Influence Analysis of Modified Polymers as a Marking Agent for Material Tracing during Cyclic Injection Molding

Abstract

:1. Introduction

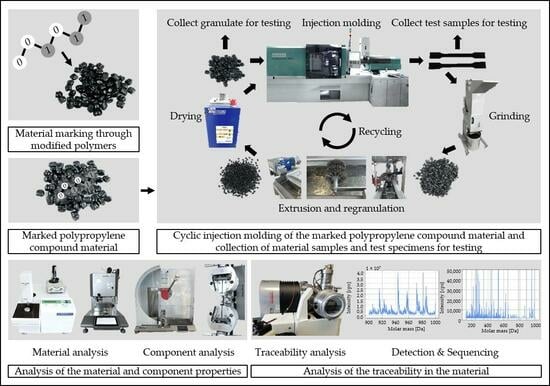

2. Materials and Methods

2.1. Injection Molding Material

2.2. Modified Polymer

2.3. Production of the Master Batch

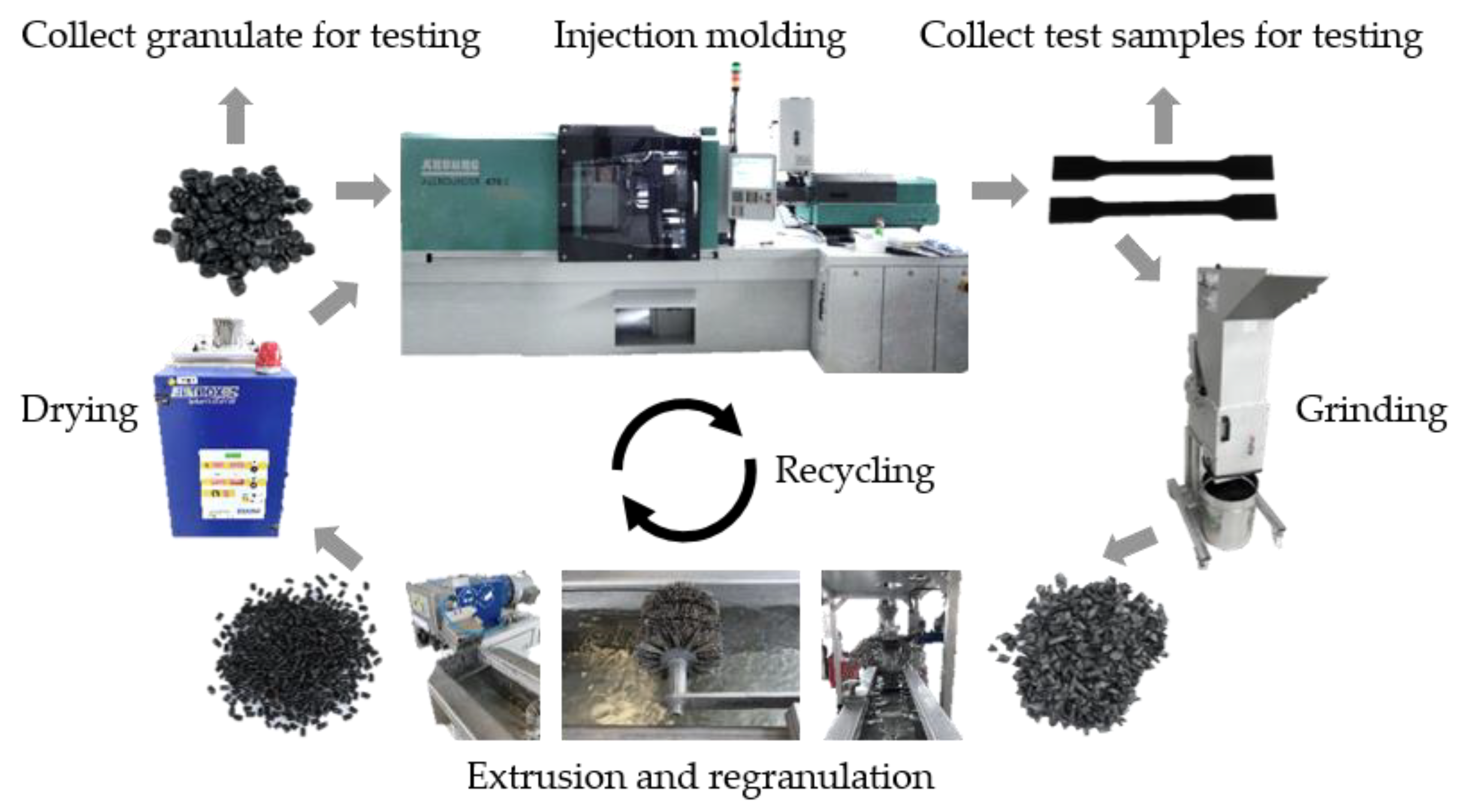

2.4. Injection Molding Processing and Recycling Procedure

2.5. Thermogravimetric Analysis

2.6. Differential Scanning Calorimetry Testing

2.7. Melt Flow Index Test

2.8. Tensile Test

2.9. Charpy Impact Test

2.10. Vicat Softening Temperature Test

2.11. Tandem Mass Spectroscopy

3. Results

3.1. Influence of the Modified Polymer Used on the Material Properties

3.1.1. Initial Material Properties

3.1.2. Thermal Process Window

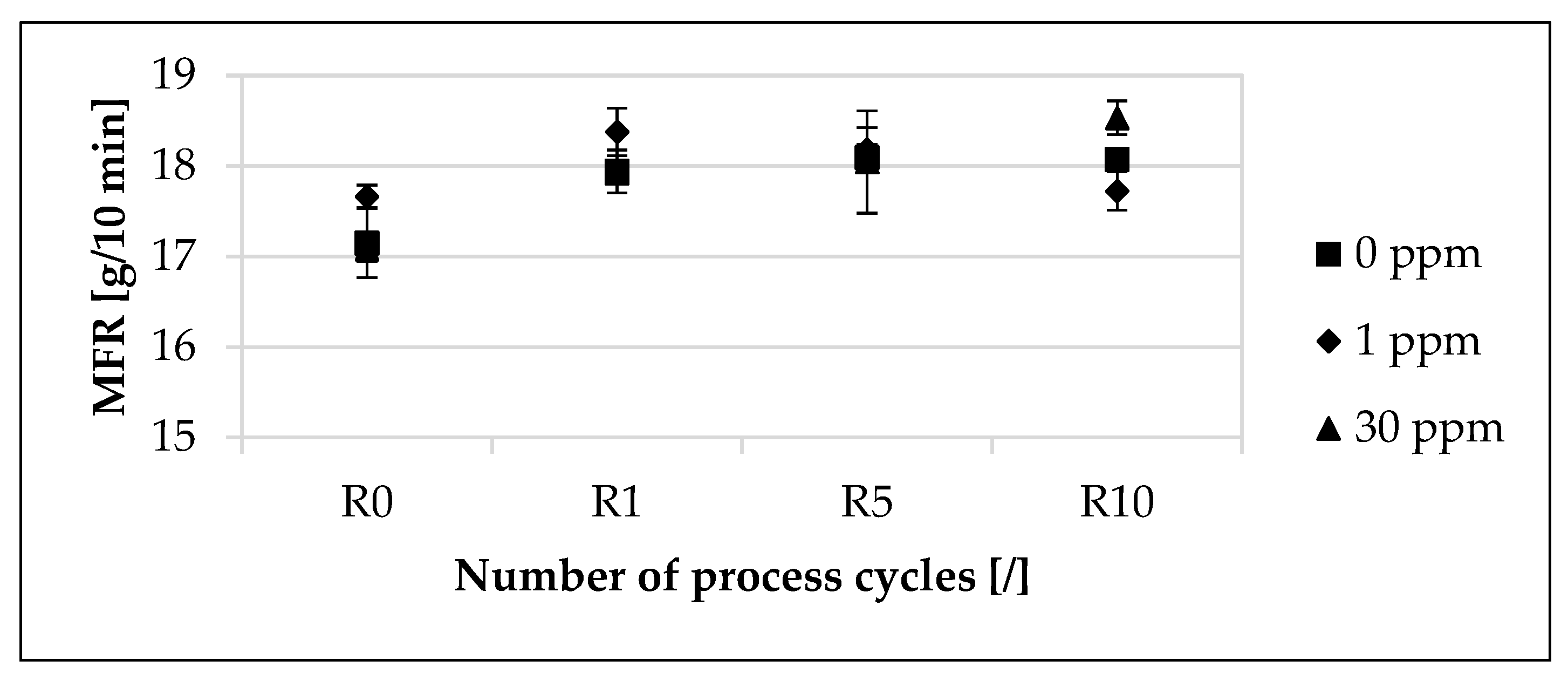

3.1.3. Melt Flow Rate

3.2. Influence of the Modified Polymer Used on the Component Properties

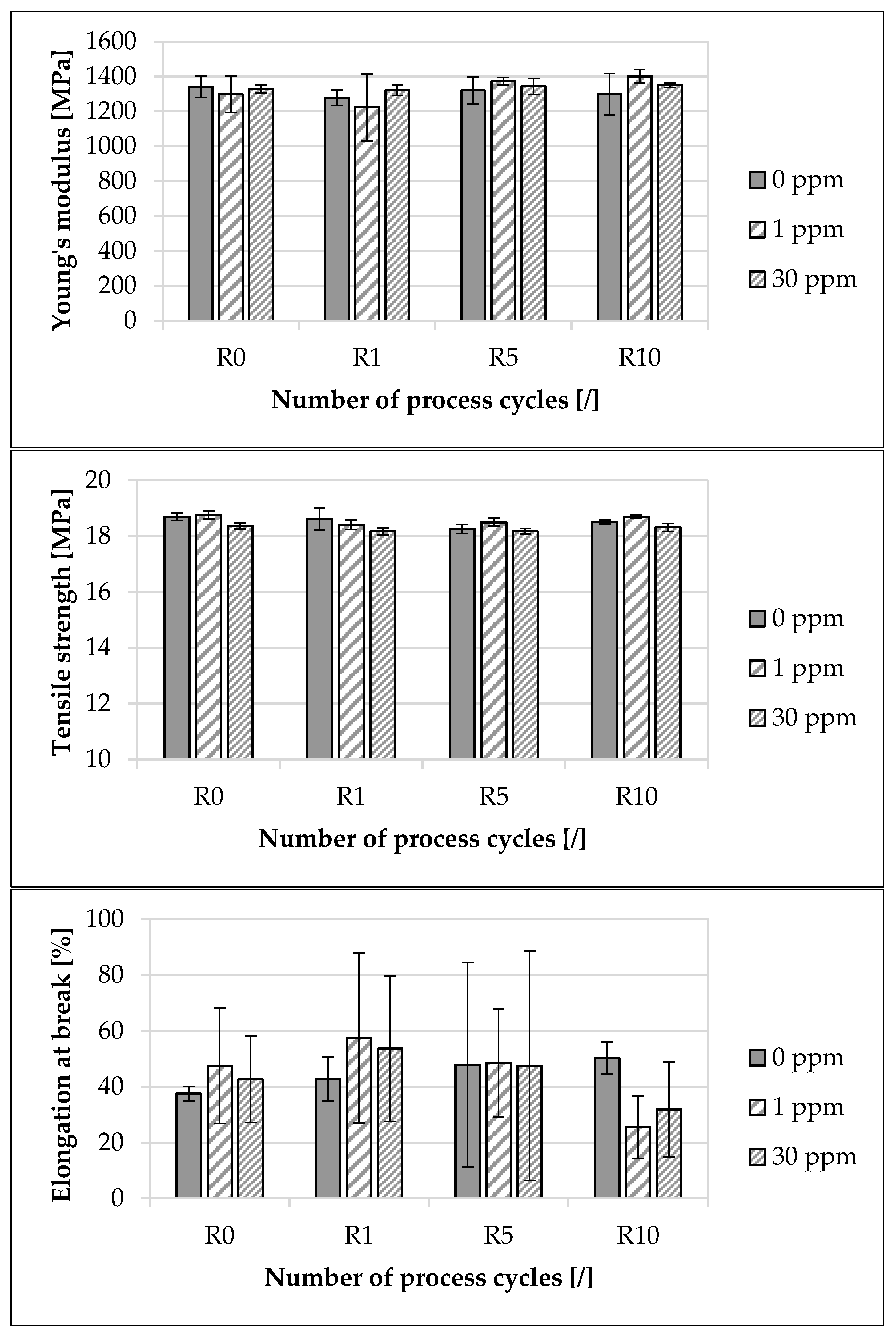

3.2.1. Tensile Test

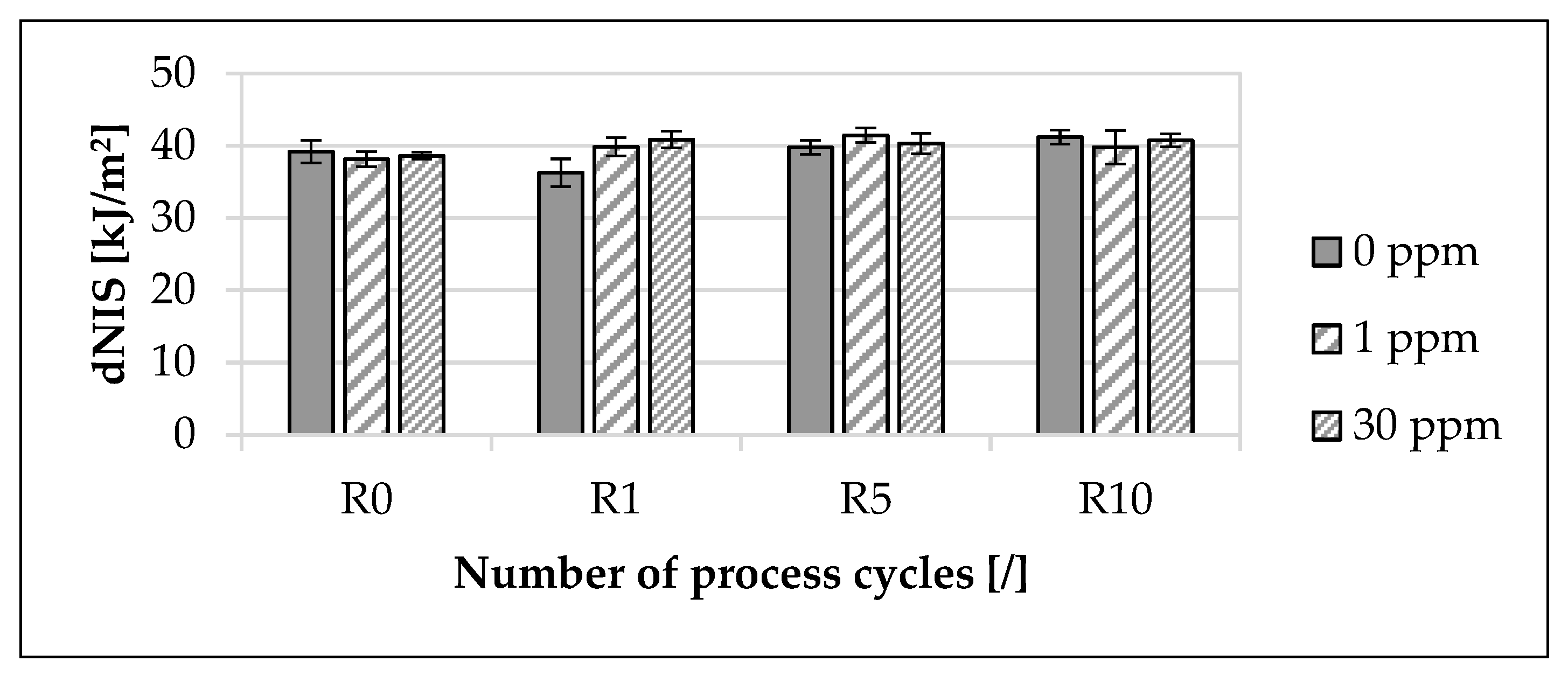

3.2.2. Charpy Impact Test

3.2.3. Vicat Softening Temperature

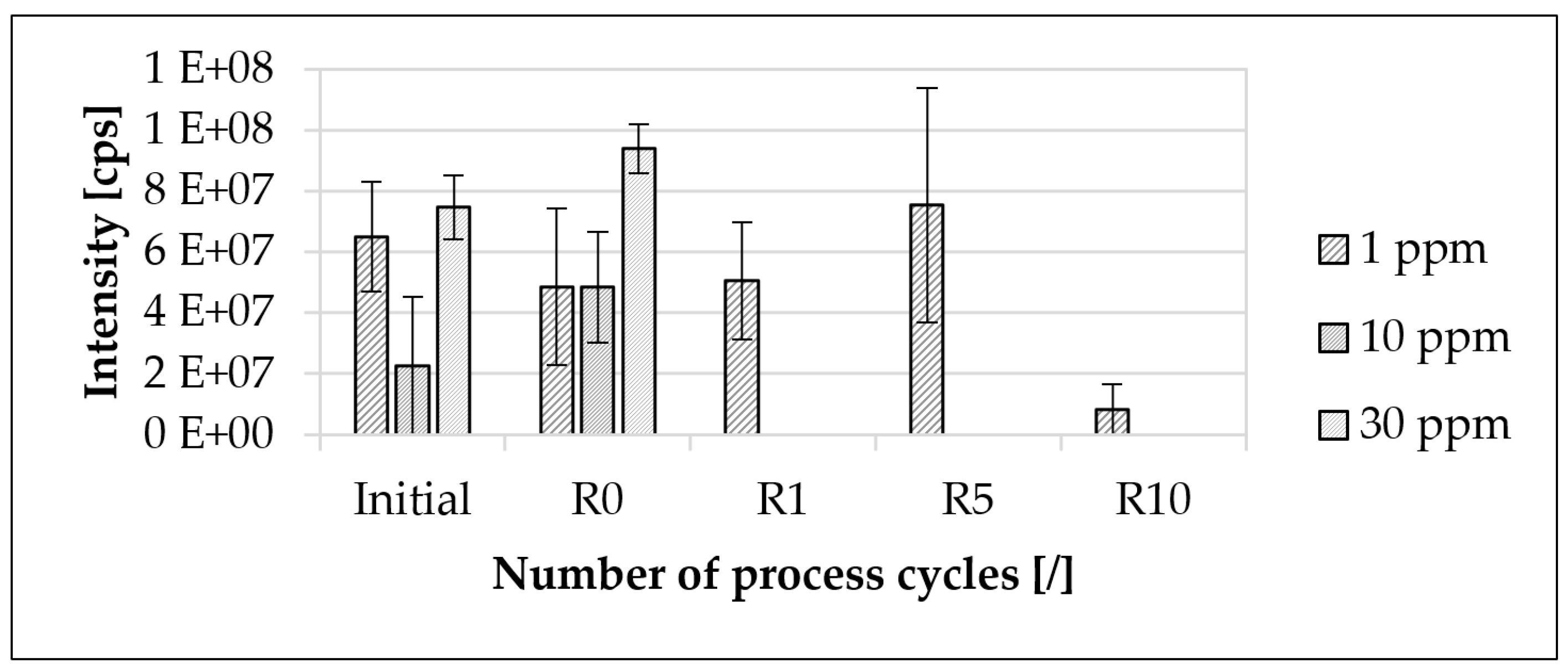

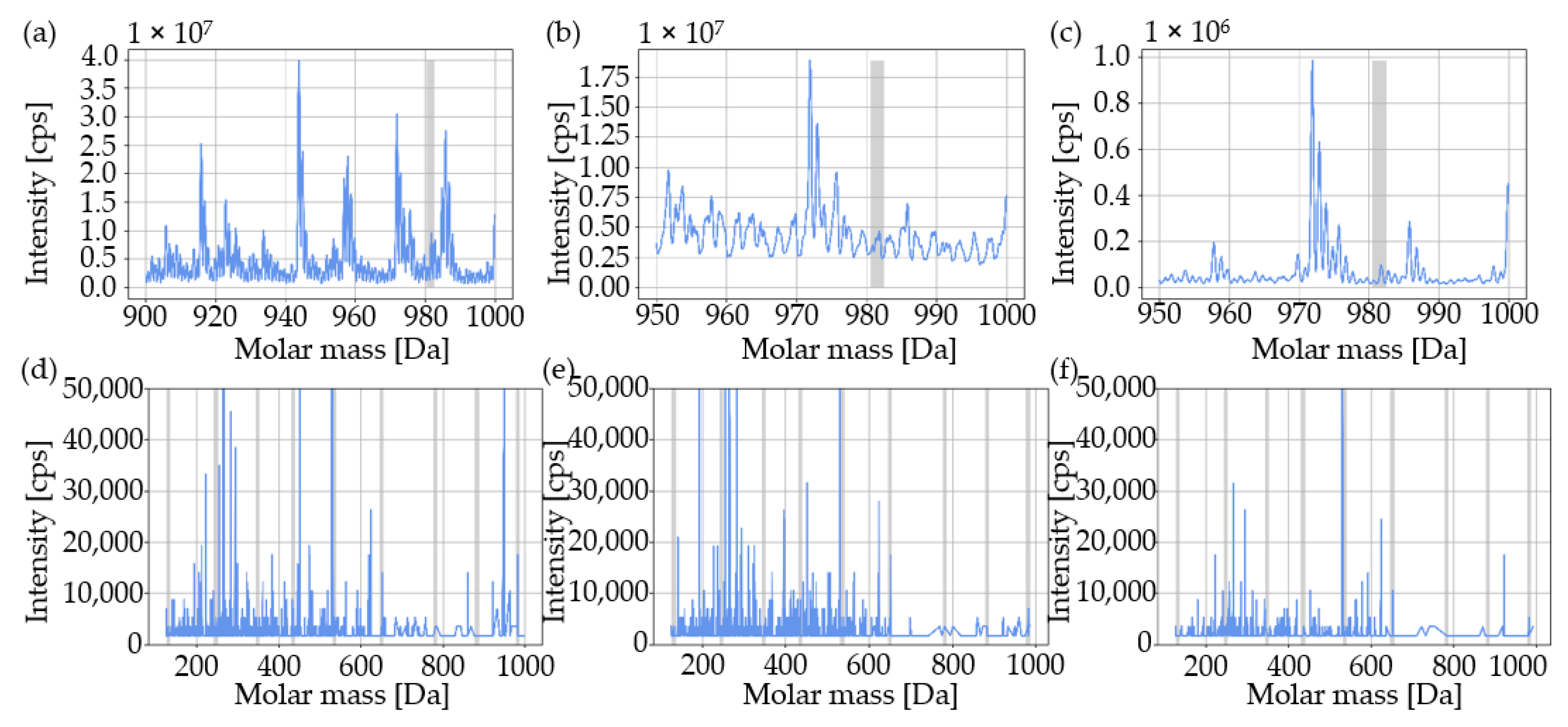

3.3. Traceability of the Modified Polymer Used

4. Discussion

5. Conclusions and Outlook

- Considering the applied investigations and concentrations of the modified polymer used in the injection molding material used, the marking technology does not have any discernible influence on the investigated properties of the material and components;

