Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys

Abstract

:1. Introduction

2. Crystal Structure and Mechanical Properties of Ni-Mn-Based Alloys

3. The Effects of Doping on the Toughness of Ni-Mn-Based Alloys

3.1. The Solid Solution and Second-Phase Toughening Effects Resulting from Doping of Transition Metal Elements

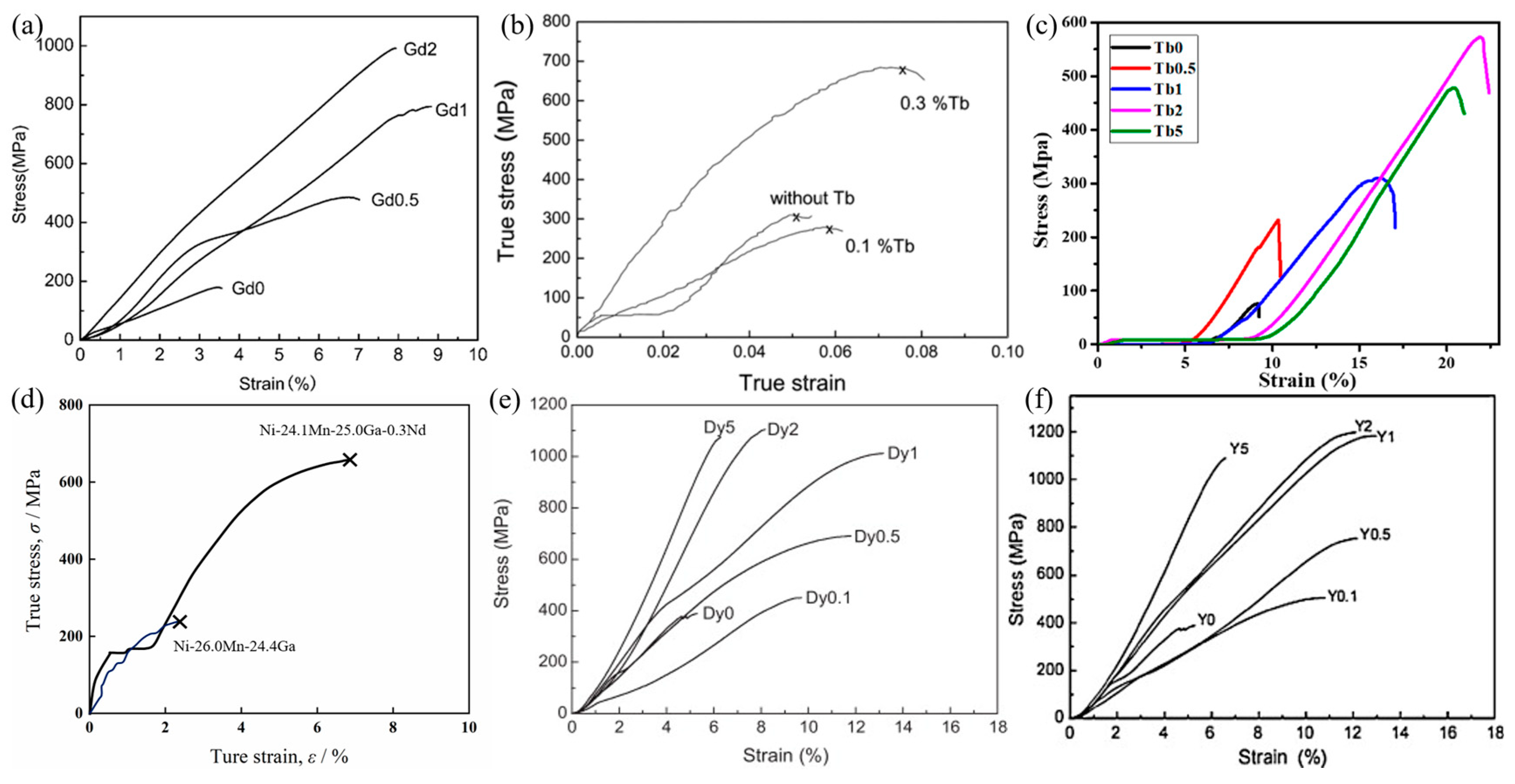

3.2. Grain Refinement and Second Phase Toughening Effects of Rare Earth Element Doping

3.3. Grain Refinement and Second Phase Toughening Effects of Metalloid Element Doping

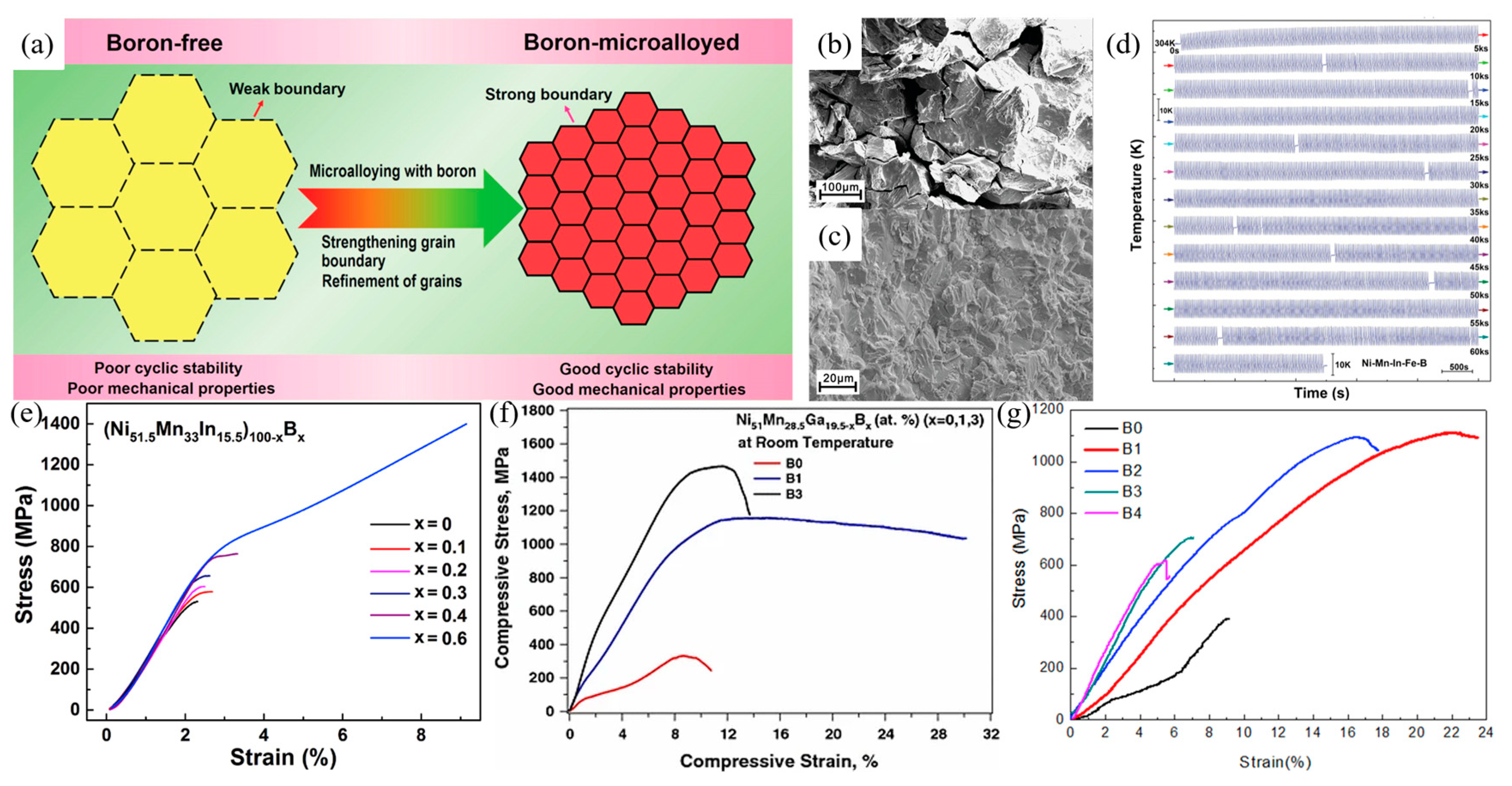

3.3.1. Second Phase Toughening by Metalloid Element Doping

