Hierarchical Multiple Precursors Induced Heterogeneous Structures in Super Austenitic Stainless Steels by Cryogenic Rolling and Annealing

Abstract

:1. Introduction

2. Materials and Methods

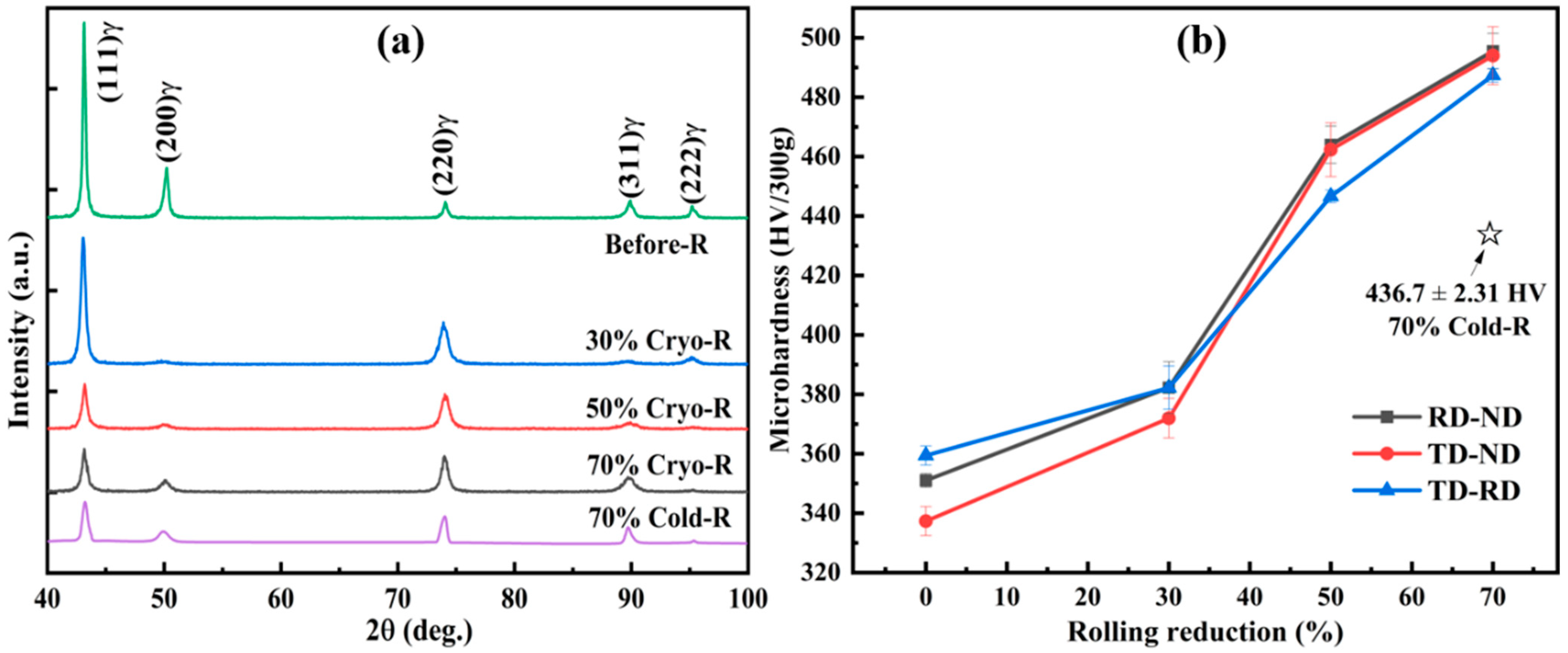

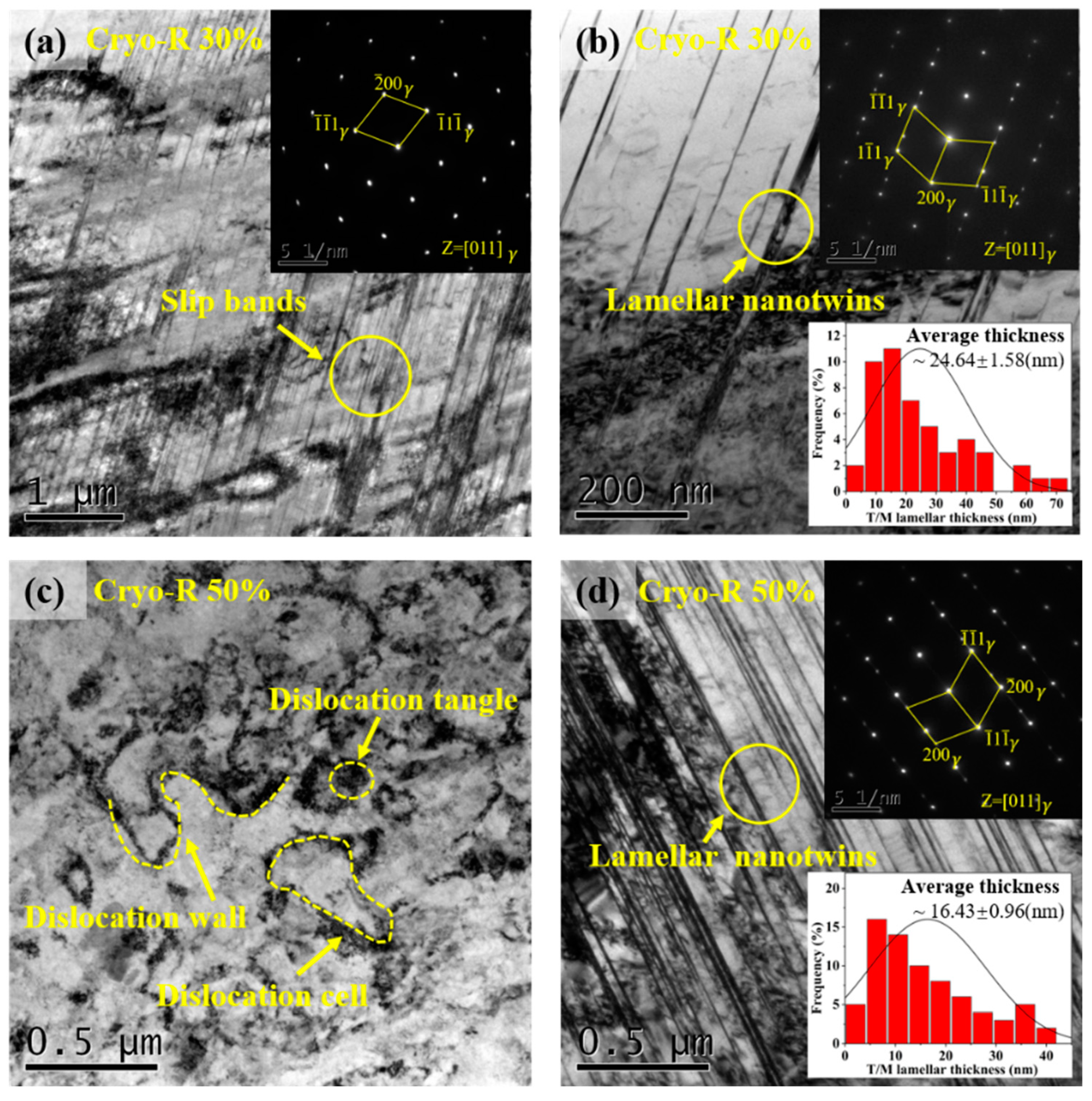

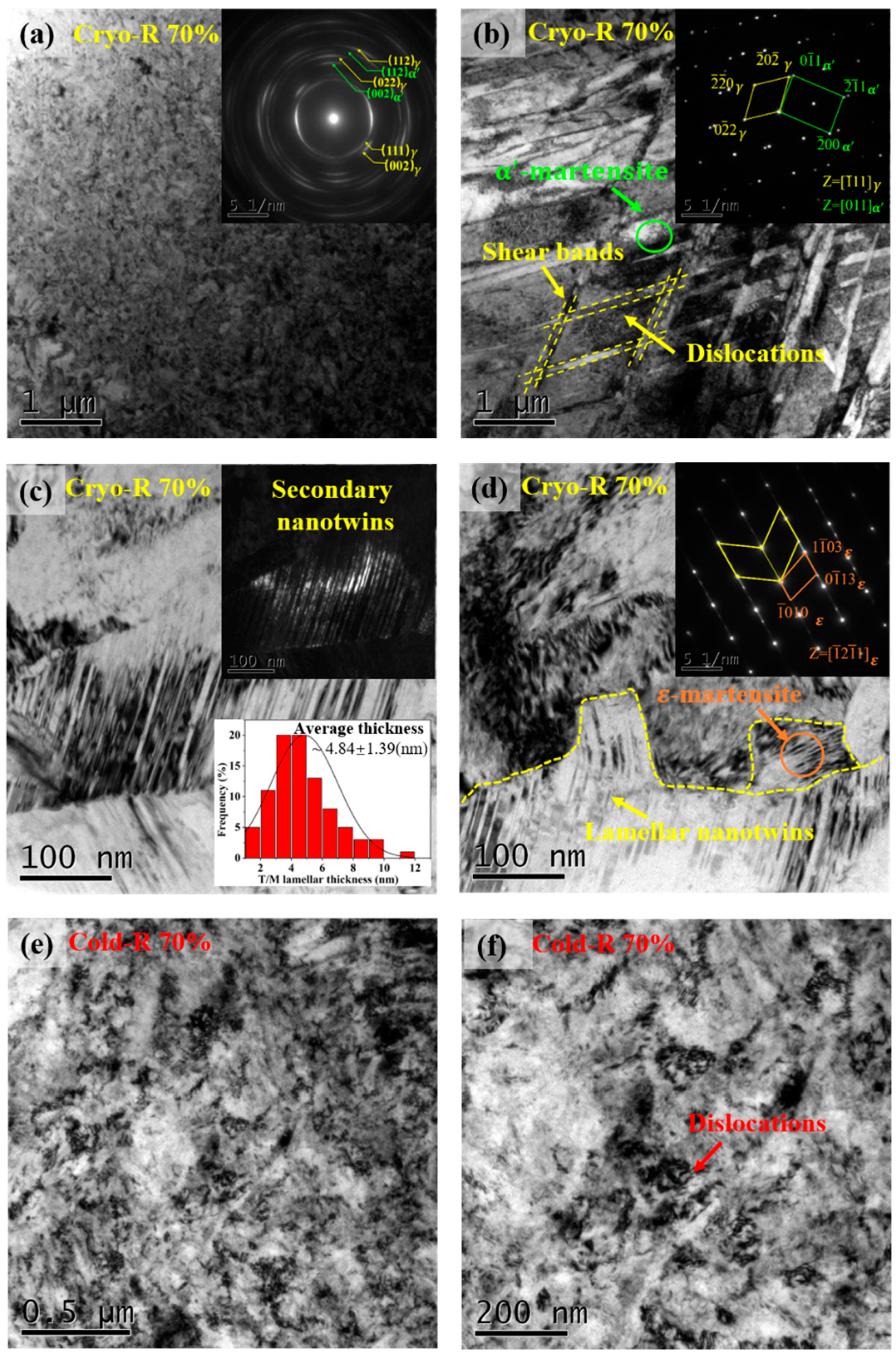

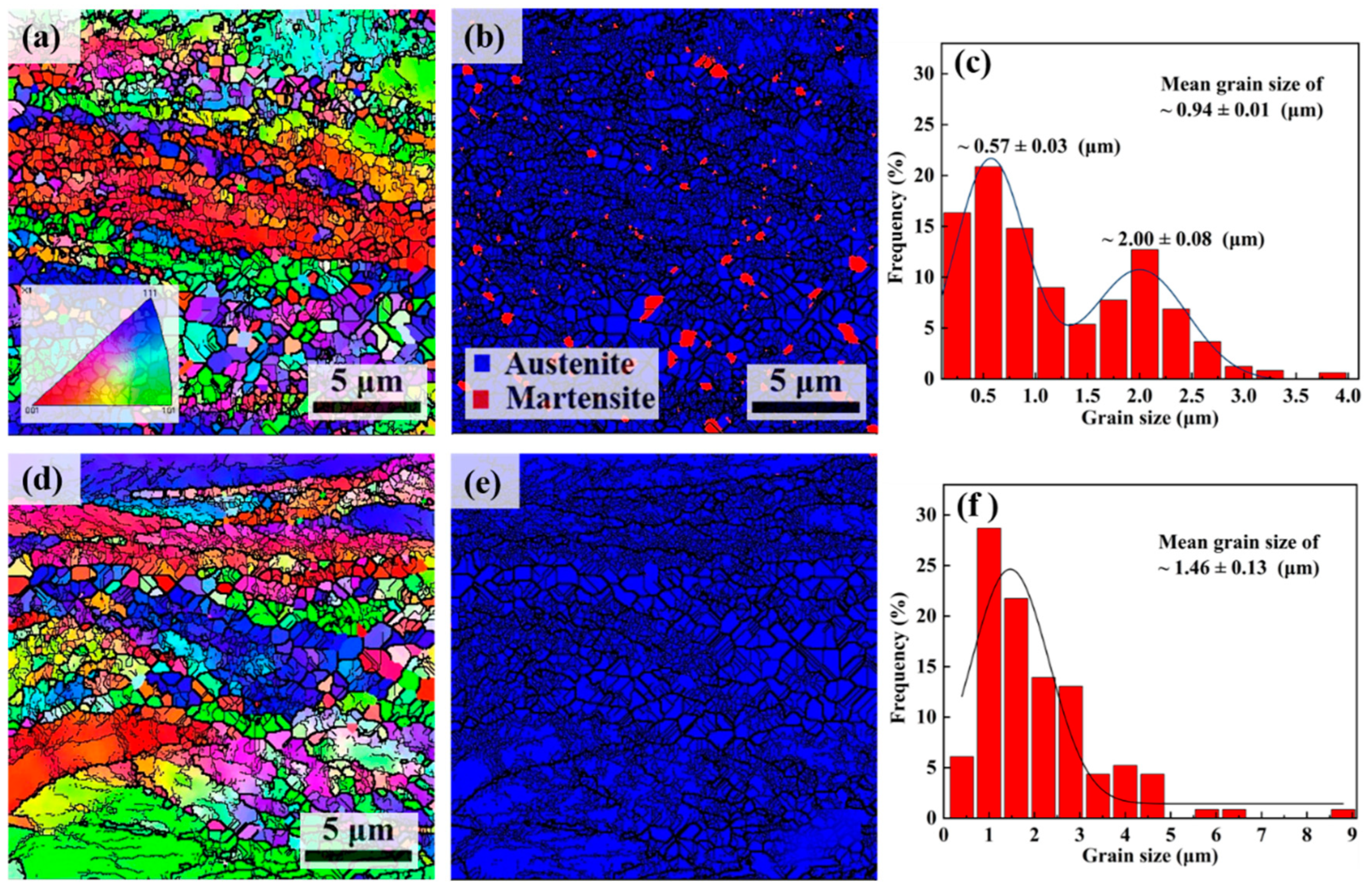

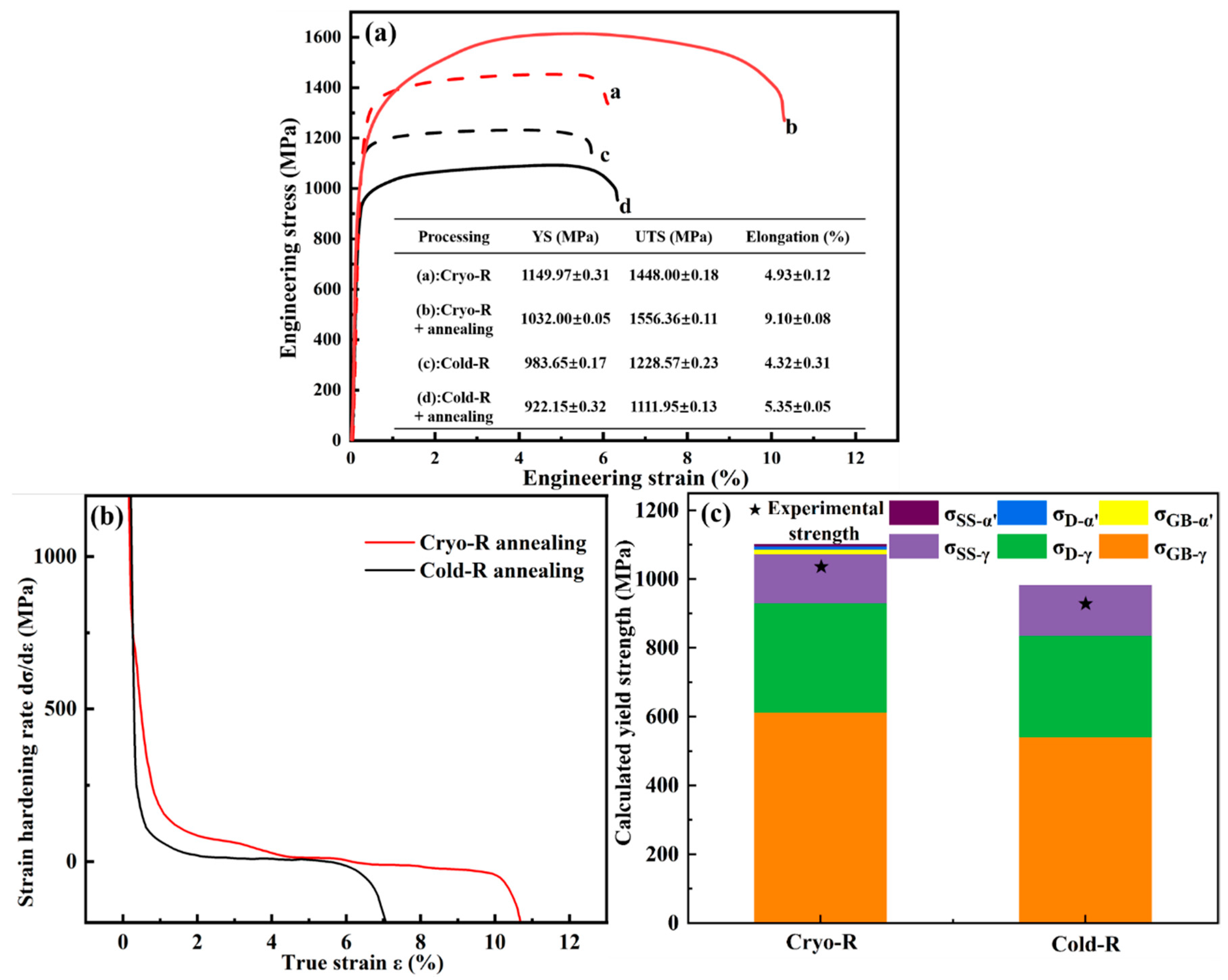

