Sensitivity Analysis of Factors Influencing Blast-like Loading on Reinforced Concrete Slabs Based on Grey Correlation Degree

Abstract

:1. Introduction

2. Grey Correlation Analysis Method

- (1)

- Determination of the sequence matrix

- (2)

- Matrix dimensionless

- (3)

- Differential sequence matrix

- (4)

- Grey correlation coefficient matrix

- (5)

- Solve for the grey correlation G

3. Modelling of Blast Loading

3.1. The Basics of Blast Loading

3.2. Blast Similarity Law

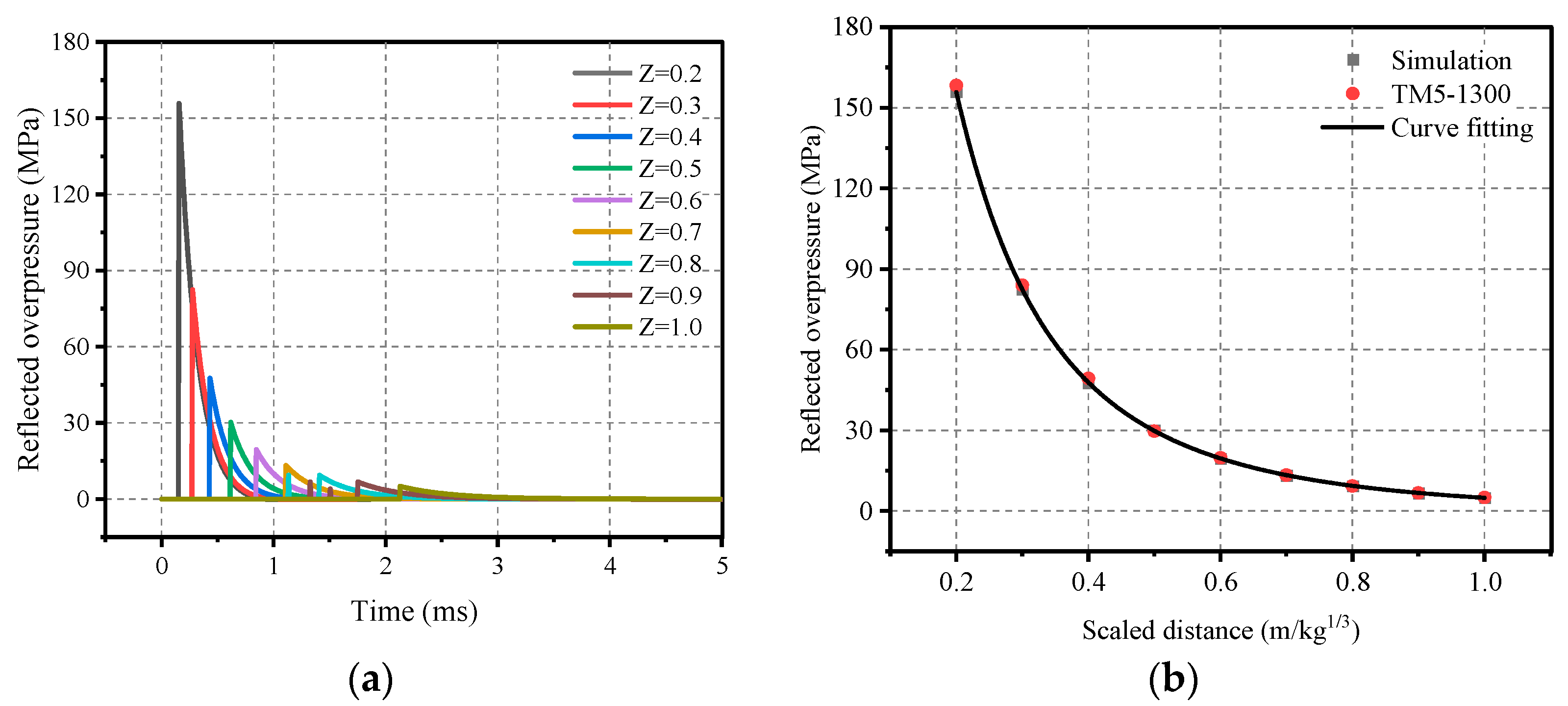

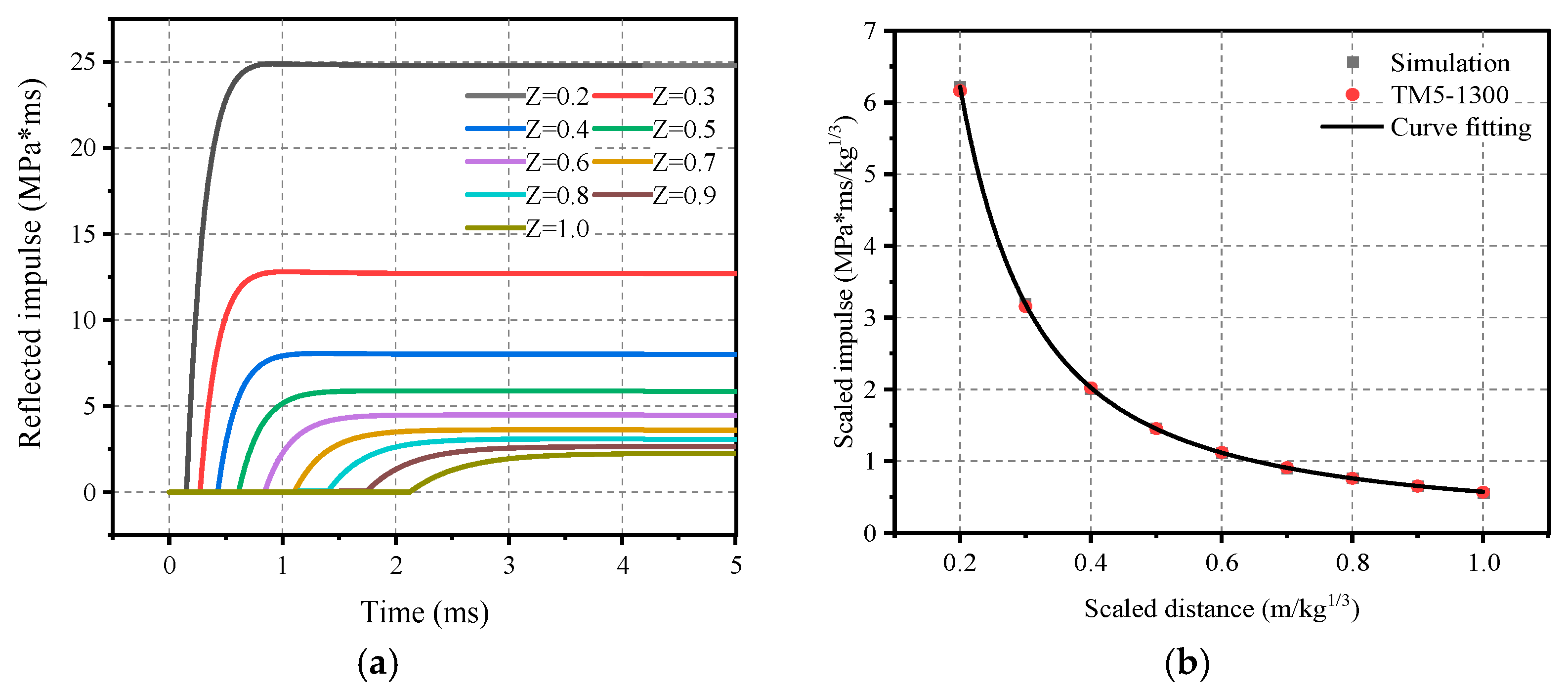

3.3. Blast Load Parameters

4. Finite Element Modelling

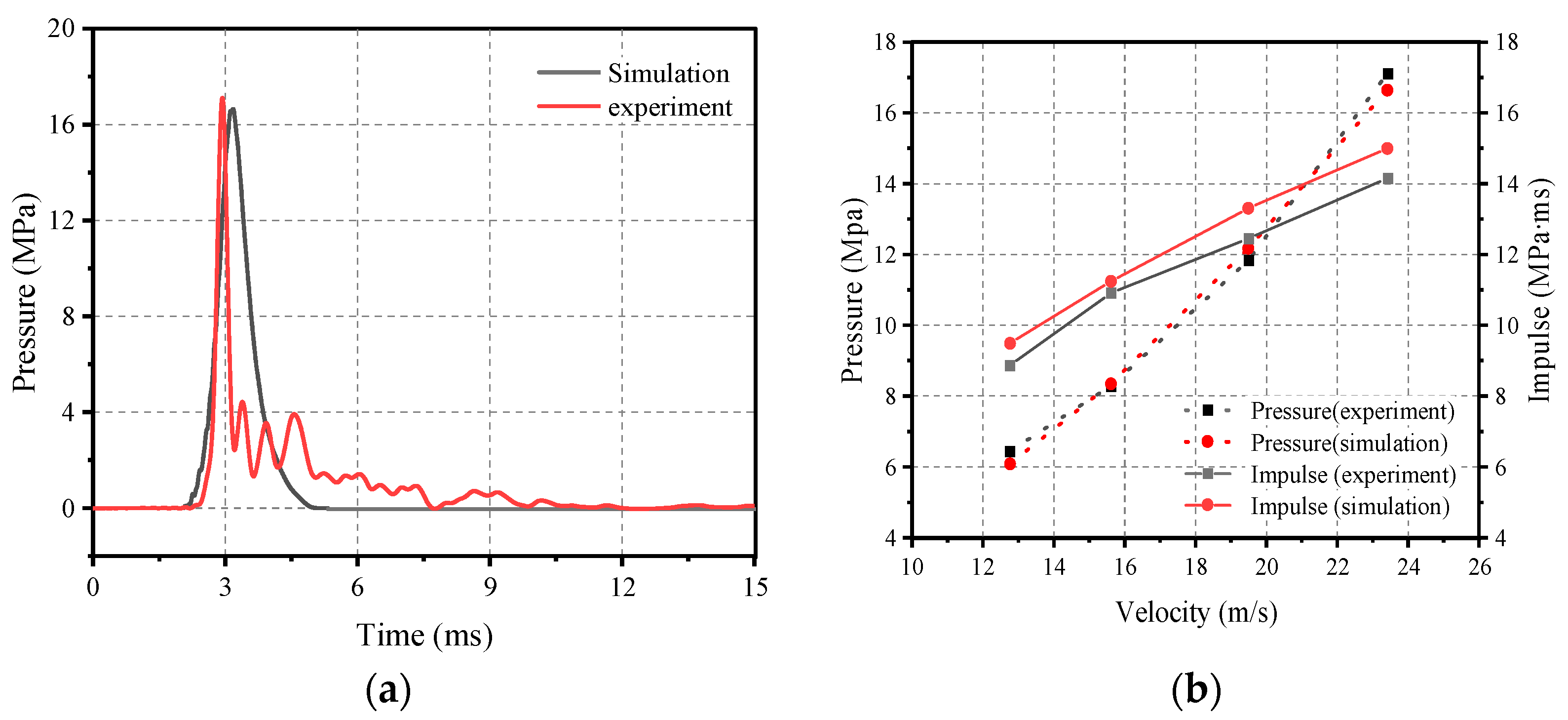

4.1. Calibrated Model

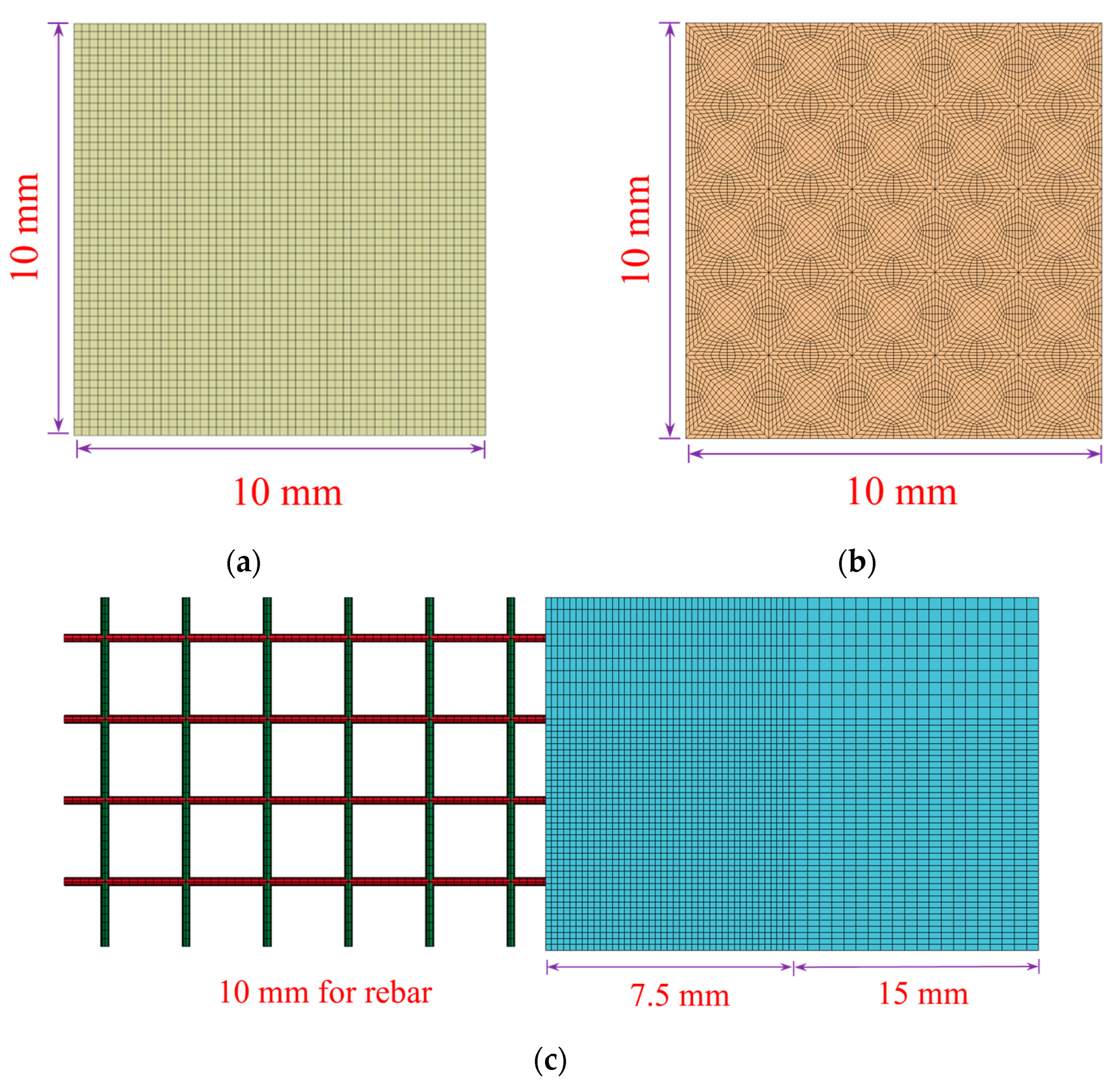

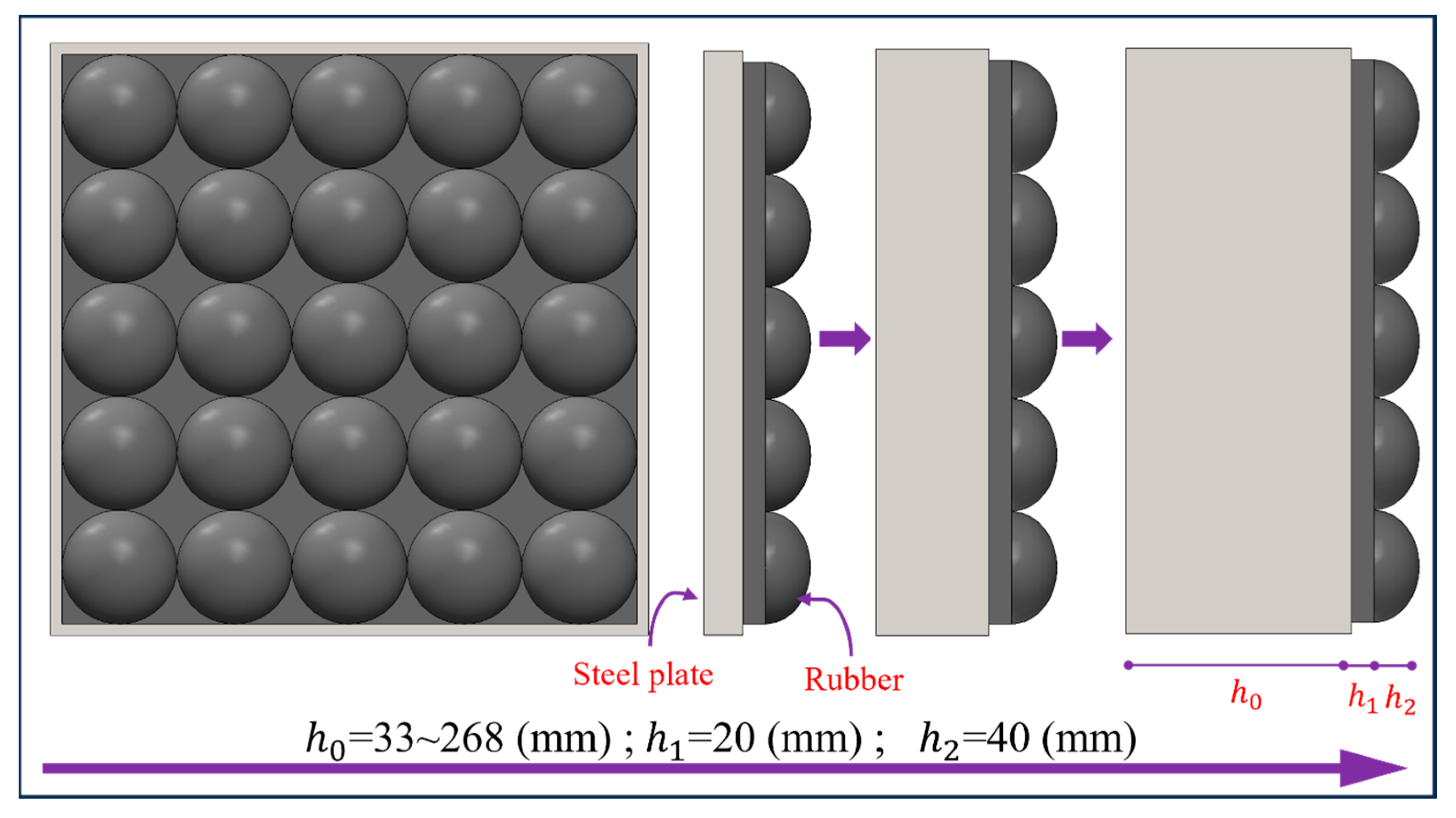

4.2. Improved Model

4.3. Material Modelling and Parameters

4.3.1. Concrete

4.3.2. Steel

4.3.3. Rubber

4.3.4. Supporting Structure

| Material | Parameter | Value | Comments |

|---|---|---|---|