3.3.2. Grain Boundary Purification and Modification due to Metalloid Element Doping

4. The Effects of Texture, Sizes, and d-Orbital Hybridization on the Toughness of Ni-Mn-Based Alloys

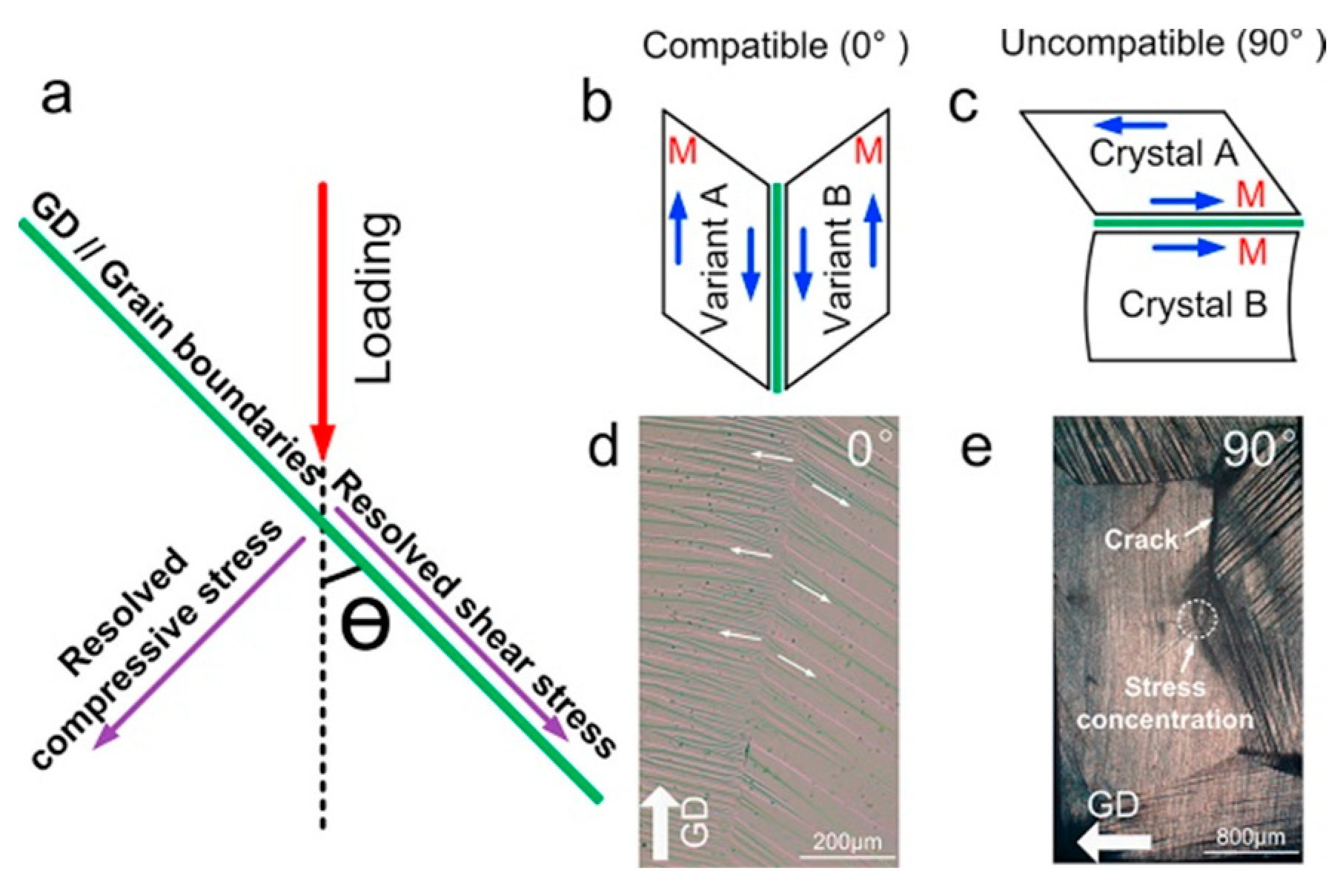

4.1. The Effects of Texture on the Toughness of Ni-Mn-Based Alloys

4.2. The Effects of Size on the Toughness of Ni-Mn-Based Alloys

4.3. The Effects of d-Orbital Hybridization on the Toughness of Ni-Mn-Based Alloys

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Moya, X.; Kar-Narayan, S.; Mathur, N.D. Caloric materials near ferroic phase transitions. Nat. Mater. 2014, 13, 439–450. [Google Scholar] [CrossRef] [PubMed]