- During injection molding, the marked material shows analogous processing behavior to the unmarked material;

- The modified polymer used can be reliably detected in the material down to a concentration of 1 ppm, even after ten recycling steps;

- The concentration of the modified polymer and the measured intensity of the marking agent in the injection molding material used do not correlate;

- The dispersion of the modified polymer used in the injection molding material is sufficient;

- The modified polymer is suitable as a marking agent in injection molding;

- The modified polymer allows encoding of the material used at the molecular level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Isayev, A.I.; Kamal, M.R.; Liu, S.-J. (Eds.) Injection Molding: Technology and Fundamentals; Hanser: Munich, Germany; Cincinnati, OH, USA, 2009; ISBN 978-3-446-41685-7. [Google Scholar]

- Yang, Y.; Gao, F.; Lu, N.; Chen, X. Injection Molding Process Control, Monitoring, and Optimization; Hanser Publishers: Munich, Germany; Cincinnati, OH, USA, 2016; ISBN 978-1-56990-593-7. [Google Scholar]

- Rosato, D.V. (Ed.) Injection Molding Handbook, 3rd ed.; Kluwer Academic: Boston, MA, USA, 2000; ISBN 978-0-7923-8619-3. [Google Scholar]

- Osswald, T.A.; Turng, L.-S.; Gramann, P.J.; Beaumont, J. Injection Molding Handbook, 2nd ed.; Hanser Gardner: Munich, Germany; Cincinnati, OH, USA, 2008; ISBN 978-3-446-40781-7. [Google Scholar]