| Concrete | RO (Density) | 2400 kg/m3 | Material test data |

| FPC (Uniaxial compression strength) | 45.6 MPa | ||

| NPLOT | 1 | According to [23,25,26] | |

| INCRE | 0 | ||

| IRATE (Rate effects options) | 1 | ||

| Elements erode | 1.1 | ||

| DAGG (Maximum aggregate size) | 24 mm | ||

| UNITS (Units options) | 4 | ||

| Steel | Density | 7800 kg/m3 | Material test data |

| Young’s modulus | 2.09 × 105 MPa | ||

| Poisson’s ratio | 0.3 | ||

| Yield stress | 435.3 or 450.1 MPa | ||

| Rubber | Density | 1.27 kg/m3 | According to [24,27] |

| Poisson’s ratio | 0.463 | ||

| Shear modulus | 24 MPa | ||

| Supporting structure | Density | 7800 kg/m3 | According to [27] |

| Young’s modulus | 2.09 × 105 MPa | ||

| Poisson’s ratio | 0.3 |

4.4. Parameter Setting

4.5. Defining Outputs

5. Study of Impact Load Characteristics

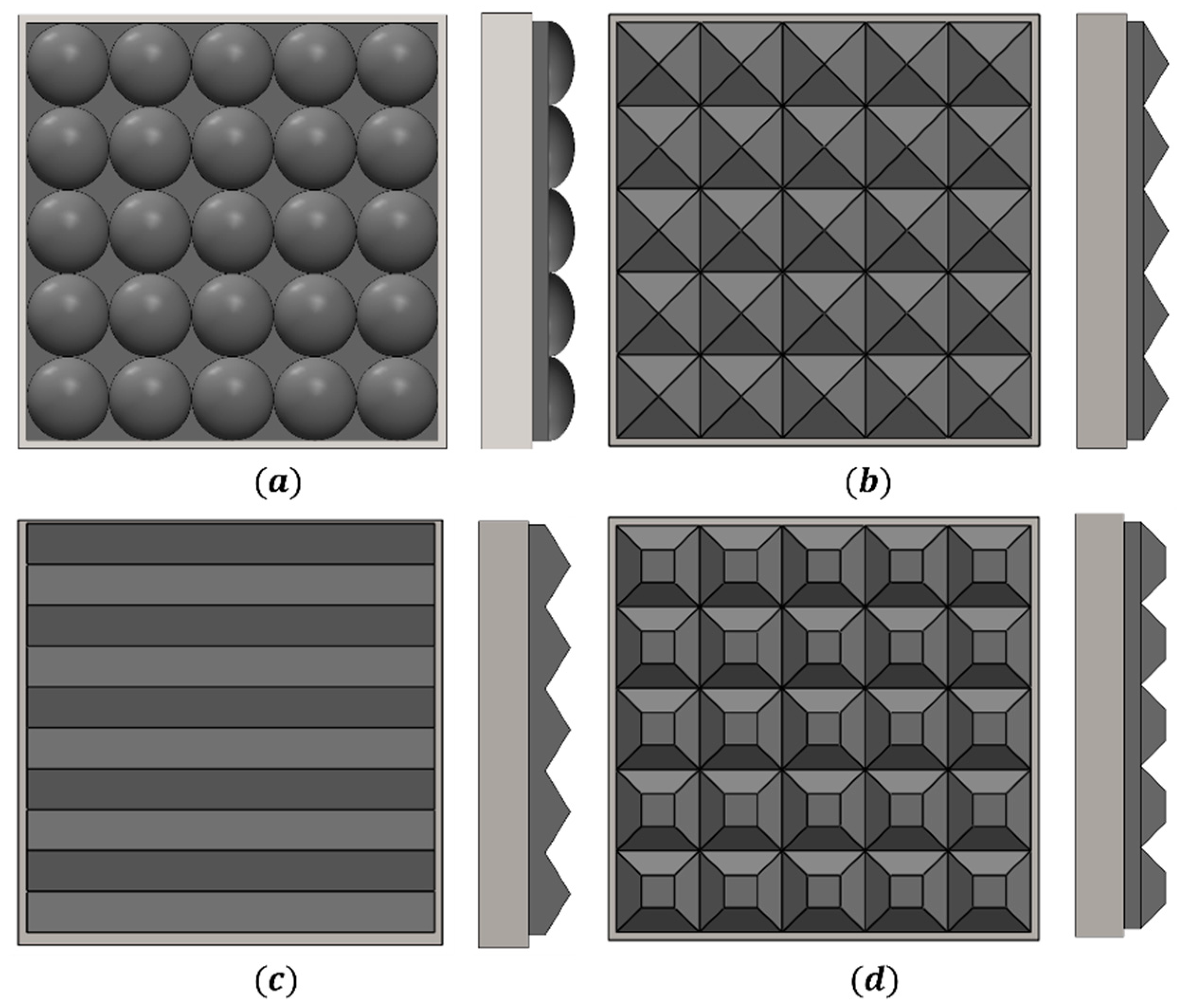

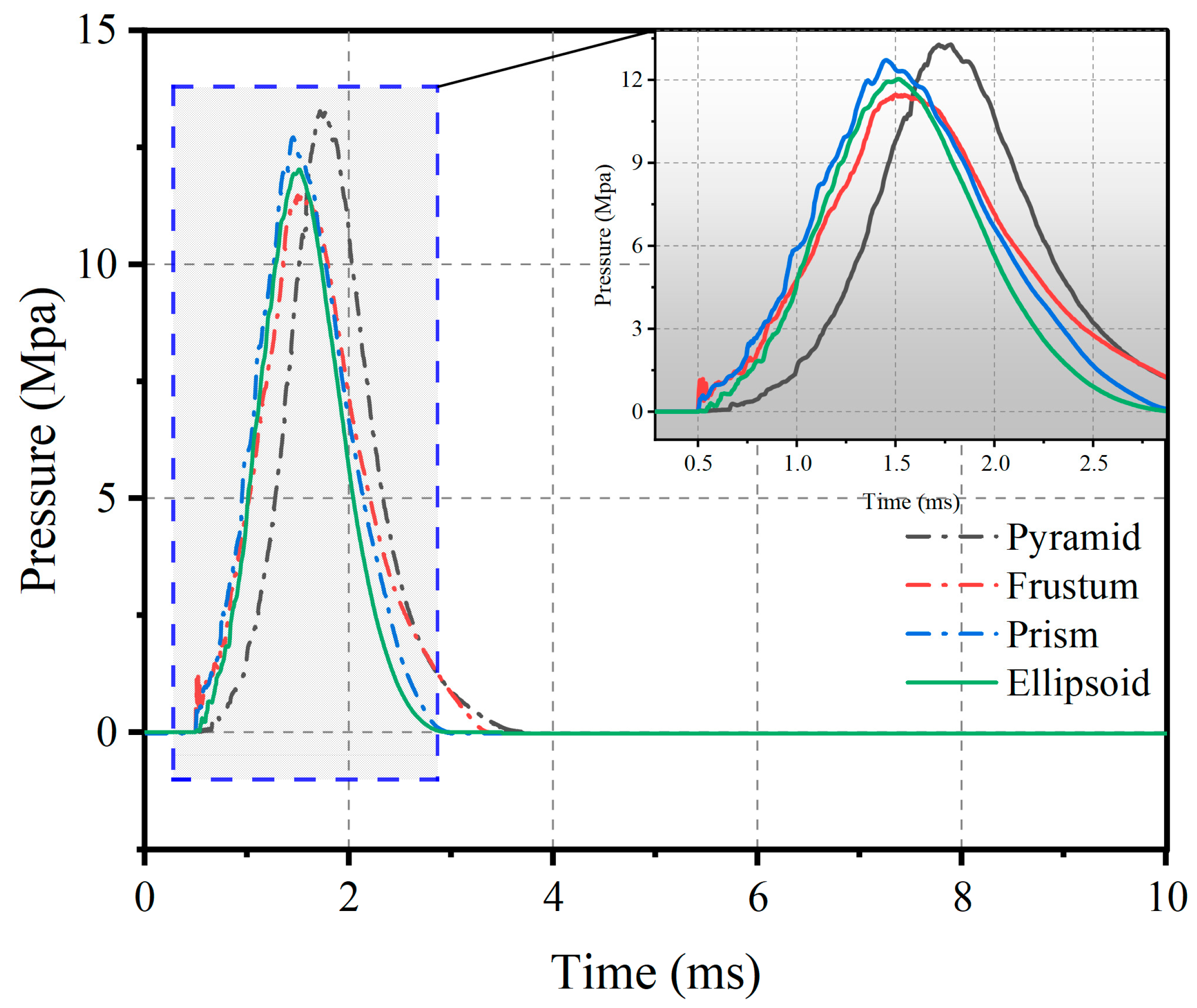

5.1. The Shape of the Impact Module

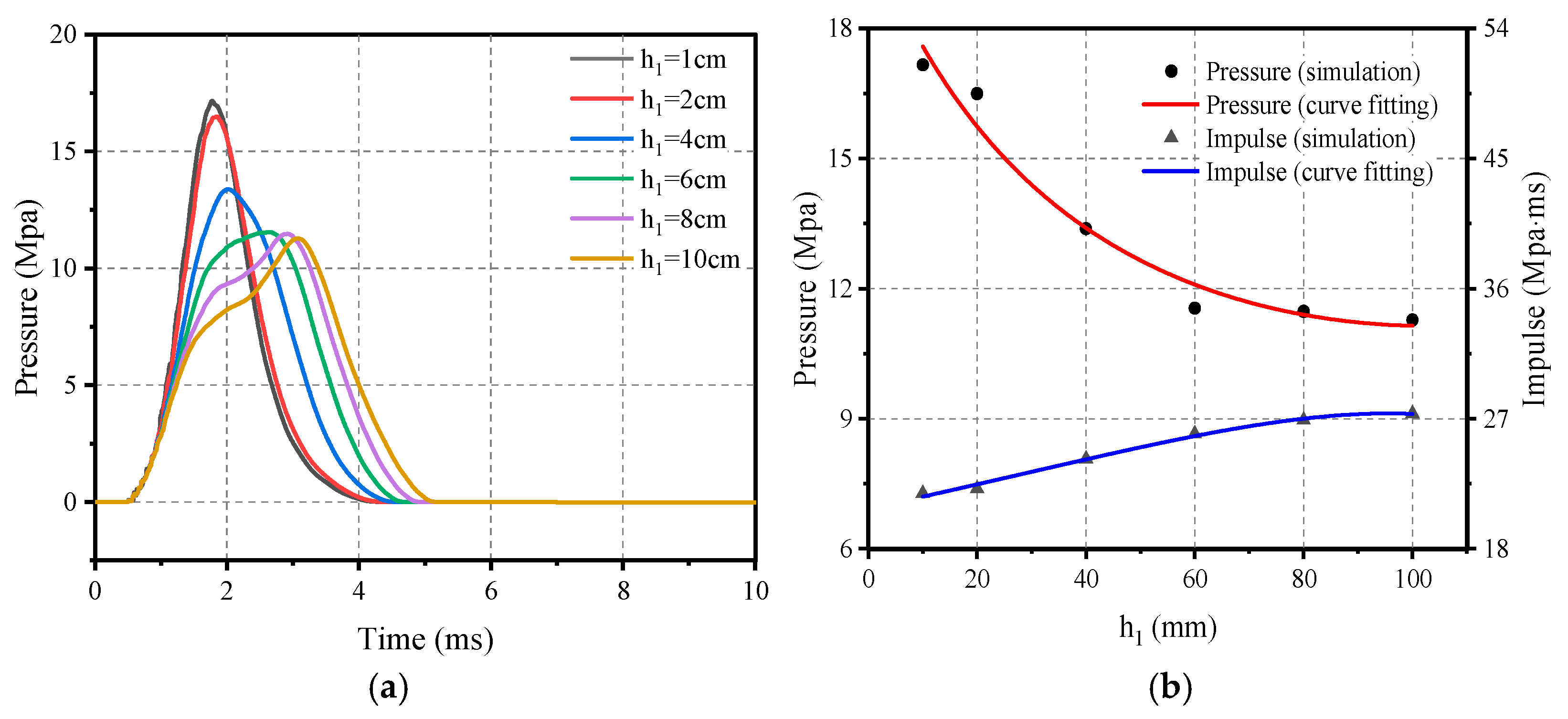

5.2. Effect of Flat Rubber Thickness

