Effects of Rapid Quenching on Grain Boundary Microstructure and Mechanical Properties of an Al-Mg-Si-Cu Alloy

Abstract

1. Introduction

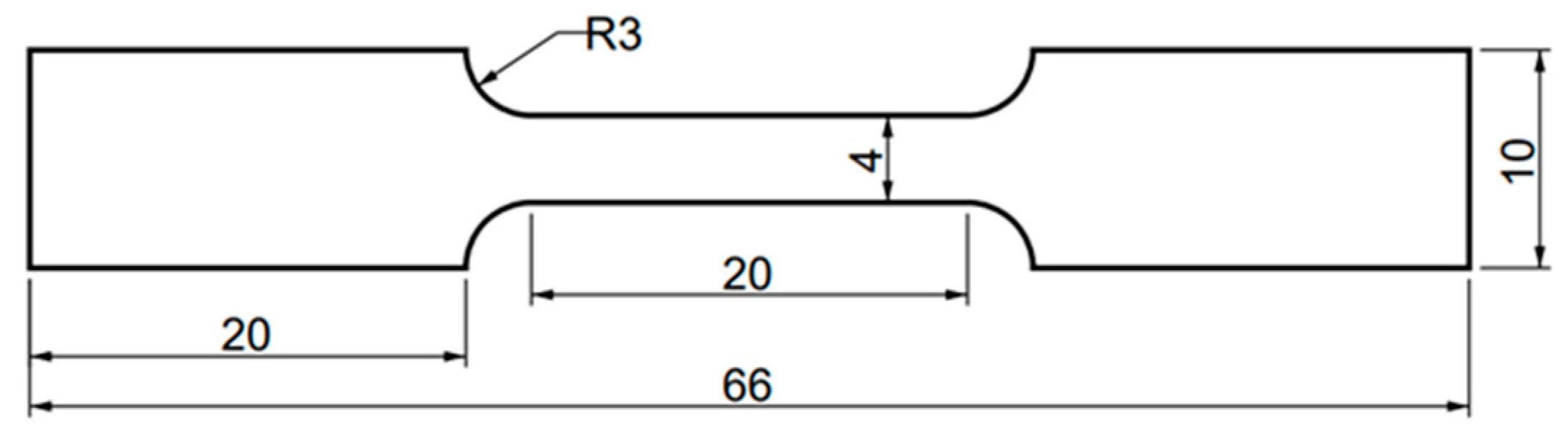

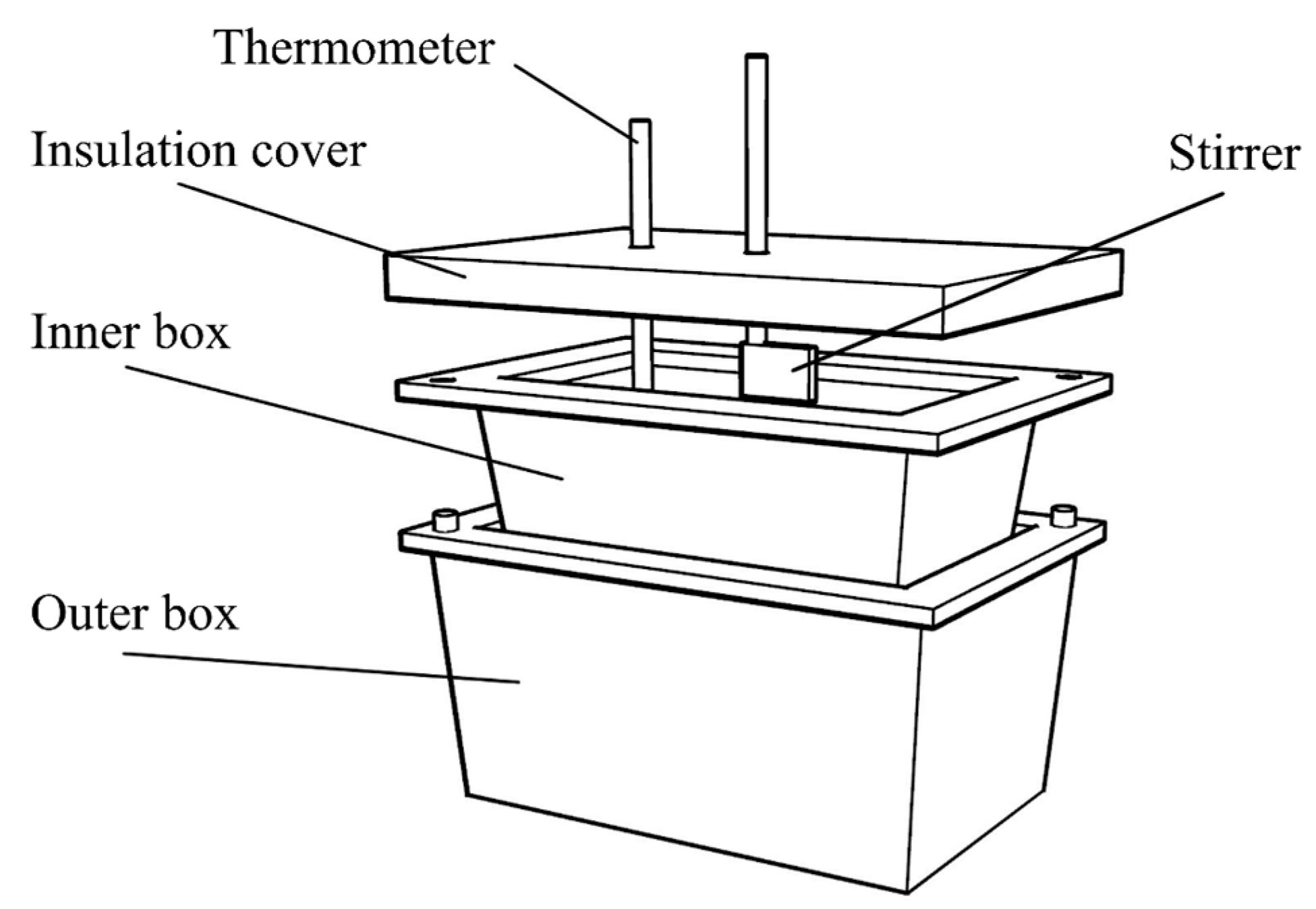