- Jansson, A.; Möller, K.; Gevert, T. Degradation of post-consumer polypropylene materials exposed to simulated recycling—Mechanical properties. Polym. Degrad. Stab. 2003, 82, 37–46. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, e2000415. [Google Scholar] [CrossRef] [PubMed]

- Lehner, R.; Weder, C.; Petri-Fink, A.; Rothen-Rutishauser, B. Emergence of Nanoplastic in the Environment and Possible Impact on Human Health. Environ. Sci. Technol. 2019, 53, 1748–1765. [Google Scholar] [CrossRef] [PubMed]

- Ölund, G.; Eriksson, E. Resthandteringsalternativ för Plastförpackningar–en Miljöpåverknadsbedömmning; CIT Ekologik Forsuring Tabell: Göteburg, Sweden, 1998. [Google Scholar]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; Wit, H.d. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Ehrenstein, G. Polymer-Werkstoffe: Struktur; Eigenschaften; Anwendung; Carl Hanser Fachbuchverlag: Munich, Germany, 2011; ISBN 978-3-446-42283-4. [Google Scholar]

- Dahlmann, R.; Haberstroh, E.; Menges, G. Menges Werkstoffkunde Kunststoffe, Vollständig neu Bearbeitete Auflage, 7th ed.; Hanser: Munich, Germany, 2022; ISBN 978-3-446-45801-7. [Google Scholar]

- Bonnet, M. Kunststoffe in der Ingenieuranwendung: Verstehen und Zuverlässig Auswählen; Vieweg + Teubner Verlag/GWV Fachverlage GmbH Wiesbaden: Wiesbaden, Germany, 2009; ISBN 978-3-8348-0349-8. [Google Scholar]

- Dostál, J.; Kašpárková, V.; Zatloukal, M.; Muras, J.; Šimek, L. Influence of the repeated extrusion on the degradation of polyethylene. Structural changes in low density polyethylene. Eur. Polym. J. 2008, 44, 2652–2658. [Google Scholar] [CrossRef]