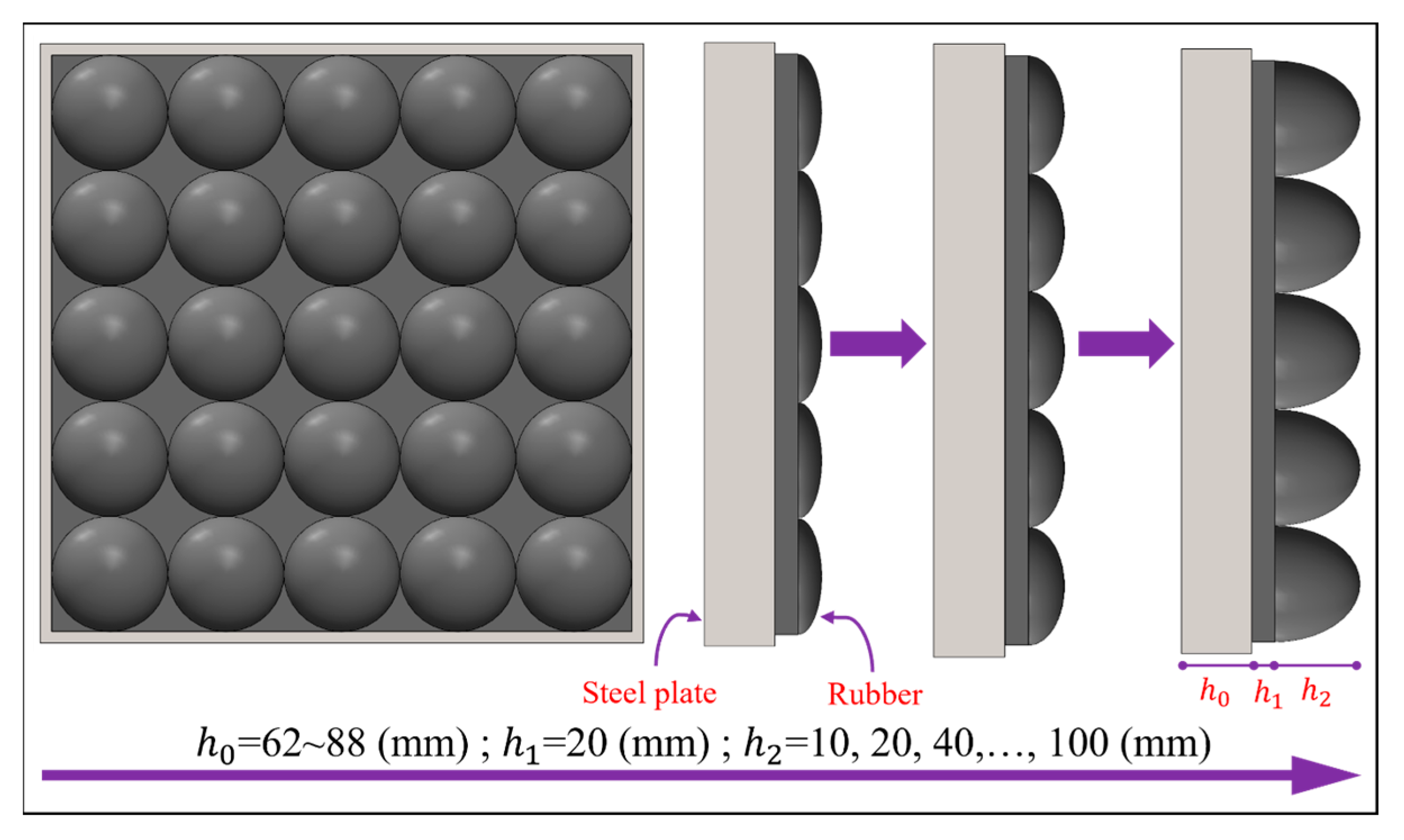

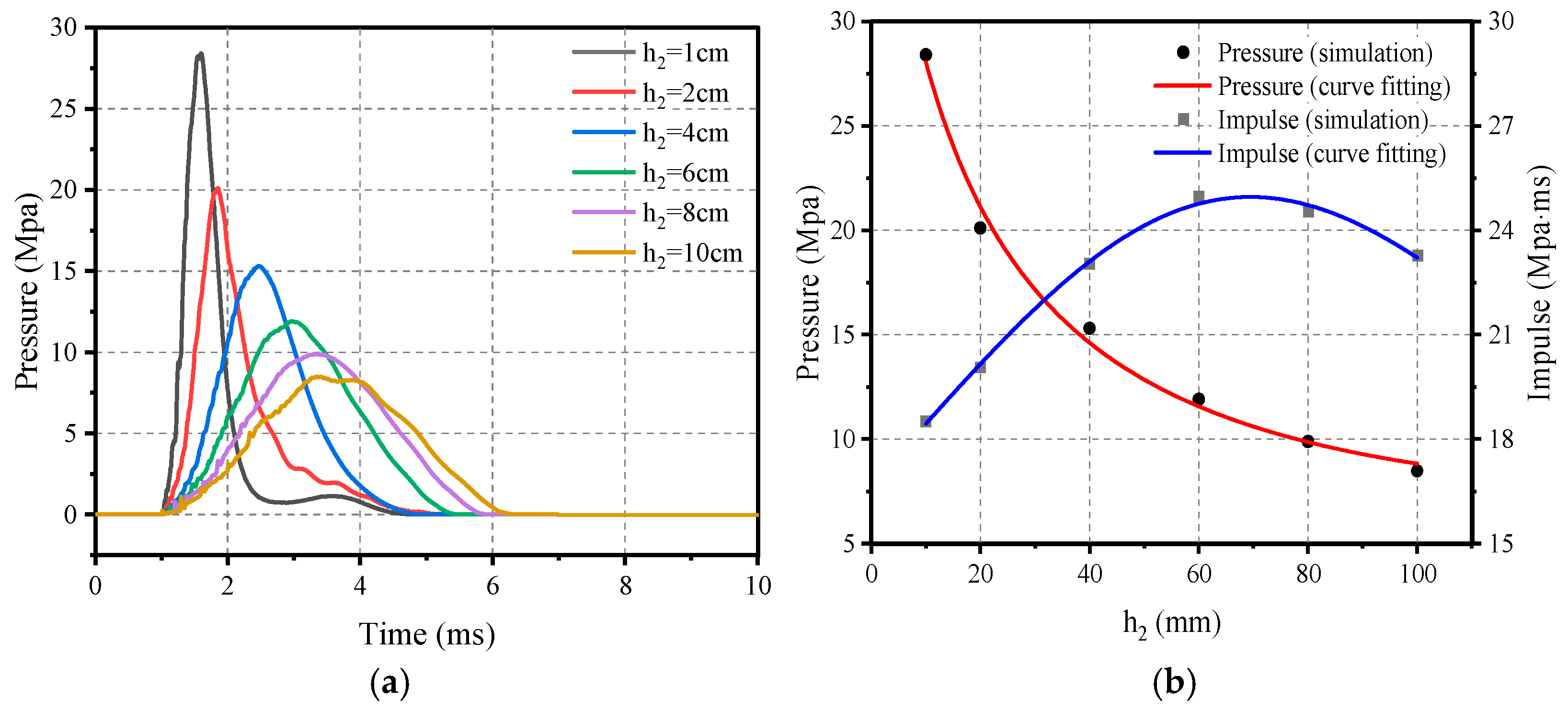

5.3. Effect of Ellipsoid Rubber Thickness

5.4. Effect of Impact Velocity

5.5. Effect of Impact Module Quality

6. Sensitivity Analyses of Influencing Factors

6.1. Relevance Calculation

6.2. Sensitivity Assessment

7. Summary and Conclusions

- (1)

- Changes in ellipsoid rubber thickness had a more positive effect on impact loading than flat layer rubber thickness. It is worth noting that, when the ellipsoid thickness increased from 10 mm to 100 mm, the peak pressure showed a maximum decrease of 29%, and the average decrease was maintained at 21%. The impulse also increased from the initial growth, and showed a decreasing trend at the later stage; however, during the growth of the flat layer rubber thickness from 10 mm to 100 mm, the peak pressure showed a maximum decrease of 19% and the average decrease was only 8%, and the impulse increased gradually and the average increase was 5%.

