Properties of Superelastic Nickel–Titanium Wires after Clinical Use

Abstract

:1. Introduction

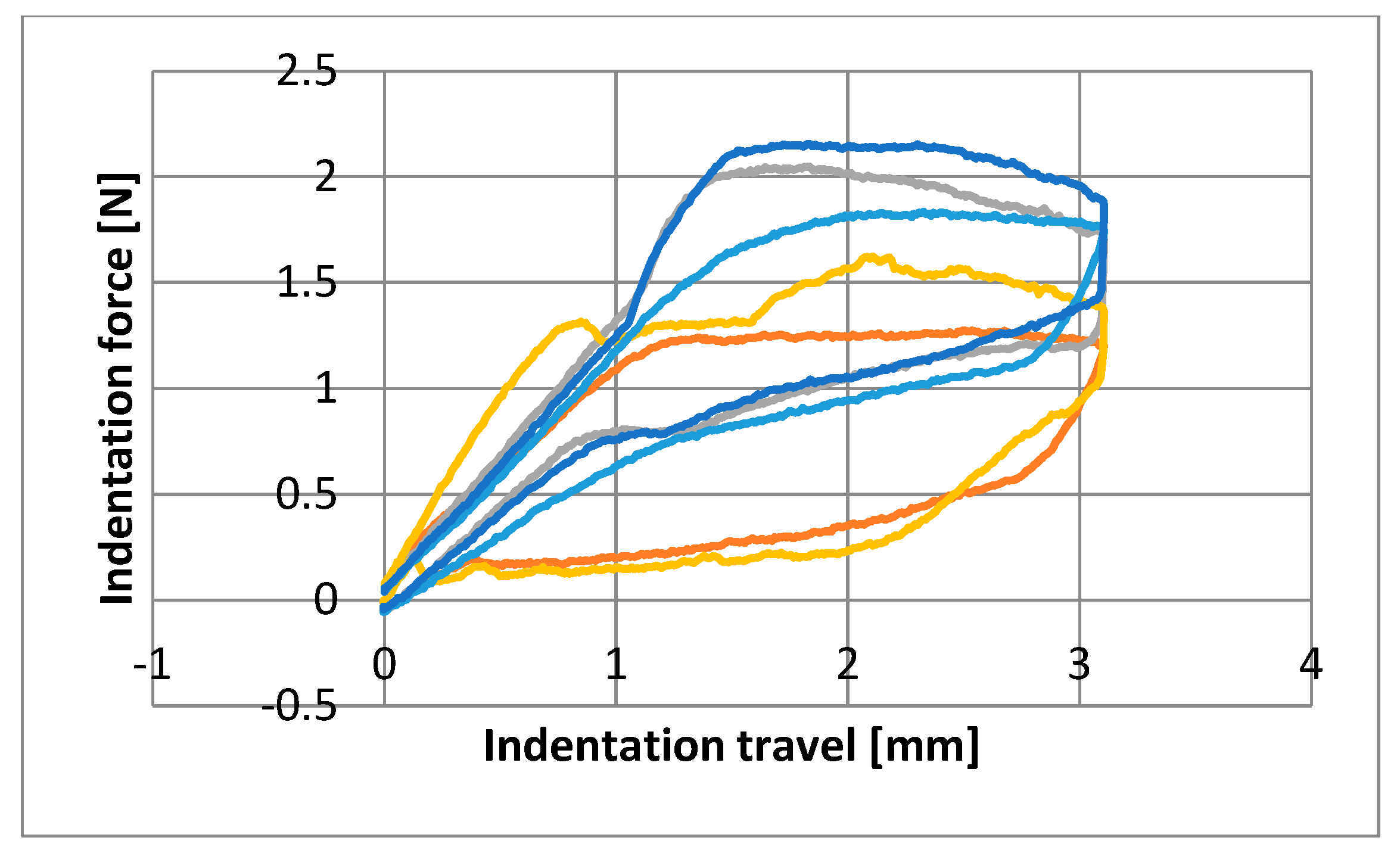

2. Materials and Methods

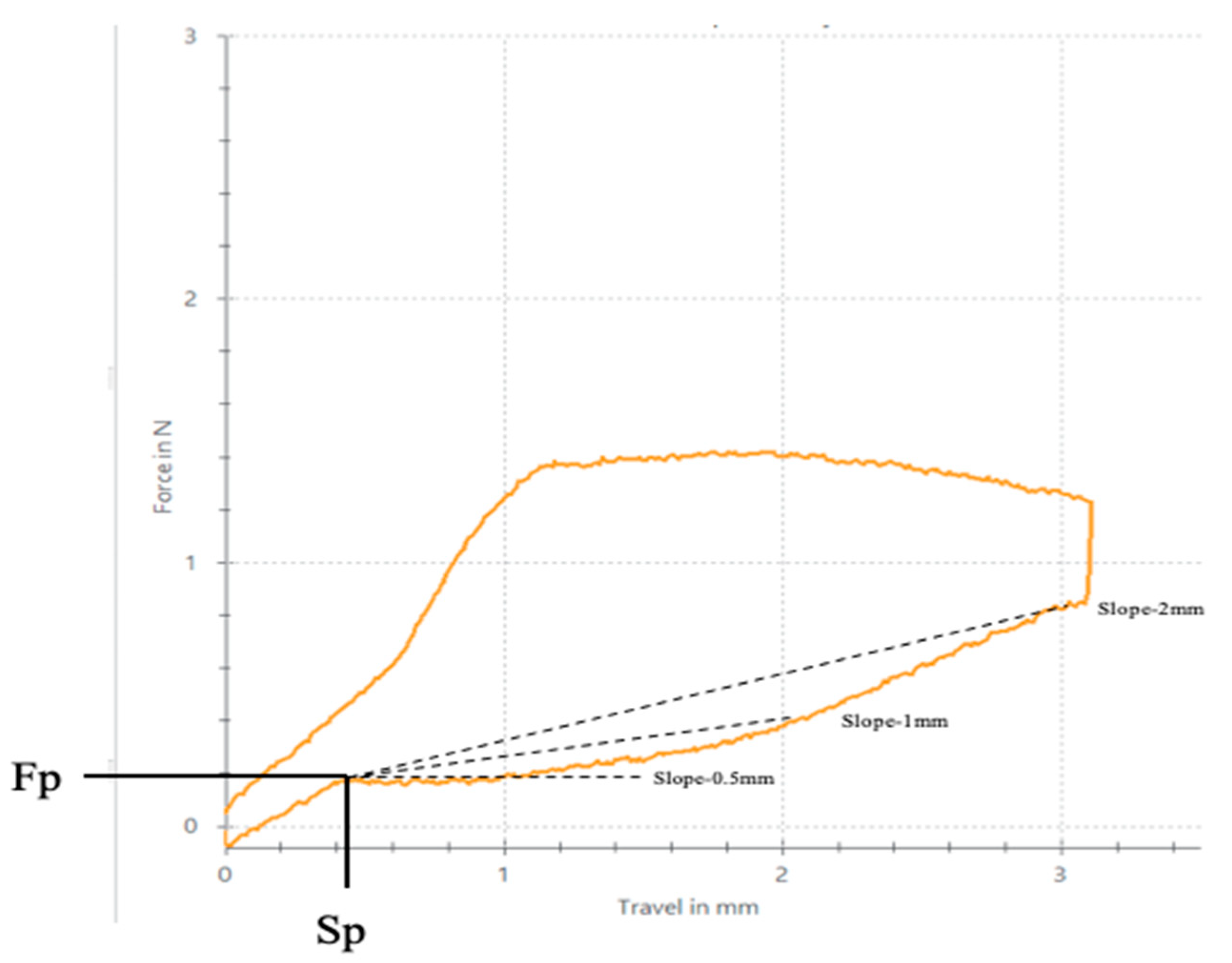

- Force level delivered in Newtons (N) with deflection at 3.0 mm, 2.0 mm, 1.0 mm, 0.5 mm (Fdef-3 mm, Fdef-2 mm, Fdef-1 mm, Fdef-0.5 mm, respectively).

- Deflection at the end of plateau in mm (Sp).

- Minimum force level at the end of superelastic plateau in N (Fp).

- Plateau slopes: between 0.5 mm and Sp (Slope-0.5 mm), between 1 mm and Sp (Slope-1 mm), and between 2 mm and Sp (Slope-2 mm) of deflection expressed in N/mm.

