Effect of Scanning Strategy on the Microstructure and Triboperformance of FeNiCrMo Coating Manufactured by Plasma Transferred Arc

Abstract

:1. Introduction

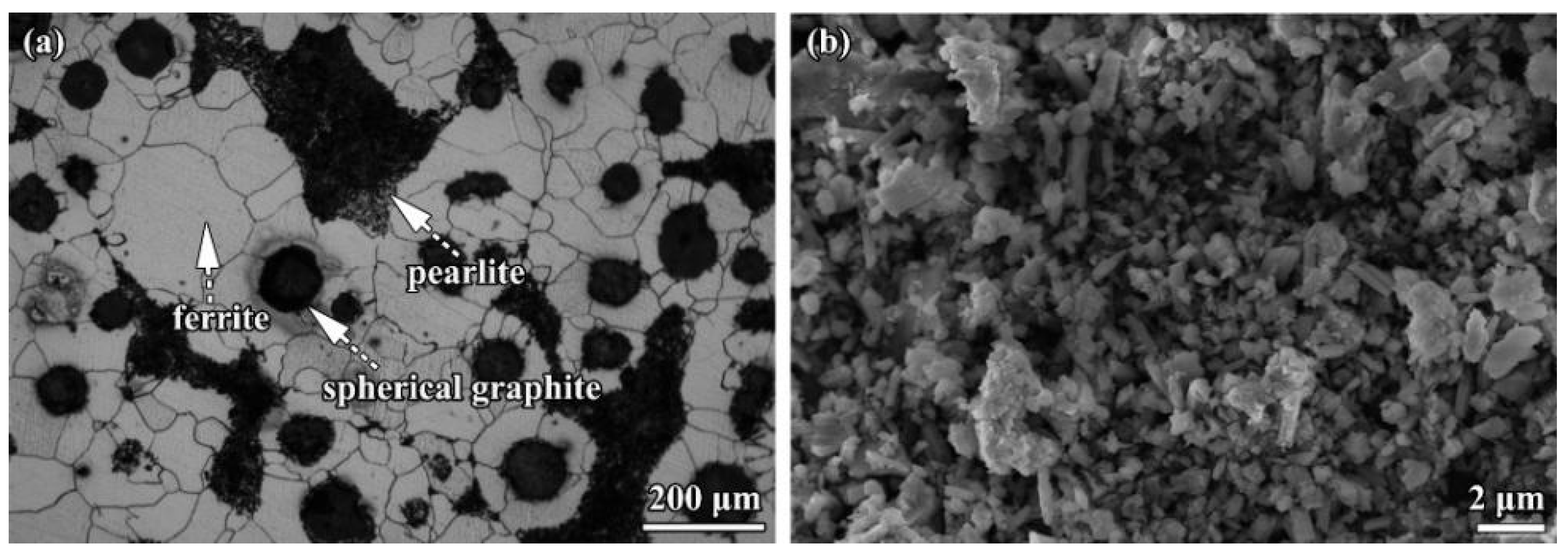

