A Circular Approach to Finished Tanned Leather: Regeneration by Cryogenic Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

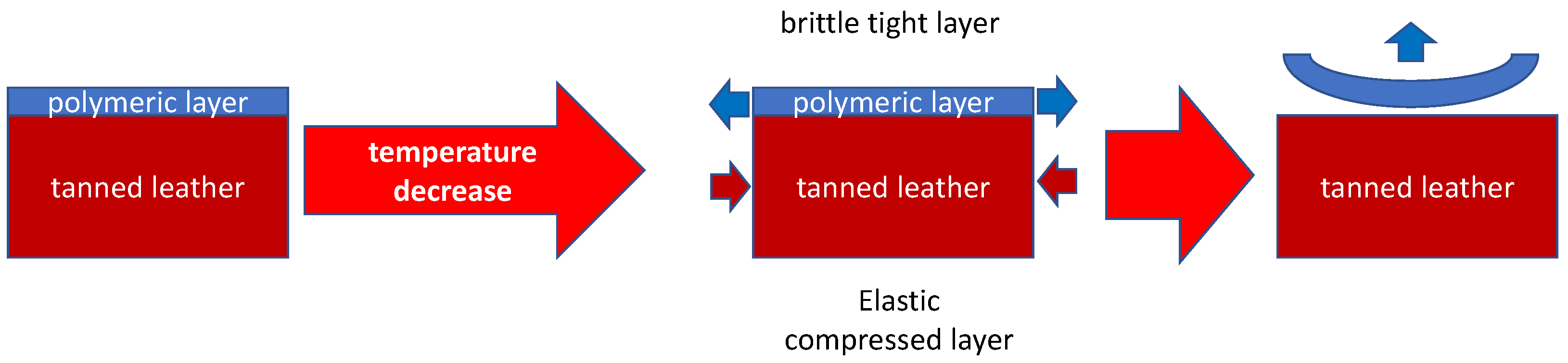

2.2. Cryogenic Delamination

- -

- The polymeric layer was removed to determine and characterize which compound it is.

- -

- The resulting crust leather, to be sure of all polymeric removal and quality maintenance.

- -

- The original sample for a better comparison.

2.3. Analysis

- -

- Differential Scanning Calorimetry: DSC was carried out on 5 mg of every sample that was heated and cooled between −60 and 180 °C for four times. The heating rate was 20 °C/min in a suitable sample holder. The instrument was a Mettler Toledo Polymer DSC. It allowed us to know the exact transition temperature.

- -

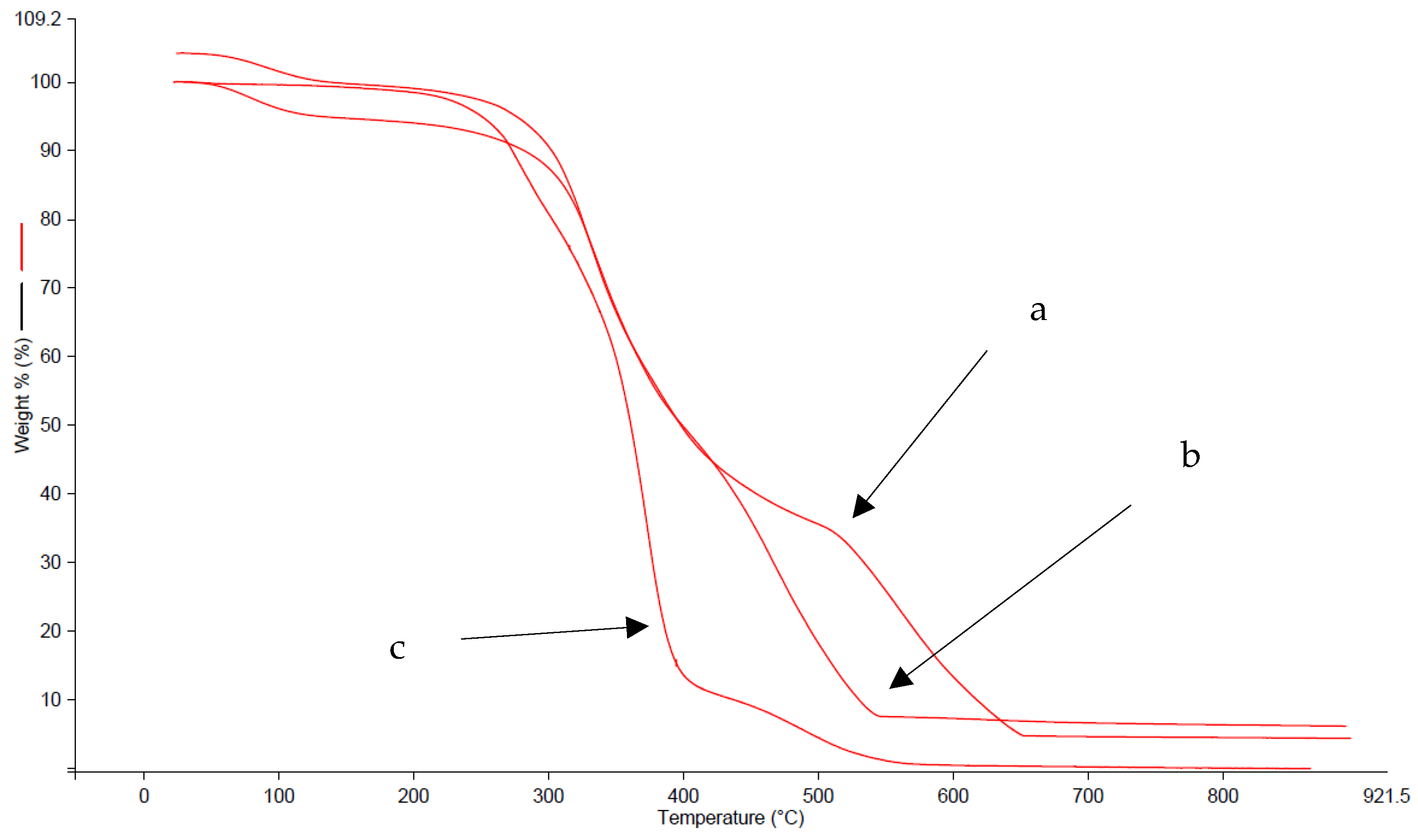

- Thermal Gravimetric Analysis-Thermal Mechanical Analysis: TGA-TMA samples were heated from 30 to 900 °C at a heating rate of 10 °C/min. The instrument was a PerkinElmer STA 6000. Two analyses were coupled, and in the analysis, it was possible to see the weight decrease and the temperature paths.

