Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste

Abstract

:1. Introduction

2. Purpose of Investigation

3. Investigational Examination Set-Up

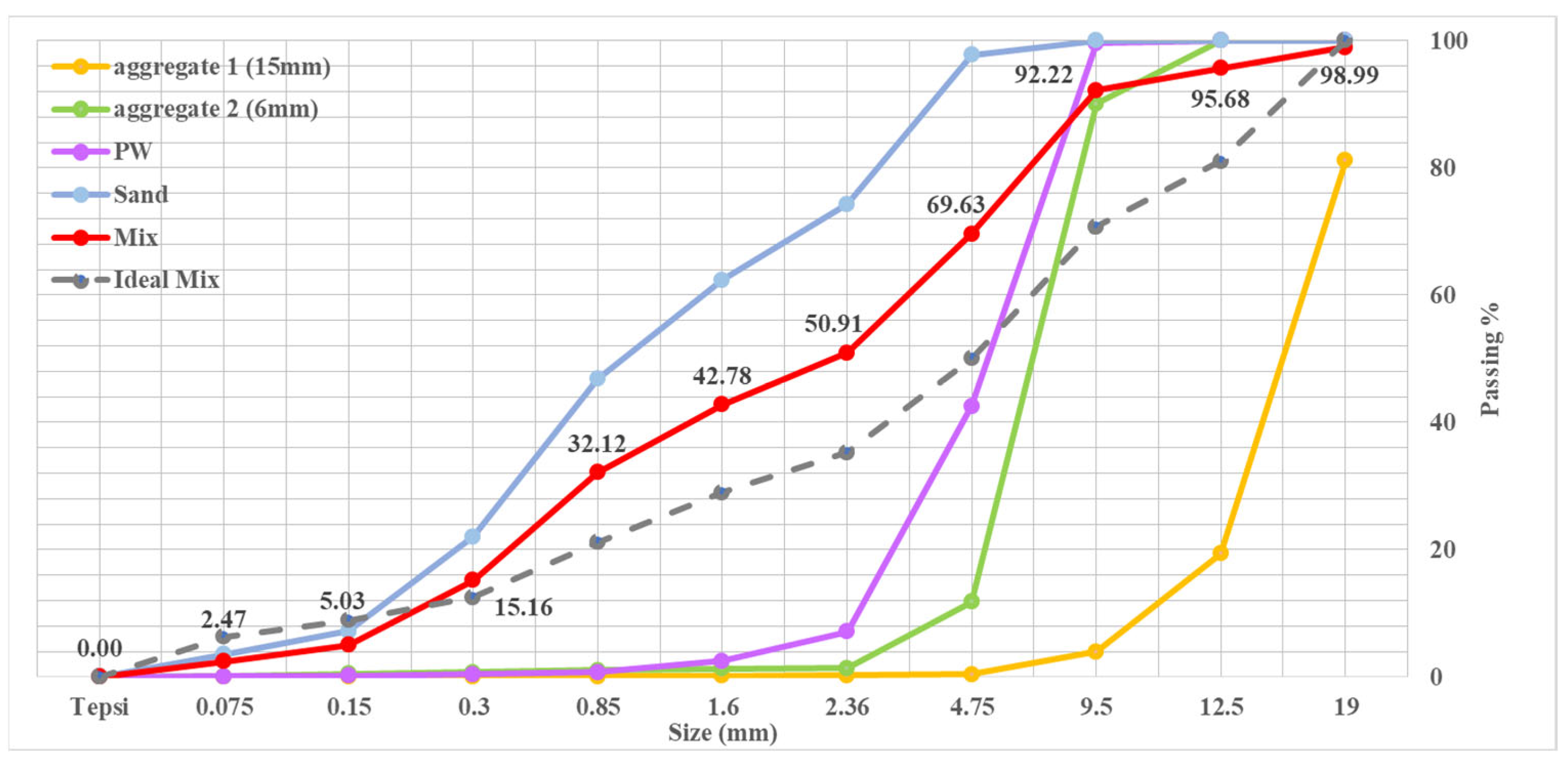

3.1. Examination of Material Properties

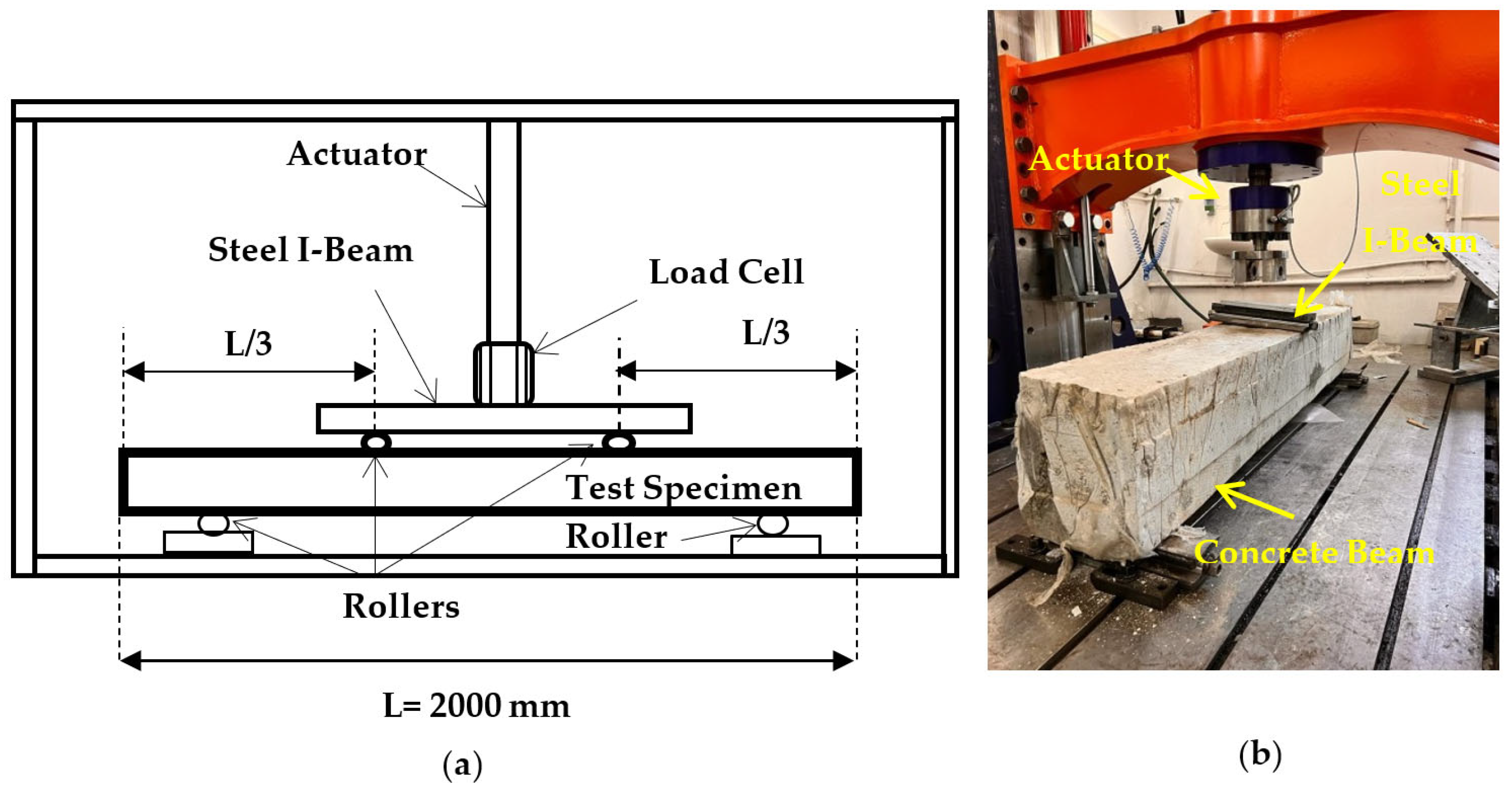

3.2. Investigational Set-Up