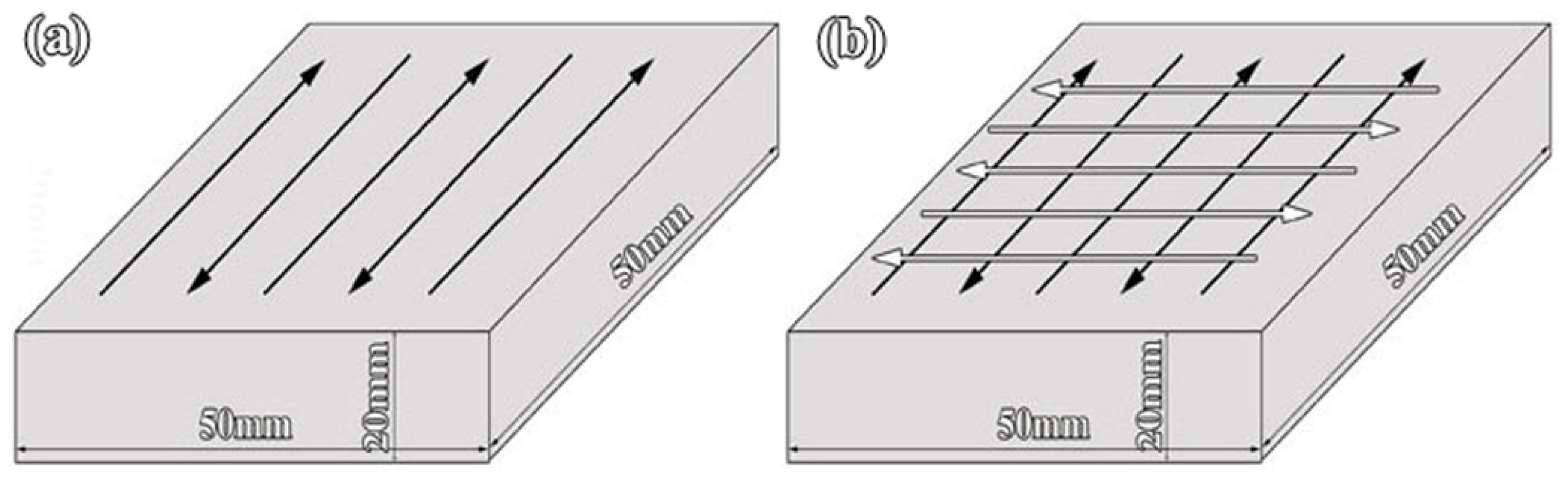

2. Experimental Procedure

3. Results and Discussion

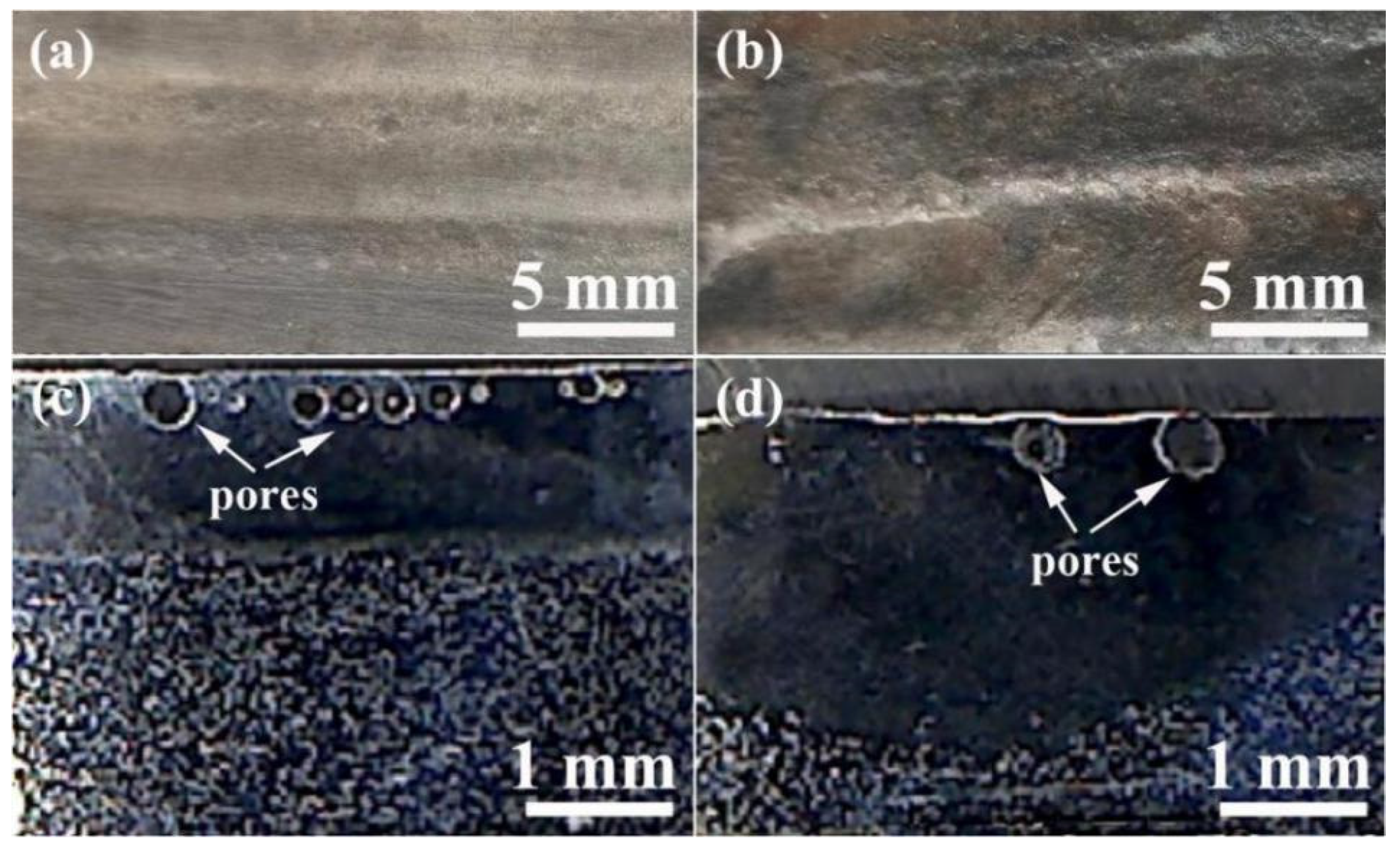

3.1. Forming Features

