Measurement of Creep Stress Exponent of TC17 Titanium Alloy by Nanoindentation Method at Room Temperature

Abstract

:1. Introduction

2. Experimental Procedures

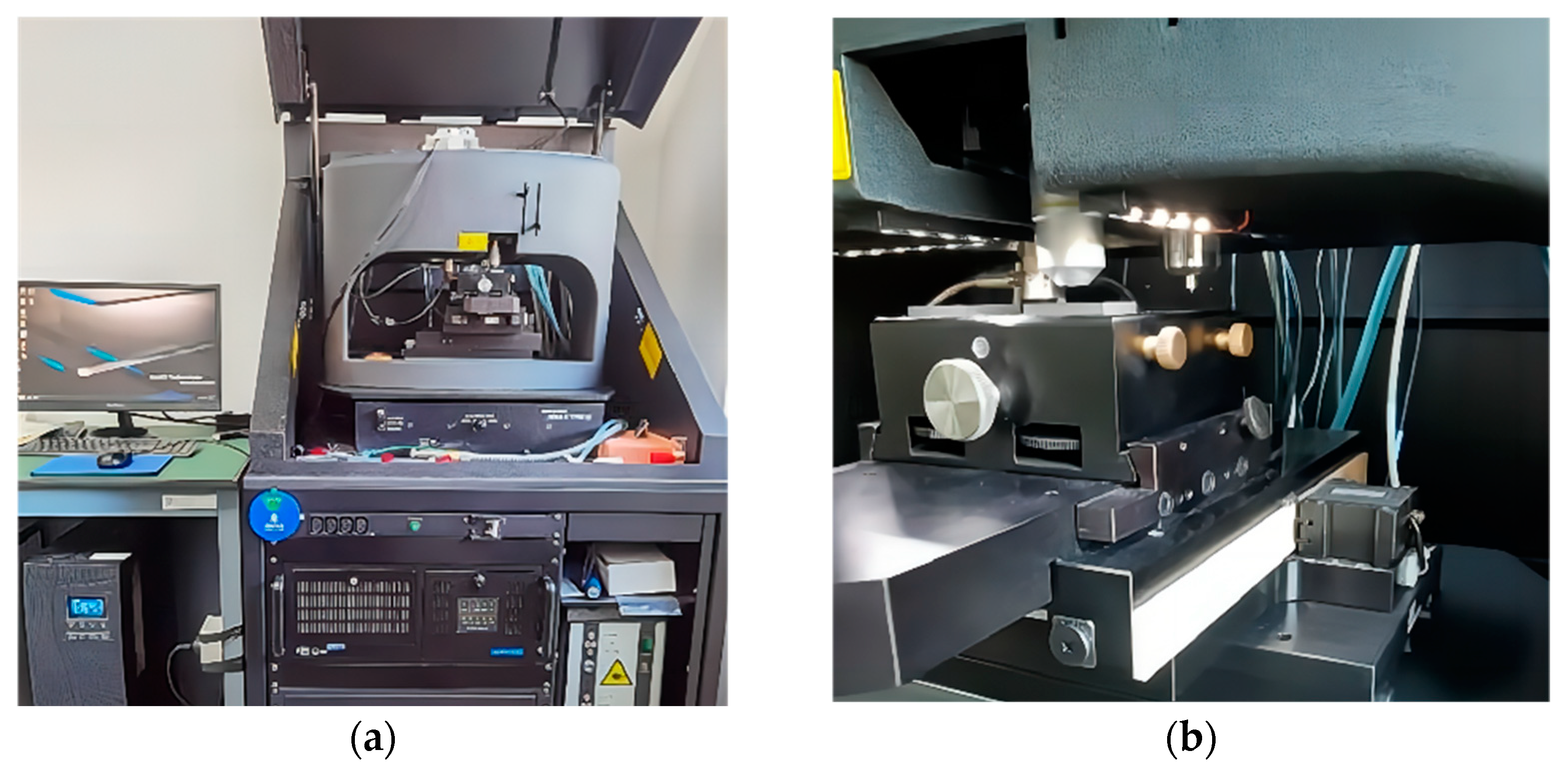

2.1. Test Sample and Equipment

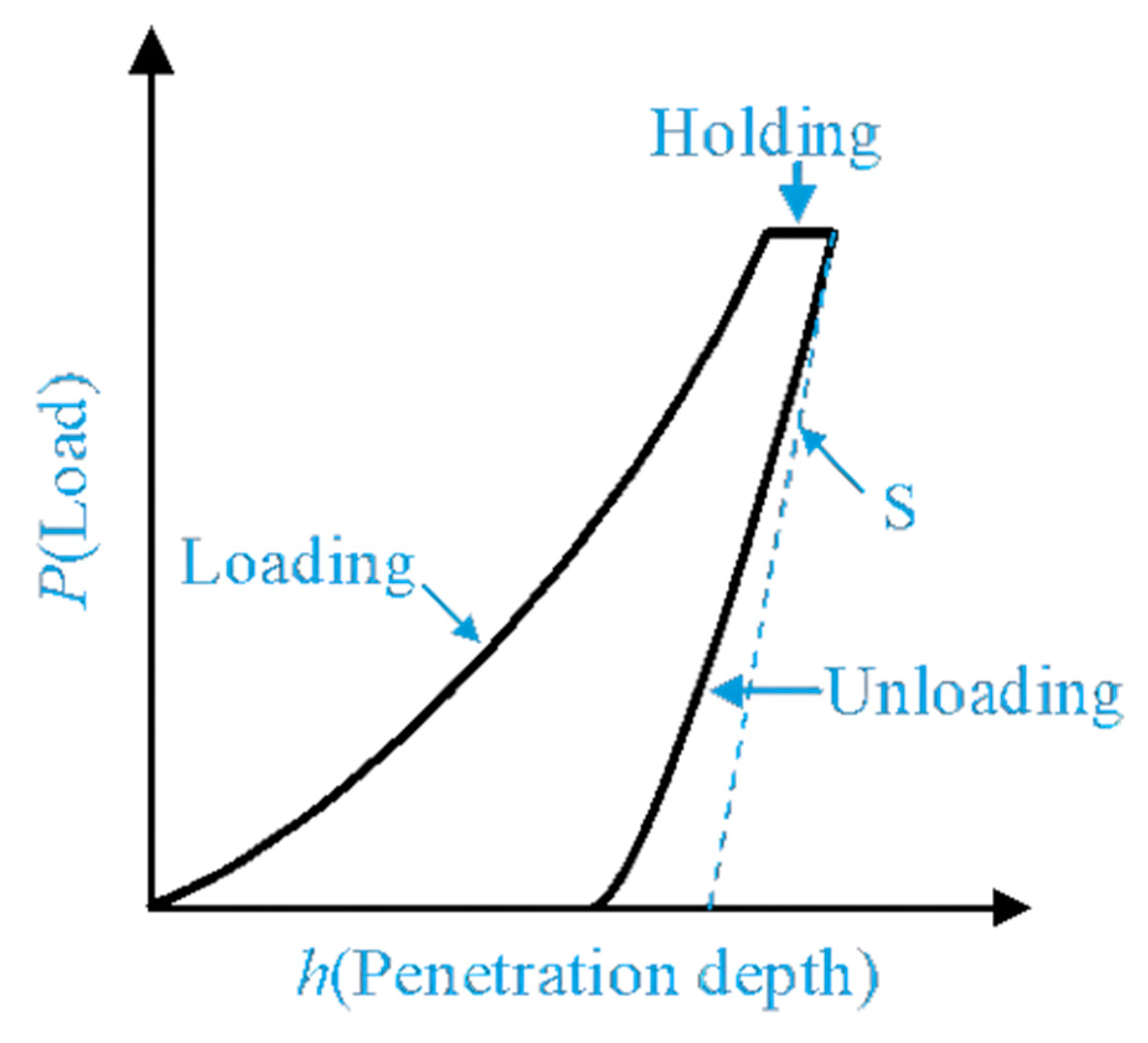

2.2. Nanoindentation Test Procedures

Nanoindentation Test Procedures at Room Temperature

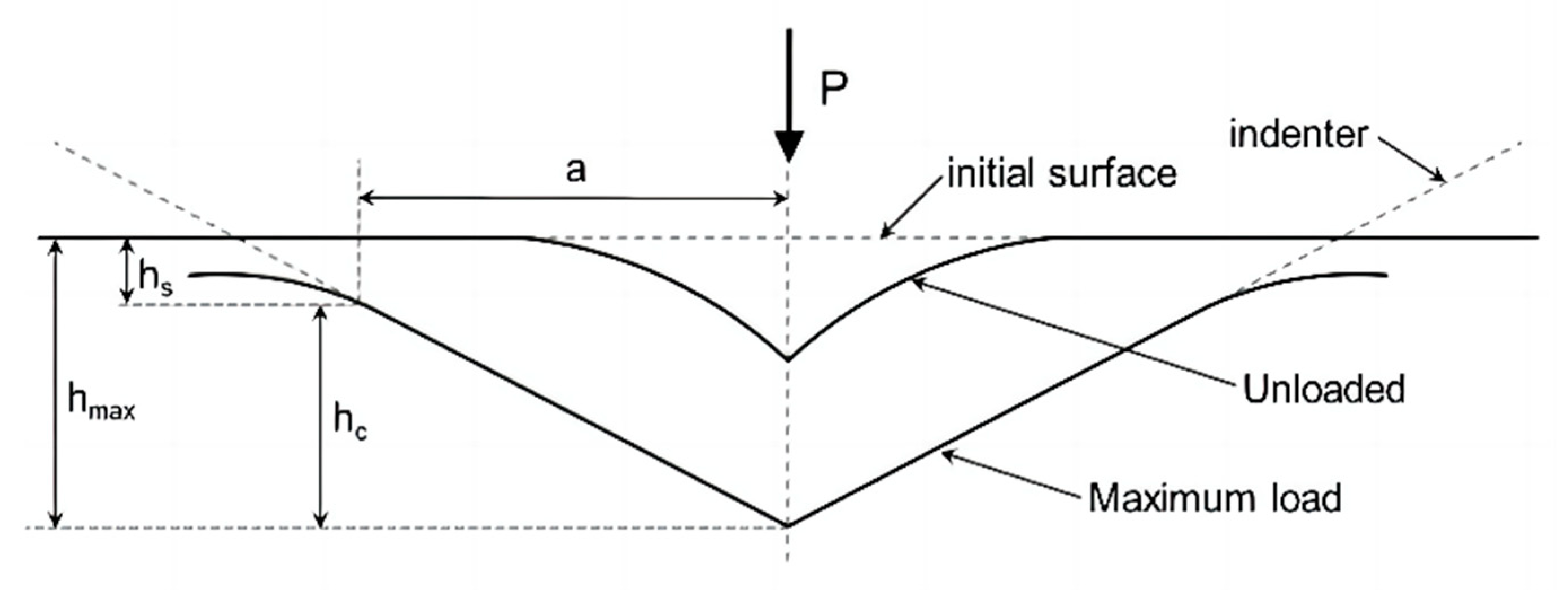

3. Calculation Methods

3.1. Indentation Strain Rate

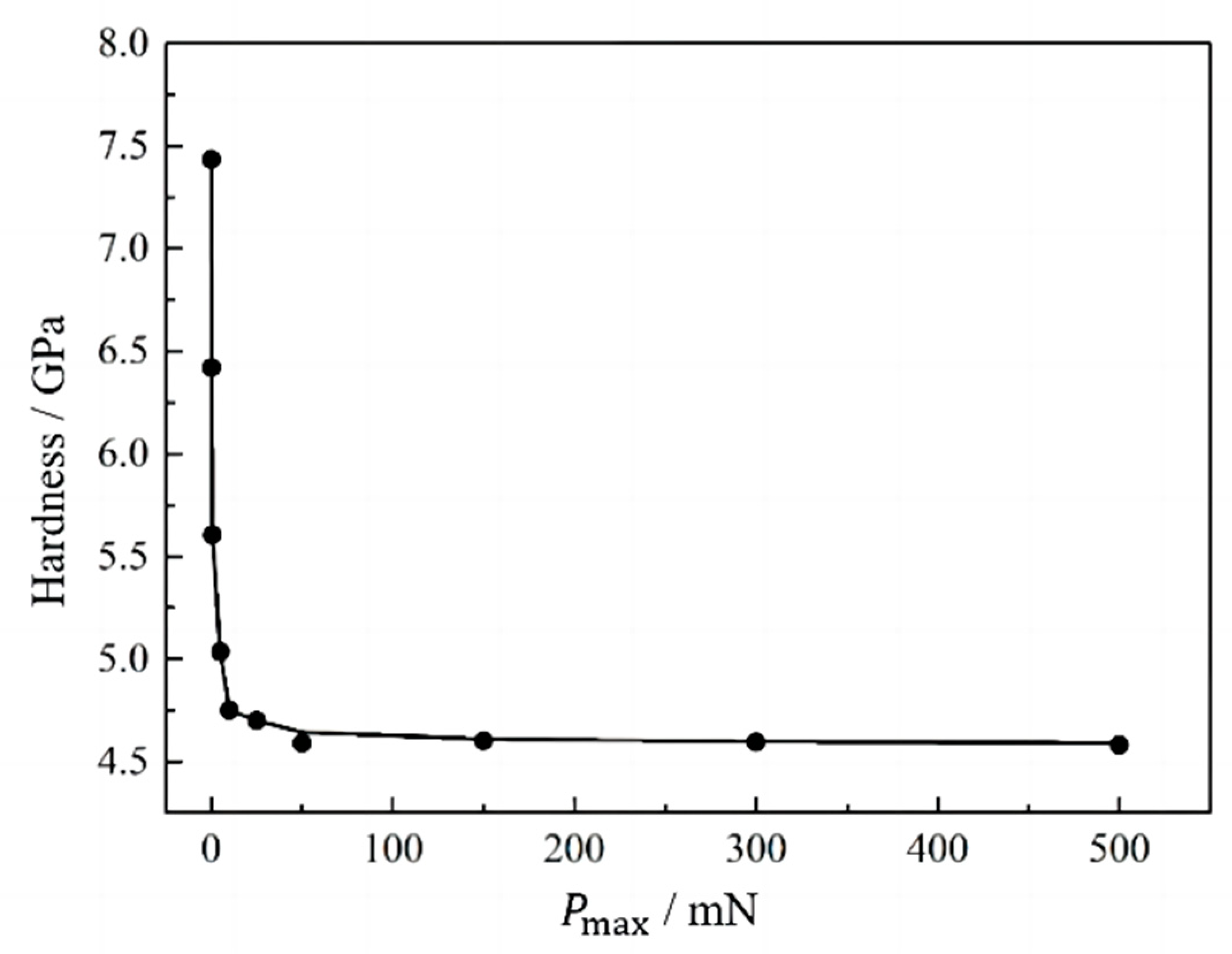

3.2. Indentation Stress

3.3. Creep Stress Exponent

4. Results and Discussions

