Understanding the Effect of Electron Beam Melting Scanning Strategies on the Aluminum Content and Materials State of Single Ti-6Al-4V Feedstock

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- Using Ti-6Al-4V powder does not always translate to Ti-6Al-4V parts. While the raster scan strategy results in a Ti-6Al-4V sample, random and Dehoff strategies result in a composition that can be approximated to Ti-5Al-4V. As such, these samples would not be able to be certified as grades 5 (aluminum content between 5.50 and 6.75 wt.%) or 23 (aluminum content between 5.50 and 6.50 wt.%).

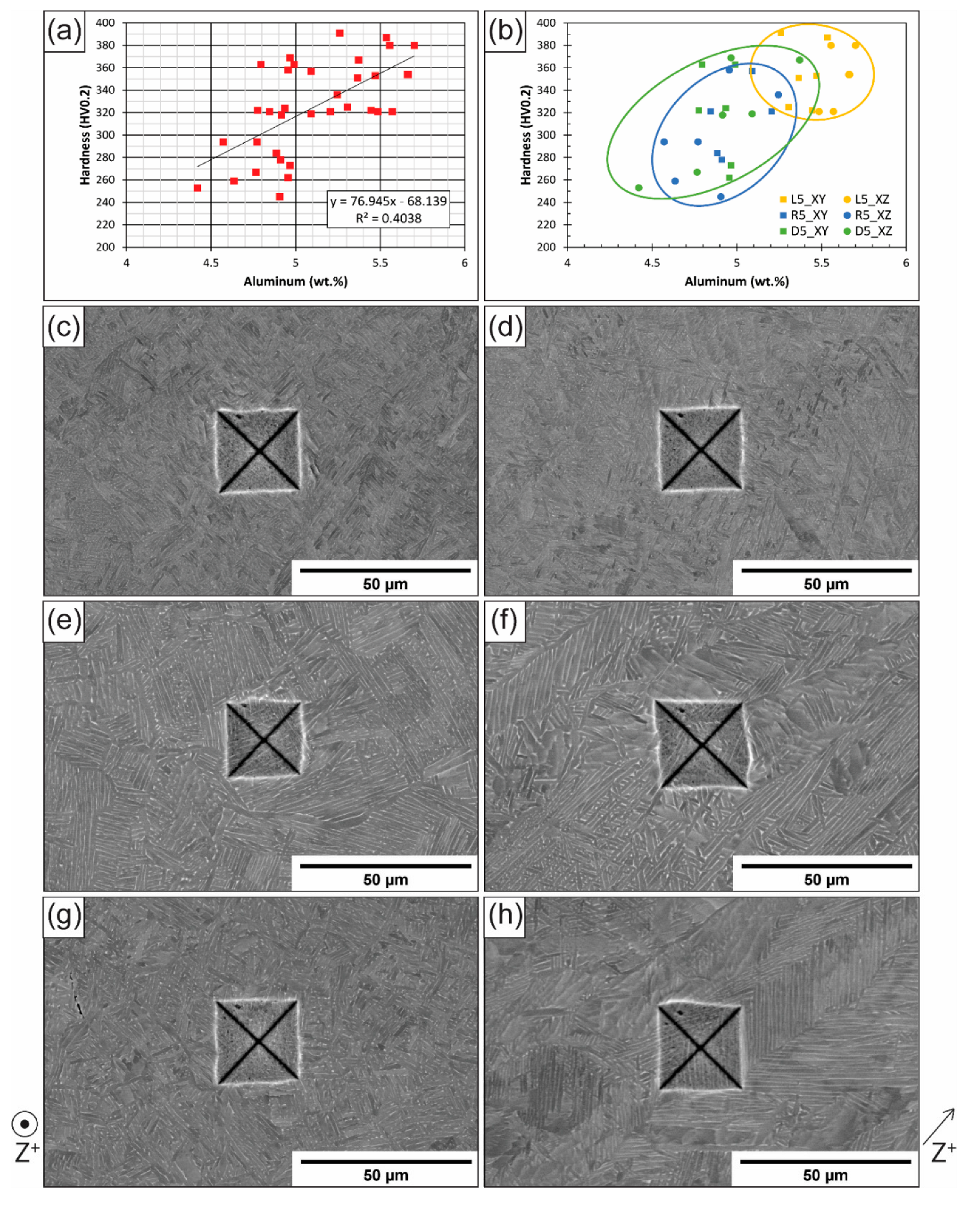

- The aluminum difference between samples results in raster samples (with higher Al contents) with higher values for density; longitudinal and shear velocities; elastic, bulk, and shear moduli; Poisson’s ratio; and hardness.