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sunny, K.T.; Naik, K.N. A systematic review about welding of super austenitic stainless steel. Mater. Today Proc. 2021, 47, 41–44. [Google Scholar] [CrossRef]

- Xin, H.; Zhuyu, W.; Lin, W.; Chen, C.; Fucheng, Z.; Wei, Z. Effect of pre-deformation on hot workability of super austenitic stainless steel. J. Mater. Res. Technol. 2022, 16, 66–75. [Google Scholar]

- Zhang, Z.B.; Mishin, O.V.; Tao, N.R.; Pantleon, W. Microstructure and annealing behavior of a modified 9Cr−1Mo steel after dynamic plastic deformation to different strains. J. Nucl. Mater. 2015, 458, 458–463. [Google Scholar] [CrossRef]

- Yan, F.K.; Liu, G.Z.; Tao, N.R.; Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 2012, 60, 1059–1071. [Google Scholar] [CrossRef]

- Tianyi, S.; Zhongxia, S.; Jaehun, C.; Jie, D.; Tongjun, N.; Yifan, Z.; Bo, Y.; Dongyue, X.; Jian, W.; Haiyan, W.; et al. Ultra-fine-grained and gradient FeCrAl alloys with outstanding work hardening capability. Acta Mater. 2021, 215, 215–223. [Google Scholar]

- Li, W.L.; Tao, N.R.; Lu, K. Fabrication of a gradient nano-micro-structured surface layer on bulk copper by means of a surface mechanical grinding treatment. Scr. Mater. 2008, 59, 546–549. [Google Scholar] [CrossRef]

- Li, J.; Mao, Q.; Nie, J.; Huang, Z.; Wang, S.; Li, Y. Impact property of high-strength 316L stainless steel with heterostructures. Mater. Sci. Eng. A 2019, 754, 457–460. [Google Scholar] [CrossRef]

- Huang, C.X.; Hu, W.P.; Wang, Q.Y.; Wang, C.; Yang, G.; Zhu, Y.T. An Ideal Ultrafine-Grained Structure for High Strength and High Ductility. Mater. Res. Lett. 2014, 3, 88–94. [Google Scholar] [CrossRef]

- Roy, B.; Kumar, R.; Das, J. Effect of cryorolling on the microstructure and tensile properties of bulk nano-austenitic stainless steel. Mater. Sci. Eng. A 2015, 631, 241–247. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef]