4. Investigational Test Results and Discussion

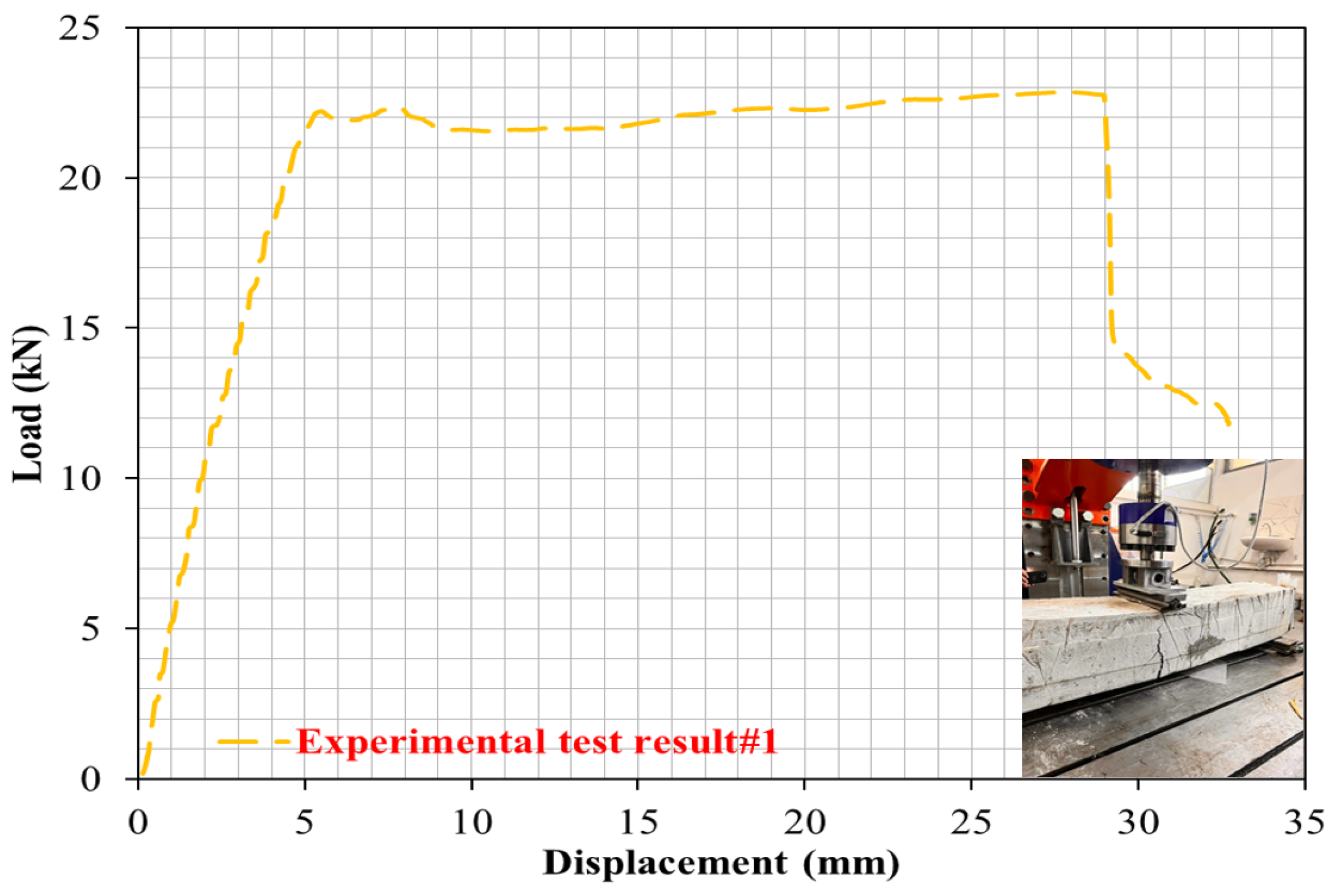

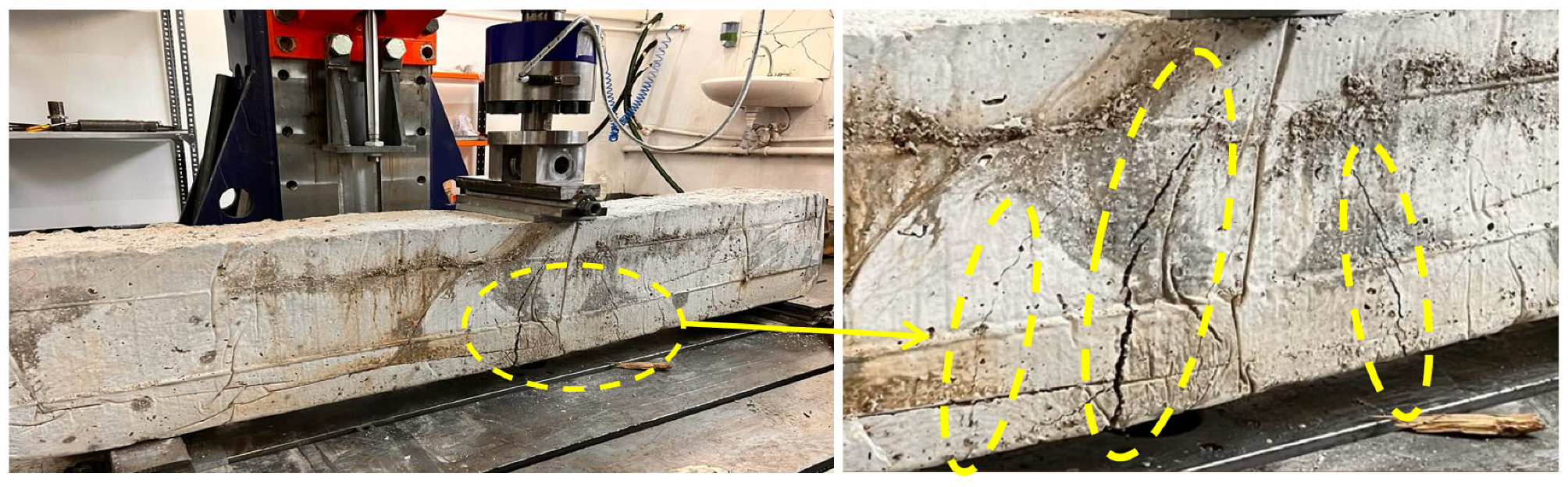