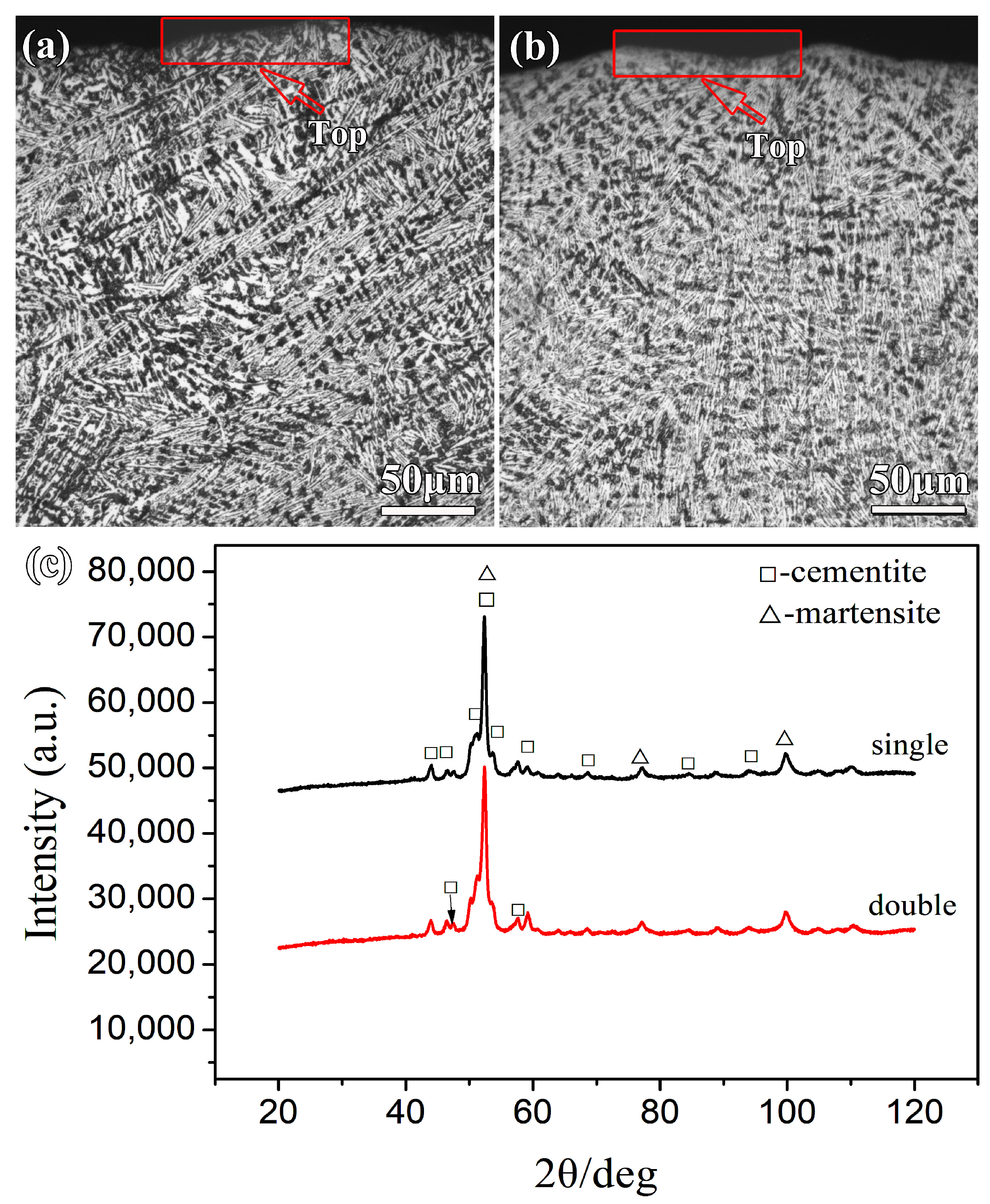

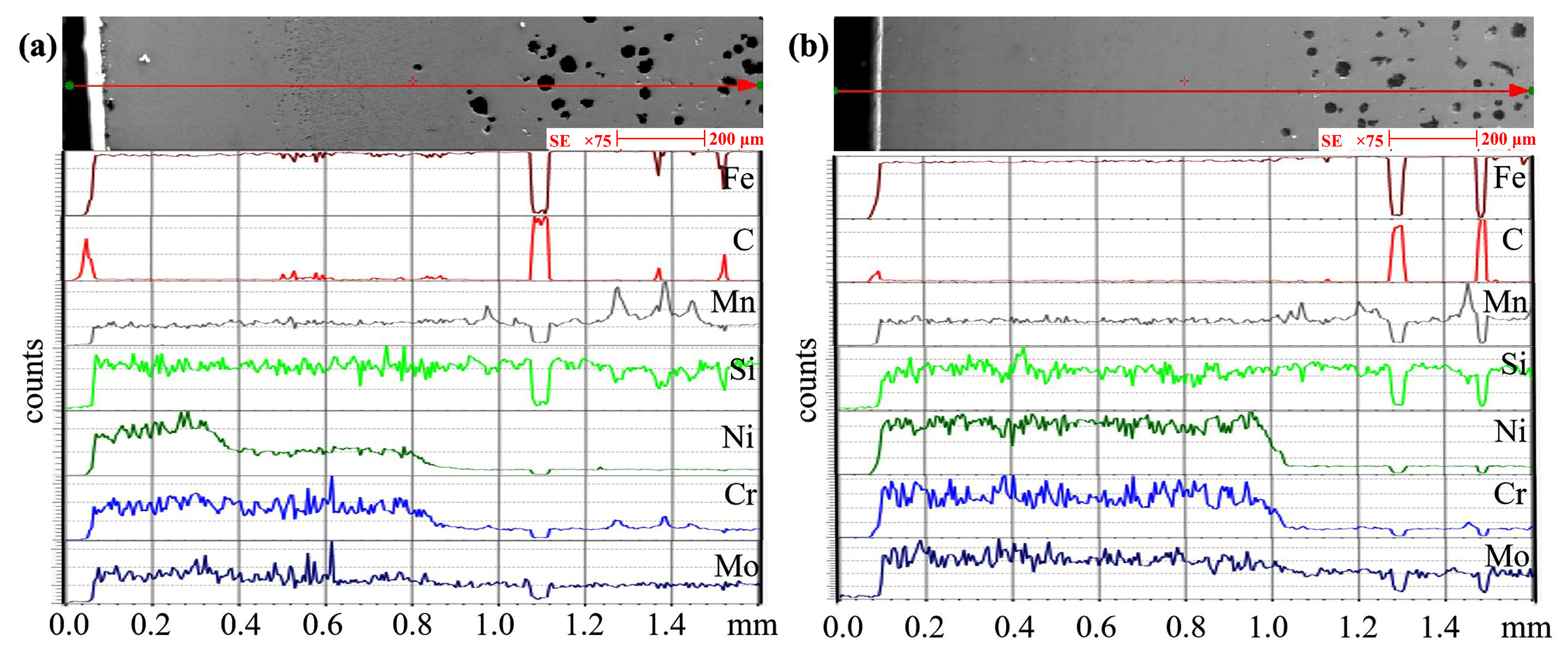

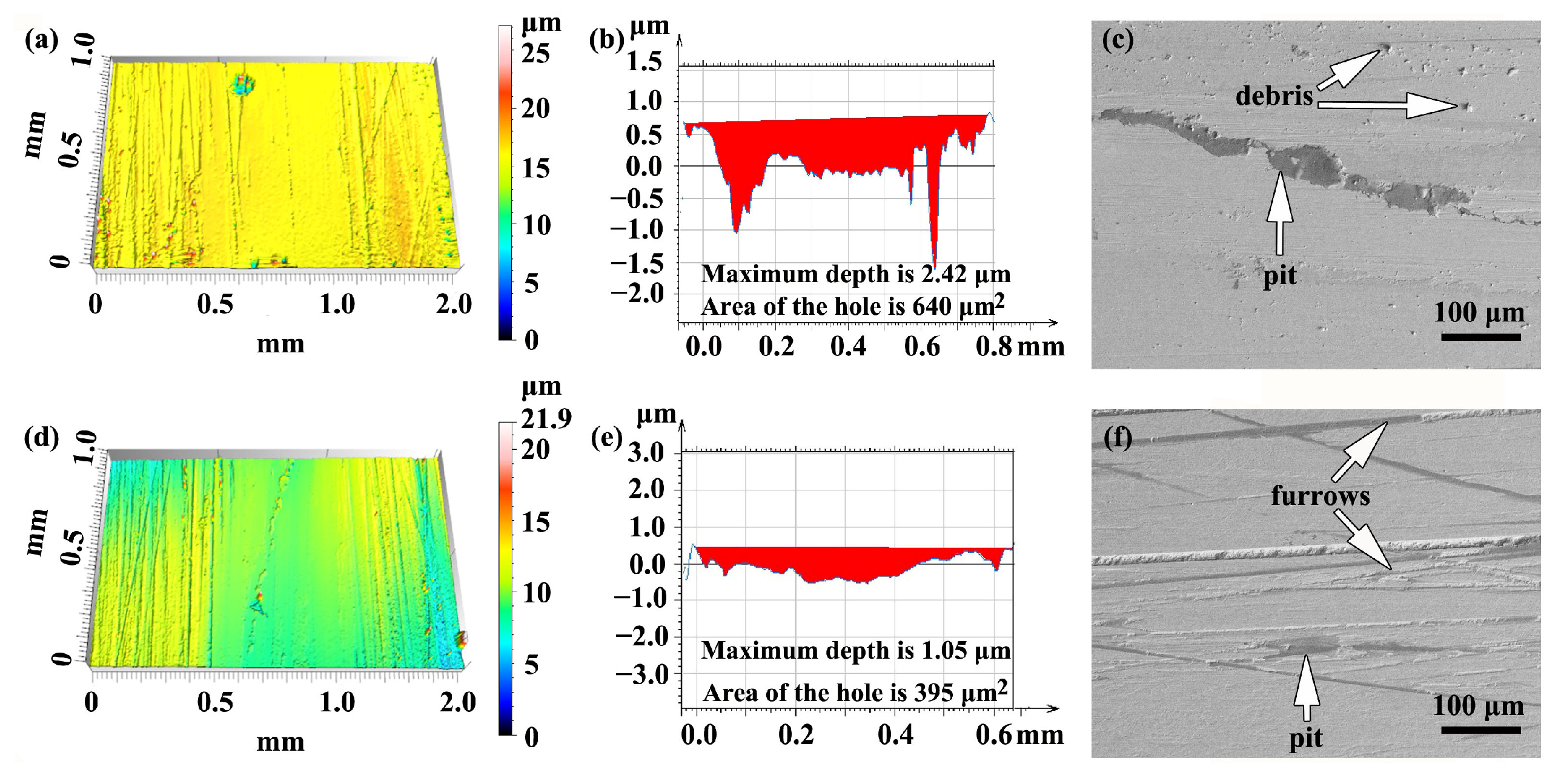

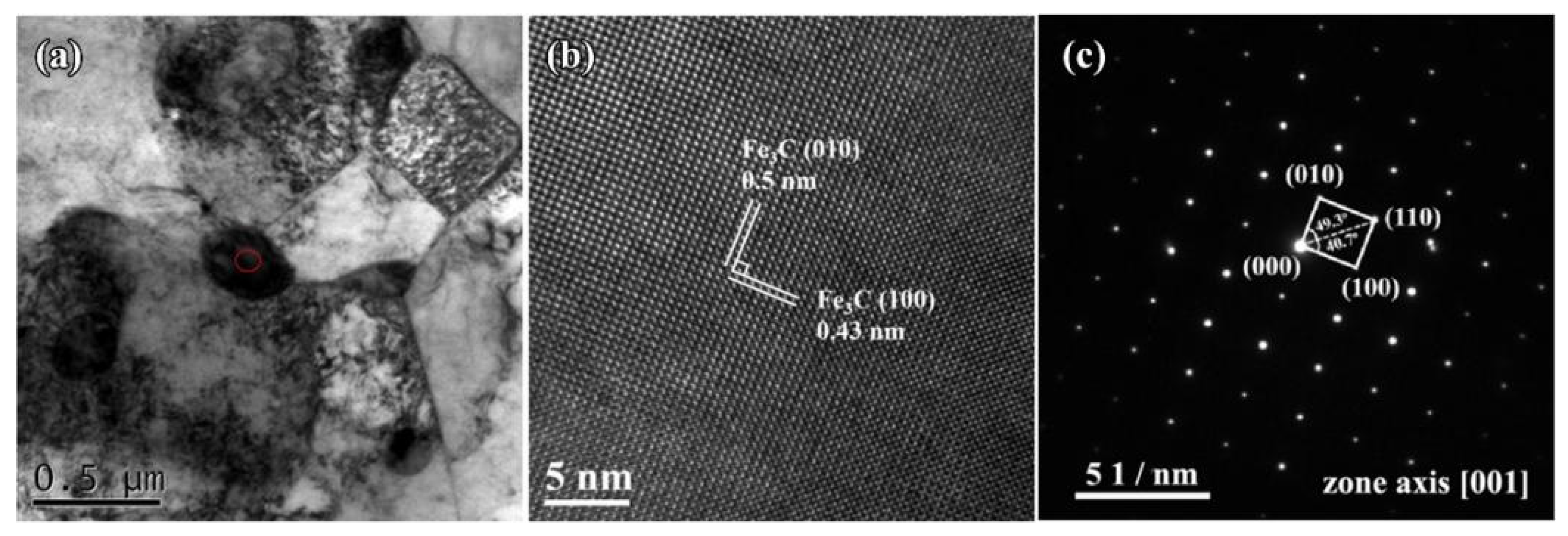

3.2. Microstructure and Phase Analysis