- Kalsar, R.; Ray, R.K.; Suwas, S. Effects of alloying addition on deformation mechanisms, microstructure, texture and mechanical properties in Fe-12Mn-0.5C austenitic steel. Mater. Sci. Eng. A 2018, 729, 385–397. [Google Scholar] [CrossRef]

- Achmad, T.L.; Fu, W.; Chen, H.; Zhang, C.; Yang, Z.-G. Effects of alloying elements concentrations and temperatures on the stacking fault energies of Co-based alloys by computational thermodynamic approach and first-principles calculations. J. Alloys Compd. 2017, 694, 1265–1279. [Google Scholar] [CrossRef]

- Fu, B.; Ge, Y.; Guan, W.; Guo, Y.; Wang, Z.; Ding, Y. Maintaining microstructure ultra-refinement in the austenitic stainless steel by inducing χ phase precipitating through severe cold rolling and annealing. Mater. Res. Express 2022, 9, 046515. [Google Scholar] [CrossRef]

- Shu, J.; Wu, Y.; Ji, Y.; Chen, M.; Wu, H.; Gao, Y.; Wei, L.; Zhao, L.; Huo, T.; Liu, R. A new electrochemical method for simultaneous removal of Mn(2+)and NH(4)(+)-N in wastewater with Cu plate as cathode. Ecotoxicol. Environ. Saf. 2020, 206, 111341. [Google Scholar] [CrossRef]

- Ye, K.L.; Luo, H.Y.; Lv, J.L. Producing Nanostructured 304 Stainless Steel by Rolling at Cryogenic Temperature. Mater. Manuf. Process. 2014, 29, 754–758. [Google Scholar] [CrossRef]

- Xiong, Y.; Yue, Y.; Lu, Y.; He, T.; Fan, M.; Ren, F.; Cao, W. Cryorolling impacts on microstructure and mechanical properties of AISI 316 LN austenitic stainless steel. Mater. Sci. Eng. A 2018, 709, 270–276. [Google Scholar] [CrossRef]

- Seol, J.-B.; Jung, J.E.; Jang, Y.W.; Park, C.G. Influence of carbon content on the microstructure, martensitic transformation and mechanical properties in austenite/ε-martensite dual-phase Fe–Mn–C steels. Acta Mater. 2013, 61, 558–578. [Google Scholar] [CrossRef]

- Lee, T.-H.; Kim, S.-J.; Jung, Y.-C. Crystallographic Details of Precipitates in Fe-22Cr-21Ni-6Mo(N) Superaustenitic Stainless Steels Aged at 900 °C. Metall. Mater. Trans. A 2000, 31, 13. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Peng, J.; Zheng, H.; Shan, A. Effect of annealing on microstructure and mechanical properties of an ultrafine-structured Al-containing FeCoCrNiMn high-entropy alloy produced by severe cold rolling. Mater. Sci. Eng. A 2020, 786, 139446. [Google Scholar] [CrossRef]

- Wang, H.; Shuro, I.; Umemoto, M.; Ho-Hung, K.; Todaka, Y. Annealing behavior of nano-crystalline austenitic SUS316L produced by HPT. Mater. Sci. Eng. A 2012, 556, 906–910. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, C.; Ren, M.; Jiang, H.; Li, L. Microstructure and mechanical behavior of an AISI 304 austenitic stainless steel prepared by cold- or cryogenic-rolling and annealing. Mater. Sci. Eng. A 2018, 724, 260–268. [Google Scholar] [CrossRef]

- Li, J.; Gao, B.; Huang, Z.; Zhou, H.; Mao, Q.; Li, Y. Design for strength-ductility synergy of 316L stainless steel with heterogeneous lamella structure through medium cold rolling and annealing. Vacuum 2018, 157, 128–135. [Google Scholar] [CrossRef]

- Mallick, P.; Tewary, N.K.; Ghosh, S.K.; Chattopadhyay, P.P. Microstructure-tensile property correlation in 304 stainless steel after cold deformation and austenite reversion. Mater. Sci. Eng. A 2017, 707, 488–500. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, F.; Jiang, P.; Wu, X. Size effects of lamellar twins on the strength and deformation mechanisms of nanocrystalline hcp cobalt. Sci. Rep. 2017, 7, 9550–9560. [Google Scholar] [CrossRef]