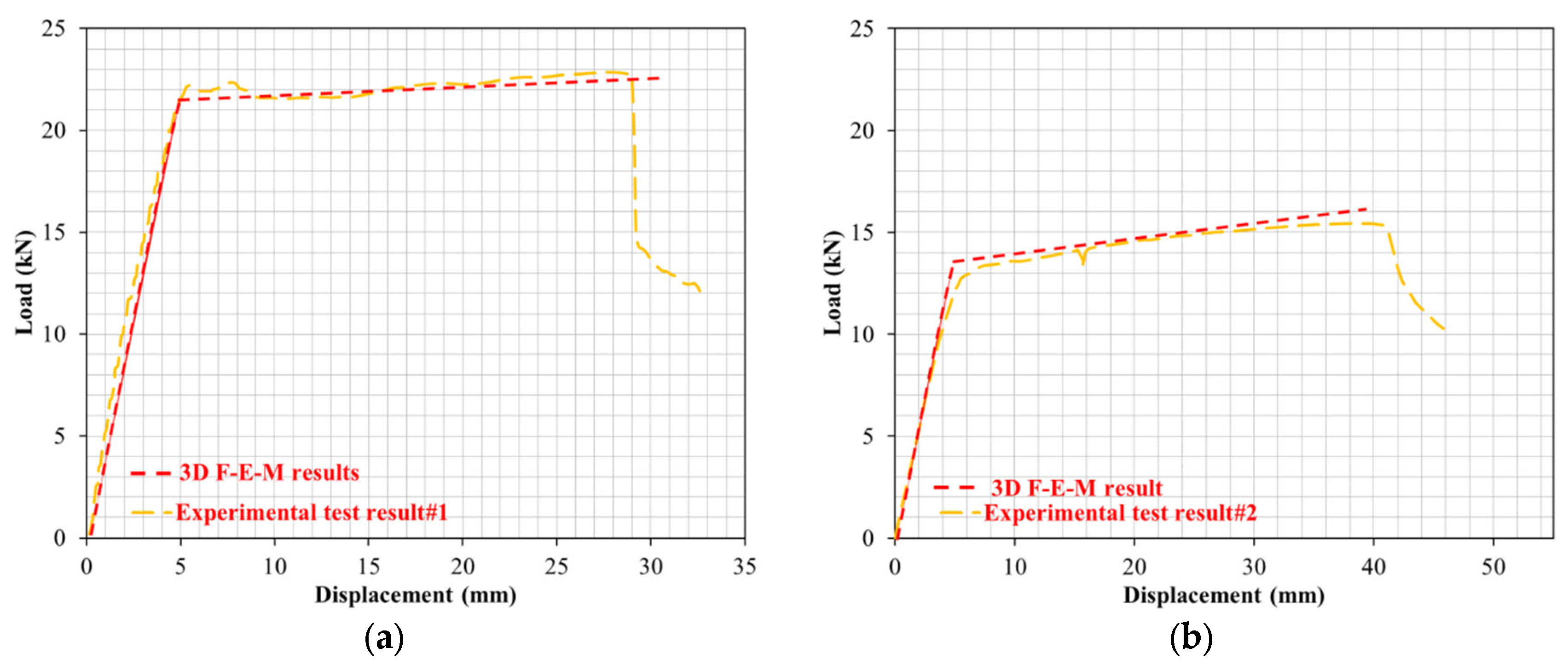

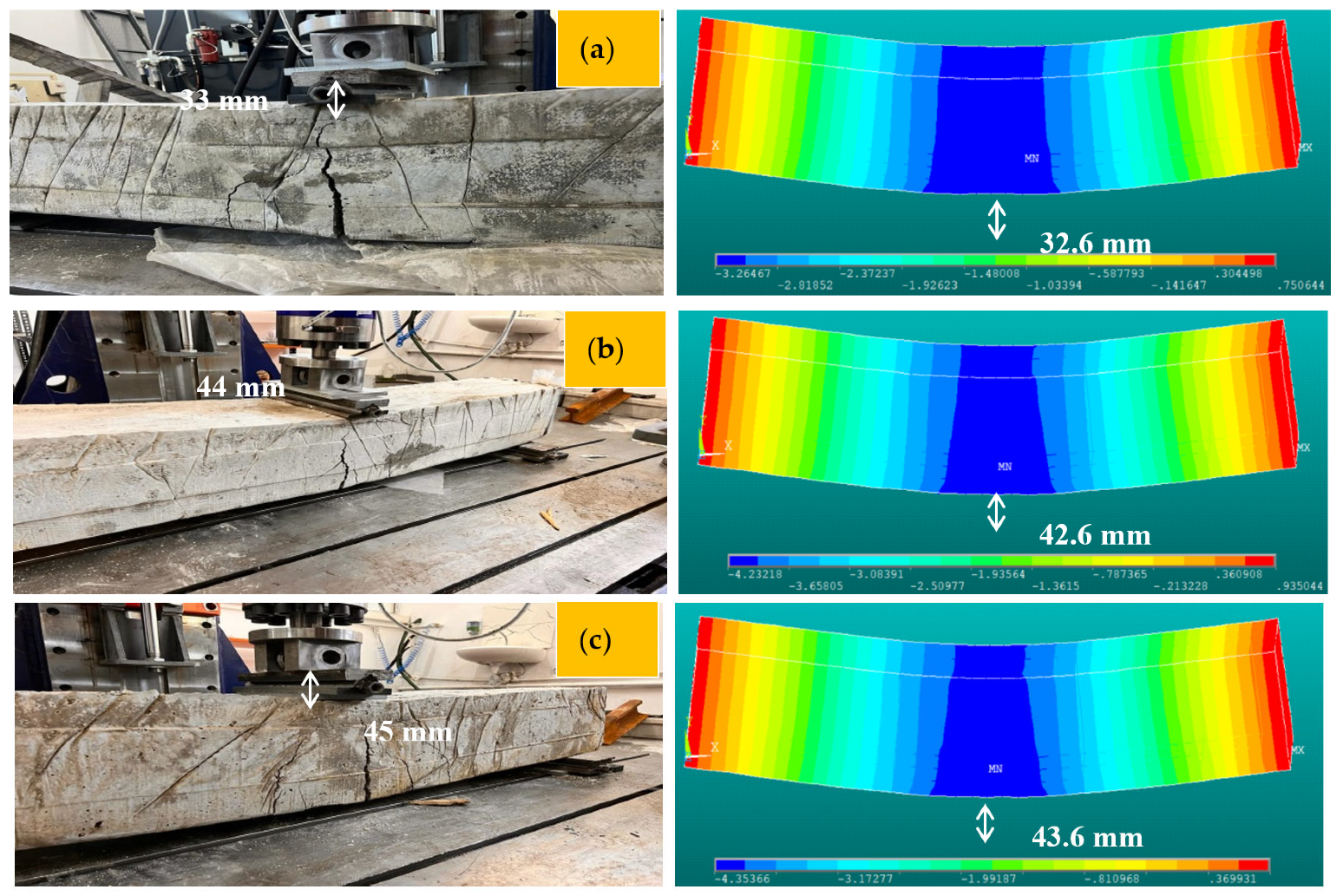

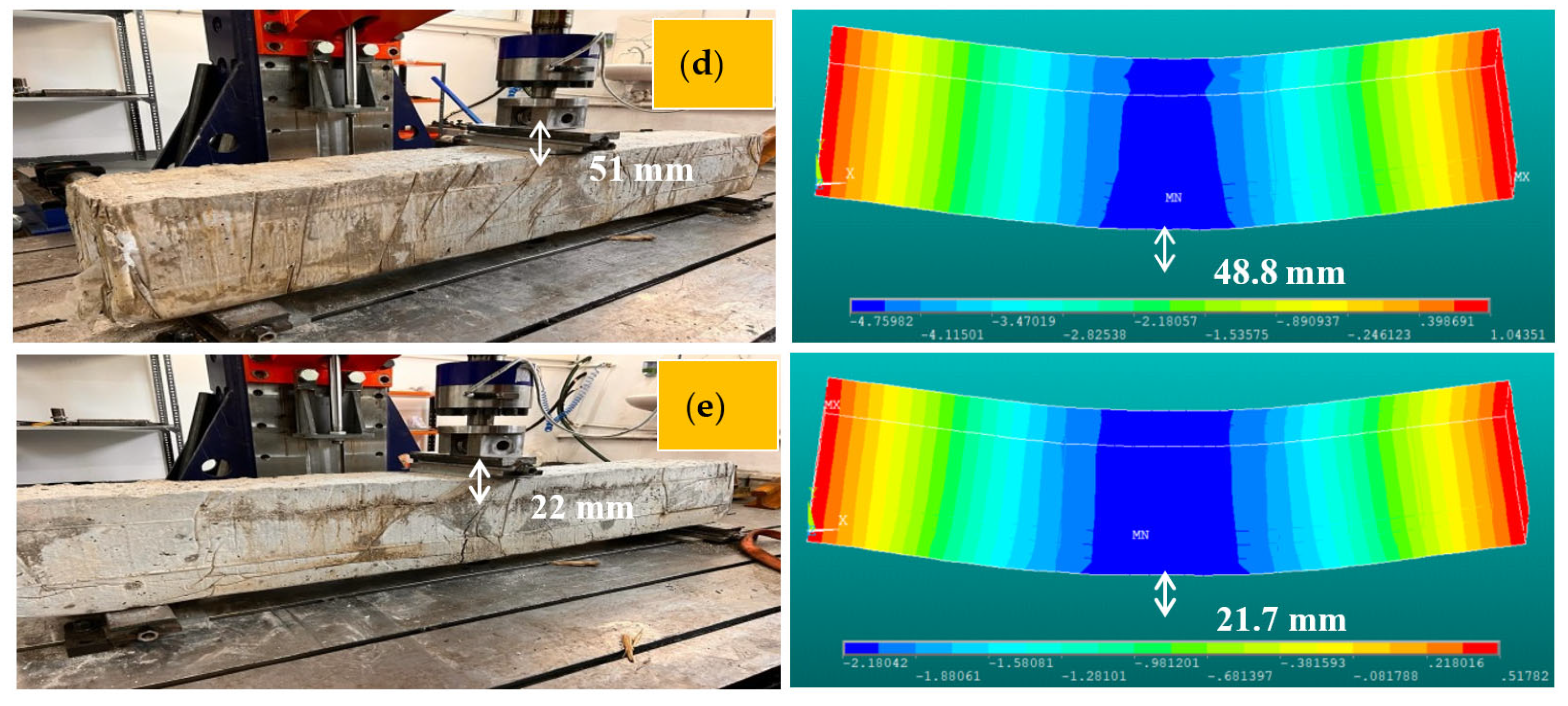

4.1. Case 1: Cracking and Deformation