- da Costa, H.M.; Ramos, V.D.; Rocha, M.C. Rheological properties of polypropylene during multiple extrusion. Polym. Test. 2005, 24, 86–93. [Google Scholar] [CrossRef]

- González-González, V.A.; Neira-Velázquez, G.; Angulo-Sánchez, J.L. Polypropylene chain scissions and molecular weight changes in multiple extrusion. Polym. Degrad. Stab. 1998, 60, 33–42. [Google Scholar] [CrossRef]

- Martins, M.H.; de Paoli, M.-A. Polypropylene compounding with post-consumer material. Polym. Degrad. Stab. 2002, 78, 491–495. [Google Scholar] [CrossRef]

- Tamrakar, S.; Couvreur, R.; Mielewski, D.; Gillespie, J.W.; Kiziltas, A. Effects of recycling and hygrothermal environment on mechanical properties of thermoplastic composites. Polym. Degrad. Stab. 2023, 207, 110233. [Google Scholar] [CrossRef]

- Kaiser, W. Kunststoffchemie für Ingenieure: Von der Synthese bis zur Anwendung, 5th ed.; Hanser: München, Germany, 2021; ISBN 978-3-446-45191-9. [Google Scholar]

- Abad, M.J.; Ares, A.; Barral, L.; Cano, J.; Díez, F.J.; García-Garabal, S.; López, J.; Ramírez, C. Effects of a mixture of stabilizers on the structure and mechanical properties of polyethylene during reprocessing. J. Appl. Polym. Sci. 2004, 92, 3910–3916. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Effect of recycling on rheological and mechanical properties of poly(lactic acid)/polystyrene polymer blend. J. Mater. Sci. 2011, 46, 3013–3019. [Google Scholar] [CrossRef]