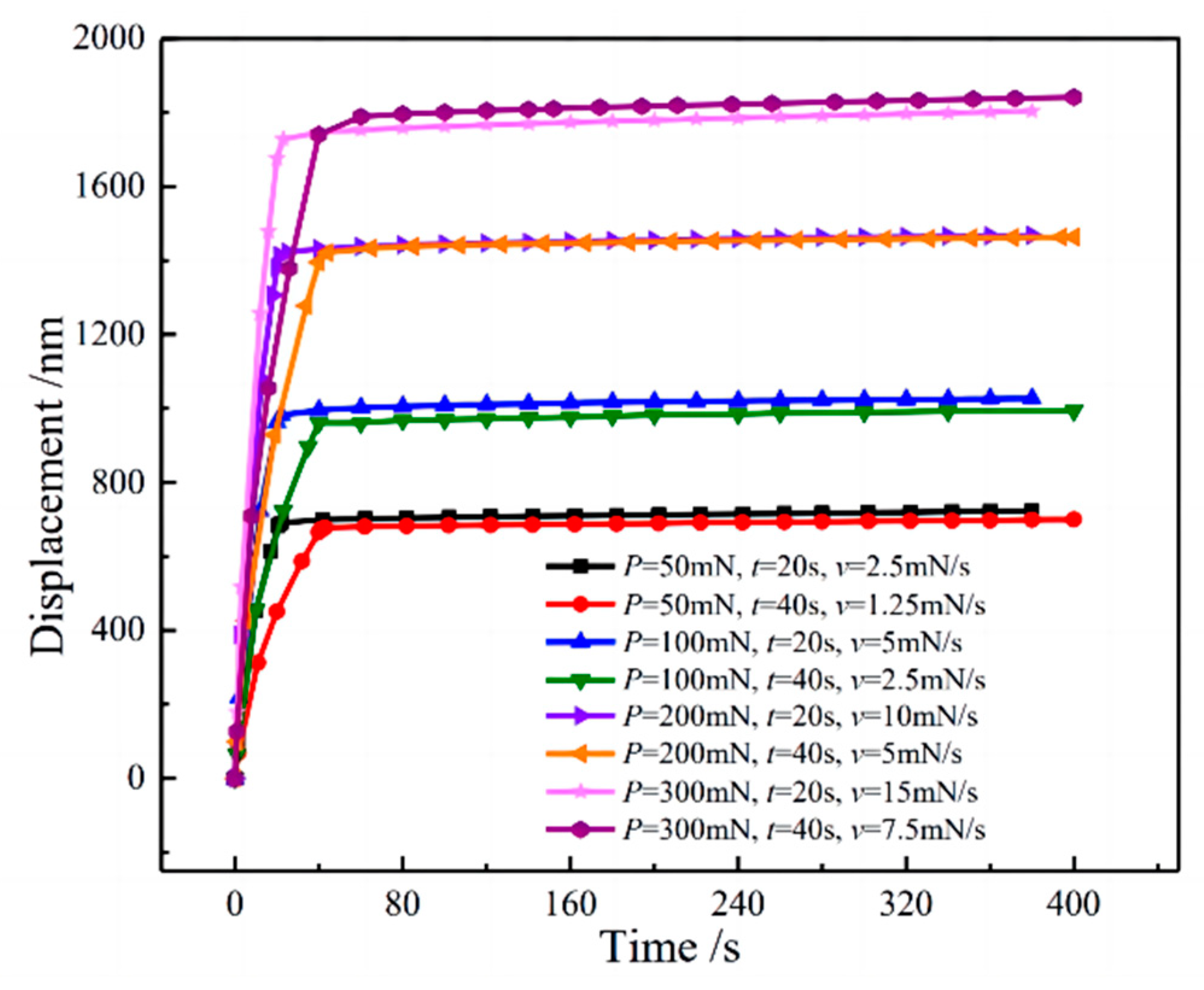

4.1. Variation of the - Curves

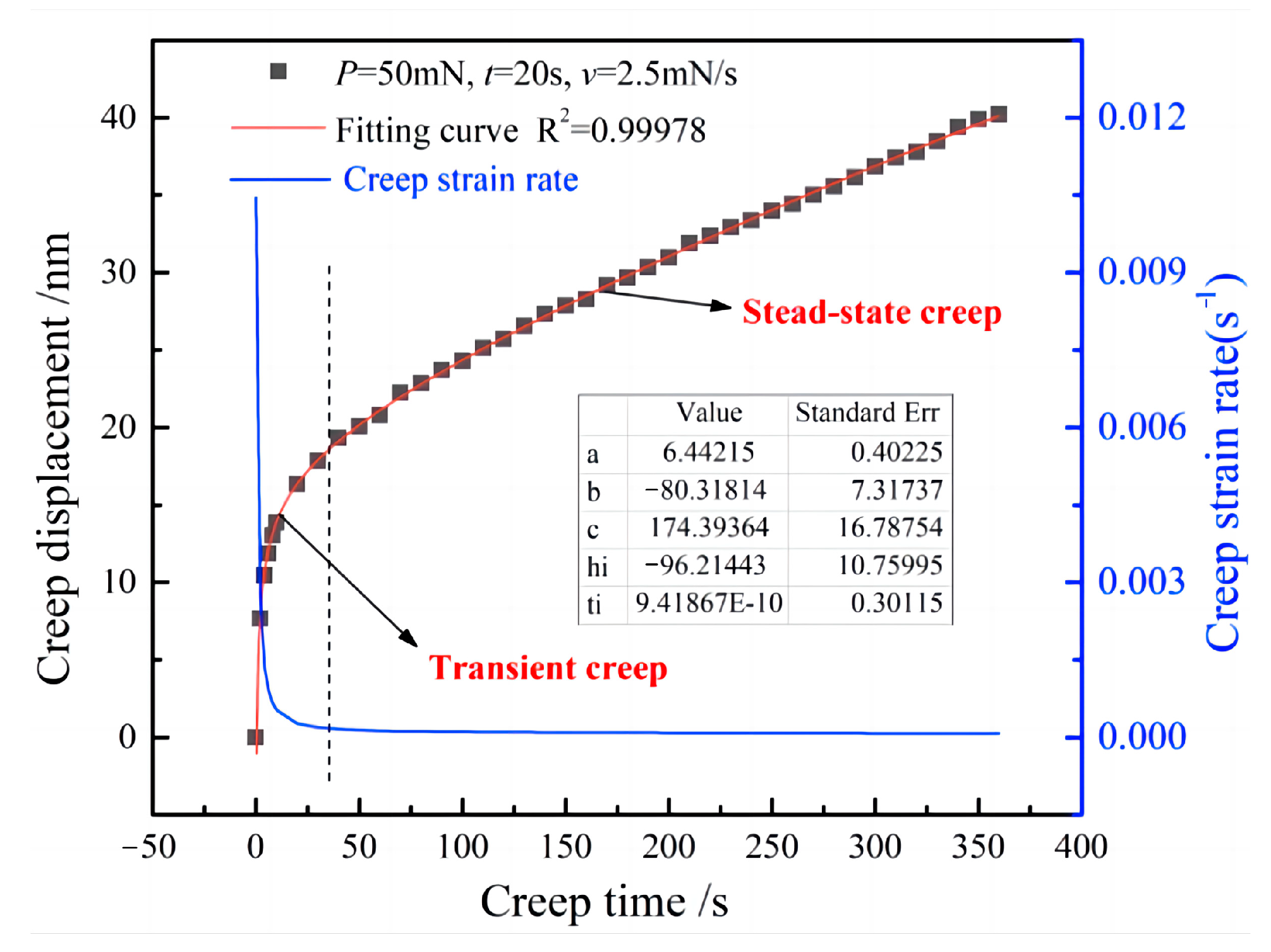

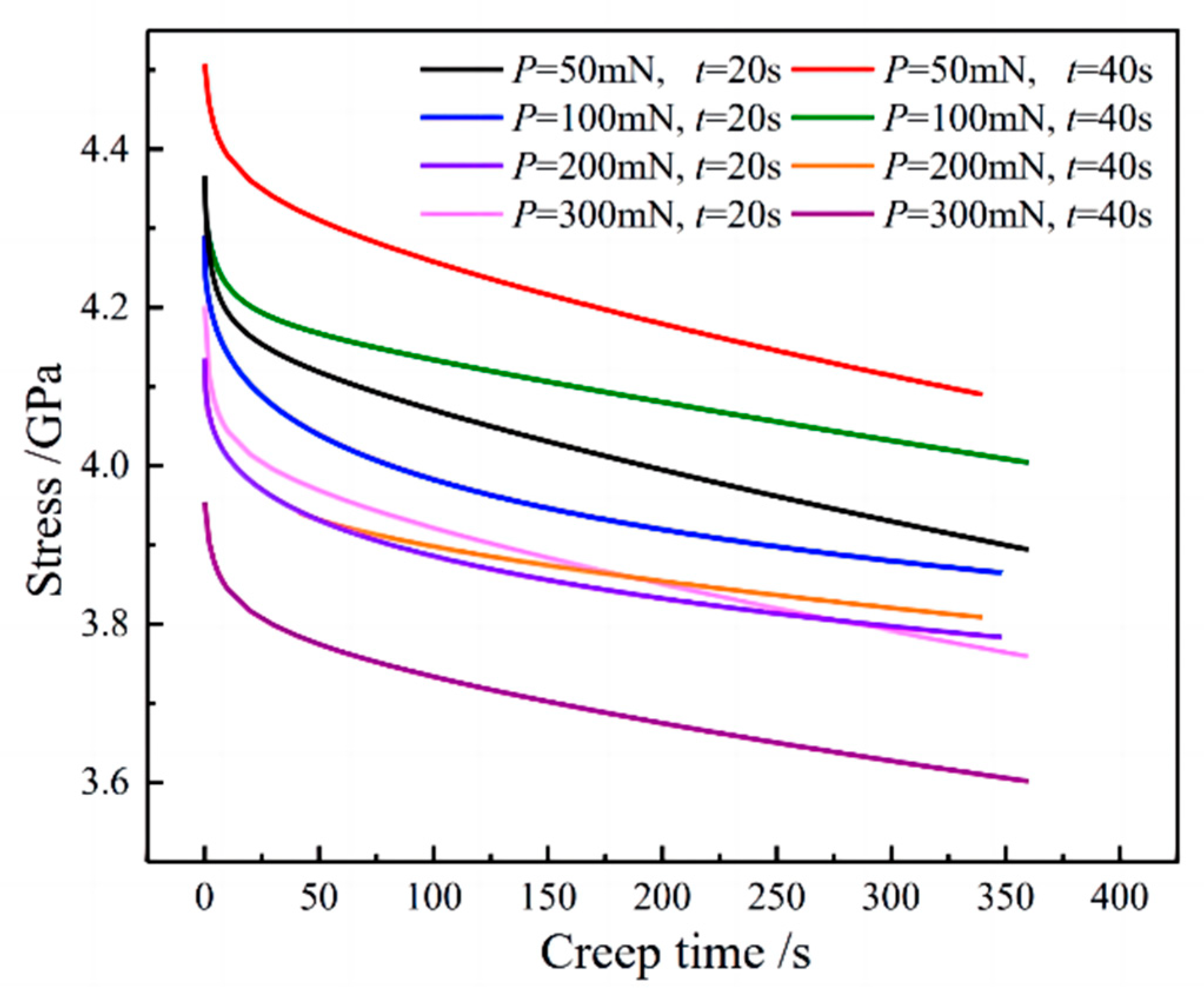

4.2. Nanoindentation Creep Behavior

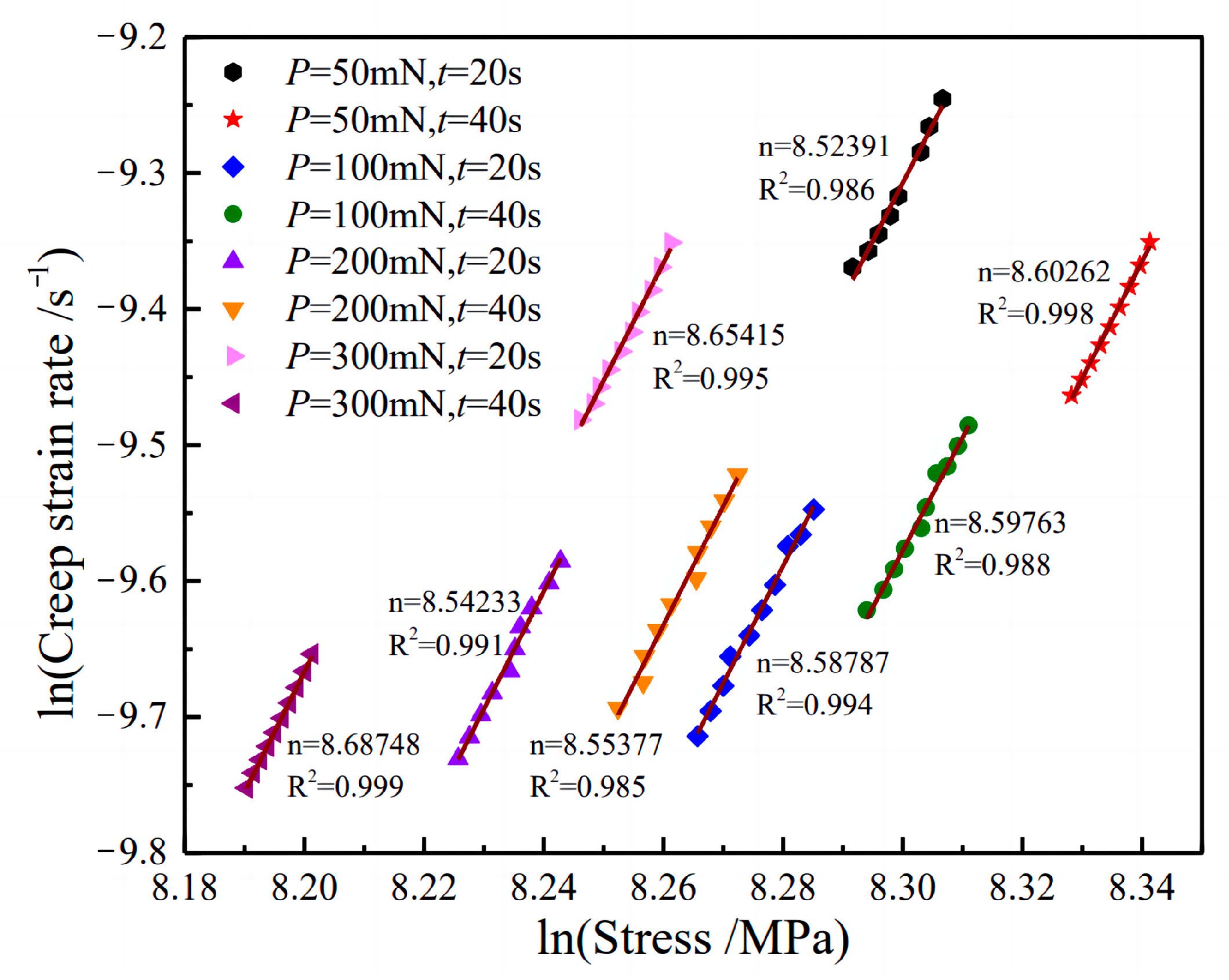

4.3. Creep Stress Exponents

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Zhao, G.L.; Xin, L.J.; Li, L.; Zhang, Y.; He, N.; Hansen, H.N. Cutting force model and damage formation mechanism in milling of 70wt% Si/Al composite. Chin. J. Aeronaut. 2023, 36, 114–128. [Google Scholar] [CrossRef]