Performance of R-C-B without Plastic Waste

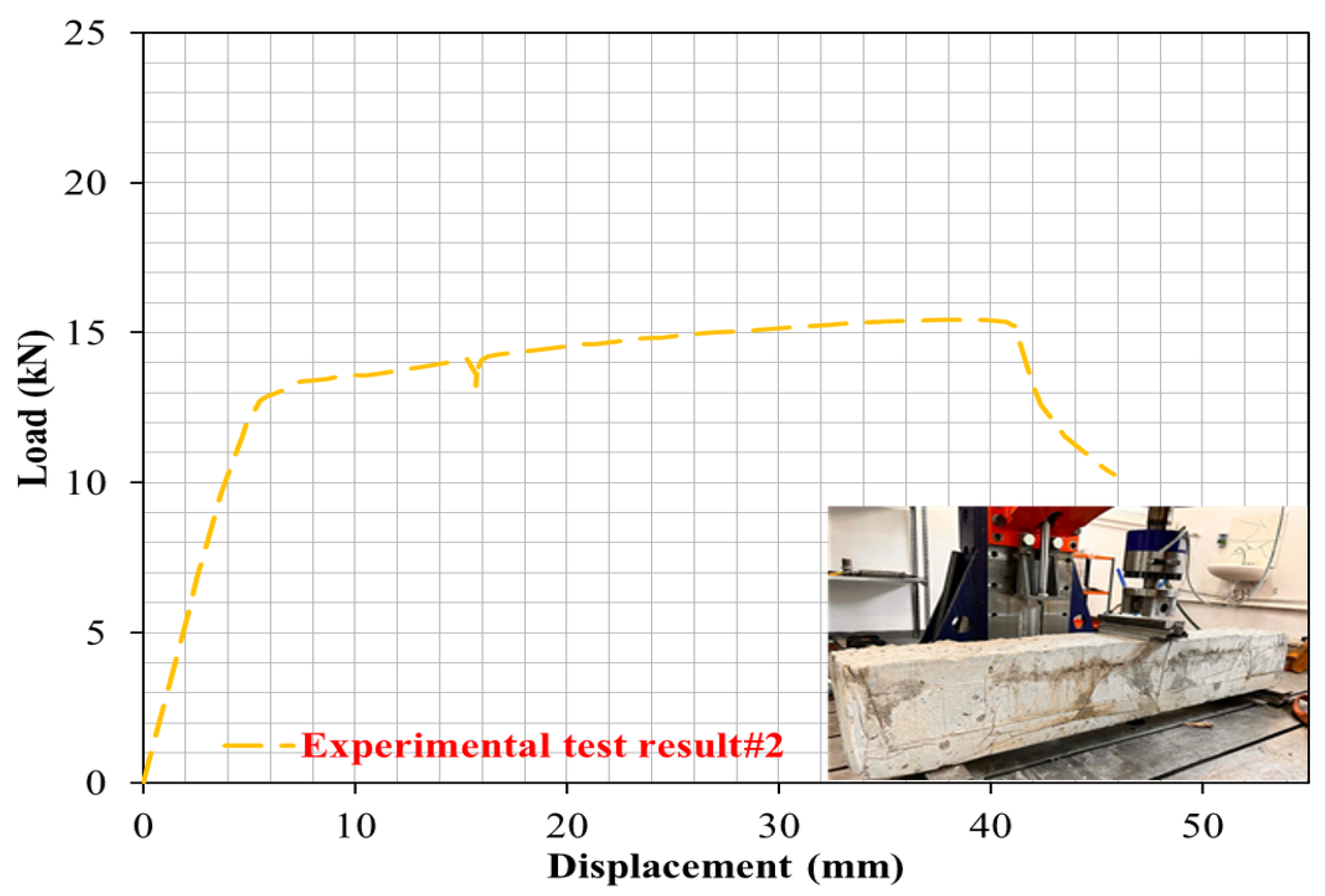

4.2. Case 2: Cracking and Deformation Performance of R-C-B Including 5% Plastic Waste

