Ag and Sn Implications in 3-Polker Coins Forgeries Evidenced by Nondestructive Methods

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Description

2.2. Investigation Methods

2.3. Statistical Analysis

3. Results

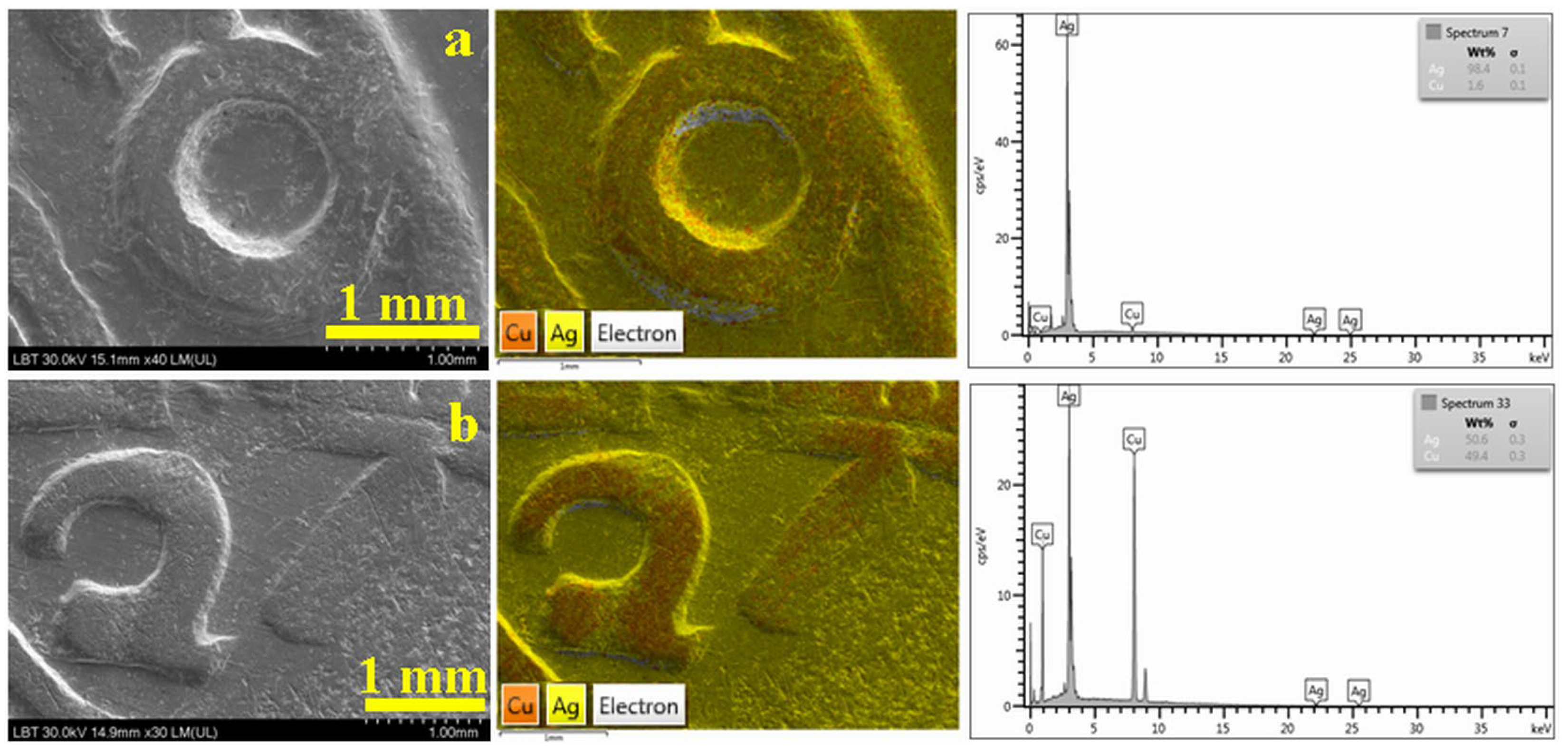

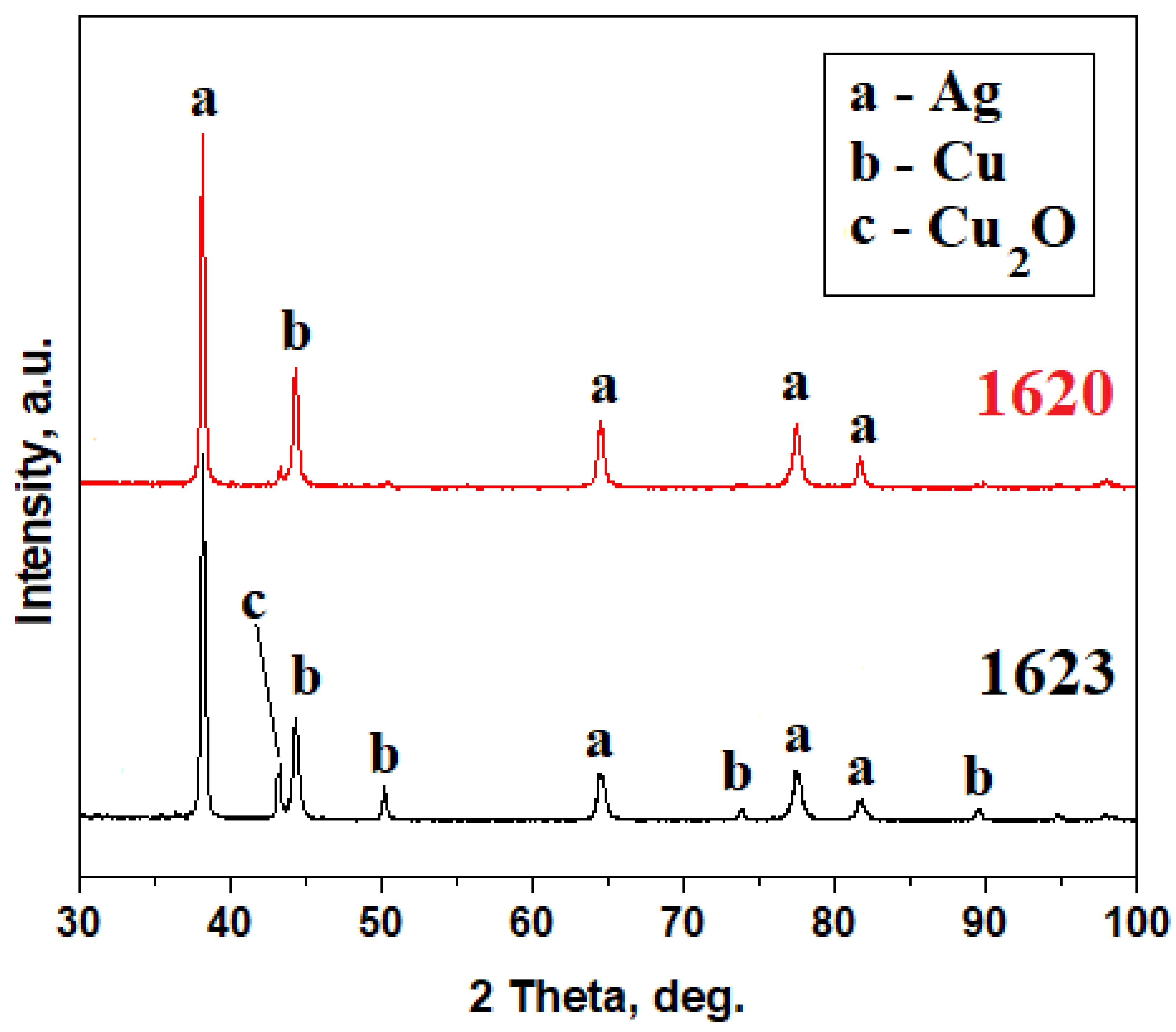