4. Conclusions

- (1)

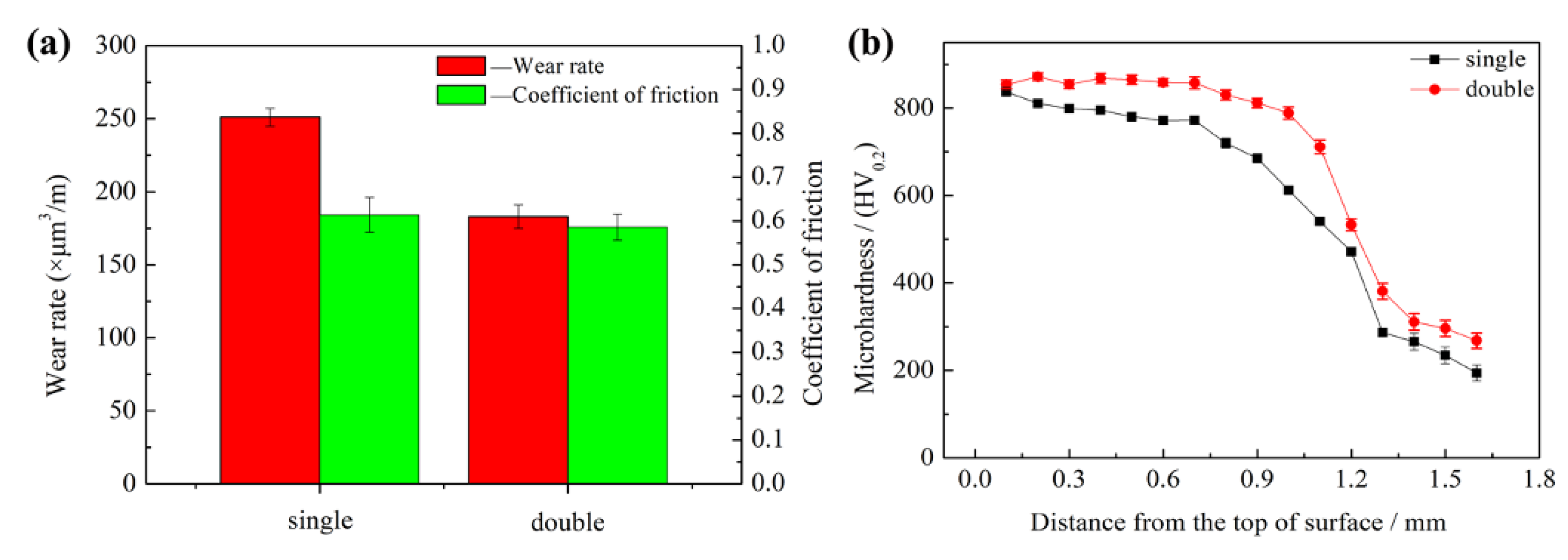

- Double-treatment tracks can increase the thickness of the alloy coating and the microhardness. The maximum microhardness of the sample fabricated by double track increased from 837 ± 10 HV0.2 for the sample fabricated by single track to 871 ± 7 HV0.2. Thereby extending the FeNiCrMo coating’s service life.

- (2)