- Wang, H.T.; Tao, N.R.; Lu, K. Strengthening an austenitic Fe–Mn steel using nanotwinned austenitic grains. Acta Mater. 2012, 60, 9–16. [Google Scholar] [CrossRef]

- Zhao, L.; Qi, X.; Xu, L.; Han, Y.; Jing, H.; Song, K. Tensile mechanical properties, deformation mechanisms, fatigue behaviour and fatigue life of 316H austenitic stainless steel: Effects of grain size. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 533–550. [Google Scholar] [CrossRef]

- Singh, R.; Sachan, D.; Verma, R.; Goel, S.; Jayaganthan, R.; Kumar, A. Mechanical behavior of 304 Austenitic stainless steel processed by cryogenic rolling. Mater. Today Proc. 2018, 5, 16880–16886. [Google Scholar] [CrossRef]

- Korznikova, G.; Mironov, S.; Konkova, T.; Aletdinov, A.; Zaripova, R.; Myshlyaev, M.; Semiatin, S. EBSD Characterization of Cryogenically Rolled Type 321 Austenitic Stainless Steel. Metall. Mater. Trans. 2018, 49, 16–23. [Google Scholar] [CrossRef]

- Yan, F.K.; Tao, N.R.; Archie, F.; Gutierrez-Urrutia, I.; Raabe, D.; Lu, K. Deformation mechanisms in an austenitic single-phase duplex microstructured steel with nanotwinned grains. Acta Mater. 2014, 81, 487–500. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Huabing, L.; Zhouhua, J.; Hao, F.; Shucai, Z.; Peide, H.; Wei, Z.; Guoping, L.; Guangwei, F. Effect of Temperature on the Corrosion Behaviour of Super Austenitic Stainless Steel S32654 in Polluted Phosphoric Acid. Int. J. Electrochem. Sci. 2015, 10, 4832–4848. [Google Scholar]

- Andersson, M.; Stalmans, R.; Gren, J.A. Unified Thermodynamic analysis of the stressassisted γ→ε martensitic transformation in Fe±Mn±Si alloys. Acta Mater. 1998, 46, 8. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y. Heterogeneous materials: A new class of materials with unprecedented mechanical properties. Mater. Res. Lett. 2017, 5, 527–532. [Google Scholar] [CrossRef]

- Shi, Y.; Zhou, J. Analysis of mechanical behaviour of single-phase austenitic stainless steels based on microstructure deformation mechanism. Micro Nano Lett. 2019, 14, 1024–1028. [Google Scholar] [CrossRef]

- Li, Y.S.; Tao, N.R.; Lu, K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 2008, 56, 230–241. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Wen, H.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J. Strengthening mechanisms in a high-strength bulk nanostructured Cu–Zn–Al alloy processed via cryomilling and spark plasma sintering. Acta Mater. 2013, 61, 2769–2782. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, D.; Fu, B.; Guan, W.; Li, Y.; Guo, Y.; Wei, L.; Ding, Y. Hierarchical Multiple Precursors Induced Heterogeneous Structures in Super Austenitic Stainless Steels by Cryogenic Rolling and Annealing. Materials 2023, 16, 6298. https://doi.org/10.3390/ma16186298

Tan D, Fu B, Guan W, Li Y, Guo Y, Wei L, Ding Y. Hierarchical Multiple Precursors Induced Heterogeneous Structures in Super Austenitic Stainless Steels by Cryogenic Rolling and Annealing. Materials. 2023; 16(18):6298. https://doi.org/10.3390/ma16186298

Chicago/Turabian StyleTan, Duo, Bin Fu, Wei Guan, Yu Li, Yanhui Guo, Liqun Wei, and Yi Ding. 2023. "Hierarchical Multiple Precursors Induced Heterogeneous Structures in Super Austenitic Stainless Steels by Cryogenic Rolling and Annealing" Materials 16, no. 18: 6298. https://doi.org/10.3390/ma16186298

APA StyleTan, D., Fu, B., Guan, W., Li, Y., Guo, Y., Wei, L., & Ding, Y. (2023). Hierarchical Multiple Precursors Induced Heterogeneous Structures in Super Austenitic Stainless Steels by Cryogenic Rolling and Annealing. Materials, 16(18), 6298. https://doi.org/10.3390/ma16186298