3. Results

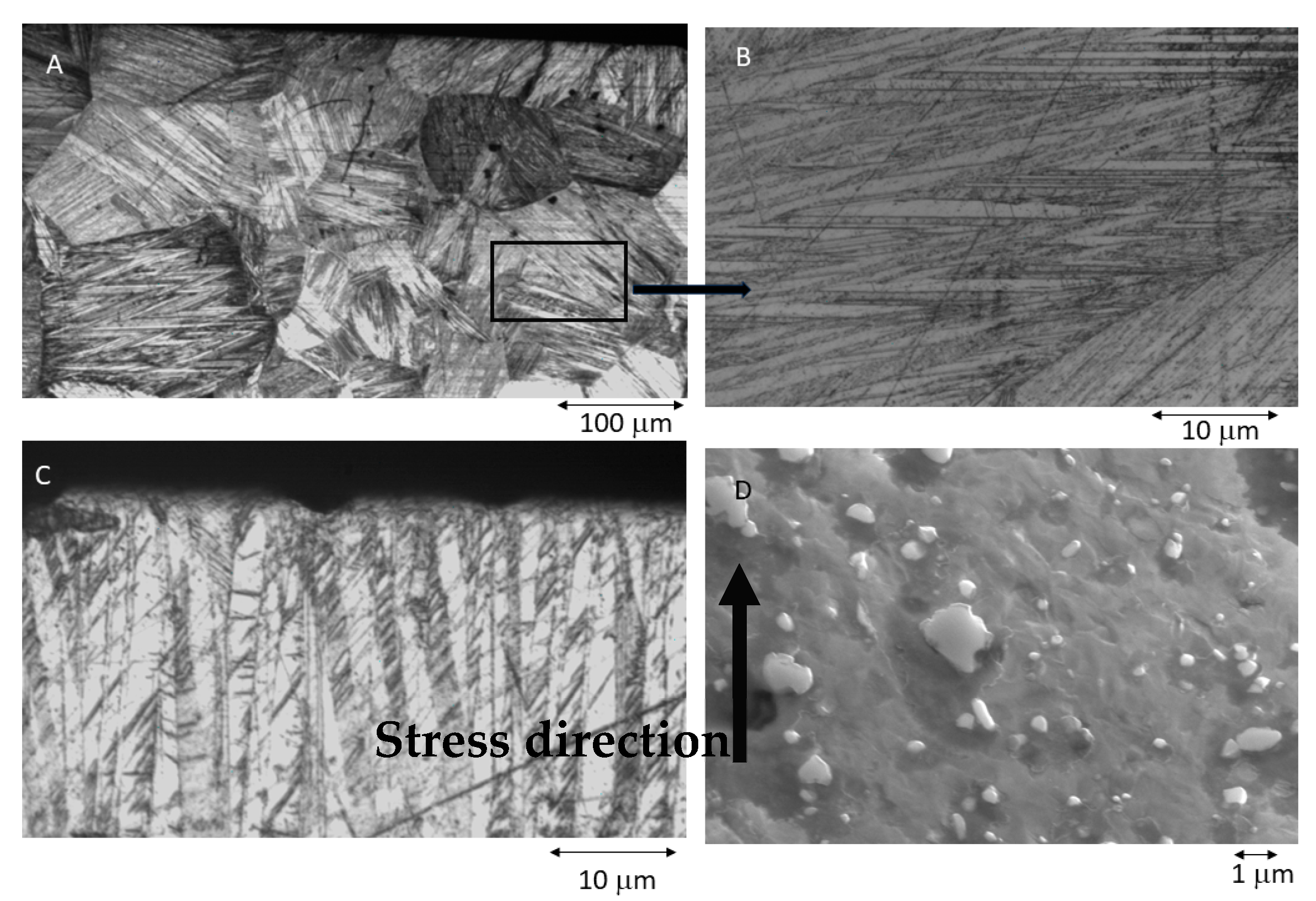

4. Discussion

5. Conclusions

- Significant differences in exerted forces, both during three months of activation (T1) and after sterilization (T2), were found among the brands.

- GC, EURO, and FOR appeared to lose their superelastic properties during three months of clinical use (T1).

- As for lower deformations (<2 mm), GAC, 3M, and FOR wires recovered their properties after sterilization (T2), while EURO archwires appeared to lose their superelasticity.