3. Results and Discussion

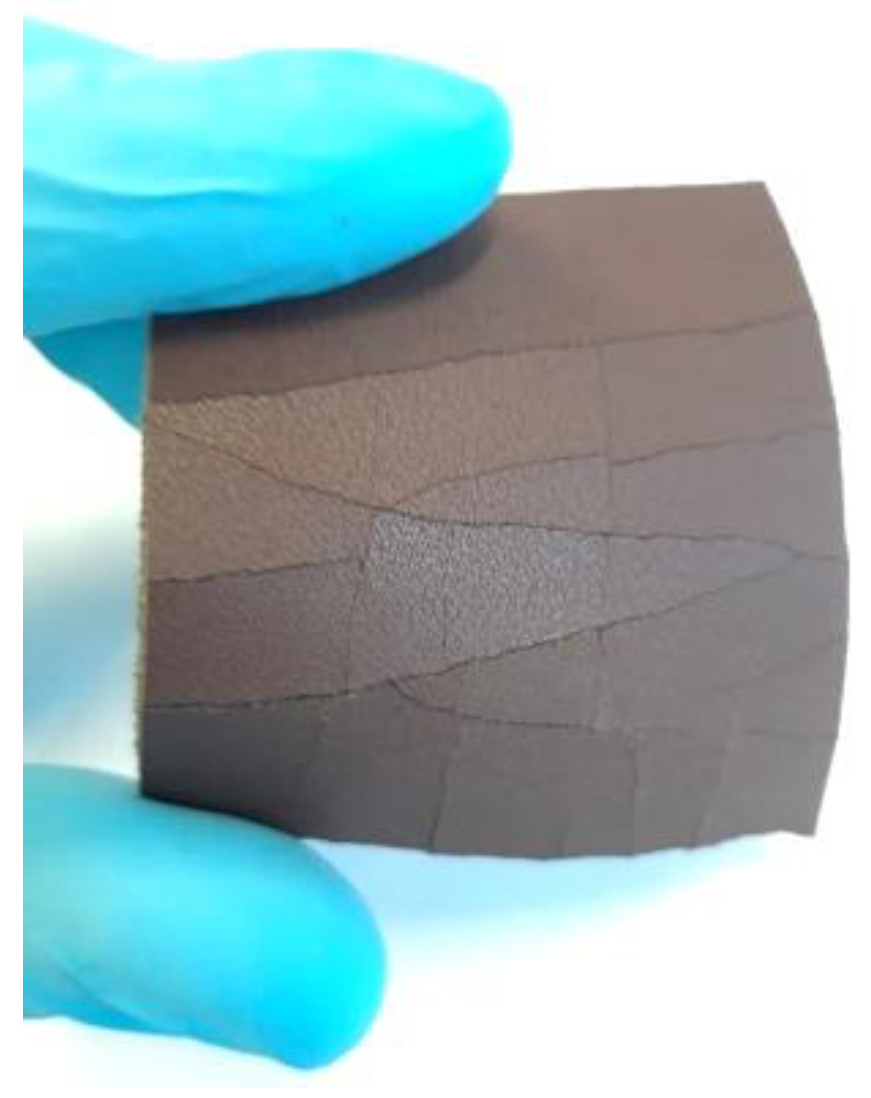

3.1. Cryogenic Removal

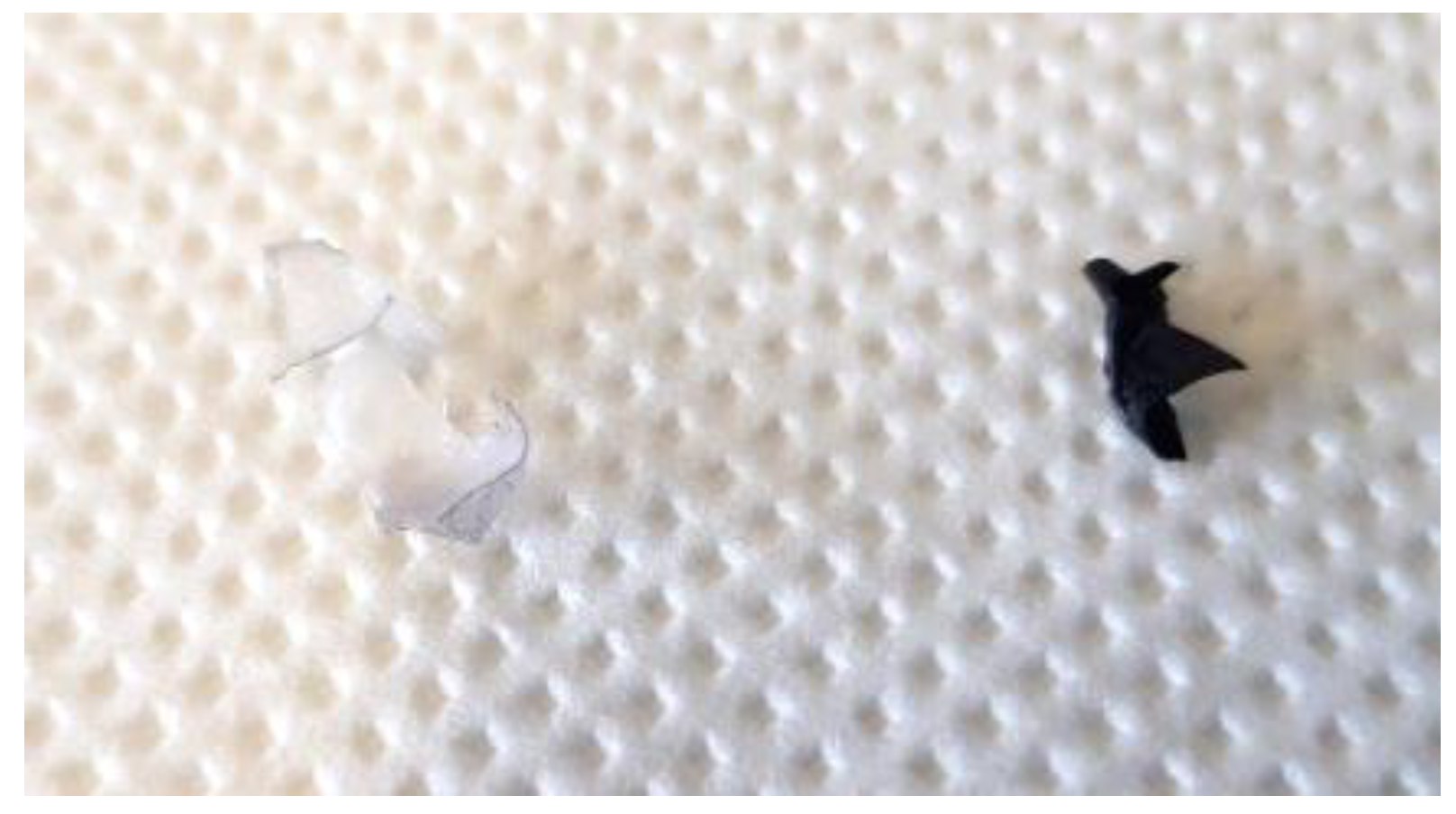

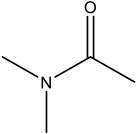

3.2. Dissolution

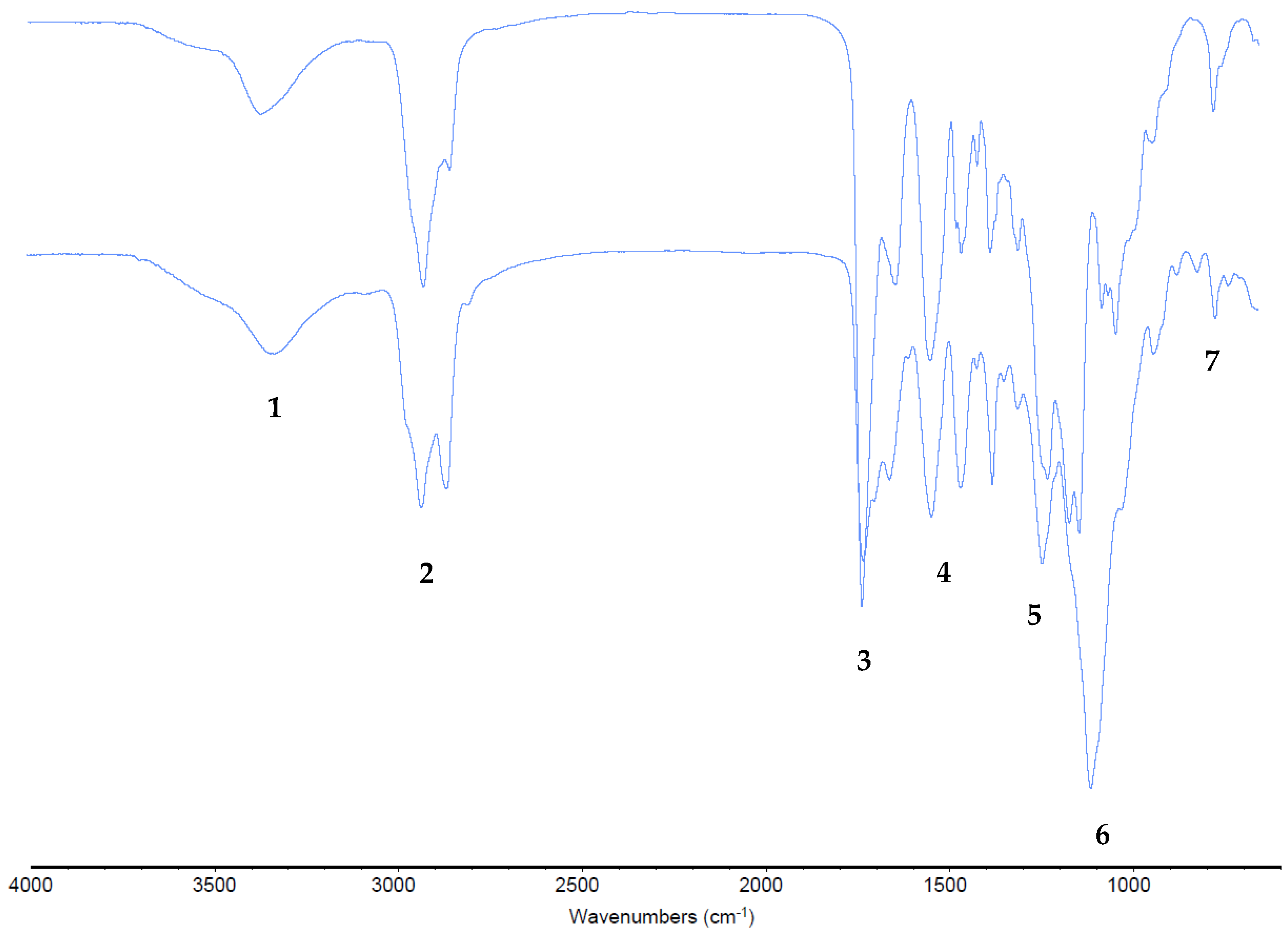

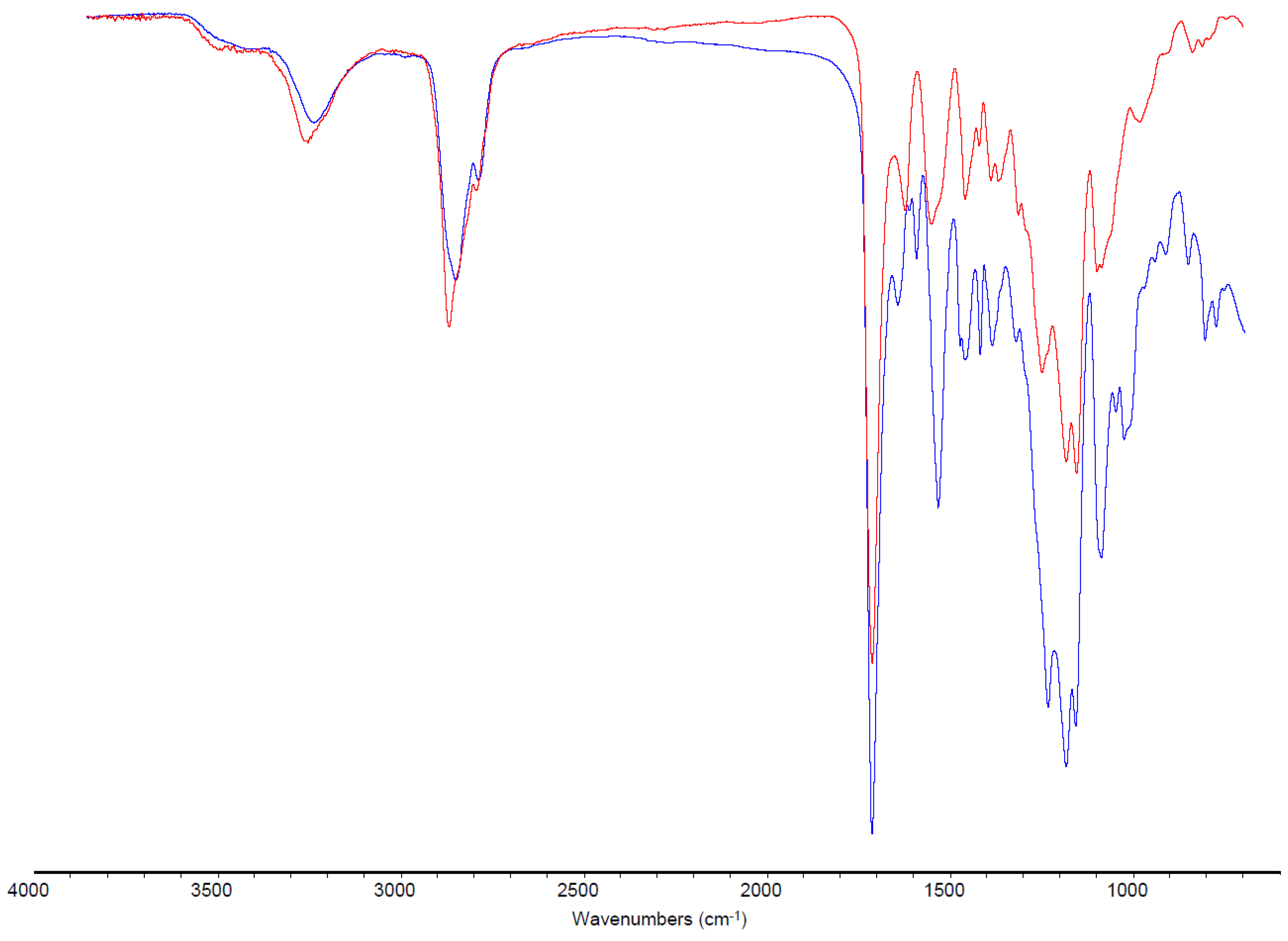

3.3. FTIR

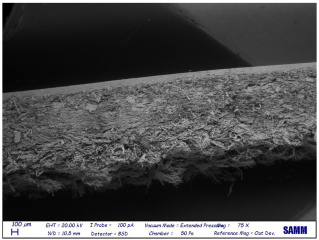

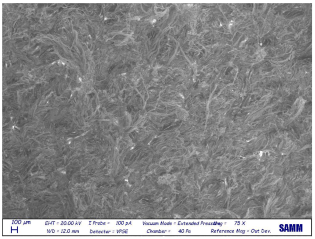

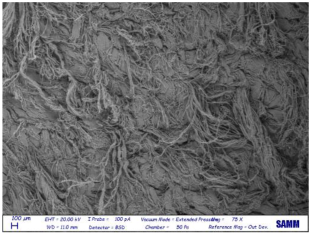

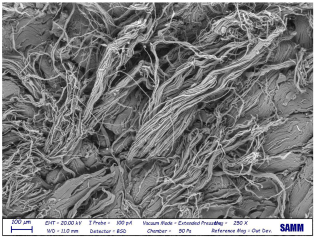

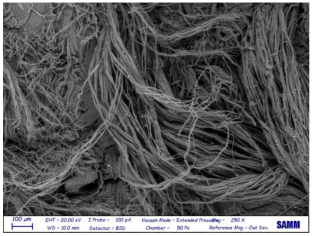

3.4. SEM

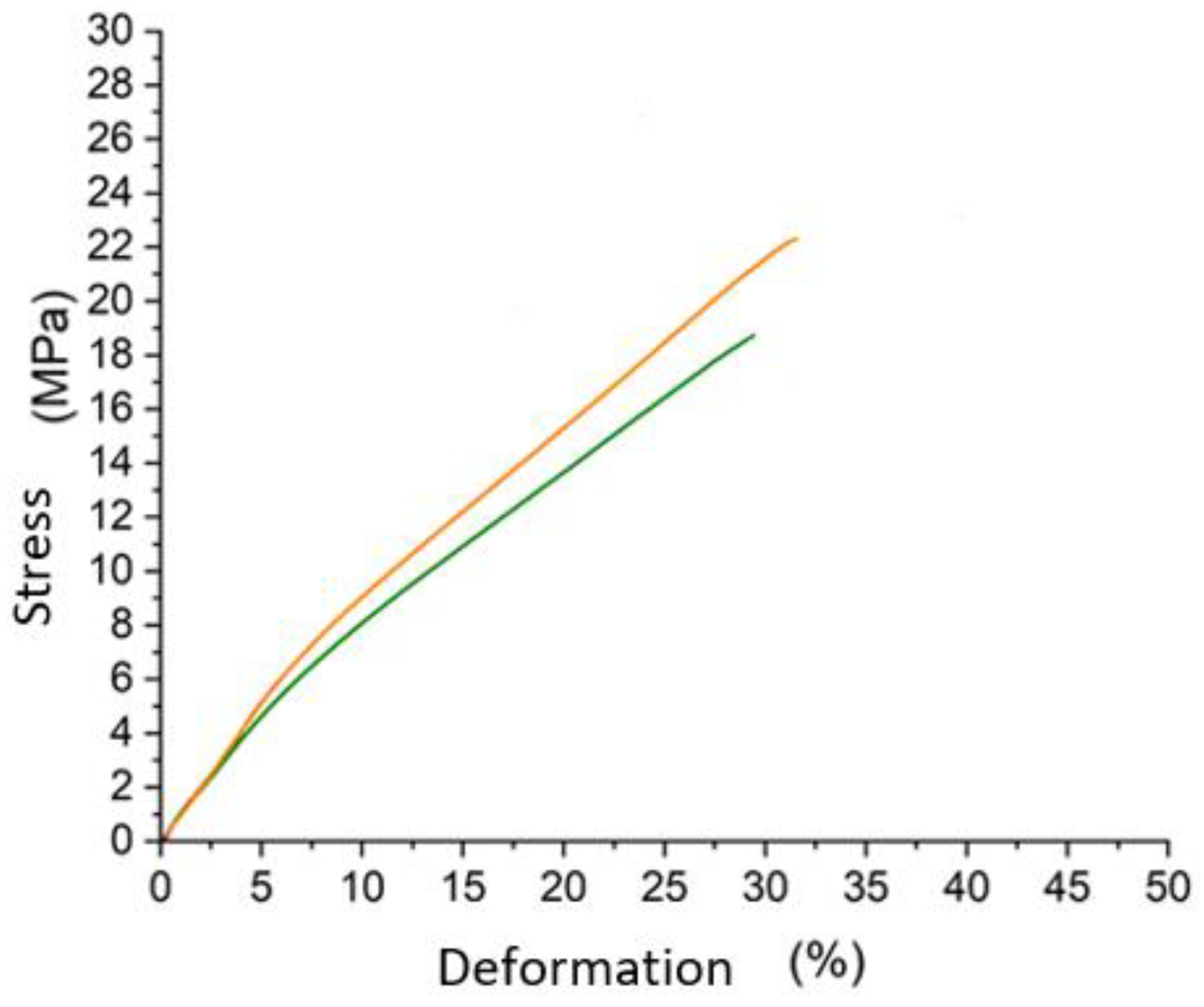

3.5. Tensile Strength according to UNI EN ISO 3376:2020

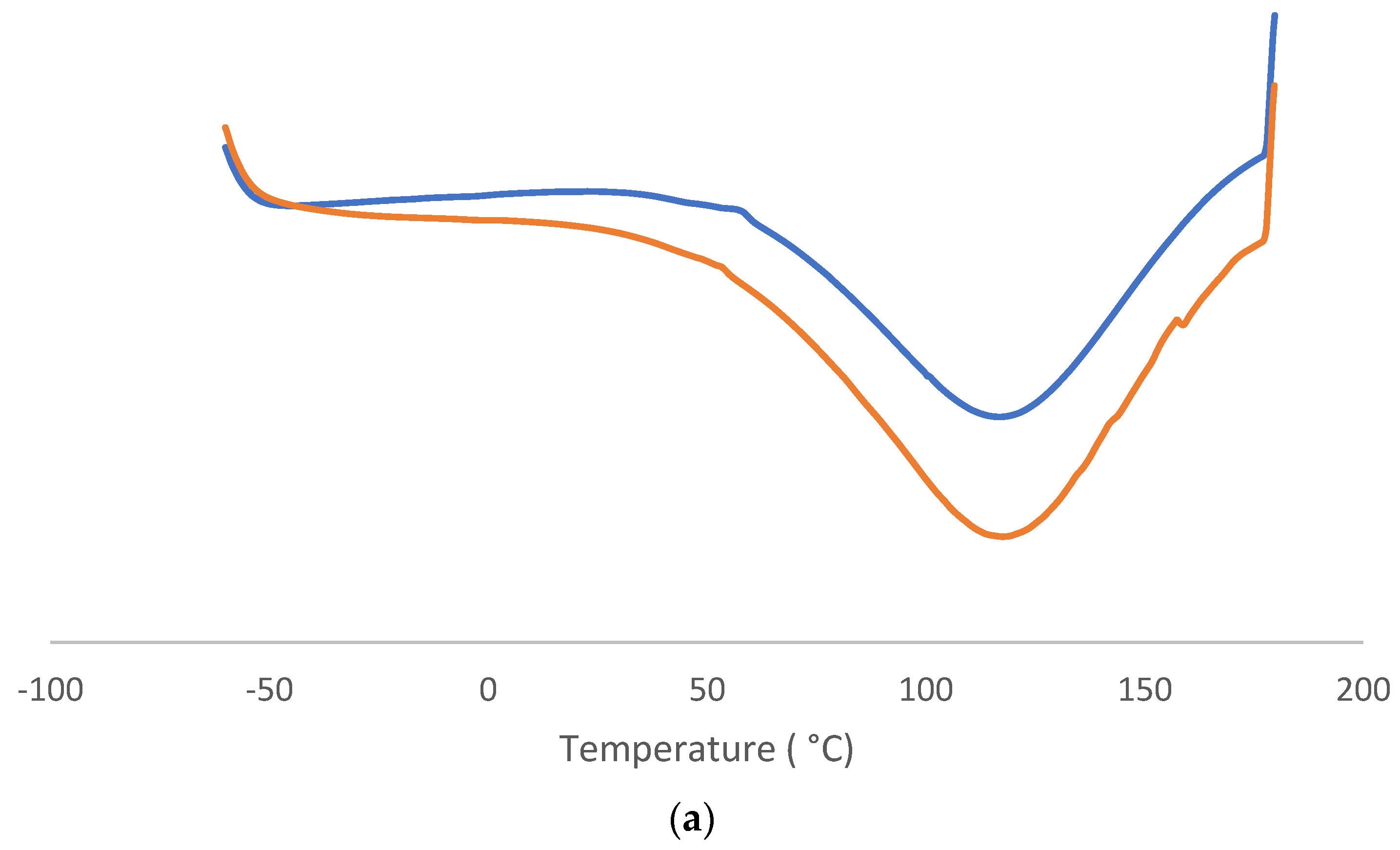

3.6. DSC

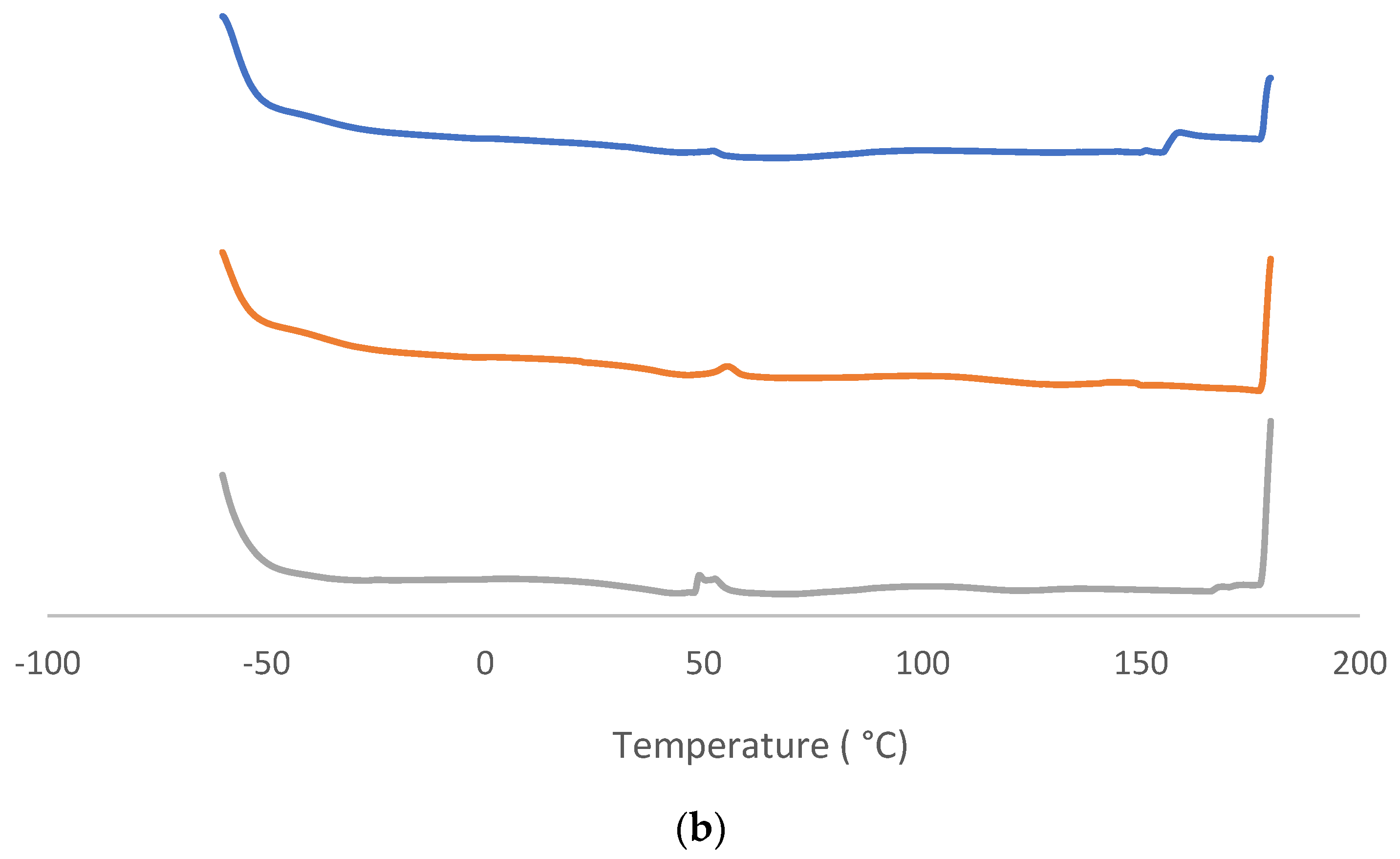

3.7. TGA-TMA