- Manosa, L.; Planes, A. Materials with Giant Mechanocaloric Effects: Cooling by Strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, Z.; Yang, J.; Li, Z.; Yang, B.; Yan, H.; Wang, D.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect driven by stress-induced two-step structural transformation in a directionally solidified Ni55Mn18Ga27 alloy. Scr. Mater. 2019, 163, 116–120. [Google Scholar] [CrossRef]

- Tang, X.; Feng, Y.; Wang, H.; Wang, P. Enhanced elastocaloric effect and cycle stability in B and Cu co-doping Ni-Mn-In polycrystals. Appl. Phys. Lett. 2019, 114, 033901. [Google Scholar] [CrossRef]

- Qu, Y.H.; Cong, D.Y.; Li, S.H.; Gui, W.Y.; Nie, Z.H.; Zhang, M.H.; Ren, Y.; Wang, Y.D. Simultaneously achieved large reversible elastocaloric and magnetocaloric effects and their coupling in a magnetic shape memory alloy. Acta Mater. 2018, 151, 41–55. [Google Scholar] [CrossRef]

- Reis, M.S. Magnetocaloric and barocaloric effects of metal complexes for solid state cooling: Review, trends and perspectives. Coord. Chem. Rev. 2020, 417, 213357. [Google Scholar] [CrossRef]

- Neese, B.; Chu, B.; Lu, S.G.; Wang, Y.; Furman, E.; Zhang, Q.M. Large electrocaloric effect in ferroelectric polymers near room temperature. Science 2008, 321, 821–823. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Guillou, F.; Porcari, G.; Yibole, H.; van Dijk, N.; Bruck, E. Taming the first-order transition in giant magnetocaloric materials. Adv. Mater. 2014, 26, 2671–2675. [Google Scholar] [CrossRef]

- Bonnot, E.; Romero, R.; Manosa, L.; Vives, E.; Planes, A. Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys. Rev. Lett. 2008, 100, 125901. [Google Scholar] [CrossRef]

- Chluba, C.; Ge, W.; de Miranda, R.L.; Strobel, J.; Kienle, L.; Quandt, E.; Wuttig, M. Ultralow-fatigue shape memory alloy films. Science 2015, 348, 4. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Graf, T.; Felser, C.; Parkin, S.S.P. Simple rules for the understanding of Heusler compounds. Progress. Solid. State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Buchelnikov, V.D.; Kainuma, R.; Koledov, V.V.; Ohtsuka, M.; Shavrov, V.G.; Takagi, T.; Taskaev, S.V.; Vasiliev, A.N. Phase transitions in Ni2+xMn1−xGa with a high Ni excess. Phys. Rev. B 2005, 72, 224408. [Google Scholar] [CrossRef]

- Aksoy, S.; Krenke, T.; Acet, M.; Wassermann, E.F.; Moya, X.; Mañosa, L.; Planes, A. Magnetization easy axis in martensitic Heusler alloys estimated by strain measurements under magnetic field. Appl. Phys. Lett. 2007, 91, 251915. [Google Scholar] [CrossRef]

- Planes, A.; Manosa, L.; Acet, M. Magnetocaloric effect and its relation to shape-memory properties in ferromagnetic Heusler alloys. J. Phys. Condens. Matter 2009, 21, 233201. [Google Scholar] [CrossRef]

- Yan, H.L.; Wang, L.D.; Liu, H.X.; Huang, X.M.; Jia, N.; Li, Z.B.; Yang, B.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Giant elastocaloric effect and exceptional mechanical properties in an all-d-metal Ni–Mn–Ti alloy: Experimental and ab-initio studies. Mater. Des. 2019, 184, 108180. [Google Scholar] [CrossRef]

- Huang, X.M.; Wang, L.D.; Liu, H.X.; Yan, H.L.; Jia, N.; Yang, B.; Li, Z.B.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Correlation between microstructure and martensitic transformation, mechanical properties and elastocaloric effect in Ni–Mn-based alloys. Intermetallics 2019, 113, 106579. [Google Scholar] [CrossRef]

- Yan, H.L.; Zhao, Y.; Liu, H.X.; Zhang, M.J.; Zhang, H.F.; Bai, J.; Jia, N.; Yang, B.; Li, Z.B.; Zhang, Y.D.; et al. Ab-initio revelation on the origins of Ti substitution for Ga, Mn and Ni on ferromagnetism, phase stability and elastic properties in Ni2MnGa. J. Alloys Compd. 2020, 821, 153481. [Google Scholar] [CrossRef]

- Czaja, P.; Chulist, R.; Tokarski, T.; Czeppe, T.; Chumlyakov, Y.I.; Cesari, E. Superelastic behavior of a metamagnetic Ni–Mn–Sn single crystal. J. Mater. Sci. 2018, 53, 10383–10395. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Villa, E.; Salazar, D.; Barandiaran, J.M. Large tensile superelasticity from intermartensitic transformations in Ni49Mn28Ga23 single crystal. Appl. Phys. Lett. 2016, 108, 071903. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Q.; Xu, K.; Zhang, C.; Wu, Y.; Jiang, C. Large room-temperature elastocaloric effect of Ni57Mn18Ga21In4 alloy undergoing a magnetostructural coupling transition. Scr. Mater. 2017, 130, 148–151. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Liaw, P.K. The fatigue behavior of shape-memory alloys. JOM-J. Miner. Met. Mater. Soc. 2000, 52, 7. [Google Scholar] [CrossRef]

- Lu, B.; Zhang, P.; Xu, Y.; Sun, W.; Liu, J. Elastocaloric effect in Ni45Mn36.4In13.6Co5 metamagnetic shape memory alloys under mechanical cycling. Mater. Lett. 2015, 148, 110–113. [Google Scholar] [CrossRef]