- (2)

- The impact velocity has a significantly greater effect on the peak pressure of the impact load than the impulse. When the velocity increases from 10 m/s to 15 m/s the peak pressure increases by 68% and the impulse increases by about 40%. However, after that, when the speed increases every 5 m/s the peak pressure can still keep a high increase of 46%. It maintains this increase until the speed reaches 40 m/s, where it can still maintain a minimum increase of 22%. The increase in impulse is rapidly reduced to 18%. When the speed increases to 40 m/s, the impulse only increased by 8%.

- (3)

- Unlike impact velocity, the mass of the impact module had a significantly greater effect on the impact load impulse than the peak pressure. When the mass increased from 100 kg to 200 kg the peak pressure increased by 54% and the impulse increased by about 108%. However, thereafter, as the mass increases by 100 kg, the increase in peak pressure decreases to 27%. It continues to decrease until the mass increases to 600 kg, where the increase is only 6%. Meanwhile, the increase in impulse decreases rapidly but still retains an increase of 32%. When the mass increases to 600 kg, the impulse also maintains a minimum increase of 18%.

- (4)

- When the four factors of impact module mass, impact velocity, ellipsoid rubber thickness, and flat rubber thickness are changed the peak load pressure and impulse can be affected. Peak load pressure and impulse are sensitive to changes in these factors, but there are differences in the degree of sensitivity to the thickness of the ellipsoid rubber and flat rubber thickness. Specifically, both peak load pressure and impulse are most sensitive to the mass of the impact module. The difference is that peak pressure is more sensitive to changes in ellipsoid rubber thickness than flat rubber thickness, while the opposite is true for impulse.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Wei, G.; Wang, X.; Yang, J. Structural damage assessment of RC slab strengthened with POZD coated steel plate under contact explosion. Structures 2023, 48, 31–39. [Google Scholar] [CrossRef]