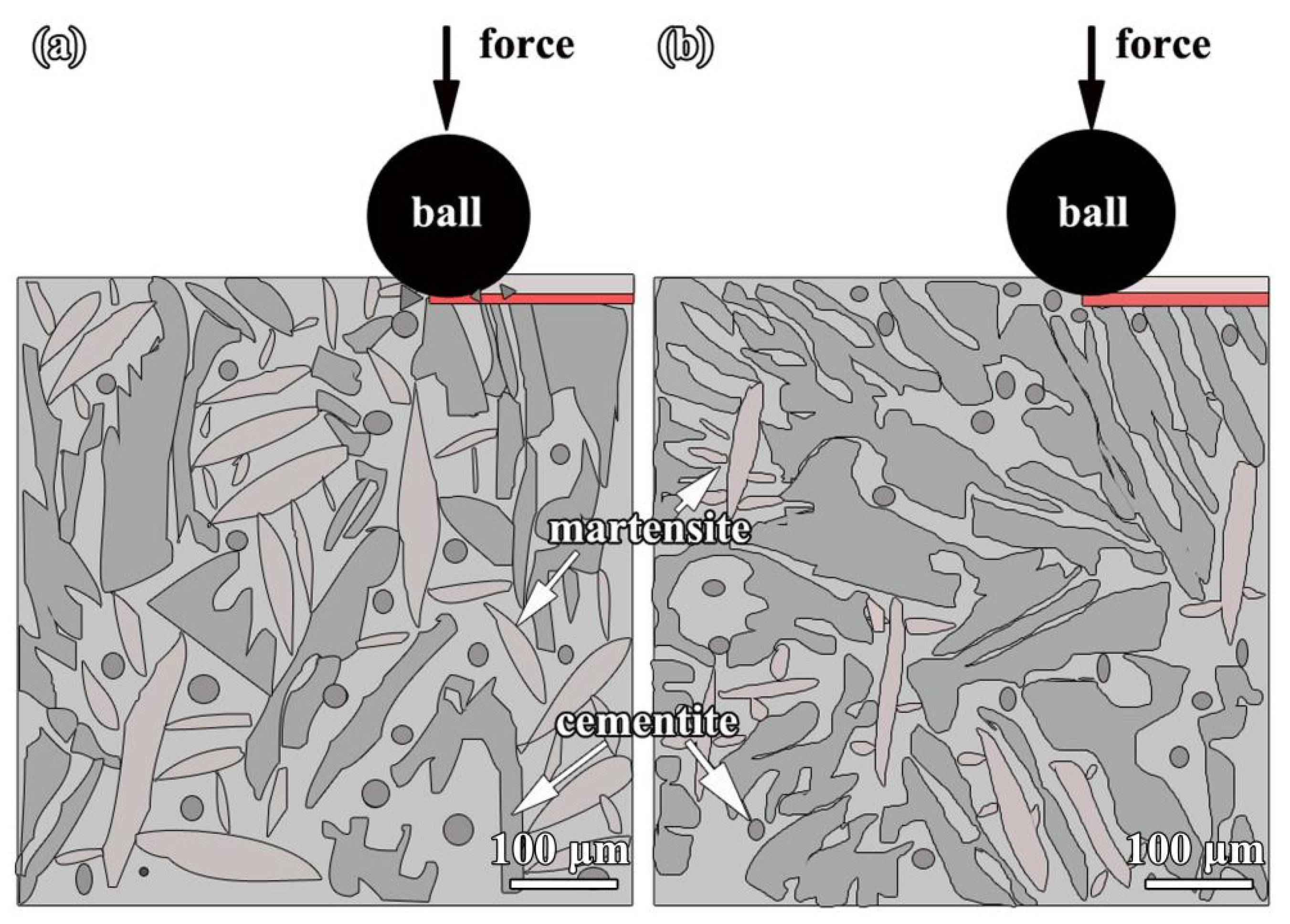

- In both samples, the coatings contain block-like and granular cementite. The block-like cementite content in the double-track PTA-treated alloy coating increases by 3.90 wt.% and the martensite content decreases by 13.04 wt.% compared to the single-track one.

- (3)

- Both single- and double-track alloy coatings possess high hardness and wear resistance, and the sample fabricated by single track presented both abrasive and adhesive wear, and the sample fabricated by double track presented abrasive wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Sayed, S.R.; Elgazzar, H.; Nofal, A. Metallographic investigation of laser-treated ductile iron surface with different laser heat inputs. Ain Shams Eng. J. 2023, 14, 102189. [Google Scholar] [CrossRef]

- Gromov, V.E.; Konovalov, S.V.; Ivanov, Y.F.; Shliarova, Y.A.; Vorobyov, S.V.; Semin, A.P. Structure and properties of the CrMnFeCoNi high-entropy alloy irradiated with a pulsed electron beam. J. Mater. Res. Technol. 2022, 19, 4258–4269. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kurbanbekov, S.; Skakov, M.; Wieleba, W.; Zhurerova, L. Effect plasma beam irradiation on the microstructure and phase composition of high-speed steel R6M5. Mater. Test. 2020, 62, 1138–1142. [Google Scholar] [CrossRef]

- Bissett, H.; van der Walt, I.J.; Havenga, J.L.; Nel, J.T. Titanium and zirconium metal powder spheroidization by thermal plasma processes. J. S. Afr. I. Min. Metall. 2015, 115, 937–942. [Google Scholar] [CrossRef]

- Xiao, B.T.; Yan, X.F.; Jiang, W.M.; Fan, Z.T.; Huang, Q.W.; Fang, J.; Xiang, J.H. Comparative study on the hardness and wear resistance of the remelted gradient layer on ductile iron fabricated by plasma transferredred arc. Metals 2022, 12, 644. [Google Scholar] [CrossRef]

- Feng, J.J.; Pan, C.X.; Lu, L.L.; Huang, Q.W.; Cao, H.T. Plasma transferred arc surface alloying of Cr-Ni-Mo powders on compacted graphite iron. J. Iron Steel Res. Int. 2016, 23, 618–624. [Google Scholar] [CrossRef]

- Matejicek, J.; Antos, J.; Rohan, P. W plus Cu and W plus Ni composites and FGMs prepared by plasma transferred arc Cladding. Materials 2021, 14, 789. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Hu, S.B.; Song, W.L.; Xiong, X.S. A comparative study on gray and nodular cast irons surface melted by plasma beam. Vacuum 2014, 101, 177–183. [Google Scholar] [CrossRef]

- Shreeram, B.; Rajendran, I.; Kumar, E.R. Tailoring of functionally graded mullite: La2O3 coatings by transferred arc plasma for thermal barrier coatings. J. Inong. Organomet. P. 2018, 28, 2484–2493. [Google Scholar] [CrossRef]

- Pan, Z.; Dong, X.P.; Cao, H.T.; Huang, Q.W. The role of distribution forms of Fe-Cr-C cladding layer in the impact abrasive wear performance of hadfield steel. Materials 2020, 13, 1818. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.J.; Zheng, Z.Z.; Wang, A.H.; Zeng, D.W.; Miao, Y.F. The microstructures and tribological properties of composite coatings formed via PTA surface alloying of copper on nodular cast iron. Surf. Coat. Technol. 2016, 286, 303–312. [Google Scholar] [CrossRef]

