In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Small-Angle Neutron Scattering

2.3. Transmission Electron Microscopy

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- David, A. Main Steam Isolation Valves Stems Failare Analysis; Report No 13-MT003; WHO: Geneva, Switzerland, 2013. [Google Scholar]

- Bai, B.; Zhang, C.Y.; Wang, J.S.; Tong, Z.F.; Lv, Q.X.; Yang, W. Thermal Aging Effect of 17-4PH Martensitic Stainless Steel Valves for Nuclear Power Plant. Mater. Sci. Forum 2016, 850, 96–100. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, K.B.; Kim, J.H. Tensile Behavior of 17-4PH Stainless Steel under Rapid Heating. Key Eng. Mater. 2005, 297–300, 1482–1488. [Google Scholar] [CrossRef]

- Malakshah, M.G.; Eslami, A.; Ashrafizadeh, F.; Berenjkoub, A. Effect of Heat Treatment on Corrosion, Fatigue, and Corrosion Fatigue Behavior of 17-4PH Stainless Steel. J. Mater. Eng. Perform. 2022, 32, 6610–6621. [Google Scholar] [CrossRef]

- Xiang, S.; Wang, J.P.; Sun, Y.L.; Yan, Y.Y.; Huang, S.G. Effect of Ageing Process on Mechanical Properties of Martensite Precipitation-Hardening Stainless Steel. Adv. Mater. Res. 2010, 146–147, 382–385. [Google Scholar] [CrossRef]

- Hsu, K.-C.; Lin, C.-K. High-Temperature Fatigue Crack Growth Behavior of 17-4 PH Stainless Steels. Metall. Mater. Trans. A 2004, 35, 3018–3024. [Google Scholar] [CrossRef][Green Version]

- Macha, J.H.; Kirby, M.L.; Hickey, W.F.; Riha, D.S.; Alston, J.K.; Holden, B.B. Investigation of Thermal Embrittlement of 17-4PH Stainless Steel Main Steam Isolation Valves. J Fail. Anal. Prev. 2021, 21, 1445–1465. [Google Scholar] [CrossRef]

- Wang, J.; Zou, H.; Li, C.; Peng, Y.; Qiu, S.; Shen, B. The Microstructure Evolution of Type 17-4PH Stainless Steel during Long-Term Aging at 350 °C. Nucl. Eng. Des. 2006, 236, 2531–2536. [Google Scholar] [CrossRef]

- Aghaie-Khafri, M.; Mousavi Anijdan, S.H.; Amirkamali, M. Microstructural Evolution under Ausforming and Aging Conditions in 17-4 PH Stainless Steel. Mater. Res. Express 2019, 6, 106532. [Google Scholar] [CrossRef]

- Yeli, G.; Auger, M.A.; Wilford, K.; Smith, G.D.W.; Bagot, P.A.J.; Moody, M.P. Sequential Nucleation of Phases in a 17-4PH Steel: Microstructural Characterisation and Mechanical Properties. Acta Mater. 2017, 125, 38–49. [Google Scholar] [CrossRef]

- Habibi Bajguirani, H.R.; Servant, C.; Cizeron, G. TEM Investigation of Precipitation Phenomena Occurring in PH 15-5 Alloy. Acta Metall. Mater. 1993, 41, 1613–1623. [Google Scholar] [CrossRef]

- Worrall, G.M.; Buswell, J.T.; English, C.A.; Hetherington, M.G.; Smith, G.D.W. A Study of the Precipitation of Copper Particles in a Ferrite Matrix. J. Nucl. Mater. 1987, 148, 107–114. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W. High-Resolution Electron Microscopy Studies of the Structure of Cu Precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Bai, B.; Hu, R.; Zhang, C.; Xue, J.; Yang, W. Effect of Precipitates on Hardening of 17-4PH Martensitic Stainless Steel Serviced at 300 °C in Nuclear Power Plant. Ann. Nucl. Energy 2021, 154, 108123. [Google Scholar] [CrossRef]