2. Materials and Methods

3. Results and Discussion

3.1. Hardness Evolution during Aging

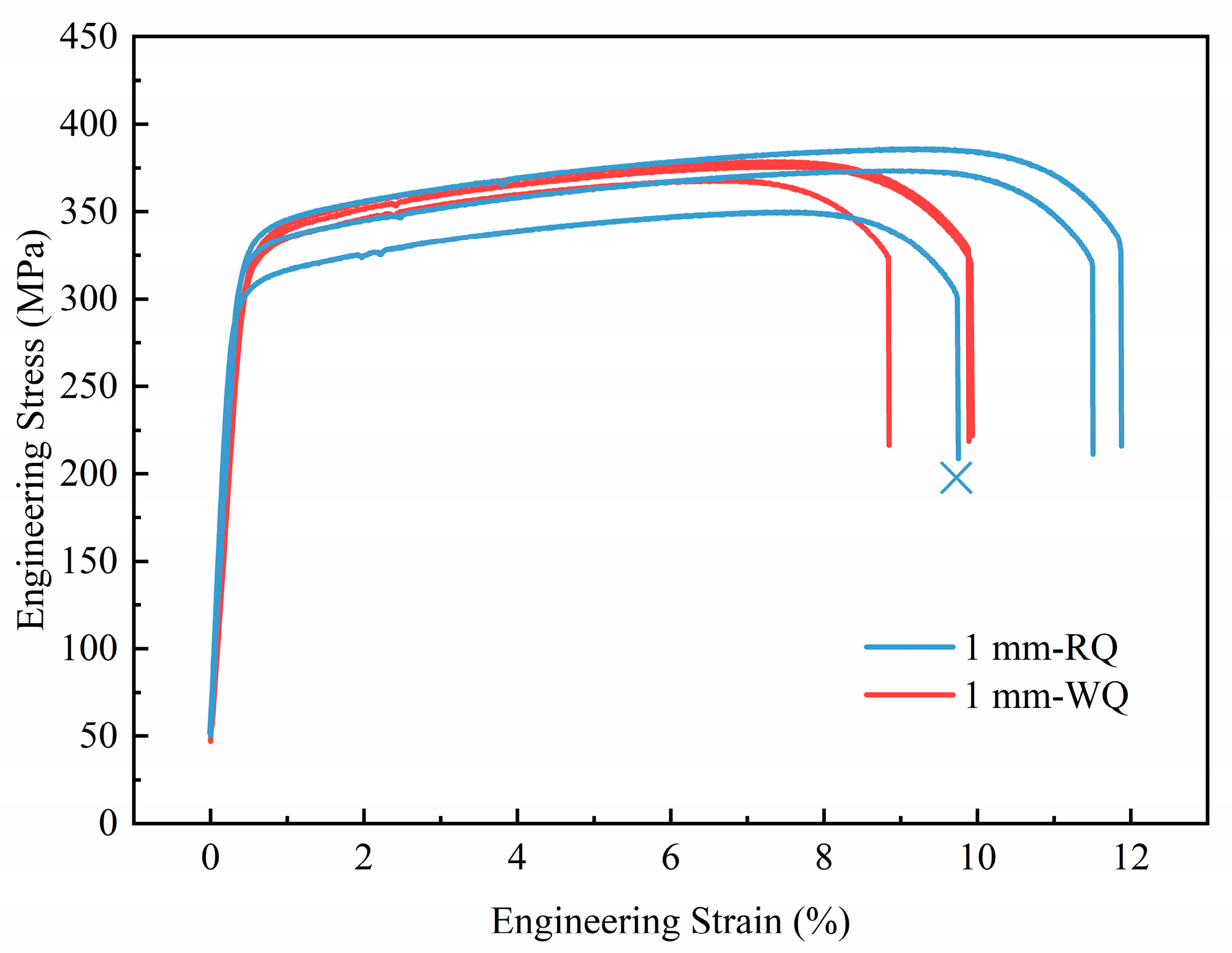

3.2. Tensile Properties

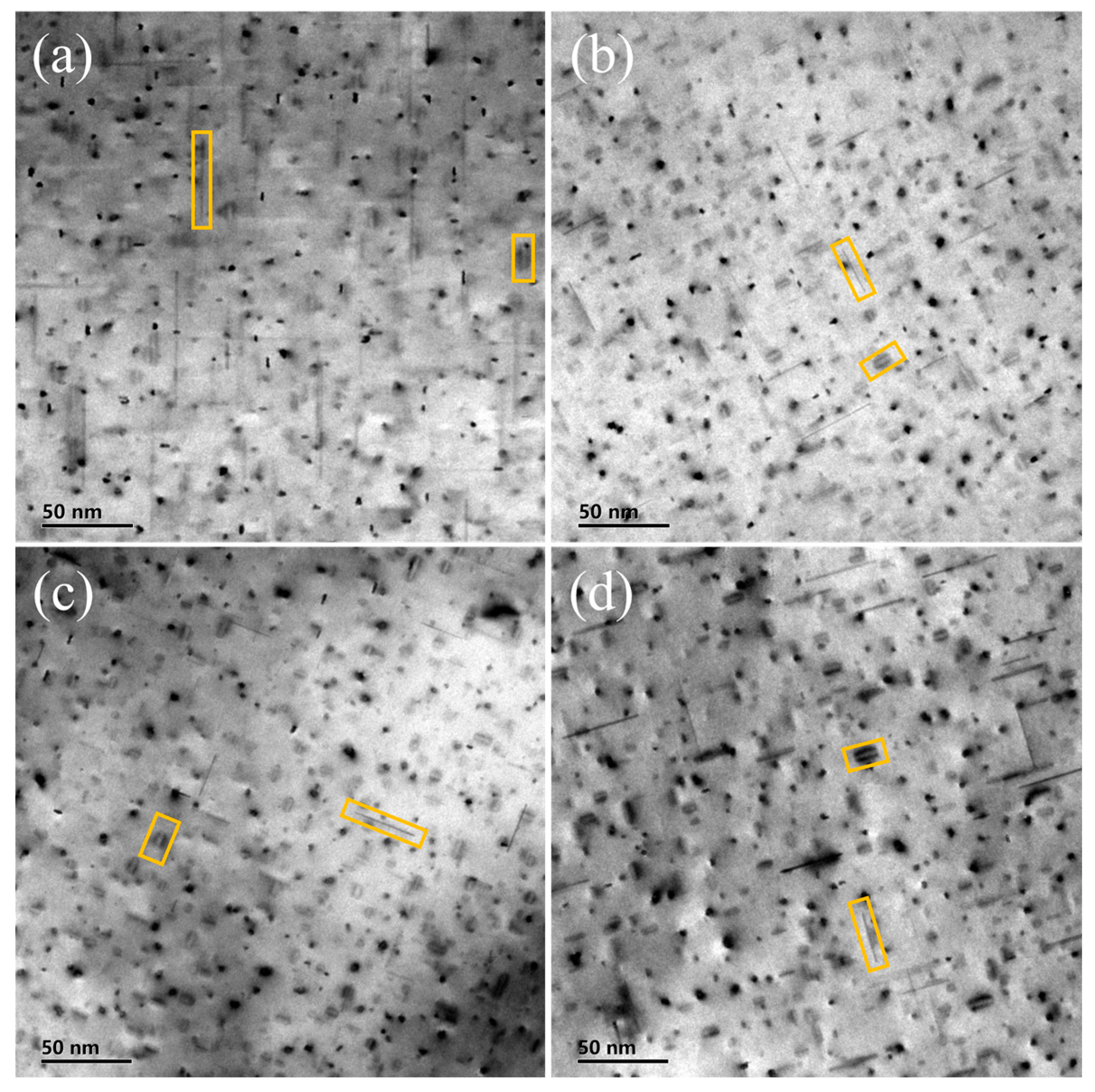

