A Study of Molecular Dynamic Simulation and Experimental Performance of the Eucommia Ulmoides Gum-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation Process

2.1.1. Original Materials

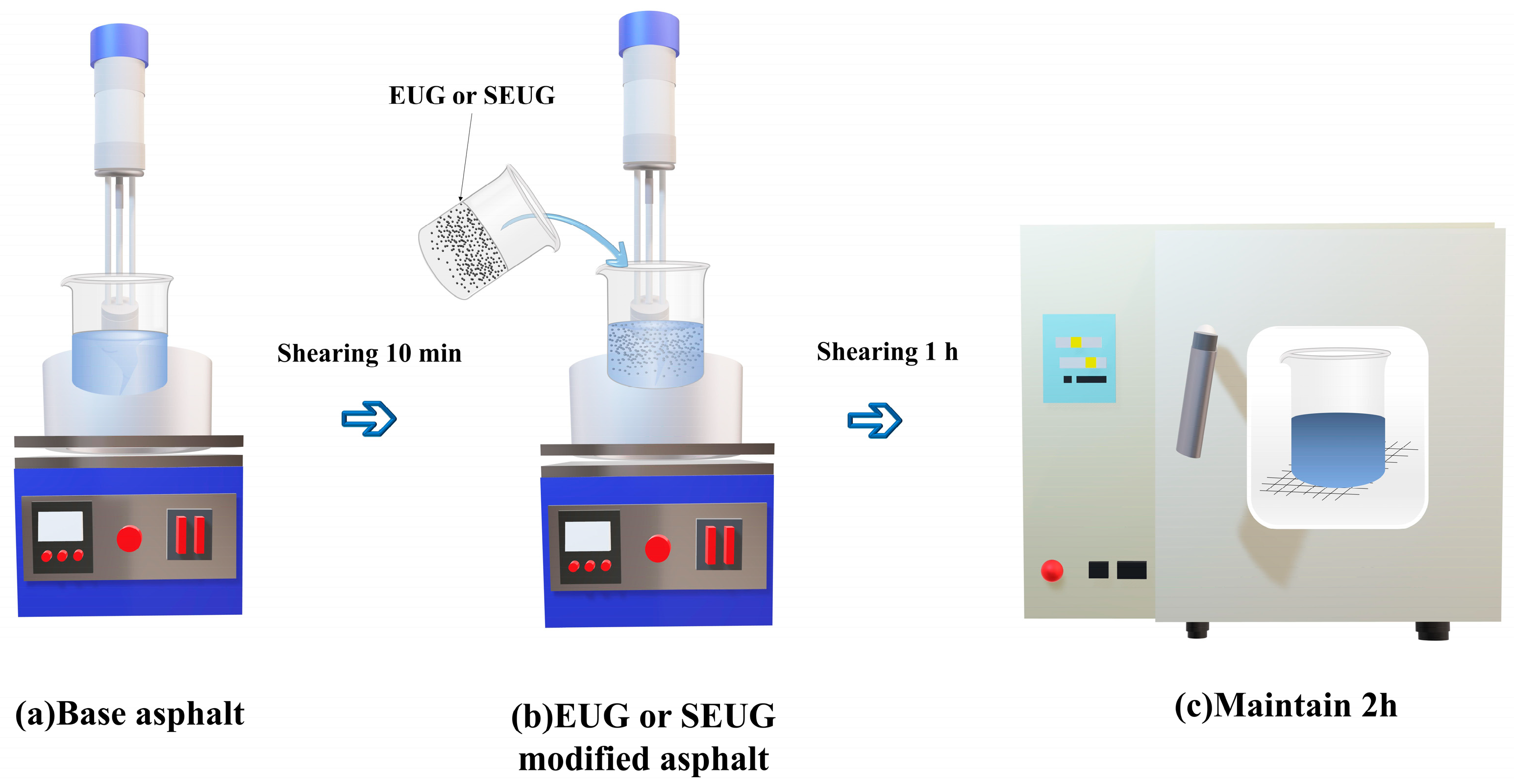

2.1.2. Preparation Process

- (1)

- The preparation process of vulcanized EUG

- (2)

- The preparation process for the preparation of EUG-modified asphalt

- (3)