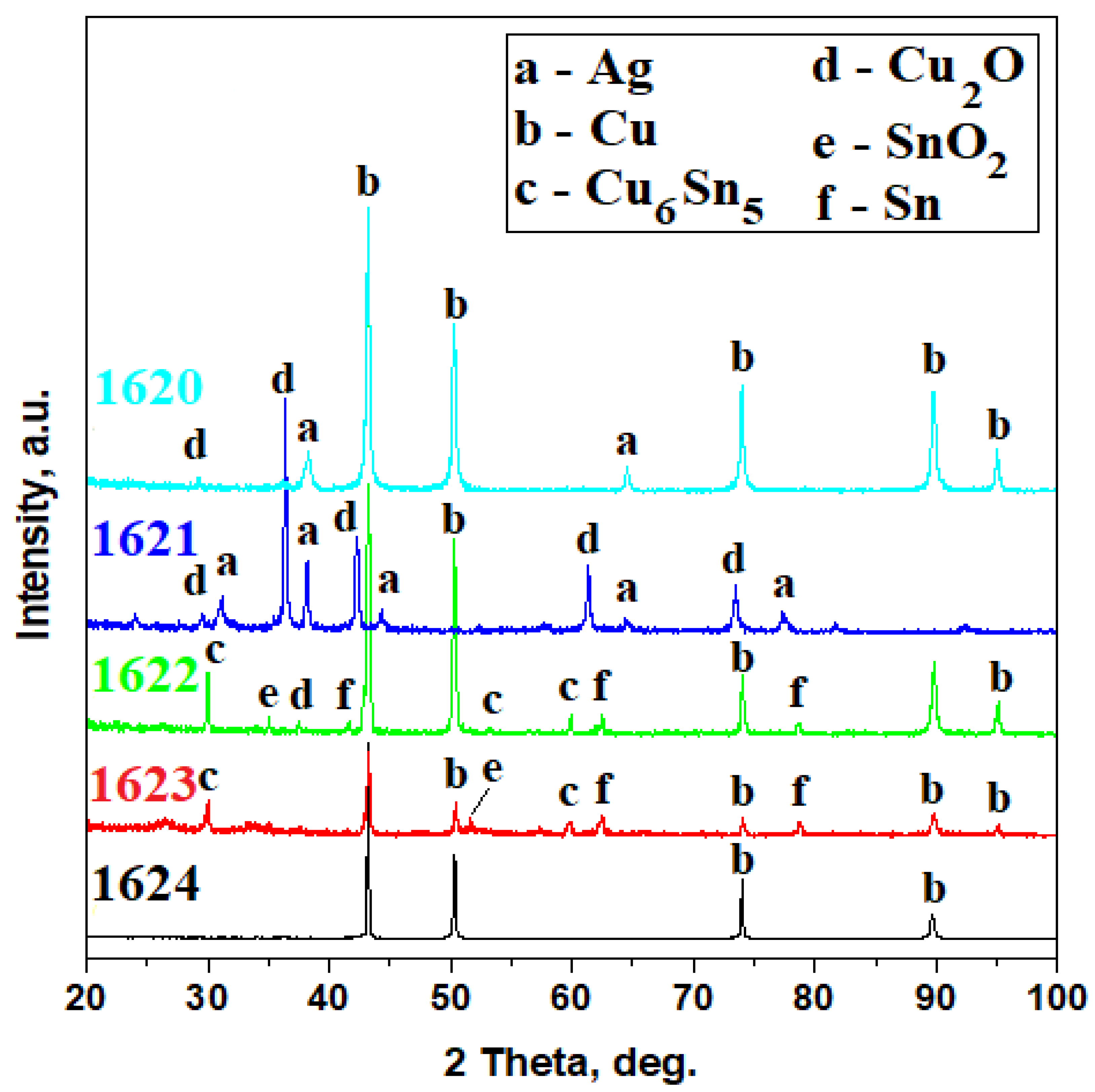

3.1. Original 3-Polkers

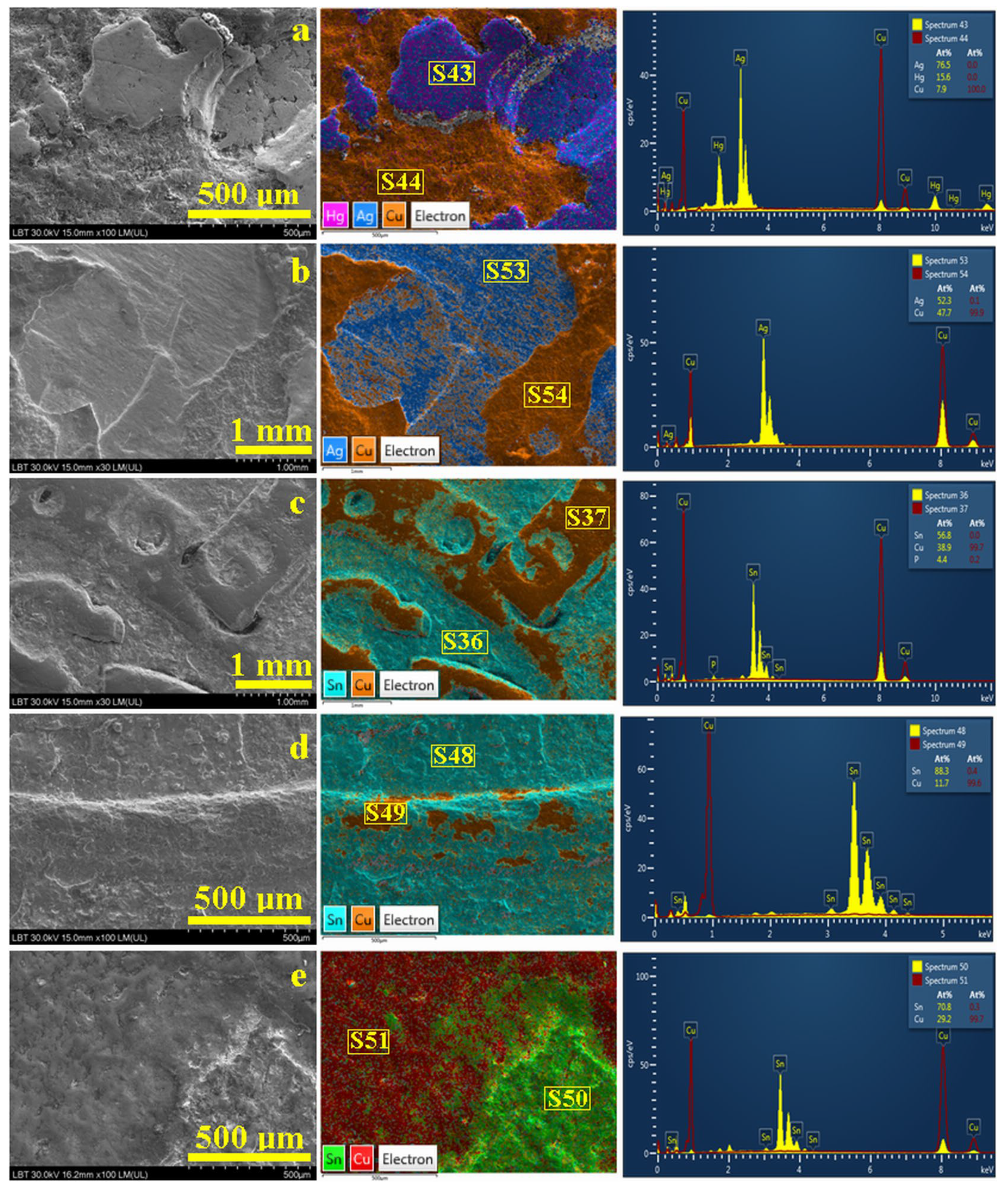

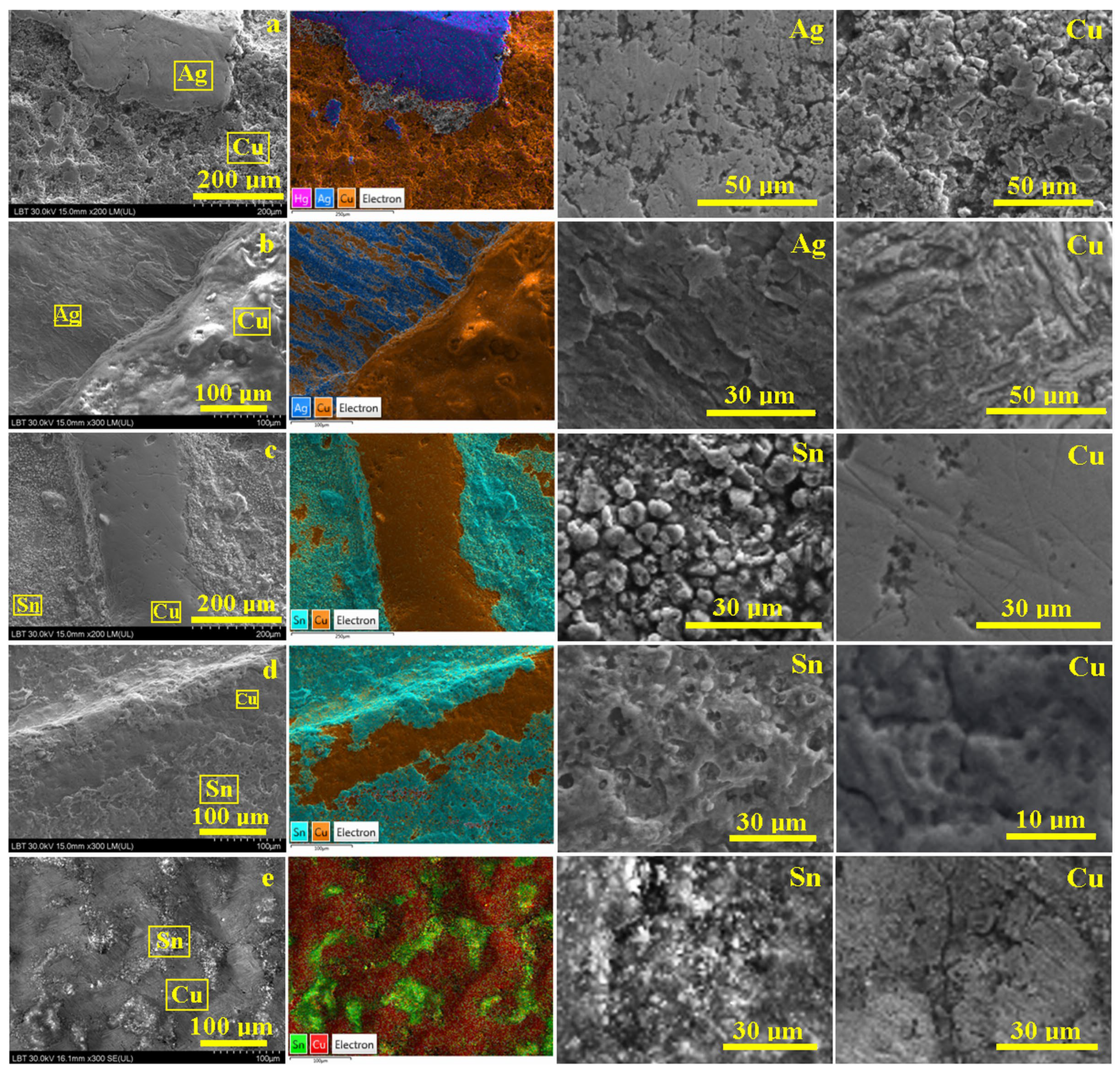

3.2. Forged 3-Polkers

3.3. Statistical Results

4. Discussion

5. Conclusions

- −

- Copper core plated with a thin silver foil via amalgamation method, evidenced on the forged coins from 1620;

- −

- Copper core plated with a relatively thick silver layer deposited by immersion into an Ag-Cu eutectic molten bath, evidenced by the forged coin from 1621;

- −

- Copper core plated with high-tin bronze bases on the bi-phase structure of Cu6Sn5 intermetallic compound and pure Sn grains, evidenced by the forged coins from 1622, 1623, and 1624.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McDougall, W.A. The Myth of the Secular: Religion, War, and Politics in the Twentieth Century. Orbis 2020, 64, 24–42. [Google Scholar] [CrossRef]

- Schaff, F.S.F. Warfare and Economic Inequality: Evidence from Preindustrial Germany (c. 1400–1800). Explor. Econ. Hist. 2022, 89, 101495. [Google Scholar] [CrossRef]

- Eyerman, R. Race in the Culture Wars. Religions 2023, 14, 721. [Google Scholar] [CrossRef]