- Roy, S.; Blackburn, E.; Valvidares, S.M.; Fitzsimmons, M.R.; Vogel, S.C.; Khan, M.; Dubenko, I.; Stadler, S.; Ali, N.; Sinha, S.K.; et al. Delocalization and hybridization enhance the magnetocaloric effect in Cu-dopedNi2MnGa. Phys. Rev. B 2009, 79, 235127. [Google Scholar] [CrossRef]

- Gautam, B.R.; Dubenko, I.; Mabon, J.C.; Stadler, S.; Ali, N. Effect of small changes in Mn concentration on phase transition temperatures and magnetic entropy variations in Ni2Mn0.75Cu0.25Ga Heusler alloys. J. Alloys Compd. 2009, 472, 35–39. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, C. A single-phase wide-hysteresis shape memory alloy Ni50Mn25Ga17Cu8. Scr. Mater. 2010, 62, 298–300. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H.; Jiang, C. Microstructure and mechanical properties of a Ni30Cu20Mn41.5Ga8.5 dual-phase shape memory alloy. Mater. Sci. Eng. A 2013, 578, 256–259. [Google Scholar] [CrossRef]

- Li, Y.; Sun, W.; Zhao, D.; Xu, H.; Liu, J. An 8 K elastocaloric temperature change induced by 1.3% transformation strain in Ni44Mn45−xSn11Cux alloys. Scr. Mater. 2017, 130, 278–282. [Google Scholar] [CrossRef]

- Feng, X.; Fang, D.; HWANG, K. Mechanical and Magnetostrictive Properties of Fe-Doped Ni52Mn24Ga24 Single Crystals. Chin. Phys. Lett. 2002, 19, 3. [Google Scholar] [CrossRef]

- Cherechukin, A.A.; Dikshtein, I.E.; Ermakov, D.I.; Glebov, A.V.; Koledov, V.V.; Kosolapov, D.A.; Shavrov, V.G.; Tulaikova, A.A.; Krasnoperov, E.P.; Takagi, P. Shape memory effect due to magnetic field-induced thermoelastic martensitic transformation in polycrystalline Ni–Mn–Fe–Ga alloy. Phys. Lett. A 2002, 291, 8. [Google Scholar] [CrossRef]

- Wang, H.B.; Chen, F.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Effect of Fe content on fracture behavior of Ni–Mn–Fe–Ga ferromagnetic shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 990–993. [Google Scholar] [CrossRef]

- Feng, Y.; Sui, J.H.; Gao, Z.Y.; Zhang, J.; Cai, W. Investigation on martensitic transformation behavior, microstructures and mechanical properties of Fe-doped Ni–Mn–In alloys. Mater. Sci. Eng. A 2009, 507, 174–178. [Google Scholar] [CrossRef]

- Pfeuffer, L.; Lemke, J.; Shayanfar, N.; Riegg, S.; Koch, D.; Taubel, A.; Scheibel, F.; Kani, N.A.; Adabifiroozjaei, E.; Molina-Luna, L.; et al. Microstructure engineering of metamagnetic Ni-Mn-based Heusler compounds by Fe-doping: A roadmap towards excellent cyclic stability combined with large elastocaloric and magnetocaloric effects. Acta Mater. 2021, 221, 117390. [Google Scholar] [CrossRef]

- Huang, L.; Cong, D.Y.; Suo, H.L.; Wang, Y.D. Giant magnetic refrigeration capacity near room temperature in Ni40Co10Mn40Sn10 multifunctional alloy. Appl. Phys. Lett. 2014, 104, 132407. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Manosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef]

- Yu, S.Y.; Ma, L.; Liu, G.D.; Liu, Z.H.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhang, B.; Zhang, X.X. Magnetic field-induced martensitic transformation and large magnetoresistance in NiCoMnSb alloys. Appl. Phys. Lett. 2007, 90, 242501. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, X.X.; Yu, S.Y.; Chen, J.L.; Cao, Z.X.; Wu, G.H. Giant magnetothermal conductivity in the Ni–Mn–In ferromagnetic shape memory alloys. Appl. Phys. Lett. 2007, 91, 012510. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Morito, H.; Sutou, Y.; Oikawa, K.; Fujita, A.; Ishida, K.; Okamoto, S.; Kitakami, O.; et al. Metamagnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy. Appl. Phys. Lett. 2006, 88, 192513. [Google Scholar] [CrossRef]

- Oikawa, K.; Ota, T.; Ohmori, T.; Tanaka, Y.; Morito, H.; Fujita, A.; Kainuma, R.; Fukamichi, K.; Ishida, K. Magnetic and martensitic phase transitions in ferromagnetic Ni–Ga–Fe shape memory alloys. Appl. Phys. Lett. 2002, 81, 5201–5203. [Google Scholar] [CrossRef]

- Oikawa, K.; Wulff, L.; Iijima, T.; Gejima, F.; Ohmori, T.; Fujita, A.; Fukamichi, K.; Kainuma, R.; Ishida, K. Promising ferromagnetic Ni–Co–Al shape memory alloy system. Appl. Phys. Lett. 2001, 79, 3290–3292. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, S.; Liu, Y.; Liu, X. The ductility and shape-memory properties of Ni–Mn–Co–Ga high-temperature shape-memory alloys. Acta Mater. 2009, 57, 3232–3241. [Google Scholar] [CrossRef]

- Shen, A.; Sun, W.; Zhao, D.; Liu, J. Influence of Cr on microstructure and elastocaloric effect in Ni–Mn–In–Co–Cr polycrystalline alloys. Phys. Lett. A 2018, 382, 2876–2879. [Google Scholar] [CrossRef]

- Li, Y.; Xin, Y.; Jiang, C.; Xu, H. Shape memory effect of grain refined Ni54Mn25Ga21 alloy with high transformation temperature. Scr. Mater. 2004, 51, 849–852. [Google Scholar] [CrossRef]

- Zhang, X.; Sui, J.; Zheng, X.; Yang, Z.; Tian, X.; Cai, W. Effect of Ni substitution for Ga on the polycrystalline Ni–Mn–Ga–Gd high-temperature shape memory alloys. J. Alloys Compd. 2013, 557, 60–66. [Google Scholar] [CrossRef]

- Zhang, X.; Sui, J.; Yu, Z.; Cai, W. Structure and shape memory effect in a Ni54Mn25Ga20Gd1 alloy with a high transformation temperature. J. Alloys Compd. 2011, 509, 8032–8037. [Google Scholar] [CrossRef]