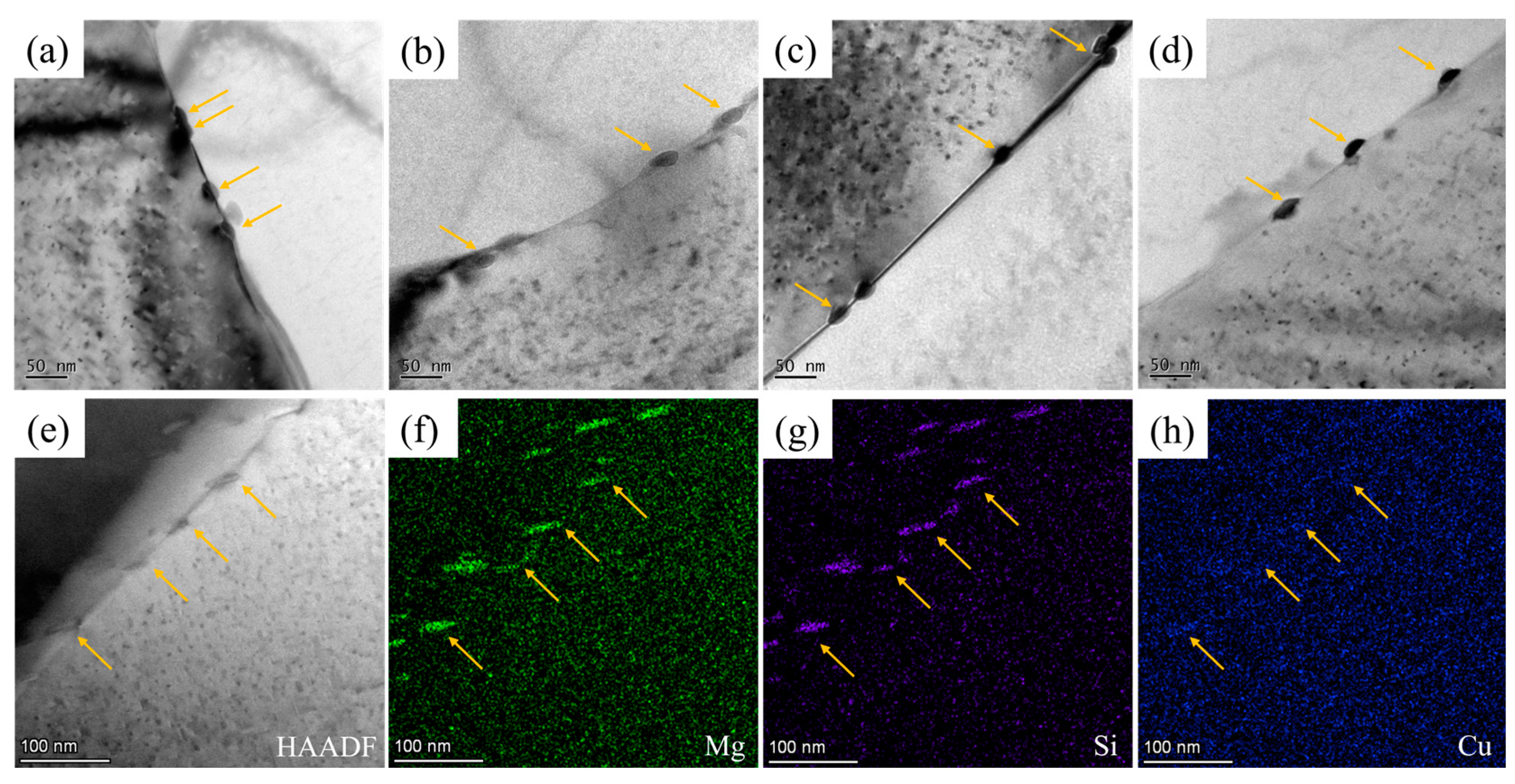

3.3. Precipitates: Intragranular and at GBs

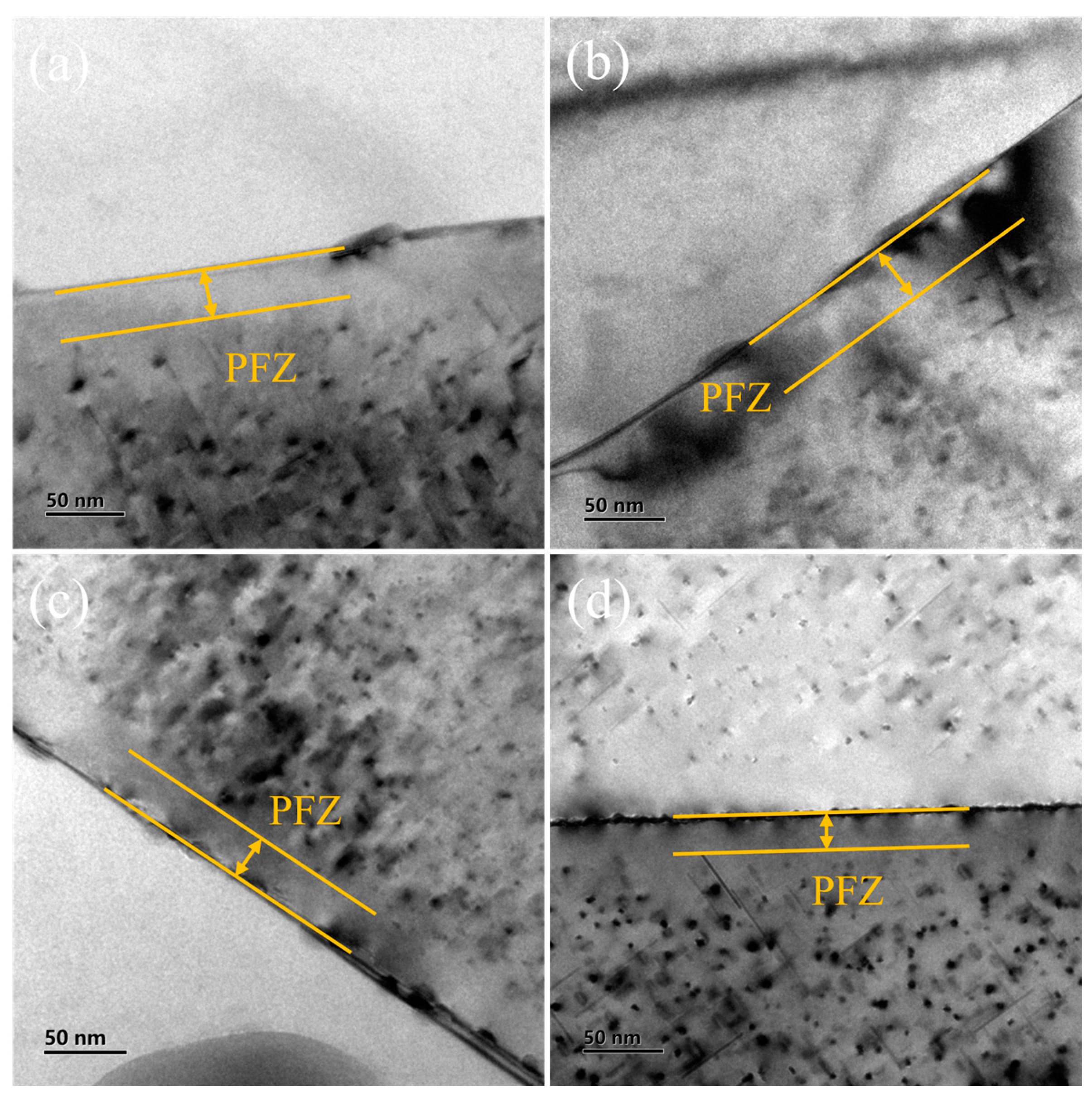

3.4. Precipitate Free Zones

4. Conclusions

- (1)

- The mechanical properties, including hardness, strength, and plasticity of rapidly quenched samples are better than those of water-quenched samples. It is shown that even when the quenching rate exceeds the critical cooling rate of 10 °C/s suggested in literature, increasing the quenching rate can improve the mechanical properties of the alloy. However, the increase in hardness and strength is negligible.