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moktadir, M.A.; Dwivedi, A.; Rahman, A.; Chiappetta Jabbour, C.J.; Paul, S.K.; Sultana, R.; Madaan, J. An investigation of key performance indicators for operational excellence towards sustainability in the leather products industry. Bus. Strategy Environ. 2020, 29, 3331–3351. [Google Scholar] [CrossRef]

- Joseph, K.; Nithya, N. Material flows in the life cycle of leather. J. Clean. Prod. 2009, 17, 676–682. [Google Scholar] [CrossRef]

- Kráľ, I.; Schmėl, F.; Buljan, J. The Future for Leather; United Nations, Industrial Development Organization: Vienna, Austria, 2014. [Google Scholar]

- Canals, L.M.I.; Domènèch, X.; Rieradevall, J.; Puig, R.; Fullana, P. Use of Life Cycle assessment in the procedure for the establishment of environmental criteria in the catalan ECO-label of leather. Int. J. Life Cycle Assess. 2002, 7, 39. [Google Scholar] [CrossRef]

- Omoloso, O.; Mortimer, K.; Wise, W.R.; Jraisat, L. Sustainability research in the leather industry: A critical review of progress and opportunities for future research. J. Clean. Prod. 2021, 285, 125441. [Google Scholar] [CrossRef]

- Exports of Leather and Leather Goods. Available online: http://man.ac.uk/04Y6Bo (accessed on 13 October 2022).

- Gounder Rajamani, S. Recent Developments in Cleaner Production and Environment Protection in World Leather Sector. In Proceedings of the 30th IULTCS Congress, Beijing, China, 18–25 October 2009. [Google Scholar]

- Moktadir, M.A.; Ahmadi, H.B.; Sultana, R.; Zohra, F.-T.; Liou, J.J.H.; Rezaei, J. Circular economy practices in the leather industry: A practical step towards sustainable development. J. Clean. Prod. 2020, 251, 119737. [Google Scholar] [CrossRef]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why