- Cao, H.T.; Dong, X.P.; Pan, Z.; Wu, X.W.; Huang, Q.W.; Pei, Y.T. Surface alloying of high-vanadium high-speed steel on ductile iron using plasma transferredred arc technique: Microstructure and wear properties. Mater. Des. 2016, 100, 223–234. [Google Scholar] [CrossRef]

- Crook, P. Corrosion characteristics of the wrought Ni-Cr-Mo alloys. Mater. Corros. 2005, 56, 606–610. [Google Scholar] [CrossRef]

- Tobie, T.; Hippenstiel, F.; Mohrbacher, H. Optimizing gear performance by alloy modification of carburizing steels. Metals 2017, 7, 415. [Google Scholar] [CrossRef]

- Walsh, D.A.; Li, L.E.; Bakare, M.S.; Voisey, K.T. Visualisation of the local electrochemical activity of thermal sprayed anti-corrosion coatings using scanning electrochemical microscopy. Electrochim. Acta 2009, 54, 4647–4654. [Google Scholar] [CrossRef]

- Milanti, A.; Matikainen, V.; Bolelli, G.; Koivuluoto, H.; Lusvarghi, L.; Vuoristo, P. Microstructure and sliding wear behavior of Fe-based coatings manufactured with HVOF and HVAF thermal spray processes. J. Therm. Spray Technol. 2016, 25, 1040–1055. [Google Scholar] [CrossRef]

- Wen, Z.H.; Bai, Y.; Yang, J.F.; Huang, J.; Zhang, L. Effect of vacuum remelting on microstructure and wear resistance of NiCrMoY coatings deposited by supersonic atmospheric plasma spraying. Surf. Coat. Technol. 2015, 281, 62–67. [Google Scholar] [CrossRef]

- Tian, J.J.; Wei, Y.K.; Li, C.X.; Yang, G.J.; Li, C.J. Effect of post-spray shot peening treatment on the corrosion behavior of NiCr-Mo coating by plasma spraying of the shell–core–structured powders. J. Therm. Spray Technol. 2018, 27, 232–242. [Google Scholar] [CrossRef]

- Cuvalci, O.; Varol, T.; Akcay, S.B.; Güler, O.; Çanakçı, A. Effect of ball mill time and wet pre-milling on the fabrication of Ti powders by recycling Ti machining chips by planetary milling. Powder Technol. 2023, 426, 118637. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.J.; Zheng, Z.Z.; Wang, A.H.; Huang, Q.W.; Zeng, D.W. Microstructure and high-temperature wear properties of in situ TiC composite coatings by plasma transferred arc surface alloying on gray cast iron. Int. J. Miner. Metall. Mater. 2015, 22, 1273–1282. [Google Scholar] [CrossRef]

- Akinribide, O.J.; Ogundare, O.D.; Oluwafemi, O.M.; Ebisike, K.; Nageri, A.K.; Akinwamide, S.O.; Gamaoun, F.; Olubambi, P.A. A review on heat treatment of cast iron: Phase evolution and mechanical characterization. Materials 2022, 15, 7109. [Google Scholar] [CrossRef] [PubMed]

- G119-09; Standard Guide for Determining Synergism between Wear and Corrosion. ASTM International: West Conshohocken, PA, USA, 2016.

- Zhang, S.T.; Zhou, J.S.; Guo, B.G.; Zhou, H.D.; Pu, Y.P.; Chen, J.M. Friction and wear behavior of laser cladding Ni/hBN self-lubricating composite coating, Mater. Sci. Eng. A 2008, 491, 47–54. [Google Scholar] [CrossRef]

- Zhu, L.J.; Liu, Y.H.; Li, Z.W.; Zhou, L.; Li, Y.J.; Xiong, A.H. Microstructure and properties of Cu-Ti-Ni composite coatings on gray cast iron fabricated by laser cladding. Opt. Laser Technol. 2020, 122, 105879. [Google Scholar] [CrossRef]

- Li, Y.J.; Dong, S.Y.; Yan, S.X.; Liu, X.T.; He, P.; Xu, B.S. Surface remanufacturing of ductile cast iron by laser cladding Ni-Cu alloy coatings. Surf. Coat. Technol. 2018, 347, 20–28. [Google Scholar] [CrossRef]

- Meng, W.; Lei, Y.L.; Wang, X.; Ma, Q.S.; Hu, L.; Xie, H.; Yin, X.H. Interface characteristics and mechanical properties of wire-arc depositing Inconel 625 superalloy on ductile cast iron. Surf. Coat. Technol. 2022, 440, 128493. [Google Scholar] [CrossRef]

- Ravikiran, K.; Mehtani, H.; Sivaprasad, K.; Prasad, M.J.N.V.; Kumar, S.; Singh, P.K.; Ghosh, M. Influence of nickel-based buttering material on welded joint between SA508 low alloy steel and 304LN stainless steel. Int. J. Press. Vessel. Pip. 2022, 195, 104576. [Google Scholar] [CrossRef]

- Ucgun, E.; Ocak, H.Y. Electronic properties of austenite and martensite Fe-9%Mn alloys. Chem.-Eur. J. 2008, 6, 808–811. [Google Scholar] [CrossRef]

- Grum, J.; Sturm, R. A new experimental technique for measuring strain and residual stresses during a laser remelting process. J. Mater. Process. 2004, 147, 351–358. [Google Scholar] [CrossRef]

- Rashidi, M.M.; Idris, M.H. The effects of solidification on the microstructure and mechanical properties of modified ductile Ni-resist iron with a high manganese content. Mater. Sci. Eng. A 2015, 597, 395–407. [Google Scholar] [CrossRef]