- Sun, Y.; Zhong, Y.; Wang, L. The Interaction between ε-Copper and Dislocation in a High Copper 17-4PH Steel. Mater. Sci. Eng. A 2019, 756, 319–327. [Google Scholar] [CrossRef]

- Gilles, R.; Mukherji, D.; Eckerlebe, H.; Strunz, P.; Rösler, J. In Situ Investigation with Neutrons on the Evolution of γ ’ Precipitates at High Temperatures in a Single Crystal Ni-Base Superalloy. Adv. Mater. Res. 2011, 278, 42–47. [Google Scholar] [CrossRef]

- Del Genovese, D.; Rösler, J.; Strunz, P.; Mukherji, D.; Gilles, R. Microstructural Characterization of a Modified 706-Type Ni-Fe Superalloy by Small-Angle Neutron Scattering and Electron Microscopy. Metall. Mater. Trans. A 2005, 36, 3439–3450. [Google Scholar] [CrossRef]

- Ioannidou, C.; Navarro-López, A.; Rijkenberg, A.; Dalgliesh, R.M.; Koelling, S.; Pappas, C.; Sietsma, J.; van Well, A.A.; Erik Offerman, S. Evolution of the Precipitate Composition during Annealing of Vanadium Micro-Alloyed Steels by in-Situ SANS. Acta Mater. 2020, 201, 217–230. [Google Scholar] [CrossRef]

- Zijun, W.; Xiaoming, D.; Tianfu, L.; Kai, S.; Xuezhu, T.; Meijuan, L.; Rongdeng, L.; Yuntao, L.; Dongfeng, C. Investigation of Cu-Enriched Precipitates in Thermally Aged Fe-Cu and Fe-Cu-Ni Model Alloys. J. Nucl. Mater. 2022, 562, 153601. [Google Scholar] [CrossRef]