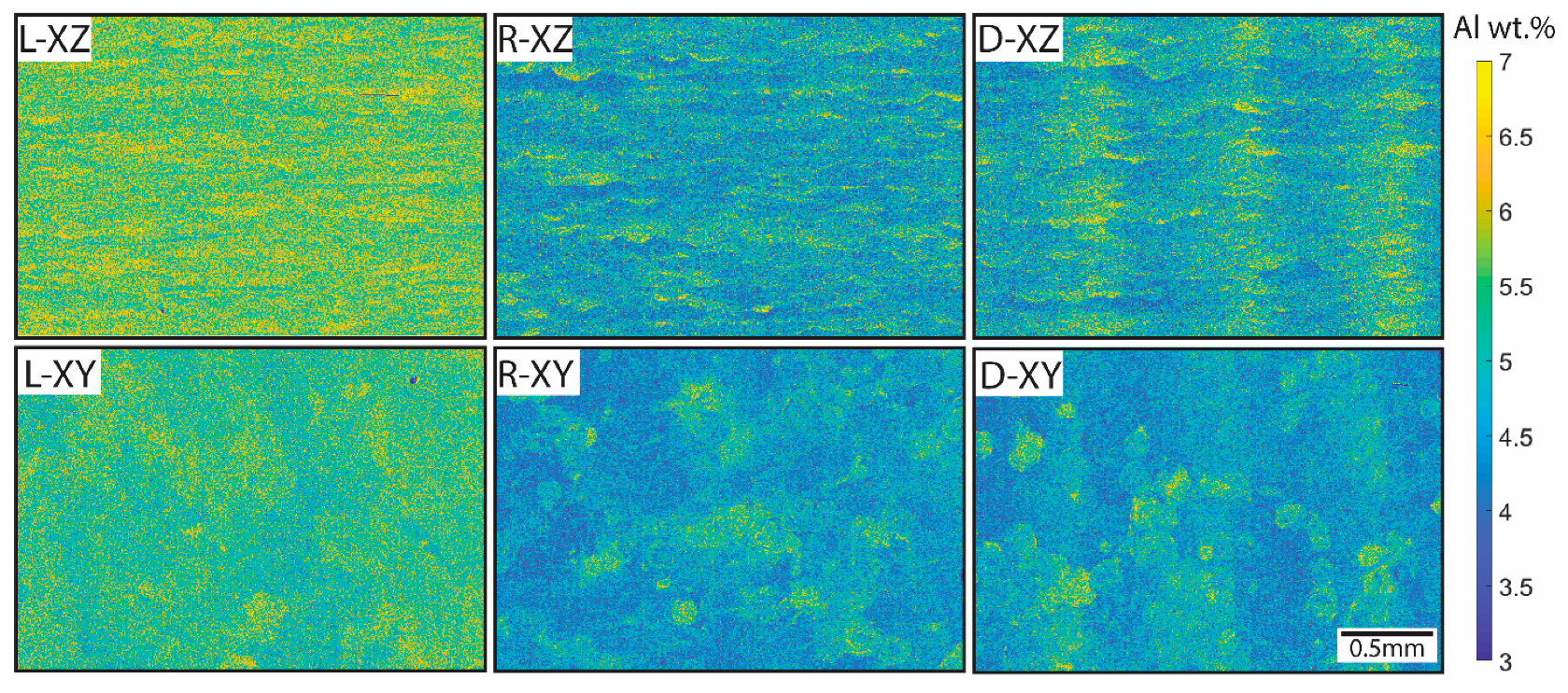

- In addition, EDS maps are clearly distinct between scanning strategies, allowing for the identification of each sample through compositional patterns alone, where point melting scan strategies show individual melt pools, while the raster scan strategy shows horizontal banding in the XZ plane and the Dehoff sample shows vertical ‘stripes’ of varying Al content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.T. Design of titanium alloys by additive manufacturing: A critical review. Adv. Powder Mater. 2022, 1, 100014. [Google Scholar]

- Zhang, L.C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Materials 2018, 20, 1700842. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural Control of Additively Manufactured Metallic Materials. Annu. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive manufacturing of structural materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Gardner, L. Metal additive manufacturing in structural engineering—Review, advances, opportunities and outlook. Structures 2023, 47, 2178–2193. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Shapiro, A.A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive manufacturing for aerospace flight applications. J. Spacecr. Rocket. 2016, 53, 952–959. [Google Scholar] [CrossRef]

