Toughening Enhancement Mechanism and Performance Optimization of Castor-Oil-Based Polyurethane Cross-Linked Modified Polybutylene Adipate/Terephthalate Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

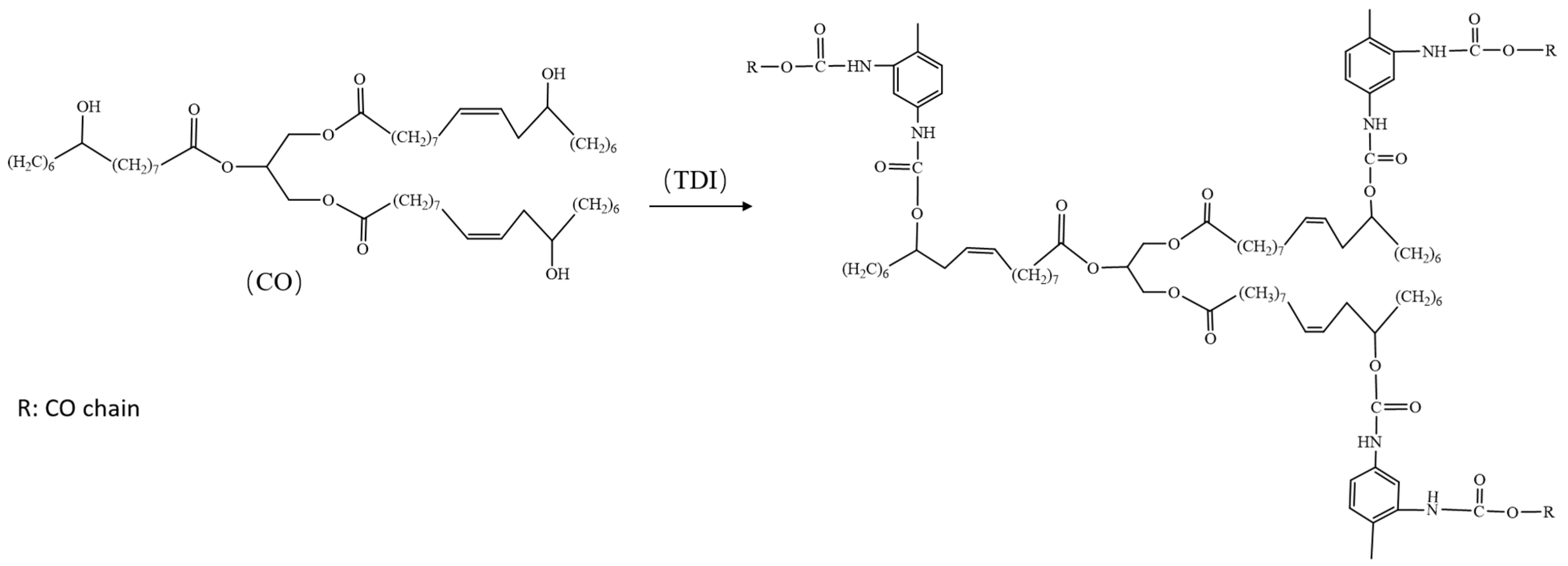

2.2.1. Preparation of PBAT-CO/TDI Composite

2.2.2. Preparation of Gel (COP)

2.3. Performance Testing and Characterization

3. Results and Discussion

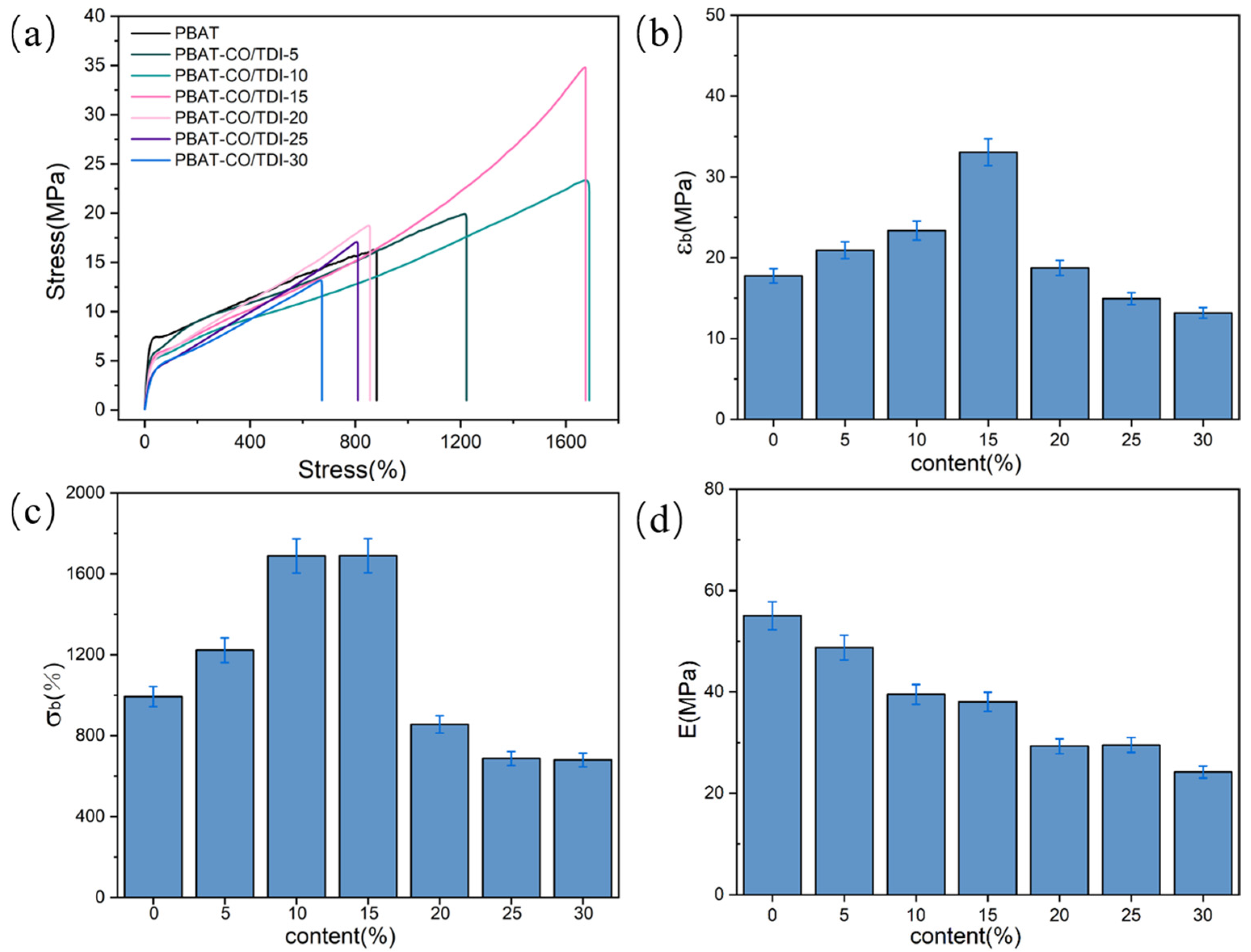

3.1. Mechanical Properties of Composite Materials

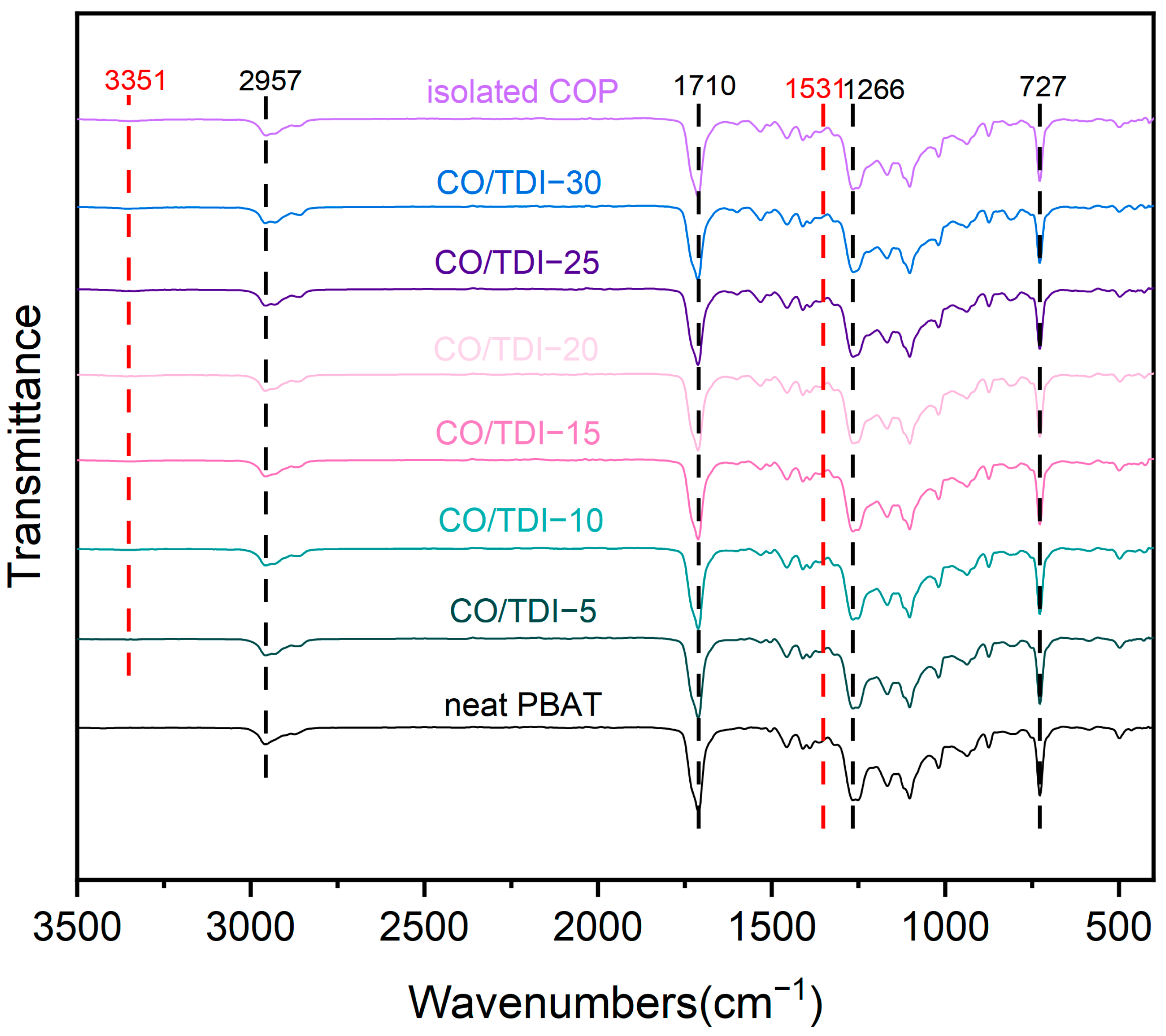

3.2. Structural Characterization of Composite Materials

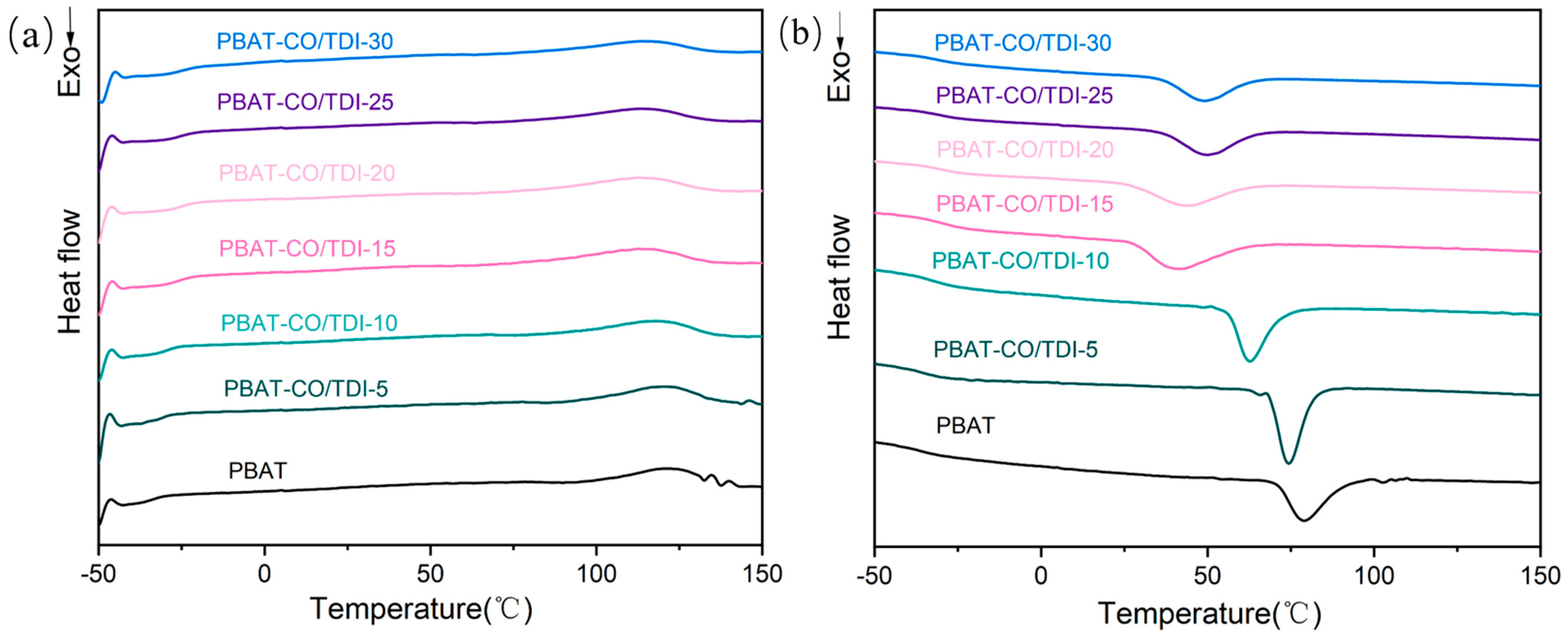

3.3. Thermal Property (DSC) Analysis of Composite Materials

3.4. X-ray Diffraction (XRD) Analysis of Composite Materials

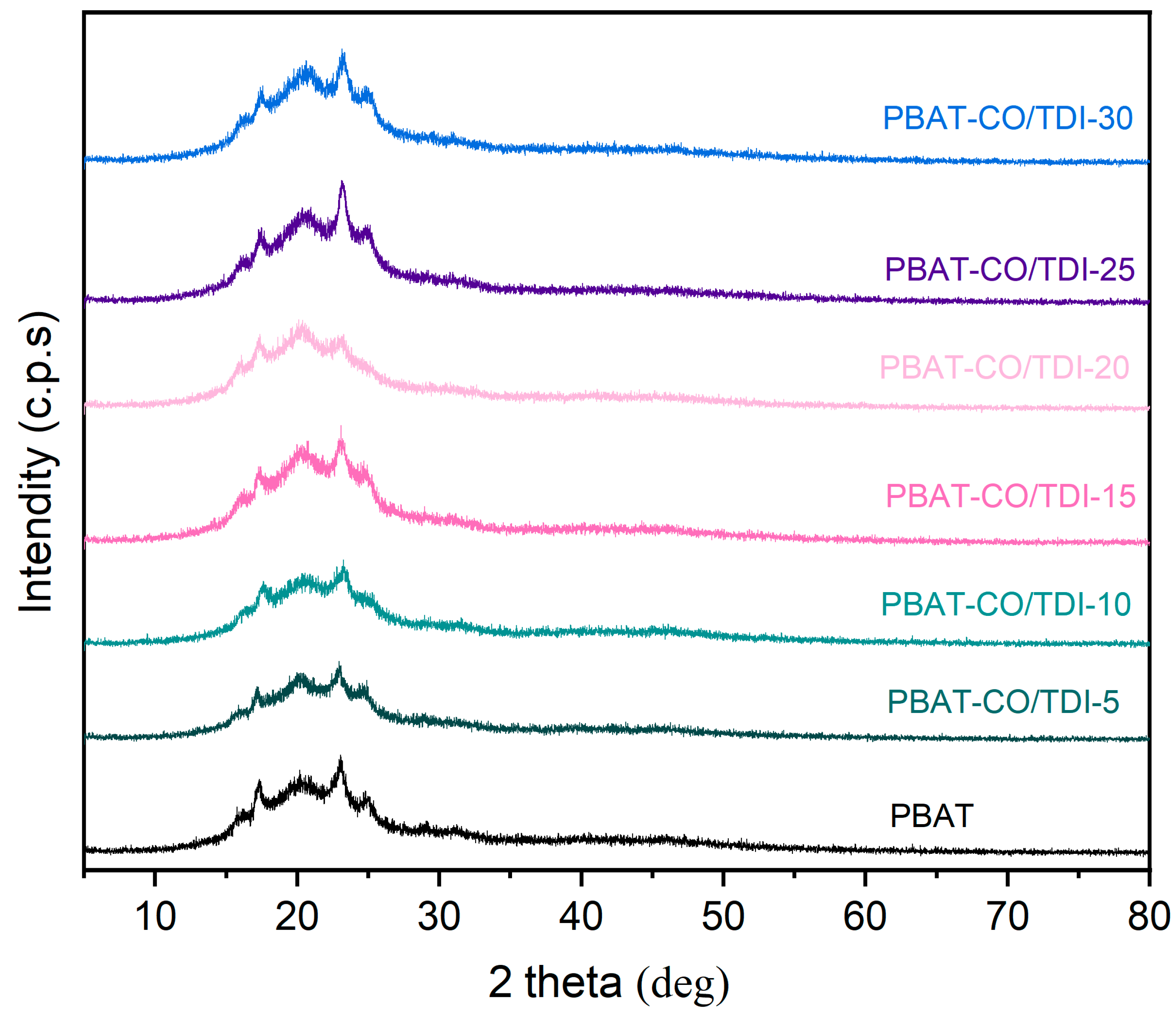