- (2)

- When the quenching rate exceeds the critical cooling rate, the PFZs in the peak-aged state of rapidly quenched samples were observed to be wider compared to those in the water-quenched samples. Additionally, the size of GBPs was found to be larger, while the size of intragranular precipitates was smaller.

- (3)

- When the quenching rate exceeds the critical cooling rate, it is speculated that the formation of PFZs is controlled by the solute depletion mechanism rather than the vacancy depletion mechanism. The nucleation and growth of GBPs lead to the depletion of solute atoms, resulting in wider PFZs at a higher quenching rate.

- (4)

- A finer and denser distribution of intragranular precipitates accounts for the slight increase in strength and hardness mentioned above, while the wider PFZs explain the notable increase in plasticity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Georgantzia, E.; Gkantou, M.; Kamaris, G.S. Aluminium alloys as structural material: A review of research. Eng. Struct. 2021, 227, 111372. [Google Scholar] [CrossRef]

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Myhr, O.R.; Grong, Ø.; Fjær, H.G.; Marioara, C.D. Modelling of the microstructure and strength evolution in Al–Mg–Si alloys during multistage thermal processing. Acta Mater. 2004, 52, 4997–5008. [Google Scholar] [CrossRef]

- Ravi, C.; Wolverton, C. First-principles study of crystal structure and stability of Al–Mg–Si–(Cu) precipitates. Acta Mater. 2004, 52, 4213–4227. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Stene, T.N.; Hasting, H.; Walmsley, J.; Van Helvoort, A.T.J.; Holmestad, R. The effect of Cu on precipitation in Al–Mg–Si alloys. Philos. Mag. 2007, 87, 3385–3413. [Google Scholar] [CrossRef]

- Christiansen, E.; Marioara, C.D.; Marthinsen, K.; Hopperstad, O.S.; Holmestad, R. Lattice rotations in precipitate free zones in an Al-Mg-Si alloy. Mater. Charact. 2018, 144, 522–531. [Google Scholar] [CrossRef]

- Unwin, P.N.T.; Lorimer, G.W.; Nicholson, R.B. The origin of the grain boundary precipitate free zone. Acta Met. 1969, 17, 1363–1377. [Google Scholar] [CrossRef]

- Kawabata, T.; Izumi, O. Ductile fracture in the interior of precipitate free zone in an Al-6.0%Zn-2.6%Mg alloy. Acta Met. 1976, 24, 817–825. [Google Scholar] [CrossRef]

- Ryum, N. The influence of a precipitate-free zone on the mechanical properties of an Al-Mg-Zn alloy. Acta Met. 1968, 16, 327–332. [Google Scholar] [CrossRef]

- Milkereit, B.; Starink, M.J. Quench sensitivity of Al–Mg–Si alloys: A model for linear cooling and strengthening. Mater. Des. 2015, 76, 117–129. [Google Scholar] [CrossRef]

- Saito, T.; Marioara, C.D.; Royset, J.; Marthinsen, K.; Holmestad, R. The effects of quench rate and pre-deformation on precipitation hardening in Al-Mg-Si alloys with different Cu amounts. Mater. Sci. Eng. A-Struct. 2014, 609, 72–79. [Google Scholar] [CrossRef]

- Steele, D.; Evans, D.; Nolan, P.; Lloyd, D.J. Quantification of grain boundary precipitation and the influence of quench rate in 6XXX aluminum alloys. Mater. Charact. 2007, 58, 40–45. [Google Scholar] [CrossRef]

- Yang, M.; Ruan, Z.; Lin, H.; Li, K.; Yang, M.; Wang, Z.; Lan, X.; Xie, Y.; Xiao, Y.; Yan, Q.; et al. Quantified effect of quench rate on the microstructures and mechanical properties of an Al–Mg–Si alloy. J. Mater. Res. Technol. 2023, 24, 6753–6761. [Google Scholar] [CrossRef]

