental temperature variations. Constr. Build. Mater. 2023, 400, 132795. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. MOT: Beijing, China, 2011.

- JTG/F40-2004; Technical Specification for Construction of Highway Asphalt Pavements. MOT: Beijing, China, 2011.

- Xu, H.; Fu, X.; Meng, A.; Cui, H.; Tan, Y. Rayleigh wave technology for analysis dynamic modulus of asphalt mixtures: Feasibility and application. Int. J. Pavement Eng. 2020, 21, 1235–1247. [Google Scholar] [CrossRef]

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. MOT: Beijing, China, 2017.

- Ma, Y.; Wang, H.; Zhao, K.; Yan, L.; Yang, D. Study of a Modified Time Hardening Model for the Creep Consolidation Effect of Asphalt Mixtures. Materials 2022, 15, 2710. [Google Scholar] [CrossRef]

- Harnaeni, S.R.; Pramesti, F.P.; Budiarto, A.; Setyawan, A.; Khan, M.I.; Sutanto, M.H. Study on Structural Performance of Asphalt Concrete and Hot Rolled Sheet through Viscoelastic Characterization. Materials 2020, 13, 1133. [Google Scholar] [CrossRef]

- Xu, Z.; Chang, Y.; Chen, Z.; Sun, J.; Liu, Y. Study on Test Standard of Asphalt Mixture Dynamic Modulus. J. Traffic Transp. Eng. 2015, 15, 1–8. [Google Scholar]

- Kaloush, K.E.; Witczak, M.W. Tertiary Flow Characteristics of Asphalt Mixtures. J. Assoc. Asph. Paving Technol. 2002, 71, 278–306. [Google Scholar]

- Gu, X.; Zhang, X.; Lv, J. Establishment and Verification of Prediction Models of Creep Instability Points of Asphalt Mixtures at High Temperatures. Constr. Build. Mater. 2018, 171, 303–311. [Google Scholar] [CrossRef]

- Du, Y.; Dai, M.; Deng, H.; Deng, D.; Wei, T.; Kong, L. Laboratory Investigation on Thermal and Road Performances of Asphalt Mixture Containing Glass Microsphere. Constr. Build. Mater. 2020, 264, 120710. [Google Scholar] [CrossRef]

- Khodaii, A.; Mehrara, A. Evaluation of Permanent Deformation of Unmodified and SBS Modified Asphalt Mixtures Using Dynamic Creep Test. Constr. Build. Mater. 2009, 23, 2586–2592. [Google Scholar] [CrossRef]

- Büchner, J.; Wistuba, M.P. Assessing Creep Properties of Asphalt Binder, Asphalt Mastic and Asphalt Mixture. Road Mater. Pavement Des. 2022, 23, 116–130. [Google Scholar] [CrossRef]

- Qi, F. Evaluation of High Temperature Stability of Asphalt Mixture by Creep Test. Master’s Thesis, Chang’an University, Xi’an, China, 2009. [Google Scholar]

| Properties | Asphalt (30#) | Asphalt (90#) | Rubber-Modified Asphalt | Methods | |

|---|---|---|---|---|---|

| Ductility (cm) | 15 °C | 56 | >100 | / | T0604-2011 |

| 5 °C | / | / | 41 | ||

| Penetration degree at 25 °C (0.1 mm) | 29.0 | 83.7 | 65 | T0605-2011 | |

| Softening point (°C) | 73.2 | 51.4 | 65.6 | T0606-2011 | |

| Dynamic viscosity at 60 °C (Pa·s) | 742 | 187 | 13014 | T0620-2011 | |

| Viscosity at 135 °C (Pa·s) | 0.67 | 1.56 | 8.65 | T0625-2011 | |

| Technical Indices | Results | Criteria | Methods |

|---|---|---|---|

| Crush value (%) | 5 | ≤28 | T0316-2005 |

| Content of acicular and flaky shape particles (%) | 8.6 | ≤15 | T0312-2005 |

| Losses of the Los Angeles abrasion test (%) | 14.3 | ≤30 | T0317-2005 |

| Water absorption (%) | 0.32 | ≤2 | T0307-2005 |

| Asphalt adhesion (graduation) | 4 | ≥4 | T0616-1993 |

| Impact value (%) | 17 | ≤30 | T0322-2000 |

| Firmness (%) | 2.9 | ≤12 | T0314-2000 |

| Mud content (%) | 0.8 | ≤1 | T0310-2005 |

| Properties | Hydrophilic Coefficient | Water Content (%) | Apparent Density (t/m3) | Size Distributions (%) | ||