3.5. Thermogravimetric (TG) Analysis of Composite Materials

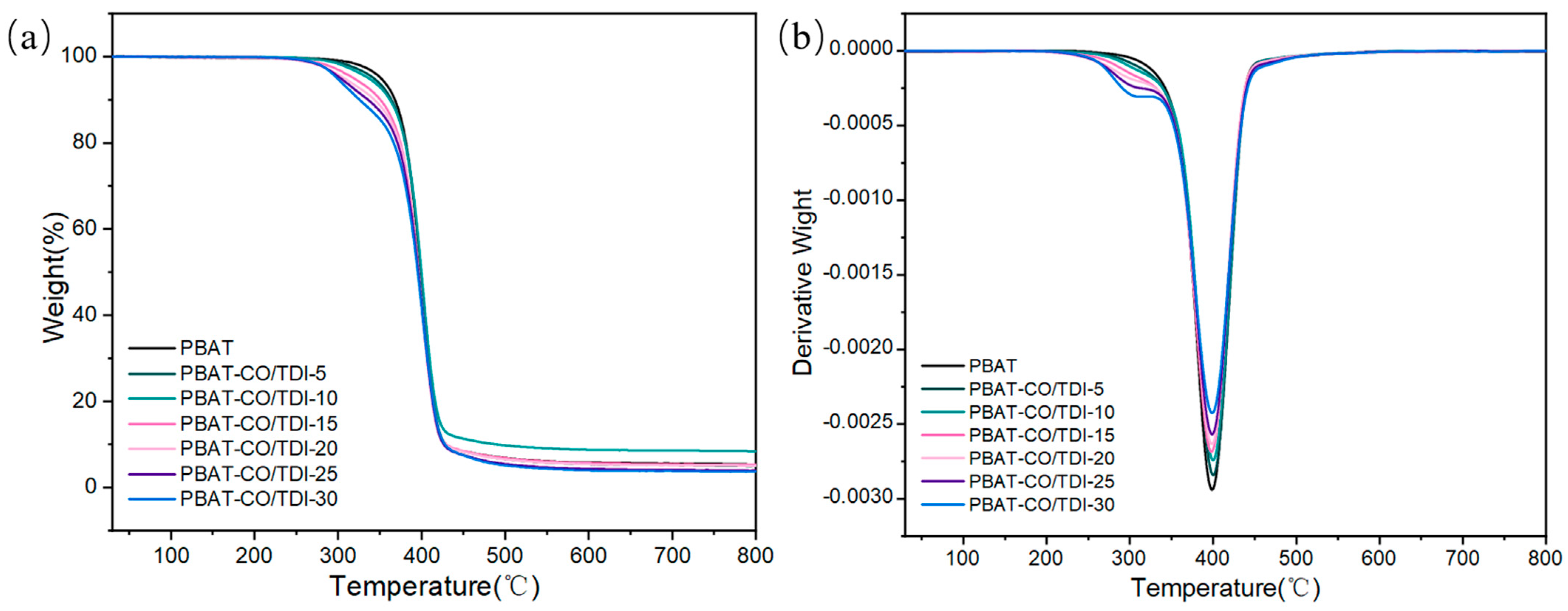

3.6. Analysis of Rheological Properties of Composite Materials

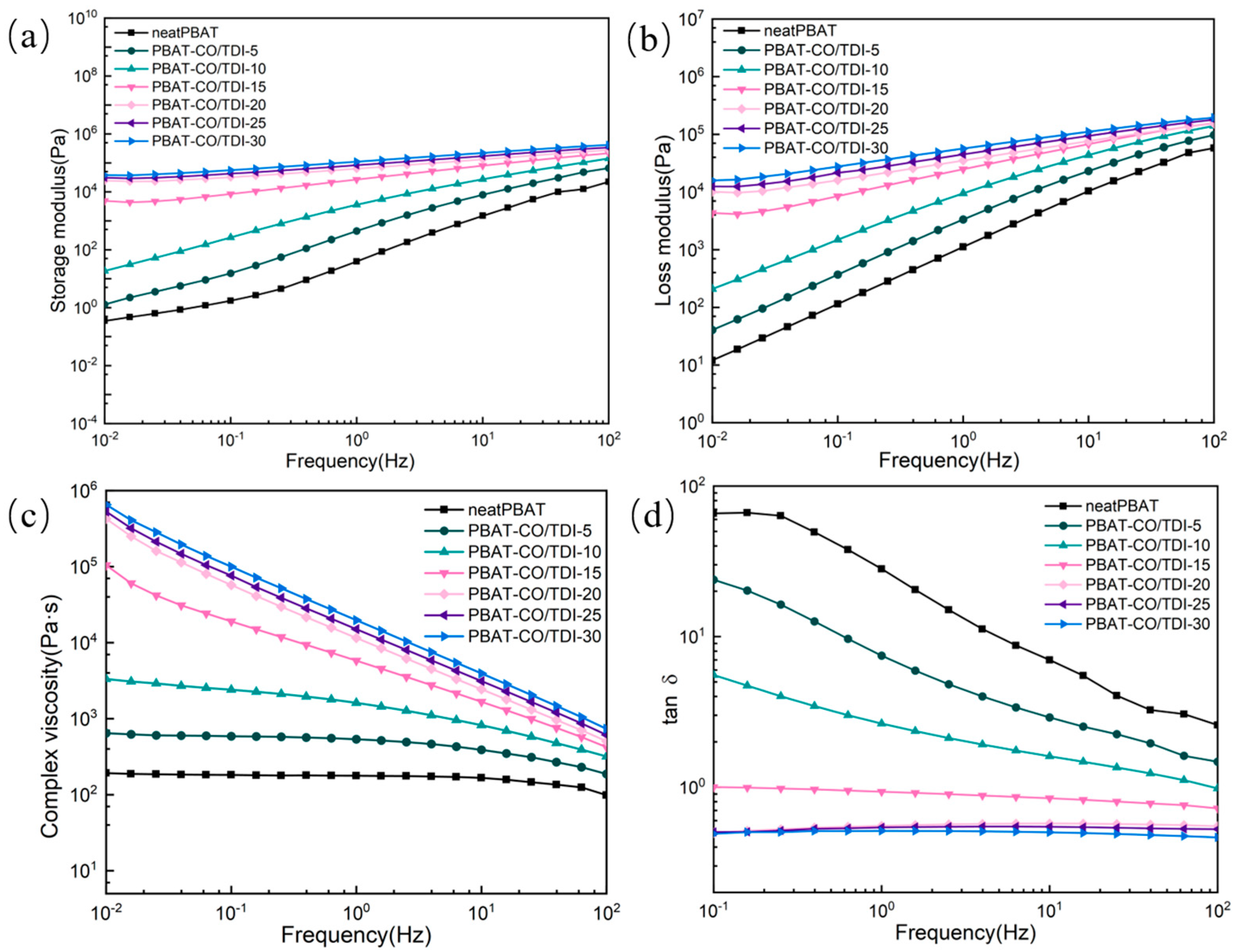

3.7. Analysis of Dynamic Thermomechanical Properties of Composite Materials

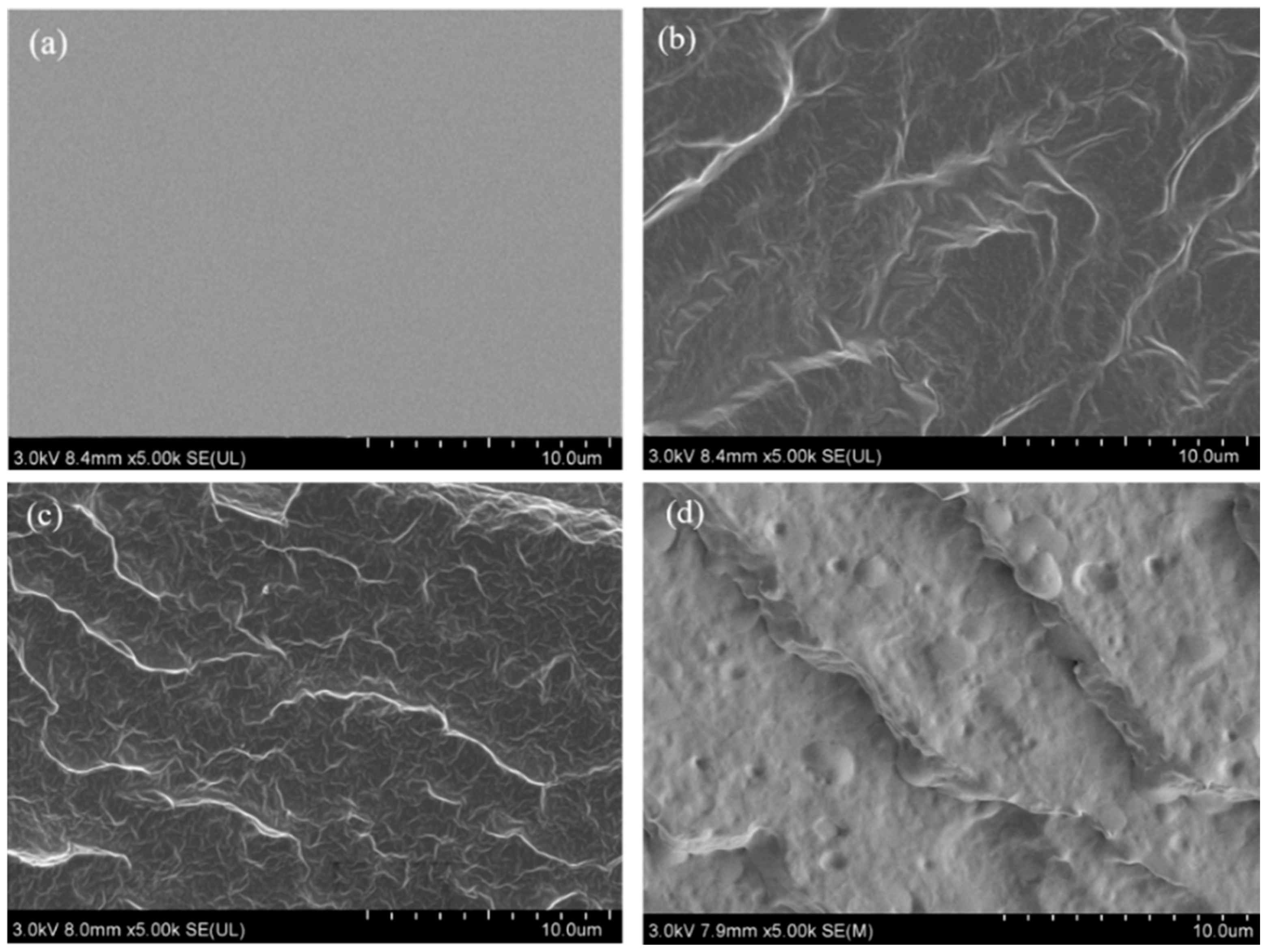

3.8. Microscopic Morphological Analysis of Composite Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, N.I.; Shahar, F.S.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Mat Yazik, M.H. Overview of Bioplastic Introduction and Its Applications in Product Packaging. Coatings 2021, 11, 1423. [Google Scholar] [CrossRef]

- Dar, S.U.; Wu, Z.; Zhang, L.; Yu, P.; Qin, Y.; Shen, Y.; Zou, Y.; Poh, L.; Eichen, Y.; Achmon, Y. On the quest for novel bio-degradable plastics for agricultural field mulching. Front. Bioeng. Biotechnol. 