- Xia, H.J.; Zhao, G.L.; Yan, J.H.; Li, L.; He, N.; Hao, X.Q. Study on laser-induced oxidation assisted micro milling of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2019, 103, 1579–1591. [Google Scholar] [CrossRef]

- Chen, K.; Luo, J.; Han, W.C.; Li, M.Q. Formation and evolution of new α grain boundary and its influence on globularization of α lamellae in TC17 alloy. J. Alloys Compd. 2022, 848, 156141. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Chen, B.; Tang, H.B.; Cheng, X.; Wang, H.M.; Li, J. Influence of heat treatments on microstructure and mechanical properties of laser additive manufacturing Ti-5Al-2Sn-2Zr-4Mo-4Cr titanium alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 36–46. [Google Scholar] [CrossRef]

- Ding, M.C.; Zhang, Y.L.; Lu, H.T. Fatigue life prediction of TC17 titanium alloy based on micro scratch. Int. J. Fatigue 2020, 139, 105793. [Google Scholar] [CrossRef]

- Yin, M.G.; Wang, W.J.; He, W.F.; Cai, Z.B. Impact-sliding tribology behavior of TC17 alloy treated by laser shock peening. Materials 2018, 11, 1229. [Google Scholar] [CrossRef]

- Sun, J.Z.; Li, M.Q.; Li, H. Deformation behavior of TC17 titanium alloy with basketweave microstructure during isothermal compression. J. Alloys Compd. 2018, 730, 533–543. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Fan, J.K.; Li, R.F.; Kou, H.C.; Chen, Z.Y.; Wang, Q.J.; Zhang, H.L.; Wang, J.; Gao, Q.; Li, J.S. Orientation dependent behavior of tensile-creep deformation of hot rolled Ti65 titanium alloy sheet. J. Mater. Sci. Technol. 2021, 75, 265–275. [Google Scholar] [CrossRef]

- Ma, X.K.; Li, F.G.; Zhao, C.; Zhu, G.; Li, W.N.; Sun, Z.K.; Yuan, Z.W. Indenter load effects on creep deformation behavior for Ti-10V-2Fe-3Al alloy at room temperature. J. Alloys Compd. 2017, 709, 322–328. [Google Scholar] [CrossRef]

- Dastidar, I.G.; Khademi, V.; Bieler, T.R.; Pilchak, A.L.; Crimp, M.A.; Boehlert, C.J. The tensile and tensile-creep deformation behavior of Ti-8Al-1Mo-1V(wt.%). Mater. Sci. Eng. A 2015, 636, 289–300. [Google Scholar] [CrossRef]

- Morris, M.A. Creep and high temperature deformation of titanium aluminide alloys: Influence of α2 phase distribution and B2 phase decomposition. Mater. Sci. Eng. A 1991, 148, 33–43. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Qu, H.L.; Wang, M.M.; Wu, H.; Zhu, K.Y. Thermal stability and creep behavior of Ti–V–Cr burn-resistant alloys. J. Alloys Compd. 2006, 407, 118–124. [Google Scholar] [CrossRef]

- Wang, T.B.; Li, B.L.; Wang, Z.Q.; Nie, Z.R. A microstructure with improved thermal stability and creep resistance in a novel near-alpha titanium alloy. Mater. Sci. Eng. A 2018, 731, 12–20. [Google Scholar] [CrossRef]

- Ponsonnet, L.; Quesne, C.; Penelle, R. Microstructure and creep deformation of a near beta titanium alloy ‘β -CEZ’. Mater. Sci. Eng. A 1999, 262, 50–63. [Google Scholar] [CrossRef]

- Gu, Y.; Zeng, F.H.; Qi, Y.L.; Xia, C.Q.; Xiong, X. Tensile creep behavior of heat-treated TC11 titanium alloy at 450–550 °C. Mater. Sci. Eng. A 2013, 575, 74–85. [Google Scholar] [CrossRef]