|---|---|---|---|---|---|---|

| <0.075 mm | <0.15 mm | <0.6 mm | ||||

| Results | 0.634 | 0.5 | 2.720 | 80.7 | 96.3 | 100 |

| Criteria | <1 | ≤1 | ≥2.50 | 75~100 | 90~100 | 100 |

| Methods | T0353-2000 | T0350-1994 | T0352-2000 | T0351-2000 | ||

| Gradation Type | Asphalt Content (%) | Compressive Strength (MPa) | Resilient Modulus (MPa) | Shear Strength (MPa) | Splitting Strength (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 90# | 30# | RM | 90# | 30# | RM | 90# | 30# | RM | 90# | 30# | RM | ||

| Gradation 1 | 3.9 | 3.08 | 6.54 | 3.74 | 1293 | 2581 | 1173 | 1.07 | 1.55 | 1.52 | 1.01 | 1.63 | 0.87 |

| 4.2 | 3.23 | 6.80 | 3.91 | 1391 | 2752 | 1315 | 0.99 | 1.48 | 1.50 | 1.19 | 1.67 | 0.86 | |

| 4.5 | 2.96 | 6.73 | 4.11 | 1388 | 2609 | 1243 | 0.96 | 1.33 | 1.63 | 1.14 | 1.71 | 0.93 | |

| 4.8 | 2.86 | 6.71 | 4.39 | 1235 | 2407 | 1162 | 0.89 | 1.31 | 1.45 | 1.00 | 1.63 | 0.96 | |

| 5.1 | 2.75 | 6.45 | 3.82 | 1094 | 2378 | 1091 | 0.85 | 1.22 | 1.38 | 0.94 | 1.54 | 0.95 | |

| Gradation 2 | 3.9 | 2.78 | 5.89 | 3.37 | 1165 | 2326 | 1056 | 1.73 | 2.46 | 2.62 | 0.69 | 1.64 | 0.96 |

| 4.2 | 3.38 | 7.12 | 4.09 | 1456 | 2880 | 1376 | 1.81 | 2.51 | 2.66 | 0.71 | 1.76 | 1.04 | |

| 4.5 | 3.02 | 6.87 | 4.20 | 1419 | 2666 | 1270 | 1.98 | 2.92 | 2.79 | 0.79 | 1.83 | 1.08 | |

| 4.8 | 3.23 | 7.59 | 4.96 | 1397 | 2721 | 1313 | 1.88 | 2.67 | 2.89 | 0.75 | 1.77 | 1.00 | |

| 5.1 | 3.12 | 7.32 | 4.33 | 1243 | 2701 | 1238 | 1.81 | 2.57 | 3.07 | 0.66 | 1.58 | 0.97 | |

| Gradation 3 | 3.9 | 3.58 | 5.33 | 3.51 | 1323 | 2138 | 1110 | 1.67 | 1.89 | 2.49 | 0.89 | 1.63 | 1.03 |

| 4.2 | 3.89 | 5.86 | 3.99 | 1646 | 2367 | 1234 | 2.11 | 2.06 | 2.56 | 1.00 | 1.74 | 1.05 | |

| 4.5 | 3.38 | 5.87 | 3.78 | 1528 | 2104 | 1326 | 2.14 | 2.15 | 2.61 | 1.09 | 1.72 | 1.10 | |

| 4.8 | 3.26 | 5.52 | 3.83 | 1460 | 1966 | 1270 | 1.96 | 2.06 | 2.80 | 0.98 | 1.64 | 1.23 | |