- Superelastic properties and released forces were found to differ significantly among all groups studied (T0, T1, and T2).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kotha, R.; Alla, R.K.; Mohammed, S.; Ravi, R. An Overview of Orthodontic Wires. Trends Biomater. Artif. Organs 2014, 28, 32–36. [Google Scholar]

- Parvizi, F.; Rock, W.P. The load/deflection characteristics of thermally activated orthodontic archwires. Eur. J. Orthod. 2003, 25, 417–421. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juvvadi, S.R.; Kailasam, V.; Padmanabhan, S.; Chitharanjan, A.B. Physical, mechanical, and flexural properties of 3 orthodontic wires: An in-vitro study. Am. J. Orthod. Dentofac. Orthop. 2010, 138, 623–630. [Google Scholar] [CrossRef]

- Hurst, C.L.; Duncanson, M.G.; Nanda, R.S.; Angolkar, P.V. An evaluation of the shape-memory phenomenon of nickel-titanium orthodontic wires. Am. J. Orthod. Dentofac. Orthop. 1990, 98, 72–76. [Google Scholar] [CrossRef] [PubMed]

- Nakano, H.; Satoh, K.; Norris, R.; Jin, T.; Kamegai, T.; Ishikawa, F.; Katsura, H. Mechanical properties of several nickel-titanium alloy wires in three-point bending tests. Am. J. Orthod. Dentofacial Orthop. 1999, 115, 390–395. [Google Scholar] [CrossRef] [PubMed]

- Bartzela, T.N.; Senn, C.; Wichelhaus, A. Load-deflection characteristics of superelastic nickel-titanium wires. Angle Orthod. 2007, 77, 991–998. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tonner, R.I.M.; Waters, N.E. The characteristics of super-elastic Ni-Ti wires in three-point bending. Part l: The effect of temperature. Eur. J. Orthod. 1994, 16, 409–419. [Google Scholar] [CrossRef]

- Dechkunakorn, S.; Isarapatanapong, R.; Anuwongnukroh, N.; Chiranavanit, N.; Kajorchaiyakul, J.; Khantachawana, A. Mechanical properties of several NiTi alloy wires in three-point bending tests. Appl. Mech. Mater. 2011, 87, 14–19. [Google Scholar] [CrossRef]

- Lombardo, L.; Toni, G.; Mazzanti, V.; Mollica, G.A.S.; Siciliani, G. The mechanical behaviour of as received and retrieved nickel titanium orthodontic archwires. Prog. Orthod. 2019, 20, 1. [Google Scholar] [CrossRef] [Green Version]

- Segner, D.; Ibe, D. Properties of superelastic wires and their relevance to orthodontic treatment. Eur. J. Orthod. 1995, 17, 395–402. [Google Scholar] [CrossRef]

- Pandis, N.; Bourauel, C.P. Nickel-Titanium (NiTi) arch wires: The clinical significance of super elasticity. Semin. Orthod. 2010, 16, 249–257. [Google Scholar] [CrossRef]

- Lee, S.H.; Chang, Y.I. Effects of recycling on the mechanical properties and the surface topography of nickel-titanium alloy wires. Am. J. Orthod. Dentofac. Orthop. 2001, 120, 654–663. [Google Scholar] [CrossRef]

- Bavikati, V.N.; Singaraju, G.S.; Mandava, P.; Killamsetty, S.S.; Nettam, V.; Karnati, P.K.R. Evaluation of mechanical and physical properties of clinically used and recycled superelastic NiTi wires. J. Clin. Diagn. Res. 2016, 10, ZC35–ZC40. [Google Scholar] [CrossRef] [PubMed]

- Pastor, F.; Rodríguez, J.C.; Barrera, J.M.; Delgado García-Menocal, J.A.; Brizuela, A.; Puigdollers, A.; Espinar, E.; Gil, J. Effect of Fluoride Content of Mouthwashes on Superelastic Properties of NiTi Orthodontic Archwires. Materials 2022, 15, 6592. [Google Scholar] [CrossRef]

- Bellini, H.; Moyano, J.; Gil, J.; Puigdollers, A. Comparison of the superelasticity of different nickel-titanium orthodontic archwires and the loss of their properties by heat treatment. J. Mater. Sci. Mater. Med. 2016, 27, 158. [Google Scholar] [CrossRef] [Green Version]