2022, 10, 922974. [Google Scholar] [CrossRef] [PubMed]

- Rangel-Buitrago, N.; Neal, W.J. A geological perspective of plastic pollution. Sci. Total Environ. 2023, 893, 164867. [Google Scholar] [CrossRef] [PubMed]

- Pathak, G.; Nichter, M.; Hardon, A.; Moyer, E.; Latkar, A.; Simbaya, J.; Pakasi, D.; Taqueban, E.; Love, J. Plastic pollution and the open burning of plastic wastes. Glob. Environ. Chang. 2023, 80, 102648. [Google Scholar] [CrossRef]

- Gross, M. Biology versus plastic pollution. Curr. Biol. 2020, 30, R135–R137. [Google Scholar] [CrossRef]

- Shen, C.; Zhao, X.; Long, Y.; An, W.; Zhou, X.; Liu, X.; Xu, S.; Wang, Y.-Z. Approach for the Low Carbon Footprint of Biodegradable Plastic PBAT: Complete Recovery of Its Every Monomer via High-Efficiency Hydrolysis and Separation. ACS Sustain. Chem. Eng. 2023, 11, 2005–2013. [Google Scholar] [CrossRef]

- Kumar, R.; Sadeghi, K.; Jang, J.; Seo, J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci. Total Environ. 2023, 882, 163446. [Google Scholar] [CrossRef]

- Qin, M.; Chen, C.; Song, B.; Shen, M.; Cao, W.; Yang, H.; Zeng, G.; Gong, J. A review of biodegradable plastics to biodegradable microplastics: Another ecological threat to soil environments? J. Clean. Prod. 2021, 312, 127816. [Google Scholar] [CrossRef]

- Peng, C.; Wang, J.; Liu, X.; Wang, L. Differences in the Plastispheres of Biodegradable and Non-biodegradable Plastics: A Mini Review. Front. Microbiol. 2022, 13, 849147. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, K.; Ren, L.; Peng, A.; Zhou, S. Biodegradable Microplastics: A Review on the Interaction with Pollutants and Influence to Organisms. Bull. Environ. Contam. Toxicol. 2022, 108, 1006–1012. [Google Scholar] [CrossRef]

- Bai, J.; Pei, H.; Zhou, X.; Xie, X. Reactive compatibilization and properties of low-cost and high-performance PBAT/thermoplastic starch blends. Eur. Polym. J. 2021, 143, 110198. [Google Scholar] [CrossRef]

- Yang, F.; Chen, G.; Li, J.; Zhang, C.; Ma, Z.; Zhao, M.; Yang, Y.; Han, Y.; Huang, Z.; Weng, Y. Effects of Quercetin and Organically Modified Montmorillonite on the Properties of Poly(butylene adipate-co-terephthalate)/Thermoplastic Starch Active Packaging Films. ACS Omega 2023, 8, 663–672. [Google Scholar] [CrossRef]

- Dammak, M.; Fourati, Y.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind. Crops Prod. 2020, 144, 112061. [Google Scholar] [CrossRef]

- Song, J.; Mi, J.; Zhou, H.; Wang, X.; Zhang, Y. Chain extension of poly (butylene adipate-co-terephthalate) and its microcellular foaming behaviors. Polym. Degrad. Stab. 2018, 157, 143–152. [Google Scholar] [CrossRef]

- Tang, D.; Zhang, C.; Weng, Y. Effect of multi-functional epoxy chain extender on the weathering resistance performance of Poly(butylene adipate-co-terephthalate) (PBAT). Polym. Test. 2021, 99, 107204. [Google Scholar] [CrossRef]

- Cui, Y.; Zhou, H.; Yin, D.; Zhou, H.; Wang, X. An innovative strategy to regulate bimodal cellular structure in chain extended poly(butylene adipate-co-terephthalate) foams. J. Vinyl Addit. Technol. 2021, 27, 319–331. [Google Scholar] [CrossRef]