- The preparation process for the preparation of SEUG-modified asphalt

2.2. Experiment Methods

2.2.1. Physical Properties Test

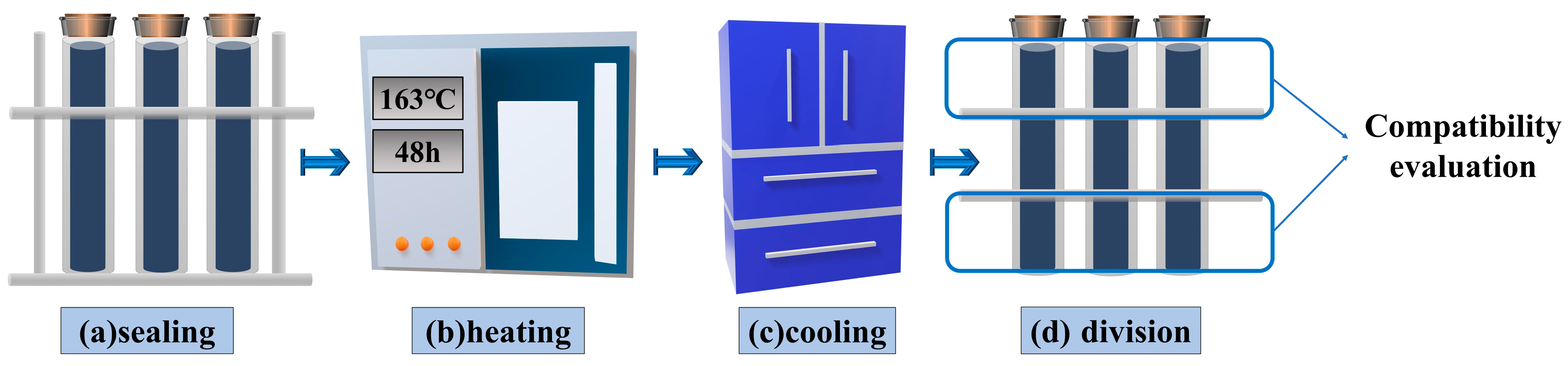

2.2.2. Segregation Experiment

2.2.3. Scanning Electron Microscope (SEM)

2.3. Construction of the Molecular Models

2.3.1. Molecular Model of BA

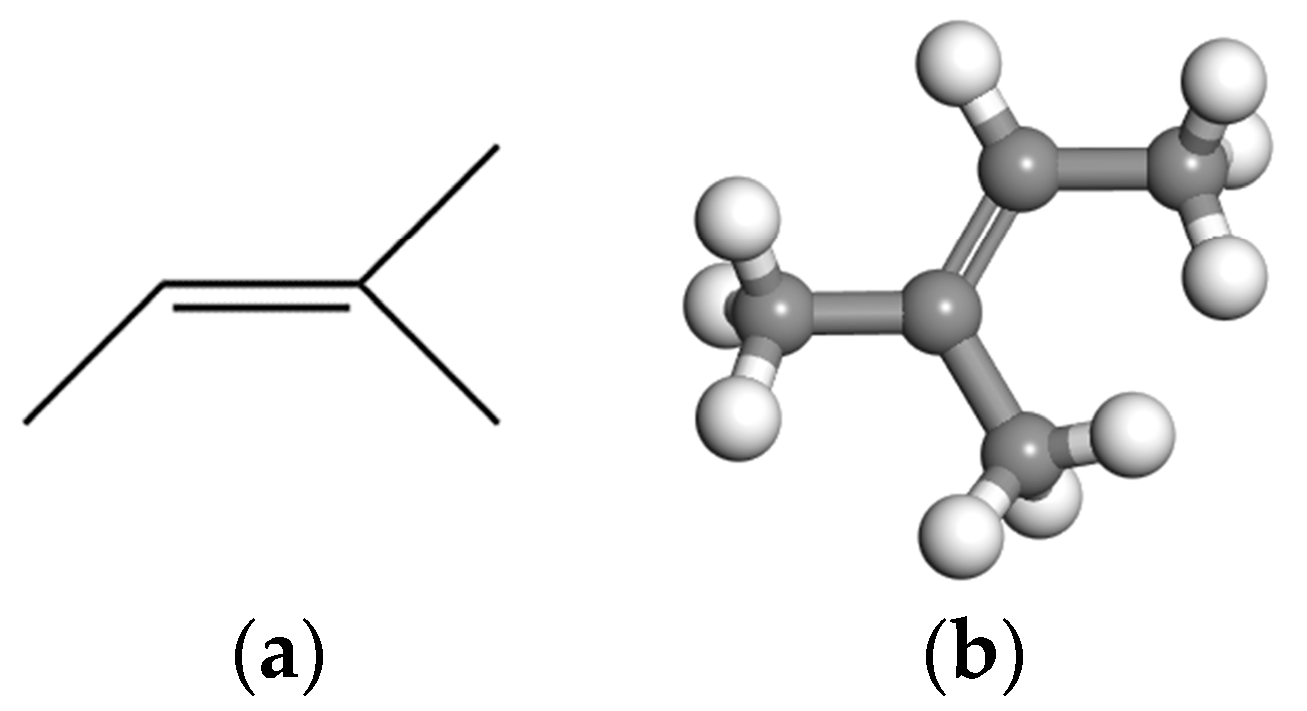

2.3.2. Molecular Model of EUG

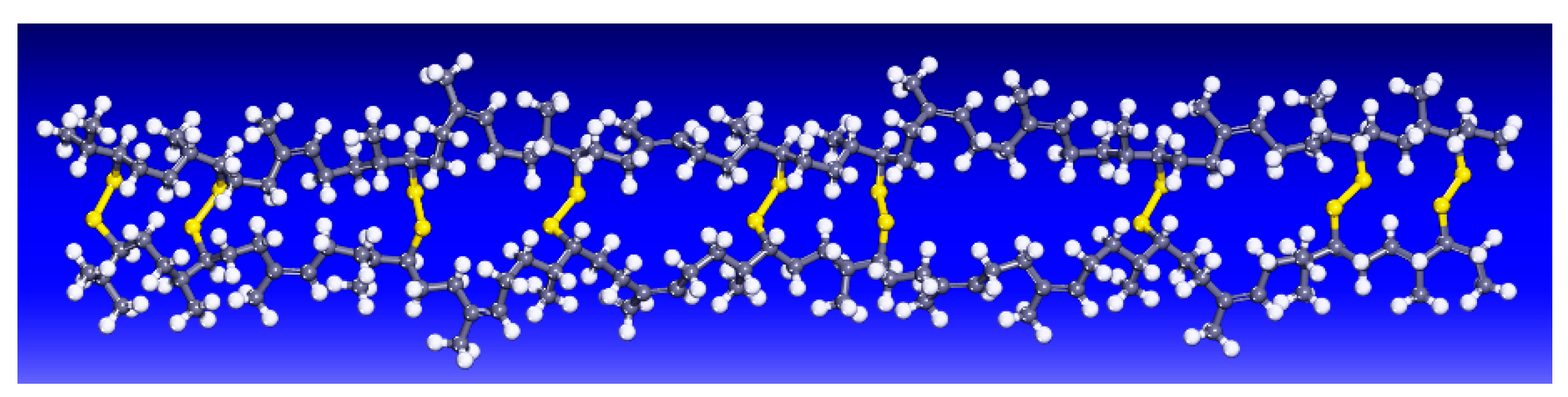

2.3.3. Molecular Model of SEUG

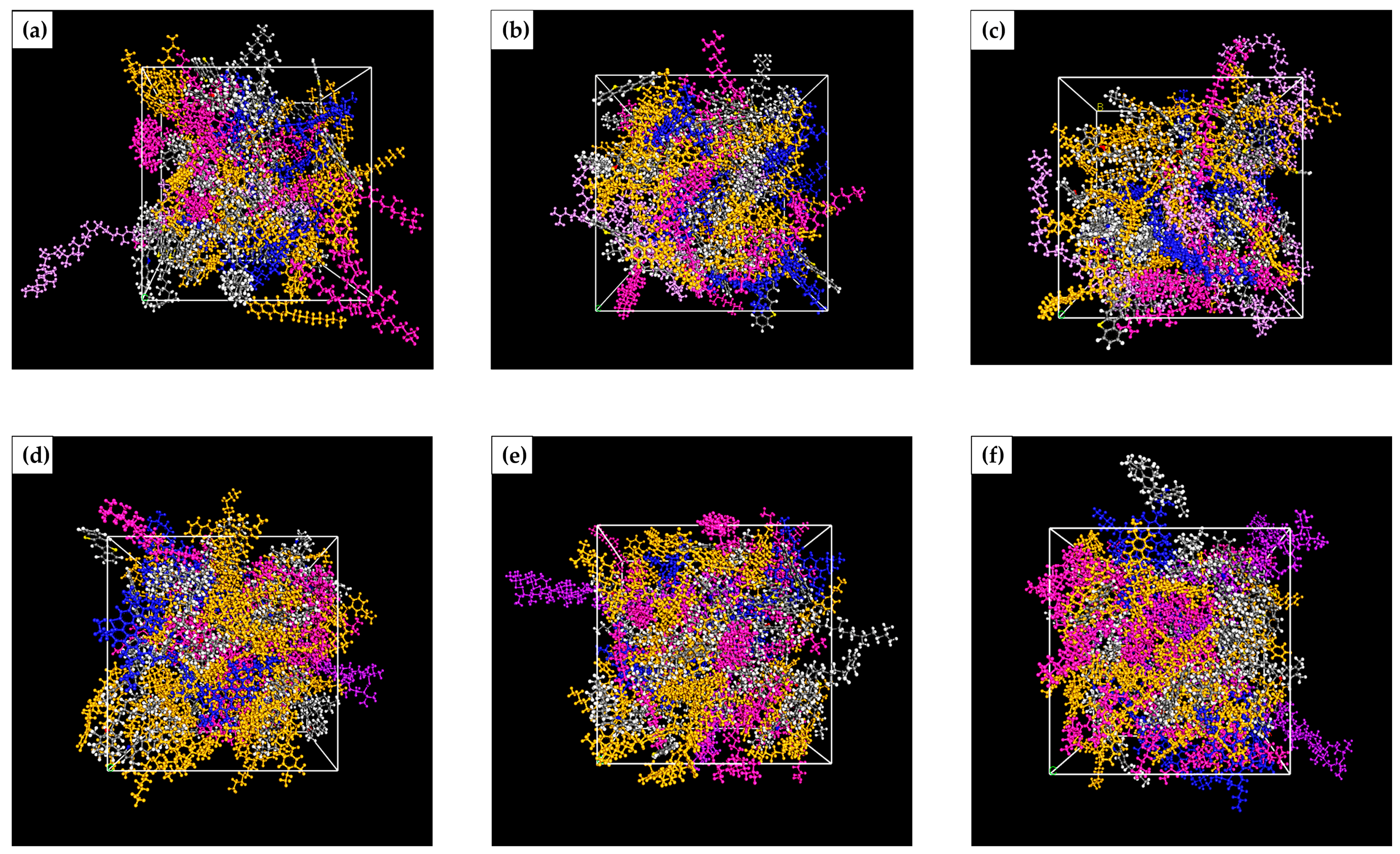

2.3.4. Molecular Model of Gutta-Percha-Modified Asphalt

2.4. MD Simulation Methods and Task

2.4.1. Theoretical Basis

- (1)

- Equations of Motion

- (2)

- Boundary Conditions

- (3)

- Force Field

- (4)

- Ensemble

2.4.2. Simulation Process

- (1)

- Due to the very high initial energy of the bitumen system, a structural optimization of the bitumen model is required to find the best local energy point before molecular dynamic simulations can be performed. This is performed by using the geometry optimization module of the forcite module for geometric optimization, selecting the smart algorithm, setting the maximum number of iterations to 50,000, selecting an accuracy of medium, a truncation radius of 12.5 Å, a force field from COMPASS II, and using the atom-based and ewald methods, respectively. The van der Waals non-bonded and electrostatic non-bonded interactions were solved with the charge set to forcefield.

- (2)

- Annealing allows the bitumen molecular chains to relax, the cell volume to decrease, and the model densities to increase, thus eliminating the local energy minimum of the system. This brings the bitumen model closer to the natural molecular state of the bitumen. Annealing of the bitumen model was carried out using the anneal task in the forcite module with a constant temperature and pressure system (NPT) set at 27–1527 °C, 5 cycles of temperature rise and fall, and a total simulation time of 200 ps.

- (3)