- Marrone, M.; La Mantia, F.P. Re-stabilisation of recycled polypropylenes. Polym. Recycl. 1996, 2, 17–26. [Google Scholar]

- Catalina, F. Degradación y estabilización de polipropileno. Rev. Plásticos Mod. 1998, 502, 391–397. [Google Scholar]

- Tiganis, B.E.; Shanks, R.A.; Long, Y. Effects of processing on the microstructure, melting behavior, and equilibrium melting temperature of polypropylene. J. Appl. Polym. Sci. 1996, 59, 663–671. [Google Scholar] [CrossRef]

- Ying, Q.; Zhao, Y.; Liu, Y. A study of thermal oxidative and thermal mechanical degradation of polypropylene. Makromol. Chem. 1991, 192, 1041–1058. [Google Scholar] [CrossRef]

- Hinsken, H.; Moss, S.; Pauquet, J.-R.; Zweifel, H. Degradation of polyolefins during melt processing. Polym. Degrad. Stab. 1991, 34, 279–293. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Chanda, M.; Roy, S.K. Plastics Fabrication and Recycling; CRC Press: Boca Raton, FL, USA, 2016; ISBN 9781420080636. [Google Scholar]

- Marrone, M.; La Mantia, F.P. Monopolymers blends of virgin and recycled polypropylene. Polym. Recycl. 1996, 2, 9–15. [Google Scholar]

- Steigemann, U. Werkstoff- und ressourcenschonende Recyclingstrategien. Lightweight Des. 2012, 5, 26–31. [Google Scholar] [CrossRef]

- Wenguang, M.; La Mantia, F.P. Processing and mechanical properties of recycled PVC and of homopolymer blends with virgin PVC. J. Appl. Polym. Sci. 1996, 59, 759–767. [Google Scholar] [CrossRef]

- Wenguang, M.A.; La Mantia, F.P. Recycling of Post-consumer Polyethylene Greenhouse Films: Monopolymer Blends of recycled and virgin Polyethylene. Polym. Netw. Blends 1995, 5, 173–180. [Google Scholar]

- Valenza, A.; La Mantia, F.P. Recycling of polymer waste: Part II—Stress degraded polypropylene. Polym. Degrad. Stab. 1988, 20, 63–73. [Google Scholar] [CrossRef]

- Pfaendner, R.; Herbst, H.; Hoffmann, K.; Sitek, F. Recycling and restabilization of polymers for high quality applications. An Overview. Angew. Makromol. Chem. 1995, 232, 193–227. [Google Scholar] [CrossRef]

- Auer, M.; Schmidt, J.; Diemert, J.; Gerhardt, G.; Renz, M.; Galler, V.; Woidasky, J. Quality Aspects in the Compounding of Plastic Recyclate. Recycling 2023, 8, 18. [Google Scholar] [CrossRef]

- Eggers, T.; von Lacroix, F.; van de Kraan, F.; Reichler, A.-K.; Hürkamp, A.; Dröder, K. Investigations for Material Tracing in Selective Laser Sintering: Part I: Methodical Selection of a Suitable Marking Agent. Materials 2023, 16, 1043. [Google Scholar] [CrossRef]

- Eggers, T.; von Lacroix, F.; Goede, M.F.; Persch, C.; Berlin, W.; Dröder, K. Investigations for Material Tracing in Selective Laser Sintering: Part II: Validation of Modified Polymers as Marking Agents. Materials 2023, 16, 2631. [Google Scholar] [CrossRef]

- Lutz, J.-F. Coding macromolecules: Inputting information in polymers using monomer-based alphabets. Macromolecules 2015, 48, 4759–4767. [Google Scholar] [CrossRef]

- Lutz, J.-F. Les Polymères, Messagers à l’Échelle Moléculaire. IT Ind. Technol. 2021, 1–11. [Google Scholar]

- Fearon, P.K.; Marshall, N.; Billingham, N.C.; Bigger, S.W. Evaluation of the oxidative stability of multiextruded polypropylene as assessed by physicomechanical testing and simultaneous differential scanning calorimetry-chemiluminescence. J. Appl. Polym. Sci. 2001, 79, 733–741. [Google Scholar] [CrossRef]

- Incarnato, L.; Scarfato, P.; Acierno, D. Rheological and mechanical properties of recycled polypropylene. Polym. Eng. Sci. 1999, 39, 749–755. [Google Scholar] [CrossRef]

- Incarnato, L.; Scarfato, P.; Gorrasi, G.; Vittoria, V.; Acierno, D. Structural modifications induced by recycling of polypropylene. Polym. Eng. Sci. 1999, 39, 1661–1666. [Google Scholar] [CrossRef]

- Kartalis, C.N.; Papaspyrides, C.D.; Pfaendner, R.; Hoffmann, K.; Herbst, H. Mechanical recycling of postused high-density polyethylene crates using the restabilization technique. I. Influence of reprocessing. J. Appl. Polym. Sci. 1999, 73, 1775–1785. [Google Scholar] [CrossRef]

- Dintcheva, N.; Jilov, N.; La Mantia, F.P. Recycling of plastics from packaging. Polym. Degrad. Stab. 1997, 57, 191–203. [Google Scholar] [CrossRef]

- Hopmann, C.; Michaeli, W. Einführung in die Kunststoffverarbeitung; Hanser: München, Germany, 2017; ISBN 978-3-446-45355-5. [Google Scholar]

- Moalli, J. (Ed.) Plastics Failure: Analysis and Prevention; Plastics Design Library: Norwich, NY, USA, 2010; ISBN 9781884207921. [Google Scholar]

- Eyerer, P.; Elsner, P.; Hirth, T. Polymer Engineering: Technologien und Praxis; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-72402-5. [Google Scholar]

- Baur, E.; Brinkmann, S.; Osswald, T.A.; Schmachtenberg, E. Saechtling Kunststoff Taschenbuch; Hanser: München, Germany, 2013; ISBN 978-3-446-43442-4. [Google Scholar]

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. (Eds.) Kunststoffe: Eigenschaften und Anwendungen; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 9783642161728. [Google Scholar]

- Pasquini, N.; Addeo, A. (Eds.) Polypropylene Handbook, 2nd ed.; Hanser: Munich, Germany, 2005; ISBN 3-446-22978-7. [Google Scholar]

- Gruden, D. Umweltschutz in der Automobilindustrie: Motor, Kraftstoffe, Recycling; Vieweg + Teubner/GWV Fachverlage GmbH Wiesbaden: Wiesbaden, Germany, 2008; ISBN 978-3-8348-0404-4. [Google Scholar]

- Dost, G.; Kummer, B.; Matloubi, M.; Moesslein, J.; Treick, A. Produkt- und Materialpässe Nützen der Kreislaufwirtschaft Nur, Wenn sie Tatsächlich Robust mit Produkten und Materialien Verknüpft Sind! Kurzfassung, Freiburg, Germany. 2022. Available online: https://polysecure.eu/fileadmin/main/Unternehmen/Media-Files/220425_Produkt_Materialpass_Kurzfassung_Dt.pdf (accessed on 20 August 2022).