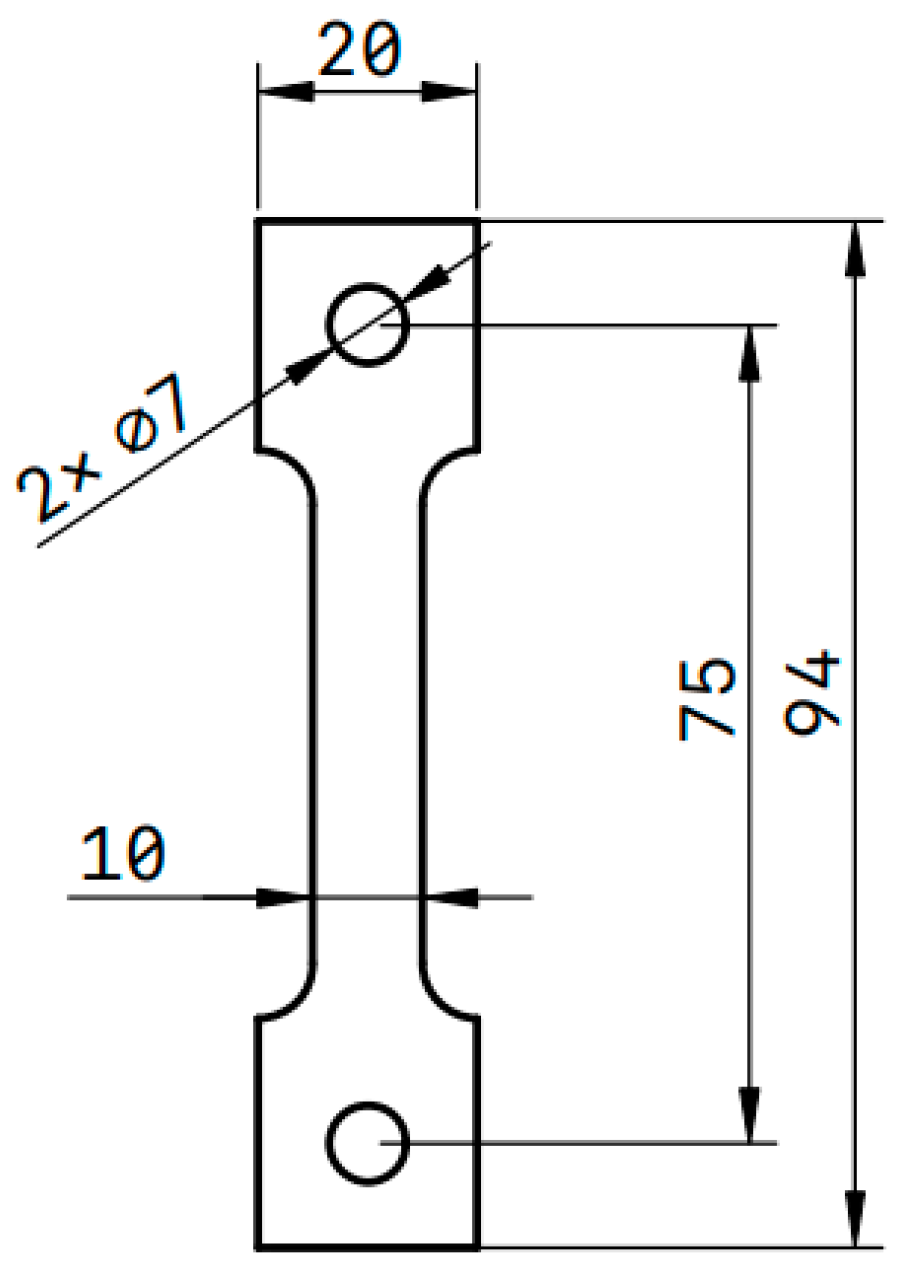

- GB/T 2039-2012; Metallic Materials—Uniaxial Creep Testing Method in Tension. Standardization Administration of China: Beijing, China, 2012.

- Guinier, A.; Fournet, G. Small-Angle Scattering of X-rays; John Wiley and Sons: New York, NY, USA, 1955. [Google Scholar]

- Zhang, H.; Cheng, H.; Yuan, G.; Han, C.C.; Zhang, L.; Li, T.; Wang, H.; Liu, Y.T.; Chen, D. Thirty Meters Small Angle Neutron Scattering Instrument at China Advanced Research Reactor. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2014, 735, 490–495. [Google Scholar] [CrossRef]

- Hammersley, A.P. FIT2D: A Multi-Purpose Data Reduction, Analysis and Visualization Program. J. Appl. Crystallogr. 2016, 49, 646–652. [Google Scholar] [CrossRef]

- SasView. Available online: http://www.sasview.org (accessed on 25 May 2023).

- Ma, X.; Wang, Z.; Tong, X.; Du, X.; Li, T.; Liu, R.; Liu, Y.; Chen, D. Spinodal decomposition of precipitation hardening Fe-17Cr-4Ni-4Cu stainless steel at 475 °C. Mater. Tehnol. 2022, 56, 336. [Google Scholar] [CrossRef]

- Primig, S.; Stechauner, G.; Kozeschnik, E. Early Stages of Cu Precipitation in 15-5 PH Maraging Steel Revisited—Part I: Experimental Analysis. Steel Res. Int. 2017, 88, 1600084. [Google Scholar] [CrossRef]

- Habibi Bajguirani, H.R. The Effect of Ageing upon the Microstructure and Mechanical Properties of Type 15-5 PH Stainless Steel. Mater. Sci. Eng. A 2002, 338, 142–159. [Google Scholar] [CrossRef]

- Ratel, N.; Demé, B.; Bastie, P.; Caron, P. In Situ SANS Investigation of the Kinetics of Rafting of Γ′ Precipitates in a Fourth-Generation Single-Crystal Nickel-Based Superalloy. Scr. Mater. 2008, 59, 1167–1170. [Google Scholar] [CrossRef]