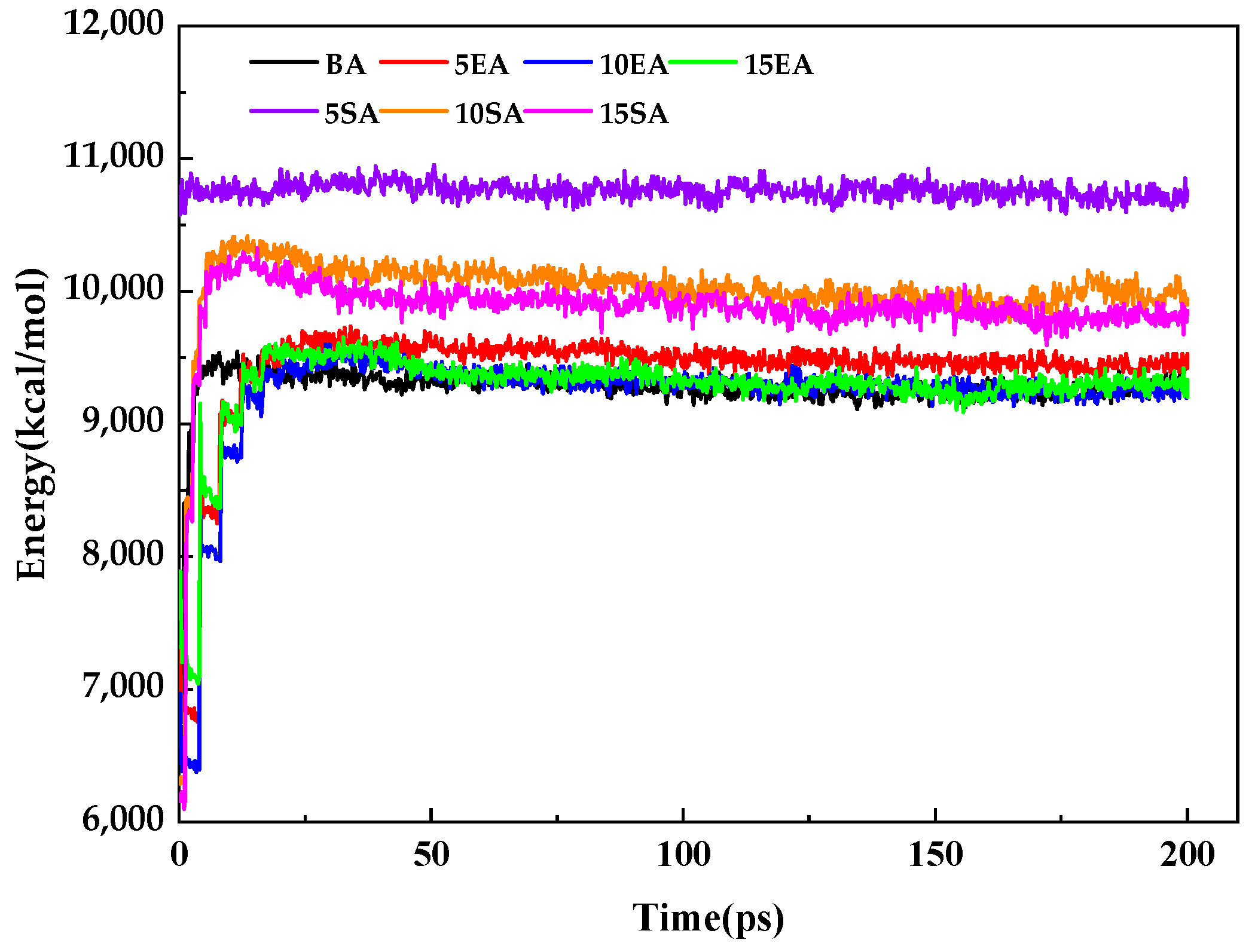

- The premise of the system calculation is that the system is in thermodynamic equilibrium; so, the asphalt model in this study was subjected to a time step of 1 fs and had a total simulation time of 200 ps for the constant volume system (NVT) calculation and 200 ps for the constant pressure system (NPT) kinetic calculation. According to existing studies [60], thermodynamic parameters, such as energy, change by 5~10% as the simulation time increases, and the system is assumed to reach a steady state. The simulation results are shown in Figure 11.

2.4.3. Simulation Task

- (a)

- Solubility parameters

- (b)

- Intermolecular potential energy

- (c)

- Diffusion coefficient

- (d)