- Dost, G.; Matloubi, M.; Treick, A.; Kummer, B. Booster für eine gelingende Kreislaufwirtschaft. Recycl. Mag. Sonderh 2022, 84–86. [Google Scholar]

- Youssef, I.; Carvin-Sergent, I.; Konishcheva, E.; Kebe, S.; Greff, V.; Karamessini, D.; Matloubi, M.; Ouahabi, A.A.; Moesslein, J.; Amalian, J.-A.; et al. Covalent Attachment and Detachment by Reactive DESI of Sequence-Coded Polymer Taggants. Macromol. Rapid Commun. 2022, 43, 2200412. [Google Scholar] [CrossRef]

- DIN EN ISO 19069-2:2020-01; Kunststoffe—Polypropylen (PP)-Formmassen—Teil 2: Herstellung von Probekörpern und Bestimmung von Eigenschaften (ISO 19069-2:2016). Beuth Verlag GmbH: Berlin, Germany, 2020; Deutsche Fassung EN ISO 19069-2:2016.

- DIN EN ISO 527-2:2012-06; Kunststoffe—Bestimmung der Zugeigenschaften—Teil 2: Prüfbedingungen für Form und Extrusionsmassen (ISO 527-2:2012). Beuth Verlag GmbH: Berlin, Germany, 2012; Deutsche Fassung EN ISO 527-2:2012.

- DIN EN ISO 11358-1:2022-07; Kunststoffe—Thermogravimetrie (TG) von Polymeren—Teil 1: Allgemeine Grundsätze (ISO 11358-1:2022). Beuth Verlag GmbH: Berlin, Germany, 2022; Deutsche Fassung EN ISO 11358-1:2022.

- Frick, A.; Stern, C. Einführung in die Kunststoffprüfung: Prüfmethoden und Anwendungen; Hanser: München, Germany, 2017; ISBN 978-3-446-44351-8. [Google Scholar]

- DIN EN ISO 11357-1:2023-06; Kunststoffe—Dynamische Differenzkalorimetrie (DSC)—Teil 1: Allgemeine Grundlagen (ISO 11357-1:2023). Beuth Verlag GmbH: Berlin, Germany, 2023; Deutsche Fassung EN ISO 11357-1:2023.

- DIN EN ISO 1133-1:2012-03; Kunststoffe—Bestimmung der Schmelze-Massefließrate (MFR) und der Schmelze-Volumenfließrate (MVR) von Thermoplasten—Teil 1: Allgemeines Prüfverfahren (ISO 1133-1:2011). Beuth Verlag GmbH: Berlin, Germany, 2012; Deutsche Fassung EN ISO 1133-1:2011.

- Mielicki, C. Prozessnahes Qualitätsmanagement beim Lasersintern von Polyamid 12. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg/Essen, Germany, 2014. [Google Scholar]

- DIN EN ISO 527-1:2019-12; Kunststoffe—Bestimmung der Zugeigenschaften—Teil 1: Allgemeine Grundsätze (ISO 527-1:2019). Beuth Verlag GmbH: Berlin, Germany, 2019; Deutsche Fassung EN ISO 527-1:2019.

- DIN EN ISO 179-1:2010-11; Kunststoffe—Bestimmung der Charpy-Schlageigenschaften—Teil 1: Nicht Instrumentierte Schlagzähigkeitsprüfung (ISO 179-1:2010). Beuth Verlag GmbH: Berlin, Germany, 2010; Deutsche Fassung EN ISO 179-1:2010.

- DIN EN ISO 3167:2014-11; Kunststoffe—Vielzweckprobekörper (ISO 3167:2014). Beuth Verlag GmbH: Berlin, Germany, 2014; Deutsche Fassung EN ISO 3167:2014.

- DIN EN ISO 306:2023-03; Kunststoffe—Thermoplaste—Bestimmung der Vicat-Erweichungstemperatur (VST) (ISO 306:2022). Beuth Verlag GmbH: Berlin, Germany, 2023; Deutsche Fassung EN ISO 306:2022.

- Grellmann, W.; Seidler, S. (Eds.) Kunststoffprüfung; Hanser-Verlag: München, Germant, 2011; ISBN 9783446427228. [Google Scholar]

- Arndt, K.-F.; Lechner, M.D. Polymer Solids and Polymer Melts–Mechanical and Thermomechanical Properties of Polymers; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-55165-9. [Google Scholar]

- Al Ouahabi, A.; Amalian, J.-A.; Charles, L.; Lutz, J.-F. Mass spectrometry sequencing of long digital polymers facilitated by programmed inter-byte fragmentation. Nat. Commun. 2017, 8, 967. [Google Scholar] [CrossRef]

- Gunay, U.S.; Petit, B.E.; Karamessini, D.; Al Ouahabi, A.; Amalian, J.-A.; Chendo, C.; Bouquey, M.; Gigmes, D.; Charles, L.; Lutz, J.-F. Chemoselective synthesis of uniform sequence-coded polyurethanes and their use as molecular tags. Chem 2016, 1, 114–126. [Google Scholar] [CrossRef]

- Lutz, J.-F.; Ouchi, M.; Liu, D.R.; Sawamoto, M. Sequence-controlled polymers. Science 2013, 341, 1238149. [Google Scholar] [CrossRef] [PubMed]

- Guerrica-Echevarría, G.; Eguiazábal, J.I.; Nazábal, J. Effects of reprocessing conditions on the properties of unfilled and talc-filled polypropylene. Polym. Degrad. Stab. 1996, 53, 1–8. [Google Scholar] [CrossRef]

- Setnescu, R.; Barcutean, C.; Jipa, S.; Setnescu, T.; Negoiu, M.; Mihalcea, I.; Dumitru, M.; Zaharescu, T. The effect of some thiosemicarbazide compounds on thermal oxidation of polypropylene. Polym. Degrad. Stab. 2004, 85, 997–1001. [Google Scholar] [CrossRef]

- Jipa, S.; Setnescu, R.; Setnescu, T.; Zaharescu, T. Efficiency assessment of additives in thermal degradation of i-PP by chemiluminescence I. Triazines. Polym. Degrad. Stab. 2000, 68, 159–164. [Google Scholar] [CrossRef]

- Gregorová, A.; Cibulková, Z.; Košíková, B.; Šimon, P. Stabilization effect of lignin in polypropylene and recycled polypropylene. Polym. Degrad. Stab. 2005, 89, 553–558. [Google Scholar] [CrossRef]

- Tocháček, J. Effect of secondary structure on physical behaviour and performance of hindered phenolic antioxidants in polypropylene. Polym. Degrad. Stab. 2004, 86, 385–389. [Google Scholar] [CrossRef]

- Gugumus, F. Aspects of the impact of stabilizer mass on performance in polymers 2. Effect of increasing molecular mass of polymeric HALS in PP. Polym. Degrad. Stab. 2000, 67, 299–311. [Google Scholar] [CrossRef]

- Chmela, Š.; Hrdlovič, P. The influence of substituents on the photo-stabilizing efficiency of hindered amine stabilizers in polypropylene. Polym. Degrad. Stab. 1990, 27, 159–167. [Google Scholar] [CrossRef]

- Hamid, S.H. Handbook of Polymer Degradation; CRC Press: Boca Raton, FL, USA, 2000; ISBN 9780429082580. [Google Scholar]