- Opapaiboon, J.; Inthidech, S.; Visuttipitukul, P.; Matsubara, Y. Solidification structure and heat treatment behavior of multi-alloyed white cast iron with extensive molybdenum content for applying to hot work rolls. Int. J. Metalcast. 2022, 16, 2065–2078. [Google Scholar] [CrossRef]

- Lee, K.; Park, S.J.; Lee, J.; Moon, J.; Kang, J.Y.; Kim, D.I.; Suh, J.Y.; Han, H.N. Effect of aging treatment on microstructure and intrinsic mechanical behavior of Fe–31.4Mn–11.4Al–0.89C lightweight steel. J. Alloys Compd. 2016, 656, 805–811. [Google Scholar] [CrossRef]

- Xia, S.Q.; Xia, Z.X.; Zhao, D.; Xie, Y.; Liu, X.; Wang, L. Microstructure formation mechanism and corrosion behavior of FeCrCuTiV two-phase high entropy alloy prepared by different processes. Fusion Eng. Des. 2021, 172, 112792. [Google Scholar] [CrossRef]

- de la Torre, U.; Loizaga, A.; Lacaze, J.; Sertucha, J. As cast high silicon ductile irons with optimised mechanical properties and remarkable fatigue properties. Mater. Sci. Technol. 2014, 30, 1425–1431. [Google Scholar] [CrossRef]

- Goto, S.; Kami, C.; Kawamura, S. Effect of alloying elements and hot-rolling conditions on microstructure of bainitic-ferrite/martensite dual phase steel with high toughness. Mater. Sci. Eng. A 2015, 648, 436–442. [Google Scholar] [CrossRef]

- Zhang, R.J.; Su, Z.B. Structures and high temperature frictional behaviors of carbonaceous mesophases doped with metallic element nickel (Ni) through mechanical alloying. Tribol. Lett. 2006, 22, 113–118. [Google Scholar]

- Farías, I.; Jimenez, O.; Flores, M.; Rivera-Tello, C.D.; González, M.A.; Olmos, L. Tribocorrosion behavior of spark plasma sintering TiC reinforced Ti-based composites. Mater. Lett. 2020, 277, 128298. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, W.; Qu, Y.D.; Dong, S.L.; Li, R.D.; Zhou, G.P.; Chen, R.R.; Wang, Q.; Sun, W.; Li, G.L. Effect of TiC particles addition on tribological behavior of ductile iron. Tribol. Lett. 2023, 71, 27. [Google Scholar] [CrossRef]

- Janicki, D.; Gorka, J.; Kwasny, W.; Pakieła, W.; Matus, K. Influence of solidification conditions on the microstructure of laser-surface-melted ductile cast iron. Materals 2020, 13, 1174. [Google Scholar] [CrossRef]

- Shah, M.; Sahoo, K.L.; Das, S.K.; Das, G. Wear mechanism of high chromium white cast iron and its microstructural evolutions during the comminution process. Tribol. Lett. 2020, 68, 77. [Google Scholar] [CrossRef]

- Saleh, A.A.; Casillas, G.; Pereloma, E.V.; Carpenter, K.R.; Killmore, C.R.; Gazder, A.A. A transmission Kikuchi diffraction study of cementite in a quenched and tempered steel. Mater. Charact. 2016, 114, 146–150. [Google Scholar] [CrossRef]

| Rare Earth Oxide (REO) | CeO2 | F | H2O |

|---|---|---|---|

| 83.26 | 48.58 | 26.20 | <0.50 |

| Single Track | Double Track | |

|---|---|---|

| cementite | 77% | 80% |

| martensite | 23% | 20% |

| Point | Element (at.%) | |||||

|---|---|---|---|---|---|---|

| Fe | C | Si | Ni | Cr | Mo | |

| A | 63.58 | 30.50 | 3.61 | 1.82 | 0.30 | 0.19 |

| B | 59.33 | 37.74 | 1.21 | 0.65 | 0.82 | 0.24 |

| C | 59.04 | 36.59 | 2.66 | 1.26 | 0.32 | 0.14 |

| D | 58.09 | 36.64 | 3.20 | 1.81 | 0.22 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, B.; Li, S.; Song, X.; Huang, Q.; Lou, J.; Fang, J.; Hou, P.; Cao, H. Effect of Scanning Strategy on the Microstructure and Triboperformance of FeNiCrMo Coating Manufactured by Plasma Transferred Arc. Materials 2023, 16, 5931. https://doi.org/10.3390/ma16175931

Xiao B, Li S, Song X, Huang Q, Lou J, Fang J, Hou P, Cao H. Effect of Scanning Strategy on the Microstructure and Triboperformance of FeNiCrMo Coating Manufactured by Plasma Transferred Arc. Materials. 2023; 16(17):5931. https://doi.org/10.3390/ma16175931

Chicago/Turabian StyleXiao, Botao, Shang Li, Xianglin Song, Qiwen Huang, Jin Lou, Jun Fang, Pengfei Hou, and Huatang Cao. 2023. "Effect of Scanning Strategy on the Microstructure and Triboperformance of FeNiCrMo Coating Manufactured by Plasma Transferred Arc" Materials 16, no. 17: 5931. https://doi.org/10.3390/ma16175931

APA StyleXiao, B., Li, S., Song, X., Huang, Q., Lou, J., Fang, J., Hou, P., & Cao, H. (2023). Effect of Scanning Strategy on the Microstructure and Triboperformance of FeNiCrMo Coating Manufactured by Plasma Transferred Arc. Materials, 16(17), 5931. https://doi.org/10.3390/ma16175931