- Mechanical performance calculations

3. Results and Discussion

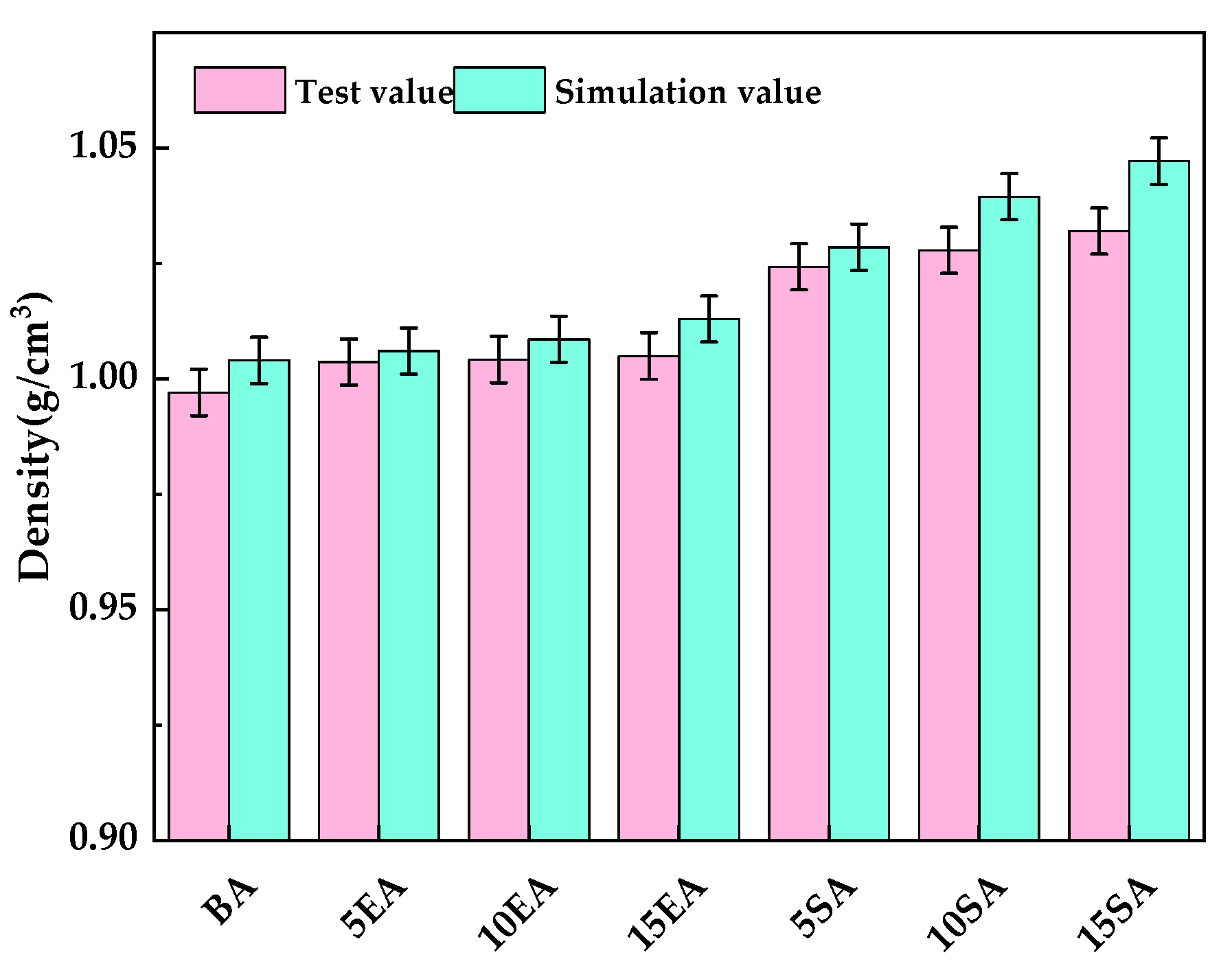

3.1. Molecular Model Validation

3.2. Simulation Results and Discussion

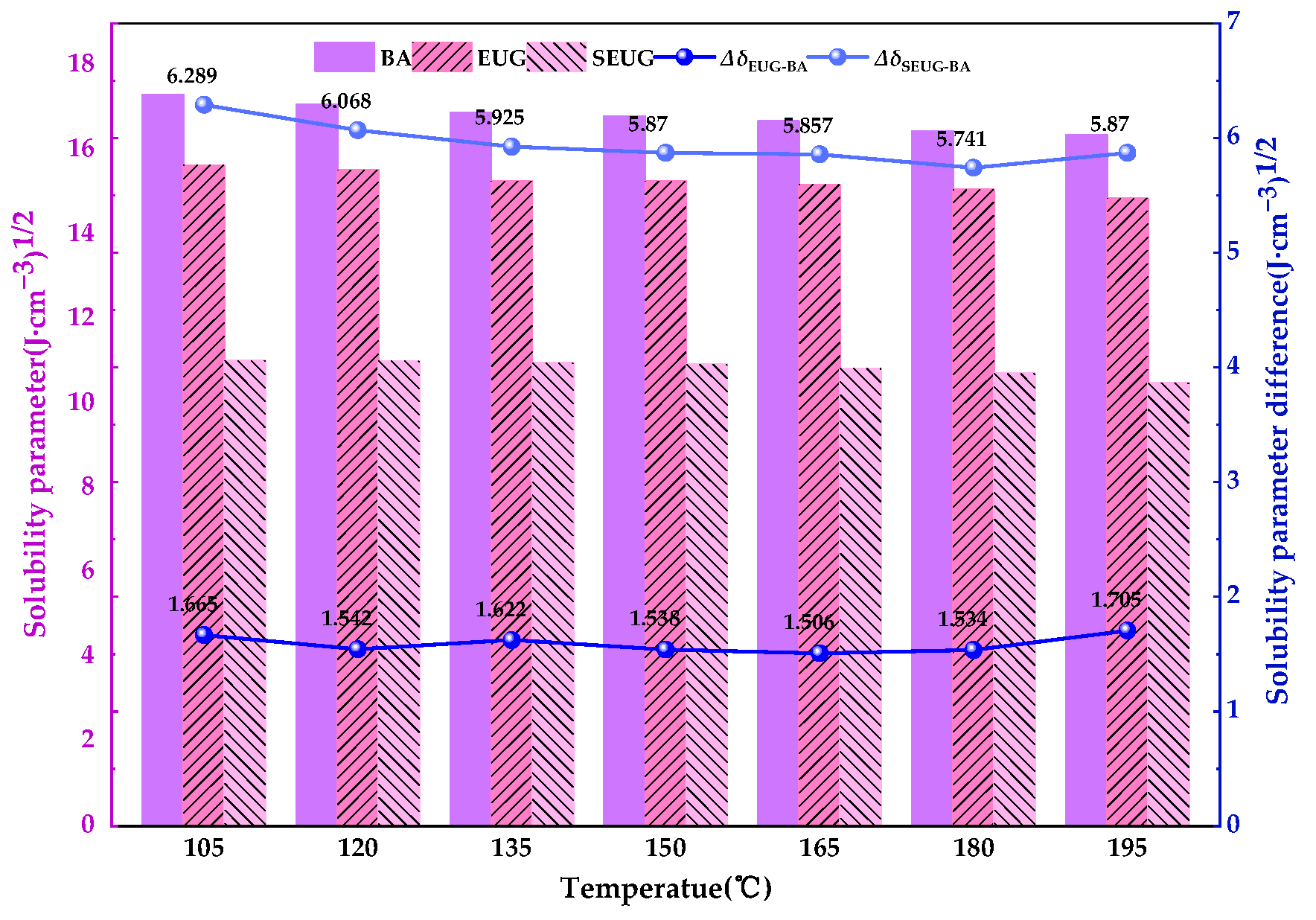

3.2.1. Solubility Parameters

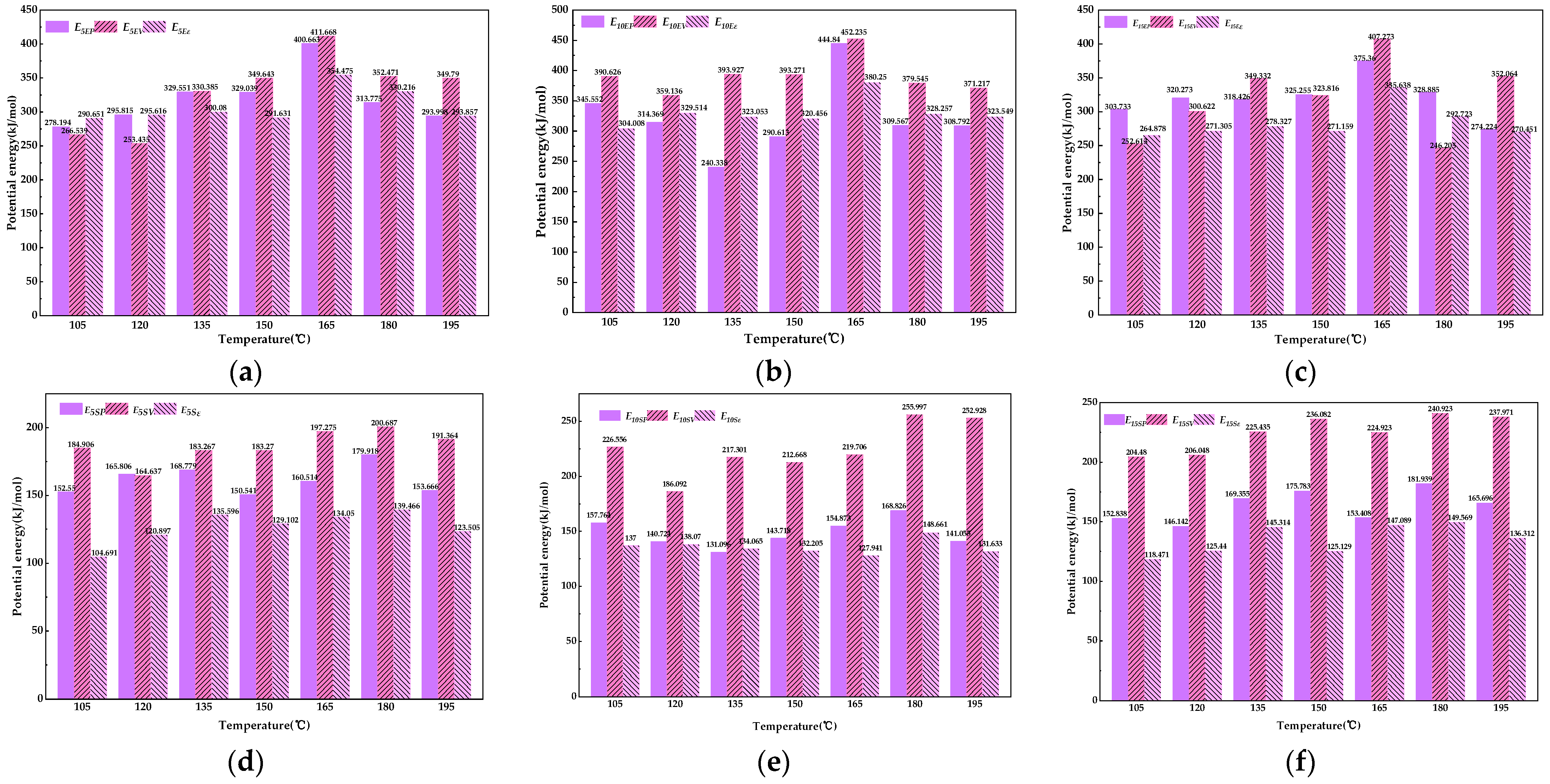

3.2.2. Intermolecular Potential Energy

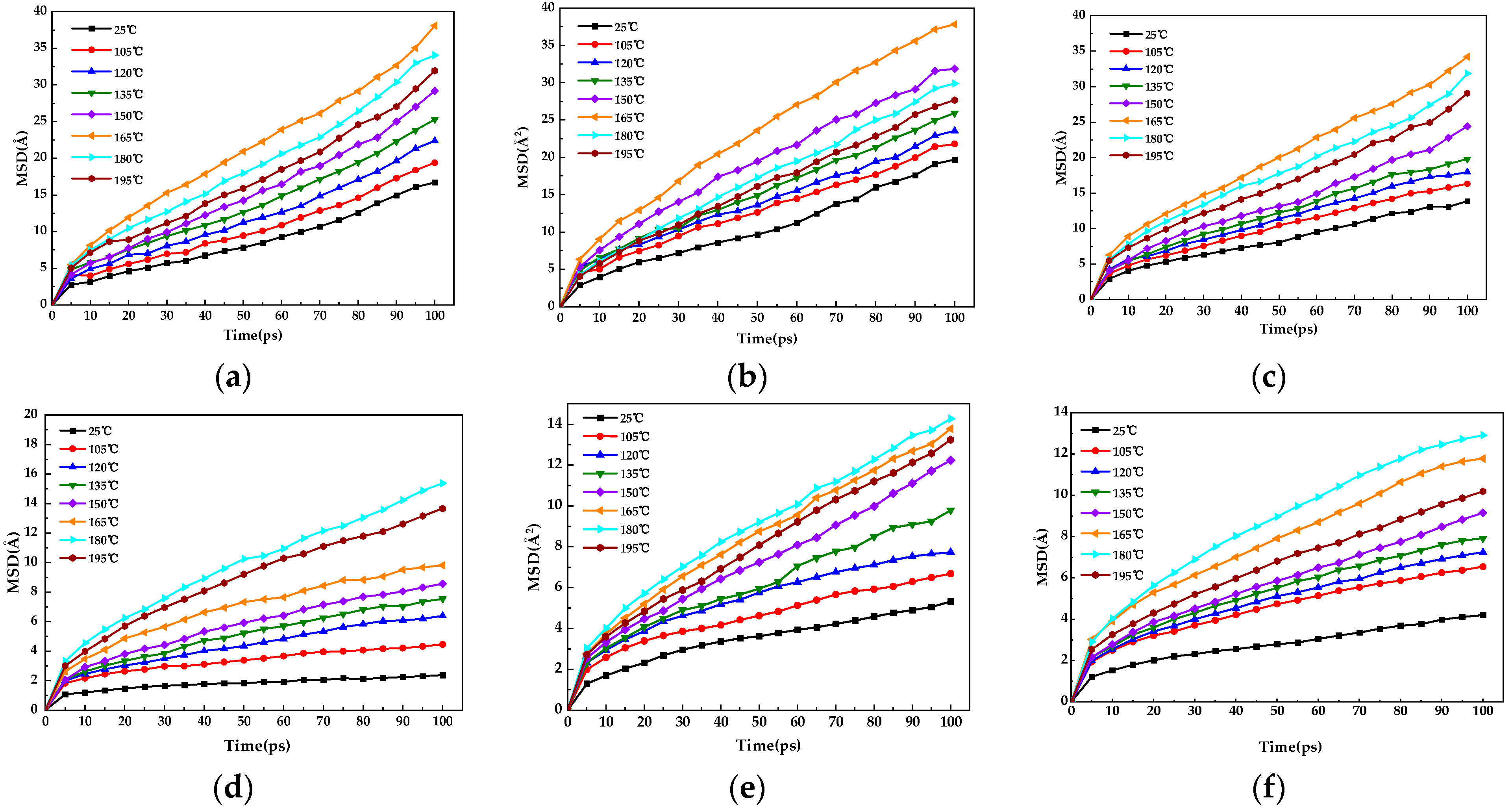

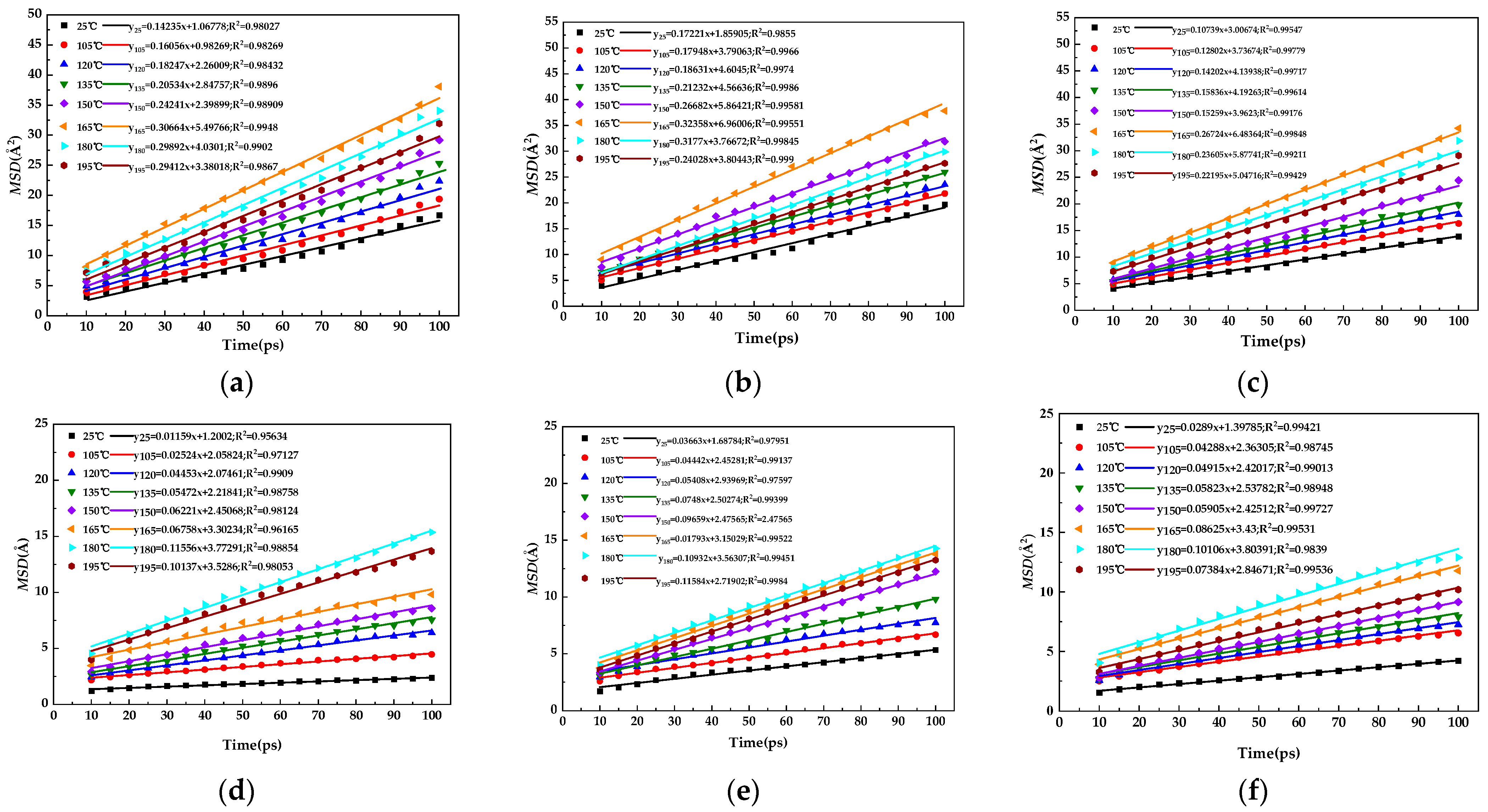

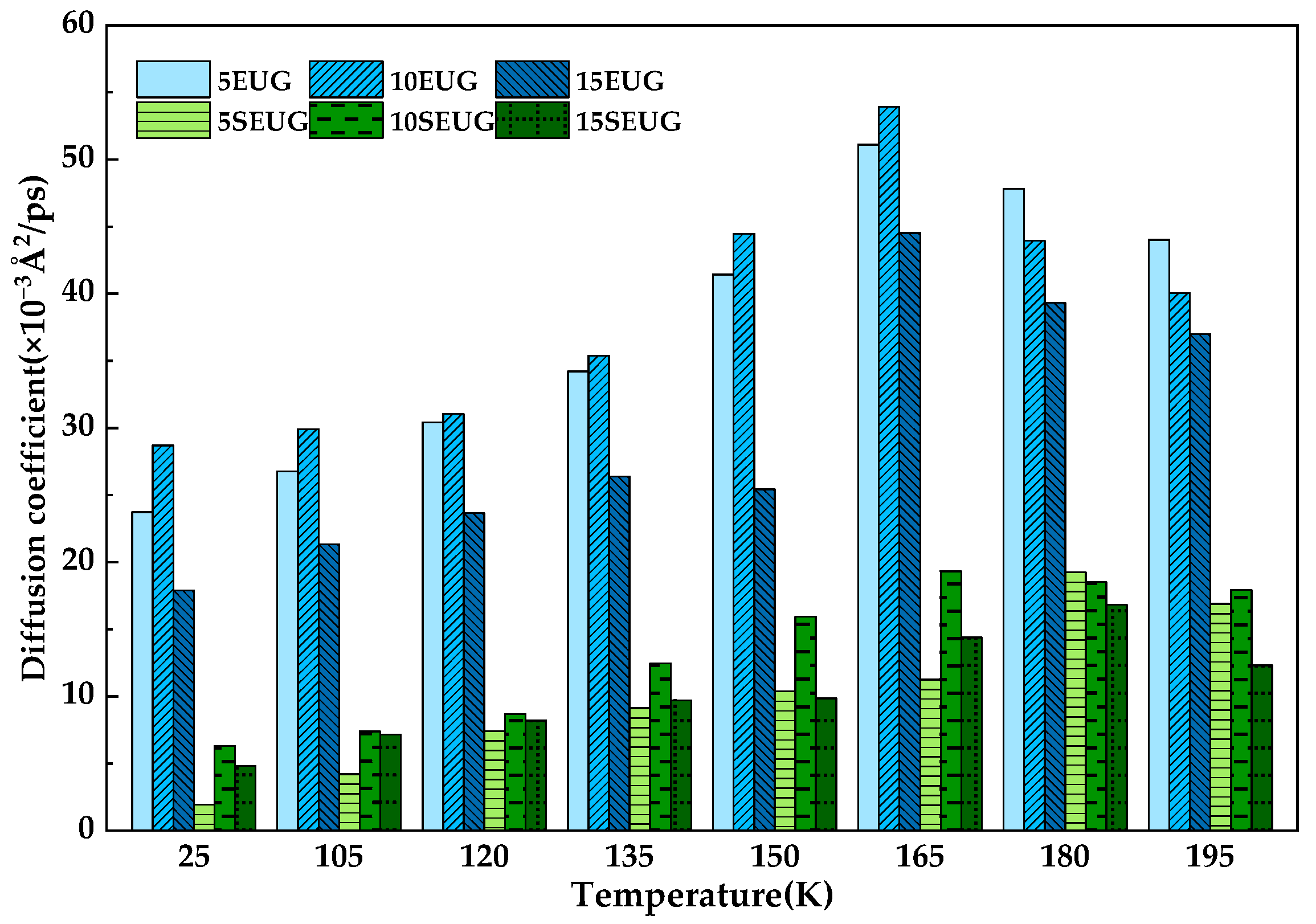

3.2.3. Diffusion Coefficient

3.2.4. Mechanical Performance Calculations

3.3. Experimental Results and Discussion

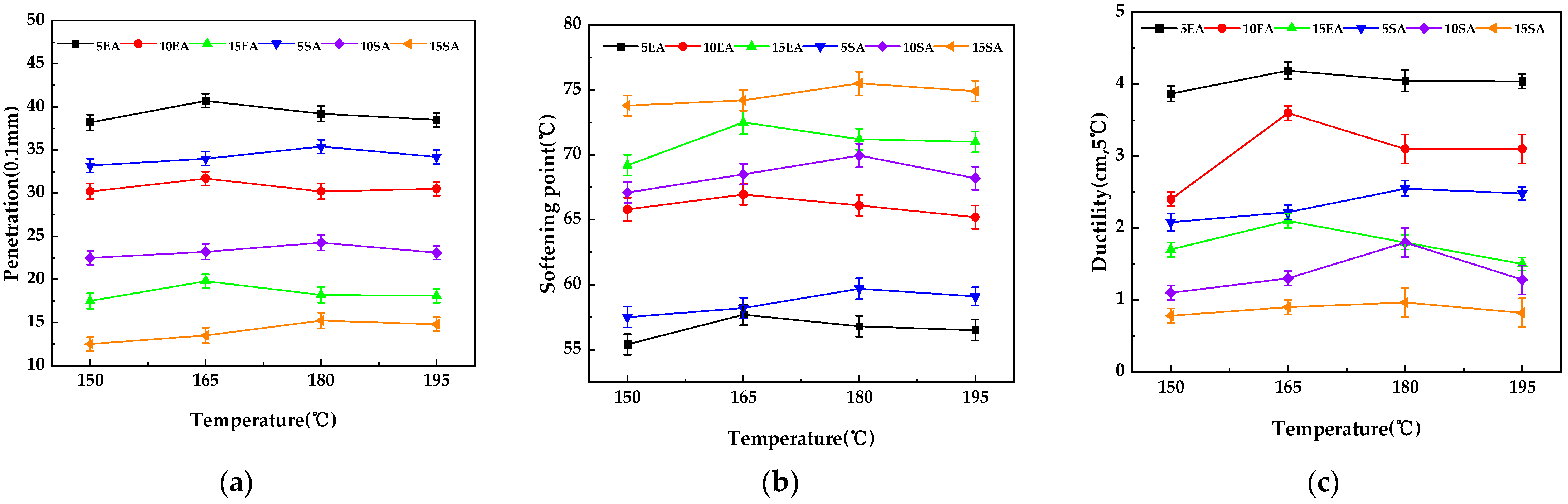

3.3.1. Physical Properties Test

3.3.2. Segregation Experiment

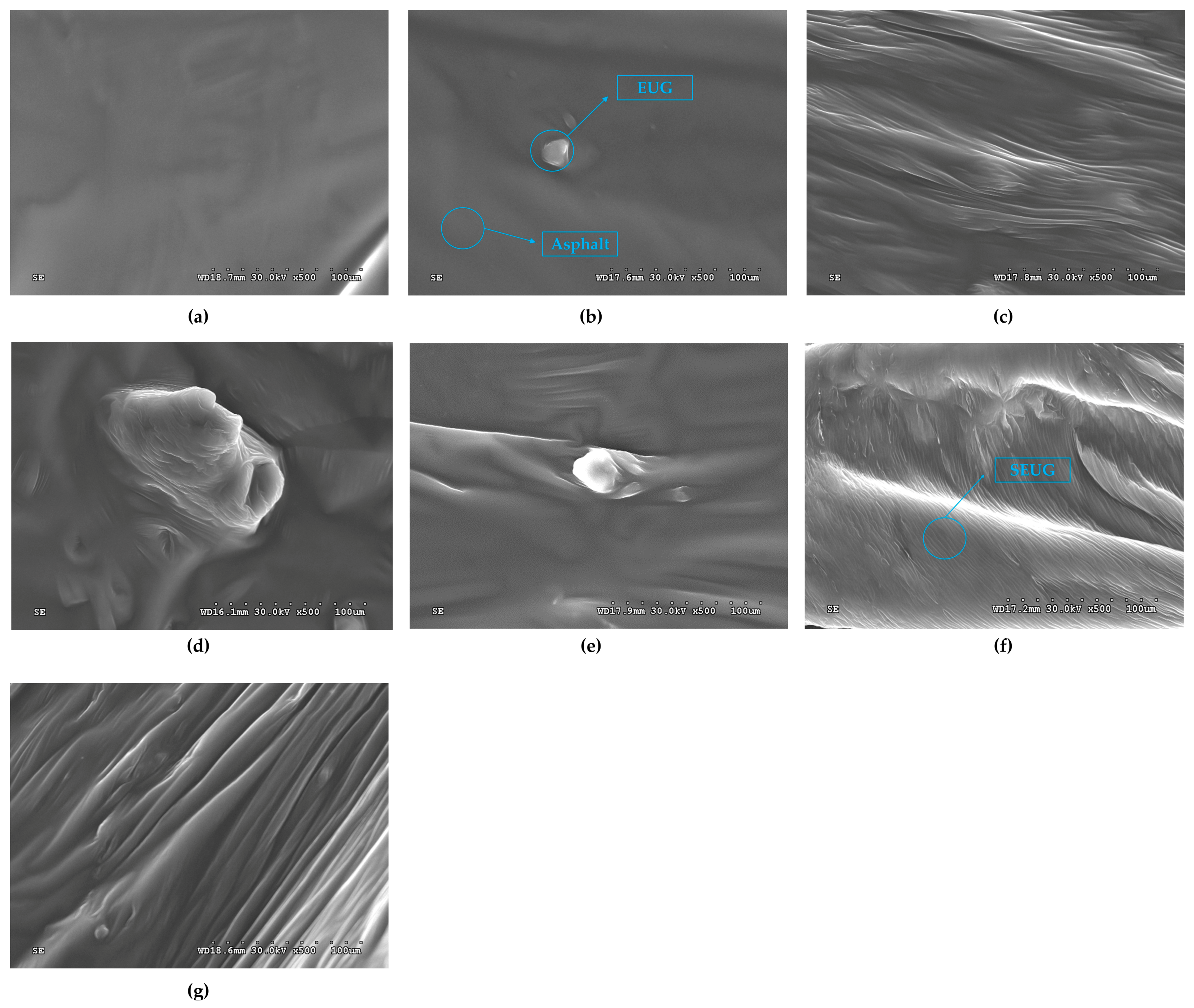

3.3.3. SEM Test

4. Conclusions

- (1)

- The solubility parameters of gutta-percha and asphalt both decrease with temperature, and the solubility difference between EUG and asphalt is smaller than SEUG. At 165 °C, the solubility parameter difference between EUG and asphalt is at its lowest value, indicating that this is the temperature where EUG and asphalt are most compatible.

- (2)

- As the temperature goes up, the electrostatic potential energy, non-bonding potential energy, and van der Waals potential energy of gutta-percha molecules all go up, then down, and then up again. The molecular potential energy fluctuation between EUG and asphalt is bigger than between SEUG, which means that the bonds between EUG and asphalt are stronger than between SEUG and asphalt.

- (3)

- As the temperature rises, the diffusion coefficients D of EUG and SEUG in asphalt typically increase and then decrease. EUG moves through asphalt more quickly than SEUG because its D value is higher.

- (4)

- The mechanical performance parameters of asphalt modified with 10 wt% SEUG were the best, and E, K, G, and v showed a tendency to rise and then fall with the amount of dulce de leche doped. It shows that even though SEUG and asphalt do not mix as well as EUG, SEUG-modified asphalt performs better mechanically.

- (5)

- The three index tests, the segregation experiment, and the SEM test were also used to confirm the validity of the molecular dynamic simulation. Gutta-percha was found to significantly enhance the performance of asphalt at both high and low temperatures. When storing asphalt, EUG is less likely to segregate than SEUG, and 10 wt% EUG-modified asphalt has a smoother micromorphology.

- (6)