- Gijsman, P.; Gitton, M. Hindered amine stabilisers as long-term heat stabilisers for polypropylene. Polym. Degrad. Stab. 1999, 66, 365–371. [Google Scholar] [CrossRef]

- Buttitta, A. “Tracer-Based-Sorting”—Die Zukunft der Kunststoffverwertung. EU-Recycl. Fachmag. Eur. Recycl. 2021, 38, 16–18. [Google Scholar]

- Kausch, H.-H. (Ed.) Intrinsic Molecular Mobility and Toughness of Polymers II; Springer-Verlag GmbH: Berlin/Heidelberg, Germany, 2005; ISBN 978-3-540-26162-9. [Google Scholar]

- Canevarolo, S.V. Chain scission distribution function for polypropylene degradation during multiple extrusions. Polym. Degrad. Stab. 2000, 70, 71–76. [Google Scholar] [CrossRef]

- Wortberg, J. Qualitätssicherung in der Kunststoffverarbeitung: Rohstoff-, Prozess- und Produktqualität; Tabellen; Hanser: München, Germany; Wien, Austria, 1996; ISBN 9783446171336. [Google Scholar]

- Pahl, M.; Gleißle, W.; Laun, H.-M. (Eds.) Praktische Rheologie der Kunststoffe und Elastomere; VDI-Verlag: Düsseldorf, Germany, 1995; ISBN 978-3-18-234192-5. [Google Scholar]

- World Encyclopedia. Modern Plastics Worldwide. 2007, pp. 160–217. Available online: https://www.plasticstoday.com/resin-pricing/ (accessed on 17 June 2023).

- Meneghetti, G.; Ricotta, M.; Sanità, M.; Refosco, D. Fully Reversed Axial Notch Fatigue Behaviour of Virgin and Recycled Polypropylene Compounds. Procedia Struct. Integr. 2016, 2, 2255–2262. [Google Scholar] [CrossRef]

- Elloumi, A.; Pimbert, S.; Bourmaud, A.; Bradai, C. Thermomechanical properties of virgin and recycled polypropylene impact copolymer/CaCO3 nanocomposites. Polym. Eng. Sci. 2010, 50, 1904–1913. [Google Scholar] [CrossRef]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145. [Google Scholar] [CrossRef]

- Brostow, W.; Corneliussen, R.D. (Eds.) Failure of Plastics; Hanser: Munich, Germany, 1986; ISBN 9780029475102. [Google Scholar]

- Coulier, L.; Orbons, H.G.; Rijk, R. Analytical protocol to study the food safety of (multiple-)recycled high-density polyethylene (HDPE) and polypropylene (PP) crates: Influence of recycling on the migration and formation of degradation products. Polym. Degrad. Stab. 2007, 92, 2016–2025. [Google Scholar] [CrossRef]

- Scaffaro, R.; La Mantia, F.P.; Botta, L.; Morreale, M.; Tz. Dintcheva, N.; Mariani, P. Competition between chain scission and branching formation in the processing of high-density polyethylene: Effect of processing parameters and of stabilizers. Polym. Eng. Sci. 2009, 49, 1316–1325. [Google Scholar] [CrossRef]

- Mendes, A.A.; Cunha, A.M.; Bernardo, C.A. Study of the degradation mechanisms of polyethylene during reprocessing. Polym. Degrad. Stab. 2011, 96, 1125–1133. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, X.Y.; Sun, Z.Y. Study on the Properties of Multi-Extruded Recycled PE and PP. AMR 2014, 1003, 96–99. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Shanks, R.A.; Combe, M.; Collister, T. Mechanical reprocessing of polyolefin waste: A review. Polym. Eng. Sci. 2015, 55, 2899–2909. [Google Scholar] [CrossRef]

- Baltes, L.; Costiuc, L.; Patachia, S.; Tierean, M. Differential scanning calorimetry—A powerful tool for the determination of morphological features of the recycled polypropylene. J. Therm. Anal. Calorim. 2019, 138, 2399–2408. [Google Scholar] [CrossRef]

- Gupta, V.B.; Mittal, R.K.; Sharma, P.K.; Mennig, G.; Wolters, J. Some studies on glass fiber-reinforced polypropylene. Part II: Mechanical properties and their dependence on fiber length, interfacial adhesion, and fiber dispersion. Polym. Compos. 1989, 10, 16–27. [Google Scholar] [CrossRef]

- Battisti, M. Spritzgießcompoundieren von Polymer-Nanocomposites auf Basis von Schichtsilikaten. Ph.D. Thesis, University of Leoben, Leoben, Austria, 2015. [Google Scholar]

- Celina, M.; George, G.A. A heterogeneous model for the thermal oxidation of solid polypropylene from chemiluminescence analysis. Polym. Degrad. Stab. 1993, 40, 323–335. [Google Scholar] [CrossRef]

- Celina, M.; George, G.A. Heterogeneous and homogeneous kinetic analyses of the thermal oxidation of polypropylene. Polym. Degrad. Stab. 1995, 50, 89–99. [Google Scholar] [CrossRef]

- Gugumus, F. Thermooxidative degradation of polyolefins in the solid state—6. Kinetics of thermal oxidation of polypropylene. Polym. Degrad. Stab. 1998, 62, 235–243. [Google Scholar] [CrossRef]

- Gugumus, F. Thermooxidative degradation of polyolefins in the solid state—7. Effect of sample thickness and heterogeneous oxidation kinetics for polypropylene. Polym. Degrad. Stab. 1998, 62, 245–257. [Google Scholar] [CrossRef]

- Knight, J.B.; Calvert, P.D.; Billingham, N.C. Localization of oxidation in polypropylene. Polymer 1985, 26, 1713–1718. [Google Scholar] [CrossRef]

- Richters, P. Initiation Process in the Oxidation of Polypropylene. Macromolecules 1970, 3, 262–264. [Google Scholar] [CrossRef]

- Ibhadon, A.O. Fracture mechanics of polypropylene: Effect of molecular characteristics, crystallization conditions, and annealing on morphology and impact performance. J. Appl. Polym. Sci. 1998, 69, 2657–2661. [Google Scholar] [CrossRef]

- Greco, R.; Coppola, F. Influence of crystallization conditions on the mechanical properties of isotactic polypropylene. Plast. Rubber Process. Appl. 1986, 6, 35–41. [Google Scholar]

- Seiffert, S.; Kummerlöwe, C.; Vennemann, N. (Eds.) Makromolekulare Chemie: Ein Lehrbuch für Chemiker, Physiker, Materialwissenschaftler und Verfahrenstechniker; Springer Spektrum: Berlin, Germany, 2020; ISBN 978-3-662-61108-1. [Google Scholar]

- Karger-Kocsis, J. Polypropylene Structure, Blends and Composites: Volume 3 Composites; Springer: Dordrecht, The Netherlands, 1995; ISBN 978-94-010-4233-8. [Google Scholar]

- Greco, R.; Ragosta, G. Isotactic polypropylenes of different molecular characteristics: Influence of crystallization conditions and annealing on the fracture behaviour. J. Mater. Sci. 1988, 23, 4171–4180. [Google Scholar] [CrossRef]

- Sugimoto, M.; Ishikawa, M.; Hatada, K. Toughness of polypropylene. Polymer 1995, 36, 3675–3682. [Google Scholar] [CrossRef]

- Tjong, S.C.; Shen, J.S.; Li, R. Morphological behaviour and instrumented dart impact properties of β-crystalline-phase polypropylene. Polymer 1996, 37, 2309–2316. [Google Scholar] [CrossRef]

- Jancar, J.; DiAnselmo, A.; DiBenedetto, A.T.; Kucera, J. Failure mechanics in elastomer toughened polypropylene. Polymer 1993, 34, 1684–1694. [Google Scholar] [CrossRef]

- DIN EN ISO 179-2:2020-09; Kunststoffe—Bestimmung der Charpy-Schlageigenschaften—Teil 2: Instrumentierte Schlagzähigkeitsprüfung (ISO 179-2:2020). Beuth Verlag GmbH: Berlin, Germany, 2020; Deutsche Fassung EN ISO 179-2:2020.