- Moorehead, M.; Bertsch, K.; Niezgoda, M.; Parkin, C.; Elbakhshwan, M.; Sridharan, K.; Zhang, C.; Thoma, D.; Couet, A. High-throughput synthesis of Mo-Nb-Ta-W high-entropy alloys via additive manufacturing. Mater. Des. 2020, 187, 108358. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Niroumand, B.; Aversa, A.; Saboori, A. In-situ alloying in laser-based additive manufacturing processes: A critical review. J. Alloys Compd. 2021, 872, 159567. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. 2019, 764, 138209. [Google Scholar] [CrossRef]

- Ivanchenko, V.G.; Ivasishin, O.M.; Semiatin, S.L. Evaluation of Evaporation Losses during Electron-Beam Melting of Ti-Ai-V Alloys. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2003, 34, 911–915. [Google Scholar] [CrossRef]

- Klassen, A. Simulation of Evaporation Phenomena in Selective Electron Beam Melting; FAU: Boca Raton, FL, USA, 2018. [Google Scholar]

- Damri, E.; Tiferet, E.; Braun, D.; Ganor, Y.I.; Chonin, M.; Orion, I. Effects of gas pressure during electron beam energy deposition in the ebm additive manufacturing process. Metals 2021, 11, 601. [Google Scholar] [CrossRef]

- Nandwana, P.; Peter, W.H.; Dehoff, R.R.; Lowe, L.E.; Kirka, M.M.; Medina, F.; Babu, S.S. Recyclability Study on Inconel 718 and Ti-6Al-4V Powders for Use in Electron Beam Melting. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2016, 47, 754–762. [Google Scholar] [CrossRef]

- Brice, C.A.; Rosenberger, B.T.; Sankaran, S.N.; Taminger, K.M.; Woods, B.; Nasserrafi, R. Chemistry control in electron beam deposited titanium alloys. Mater. Sci. Forum 2009, 618–619, 155–158. [Google Scholar] [CrossRef]

- Choi, W.; Jourdan, J.; Matveichev, A.; Jardy, A.; Bellot, J.-P. Kinetics of Evaporation of Alloying Elements under Vacuum: Application to Ti alloys in Electron Beam Melting. High Temp. Mater. Process. 2017, 36, 815–823. [Google Scholar] [CrossRef]

- Karunakaran, R.; Ortgies, S.; Tamayol, A.; Bobaru, F.; Sealy, M.P. Additive manufacturing of magnesium alloys. Bioact. Mater. 2020, 5, 44–54. [Google Scholar] [CrossRef]

- Powell, A.C., IV. Transport Phenomena in Electron Beam Melting and Evaporation; MIT: Cambridge, MA, USA, 1997. [Google Scholar]

- Lütjering, G.; Williams, J.C. Titanium; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Ankem, S.; Scarr, G.K.; Caplan, I.L. Multiple Regression Analysis of the Effects of Various Alloying Elements on the Properties of Titanium Alloys. Sixth World Conf. Titan. 1988, 265–268. [Google Scholar]

- Hayes, B.J.; Martin, B.W.; Welk, B.; Kuhr, S.J.; Ales, T.K.; Brice, D.A.; Ghamarian, I.; Baker, A.H.; Haden, C.V.; Harlow, D.G.; et al. Predicting tensile properties of Ti-6Al-4V produced via directed energy deposition. Acta Mater. 2017, 133, 120–133. [Google Scholar] [CrossRef]

- Mohr, M.; Wunderlich, R.; Novakovic, R.; Ricci, E.; Fecht, H.-J. Precise Measurements of Thermophysical Properties of Liquid Ti–6Al–4V (Ti64) Alloy on Board the International Space Station. Adv. Eng. Mater. 2020, 22, 2000169. [Google Scholar] [CrossRef]

- Mandil, G.; Le, V.T.; Paris, H.; Suard, M. Building new entities from existing titanium part by electron beam melting: Microstructures and mechanical properties. Int. J. Adv. Manuf. Technol. 2016, 85, 1835–1846. [Google Scholar] [CrossRef]

- Nandwana, P.; Lee, Y. Influence of scan strategy on porosity and microstructure of Ti-6Al-4V fabricated by electron beam powder bed fusion. Mater. Today Commun. 2020, 24, 100962. [Google Scholar] [CrossRef]

- Shao, M.; Vijayan, S.; Nandwana, P.; Jinschek, J.R. The effect of beam scan strategies on microstructural variations in Ti-6Al-4V fabricated by electron beam powder bed fusion. Mater. Des. 2020, 196, 109165. [Google Scholar] [CrossRef]

