Surface Roughening of Irradiation-Activated Basalt Fiber through In Situ Growth of SiO2: Effects on Crystallization and Properties of PP Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Irradiation Treatment of BF and In Situ Growth of SiO2 Nanoparticles

2.3. Preparation of BF/PP Composites

2.4. Characterization

3. Results and Discussion

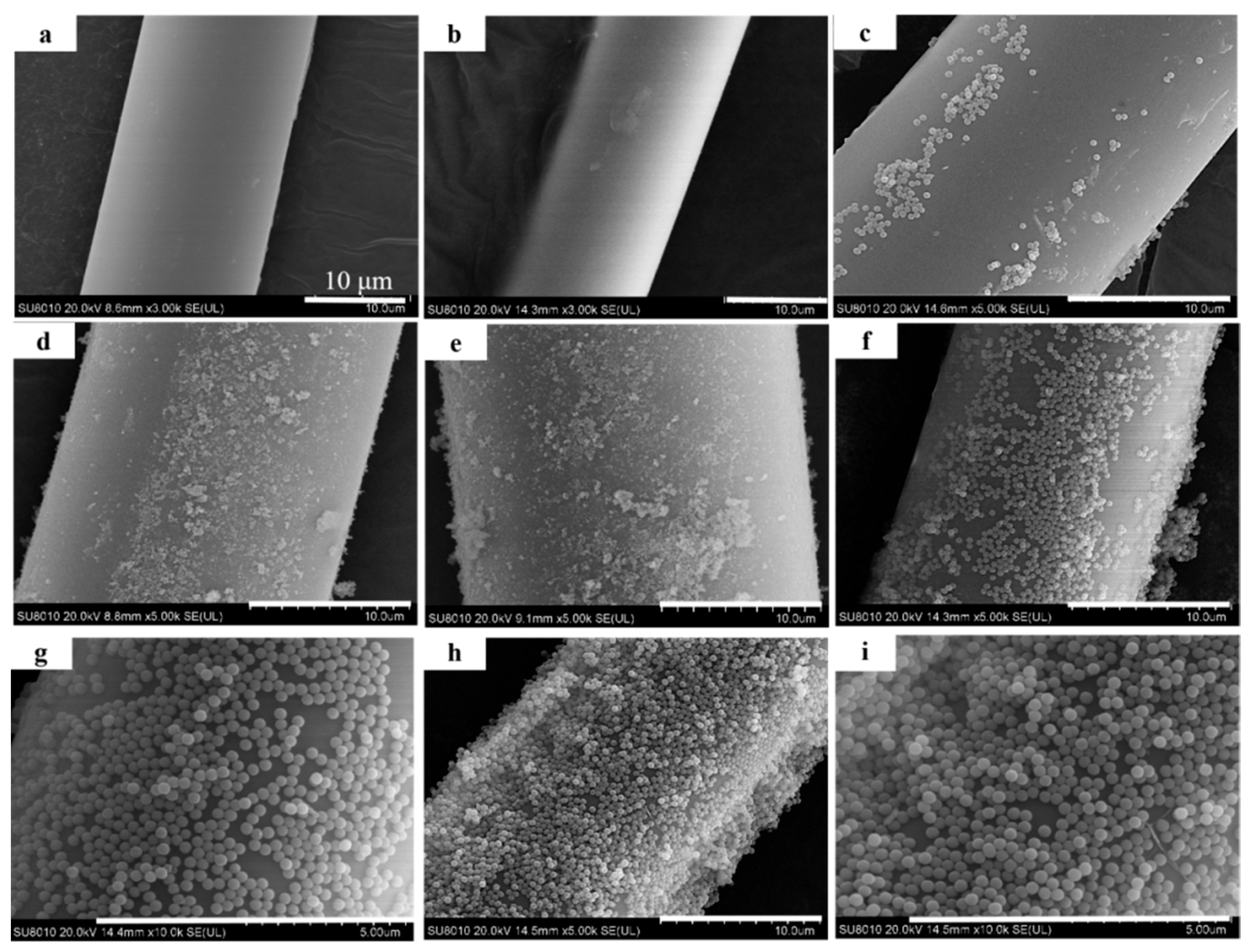

3.1. Characterization of BF with In Situ Growth of SiO2 Nanoparticles

3.2. Crystal Structure of the BF/PP Composites

3.3. Dynamic Mechanical Properties of the BF/PP Composites

3.4. Thermal Stability of the BF/PP Composites

3.5. Mechanical Properties of the BF/PP Composites

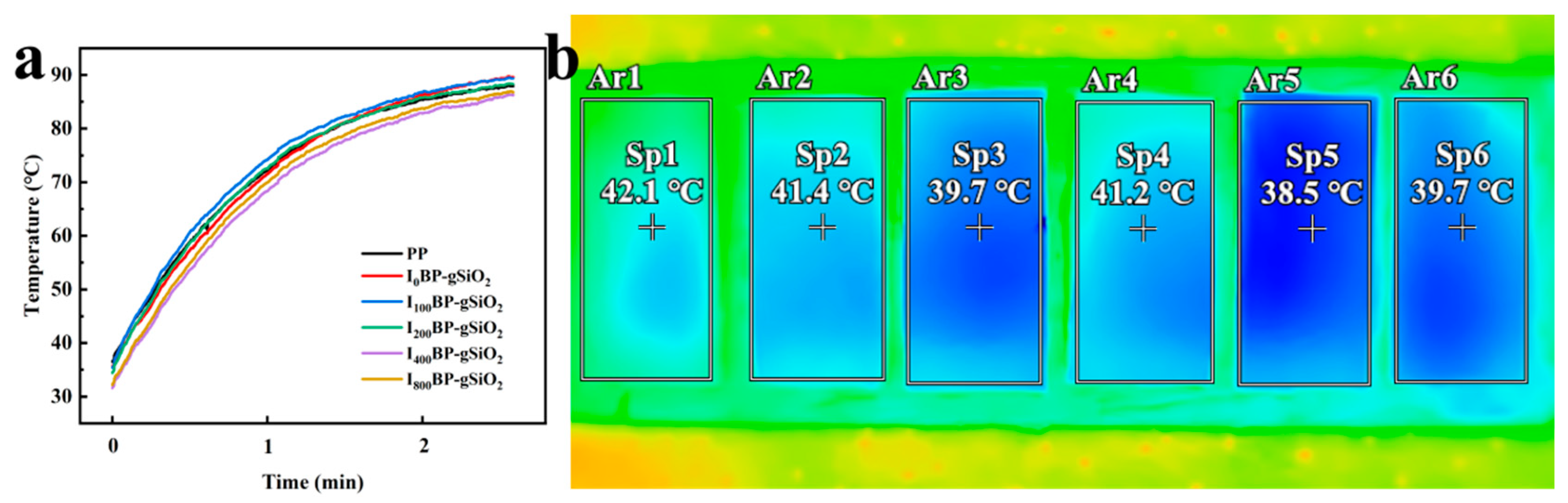

3.6. Thermal Insulation Properties of the BF/PP Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef]

- Shuaib, N.A.; Mativenga, P.T. Energy demand in mechanical recycling of glass fibre reinforced thermoset plastic composites. J. Clean. Prod. 2016, 120, 198–206. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.A.; Retegi, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of short flax fibre bundle/polypropylene composites: Influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos. Sci. Technol. 2005, 65, 1582–1592. [Google Scholar] [CrossRef]

- Gassan, J.; Bledzki, A.K. Thermal degradation of flax and jute fibers. J. Appl. Polym. Sci. 2001, 82, 1417–1422. [Google Scholar] [CrossRef]

- Bensadoun, F.; Vanderfeesten, B.; Verpoest, I.; Van Vuure, A.W.; Van Acker, K. Environmental impact assessment of end of life options for flax-MAPP composites. Ind. Crops Prod. 2016, 94, 327–341. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber—A review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Chen, C.; Liu, X.; Zhou, Q.Q.; Ma, Y.L. Effect of basalt fiber on the thermal conductivity and wear resistance of sintered WC-based diamond composites. Int. J. Refract. Met. Hard Mater. 2022, 105, 105829. [Google Scholar] [CrossRef]

- Li, M.; Shen, D.; Yang, Q.; Cao, X.; Liu, C.; Kang, J. Rehabilitation of seismic-damaged reinforced concrete beam-column joints with different corrosion rates using basalt fiber-reinforced polymer sheets. Compos. Struct. 2022, 289, 115397. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, Y.; Zhang, P. Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol. Rev. 2022, 11, 2169–2189. [Google Scholar] [CrossRef]