- Gil, F.J.; Cenizo, M.; Espinar, E.; Rodriguez, A.; Rúperez, E.; Manero, J.M. NiTi superelastic orthodontic wires with variable stress obtained by ageing treatments. Mater. Lett. 2013, 104, 5–7. [Google Scholar] [CrossRef]

- Briceño, J.; Romeu, A.; Espinar, E.; Llamas, J.M.; Gil, F.J. Influence of the microstructure on electrochemical corrosion and nickel release in NiTi orthodontic archwires. Mater. Sci. Eng. C 2013, 33, 4989–4993. [Google Scholar] [CrossRef]

- Gil, F.J.; Espinar, E.; Llamas, J.M.; Manero, J.M.; Ginebra, M.P. Variation of the superelastic properties and nickel release from original and reused NiTi orthodontic archwires. J. Mech. Beh. Biomed. Mater. 2012, 6, 113–119. [Google Scholar] [CrossRef]

- Sánchez, P.; Vidi, B.; Mena-Alvarez, J.; Gil, J.; Rico, C.; Aragoneses, J.M. Effect of Stabilized Martensite on the Long-Term Performance of Superelastic NiTi Endodontic Files. Materials 2023, 16, 4089. [Google Scholar] [CrossRef]

- Rupérez, E.; Manero, J.M.; Bravo-González, L.A.; Espinar, E.; Gil, F.J. Development of biomimetic NiTi alloy: Influence of thermo-chemical treatment on the physical, mechanical and biological behavior. Materials 2016, 9, 402. [Google Scholar] [CrossRef] [Green Version]

- Gil, F.J.; Rupérez, E.; Velasco, E.; Aparicio, C.; Manero, J.M. Mechanism of fracture of NiTi superelastic endodontic rotary instruments. J. Mater. Sci. Mater. Med. 2018, 29, 205. [Google Scholar] [CrossRef] [PubMed]

- Godoy-Gallardo, M.; Wang, Z.; Shen, Y.; Manero, J.M.; Gil, F.J.; Rodriguez, D.; Haapasalo, M. Antibacterial Coatings on Titanium Surfaces: A Comparison Study Between In Vitro Single-Species and Multispecies Biofilm. ACS Appl. Mater. Interfaces 2015, 7, 5992–6001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kusy, R.P. A review of contemporary archwires: Their properties and characteristics. Angle Orthod. 1997, 67, 197–208. [Google Scholar]

- Stoyanova-Ivanova, A.; Georgieva, M.; Petrov, V.; Andreeva, L.; Petkov, A.; Georgiev, V. Effects of Clinical Use on the Mechanical Properties of Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel-Titanium Orthodontic Archwires. Materials 2023, 16, 483. [Google Scholar] [CrossRef] [PubMed]

- Munir, A.; Razali, M.F.; Hassan, M.H.; Franz, G. Effect of Short-Term Ageing Treatment on Bending Force Behavior of Commercial Nickel-Titanium Archwire. Materials 2023, 16, 1008. [Google Scholar] [CrossRef] [PubMed]

- ISO 15841:2006; Dentistry—Wires for Use in Orthodontics. International Organization for Standardization: Geneva, Switzerland, 2006.

- Eliades, T.; Eliades, G.; Athanasiou, A.E.; Bradley, T.G. Surface characterization of retrieved NiTi orthodontic archwires. Eur. J. Orthod. 2000, 22, 317–326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eliades, T.; Athanasiou, A.E. In Vivo Aging of Orthodontic Alloys: Implications for Corrosion Potential, Nickel Release, and Biocompatibility. Angle Orthod. 2002, 72, 222–237. [Google Scholar]

- Perinetti, G.; Contardo, L.; Ceschi, M.; Antoniolli, F.; Franchi, L.; Baccetti, T.; Di Lenarda, R. Surface corrosion and fracture resistance of two nickel-titanium-based archwires induced by fluoride, pH, and thermocycling. An in vitro comparative study. Eur. J. Orthod. 2012, 34, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Bourauel, C.; Scharold, W.; Jäger, A.; Eliades, T. Fatigue failure of as-received and retrieved NiTi orthodontic archwires. Dent. Mater. 2008, 24, 1095–1101. [Google Scholar] [CrossRef]