- The mechanical, rheological, anti-fatigue, and anti-aging properties of gutta-percha-modified asphalt on a larger scale will be further investigated.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prospective Industry Research Institute. China Asphalt Industry Market Demand Forecast and Investment Strategic Planning Analysis Report; Prospective Industry Research Institute: Shenzhen, China, 2023. [Google Scholar]

- Munera, J.; Ossa, E. Polymer modified bitumen: Optimization and selection. Mater. Des. 2014, 62, 91–97. [Google Scholar] [CrossRef]

- Belyaev, P.S.; Polushkin, D.L.; Makeev, P.V.; Frolov, V.A. Petroleum Bitumen Modified by Polymer Materials for Asphalt Concrete Surfacing with Improved Operational Performance. Vestnik Tambov. Gos. Teh. Univ. 2016, 22, 264–271. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Farsi, M.; Azizi, M. Enhancement of rheological and mechanical properties of bitumen using styrene acrylonitrile copolymer. J. Appl. Polym. Sci. 2015, 132, 1–19. [Google Scholar] [CrossRef]

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Bratychak, M. Polymer Modified Bitumen: Review. Chem. Chem. Technol. 2016, 10, 631–636. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Ji, Y.H.; Guo, S.H.; Li, R. Compatibility and stability mechanism of SBS modified bitumen. Shih Yu Hsueh Pao 2002, 3, 23–29. [Google Scholar]

- Lu, Y.Y.; Yu, L.M.; Fang, J.; Yun, Q.Q.; Lu, J.Y. Research progress of polymer modified bitumen. New Chem. Mater. 2020, 48, 222–225. [Google Scholar] [CrossRef]

- Huang, B.; Ma, L.P.; Xu, W.J. Research progress of modified asphalt. Mater. Rep. 2010, 24, 137–141. [Google Scholar]

- Liang, J.K.; Okumura, Y.M.; Yuan, W.J. Study on the enhancement effect of C9 petroleum resin on the properties of SBS modified bitumen. J. Zhengzhou Univ. Eng. Sci. 2022, 43, 106–110. [Google Scholar] [CrossRef]

- Guiding Opinions on Accelerating the Development of Renewable Resources Industry, No. 440; Ministry of Industry and Information Technology: Beijing, China; Ministry of Commerce: New Delhi, India, 2016.

- Notice on the Issuance of the “2020 Volatile Organic Compounds Control Plan”, NO.33; Ecological & Environmental Departments: Quezon City, Philippines, 2020.

- Fa, G. The State Council’s Guiding Opinions on Accelerating the Establishment and Improvement of a Green and Low-Carbon Circular Development Economic System, No. 4; State Council: Beijing, China, 2021. [Google Scholar]

- Li, P.; Li, D.F.; Lu, X.Y.; Peng, Q.H.; Lu, P.; Ji, J.H. Recycled PE mulch film residue is applied in new materials for high-performance asphalt pavement. China Plast. Chung-Kuo Su Liao 2021, 35, 84–87. [Google Scholar] [CrossRef]