- Xing, G.; Wang, H.; Chang, Z.; Ma, K. Prediction of the seismic behavior of concrete beams strengthened with aluminum alloy bars and/or basalt fiber-reinforced polymer bars. Struct. Des. Tall Spec. Build. 2021, 31, e1911. [Google Scholar] [CrossRef]

- Czigány, T. Special manufacturing and characteristics of basalt fiber reinforced hybrid polypropylene composites: Mechanical properties and acoustic emission study. Compos. Sci. Technol. 2006, 66, 3210–3220. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A.-M. Investigation of basalt fiber composite mechanical properties for applications in transportation. Polym. Compos. 2006, 27, 41–48. [Google Scholar] [CrossRef]

- Acar, V.; Cakir, F.; Alyamaç, E.; Seydibeyoğlu, M.Ö. Basalt fibers. In Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: Sawston, UK, 2017; pp. 169–185. [Google Scholar]

- Kurniawan, D.; Kim, B.S.; Lee, H.Y.; Lim, J.Y. Effect of Silane Treatment on Mechanical Properties of Basalt Fiber/Polylactic Acid Ecofriendly Composites. Polym.-Plast. Technol. Eng. 2013, 52, 97–100. [Google Scholar] [CrossRef]

- Liu, H.; Luo, B.; Shen, S.; Li, L. Design and mechanical tests of basalt fiber cloth with MAH grafted reinforced bamboo and poplar veneer composite. Eur. J. Wood Wood Prod. 2019, 77, 271–278. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wu, Z. Fatigue degradation and life prediction of basalt fiber-reinforced polymer composites after saltwater corrosion. Mater. Des. 2019, 163, 107529. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, S.; Yao, Y.; Li, G.; Du, Y.; Shi, C. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete. Cem. Concr. Compos. 2019, 96, 33–45. [Google Scholar] [CrossRef]

- Zhu, M.; Ma, J. Basalt fiber modified with lanthanum-ethylenediaminetetraacetic acid as potential reinforcement of cyanate matrix composites. Appl. Surf. Sci. 2019, 464, 636–643. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Surface modification and characterization of basalt fibers with hybrid sizings. Compos. Part A Appl. Sci. Manuf. 2011, 42, 22–29. [Google Scholar] [CrossRef]

- Arslan, C.; Dogan, M. The effects of silane coupling agents on the mechanical properties of basalt fiber reinforced poly(butylene terephthalate) composites. Compos. Part B Eng. 2018, 146, 145–154. [Google Scholar] [CrossRef]

- Khalili, S.M.R.; Farsani, R.E.; Soleimani, N.; Hedayatnasab, Z. Charpy impact behavior of clay/basalt fiber-reinforced polypropylene nanocomposites at various temperatures. J. Thermoplast. Compos. Mater. 2014, 29, 1416–1428. [Google Scholar] [CrossRef]

- Yuan, Q.; Misra, R.D.K. Impact fracture behavior of clay reinforced polypropylene nanocomposites. Polymer 2006, 47, 4421–4433. [Google Scholar] [CrossRef]

- Bozkurt, Ö.Y.; Erkliğ, A.; Bulut, M. Hybridization effects on charpy impact behavior of basalt/aramid fiber reinforced hybrid composite laminates. Polym. Compos. 2018, 39, 467–475. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the Mechanical Properties of Basalt Fiber-Wood-Plastic Composites via Maleic Anhydride Grafted High-Density Polyethylene (MAPE) Addition. Materials 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.F.; Xin, Y. Mechanical Properties of Basalt-fiber-reinforced Polyamide-6/Polypropylene Composites. Mech. Compos. Mater. 2014, 50, 509–514. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Wan, J.; Yan, Z.; Sun, J.; Zhao, S. Mechanical and tribological performance of chopped basalt fiber/acrylonitrile-butadiene rubber composites. Polym. Compos. 2019, 40, 630–637. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Khalina, A.; Cardona, F.; Lee, C.H. Mechanical Characteristics of Green Composites of Short Kenaf Bast Fiber Reinforced in Cardanol. Adv. Mater. Sci. Eng. 2019, 2019, 8645429. [Google Scholar] [CrossRef]