- Véron, M.; Bastie, P. Strain Induced Directional Coarsening in Nickel Based Superalloys: Investigation on Kinetics Using the Small Angle Neutron Scattering (SANS) Technique. Acta Mater. 1997, 45, 3277–3282. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | Cu | Nb |

|---|---|---|---|---|---|---|---|---|---|

| Wt/% | <0.07 | <1 | <1 | <0.003 | <0.003 | 15–17 | 3–5 | 3–5 | 0.15–0.45 |

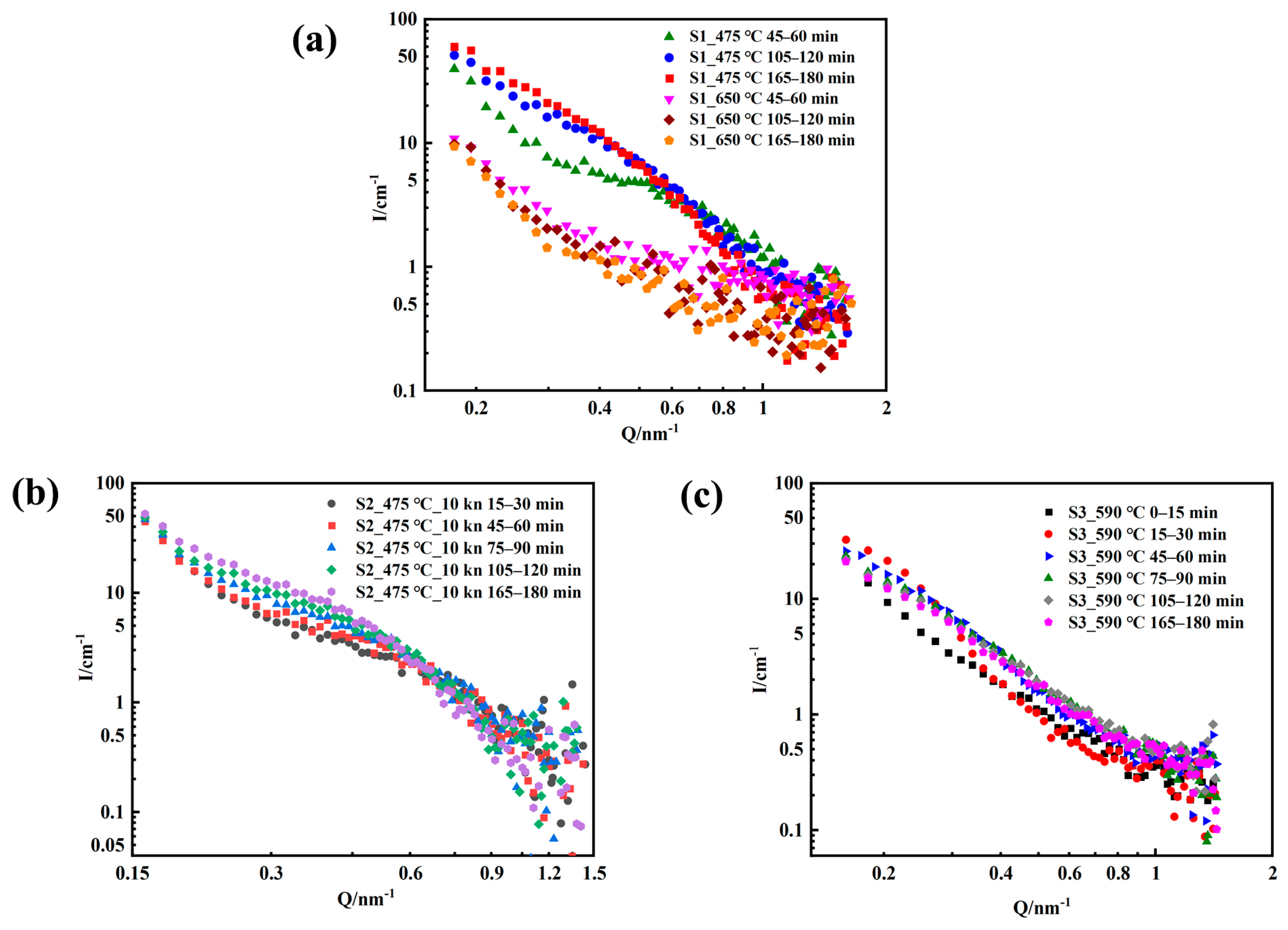

| No. | Temperature (°C) | Tensile (Kn) | Time (h) |

|---|---|---|---|