- Liu, H.M. Study on Key Gene Modes of Action and Non-Coding RNA Regulation of Eucommia Gum Biosynthesis. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2018. [Google Scholar]

- Ye, Z.; Sun, W.P.; Zhu, T.C.; Du, H.Y.; Hu, W.Z.; Yu, Y. China Eucommia Rubber Resources Cultivation and Industry Development Report. Du Zhong Industry Green Paper; The Report on Development of China’s Eucommia Rubber Resources and Industry (2016–2017); Social Sciences Academic Press: Beijing, China, 2015. [Google Scholar]

- Yan, R.F. The theoretical basis of the industrialization and development of eucommia gum materials—Eucommia gum material engineering. Chem. Technol. Mark. 1999, 7, 3–4. [Google Scholar]

- Li, F.-Z.; Lu, Z.-L.; Tian, D.-P. A Combined Experimental and Molecular Dynamics Simulation Study on the Miscibility of Eucommia Ulmoides Gum with Several Rubbers. Polym. Polym. Compos. 2017, 25, 87–92. [Google Scholar] [CrossRef]

- Wang, Y.; Yue, J.; Xie, R.; Liu, C.; Gan, L.; Huang, J. High-value use of lignocellulosic-rich eucommia residue for promoting mechanical properties and flame retardancy of poly(butylene succinate). J. Appl. Polym. Sci. 2019, 137, 48543. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, L.; Xin, Z. Triple shape memory effect of foamed natural Eucommia ulmoides gum/high-density polyethylene composites. Polym. Adv. Technol. 2018, 29, 190–197. [Google Scholar] [CrossRef]

- Xia, L.; Chen, S.; Fu, W.; Qiu, G. Shape Memory Behavior of Natural Eucommia ulmoides Gum and Low-Density Polyethylene Blends with Two Response Temperatures. Polymers 2019, 11, 580. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, T.; Zhang, J.; Hou, G.; Yu, M.; Liu, L. Mechanism analysis of Eucommia ulmoides gum reducing the rolling resistance and the application study in green tires. Polym. Test. 2020, 87, 106539. [Google Scholar] [CrossRef]

- Chen, B.; Wu, Q.; Li, J.; Lin, K.; Chen, D.; Zhou, C.; Wu, T.; Luo, X.; Liu, Y. A novel and green method to synthesize a epoxidized biomass eucommia gum as the nanofiller in the epoxy composite coating with excellent anticorrosive performance. Chem. Eng. J. 2020, 379, 122323. [Google Scholar] [CrossRef]

- Kang, H.; Xu, M.; Wang, H.; Li, L.; Li, J.; Fang, Q.; Zhang, J. Heat-responsive shape memory Eucommia ulmoides gum composites reinforced by zinc dimethacrylate. J. Appl. Polym. Sci. 2020, 137, 49133. [Google Scholar] [CrossRef]