- Kishore, K.B.; Gangolu, J.; Ramancha, M.K.; Bhuyan, K.; Sharma, H. Performance-based probabilistic deflection capacity models and fragility estimation for reinforced concrete column and beam subjected to blast loading. Reliab. Eng. Syst. Saf. 2022, 227, 108729. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Hao, H.; Wang, Z.; Su, Y. Experimental investigation of ultra-high performance concrete slabs under contact explosions. Int. J. Impact Eng. 2016, 93, 62–75. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, D.; Lu, F.; Wang, S.; Tang, F. Experimental study on scaling the explosion resistance of a one-way square reinforced concrete slab under a close-in blast loading. Int. J. Impact Eng. 2012, 49, 158–164. [Google Scholar] [CrossRef]

- Li, M.; Zong, Z.; Hao, H.; Zhang, X.; Lin, J.; Xie, G. Experimental and numerical study on the behaviour of CFDST columns subjected to close-in blast loading. Eng. Struct. 2019, 185, 203–220. [Google Scholar] [CrossRef]

- Schenker, A.; Anteby, I.; Gal, E.; Kivity, Y.; Nizri, E.; Sadot, O.; Michaelis, R.; Levintant, O.; Ben-Dor, G. Full-scale field tests of concrete slabs subjected to blast loads. Int. J. Impact Eng. 2008, 35, 184–198. [Google Scholar] [CrossRef]

- Chen, W.; Hao, H. Experimental investigations and numerical simulations of multi-arch double-layered panels under uniform impulsive loadings. Int. J. Impact Eng. 2014, 63, 140–157. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Kumar, V.; Mittal, A.K. Experimental and numerical studies on the drop impact resistance of prestressed concrete plates. Int. J. Impact Eng. 2019, 123, 98–117. [Google Scholar] [CrossRef]

- Kumar, V.; Iqbal, M.A.; Mittal, A.K. Experimental investigation of prestressed and reinforced concrete plates under falling weight impactor. Thin-Walled Struct. 2018, 126, 106–116. [Google Scholar] [CrossRef]