- Wang, J.S. Thermodynamic Study of Equilibrium Phase in Quasicrystalline Strengthened Magnesium Alloys. Mater. Sci. Forum 2020, 993, 1043–1050. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, X. Thermodynamic and Kinetic Calculation of High Strength Aluminum-Lithium Alloy. Crystals 2022, 12, 472. [Google Scholar] [CrossRef]

- Zhang, Y.; Milkereit, B.; Kessler, O.; Schick, C.; Rometsch, P.A. Development of continuous cooling precipitation diagrams for aluminium alloys AA7150 and AA7020. J. Alloys Compd. 2014, 584, 581–589. [Google Scholar] [CrossRef]

- Milkereit, B.; Wanderka, N.; Schick, C.; Kessler, O. Continuous cooling precipitation diagrams of Al–Mg–Si alloys. Mater. Sci. Eng. A 2012, 550, 87–96. [Google Scholar] [CrossRef]

- Raulea, L.V.; Goijaerts, A.M.; Govaert, L.E.; Baaijens, F.P.T. Size effects in the processing of thin metal sheets. J. Mater. Process. Technol. 2001, 115, 44–48. [Google Scholar] [CrossRef]

- Yu, H.; Tieu, A.K.; Lu, C.; Liu, X.; Godbole, A.; Kong, C. Mechanical properties of Al–Mg–Si alloy sheets produced using asymmetric cryorolling and ageing treatment. Mater. Sci. Eng. A 2013, 568, 212–218. [Google Scholar] [CrossRef]

- Garric, V.; Colas, K.; Donnadieu, P.; Renou, G.; Urvoy, S.; Kapusta, B. Correlation between quenching rate, mechanical properties and microstructure in thick sections of AlMgSi(Cu) alloys. Mater. Sci. Eng. A 2019, 753, 253–261. [Google Scholar] [CrossRef]

- Schumacher, P.; Pogatscher, S.; Starink, M.J.; Schick, C.; Mohles, V.; Milkereit, B. Quench-induced precipitates in Al–Si alloys: Calorimetric determination of solute content and characterisation of microstructure. Thermochim. Acta 2015, 602, 63–73. [Google Scholar] [CrossRef]

- Dutta, I.; Allen, S.M. A calorimetric study of precipitation in commercial aluminium alloy 6061. J. Mater. Sci. Lett. 1991, 10, 323–326. [Google Scholar] [CrossRef]

- Ding, L.; Jia, Z.; Zhang, Z.; Sanders, R.E.; Liu, Q.; Yang, G. The natural aging and precipitation hardening behaviour of Al-Mg-Si-Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng. A 2015, 627, 119–126. [Google Scholar] [CrossRef]

- Esmaeili, S.; Wang, X.; Lloyd, D.J.; Poole, W.J. On the precipitation-hardening behavior of the Al−Mg−Si−Cu alloy AA6111. Met. Mater. Trans. A 2003, 34, 751–763. [Google Scholar] [CrossRef]

- Weng, Y.; Jia, Z.; Ding, L.; Pan, Y.; Liu, Y.; Liu, Q. Effect of Ag and Cu additions on natural aging and precipitation hardening behavior in Al-Mg-Si alloys. J. Alloys Compd. 2017, 695, 2444–2452. [Google Scholar] [CrossRef]

- Zurob, H.S.; Seyedrezai, H. A model for the growth of solute clusters based on vacancy trapping. Scr. Mater. 2009, 61, 141–144. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Ebner, T.; Uggowitzer, P.J. Mechanisms controlling the artificial aging of Al–Mg–Si Alloys. Acta Mater. 2011, 59, 3352–3363. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, X. Thermodynamic, Kinetic and Strength Calculation of High Zinc Containing Al-Zn-Mg-Cu Alloys. Crystals 2022, 12, 181. [Google Scholar] [CrossRef]

- Pogatscher, S.; Antrekowitsch, H.; Leitner, H.; Pöschmann, D.; Zhang, Z.L.; Uggowitzer, P.J. Influence of interrupted quenching on artificial aging of Al–Mg–Si alloys. Acta Mater. 2012, 60, 4496–4505. [Google Scholar] [CrossRef]