- Leng, Z.J.; Yue, P.P.; Chen, J.; Hao, X.; Peng, F. Research progress on modification and application of natural eucommia gum. Biomass Chem. Eng. 2021, 55, 49–58. [Google Scholar]

- Li, M.H.; Liu, L.; Lan, T.; Wang, B.L.; Gao, P.; He, W. Characteristics and research progress of eucommia gum, a natural polymer material. Appl. Chem. Ind. Ying Yung Hua K. 2018, 47, 1026–1029. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Xia, L.; Shen, M.; Wei, L.; Xin, Z.; Kim, J. Fully Biobased Shape Memory Thermoplastic Vulcanizates from Poly(Lactic Acid) and Modified Natural Eucommia Ulmoides Gum with Co-Continuous Structure and Super Toughness. Polymers 2019, 11, 2040. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.L. Self-Healing of Eucommia Gum and Preparation of Dielectric Functional Materials. Master’s Thesis, Shenyang University of Chemical Technology, Shenyang, China, 2019. [Google Scholar]

- Dong, M.; Zhang, J.; Liu, L.; Hou, G.; Yu, Y.; Yuan, C.; Wang, X. New gutta percha composite with high thermal conductivity and low shear viscosity contributed by the bridging fillers containing ZnO and CNTs. Compos. Part B Eng. 2019, 173, 106903. [Google Scholar] [CrossRef]

- Yue, P.-P.; Leng, Z.-J.; Bian, J.; Li, M.-F.; Peng, F.; Sun, R.-C. Fast and simple construction of composite films with renewable Eucommia ulmoides gum and Poly(ε-caprolactone). Compos. Sci. Technol. 2019, 179, 145–151. [Google Scholar] [CrossRef]

- Sun, Q.; Zhao, X.; Wang, D.; Dong, J.; She, D.; Peng, P. Preparation and characterization of nanocrystalline cellulose/Eucommia ulmoides gum nanocomposite film. Carbohydr. Polym. 2018, 181, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Zhi, G.L.; Cong, L. Study on Vulcanizing and Asphalt Modifying of Eucommia Ulmoides Gum. Appl. Mech. Mater. 2014, 2916, 765–768. [Google Scholar]

- Li, Z.; Li, C. Improvement of properties of styrene–butadiene–styrene-modified bitumen by grafted eucommia ulmoides gum. Road Mater. Pavement Des. 2013, 14, 404–414. [Google Scholar] [CrossRef]

- Siqi, D.; Yirui, F.; Qingcheng, Z. An Analysis of the Optimized Modification Content of Eucommia Ulmoides Gum and the Effect of It on Crumb Rubber. Traffic Eng. Technol. Natl. Def. 2019, 20–23, 52. [Google Scholar]

- Ji, C.; Zhu, W.Q.; Yang, H.J.; Li, Z.G. Analysis of the effect of grafted eucommia gum modified rubber powder based on different grafting processes. Highway 2022, 67, 379–383. [Google Scholar]

- Yu, Z.H.; Gao, Z. Application of eucommia gum modified asphalt in highway construction of the XPCC. Fujian Trans. Sci. Tech. 2021, 1, 33–36. [Google Scholar]

- Li, N.; Xu, J.; Xu, T. Preparation, properties and modification mechanism of vulcanized eucommia ulmoides gum modified asphalt. Constr. Build. Mater. 2021, 274, 121992. [Google Scholar] [CrossRef]

- Li, Z.G.; Deng, S.Q.; Tan, F.M.; Xu, L. Analysis of temperature and time parameters of the mixing and preparation of eucommia gum modified rubber powder. Dongnan Daxue Xuebao Ziran Kexueban 2020, 50, 1109–1114. [Google Scholar] [CrossRef]

- DIN 53479; Testing of Plastics and Elastomers. Determination of Density. Standards Store: Minneapolis, MN, USA, 1976.

- DIN 53504; Testing of Rubber and Elastomers. Determination of Tensile Strength, Tensile Strength, Elongation at Break and Stress Values in Tensile Tests. Standards Store: Minneapolis, MN, USA, 2017.

- DIN 53505; Shore A And Shore D Hardness Testing of Rubber. Standards Store: Minneapolis, MN, USA, 1973.

- Yan, S.; Guo, N.; Jin, X.; Chu, Z.; Yan, S. The Study on Mathematical Simulation and Analysis of the Molecular Discrete System of the Sulfurated Eucommia Ulmoides Gum. Mathematics 2023, 11, 964. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Corbett, L.W. Composition of asphalt based on generic fractionation, using solvent deasphaltening, elution-adsorption chromatography, and densimetric characterization. Anal. Chem. 1969, 41, 576–579. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.-J.; Tan, Y.-Q.; Liu, Z.-Y. Investigating the Interactions of the Saturate, Aromatic, Resin, and Asphaltene Four Fractions in Asphalt Binders by Molecular Simulations. Energy Fuels 2014, 29, 112–121. [Google Scholar] [CrossRef]

- Yao, H.; Liu, J.; Xu, M.; Ji, J.; Dai, Q.; You, Z. Discussion on molecular dynamics (MD) simulations of the asphalt materials. Adv. Colloid Interface Sci. 2022, 299, 102565. [Google Scholar] [CrossRef]

- Engelmann, S.; Meyer, J.; Hentschke, R. Computer simulation of thermal conductivity in vulcanized polyisoprene at variable strain and temperature. Phys. Rev. B 2017, 96, 054110. [Google Scholar] [CrossRef]

- Vasilev, A.; Lorenz, T.; Breitkopf, C. Thermal Conductivities of Crosslinked Polyisoprene and Polybutadiene from Molecular Dynamics Simulations. Polymers 2021, 13, 315. [Google Scholar] [CrossRef] [PubMed]

- Kikugawa, G.; Desai, T.G.; Keblinski, P.; Ohara, T. Effect of crosslink formation on heat conduction in amorphous polymers. J. Appl. Phys. 2013, 114, 034302. [Google Scholar] [CrossRef]

- Yi, B. Study on the Modification Effect of Rubber on Asphalt Based on Molecular Simulation Technology. Master’s Thesis, Xinjiang University, Xinjiang, China, 2020. [Google Scholar] [CrossRef]

- Habasaki, J.; Casalini, R.; Ngai, K.L. Molecular Dynamics Study of Thermodynamic Scaling of the Glass-Transition Dynamics in Ionic Liquids over Wide Temperature and Pressure Ranges. J. Phys. Chem. B 2010, 114, 3902–3913. [Google Scholar] [CrossRef]

- de Arenaza, I.M.; Meaurio, E.; Coto, B.; Sarasua, J.-R. Molecular dynamics modelling for the analysis and prediction of miscibility in polylactide/polyvinilphenol blends. Polymer 2010, 51, 4431–4438. [Google Scholar] [CrossRef]

- Dai, X.R.; Zhao, J.J.; Showy, F.; Liu, Y.; Qiao, X.S.; Du, J.C.; Fan, X.P. Research progress in using molecular dynamics to simulate glass structure and calculate glass properties. Kuei Suan Yen Hsueh Pao Acta Silic. Sin. J. Chin. Silic. Soc. J. Chin. Ceram. Soc. 2021, 49, 2691–2709. [Google Scholar] [CrossRef]

- Alipour, P.; Toghraie, D.; Karimipour, A.; Hajian, M. Molecular dynamics simulation of fluid flow passing through a nanochannel: Effects of geometric shape of roughnesses. J. Mol. Liq. 2018, 275, 192–203. [Google Scholar] [CrossRef]

- Shao, J. Asymptotic Properties and Ergoric Study of Non-Temporal Diffusion Process. Master’s Thesis, Nanjing University of Aeronautics and Astronaut, Nanjing, China, 2019. [Google Scholar] [CrossRef]

- Song, Z.Y. Study on Mechanical Behavior and Properties of Rubber Polymer Composites. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019. [Google Scholar] [CrossRef]

- Sun, H. COMPASS: An ab Initio Force-Field Optimized for Condensed-Phase Applications Overview with Details on Alkane and Benzene Compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Sun, H.; Jin, Z.; Yang, C.; Akkermans, R.L.C.; Robertson, S.H.; Spenley, N.A.; Miller, S.; Todd, S.M. COMPASS II: Extended coverage for polymer and drug-like molecule databases. J. Mol. Model. 2016, 22, 47–57. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, Q.H.; Zhang, P.; Cheng, M.; Yi, J.Y. Study on the interaction mechanism between montmorillonite and asphalt based on molecular dynamics simulation. J. Mun. Technol. 2022, 40, 13–20. [Google Scholar] [CrossRef]

- Hildebrand, J.H.; Scott, R.L. The Solubility of Nonelectrolytes. Chem. Educ. 1965, 42, A318. [Google Scholar] [CrossRef]

- Su, M.M.; Zhang, H.L.; Zhang, Y.P.; Zhang, Z.P. Molecular dynamics simulation of SBS and bitumen compatibility and mechanical properties. J. Chang. Univ. Nat. Sci. Ed. 2017, 37, 24–32. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, D.; Li, Q.; Gao, H. Molecular dynamics simulation of diffusivity. Front. Energy Power Eng. 2008, 2, 359–362. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhao, X. Electronic, optical, and mechanical properties of Cu2ZnSnS4with four crystal structures. J. Semicond. 2015, 36, 48–60. [Google Scholar] [CrossRef]

- Li, F.Z. Study on the Compatibility Mechanism and Properties of Eucommia Gum and Commonly Used Rubber. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2019. [Google Scholar]