- Ludwig, B. Baroque Origins of the Greenery of Urban Interiors in Lower Silesia and the Border Areas of the Former Neumark and Lusatia. Sustainability 2021, 13, 2623. [Google Scholar] [CrossRef]

- Buza, J. Inflációs Pénzforgalom Törvénye Segédlettel; az 1622. évi 77. törvénycikk (Inflationary money circulation is legal with assistance; Article 77 of 1622). In A Rendtartó Történész Tanulmányok Imreh István Születésének Századik Évfordulójára; Tamas, F., Emoke, G., Eds.; Erdélyi Múzeum Publishing House: Budapest, Hungary, 2021; pp. 147–160. [Google Scholar]

- Karaman, K.K.; Pamuk, Ş.; Yıldırım-Karaman, S. Money and monetary stability in Europe, 1300–1914. J. Monet. Econ. 2020, 115, 279–300. [Google Scholar] [CrossRef]

- Boubaker, H.; Cunado, J.; Gil-Alana, L.A.; Gupta, R. Global crises and gold as a safe haven: Evidence from over seven and a half centuries of data. Phys. A Stat. Mech. Its Appl. 2020, 540, 123093. [Google Scholar] [CrossRef]

- Mihailescu, S.G. Nagy SzabóFerencz of Târgu Mureș Memorial (1580–1658). In Translation, Notes and Introductive Study; Kriterion Publishing House: Bucharest, Romania, 1993; p. 245. [Google Scholar]

- Sandor, S. Erdélyi Országgűlési Emlékek (Monumenta Comitialia Regni Transylvaniae; Monuments of the Transylvania Shire); Akademia Konyvkiado-Hivatala: Budapest, Hungary, 1882; Volume VIII (1621–1629), pp. 94–95. [Google Scholar]

- Petean, I.; Paltinean, G.A.; Pripon, E.; Borodi, G.; Barbu Tudoran, L. Silver Depreciation in 3-Polker Coins Issued during 1619–1627 by Sigismund III Vasa King of Poland. Materials 2022, 15, 7514. [Google Scholar] [CrossRef]

- Kiritescu, C. Sistemul Bănesc al Leului și Precursorii săi; Romanian Academy Publishing House: Bucharest, Romania, 1964. [Google Scholar]

- Ingo, G.M.; Riccucci, C.; Faraldi, F.; Pascucci, M.; Messina, E.; Fierro, G.; Di Carlo, G. Roman sophisticated surface modification methods to manufacture silver counterfeited coins. Appl. Surf. Sci. 2017, 421, 109–119. [Google Scholar] [CrossRef]

- Constantinescu, B.; Săşianu, A.; Bugoi, R. Adulterations in first century BC: The case of Greek silver drachmae analyzed by X-ray methods. Spectrochim. Acta Part B At. Spectrosc. 2003, 58, 759–765. [Google Scholar] [CrossRef]

- Pense, A.W. The decline and fall of the roman denarius. Mater. Charact. 1992, 29, 213–222. [Google Scholar] [CrossRef]

- Zwicker, U.; Oddy, A.; La Niece, S. Roman techniques of manufacturing silver-plated coins. In Metal Plating and Patination; La Niece, S., Craddock, P., Eds.; Butterworth-Heinemann: Oxford, UK, 1993; pp. 223–246. [Google Scholar] [CrossRef]

- Hložek, M.; Trojek, T. Silver and tin plating as medieval techniques of producing counterfeit coins and their identification by means of micro-XRF. Radiat. Phys. Chem. 2017, 137, 234–237. [Google Scholar] [CrossRef]

- Beck, L. Ion Beam Analysis and 14C Accelerator Mass Spectroscopy to Identify Ancient and Recent Art Forgeries. Physics 2022, 4, 462–472. [Google Scholar] [CrossRef]

- Fajfar, H.; Rupnik, Z.; Smit, Z. Analysis of metals with luster: Roman brass and silver. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 362, 194–201. [Google Scholar] [CrossRef]

- Ingo, G.M.; Riccucci, C.; Lavorgna, M.; Salzano de Luna, M.; Pascucci, M.; Di Carlo, G. Surface investigation of naturally corroded gilded copper-based objects. Appl. Surf. Sci. 2016, 387, 244–251. [Google Scholar] [CrossRef]