Sustainability Is Now the Key Driver of Innovation. Harv. Bus. Rev. 2009, 87, 56–64. [Google Scholar]

- Rigueto, C.V.; Rosseto, M.; Krein, D.D.; Ostwald, B.E.; Massuda, L.A.; Zanella, B.B.; Dettmer, A. Alternative uses for tannery wastes: A review of environmental, sustainability, and science. J. Leather Sci. Eng. 2020, 2, 21. [Google Scholar] [CrossRef]

- Marconi, M.; Barbanera, M.; Calabrò, G.; Baffo, I. Reuse of leather scraps for insulation panels: Technical and environmental feasibility evaluation. Procedia CIRP 2020, 90, 55–60. [Google Scholar] [CrossRef]

- Barbanera, M.; Belloni, E.; Buratti, C.; Calabrò, G.; Marconi, M.; Merli, F.; Armentano, I. Recycled leather cutting waste-based boards: Thermal, acoustic, hygrothermal and ignitability properties. J. Mater. Cycles Waste Manag. 2020, 22, 1339–1351. [Google Scholar] [CrossRef]

- Olaitan, O.; Alfnes, E. Optimizing Leather Cutting Process to Reduce Waste. 2017. Available online: https://www.researchgate.net/publication/322977368 (accessed on 13 October 2022).

- Brun, A.; Ciccullo, F. Factors affecting sustainability-oriented innovation in the leather supply chain. Strateg. Chang. 2022, 31, 305–321. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, Z.; Zhou, R.; Deng, W.; Wang, M.; Ma, S. Ecological utilization of leather tannery waste with circular economy model. J. Clean. Prod. 2011, 19, 221–228. [Google Scholar] [CrossRef]

- Candas, A.; Zengin, A.; Bitlisli, B.O. The Effects of Leather Finishing Types on Foot Wear Comfort Properties 2018. Available online: https://www.researchgate.net/publication/323144238 (accessed on 13 October 2022).