- Arul Jeya Kumar, A.; Prakash, M.; Lakshmankumar, A.; Haswanth, K. Wear characterization of basalt fiber reinforced polypropylene/polylactic acid hybrid polymer composite. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 236, 250–258. [Google Scholar] [CrossRef]

- Godat, A.; Alghafri, E.; Al Tamimi, N.; Aljaberi, H.; Aldaweela, S. Bond Behavior of Basalt Fiber Reinforced Polymer Bars in Recycled Coarse Aggregate Concrete. Sustainability 2022, 14, 1374. [Google Scholar] [CrossRef]

- Li, R.; Gu, Y.; Yang, Z.; Li, M.; Wang, S.; Zhang, Z. Effect of γ irradiation on the properties of basalt fiber reinforced epoxy resin matrix composite. J. Nucl. Mater. 2015, 466, 100–107. [Google Scholar] [CrossRef]

- Shin, H.K.; Jeun, J.P.; Kang, P.H. The characterization of polyacrylonitrile fibers stabilized by electron beam irradiation. Fibers Polym. 2012, 13, 724–728. [Google Scholar] [CrossRef]

- Wang, H.-T.; Jiang, H.-Q.; Shen, R.-F.; Ding, X.-J.; Zhang, C.; Li, L.-F.; Li, J.-Y. Electron-beam radiation effects on the structure and properties of polypropylene at low dose rates. Nucl. Sci. Tech. 2018, 29, 87. [Google Scholar] [CrossRef]

- Tsou, C.-H.; Wu, C.-S.; Hung, W.-S.; De Guzman, M.R.; Gao, C.; Wang, R.-Y.; Chen, J.; Wan, N.; Peng, Y.-J.; Suen, M.-C. Rendering polypropylene biocomposites antibacterial through modification with oyster shell powder. Polymer 2019, 160, 265–271. [Google Scholar] [CrossRef]

- Gloger, D.; Mileva, D.; Albrecht, A.; Hubner, G.; Androsch, R.; Gahleitner, M. Long-Chain Branched Polypropylene: Effects of Chain Architecture, Melt Structure, Shear Modification, and Solution Treatment on Melt Relaxation Dynamics. Macromolecules 2022, 55, 2588–2608. [Google Scholar] [CrossRef]

- Wei, W.; Shim, E.; Song, Y.; Pourdeyhimi, B. Synthesizing heat transfer factors on thermal bonding structure of mineral added polypropylene spun-bond. J. Appl. Polym. Sci. 2022, 139, 52138. [Google Scholar] [CrossRef]

- Nair, S.T.; Vijayan, P.P.; George, S.C.; Kalarikkal, N.; Thomas, S. Enhanced mechanical and thermal performance of multiwalled carbon nanotubes-filled polypropylene/natural rubber thermoplastic elastomers. New J. Chem. 2021, 45, 4963–4976. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Han, R.; Yang, Q.; Wang, Z.; Cao, D.; Li, G.; Zheng, L.; Peng, B.; Gao, X.; Chen, G. 3D printing-enabled self-assembling β-nucleating agent alignment: Structural evolution and mechanical performances. Polymer 2022, 246, 124736. [Google Scholar] [CrossRef]

- Jones, A.T.; Aizlewood, J.M.; Beckett, D.R. Crystalline forms of isotactic polypropylene. Die Makromol. Chem. 1964, 75, 134–158. [Google Scholar] [CrossRef]

- Zhao, W.; Su, Y.; Wen, X.; Wang, D. Manipulating crystallization behavior of poly(ethylene oxide) by functionalized nanoparticle inclusion. Polymer 2019, 165, 28–38. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, H.; Fu, Q. Kinetics-controlled compatibilization of immiscible polypropylene/polystyrene blends using nano-SiO2 particles. Polymer 2004, 45, 1913–1922. [Google Scholar] [CrossRef]

- Qian, J.; He, P.; Nie, K. Nonisothermal crystallization of PP/nano-SiO2 composites. J. Appl. Polym. Sci. 2004, 91, 1013–1019. [Google Scholar] [CrossRef]

- Han, R.; Li, Y.; Wang, Q.; Nie, M. Critical formation conditions for β-form hybrid shish-kebab and its structural analysis. RSC Adv. 2014, 4, 65035–65043. [Google Scholar] [CrossRef]