- Wang, R.; Sun, X.; Chen, L.; Liang, W. Morphological and mechanical properties of biodegradable poly(glycolic acid)/poly(butylene adipate-co-terephthalate) blends with in situ compatibilization. RSC Adv. 2021, 11, 1222–1908. [Google Scholar] [CrossRef]

- Nayak, S.K. Biodegradable PBAT/Starch Nanocomposites. Polym. Plast. Technol. Eng. 2010, 49, 1406–1418. [Google Scholar] [CrossRef]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.A.; Fu, H.; Wu, D.; Yang, Z. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 505. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable Polymers- A Review on Recent Trends and Emerging Perspectives. J. Polym. Environ. 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Bari, S.S.; Chatterjee, A.; Mishra, S. Biodegradable polymer nanocomposites: An overview. Polym. Rev. 2016, 56, 287–328. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly(butylene adipate-co-terephthalate)–PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15. [Google Scholar] [CrossRef]

- Fukushima, K.; Wu, M.-H.; Bocchini, S.; Rasyida, A.; Yang, M.-C. PBAT based nanocomposites for medical and industrial applications. Mater. Sci. Eng. C 2012, 32, 1331–1351. [Google Scholar] [CrossRef] [PubMed]

- Torrentes-Espinoza, G.; Miranda, B.C.; Vega-Baudrit, J.; Mata-Segreda, J.F. Castor oil (Ricinus communis) supercritical methanolysis. Energy 2017, 140, 426–435. [Google Scholar] [CrossRef]

- Chen, J.-H.; Yuan, W.-Q.; Li, Y.-D.; Weng, Y.-X.; Zeng, J.-B. Malleable and Sustainable Poly(ester amide) Networks Synthesized via Melt Condensation Polymerization. ACS Sustain. Chem. Eng. 2019, 7, 15147–15153. [Google Scholar] [CrossRef]

- Su, Y.; Ma, S.; Wang, B.; Xu, X.; Feng, H.; Hu, K.; Zhang, W.; Zhou, S.; Weng, G.; Zhu, J. High-performance castor oil-based polyurethane thermosets: Facile synthesis and properties. React. Funct. Polym. 2023, 183, 105496. [Google Scholar] [CrossRef]

- Li, C.; Chen, F.; Lin, B.; Zhang, C.; Liu, C. High content corn starch/Poly (butylene adipate-co-terephthalate) composites with high-performance by physical–chemical dual compatibilization. Eur. Polym. J. 2021, 159, 110737. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Meng, W.; Li, C.; Cui, R.; Xia, Z.; Liu, C. Polyurethane prepolymer-modified high-content starch-PBAT films. Carbohydr. Polym. 2021, 253, 117168. [Google Scholar] [CrossRef]

- Freitas, A.L.P.d.L.; Tonini Filho, L.R.; Calvão, P.S.; Souza, A.M.C.D. Effect of montmorillonite and chain extender on rheological, morphological and biodegradation behavior of PLA/PBAT blends. Polym. Test. 2017, 62, 189–195. [Google Scholar] [CrossRef]

- Zhao, T.H.; He, Y.; Li, Y.D. Dynamic vulcanization of castor oil in a polylactide matrix for toughening. RSC Adv. 2016, 6, 79542–79553. [Google Scholar] [CrossRef]

- Fazeli, M.; Florez, J.P.; Simao, R.A. Improvement in adhesion of cellulose fibers to the thermoplastic starch matrix by plasma treatment modification. Compos. Part B Eng. 2019, 163, 207–216. [Google Scholar] [CrossRef]

- Sun, J.M.; Pang, Y.; Yang, Y.N. Improvement of Rice Husk/HDPE Bio-Composites Interfacial Properties by Silane Coupling Agent and Compatibilizer Complementary Modification. Polymers 2019, 11, 1928. [Google Scholar] [CrossRef] [PubMed]

- Kabir, M.M.; Wang, H.; Lau, K.T. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Boronat, T.; Montanes, N. Injection-molded parts of fully bio-based polyamide 1010 strengthened with waste derived slate fibers pretreated with glycidyl- and amino-silane coupling agents. Polym. Test. 2019, 77, 105875. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Saba, N. Effect of benzoyl treatment on flexural and compressive properties of sugar palm/glass fibres/epoxy hybrid composites. Polym. Test. 2018, 71, 362–369. [Google Scholar] [CrossRef]

- Wang, H.-H.; Zhou, S.-J.; Xiong, S.-J. High-performance thermoplastic starch/poly(butylene adipate-co-terephthalate) blends through synergistic plasticization of epoxidized soybean oil and glycerol. Int. J. Biol. Macromol. 2023, 242, 124716. [Google Scholar] [CrossRef] [PubMed]

- Fourati, Y.; Tarrés, Q.; Mutjé, P.; Boufi, S. PBAT/thermoplastic starch blends: Effect of compatibilizers on the rheological, mechanical and morphological properties. Carbohydr. Polym. 2018, 199, 51–57. [Google Scholar] [CrossRef]

- Fang, H.; Jiang, F.; Wu, Q.; Ding, Y.; Wang, Z. Supertough Polylactide Materials Prepared through In Situ Reactive Blending with PEG-Based Diacrylate Monomer. ACS Appled Mater. Interfaces 2014, 6, 13552–13563. [Google Scholar] [CrossRef]

- Winter, H.H.; Chambon, F. Analysis of Linear Viscoelasticity of a Crosslinking Polymer at the Gel Point. J. Rheol. 1986, 30, 367–382. [Google Scholar] [CrossRef]