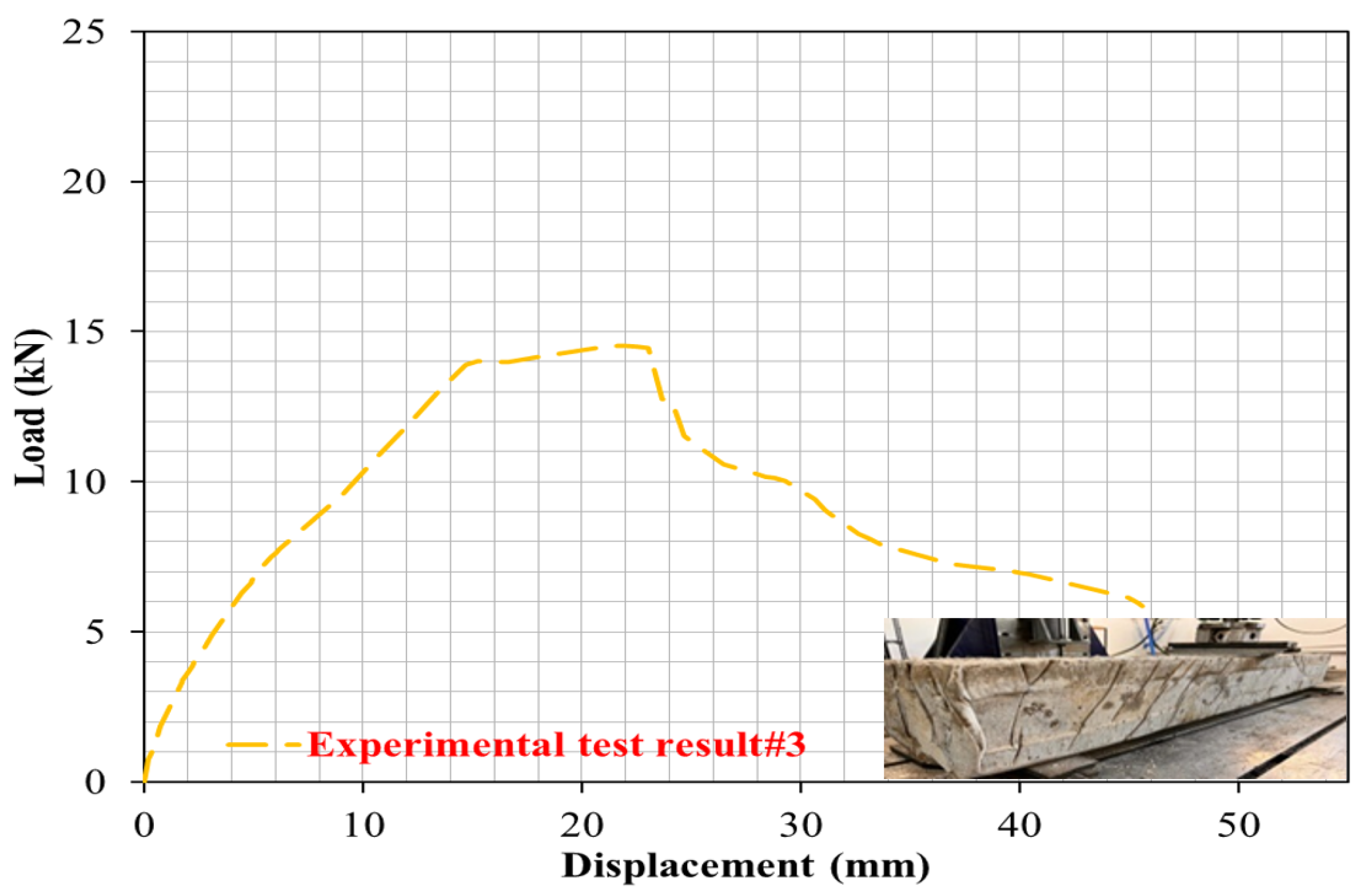

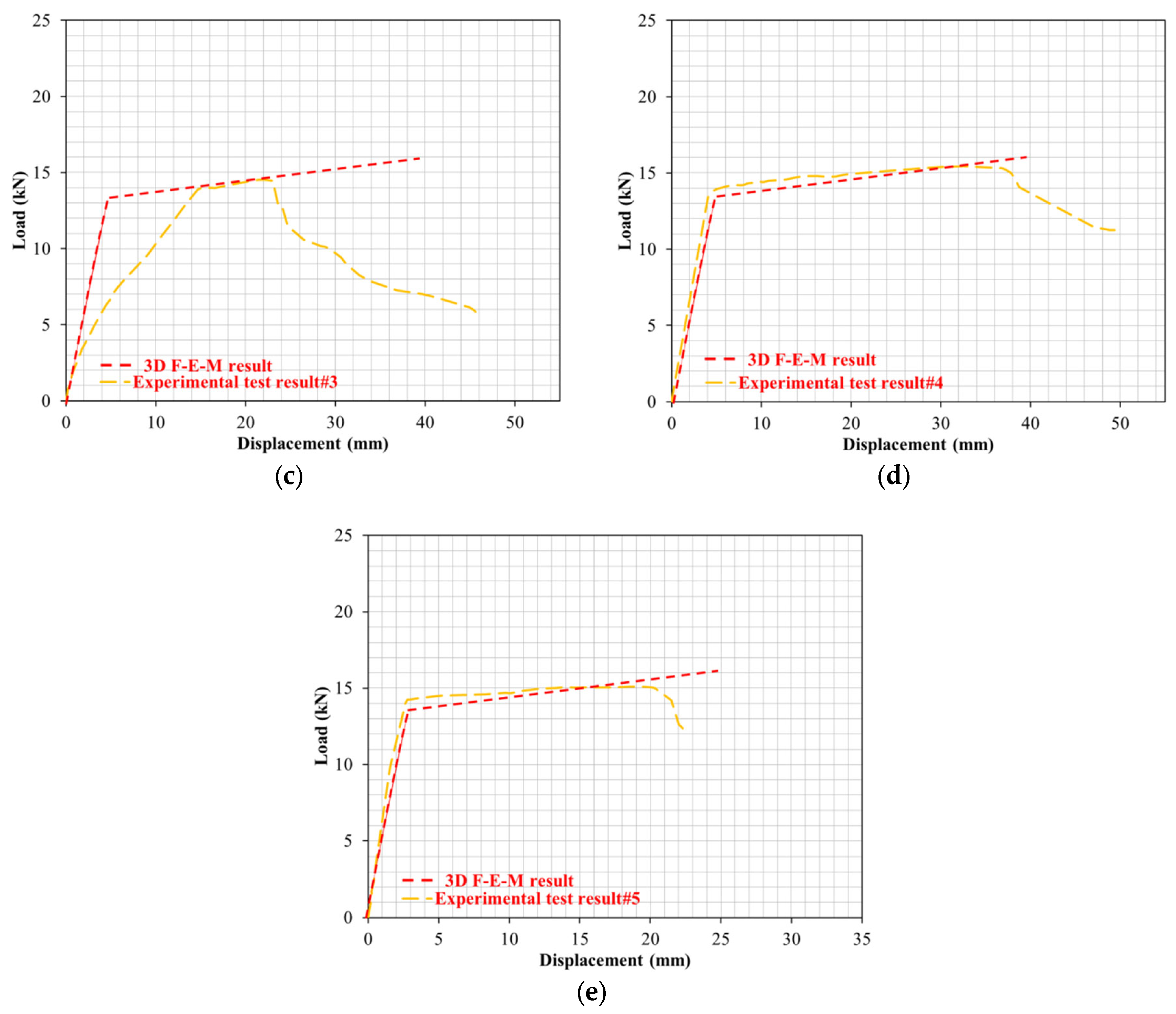

4.3. Case 3: Cracking and Deformation Performance