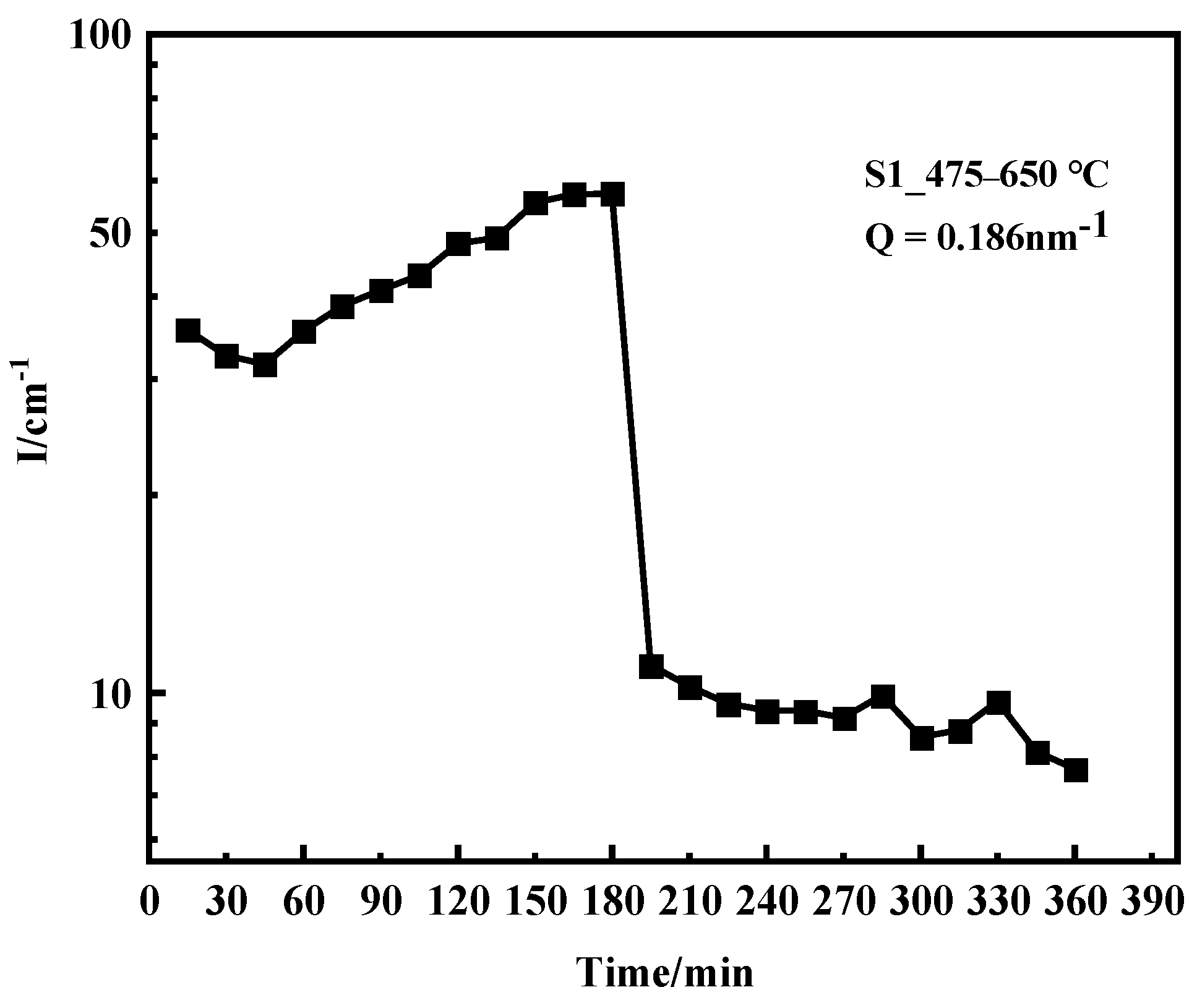

| S1 | 475, 650 | 0 | 6 (475 °C—3 h, 650 °C—3 h) |

| S2 | 475 | 10 | 3 |

| S3 | 590 | 0 | 3 |

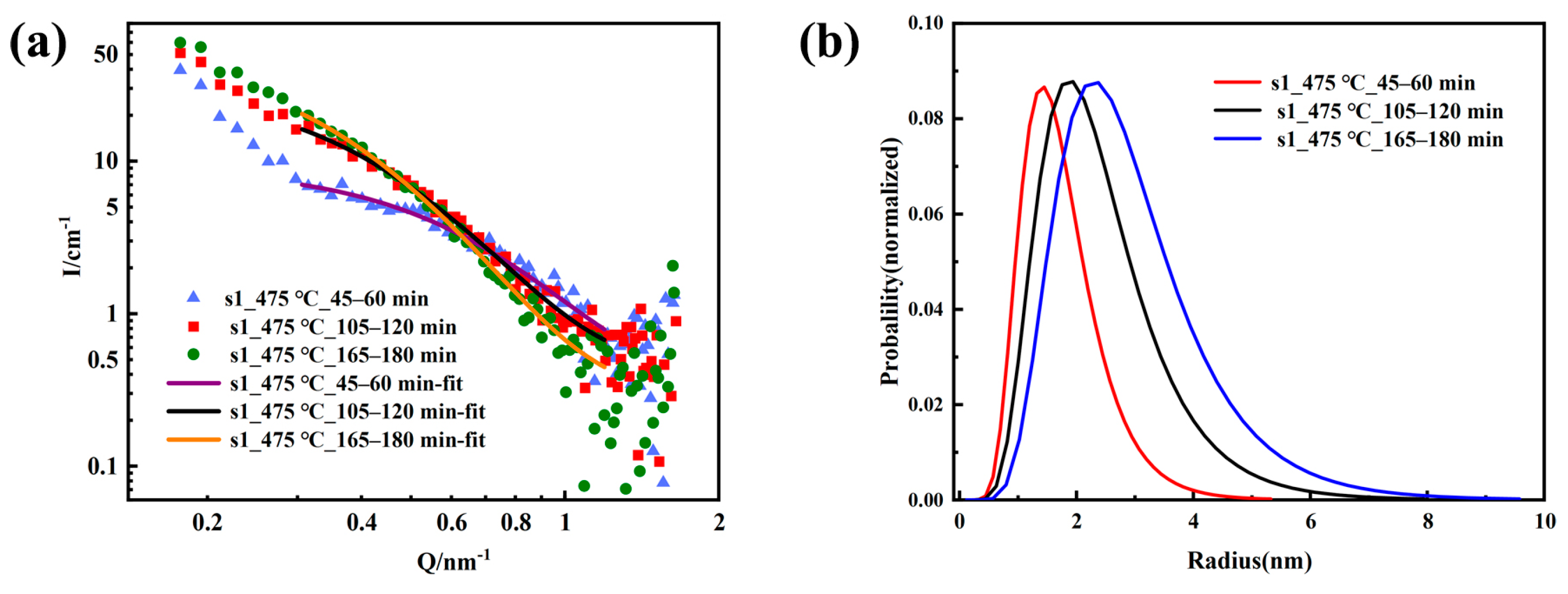

| No. | Model | Q Range/nm−1 | Size/nm | Polydispersity Ratio |

|---|---|---|---|---|

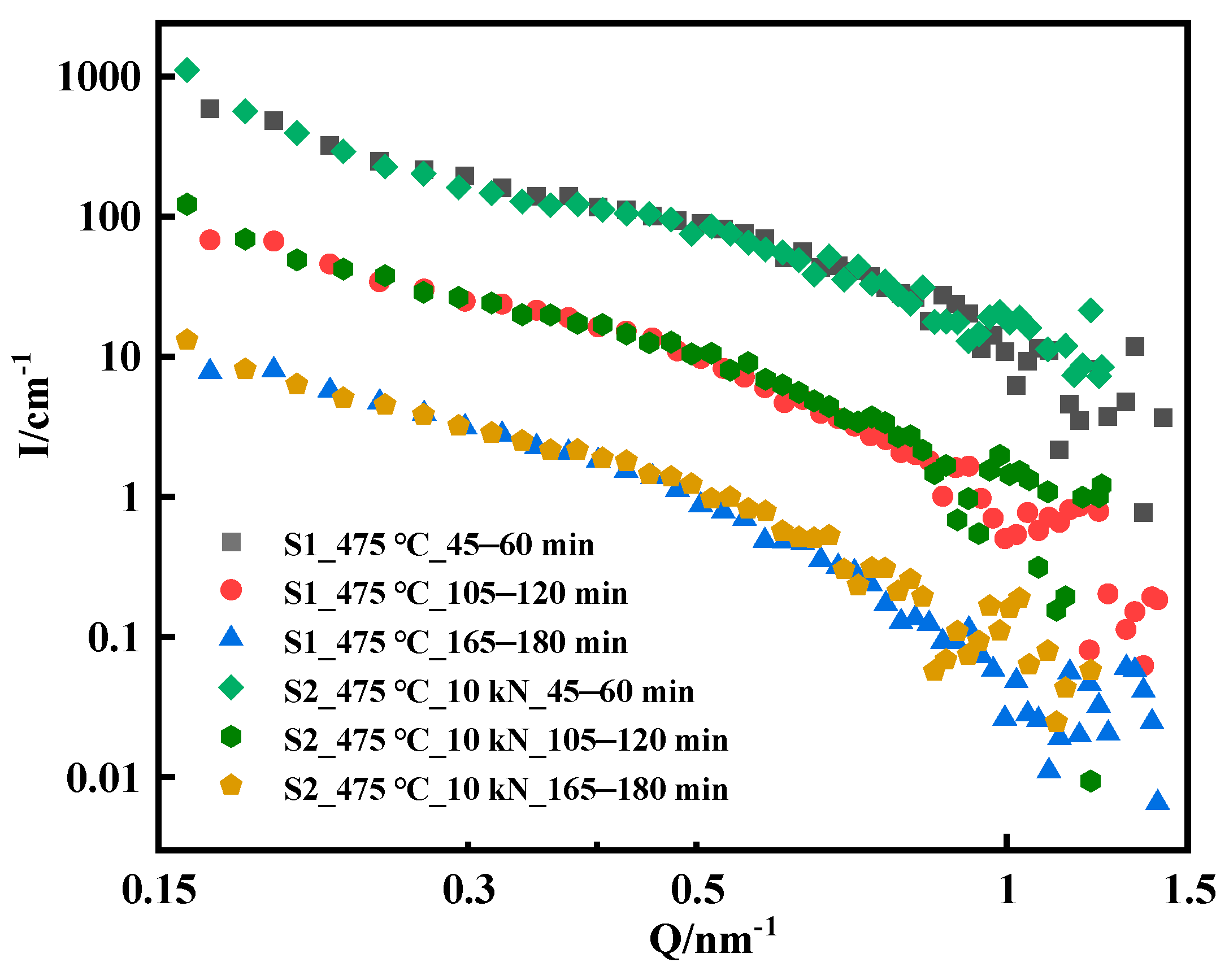

| S1_45–60 min | Sphere | 0.3–1.2 | R = 1.63 | 0.38 |

| S1_105–120 min | Sphere | 0.3–1.2 | R = 2.22 | 0.41 |

| S1_165–180 min | Sphere | 0.3–1.2 | R = 2.71 | 0.41 |