- Chambon, F.; Winter, H.H. Linear Viscoelasticity at the Gel Point of a Crosslinking PDMS with Imbalanced Stoichiometry. J. Rheol. 1987, 31, 31683. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.; Yang, J.; Zhang, J.; Niu, Y.; Wang, Z. Thermal Annealing Induced Enhancements of Electrical Conductivities and Mechanism for Multiwalled Carbon Nanotubes Filled Poly(Ethylene-co-Hexene) Composites. ACS Appl. Mater. Interfaces 2012, 4, 6468–6478. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Li, L. Percolation and gel-like behavior of multiwalled carbon nanotube/polypropylene composites influenced by nanotube aspect ratio. Polymer 2013, 54, 1218–1226. [Google Scholar] [CrossRef]

| Equipment Name | Model | Manufacturer |

|---|---|---|

| Hot press | R302 | China Wuhan Qien Technology Co. |

| Dynamic mechanical thermal analyzer | Q800 | TA Instruments, Wilmington (Delaware), USA |

| Differential scanning calorimeter | DSC-214 | Selbnech Instruments, Germany |

| NMR spectrometer | 600 MHz | NETZSCH GmbH, Bavaria, Germany. |

| Universal testing machine | CMT6503 | China Shenzhen Sansi Testing Instrument Co. |

| X-ray diffractometer | D8-ADVANCE | NETZSCH GmbH, Bavaria, Germany. |

| Fourier transform infrared spectrometer | RF-5301PC | Shimadzu Manufacturing, Kyoto, Japan |

| Rotational rheometer | TA DHR-1 | TA Instruments, Wilmington (Delaware), USA |

| Internal mixer | SU-7 | China Changzhou Suyan Technology Co. |

| High speed universal pulverizer | FW100 | China Tianjin Tester Co. |

| Thermogravimetric analyzer | Q500 | TA Instruments, Wilmington (Delaware), USA |

| Scanning electron microscope | S4800 | Hitachi, Tokyo, Japan |

| Samples | Tg (°C) | Tc (°C) | Tm (°C) | ΔHm (J/g) | χcDSC (%) |

|---|---|---|---|---|---|

| PBAT | −36.4 | 79.1 | 121.5 | 8.59 | 7.53 |

| CO/TDI-5 | −30.4 | 74.5 | 121.1 | 13.38 | 12.35 |

| CO/TDI-10 | −28.7 | 62.9 | 118.1 | 13.87 | 13.51 |

| CO/TDI-15 | −26.0 | 40.7 | 112.9 | 14.11 | 14.56 |

| CO/TDI-20 | −26.4 | 44.2 | 112.8 | 13.22 | 14.49 |

| CO/TDI-25 | −26.9 | 48.7 | 112.9 | 12.23 | 14.30 |

| CO/TDI-30 | −26.1 | 48.8 | 113.2 | 11.33 | 14.19 |

| Sample | T5% (°C) | Tmax (°C) | Residual Mass (600 °C) (%) |

|---|---|---|---|

| PBAT | 351.3 | 399.7 | 5.81 |

| PBAT-CO/TDI-5 | 342.83 | 401.33 | 5.42 |

| PBAT-CO/TDI-10 | 336.66 | 401 | 8.75 |

| PBAT-CO/TDI-15 | 318.66 | 399.5 | 5.70 |

| PBAT-CO/TDI-20 | 307 | 399.83 | 5.38 |

| PBAT-CO/TDI-25 | 302.83 | 399.5 | 4.32 |

| PBAT-CO/TDI-30 | 298.66 | 400.66 | 3.96 |

| Sample | E′ | E″ (MPa) | Tg a (°C) | Tg b (°C) |

|---|---|---|---|---|

| PBAT | 2438.57 | 81.60 | −26.25 | −22.04 |

| PBAT−CO/TDI−5 | 2494.27 | 70.87 | −23.95 | −19.62 |

| PBAT−CO/TDI−10 | 2455.45 | 73.00 | −23.74 | −17.39 |

| PBAT−CO/TDI−15 | 2416.03 | 68.66 | −20.85 | −14.22 |

| PBAT−CO/TDI−20 | 2359.46 | 67.47 | −21.11 | −15.11 |

| PBAT−CO/TDI−25 | 2272.06 | 72.86 | −21.22 | −15.94 |

| PBAT−CO/TDI−30 | 2361.76 | 73.71 | −20.71 | −15.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Huang, J.; Zhou, N. Toughening Enhancement Mechanism and Performance Optimization of Castor-Oil-Based Polyurethane Cross-Linked Modified Polybutylene Adipate/Terephthalate Composites. Materials 2023, 16, 6256. https://doi.org/10.3390/ma16186256

Zhang Q, Huang J, Zhou N. Toughening Enhancement Mechanism and Performance Optimization of Castor-Oil-Based Polyurethane Cross-Linked Modified Polybutylene Adipate/Terephthalate Composites. Materials. 2023; 16(18):6256. https://doi.org/10.3390/ma16186256

Chicago/Turabian StyleZhang, Qing, Jin Huang, and Na Zhou. 2023. "Toughening Enhancement Mechanism and Performance Optimization of Castor-Oil-Based Polyurethane Cross-Linked Modified Polybutylene Adipate/Terephthalate Composites" Materials 16, no. 18: 6256. https://doi.org/10.3390/ma16186256

APA StyleZhang, Q., Huang, J., & Zhou, N. (2023). Toughening Enhancement Mechanism and Performance Optimization of Castor-Oil-Based Polyurethane Cross-Linked Modified Polybutylene Adipate/Terephthalate Composites. Materials, 16(18), 6256. https://doi.org/10.3390/ma16186256