- Huang, M.; Zhang, H.; Gao, Y.; Wang, L. Study of diffusion characteristics of asphalt–aggregate interface with molecular dynamics simulation. Int. J. Pavement Eng. 2021, 22, 319–330. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Mechanism of Crumb Rubber Modifier Dissolution into Asphalt Matrix and Its Effect on Final Physical Properties of Crumb Rubber–Modified Binder. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 92–101. [Google Scholar] [CrossRef]

| Technical Properties | Test Result | Specification Limits | Standards in Swiss |

|---|---|---|---|

| Density (g/cm3) | 0.944 | ≥0.940 | DIN 53479 [39] |

| Tensile strength (N/mm2) | 38.20 | ≥25 | DIN 53504 [40] |

| Elongation at break (%) | 453.6% | ≥400% | DIN 53504 |

| Hardness (shore D) | 46 | ≥40 | DIN 53505 [41] |

| Modulus in tension (100%, N/mm2) | 7.5 | ≥5 | DIN 53504 |

| Technical Properties | Test Result | Specification Limits | Standard in China (JTG E20–2011) [43] | |

|---|---|---|---|---|

| Penetration (25 °C, 0.1 mm) | 90.5 | 80~100 | T0604—2011 | |

| Softening point (R&B, °C) | 47.7 | ≥40 | T0606—2011 | |

| Ductility (5 °C, cm) | 9.5 | - | T0605—2011 | |

| Flashpoint (°C) | 281 | ≥245 | T0611—2011 | |

| Density (15 °C, g/cm3) | 1.002 | - | T0603—2011 | |

| Solution (Chloral, %) | 99.25 | ≥99.5 | T0607—2011 | |

| RTFOT Residuum | Mass loss rate (%) | 0.05 | ≤±0.8 | T0610—2011 |

| Penetration ratio (25 °C, %) | 61.1 | ≥57 | T0610—2011 | |

| Ductility (5 °C, cm) | 8.2 | ≥8 | T0610—2011 | |

| SARA | Molecules | Number in Model System | Molecular Representation | Molar Mass (g/mol) |

|---|---|---|---|---|

| Asphaltene | Phenol | 3 | C42H54O | 575.0 |

| Pyrrole | 2 | C66H81N | 888.5 | |

| Thiophene | 3 | C51H62S | 707.2 | |

| Aromatic | PHPN | 11 | C35H44 | 464.8 |

| DOCHN | 13 | C30H46 | 406.7 | |

| Resin | Quinolinohopane | 4 | C40H59N | 553.9 |

| Thio-isorenieratane | 4 | C40H60S | 573.0 | |

| Benzobisbenzothiophene | 15 | C18H10S2 | 290.4 | |

| Pyridinohopane | 4 | C36H57N | 503.9 | |

| Trimethylbenzene-oxane | 5 | C29H50N | 414.7 | |

| Saturate | Squalane | 4 | C30H62 | 422.8 |

| Hopane | 4 | C35H62 | 482.9 | |

| Total number of atoms in the model | 5572 | |||

| Lengths A, B, and C of lattice (Å) | 37.82 × 37.82 × 37.82 | |||

| Name | Asphalt Type | Quantity of Modifier | Modifier Mass Fraction (%) |

|---|---|---|---|

| BA | Base asphalt | 0 | 0 |

| 5 EA | EUG-modified asphalt | 1 | 5 |

| 10 EA | 2 | 10 | |

| 15 EA | 3 | 15 | |

| 5 SA | SEUG-modified asphalt | 1 | 5 |

| 10 SA | 2 | 10 | |

| 15 SA | 3 | 15 |

| Molecular Species | Potential Energy (kJ/mol) | Temperature (°C) | ||||||

|---|---|---|---|---|---|---|---|---|

| 105 | 120 | 135 | 150 | 165 | 180 | 195 | ||

| EUG | EEP | 127.65 | 291.85 | 406.67 | 448.02 | 572.41 | 671.70 | 747.86 |

| EEV | −418.31 | −416.80 | −382.26 | −375.65 | −370.45 | −362.35 | −332.11 | |

| EEε | −698.34 | −698.61 | −696.53 | −697.16 | −699.40 | −699.33 | −693.36 | |

| SEUG | ESP | 1562.33 | 1762.20 | 1972.68 | 2096.02 | 2379.05 | 2538.66 | 2659.48 |

| ESV | −304.12 | −298.91 | −284.90 | −276.63 | −258.77 | −213.81 | −196.03 | |

| ESε | −1251.69 | −1260.94 | −1264.13 | −1258.74 | −1267.07 | −1261.42 | −1254.38 | |

| BA | EAP | 10,594.24 | 11,112.35 | 11,243.73 | 11,628.45 | 11,828.59 | 12,074.78 | 12,362.09 |

| EAV | −806.12 | −698.18 | −720.82 | −681.41 | −641.24 | −567.73 | −571.73 | |

| EAε | −861.26 | −863.80 | −873.98 | −862.87 | −863.76 | −868.76 | −862.02 | |

| 5 EA | E5EAP | 11,000.09 | 11,700.01 | 11,979.95 | 12,405.51 | 12,801.67 | 13,060.26 | 13,403.95 |

| E5EA V | −957.88 | −861.55 | −772.69 | −707.42 | −600.02 | −577.61 | −554.05 | |

| E5EAε | −1268.95 | −1266.79 | −1270.43 | −1268.40 | −1208.68 | −1237.87 | −1261.52 | |

| 10 EA | E10EAP | 11,067.45 | 11,718.57 | 11,890.74 | 12,367.08 | 12,845.84 | 13,056.05 | 13,418.74 |

| E10EAV | −833.80 | −755.84 | −709.15 | −663.79 | −559.45 | −550.54 | −532.62 | |

| E10EAε | −1255.59 | −1232.89 | −1247.46 | −1239.58 | −1182.90 | −1239.83 | −1231.83 | |

| 15 EA | E15EAP | 11,025.63 | 11,724.47 | 11,968.83 | 12,401.72 | 12,776.36 | 13,075.37 | 13,384.18 |

| E15EAV | −857.62 | −814.36 | −753.75 | −733.25 | −604.41 | −683.88 | −551.77 | |

| E15EAε | −1294.72 | −1291.10 | −1292.18 | −1288.87 | −1227.51 | −1275.36 | −1284.93 | |

| 5 SEA | E5SAP | 12,309.123 | 13,040.353 | 13,385.187 | 13,875.004 | 14,368.156 | 14,793.358 | 15,175.237 |

| E5SAV | −925.33 | −832.45 | −822.45 | −760.25 | −702.73 | −556.86 | −545.40 | |

| E5SAε | −2008.26 | −2003.842 | −2002.518 | −1992.508 | −1996.775 | −1990.716 | −1992.89 | |

| 10 SEA | E10SAP | 12,314.337 | 13,015.27 | 13,347.50 | 13,868.18 | 14,362.52 | 14,782.266 | 15,162.63 |

| E10SAV | −883.677 | −810.994 | −788.414 | −745.369 | −680.3 | −525.546 | −514.832 | |

| E10SAε | −1975.95 | −1986.67 | −2004.05 | −1989.41 | −2002.88 | −1981.52 | −1984.76 | |

| 15 SA | E15SAP | 12,309.41 | 13,020.69 | 13,385.76 | 13,900.25 | 14,361.05 | 14,795.38 | 15,187.27 |

| E15SAV | −905.75 | −791.04 | −780.28 | −721.955 | −675.083 | −540.62 | −529.789 | |

| E15SAε | −1994.48 | −1999.299 | −1992.8 | −1996.481 | −1983.736 | −1980.613 | −1980.083 | |

| Asphalt Species | λ | μ | E (GPa) | K (GPa) | G (GPa) | ν |

|---|---|---|---|---|---|---|

| BA | 2.1042 | 1.2713 | 3.3351 | 2.6286 | 1.2713 | 0.3117 |

| 5 EUG AS | 2.2422 | 1.2878 | 3.3936 | 2.7599 | 1.2878 | 0.3176 |

| 10 EUG AS | 2.8347 | 1.3520 | 3.6194 | 3.3278 | 1.3520 | 0.3385 |

| 15 EUG AS | 2.6788 | 1.2988 | 3.4723 | 3.1921 | 1.2988 | 0.3367 |

| 5 SEUG AS | 2.7477 | 1.4301 | 3.8008 | 3.2139 | 1.4301 | 0.3288 |

| 10 SEUG AS | 2.8109 | 1.6289 | 4.2891 | 3.2202 | 1.6289 | 0.3166 |

| 15 SEUG AS | 2.7890 | 1.4840 | 3.9366 | 3.2382 | 1.4840 | 0.3264 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Guo, N.; Chu, Z.; Jin, X.; Fang, C.; Yan, S. A Study of Molecular Dynamic Simulation and Experimental Performance of the Eucommia Ulmoides Gum-Modified Asphalt. Materials 2023, 16, 5700. https://doi.org/10.3390/ma16165700

Yan S, Guo N, Chu Z, Jin X, Fang C, Yan S. A Study of Molecular Dynamic Simulation and Experimental Performance of the Eucommia Ulmoides Gum-Modified Asphalt. Materials. 2023; 16(16):5700. https://doi.org/10.3390/ma16165700

Chicago/Turabian StyleYan, Simeng, Naisheng Guo, Zhaoyang Chu, Xin Jin, Chenze Fang, and Sitong Yan. 2023. "A Study of Molecular Dynamic Simulation and Experimental Performance of the Eucommia Ulmoides Gum-Modified Asphalt" Materials 16, no. 16: 5700. https://doi.org/10.3390/ma16165700

APA StyleYan, S., Guo, N., Chu, Z., Jin, X., Fang, C., & Yan, S. (2023). A Study of Molecular Dynamic Simulation and Experimental Performance of the Eucommia Ulmoides Gum-Modified Asphalt. Materials, 16(16), 5700. https://doi.org/10.3390/ma16165700