- Eliades, T.; Bourauel, C. Intraoral aging of orthodontic materials: The picture we miss and its clinical relevance. Am. J. Orthod. Dentofac. Orthop. 2005, 127, 403–412. [Google Scholar] [CrossRef]

- Kapila, S.; Reichhold, G.W.; Anderson, R.S.; Watanabe, L.G.; Francisco, S.; Valley, C. Effects of clinical recycling on mechanical properties of nickel-titanium alloy wires. Am. J. Orthod. 1991, 100, 428–435. [Google Scholar] [CrossRef] [PubMed]

- Pop, S.I.; Dudescu, M.; Merie, V.V.; Pacurar, M.; Bratu, C.D. Evaluation of the mechanical properties and surface topography of as-received, immersed and as-retrieved orthodontic archwires. Clujul Med. 2017, 90, 313–326. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miura, F.; Mogi, M.; Ohura, Y.; Hamanaka, H. The super-elastic property of the Japanese NiTi alloy wire for use in orthodontics. Am. J. Orthod. Dentofac. Orthop. 1986, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Brauchli, L.M.; Keller, H.; Senn, C.; Wichelhaus, A. Influence of bending mode on the mechanical properties of nickel-titanium archwires and correlation to differential scanning calorimetry measurements. Am. J. Orthod. Dentofac. Orthop. 2011, 139, e449–e454. [Google Scholar] [CrossRef] [PubMed]

- NSI/ADA Specification No. 32-2000; Orthodontic Wires. ANSI: Washington, DC, USA, 2000.

- Deliversky, J.; Yaneva-Deliverska, M.; Lyapina, M.; Kisselova, A. European and International Standards on Medical Devices for Dentistry. J. IMAB 2015, 21, 713–717. [Google Scholar] [CrossRef] [Green Version]

- Quintão, C.C.A.; e Cal-Neto, J.P.; Menezes, L.M.; Elias, C.N. Force-deflection properties of initial orthodontic archwires. World J. Orthod. 2009, 10, 29–32. [Google Scholar]

- Devaprasad, A.P.; Chandrasekaran, T. Effects of Intraoral Ageing on Ultimate Tensile Strength and Surface Topography of Superelastic NiTi Wires from Two Different Manufacturers: A Comparative in vivo Study. J. Indian Orthod. Soc. 2012, 46, 119–125. [Google Scholar] [CrossRef]

- Oshagh, M.; Hematiyan, M.R.; Mohandes, Y.; Oshagh, M.R.; Pishbin, L. Autoclaving and clinical recycling: Effects on mechanical properties of orthodontic wires. Indian J. Dent. Res. 2012, 23, 638–642. [Google Scholar] [CrossRef]

- Sernetz, F. Standardization of orthodontic products--does it make sense? J. Orofac. Orthop. 2005, 66, 307–318. [Google Scholar] [CrossRef]

- Gil, F.J.; Planell, J.A. Thermal eficiencies of NiTiCu shape memory alloys. Thermoch. Acta 1999, 327, 151–154. [Google Scholar] [CrossRef]

| Archwire Group | Archwire | Diameter | Manufacturer | Batch |

|---|---|---|---|---|

| GC-0 GC-1 GC-2 | Nickel Titanium | 0.016 inch | GC Orthodontics Europe GmbH, Germany | 195415 |

| 3M-0 3M-1 3M-2 | Nitinol® SuperElastic | 0.016 inch | Unitek, Monrovia, CA, USA | IE6ZG |

| EURO-0 EURO-1 EURO-2 | Euro Ni-Ti Opto TH Plus | 0.016 inch | ODS, Kisdorf, Germany | 2001898 2001930 |

| FOR-0 FOR-1 FOR-2 | Titanol® Superelastic | 0.016 inch | Forestadent, Pforzheim, Germany | 48055331 46055329 |

| GAC-0 GAC-1 GAC-2 | Sentalloy® superelastic | 0.016 inch | GAC, Grenoble, France | I760004 C760001 |

| Groups | T0 ± SD | Cluster | T1 ± SD | Cluster | T2 ± SD | Cluster | T0–T1 | Cluster | T1–T2 | Cluster | T0–T2 | Cluster |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plateau 0.5 mm (N) | ||||||||||||