of R-C-B Including 15% Plastic Waste

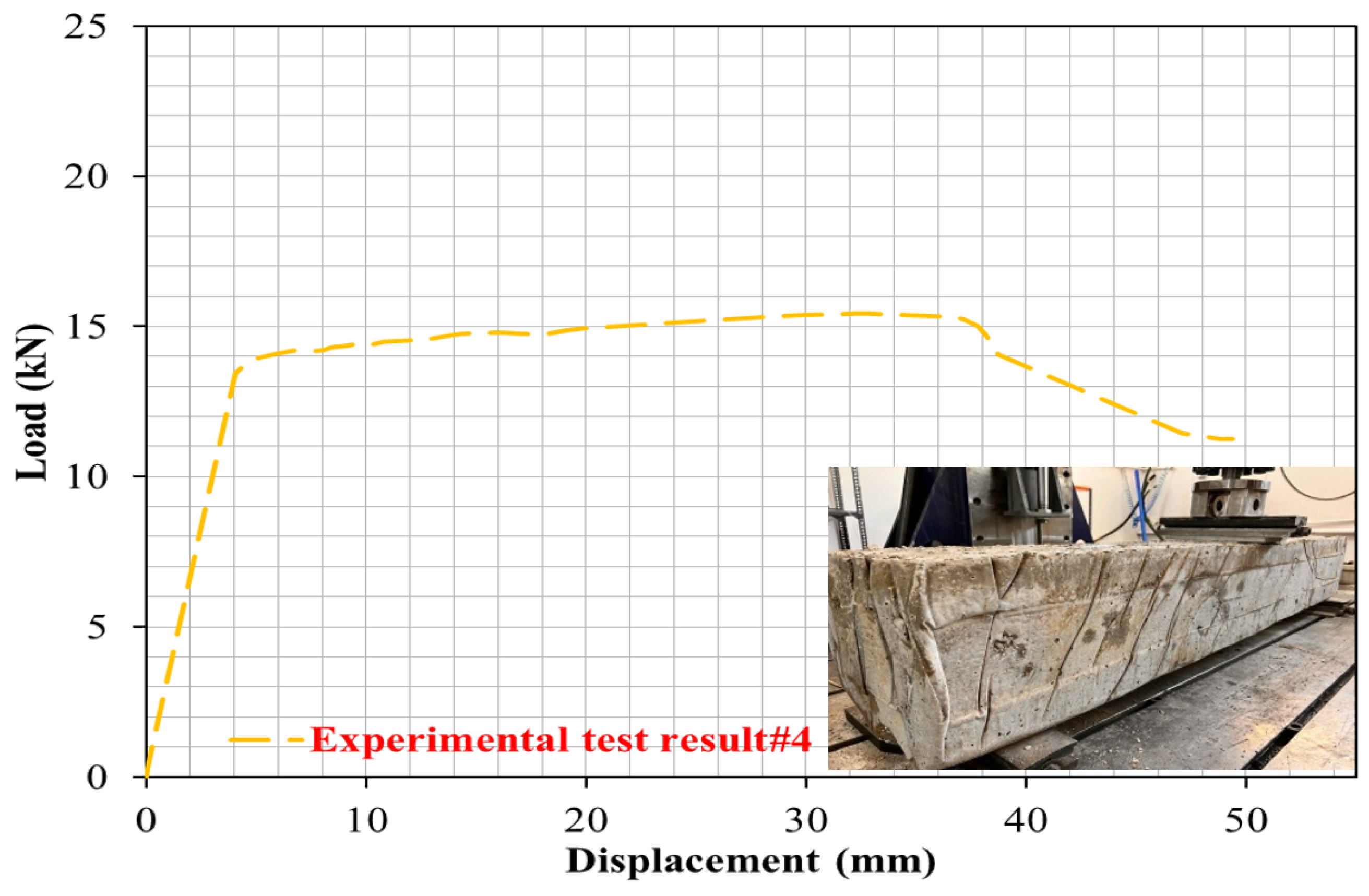

4.4. Case 4: Cracking and Deformation Performance of R-C-B Including 30% Plastic Waste