- Dong, G.F.; Zhang, H.J.; Zhang, X.L.; Wang, H.B.; Sui, J.H.; Cai, W. Microstructure and mechanical properties in Ni45.4Mn39.5In13.1Gd2 alloy with high transformation temperature. Mater. Sci. Technol. 2014, 28, 1332–1336. [Google Scholar] [CrossRef]

- Tan, C.; Zhang, K.; Tian, X.; Cai, W. Effect of Gd addition on microstructure, martensitic transformation and mechanical properties of Ni50Mn36Sn14 ferromagnetic shape memory alloy. J. Alloys Compd. 2017, 692, 288–293. [Google Scholar] [CrossRef]

- Li, H.; Meng, X.; Cai, W. Martensitic transformation and mechanical properties in Ni–Co–Mn–In–Gd metamagnetic shape memory alloys. Mater. Sci. Eng. A 2018, 725, 359–363. [Google Scholar] [CrossRef]

- Tian, X.; Zhang, K.; Tan, C.; Guo, E. Influence of Doping Tb on the Mechanical Properties and Martensitic Transformation of Ni-Mn-Sn Magnetic Shape Memory Alloys. Crystals 2018, 8, 247. [Google Scholar] [CrossRef]

- Shen, Q.; Zhao, D.; Sun, W.; Li, Y.; Liu, J. The effect of Tb on elastocaloric and mechanical properties of Ni-Mn-In-Tb alloys. J. Alloys Compd. 2017, 696, 538–542. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.; Jiang, C.; Xu, H. Martensitic transformation, shape memory effect and mechanical properties of dual-phase Ni50−xTbxMn30Ga20 (x = 0–1) alloys. Mater. Sci. Eng. A 2015, 646, 288–293. [Google Scholar] [CrossRef]

- Lee, J.M.; Oh, Y.M.; Euh, K.; Kang, S.B. Effects of Tb addition on the microstructure and properties of a Ni-Mn-Ga ferromagnetic shape memory alloy. Met. Mater. Int. 2009, 15, 459–463. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Tsutsumi, A.; Ohtsuka, H.; Umemoto, M. Modification of Ni–Mn–Ga ferromagnetic shape memory alloy by addition of rare earth elements. Mater. Sci. Eng. A 2004, 378, 370–376. [Google Scholar] [CrossRef]

- Gao, L.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Effect of rare earth Dy addition on microstructure and martensitic transformation of polycrystalline Ni50Mn29Ga21−xDyx ferromagnetic shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 1077–1080. [Google Scholar] [CrossRef]

- Gao, L.; Sui, J.H.; Cai, W.; Gao, Z.Y. Study of the precipitate phases and martensitic transformation in quaternary Heusler alloys of NiMnGaDy. Solid. State Commun. 2009, 149, 257–260. [Google Scholar] [CrossRef]

- Gao, L.; Dong, G.F.; Gao, Z.Y.; Cai, W. Effect of Dy addition on mechanical and magnetic properties of Mn-rich Ni–Mn–Ga ferromagnetic shape memory alloys. J. Alloys Compd. 2012, 520, 281–286. [Google Scholar] [CrossRef]

- Tong, W.; Liang, L.; Xu, J.; Wang, H.J.; Tian, J.; Peng, L.M. Achieving enhanced mechanical, pseudoelastic and elastocaloric properties in Ni-Mn-Ga alloys via Dy micro-alloying and isothermal mechanical cyclic training. Scr. Mater. 2022, 209, 114393. [Google Scholar] [CrossRef]

- Cai, W.; Gao, L.; Liu, A.L.; Sui, J.H.; Gao, Z.Y. Martensitic transformation and mechanical properties of Ni–Mn–Ga–Y ferromagnetic shape memory alloys. Scr. Mater. 2007, 57, 659–662. [Google Scholar] [CrossRef]

- Sui, J.; Zhang, X.; Gao, L.; Cai, W. Microstructure, phase transformation and mechanical properties of Ni–Mn–Ga–Y magnetic shape memory alloys. J. Alloys Compd. 2011, 509, 8692–8699. [Google Scholar] [CrossRef]

- Nong, N.V.; Tai, L.T.; Huy, N.T.; Trung, N.T.; Bahl, C.R.H.; Venkatesh, R.; Poulsen, F.W.; Pryds, N. Structural, magnetic and magnetocaloric properties of Heusler alloys Ni50Mn38Sb12 with boron addition. Mater. Sci. Eng. B 2011, 176, 1322–1325. [Google Scholar] [CrossRef]

- Prusik, K.; Matyja, E.; Zubko, M.; Kubisztal, M.; Chrobak, A. Effect of the Boron Addition on the Structure of the Ni-Mn-Co-In Alloys. Acta Phys. Pol. A 2016, 130, 1023–1025. [Google Scholar] [CrossRef]

- Aydogdu, Y.; Turabi, A.S.; Kok, M.; Aydogdu, A.; Tobe, H.; Karaca, H.E. Effects of the substitution of gallium with boron on the physical and mechanical properties of Ni–Mn–Ga shape memory alloys. Appl. Phys. A 2014, 117, 2073–2078. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Zeng, X.; Sui, J.; Cai, W.; Wang, H.; Feng, Y. Microstructure, mechanical properties and shape memory effect of Ni–Mn–Ga–B high-temperature shape memory alloy. Intermetallics 2016, 68, 113–117. [Google Scholar] [CrossRef]

- Barman, R.; Kaur, D. Improved magnetocaloric effect in magnetron sputtered Ni–Mn–Sb–Al ferromagnetic shape memory alloy thin films. Vacuum 2015, 120, 22–26. [Google Scholar] [CrossRef]

- Yang, Z.; Cong, D.Y.; Sun, X.M.; Nie, Z.H.; Wang, Y.D. Enhanced cyclability of elastocaloric effect in boron-microalloyed Ni-Mn-In magnetic shape memory alloys. Acta Mater. 2017, 127, 33–42. [Google Scholar] [CrossRef]

- Yang, Z.; Cong, D.; Yuan, Y.; Wu, Y.; Nie, Z.; Li, R.; Wang, Y. Ultrahigh cyclability of a large elastocaloric effect in multiferroic phase-transforming materials. Mater. Res. Lett. 2019, 7, 137–144. [Google Scholar] [CrossRef]