- Moerl, M. Steigerung der Zähigkeit von Isotaktischem Polypropylen durch Kontrolle der Morphologie Mittels 1,3,5-Benzoltrisamiden. Ph.D. Thesis, Universität Bayreuth, Bayreuth, Germany, 2017. [Google Scholar]

- Carlowitz, B. Tabellarische Übersicht über die Prüfung von Kunststoffen; Giesel-Verl. für Publizität: Isernhagen, Germany, 1992; ISBN 978-3980294201. [Google Scholar]

- Bastian, M.; Hochrein, T. Einfärben von Kunststoffen: Produktanforderungen—Verfahrenstechnik—Prüfmethodik; Hanser: Munich, Germany, 2018; ISBN 978-3-446-45398-2. [Google Scholar]

- Johnsen, U.; Spilgies, G.; Zachmann, H.G. Abhängigkeit der heterogenen Keimbildung in Polypropylen von der Kristallisationstemperatur und von der Art der Beimengung der Fremdsubstanz. Kolloid Z.U.Z.Polym. 1970, 240, 762–765. [Google Scholar] [CrossRef]

- Hornbogen, E.; Eggeler, G.; Werner, E. Werkstoffe: Aufbau und Eigenschaften von Keramik-, Metall-, Polymer- und Verbundwerkstoffen; Springer Vieweg: Berlin, Germany, 2017; ISBN 978-3-642-53866-7. [Google Scholar]

- Amalian, J.-A.; Mondal, T.; Konishcheva, E.; Cavallo, G.; Petit, B.E.; Lutz, J.-F.; Charles, L. Desorption electrospray ionization (DESI) of digital polymers: Direct tandem mass spectrometry decoding and imaging from materials surfaces. Adv. Mater. Technol. 2021, 6, 2001088. [Google Scholar] [CrossRef]

- Takats, Z.; Wiseman, J.M.; Gologan, B.; Cooks, R.G. Mass spectrometry sampling under ambient conditions with desorption electrospray ionization. Science 2004, 306, 471–473. [Google Scholar] [CrossRef]

- Cooks, R.G.; Ouyang, Z.; Takats, Z.; Wiseman, J.M. Ambient mass spectrometry. Science 2006, 311, 1566–1570. [Google Scholar] [CrossRef]

| Main Molar Mass [Da] | Sequences [Da] |

|---|---|

| 918.5 | 131.0|246.2|347.3|434.3|535.4|650.4|781.4|882.5|981.5 |

| Option | Selected Setting |

|---|---|

| Temperatures (hopper to nozzle) [°C] | 35|180|190|195|200|200 |

| Mold temperature [°C] | 40 |

| Dosing quantity [cm3] | 36.5 |

| Decompression [cm3] | 3 |

| Screw speed [m/s] | 0.25 |

| Back pressure [bar] | 80 |

| Residual mass cushion [m3] | 4.6 |

| Volume flow [cm3/s] | 16 |

| Max. injection pressure [bar] | 280 |

| Switching volume [cm3] | 7 |

| Max. hold pressure [bar] | 200 |

| Hold time [s] | 40 |

| Residual cooling time [s] | 18 |

| Type | Dimension | Number | Usage |

|---|---|---|---|

| Tensile bar 1 | 1A 2 | 5 | Tensile test |

| Tensile bar 1 | 1A 2 | 10 | Vicat softening temperature test, Charpy impact test |

| Tensile bar 1 | 1A 2 | 2 | Traceability |

| Option | Selected Setting |

|---|---|

| Temperature (hopper to nozzle) [°C] | 50|190|190|190|190|190|195|195|200|200|200 |

| Temperature at the output [°C] | 209 |

| Screw speed [1/min] | 160 |

| Nozzle head pressure [bar] | 12 |

| Volume flow [kg/h] | 8 |

| Capacity utilization [%] | 30 |

| Cut-off speed [m/min] | 33 |

| Sample | Analyzed Quantity | Extraction Method |

|---|---|---|

| Granulate | 5 g | Mixed with 10 mL of ethanol Placed in an ultrasonic bath at 40 °C for a duration of 30 min Filtration with a 22 µm filter Placed in a rotary vacuum evaporator Dilution with 2 mL of methanol and 3 mmol of ammonium acetate |

| Component 1 |

| Properties | Injection Molding Material | Master Batch |

|---|---|---|

| PE 1 onset crystallization temperature [°C] | 113.16 | 113.09 |

| PE crystallization temperature [°C] | 110.02 | 109.95 |

| PE onset melting temperature [°C] | 107.86 | 107.01 |

| PE melting temperature [°C] | 121.31 | 120.95 |

| PP 2 onset crystallization temperature [°C] | 133.30 | 133.02 |

| PP crystallization temperature [°C] | 129.69 | 129.28 |

| PP onset melting temperature [°C] | 158.43 | 159.11 |

| PP melting temperature [°C] | 168.62 | 167.75 |

| Max. pyrolytic degradation temperature [°C] | 473.95 | 475.56 |

| Residue [%] | 9.1925 | 9.2435 |

| Melt flow rate [g/10 min] | 17.73 ± 0.19 | 17.31 ± 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eggers, T.; Blumberg, S.M.; von Lacroix, F.; Berlin, W.; Dröder, K. Influence Analysis of Modified Polymers as a Marking Agent for Material Tracing during Cyclic Injection Molding. Materials 2023, 16, 6304. https://doi.org/10.3390/ma16186304

Eggers T, Blumberg SM, von Lacroix F, Berlin W, Dröder K. Influence Analysis of Modified Polymers as a Marking Agent for Material Tracing during Cyclic Injection Molding. Materials. 2023; 16(18):6304. https://doi.org/10.3390/ma16186304

Chicago/Turabian StyleEggers, Tom, Sonja Marit Blumberg, Frank von Lacroix, Werner Berlin, and Klaus Dröder. 2023. "Influence Analysis of Modified Polymers as a Marking Agent for Material Tracing during Cyclic Injection Molding" Materials 16, no. 18: 6304. https://doi.org/10.3390/ma16186304

APA StyleEggers, T., Blumberg, S. M., von Lacroix, F., Berlin, W., & Dröder, K. (2023). Influence Analysis of Modified Polymers as a Marking Agent for Material Tracing during Cyclic Injection Molding. Materials, 16(18), 6304. https://doi.org/10.3390/ma16186304