- Lee, Y.; Kirka, M.; Dinwiddie, R.; Raghavan, N.; Turner, J.; Dehoff, R.; Babu, S. Role of scan strategies on thermal gradient and solidification rate in electron beam powder bed fusion. Addit. Manuf. 2018, 22, 516–527. [Google Scholar] [CrossRef]

- Stephenson, P.; Haghdadi, N.; DeMott, R.; Liao, X.; Ringer, S.; Primig, S. Effect of scanning strategy on variant selection in additively manufactured Ti-6Al-4V. Addit. Manuf. 2020, 36, 101581. [Google Scholar] [CrossRef]

- Saville, A.I.; Vogel, S.C.; Creuziger, A.; Benzing, J.T.; Pilchak, A.L.; Nandwana, P.; Klemm-Toole, J.; Clarke, K.D.; Semiatin, S.L.; Clarke, A.J. Texture evolution as a function of scan strategy and build height in electron beam melted Ti-6Al-4V. Addit. Manuf. 2021, 46, 102118. [Google Scholar] [CrossRef]

- Kamath, R.R.; Nandwana, P.; Ren, Y.; Choo, H. Solidification texture, variant selection, and phase fraction in a spot-melt electron-beam powder bed fusion processed Ti-6Al-4V. Addit. Manuf. 2021, 46, 102136. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Kirka, M.M.; Lee, Y.; Greeley, D.A.; Okello, A.; Goin, M.J.; Pearce, M.T.; Dehoff, R.R. Strategy for Texture Management in Metals Additive Manufacturing. JOM 2017, 69, 523–531. [Google Scholar] [CrossRef]

- Quintana, M.J.; Kenney, M.J.; Agrawal, P.; Collins, P.C. Texture Analysis of Additively Manufactured Ti-6Al-4V Deposited Using Different Scanning Strategies. Met. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 6574–6583. [Google Scholar] [CrossRef]

- Quintana, M.; O’Donnell, K.; Kenney, M.; Collins, P. Differences in Defect Distribution Across Scan Strategies in Electron Beam AM Ti-6Al-4V. Adv. Mater. Process. 2021, 20–23. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M.; Eggenberger, R. Comparison of density measurement techniques for additive manufactured metallic parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Kenney, M.J.; O’Donnell, K.; Quintana, M.J.; Collins, P.C. Spherical pores as ‘microstructural informants’: Understanding compositional, thermal, and mechanical gyrations in additively manufactured Ti-6Al-4V. Scr. Mater. 2021, 198, 113827. [Google Scholar] [CrossRef]

- O’Donnell, K.; Quintana, M.J.; Kenney, M.J.; Collins, P.C. Using defects as a ‘fossil record’ to help interpret complex processes during additive manufacturing: As applied to raster scanned electron beam powder bed additively manufactured Ti-6Al-4V. J. Mater. Sci. 2023; in press. [Google Scholar]

- O’Donnell, K.; Quintana, M.J.; Collins, P.C. Microstructural and Mechanical Property Differences Resulting from Melt Pool Interactions with the Electron Beam Chamber Environment. Microsc. Microanal. 2023, 29 (Suppl. S1), 1423–1425. [Google Scholar] [CrossRef]

- Ashkani, O.; Tavighi, M.R.; Karamimoghadam, M.; Moradi, M.; Bodaghi, M.; Rezayat, M. Influence of Aluminum and Copper on Mechanical Properties of Biocompatible Ti-Mo Alloys: A Simulation-Based Investigation. Micromachines 2023, 14, 1081. [Google Scholar] [CrossRef]

- Zhou, W.; Sahara, R.; Tsuchiya, K. First-principles study of the phase stability and elastic properties of Ti-X alloys (X = Mo, Nb, Al, Sn, Zr, Fe, Co, and O). J. Alloys Compd. 2017, 727, 579–595. [Google Scholar] [CrossRef]

- Haghdadi, N.; DeMott, R.; Stephenson, P.; Liao, X.; Ringer, S.; Primig, S. Five-parameter characterization of intervariant boundaries in additively manufactured Ti-6Al-4V. Mater. Des. 2020, 196, 109177. [Google Scholar] [CrossRef]

- DeMott, R.; Haghdadi, N.; Liao, X.; Ringer, S.P.; Primig, S. 3D characterization of microstructural evolution and variant selection in additively manufactured Ti-6Al-4 V. J. Mater. Sci. 2021, 56, 14763–14782. [Google Scholar] [CrossRef]