- Cong, D.Y.; Huang, L.; Hardy, V.; Bourgault, D.; Sun, X.M.; Nie, Z.H.; Wang, M.G.; Ren, Y.; Entel, P.; Wang, Y.D. Low-field-actuated giant magnetocaloric effect and excellent mechanical properties in a NiMn-based multiferroic alloy. Acta Mater. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Wang, Y.; Choo, H. Influence of texture on Hall–Petch relationships in an Mg alloy. Acta Mater. 2014, 81, 83–97. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Yang, J.; Li, D.; Yang, B.; Yan, H.; Nie, Z.; Hou, L.; Li, X.; Zhang, Y.; et al. Large elastocaloric effect in a polycrystalline Ni45.7Co4.2Mn37.3Sb12.8 alloy with low transformation strain. Scr. Mater. 2019, 162, 486–491. [Google Scholar] [CrossRef]

- Huang, Y.J.; Hu, Q.D.; Liu, J.; Zeng, L.; Zhang, D.F.; Li, J.G. Banded-like morphology and martensitic transformation of dual-phase Ni–Mn–In magnetic shape memory alloy with enhanced ductility. Acta Mater. 2013, 61, 5702–5712. [Google Scholar] [CrossRef]

- Huang, Y.J.; Hu, Q.D.; Bruno, N.M.; Chen, J.-H.; Karaman, I.; Ross, J.H.; Li, J.G. Giant elastocaloric effect in directionally solidified Ni–Mn–In magnetic shape memory alloy. Scr. Mater. 2015, 105, 42–45. [Google Scholar] [CrossRef]

- Huang, Y.J.; Hu, Q.D.; Bruno, N.; Karaman, I.; Li, J.G. Influence of grain boundary on pseudoelasticity in highly-oriented polycrystalline Ni52Fe17Ga27Co4 ferromagnetic shape memory alloy. Mater. Lett. 2014, 114, 11–14. [Google Scholar] [CrossRef]

- Millán-Solsona, R.; Stern-Taulats, E.; Vives, E.; Planes, A.; Sharma, J.; Nayak, A.K.; Suresh, K.G.; Mañosa, L. Large entropy change associated with the elastocaloric effect in polycrystalline Ni-Mn-Sb-Co magnetic shape memory alloys. Appl. Phys. Lett. 2014, 105, 241901. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, J.; Chen, X.; Sun, W.; Li, Y.; Zhang, M.; Shao, Y.; Zhang, H.; Yan, A. Giant caloric effect of low-hysteresis metamagnetic shape memory alloys with exceptional cyclic functionality. Acta Mater. 2017, 133, 217–223. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, J.; Feng, Y.; Sun, W.; Yan, A. Giant elastocaloric effect and its irreversibility in [001]-oriented Ni45Mn36.5In13.5Co5 meta-magnetic shape memory alloys. Appl. Phys. Lett. 2017, 110, 021906. [Google Scholar] [CrossRef]

- Lu, B.; Song, M.; Zhou, Z.; Liu, W.; Wang, B.; Lu, S.; Wu, C.; Yang, L.; Liu, J. Reducing mechanical hysteresis via tuning the microstructural orientations in Heusler-type Ni44.8Mn36.9In13.3Co5.0 elastocaloric alloys. J. Alloys Compd. 2019, 785, 1023–1029. [Google Scholar] [CrossRef]

- Lu, B.; Xiao, F.; Yan, A.; Liu, J. Elastocaloric effect in a textured polycrystalline Ni-Mn-In-Co metamagnetic shape memory alloy. Appl. Phys. Lett. 2014, 105, 161905. [Google Scholar] [CrossRef]

- Cui, J.; Wu, Y.; Muehlbauer, J.; Hwang, Y.; Radermacher, R.; Fackler, S.; Wuttig, M.; Takeuchi, I. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 2012, 101, 073904. [Google Scholar] [CrossRef]

- Bechtold, C.; Chluba, C.; Lima de Miranda, R.; Quandt, E. High cyclic stability of the elastocaloric effect in sputtered TiNiCu shape memory films. Appl. Phys. Lett. 2012, 101, 091903. [Google Scholar] [CrossRef]

- Mañosa, L.; Jarque-Farnos, S.; Vives, E.; Planes, A. Large temperature span and giant refrigerant capacity in elastocaloric Cu-Zn-Al shape memory alloys. Appl. Phys. Lett. 2013, 103, 211904. [Google Scholar] [CrossRef]

- Xiao, F.; Fukuda, T.; Kakeshita, T. Significant elastocaloric effect in a Fe-31.2Pd (at. %) single crystal. Appl. Phys. Lett. 2013, 102, 161914. [Google Scholar] [CrossRef]

- Hernández-Navarro, F.; Camarillo-Garcia, J.-P.; Aguilar-Ortiz, C.-O.; Flores-Zúñiga, H.; Ríos, D.; González, J.-G.; Álvarez-Alonso, P. The influence of texture on the reversible elastocaloric effect of a polycrystalline Ni50Mn32In16Cr2 alloy. Appl. Phys. Lett. 2018, 112, 164101. [Google Scholar] [CrossRef]

- Shen, J.; Lopes, J.G.; Zeng, Z.; Choi, Y.T.; Maawad, E.; Schell, N.; Kim, H.S.; Mishra, R.S.; Oliveira, J.P. Deformation behavior and strengthening effects of an eutectic AlCoCrFeNi2.1 high entropy alloy probed by in-situ synchrotron X-ray diffraction and post-mortem EBSD. Mater. Sci. Eng. A 2023, 872, 144946. [Google Scholar] [CrossRef]

- Shen, J.; Agrawal, P.; Rodrigues, T.A.; Lopes, J.G.; Schell, N.; He, J.; Zeng, Z.; Mishra, R.S.; Oliveira, J.P. Microstructure evolution and mechanical properties in a gas tungsten arc welded Fe42Mn28Co10Cr15Si5 metastable high entropy alloy. Mater. Sci. Eng. A 2023, 867, 144722. [Google Scholar] [CrossRef]

- Dunand, D.C.; Mullner, P. Size effects on magnetic actuation in Ni-Mn-Ga shape-memory alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef] [PubMed]