| GAC | −1.92 (0.07) | a | −0.50 (0.17) | a | −0.56 (0.19) | a | −0.15 (0.14) ** | c | −0.06 (0.08) *** | b | −0.21 (0.16) ** | c |

| 3M | −2.23 (0.13) | c | −1.56 (0.11) | b | −1.66 (0.11) | b | 0.36 (0.13) *** | a | −0.10 (0.17) *** | b | 0.26 (0.14) *** | b |

| ODS | −0.35 (0.18) | a | −0.47 (0.07) | a | −0.59 (0.07) | a | −0.18 (0.09) *** | c, d | −0.12 (0.08) *** | b | −0.30 (0.12) *** | c,d |

| GC | −1.68 (0.08) | b | −1.97 (0.14) | c | −2.07 (0.1) | c | −0.29 (0.17) *** | d | −0.10 (0.17) *** | b | −0.39 (0.11) *** | d |

| FOR | −0.29 (0.08) | d | −2.22 (0.14) | d | −0.59 (0.07) | a | 0.01 (0.16) NS | b | 1.63 (0.16) *** | a | 1.64 (0.15) *** | a |

| Plateau 1 mm (N) | ||||||||||||

| GAC | −0.17 (0.09) | a | −0.36 (0.1) | a | −0.32 (0.10) | a | −0.19 (0.09) *** | d | 0.04 (0.06) *** | b | −0.15 (0.09) *** | c |

| 3M | −0.97 (0.02) | e | −0.81 (0.06) | b | −0.87 (0.06) | c | 0.17 (0.05) *** | a | −0.07 (0.09) *** | c | 0.10 (0.07) *** | b |

| ODS | −0.24 (0.06) | b | −0.34 (0.04) | a | −0.41 (0.04) | b | −0.1 (0.06) *** | c | −0.07 (0.06) *** | c | −0.17 (0.08) *** | c |

| GC | −0.57 (0.04) | c | −0.9 (0.07) | c | −0.93 (0.03) | d | −0.33 (0.07) *** | e | −0.04 (0.07) *** | c | −0.37 (0.05) *** | d |

| FOR | −0.86 (0.05) | d | −0.88 (0.07) | c | −0.41 (0.04) | b | −0.02 (0.06) NS | b | 0.47 (0.08) *** | a | 0.45 (0.07) *** | a |

| Plateau 2 mm (N) | ||||||||||||

| GAC | 0.13 (0.02) | a | 0.16 (0.026) | a | −0.06 (0.09) | a | 0.03 (0.02) ** | b | −0.22 (0.08) ** | d | −0.20 (0.08) ** | c |

| 3M | −0.30 (0.03) | e | −0.13 (0.16) | b | −0.31 (0.09) | c | 0.17 (0.16) *** | a | −0.18 (0.14) *** | c,d | −0.01 (0.10) NS | a,b |

| ODS | −0.18 (0.05) | c | −0.13 (0.04) | b | −0.24 (0.04) | b | 0.05 (0.06) ** | b | −0.11 (0.06) *** | c | −0.07 (0.07) *** | b |

| GC | −0.02 (0.04) | b | −0.28 (0.11) | c | −0.29 (0.06) | b,c | −0.27 (0.11) *** | d | −0.01 (0.11) *** | b | −0.28 (0.08) *** | d |

| FOR | −0.26 (0.04) | d | −0.36 (0.05) | c | −0.24 (0.04) | c | −0.10 (0.06) *** | c | 0.12 (0.06) *** | a | 0.02 (0.05) NS | a |

| GROUPS | T0 ± SD | Cluster | T1 ± SD | Cluster | T2 ± SD | Cluster | T0–T1 | Cluster | T1–T2 | Cluster | T0–T2 | Cluster |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Force deflection 0.5 mm (N) | ||||||||||||

| GAC | 0.15 (0.10) | c,d | 0.11 (0.09) | d | 0.21 (0.08) | b | −0.04 (0.08) NS | a | 0.10 (0.04) *** | a | 0.15 (0.10) *** | c,d |

| 3M | 0.19 (0.03) | c | 0.20 (0.05) | c | 0.21 (0.04) | b | 0.02 (0.07) NS | a | 0.01 (0.05) *** | c | 0.19 (0.03) NS | c |