- He, J.Y.; Zenk, C.H.; Zhou, X.Y.; Neumeier, S.; Makineni, S.K. On the atomic solute diffusional mechanisms during compressive creep deformation of a Co-Al-W-Ta single crystal superalloy. Acta Mater. 2020, 184, 86–99. [Google Scholar] [CrossRef]

- Xiang, Y.X.; Zhu, W.J.; Liu, C.J.; Xuan, F.Z.; Wang, Y.N.; Kuang, W.C. Creep degradation characterization of titanium alloy using nonlinear ultrasonic technique. NDT E Int. 2015, 72, 41–49. [Google Scholar] [CrossRef]

- Hayes, R.W.; Viswanathan, G.B.; Mills, M.J. Creep behavior of Ti-6Al-2Sn-4Zr-2Mo: I. The effect of nickel on creep deformation and microstructure. Acta Mater. 2002, 50, 4953–4963. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W.C.; Pharr, G.M. Influences of elasticity on the measurement of power law creep parameters by nanoindentation. J. Mech. Phys. Solids 2021, 154, 104527. [Google Scholar] [CrossRef]

- Dean, J.; Bradbury, A.; Aldrich-Smith, G.; Clyne, T.W. A procedure for extracting primary and secondary creep parameters from nanoindentation data. Mech. Mater. 2013, 65, 124–134. [Google Scholar] [CrossRef]

- Mahmudi, R.; Roumina, R.; Raeisinia, B. Investigation of stress exponent in the power-law creep of Pb–Sb alloys. Mater. Sci. Eng. A 2004, 382, 15–22. [Google Scholar] [CrossRef]

- Sargent, P.M.; Ashby, M.F. Indentation creep. Mater. Sci. Technol. 2013, 8, 594–601. [Google Scholar]

- Goodall, R.; Clyne, T.W. A critical appraisal of the extraction of creep parameters from nanoindentation data obtained at room temperature. Acta Mater. 2006, 54, 5489–5499. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhang, Q.Q.; Zhao, X.C.; Yang, X.R.; Luo, L. Ambient-temperature nanoindentation creep in ultrafine-grained titanium processed by ECAP. Mater. Sci. Eng. A 2016, 676, 73–79. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Su, C.; Herbert, E.G.; Sohn, S.; LaManna, J.A.; Oliver, W.C.; Pharr, G.M. Measurement of power-law creep parameters by instrumented indentation methods. J. Mech. Phys. Solids 2013, 61, 517–536. [Google Scholar] [CrossRef]

- Lucas, B.N.; Oliver, W.C. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Hu, J.J.; Sun, G.X.; Zhang, X.P.; Wang, G.Y.; Jiang, Z.H.; Han, S.; Zhang, J.Y.; Lian, J.S. Effects of loading strain rate and stacking fault energy on nanoindentation creep behaviors of nanocrystalline Cu, Ni-20wt.%Fe and Ni. J. Alloys Compd. 2015, 647, 670–680. [Google Scholar] [CrossRef]

| Main Component (wt.%) | Impurities (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Ti | Al | Sn | Zr | Mo | Cr | C | N | O |

| Bal. | 4.9 | 2.0 | 1.9 | 4.2 | 4.2 | 0.02 | 0.02 | 0.1 |

| Maximum Load | Loading Time | Loading Rate | Indentation Displacement (nm) |

|---|---|---|---|

| 50 | 20 | 2.5 | 682 |

| 50 | 40 | 1.25 | 672 |

| 100 | 20 | 5 | 978 |

| 100 | 40 | 2.5 | 968 |

| 200 | 20 | 10 | 1403 |

| 200 | 40 | 5 | 1406 |

| 300 | 20 | 15 | 1711 |

| 300 | 40 | 7.5 | 1758 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Chen, X.; Wang, Y.; Zhao, G.; Yang, Y. Measurement of Creep Stress Exponent of TC17 Titanium Alloy by Nanoindentation Method at Room Temperature. Materials 2023, 16, 5702. https://doi.org/10.3390/ma16165702

Li F, Chen X, Wang Y, Zhao G, Yang Y. Measurement of Creep Stress Exponent of TC17 Titanium Alloy by Nanoindentation Method at Room Temperature. Materials. 2023; 16(16):5702. https://doi.org/10.3390/ma16165702

Chicago/Turabian StyleLi, Fagui, Xiyu Chen, Yuannan Wang, Guolong Zhao, and Yinfei Yang. 2023. "Measurement of Creep Stress Exponent of TC17 Titanium Alloy by Nanoindentation Method at Room Temperature" Materials 16, no. 16: 5702. https://doi.org/10.3390/ma16165702

APA StyleLi, F., Chen, X., Wang, Y., Zhao, G., & Yang, Y. (2023). Measurement of Creep Stress Exponent of TC17 Titanium Alloy by Nanoindentation Method at Room Temperature. Materials, 16(16), 5702. https://doi.org/10.3390/ma16165702