| 5.1 | 3.10 | 5.07 | 3.62 | 1256 | 2021 | 1093 | 1.83 | 1.94 | 2.56 | 0.94 | 1.57 | 1.07 | |

| Gradation Type | Asphalt Type | Dynamic Modulus | Compressive Strength | Resilient Modulus | Shear Strength | Splitting Strength | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| p | Significance | p | Significance | p | Significance | p | Significance | p | Significance | ||

| Gradation 1 | 90# | 0.0041 | ** | 0.0523 | - | 0.1710 | - | 0.1771 | - | 0.0204 | * |

| 30# | 0.0008 | *** | 0.4557 | - | 0.0588 | - | 0.0689 | - | 0.4392 | - | |

| RM | 0.0483 | * | 0.0492 | * | 0.1585 | - | 0.3581 | - | 0.2447 | - | |

| Gradation 2 | 90# | 0.0057 | ** | 0.1127 | - | 0.1591 | - | 0.2366 | - | 0.1109 | - |

| 30# | 0.0206 | * | 0.0733 | - | 0.1675 | - | 0.0648 | - | 0.1105 | - | |

| RM | 0.0483 | * | 0.1516 | - | 0.0443 | * | 0.0450 | * | 0.3659 | - | |

| Gradation 3 | 90# | 0.0210 | * | 0.0325 | * | 0.1522 | - | 0.0427 | * | 0.2240 | - |

| 30# | 0.0268 | * | 0.0991 | - | 0.0579 | - | 0.0819 | - | 0.4635 | - | |

| RM | 0.0518 | - | 0.3828 | - | 0.3159 | - | 0.1655 | - | 0.2329 | - | |

| Frequency (Hz) | Permanent Deformation Control Standard (Times/mm) | Relational Expression | |||||

|---|---|---|---|---|---|---|---|

| 800 | 2400 | 2800 | 3000 | 4000 | 5000 | ||

| 25 | 4462 | 10,207 | 11,643 | 12,362 | 15,952 | 19,543 | DS = 0.2785 × |E*| − 442 |

| 10 | 2794 | 7851 | 9115 | 9747 | 12,908 | 16,068 | DS = 0.3164 × |E*| − 84 |

| 5 | 2027 | 6616 | 7763 | 8336 | 11,204 | 14,072 | DS = 0.3487 × |E*| + 93 |

| 1 | 682 | 3890 | 4692 | 5093 | 7098 | 9103 | DS = 0.4988 × |E*| + 460 |

| 0.5 | 424 | 3041 | 3695 | 4022 | 5658 | 7293 | DS = 0.6114 × |E*| + 541 |

| 0.1 | 163 | 1624 | 1989 | 2172 | 3085 | 3998 | DS = 1.0953 × |E*| + 621 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, W.; Meng, Y.; Shang, Y.; Zhou, X.; Xu, H. Investigation of the Relationship between Permanent Deformation and Dynamic Modulus Performance for Bearing-Layer Asphalt Mixture. Materials 2023, 16, 6409. https://doi.org/10.3390/ma16196409

Ji W, Meng Y, Shang Y, Zhou X, Xu H. Investigation of the Relationship between Permanent Deformation and Dynamic Modulus Performance for Bearing-Layer Asphalt Mixture. Materials. 2023; 16(19):6409. https://doi.org/10.3390/ma16196409

Chicago/Turabian StyleJi, Weidong, Yunrui Meng, Yunlong Shang, Xiwei Zhou, and Huining Xu. 2023. "Investigation of the Relationship between Permanent Deformation and Dynamic Modulus Performance for Bearing-Layer Asphalt Mixture" Materials 16, no. 19: 6409. https://doi.org/10.3390/ma16196409

APA StyleJi, W., Meng, Y., Shang, Y., Zhou, X., & Xu, H. (2023). Investigation of the Relationship between Permanent Deformation and Dynamic Modulus Performance for Bearing-Layer Asphalt Mixture. Materials, 16(19), 6409. https://doi.org/10.3390/ma16196409