- Kiliç, T.; Zengin, G. Effect of Viscosity on the Characteristic Properties of Solvent Free Patent Finished Leathers. Tekst. Ve Konfeksiyon 2021, 31, 137–145. [Google Scholar] [CrossRef]

- Li, Y.; Guo, R.; Lu, W.; Zhu, D. Research progress on resource utilization of leather solid waste. J. Leather Sci. Eng. 2019, 1, 6. [Google Scholar] [CrossRef]

- Cimatti, B.; Campana, G.; Carluccio, L. Eco Design and Sustainable Manufacturing in Fashion: A Case Study in the Luxury Personal Accessories Industry. Procedia Manuf. 2017, 8, 393–400. [Google Scholar] [CrossRef]

- Kurane, A.S.; Sawant, P.J. IRJET-Topological Optimization Approach for Design of Bell Housing of Leather Shaving Machine by using FEA. Int. Res. J. Eng. Technol. 2020, 7, 1178–1182. Available online: https://www.irjet.net/ (accessed on 13 October 2022).

- Fakhfakh, R.; Mihoubi, D.; Kechaou, N. Moisture sorption isotherms and thermodynamic properties of bovine leather. Heat Mass Transf. 2017, 54, 1163–1176. [Google Scholar] [CrossRef]

- Deli, Z.; Shengyang, D.; Zhankun, X.; He, Y.; Jiawei, Y.; Lihu, G.; Lixia, Y.; Jian, W.; Chenglong, Z. A kind of pull-away method and device. Chinese Patent CN107300281A, 27 October 2017. [Google Scholar]

- Masi, M.; Rossi, F.; Salmi, O. Metodo di rimozione di strati di rifinitura da pelli conciate e finite. P07501/IT, 30 March 2023. [Google Scholar]

- Jeyapalina, S. Studies on the Hydro-Thermal and Viscoelastic Properties of Leather; University of Leicester: Leicester, UK, 2004. [Google Scholar]

- Máša, V.; Horňák, D.; Petrilák, D. Industrial use of dry ice blasting in surface cleaning. J. Clean. Prod. 2021, 329, 129630. [Google Scholar] [CrossRef]

- Darrie, G. Commercial Extraction Technology and Process Waste Disposal in the Manufacture of Chromium Chemicals from Ore. Environ. Geochem. Health 2001, 23, 187–193. [Google Scholar] [CrossRef]

- Osin, Y.N.; Makhotkina, L.Y.; Abutalipova, L.N.; Abdullin, I.S. SEM and X-ray analysis of surface microstructure of a natural leather processed in a low temperature plasma. Vacuum 1998, 51, 221–225. [Google Scholar] [CrossRef]

- ISO 3376:2020; Leather—Physical and Mechanical Tests—Determination of Tensile Strength and Percentage Elongation. European Committee for Standardization: Brussels, Belgium, 2020.

- Chahine, C. Changes in hydrothermal stability of leather and parchment with deterioration: A DSC study. Thermochim. Acta 2000, 365, 101–110. [Google Scholar] [CrossRef]

- Creemers, E.; Nijs, M.; Vanheusden, E.; Ombelet, W. Cryopreservation of human sperm: Efficacy and use of a new nitrogen-free controlled rate freezer versus liquid nitrogen vapour freezing. Andrologia 2011, 43, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.L.; Beyer, S.R.; Khan, S. Effect Of ‘Freezing’ Treatments on the Hydrothermal Stability of Collagen. J. Am. Inst. Conserv. 1995, 34, 107–112. [Google Scholar] [CrossRef]

- Pena, A.C.C.; Agustini, C.B.; Trierweiler, L.F.; Gutterres, M. Influence of period light on cultivation of microalgae consortium for the treatment of tannery wastewaters from leather finishing stage. J. Clean. Prod. 2020, 263, 121618. [Google Scholar] [CrossRef]

- Zinck, P.; Terrier, M.; Mortreux, A.; Visseaux, M. On the number-average molecular weight of poly(1,4-trans isoprene) determined by conventional GPC. Polym. Test. 2009, 28, 106–108. [Google Scholar] [CrossRef]

- Sur, S.-H.; Choi, P.-J.; Ko, J.-W.; Lee, J.-Y.; Lee, Y.-H.; Kim, H.-D. Preparation and Properties of DMF-Based Polyurethanes for Wet-Type Polyurethane Artificial Leather. Int. J. Polym. Sci. 2018, 2018, 7370852. [Google Scholar] [CrossRef]

- Maiti, P.; Radhakrishnan, G.; Aruna, P.; Ghosh, G. Novel Polyurethane Gels: The Effect of Structure on Gelation. Macromol. Symp. 2006, 241, 51–59. [Google Scholar] [CrossRef]

- Žagar, E.; Žigon, M. Solution properties of carboxylated polyurethanes and related ionomers in polar solvents (DMF and LiBr/DMF). Polymer 2000, 41, 3513–3521. [Google Scholar] [CrossRef]

- Jiao, L.; Xiao, H.; Wang, Q.; Sun, J. Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym. Degrad. Stab. 2013, 98, 2687–2696. [Google Scholar] [CrossRef]

- Trovati, G.; Sanches, E.A.; Neto, S.C.; Mascarenhas, Y.P.; Chierice, G.O. Characterization of polyurethane resins by FTIR, TGA, and XRD. J. Appl. Polym. Sci. 2010, 115, 263–268. [Google Scholar] [CrossRef]

- Covington, A.D.; Wise, W.R. Current trends in leather science. J. Leather Sci. Eng. 2020, 2, 28. [Google Scholar] [CrossRef]

- Tian, S. Recent Advances in Functional Polyurethane and Its Application in Leather Manufacture: A Review. Polymers 2020, 12, 1996. [Google Scholar] [CrossRef] [PubMed]

- Belbachir, K.; Noreen, R.; Gouspillou, G.; Petibois, C. Collagen types analysis and differentiation by FTIR spectroscopy. Anal. Bioanal. Chem. 2009, 395, 829–837. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Ma, J.; Lyu, B.; Gao, D.; Zhang, J. Enhancement of chromium uptake in tanning process of goat garment leather using nanocomposite. J. Clean. Prod. 2016, 133, 487–494. [Google Scholar] [CrossRef]