- Rezk, R.A.; Abdel Ghany, N.A.; Mostafa, A.M. Laser-Assisted Method for Cleaning and Analysis of Archaeological Metallic Coins. Coatings 2022, 12, 1548. [Google Scholar] [CrossRef]

- Drob, A.; Vasilache, V.; Bolohan, N. The Interdisciplinary Approach of Some Middle Bronze Age Pottery from Eastern Romania. Appl. Sci. 2021, 11, 4885. [Google Scholar] [CrossRef]

- Gupta, S.; Sharma, A.K.; Agrawal, D.; Lanagan, M.T.; Sikora, E.; Singh, I. Characterization of AZ31/HA Biodegradable Metal Matrix Composites Manufactured by Rapid Microwave Sintering. Materials 2023, 16, 1905. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, Z.; Meng, X.; Xiao, L.; Pei, Y.; Gan, X. Experimental and Numerical Studies on Hot Compressive Deformation Behavior of a Cu–Ni–Sn–Mn–Zn Alloy. Materials 2023, 16, 1445. [Google Scholar] [CrossRef]

- Farcas, I.A.; Dippong, T.; Petean, I.; Moldovan, M.; Filip, M.R.; Ciotlaus, I.; Tudoran, L.B.; Borodi, G.; Paltinean, G.A.; Pripon, E.; et al. Material Evidence of Sediments Recovered from Ancient Amphorae Found at the Potaissa Roman Fortress. Materials 2023, 16, 2628. [Google Scholar] [CrossRef]

- Rusca, M.; Rusu, T.; Avram, S.E.; Prodan, D.; Paltinean, G.A.; Filip, M.R.; Ciotlaus, I.; Pascuta, P.; Rusu, T.A.; Petean, I. Physicochemical Assessment of the Road Vehicle Traffic Pollution Impact on the Urban Environment. Atmosphere 2023, 14, 862. [Google Scholar] [CrossRef]

- Chirila, E.; Gudea, N.; Cabuz, I. Salajeni Hoard XVII—Century. In Monetary Hoards in the Northen Transylvania between XVI–XVIII Centuries; Zalau Museum Publishing House: Zalau, Romania, 1970; pp. 33–43. [Google Scholar]

- Chirila, E.; Bajusz, I. Monetary hoard of Verveghiu XVI–XVII centuries. Acta Musei Porolisensis 1978, 9, 119–127. [Google Scholar]

- Pripon, E. Medieval and Pre-Modern Monetary Hoards Discovered on the Area of Zalau City; Mega Publishing House: Cluj-Napoca, Romania, 2018; p. 99. [Google Scholar]

- Chirila, E. Mineu monetary hoard XVII century. In Monetary Hoards in the Northen Transylvania between XVI–XVIII Centuries; Zalau Museum Publishing House: Zalau, Romania, 1970; pp. 55–63. [Google Scholar]

- Chirila, E.; Lucacel, V. Feudal hoard of Aghires XVI–XVII centuries. Stud. Univ. Babeș-Bolyai Ser. Hist. 1965, 2, 33–55. [Google Scholar]

- Moxon, R.; Xu, Z.; Chris-Okoro, I.; Cherono, S.; Kumar, D. Determination and Calculations of Mercury Vapor Concentration and Energy Released from Freshly Condensed Dental Amalgams Having Various Copper Percentages within the Alloy. Materials 2023, 16, 3452. [Google Scholar] [CrossRef]

- Barek, J.; Fischer, J.; Navratil, T.; Peckova, K.; Yosypchuk, B. Silver Solid Amalgam Electrodes as Sensors for Chemical Carcinogens. Sensors 2006, 6, 445–452. [Google Scholar] [CrossRef]

- Liang, P.; Zhang, J.; Kong, N.; Li, H.; Zhu, H. The Microstructure Characteristics Evolution of Bulk High-Purity Silver for High Relief Application. Metals 2023, 13, 463. [Google Scholar] [CrossRef]

- Ning, Z.; Wang, Q.; Zhao, D.; Pei, W.; Wen, M. Structural Evolution of Bulk Silver during Cold Rolling and Annealing. Metals 2022, 12, 1525. [Google Scholar] [CrossRef]