- Kumar, V.; Iqbal, M.A.; Mittal, A.K. Impact resistance of prestressed and reinforced concrete slabs under falling weight indenter. Procedia Struct. Integr. 2017, 6, 95–100. [Google Scholar] [CrossRef]

- Wang, Y.; Liew, J.R.; Lee, S.C. Experimental and numerical studies of non-composite Steel–Concrete–Steel sandwich panels under impulsive loading. Mater. Des. 2015, 81, 104–112. [Google Scholar] [CrossRef]

- Li, G.; Liu, D. Laboratory Blast Simulator for Composite Materials Characterization. In Dynamic Behavior of Materials; Technical Papers; Proulx, T., Ed.; Springer New York: New York, NY, USA, 2011; Volume 1, pp. 233–238. ISBN 978-1-4419-8227-8. [Google Scholar]

- Louar, M.A.; Belkassem, B.; Ousji, H.; Spranghers, K.; Kakogiannis, D.; Pyl, L.; Vantomme, J. Explosive driven shock tube loading of aluminium plates: Experimental study. Int. J. Impact Eng. 2015, 86, 111–123. [Google Scholar] [CrossRef]

- Ousji, H.; Belkassem, B.; Louar, M.A.; Kakogiannis, D.; Reymen, B.; Pyl, L.; Vantomme, J. Parametric Study of an Explosive-Driven Shock Tube as Blast Loading Tool. Exp. Tech. 2016, 40, 1307–1325. [Google Scholar] [CrossRef]

- Chen, A.; Kim, H.; Asaro, R.J.; Bezares, J. Non-explosive simulated blast loading of balsa core sandwich composite beams. Compos. Struct. 2011, 93, 2768–2784. [Google Scholar] [CrossRef]

- D’Mello, R.J.; Guntupalli, S.; Hansen, L.R.; Waas, A.M. Dynamic axial crush response of circular cell honeycombs. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 2981–3005. [Google Scholar] [CrossRef]

- Gram, M.M.; Clark, A.J.; Hegemier, G.A.; Seible, F. Laboratory simulation of blast loading on building and bridge structures. Struct. Under Shock Impact IX 2006, 87, 33–44. [Google Scholar] [CrossRef]

- Freidenberg, A.; Aviram, A.; Stewart, L.K.; Whisler, D.; Kim, H.; Hegemier, G.A. Demonstration of tailored impact to achieve blast-like loading. Int. J. Impact Eng. 2014, 71, 97–105. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, W.; Yu, G.; Ma, J.; Zhang, W.; Wu, L. Experimental and Numerical Study of Non-Explosive Simulated Blast Loading on Reinforced Concrete Slabs. Materials 2023, 16, 4410. [Google Scholar] [CrossRef]

- Wu, C. Modeling of simultaneous ground shock and airblast pressure on nearby structures from surface explosions. Int. J. Impact Eng. 2004. [Google Scholar] [CrossRef]

- U.S. Departments of the Army, the Navy and the Air Force. Structures to Resist the Effects of Accidental Explosions (TM 5-1300/NAVFAC P-397/AFR 88-22, Revision 1); Departments of the Army, Air Force, and Navy and the Defense Special Weapons Agency: Washington, DC, USA, 1990. [Google Scholar]

- Hyde, D.W. Microcomputer Programs CONWEP and FUNPRO, Applications of TM 5-855-1, ‘Fundamentals of Protective Design for Conventional Weapons’ (User’s Guide); Defense Technical Information Center: Fort Belvoir, VA, USA, 1988. [Google Scholar]

- Trentacoste, M. Users Manual for LS-DYNA Concrete Material Model 159; U.S. Department of Transportation: San Francisco, CA, USA, 2007. [Google Scholar]

- Blatz, P.J.; Ko, W.L. Application of Finite Elastic Theory to the Deformation of Rubbery Materials. J. Rheol. 1962, 6, 223–252. [Google Scholar] [CrossRef]

- Murray, Y.D. (Ed.) Theory and Evaluation of Concrete Material Model 159. In Proceedings of the 8th International LS-DYNA Users Conference, Detroit, MI, USA, 2–4 May 2004. [Google Scholar]

- Parfilko, Y. Study of Damage Progression in CSCM Concretes Under Repeated Impacts. Master’s Thesis, Kate Gleason College of Engineering, Rochester, NY, USA, 2017. [Google Scholar]

- ANSYS. ANSYS LS-DYNA User’s Guide; ANSYS Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

- Stewart, L.K.; Freidenberg, A.; Rodriguez-Nikl, T.; Oesterle, M.; Wolfson, J.; Durant, B.; Arnett, K.; Asaro, R.J.; Hegemier, G.A. Methodology and validation for blast and shock testing of structures using high-speed hydraulic actuators. Eng. Struct. 2014, 70, 168–180. [Google Scholar] [CrossRef]

- Larcher, M.; Valsamos, G.; Solomos, G. Numerical Simulations in Support of the Blast Actuator Development; European Commission: Luxembourg, 2013. [Google Scholar]

| T = 0 | |||

|---|---|---|---|

|  |  |  |

| Initial | Acceleration | Separation | Impact |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Z.; Wang, W.; Wu, Y.; Liu, W. Sensitivity Analysis of Factors Influencing Blast-like Loading on Reinforced Concrete Slabs Based on Grey Correlation Degree. Materials 2023, 16, 5678. https://doi.org/10.3390/ma16165678

Xiong Z, Wang W, Wu Y, Liu W. Sensitivity Analysis of Factors Influencing Blast-like Loading on Reinforced Concrete Slabs Based on Grey Correlation Degree. Materials. 2023; 16(16):5678. https://doi.org/10.3390/ma16165678

Chicago/Turabian StyleXiong, Zhixiang, Wei Wang, Yangyong Wu, and Wei Liu. 2023. "Sensitivity Analysis of Factors Influencing Blast-like Loading on Reinforced Concrete Slabs Based on Grey Correlation Degree" Materials 16, no. 16: 5678. https://doi.org/10.3390/ma16165678

APA StyleXiong, Z., Wang, W., Wu, Y., & Liu, W. (2023). Sensitivity Analysis of Factors Influencing Blast-like Loading on Reinforced Concrete Slabs Based on Grey Correlation Degree. Materials, 16(16), 5678. https://doi.org/10.3390/ma16165678