- Han, R.; Nie, M.; Wang, Q. Control over β-form hybrid shish-kebab crystals in polypropylene pipe via coupled effect of self-assembly β nucleating agent and rotation extrusion. J. Taiwan Inst. Chem. Eng. 2015, 52, 158–164. [Google Scholar] [CrossRef]

- Han, R.; Nie, M.; Wang, Q.; Yan, S. Self-Assembly β Nucleating Agent Induced Polymorphic Transition from α-Form Shish Kebab to β-Form Highly Ordered Lamella under Intense Shear Field. Ind. Eng. Chem. Res. 2017, 56, 2764–2772. [Google Scholar] [CrossRef]

- Chen, J.; Schneider, K.; Kretzschmar, B.; Heinrich, G. Nucleation and growth behavior of β-nucleated iPP during shear induced crystallization investigated by in-situ synchrotron WAXS and SAXS. Polymer 2014, 55, 5477–5487. [Google Scholar] [CrossRef]

| Sample | Tm (°C) | FWHM of Tm (°C) | Tc (°C) | ∆Hm (J/g) | Xc (%) |

|---|---|---|---|---|---|

| PP | 164.99 | 10.37 | 107.03 | 75.88 | 45.38 |

| BP | 164.69 | 10.65 | 109.41 | 75.18 | 44.96 |

| I0BF-gSiO2 | 162.55 | 9.63 | 107.14 | 70.65 | 42.26 |

| I100BF-gSiO2 | 164.88 | 9.24 | 111.32 | 77.48 | 46.34 |

| I200BF-gSiO2 | 165.13 | 8.93 | 114.31 | 80.34 | 48.05 |

| I400BF-gSiO2 | 164.62 | 8.16 | 114.17 | 89.66 | 53.62 |

| I800BF-gSiO2 | 164.46 | 10.55 | 114.22 | 83.77 | 50.10 |

| Sample | L (nm) | Da (nm) | Dc (nm) |

|---|---|---|---|

| PP | 12.68 | 5.01 | 7.67 |

| BP | 12.92 | 5.00 | 7.92 |

| I100BF-gSiO2 | 13.02 | 5.06 | 7.96 |

| I400BF-gSiO2 | 13.27 | 4.98 | 8.29 |

| Sample | Storage Modulus at −100 °C (MPa) | Storage Modulus at 25 °C (MPa) | Tg (°C) |

|---|---|---|---|

| PP | 6280 | 3180 | 21.80 |

| BP | 7768 | 3905 | 22.47 |

| I0BF-gSiO2 | 7646 | 4136 | 22.73 |

| I100BF-gSiO2 | 7546 | 3777 | 21.94 |

| I400BF-gSiO2 | 7909 | 3642 | 23.03 |

| I800BF-gSiO2 | 7306 | 3736 | 20.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; He, P.; Jing, S.; Chen, G.; Li, G.; Wang, Z.; Han, R.; Li, Y. Surface Roughening of Irradiation-Activated Basalt Fiber through In Situ Growth of SiO2: Effects on Crystallization and Properties of PP Composites. Materials 2023, 16, 5657. https://doi.org/10.3390/ma16165657

Zhang S, He P, Jing S, Chen G, Li G, Wang Z, Han R, Li Y. Surface Roughening of Irradiation-Activated Basalt Fiber through In Situ Growth of SiO2: Effects on Crystallization and Properties of PP Composites. Materials. 2023; 16(16):5657. https://doi.org/10.3390/ma16165657

Chicago/Turabian StyleZhang, Shuai, Pan He, Shuoyi Jing, Gang Chen, Guangzhao Li, Zhongzui Wang, Rui Han, and Yijun Li. 2023. "Surface Roughening of Irradiation-Activated Basalt Fiber through In Situ Growth of SiO2: Effects on Crystallization and Properties of PP Composites" Materials 16, no. 16: 5657. https://doi.org/10.3390/ma16165657

APA StyleZhang, S., He, P., Jing, S., Chen, G., Li, G., Wang, Z., Han, R., & Li, Y. (2023). Surface Roughening of Irradiation-Activated Basalt Fiber through In Situ Growth of SiO2: Effects on Crystallization and Properties of PP Composites. Materials, 16(16), 5657. https://doi.org/10.3390/ma16165657