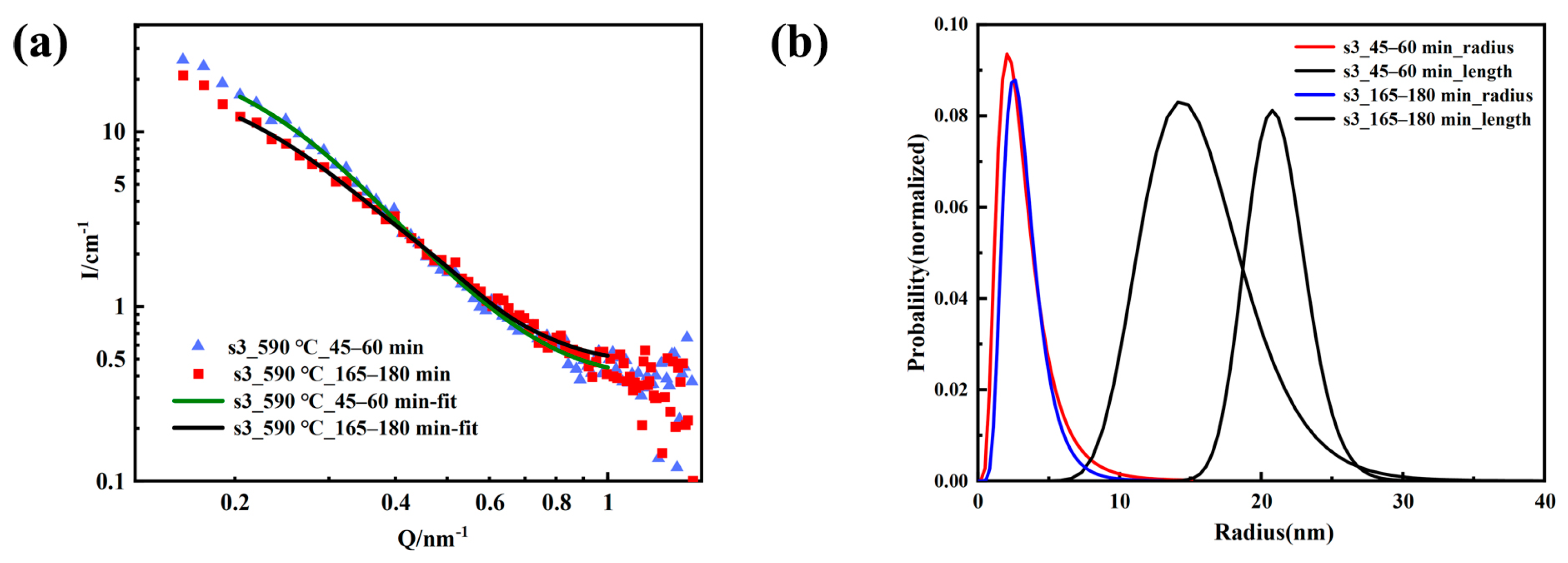

| No. | Model | Q Range/nm−1 | Size/nm | Polydispersity Ratio |

|---|---|---|---|---|

| S3_45–60 min | Cylinder | 0.2–1 | R = 2.83 L = 15.24 | R~0.54 L~0.24 |

| S3_165–180 min | Cylinder | 0.2–1 | R = 3.01 L = 21.00 | R~0.42 L~0.10 |

| No. | Model | Q Range/nm−1 | Size/nm | Polydispersity Ratio |

|---|---|---|---|---|

| S1_165–180 min | Sphere | 0.3–0.8 | R = 2.71 | 0.41 |

| S2_165–180 min | Sphere | 0.3–0.8 | R = 2.82 | 0.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, S.; Wang, Z.; Li, T.; Chen, Z.; Du, X.; Liu, Y.; Chen, D.; Sun, K.; Liu, R.; Bai, B.; et al. In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering. Materials 2023, 16, 5583. https://doi.org/10.3390/ma16165583

Yan S, Wang Z, Li T, Chen Z, Du X, Liu Y, Chen D, Sun K, Liu R, Bai B, et al. In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering. Materials. 2023; 16(16):5583. https://doi.org/10.3390/ma16165583

Chicago/Turabian StyleYan, Shibo, Zijun Wang, Tianfu Li, Zhong Chen, Xiaoming Du, Yuntao Liu, Dongfeng Chen, Kai Sun, Rongdeng Liu, Bing Bai, and et al. 2023. "In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering" Materials 16, no. 16: 5583. https://doi.org/10.3390/ma16165583

APA StyleYan, S., Wang, Z., Li, T., Chen, Z., Du, X., Liu, Y., Chen, D., Sun, K., Liu, R., Bai, B., He, X., Liu, K., & Wang, S. (2023). In Situ Characterization of 17-4PH Stainless Steel by Small-Angle Neutron Scattering. Materials, 16(16), 5583. https://doi.org/10.3390/ma16165583