- Ueland, S.M.; Chen, Y.; Schuh, C.A. Oligocrystalline Shape Memory Alloys. Adv. Funct. Mater. 2012, 22, 2094–2099. [Google Scholar] [CrossRef]

- Zhukov, A.; Garcia, C.; Ilyn, M.; Varga, R.; del Val, J.J.; Granovsky, A.; Rodionova, V.; Ipatov, M.; Zhukova, V. Magnetic and transport properties of granular and Heusler-type glass-coated microwires. J. Magn. Magn. Mater. 2012, 324, 3558–3562. [Google Scholar] [CrossRef]

- Zhukov, A.; Rodionova, V.; Ilyn, M.; Aliev, A.M.; Varga, R.; Michalik, S.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Ipatov, M.; et al. Magnetic properties and magnetocaloric effect in Heusler-type glass-coated NiMnGa microwires. J. Alloys Compd. 2013, 575, 73–79. [Google Scholar] [CrossRef]

- Zhukova, V.; Chernenko, V.; Ipatov, M.; Zhukov, A. Magnetic Properties of Heusler-Type NiMnGa Glass-Coated Microwires. IEEE Trans. Magn. 2015, 51, 2501604. [Google Scholar] [CrossRef]

- Zhukova, V.; Ipatov, M.; Granovsky, A.; Zhukov, A. Magnetic properties of Ni-Mn-In-Co Heusler-type glass-coated microwires. J. Appl. Phys. 2014, 115, 17A939. [Google Scholar] [CrossRef]

- Zhukova, V.; Rodionova, V.; Fetisov, L.; Grunin, A.; Goikhman, A.; Torcunov, A.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Perov, N.; et al. Magnetic Properties of Heusler-Type Microwires and Thin Films. IEEE Trans. Magn. 2014, 50, 2505504. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, M.; Wang, Y.D.; Lin, J.P.; Dahmen, K.A.; Wang, Z.L.; Liaw, P.K. Superelasticity and Serration Behavior in Small-Sized NiMnGa Alloys. Adv. Eng. Mater. 2014, 16, 955–960. [Google Scholar] [CrossRef]

- Glock, S.; Zhang, X.X.; Kucza, N.J.; Müllner, P.; Michaud, V. Structural, physical and damping properties of melt-spun Ni–Mn–Ga wire-epoxy composites. Compos. Part. A Appl. Sci. Manuf. 2014, 63, 68–75. [Google Scholar] [CrossRef]

- Liu, D.M.; Cong, D.Y.; Sun, X.M.; Chen, H.Y.; Nie, Z.H.; Chen, Z.; Zhang, Y.; Zhu, C.; Qu, Y.H.; Zhu, J.; et al. Low-hysteresis tensile superelasticity in a Ni-Co-Mn-Sn magnetic shape memory microwire. J. Alloys Compd. 2017, 728, 655–658. [Google Scholar] [CrossRef]

- Ding, Z.; Zhu, J.; Zhang, X.; Liu, D.; Qi, Q.; Zhang, Y.; Cong, D. 14% recoverable strain in Ni52.87Mn23.82Ga23.32 microwires. J. Phys. D Appl. Phys. 2017, 50, 095303. [Google Scholar] [CrossRef]

- Li, F.Q.; Qu, Y.H.; Yan, H.L.; Chen, Z.; Cong, D.Y.; Sun, X.M.; Li, S.H.; Wang, Y.D. Giant tensile superelasticity originating from two-step phase transformation in a Ni-Mn-Sn-Fe magnetic microwire. Appl. Phys. Lett. 2018, 113, 112402. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, H.; Gao, L.; Wang, H.; Bian, X.; Gong, M. Effect of wheel speed and annealing temperature on microstructure and texture evolution of Ni45Mn36.6In13.4Co5 ribbon. Mater. Charact. 2016, 122, 170–176. [Google Scholar] [CrossRef]

- Hernando, B.; Sánchez Llamazares, J.L.; Prida, V.M.; Baldomir, D.; Serantes, D.; Ilyn, M.; González, J. Magnetocaloric effect in preferentially textured Mn50Ni40In10 melt spun ribbons. Appl. Phys. Lett. 2009, 94, 222502. [Google Scholar] [CrossRef]

- Akkera, H.S.; Singh, I.; Kaur, D. Martensitic phase transformation of magnetron sputtered nanostructured Ni–Mn–In ferromagnetic shape memory alloy thin films. J. Alloys Compd. 2015, 642, 53–62. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Liu, E.K.; Chen, J.H.; Li, Y.; Liu, G.D.; Luo, H.Z.; Xi, X.K.; Zhang, H.W.; Wang, W.H.; Wu, G.H. Realization of multifunctional shape-memory ferromagnets in all-d-metal Heusler phases. Appl. Phys. Lett. 2015, 107, 022406. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Liu, E.K.; Li, Y.; Han, X.L.; Du, Z.W.; Luo, H.Z.; Liu, G.D.; Xi, X.K.; Zhang, H.W.; Wang, W.H.; et al. Magnetostructural martensitic transformations with large volume changes and magneto-strains in all-d-metal Heusler alloys. Appl. Phys. Lett. 2016, 109, 071904. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Sun, W.; Shen, Q.; Shen, Y.; Zhang, Y.F.; Liu, E.K.; Liu, J. Elastocaloric effect of all-d-metal Heusler NiMnTi(Co) magnetic shape memory alloys by digital image correlation and infrared thermography. Appl. Phys. Lett. 2019, 114, 101903. [Google Scholar] [CrossRef]

- Shen, Y.; Sun, W.; Wei, Z.Y.; Shen, Q.; Zhang, Y.F.; Liu, J. Orientation dependent elastocaloric effect in directionally solidified Ni-Mn-Sn alloys. Scr. Mater. 2019, 163, 14–18. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Y.-S.; Zhang, C.; Li, L.-F. Elastocaloric effect and mechanical behavior for NiTi shape memory alloys. Chin. Phys. B 2018, 27, 106501. [Google Scholar] [CrossRef]

- Aznar, A.; Gràcia-Condal, A.; Planes, A.; Lloveras, P.; Barrio, M.; Tamarit, J.-L.; Xiong, W.; Cong, D.; Popescu, C.; Mañosa, L. Giant barocaloric effect in all-d-metal Heusler shape memory alloys. Phys. Rev. Mater. 2019, 3, 044406. [Google Scholar] [CrossRef]