- DeMott, R.; Haghdadi, N.; Gandomkar, Z.; Liao, X.; Ringer, S.; Primig, S. Formation and 3D morphology of interconnected α microstructures in additively manufactured Ti-6Al-4V. Materialia 2021, 20, 101201. [Google Scholar] [CrossRef]

- DeMott, R.; Collins, P.; Kong, C.; Liao, X.; Ringer, S.; Primig, S. 3D electron backscatter diffraction study of α lath morphology in additively manufactured Ti-6Al-4V. Ultramicroscopy 2020, 218, 113073. [Google Scholar] [CrossRef] [PubMed]

| Sample | Large-Scale EDS Maps (Figure 1) | Small-Scale EDS Maps | Centerline Area Analyses | Hardness Area Analyses | Average |

|---|---|---|---|---|---|

| Raster (L5) | 5.48 ± 0.25 | 5.40 ± 0.20 | 5.54 ± 0.04 | 5.50 ± 0.16 | 5.47 ± 0.17 |

| Random (R5) | 4.63 ± 0.11 | 4.66 ± 0.20 | 4.58 ± 0.01 | 4.89 ± 0.25 | 4.83 ± 0.26 |

| Dehoff (D5) | 4.72 ± 0.20 | 4.87 ± 0.23 | 4.80 ± 0.08 | 4.91 ± 0.26 | 4.89 ± 0.25 |

| Raster | Random | |

|---|---|---|

| Carbon | 0.019 | 0.023 |

| Nitrogen | 0.012 | 0.013 |

| Oxygen | 0.139 | 0.161 |

| Aluminum | 5.88 | 4.87 |

| Silicon | 0.014 | 0.014 |

| Titanium | Balance | Balance |

| Vanadium | 4.18 | 4.27 |

| Chromium | 0.012 | 0.010 |

| Iron | 0.21 | 0.21 |

| Nickel | 0.0098 | 0.0094 |

| Copper | 0.0020 | 0.0020 |

| Sample | Density (kg/m3) | Longitudinal Velocity (m/s) | Shear Velocity (m/s) | Elastic Modulus (GPa) | Poisson’s Ratio | Shear Modulus (GPa) | Bulk Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| Raster | 4420 | 6220 | 3170 | 117.6 | 0.325 | 44.4 | 111.9 |

| Random | 4380 | 6120 | 3150 | 115.0 | 0.320 | 43.5 | 106.4 |

| Sample | Region | Vickers Hardness [HV0.2] | ||

|---|---|---|---|---|

| Average | Range | 95% Confidence Interval | ||

| L5 | XY Plane | 353 ± 17.7 | 322–391 | 4.3 |

| XZ Plane | 354 ± 14.9 | 321–380 | 2.5 | |

| Overall | 353 ± 15.8 | 321–391 | - | |

| R5 | XY Plane | 321 ± 17.7 | 278–378 | 4.4 |

| XZ Plane | 294 ± 19.5 | 245–358 | 3.3 | |

| Overall | 303 ± 22.7 | 245–378 | - | |

| D5 | XY Plane | 322 ± 20.0 | 262–363 | 5.0 |

| XZ Plane | 319 ± 23.3 | 253–369 | 3.9 | |

| Overall | 320 ± 22.3 | 253–369 | - | |

| Wrought Ti-6Al-4V | N/A | 355 ± 17.1 | 320–389 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

O’Donnell, K.; Quintana, M.J.; Collins, P.C. Understanding the Effect of Electron Beam Melting Scanning Strategies on the Aluminum Content and Materials State of Single Ti-6Al-4V Feedstock. Materials 2023, 16, 6366. https://doi.org/10.3390/ma16196366

O’Donnell K, Quintana MJ, Collins PC. Understanding the Effect of Electron Beam Melting Scanning Strategies on the Aluminum Content and Materials State of Single Ti-6Al-4V Feedstock. Materials. 2023; 16(19):6366. https://doi.org/10.3390/ma16196366

Chicago/Turabian StyleO’Donnell, Katie, Maria J. Quintana, and Peter C. Collins. 2023. "Understanding the Effect of Electron Beam Melting Scanning Strategies on the Aluminum Content and Materials State of Single Ti-6Al-4V Feedstock" Materials 16, no. 19: 6366. https://doi.org/10.3390/ma16196366

APA StyleO’Donnell, K., Quintana, M. J., & Collins, P. C. (2023). Understanding the Effect of Electron Beam Melting Scanning Strategies on the Aluminum Content and Materials State of Single Ti-6Al-4V Feedstock. Materials, 16(19), 6366. https://doi.org/10.3390/ma16196366