- Sizeland, K.H.; Edmonds, R.L.; Basil-Jones, M.M.; Kirby, N.; Hawley, A.; Mudie, S.; Haverkamp, R.G. Changes to Collagen Structure during Leather Processing. J. Agric. Food Chem. 2015, 63, 2499–2505. [Google Scholar] [CrossRef] [PubMed]

- Pringle, T.; Barwood, M.; Rahimifard, S. The Challenges in Achieving a Circular Economy within Leather Recycling. Procedia CIRP 2016, 48, 544–549. [Google Scholar] [CrossRef]

- Nahar, S.; Khan, M.A.; Khan, R.A.; Abdullah, E.C.; Khan, M.J.; Islam, R.; Karim, F.; Rahman, M.; Rahman, A.; Mahmood, A.A.; et al. An Approach to Utilize Crust Leather Scrapes, Dumped into the Land, for the Production of Environmental Friendly Leather Composite. Eng. J. 2013, 17, 17–24. [Google Scholar] [CrossRef][Green Version]

- Thanikaivelan, P.; Rao, J.R.; Nair, B.U.; Ramasami, T. Recent Trends in Leather Making: Processes, Problems, and Pathways. Crit. Rev. Environ. Sci. Technol. 2005, 35, 37–79. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Z.; Liu, X.; Shi, J.; Chen, H.; Gong, Y. SEM, FTIR and DSC Investigation of Collagen Hydrolysate Treated Degraded Leather. J. Cult. Herit. 2021, 48, 205–210. [Google Scholar] [CrossRef]

- Jeyapalina, S.; Attenburrow, G.E.; Covington, A.D. Dynamic Mechanical Thermal Analysis (DMTA) of Leather-Part 1: Effect of Tanning Agent on the Glass Transition Temperature of Collagen 2007. Available online: https://www.researchgate.net/publication/31870705 (accessed on 5 November 2022).

- Shi, H.; Chen, Y.; Fan, H.; Xiang, J.; Shi, B. Thermosensitive polyurethane film and finished leather with controllable water vapor permeability. J. Appl. Polym. Sci. 2010, 117, 1820–1827. [Google Scholar] [CrossRef]

- Elsayed, H.; Attia, R.; Mohamed, O.; Haroun, A.; El-Sayed, N. Preparation of Polyurethane Silicon Oxide Nanomaterials as a Binder in Leather Finishing. Fibers Polym. 2018, 19, 832–842. [Google Scholar] [CrossRef]

- Saikia, P.; Goswami, T.; Dutta, D.; Dutta, N.K.; Sengupta, P.; Neog, D. Development of a flexible composite from leather industry waste and evaluation of their physico-chemical properties. Clean. Technol. Environ. Policy 2017, 19, 2171–2178. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Moustafa, A.B.; Mehawed, M.A.; El-Sayed, N.H. Styrene and butyl methacrylate copolymers and their application in leather finishing. J. Appl. Polym. Sci. 2009, 111, 1488–1495. [Google Scholar] [CrossRef]

| Sample | Thickness before (b) and after (a) (mm) | Look | Color | Photo before | Photo after |

|---|---|---|---|---|---|

| Entry 1 | 1.64 (b) 1.54 (a) | Full hand | black |  |  |

| Entry 2 | 1.56 (b) 1.36 (a) | Compact touch | brown |  |  |

| Entry 3 | 1.29 (b) 1.11 (a) | Soft hand | Light brown |  |  |

| Sample | Solvent | Dissolution Activity | |

|---|---|---|---|

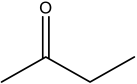

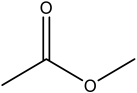

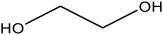

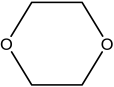

| Name | Structure | ||

| Sample 1 finished layer | Distilled water | Negative | |

| DMSO |  | Partially | |

| THF |  | Negative | |

| Chloroform |  | Polymer separation | |

| Acetonitrile |  | Negative | |

| Ethanol |  | Negative | |

| n-hexane |  | Negative | |

| DCM |  | Negative | |

| Cyclohexanone |  | Polymer separation | |

| Acetone |  | Negative | |

| Methyl tert-butyl ether |  | Negative | |

| Toluene |  | Negative | |

| Butanone |  | Negative | |

| Methyl acetate |  | Negative | |

| Ethylene glycol |  | Negative | |

| DMS |  | Negative | |

| Dioxane |  | Negative | |

| DMF |  | Partially | |

| Sample 1 uncolored finished layer | THF | Negative | |

| Acetone | Negative | ||

| Acetonitrile | Negative | ||

| Methanol |  | Negative | |

| Distiller water | Negative | ||

| Toluene | Negative | ||

| DCM | Negative | ||

| DMF (100 °C) | Negative | ||

| Dioxane | Negative | ||

| Sample 2 finished layer | DMSO | Partially | |

| Sample 3 finished layer | DMSO | Negative | |

| Before | After |

|---|---|

|  |

| Leather side | |

|  |

| Leather top | |

|  |

| Leather down | |

| Entry | Deformation at Maximum Stress (%) | Maximum Stress (MPa) |

|---|---|---|

| 1 | 36.7 | 20.6 |

| 2 | 40.4 | 23.4 |

| 3 | 31.6 | 22.3 |

| 4 | 29.8 | 18.7 |

| 5 | 35.1 | 22.3 |

| 6 | 34.1 | 20.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salmi, O.; Gelosa, S.; Rossi, F.; Masi, M. A Circular Approach to Finished Tanned Leather: Regeneration by Cryogenic Technology. Materials 2023, 16, 6166. https://doi.org/10.3390/ma16186166

Salmi O, Gelosa S, Rossi F, Masi M. A Circular Approach to Finished Tanned Leather: Regeneration by Cryogenic Technology. Materials. 2023; 16(18):6166. https://doi.org/10.3390/ma16186166

Chicago/Turabian StyleSalmi, Omar, Simone Gelosa, Filippo Rossi, and Maurizio Masi. 2023. "A Circular Approach to Finished Tanned Leather: Regeneration by Cryogenic Technology" Materials 16, no. 18: 6166. https://doi.org/10.3390/ma16186166

APA StyleSalmi, O., Gelosa, S., Rossi, F., & Masi, M. (2023). A Circular Approach to Finished Tanned Leather: Regeneration by Cryogenic Technology. Materials, 16(18), 6166. https://doi.org/10.3390/ma16186166