- Shen, Y.; Wei, Z.; Sun, W.; Zhang, Y.; Liu, E.; Liu, J. Large elastocaloric effect in directionally solidified all-d-metal Heusler metamagnetic shape memory alloys. Acta Mater. 2020, 188, 677–685. [Google Scholar] [CrossRef]

- Li, G.; Liu, E.; Wang, W.; Wu, G. Theoretical investigations on elastic properties, phase stability, and magnetism in Ni2Mn-based all-d−metal Heusler compounds. Phys. Rev. B 2023, 107, 134440. [Google Scholar] [CrossRef]

| Toughening Method | Toughening Mechanism | Toughening Effect | Reference |

|---|---|---|---|

| Ni-Mn-Ga alloy doped with Cu | Solid solution strengthening and toughening | Shape memory effect of 6.2%, compressive plasticity of 22%, and compressive strength of 878 MPa | [27] |

| Ni-Mn-Ga alloy doped with Cu | Second phase strengthening and toughening | Compressive strain > 70%, maximum compressive strength of 785.6 MPa, tensile strain of 6.2% | [28] |

| Ni-Mn-Sn alloy doped with Cu | Second phase strengthening and toughening | Breaking strength of 1150 MPa | [29] |

| Ni-Mn-Ga single crystal alloy doped with Fe | Solid solution strengthening and toughening | Brittleness of the alloy is obviously improved, and the Vickers hardness is 6.4 GPa | [30] |

| Ni-Mn-Ga alloy doped with Fe | Solid solution and second phase strengthening and toughening | Transgranular fracture, fracture toughness of 18 N/mm3/2 | [32] |

| Ni-Mn-In alloy doped with Fe | Solid solution and second phase strengthening and toughening | Compressive strength of 1200 MPa, maximum compressive strain of 15.8% | [33] |

| Ni-Mn-In alloy doped with Fe | Second phase strengthening and toughening | More than 16,000 mechanical cycles under 300 MPa without structural degradation | [34] |

| Ni-Mn-Ga alloy doped with Co | Second phase strengthening and toughening | Tensile strength of 729 MPa, breaking strain of 14.1% | [42] |

| Ni-Mn-Ga alloy doped with Cr and Co | Second phase strengthening and toughening | Ni45Mn36In13Co5Cr alloy breaking strain of 5%, Ni45Mn35In13Co5Cr2 alloy breaking strength of 550 MPa | [43] |

| Ni-Mn-Ga alloy doped with Gd | Grain refinement strengthening and toughening | Shape memory recovery rate of Gd1 alloy is 100%, and the maximum shape memory strain is 1.9% | [45,46] |

| Ni-Mn-Sn alloy and Ni-Mn-In alloy doped with Gd | Second phase strengthening and toughening, changing the fracture mode of alloy | Compressive strength increased from 448 MPa to 707 MPa, the compressive strain increased from 4.5% to 9.0% | [48] |

| Ni-Co-Mn-In alloy doped with Gd | Second phase strengthening and toughening, distorting the lattice | Compressive elongation is 8.8%; compressive strength is 992 MPa, 5.5 times that of undoped alloy | [49] |

| Ni-Mn-Sn alloy doped with Tb | Grain refinement and second phase strengthening and toughening | Compressive strength of Tb2 alloy is 571.8 MPa, and the fracture strain is 22.0%, which is higher than the 74.3 MPa and 9.2% of the undoped alloy | [50] |

| Ni-Mn-In alloy and Ni-Mn-Ga alloy doped with Tb | Second phase strengthening and toughening, changing the fracture mode of alloy | Tb0.4 alloy can withstand 622 MPa uniaxial stress; Tb1 alloy shape memory strain of 2.68% | [51] |

| Ni-Mn-Ga alloy doped with Tb | Grain refinement and increasing grain boundary strength | Tb0.3 alloy compressive strength of 780 MPa | [53] |

| Ni-Mn-Ga alloy doped with Nd | Enhancing the bonding force of the grain boundary | Fracture strain of 6% | [54] |

| Ni-Mn-Ga alloy doped with Dy | Changing the fracture mode of alloy | Dy1 alloy compressive strain reaches its maximum | [55,56,57] |

| Ni-Mn-Ga alloy doped with Dy | Forming granular precipitates | Compressive strength of ~855.9 MPa, fracture strain of ~12.7% | [58] |

| Ni-Mn-Ga alloy doped with Y | Second phase strengthening and toughening, changing the fracture mode of alloy | The type of fracture changes from intergranular fracture to transgranular fracture | [60] |

| Ni-Mn-In-Co alloy doped with B | Modifying alloy grain boundary, second phase strengthening and toughening | Form a structure similar to sub-grain, the average size of the second phase is 1–2 μm | [62] |

| Ni-Mn-In alloy and Ni-Mn-In-Fe alloy doped with B | Enhancing the bonding force of the grain boundary by microalloying, grain refinement | No decay of the elastocaloric effect after 150 cycles | [66] |

| Ni-Mn-In-Cu alloy doped with B | Second phase strengthening and toughening | Stable for 100 cycles at 3% strain | [4] |

| Ni-Co-Mn-Sn alloy doped with Al | Reducing stacking fault energy | Compressive fracture strain of 8.7%, compressive strength of 1050 MPa | [68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Zhang, X.; Zheng, G.; Qian, M.; Geng, L. Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys. Materials 2023, 16, 5725. https://doi.org/10.3390/ma16165725

Ma S, Zhang X, Zheng G, Qian M, Geng L. Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys. Materials. 2023; 16(16):5725. https://doi.org/10.3390/ma16165725

Chicago/Turabian StyleMa, Siyao, Xuexi Zhang, Guangping Zheng, Mingfang Qian, and Lin Geng. 2023. "Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys" Materials 16, no. 16: 5725. https://doi.org/10.3390/ma16165725

APA StyleMa, S., Zhang, X., Zheng, G., Qian, M., & Geng, L. (2023). Toughening of Ni-Mn-Based Polycrystalline Ferromagnetic Shape Memory Alloys. Materials, 16(16), 5725. https://doi.org/10.3390/ma16165725