| ODS | 0.10 (0.04) | d | 0.08 (0.04) | d | 0.17 (0.03) | b | −0.01 (0.05) NS | a | 0.09 (0.04) *** | a,b | 0.10 (0.04) *** | d |

| GC | 0.91 (0.03) | a | 0.39 (0.04) | b | 0.45 (0.05) | a | −0.52 (0.05) *** | b | 0.06 (0.03) *** | b | 0.91 (0.03) *** | a |

| FOR | 0.52 (0.08) | b | 0.50 (0.06) | a | 0.17 (0.03) | b | −0.02 (0.09) NS | a | −0.33 (0.08) *** | d | 0.52 (0.08) *** | b |

| Force deflection 1 mm (N) | ||||||||||||

| GAC | 0.19 (0.09) | d | 0.15 (0.08) | d | 0.24 (0.08) | c | −0.04 (0.07) NS | b | 0.10 (0.04) *** | a | 0.19 (0.09) ** | d |

| 3M | 0.57 (0.04) | c | 0.51 (0.07) | c | 0.52 (0.07) | b | −0.06 (0.08) * | b | 0.01 (0.07) *** | b | 0.57 (0.04) * | c |

| ODS | 0.07 (0.03) | e | 0.12 (0.05) | b | 0.18 (0.03) | d | 0.05 (0.05) ** | a | 0.06 (0.04) *** | a | 0.07 (0.03) *** | e |

| GC | 1.03 (0.04) | a | 0.75 (0.06) | d | 0.80 (0.05) | a | −0.29 (0.09) *** | c | 0.05 (0.07) *** | a,b | 1.03 (0.04) *** | a |

| FOR | 0.95 (0.03) | b | 0.93 (0.05) | a | 0.18 (0.03) | d | −0.03 (0.07) * | b | −0.75 (0.07) *** | c | 0.95 (0.03) *** | b |

| Force deflection 2 mm (N) | ||||||||||||

| GAC | 0.38 (0.06) | c | 0.35 (0.06) | b | 0.40 (0.06) | c | −0.02 (0.05) NS | b,c | 0.05 (0.04) *** | a | 0.38 (0.06) NS | c |

| 3M | 0.97 (0.02) | b | 0.97 (0.16) | a | 0.84 (0.09) | b | 0.01 (0.17) NS | b | −0.13 (0.13) *** | c | 0.97 (0.02) *** | b |

| ODS | 0.10 (0.03) | d | 0.28 (0.04) | b | 0.26 (0.02) | d | 0.18 (0.05) *** | a | −0.02 (0.04) *** | b | 0.10 (0.03) *** | d |

| GC | 1.09 (0.04) | a | 1.00 (0.07) | a | 1.04 (0.05) | a | −0.09 (0.09) *** | c | 0.04 (0.09) *** | a,b | 1.09 (0.04) NS | a |

| FOR | 1.09 (0.03) | a | 0.99 (0.06) | a | 0.26 (0.02) | d | −0.09 (0.07) *** | c | −0.73 (0.07) *** | d | 1.09 (0.03) *** | a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alcaraz, I.; Moyano, J.; Pàmies, A.; Ruiz, G.; Artés, M.; Gil, J.; Puigdollers, A. Properties of Superelastic Nickel–Titanium Wires after Clinical Use. Materials 2023, 16, 5604. https://doi.org/10.3390/ma16165604

Alcaraz I, Moyano J, Pàmies A, Ruiz G, Artés M, Gil J, Puigdollers A. Properties of Superelastic Nickel–Titanium Wires after Clinical Use. Materials. 2023; 16(16):5604. https://doi.org/10.3390/ma16165604

Chicago/Turabian StyleAlcaraz, Inés, Javier Moyano, Ariadna Pàmies, Guillem Ruiz, Montserrat Artés, Javier Gil, and Andreu Puigdollers. 2023. "Properties of Superelastic Nickel–Titanium Wires after Clinical Use" Materials 16, no. 16: 5604. https://doi.org/10.3390/ma16165604

APA StyleAlcaraz, I., Moyano, J., Pàmies, A., Ruiz, G., Artés, M., Gil, J., & Puigdollers, A. (2023). Properties of Superelastic Nickel–Titanium Wires after Clinical Use. Materials, 16(16), 5604. https://doi.org/10.3390/ma16165604