- Wang, J.S. Kinetic and Strength Calculation of Age-Hardening Phases in Heat-Resistant Aluminum Alloys with Silver. Mater. Sci. Forum 2020, 993, 1051–1056. [Google Scholar] [CrossRef]

- Strobel, K.; Lay, M.D.H.; Easton, M.A.; Sweet, L.; Zhu, S.; Parson, N.C.; Hill, A.J. Effects of quench rate and natural ageing on the age hardening behaviour of aluminium alloy AA6060. Mater. Charact. 2016, 111, 43–52. [Google Scholar] [CrossRef]

- Holmestad, J.; Ervik, M.; Marioara, C.D.; Walmsley, J.C. Investigation of Grain Boundaries in an Al-Mg-Si-Cu Alloy. Mater. Sci. Forum 2014, 794–796, 951–956. [Google Scholar] [CrossRef]

- Wenner, S.; Jones, L.; Marioara, C.D.; Holmestad, R. Atomic-resolution chemical mapping of ordered precipitates in Al alloys using energy-dispersive X-ray spectroscopy. Micron 2017, 96, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Poole, W.J.; Wang, X.; Embury, J.D.; Lloyd, D.J. The effect of manganese on the microstructure and tensile response of an Al-Mg-Si alloy. Mater. Sci. Eng. A 2019, 755, 307–317. [Google Scholar] [CrossRef]

- Wang, J.S. Thermodynamic Study on Equilibrium Phases in Nickel-Base Single Crystal Superalloys. Mater. Sci. Forum 2019, 944, 149–154. [Google Scholar] [CrossRef]

- Liu, W.; Qiu, Q.; Chen, Y.; Tang, C. Simulation of PFZ on intergranular fracture based on XFEM and CPFEM. J. Cent. South Univ. 2016, 23, 2500–2505. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, Z.K.; Li, W.C.; Lu, J.T.; Wen, S.P.; Huang, H.; Nie, Z.R. Effect of Retrogression and Re-aging Treatment on Properties and Microstructure of a New Type of Al–Zn–Mg–Er–Zr Alloy. J. Mater. Eng. Perform. 2022, 31, 4282–4293. [Google Scholar] [CrossRef]

- Shan, Z.; Liu, S.; Ye, L.; Li, Y.; He, C.; Chen, J.; Tang, J.; Deng, Y.; Zhang, X. Mechanism of Precipitate Microstructure Affecting Fatigue Behavior of 7020 Aluminum Alloy. Materials 2020, 13, 3248. [Google Scholar] [CrossRef]

- Liu, M.; Čížek, J.; Chang, C.S.T.; Banhart, J. Early stages of solute clustering in an Al–Mg–Si alloy. Acta Mater. 2015, 91, 355–364. [Google Scholar] [CrossRef]

| Element | Mg | Si | Cu | Mn | Fe | Al |

|---|---|---|---|---|---|---|

| Measured Composition | 1.12 | 0.78 | 0.56 | 0.51 | 0.47 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Q.; Qiu, Y.; Yang, M.; Lu, Q.; Lin, H.; Yang, M.; Li, K.; Du, Y. Effects of Rapid Quenching on Grain Boundary Microstructure and Mechanical Properties of an Al-Mg-Si-Cu Alloy. Materials 2023, 16, 5609. https://doi.org/10.3390/ma16165609

Yan Q, Qiu Y, Yang M, Lu Q, Lin H, Yang M, Li K, Du Y. Effects of Rapid Quenching on Grain Boundary Microstructure and Mechanical Properties of an Al-Mg-Si-Cu Alloy. Materials. 2023; 16(16):5609. https://doi.org/10.3390/ma16165609

Chicago/Turabian StyleYan, Qiao, Yu Qiu, Mingjun Yang, Qiang Lu, Han Lin, Mingbo Yang, Kai Li, and Yong Du. 2023. "Effects of Rapid Quenching on Grain Boundary Microstructure and Mechanical Properties of an Al-Mg-Si-Cu Alloy" Materials 16, no. 16: 5609. https://doi.org/10.3390/ma16165609

APA StyleYan, Q., Qiu, Y., Yang, M., Lu, Q., Lin, H., Yang, M., Li, K., & Du, Y. (2023). Effects of Rapid Quenching on Grain Boundary Microstructure and Mechanical Properties of an Al-Mg-Si-Cu Alloy. Materials, 16(16), 5609. https://doi.org/10.3390/ma16165609