- Xu, J.; Gao, J.; Qin, H.; Liu, Z.; Zhu, L.; Geng, H.; Yao, L.; Zhao, Z. Cu Nanowires and Nanoporous Ag Matrix Fabricated through Directional Solidification and Selective Dissolution of Ag–Cu Eutectic Alloys. Materials 2022, 15, 8189. [Google Scholar] [CrossRef] [PubMed]

- Zuo, X.; Zhao, C.; Zhang, L.; Wang, E. Influence of Growth Rate and Magnetic Field on Microstructure and Properties of Directionally Solidified Ag–Cu Eutectic Alloy. Materials 2016, 9, 569. [Google Scholar] [CrossRef]

- Riccucci, C.; Ingo, G.M.; Pascucci, M.; Staccioli, M.P.; Pierigè, M.I.; Albini, M. Micro-structural and micro-chemical investigation of Samnite high-tin bronze cuirass discs: Ancient metallurgy in central Italy. Microchem. J. 2022, 175, 107136. [Google Scholar] [CrossRef]

- Ingo, G.M.; Riccucci, C.; Giuliani, C.; Faustoferri, A.; Pierigè, I.; Fierro, G.; Pascucci, M.; Albini, M.; Di Carlo, G. Surface studies of patinas and metallurgical features of uncommon high-tin bronze artefacts from the Italic necropolises of ancient Abruzzo (Central Italy). Appl. Surf. Sci. 2019, 470, 74–83. [Google Scholar] [CrossRef]

- Park, J.S.; Park, C.W.; Lee, C.J. Implication of peritectic composition in historical high-tin bronze metallurgy. Mater. Charact. 2009, 60, 1268–1275. [Google Scholar] [CrossRef]

- Petan, A.; Petean, I.; Paltinean, G.A.; Filip, M.R.; Borodi, G.; Tudoran, L.B. Microstructural Investigation of Some Bronze Artifacts Discovered in a Dacian Site Using Non-Destructive Methods. Metals 2023, 13, 863. [Google Scholar] [CrossRef]

| Forged Coin Year | EDS Spectrum No. | Elemental Composition at. % | ||

|---|---|---|---|---|

| Sn | Cu | P | ||

| Coating areas | ||||

| 1622 | 36 | 56.8 | 38.9 | 4.4 |

| 1623 | 48 | 88.3 | 11.7 | - |

| 1624 | 50 | 70.8 | 29.2 | - |

| Copper substrate | ||||

| 1622 | 37 | - | 99.7 | 0.2 |

| 1623 | 49 | 0.4 | 99.6 | - |

| 1624 | 51 | 0.3 | 99.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petean, I.; Paltinean, G.A.; Taut, A.C.; Avram, S.E.; Pripon, E.; Barbu Tudoran, L.; Borodi, G. Ag and Sn Implications in 3-Polker Coins Forgeries Evidenced by Nondestructive Methods. Materials 2023, 16, 5809. https://doi.org/10.3390/ma16175809

Petean I, Paltinean GA, Taut AC, Avram SE, Pripon E, Barbu Tudoran L, Borodi G. Ag and Sn Implications in 3-Polker Coins Forgeries Evidenced by Nondestructive Methods. Materials. 2023; 16(17):5809. https://doi.org/10.3390/ma16175809

Chicago/Turabian StylePetean, Ioan, Gertrud Alexandra Paltinean, Adrian Catalin Taut, Simona Elena Avram, Emanoil Pripon, Lucian Barbu Tudoran, and Gheorghe Borodi. 2023. "Ag and Sn Implications in 3-Polker Coins Forgeries Evidenced by Nondestructive Methods" Materials 16, no. 17: 5809. https://doi.org/10.3390/ma16175809

APA StylePetean, I., Paltinean, G. A., Taut, A. C., Avram, S. E., Pripon, E., Barbu Tudoran, L., & Borodi, G. (2023). Ag and Sn Implications in 3-Polker Coins Forgeries Evidenced by Nondestructive Methods. Materials, 16(17), 5809. https://doi.org/10.3390/ma16175809