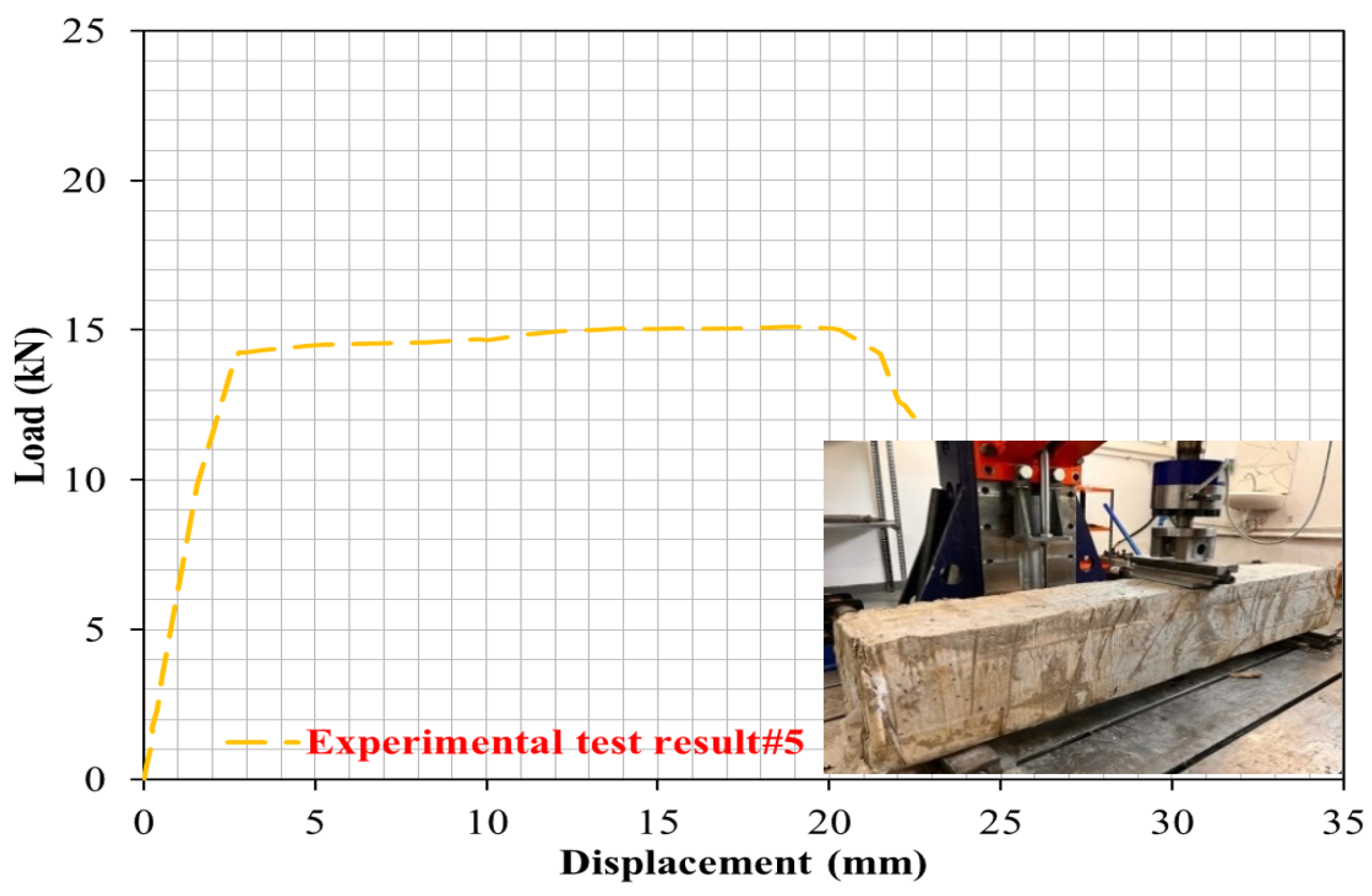

4.5. Case 5: Cracking and Deformation Performance of R-C-B Including 45% Plastic Waste

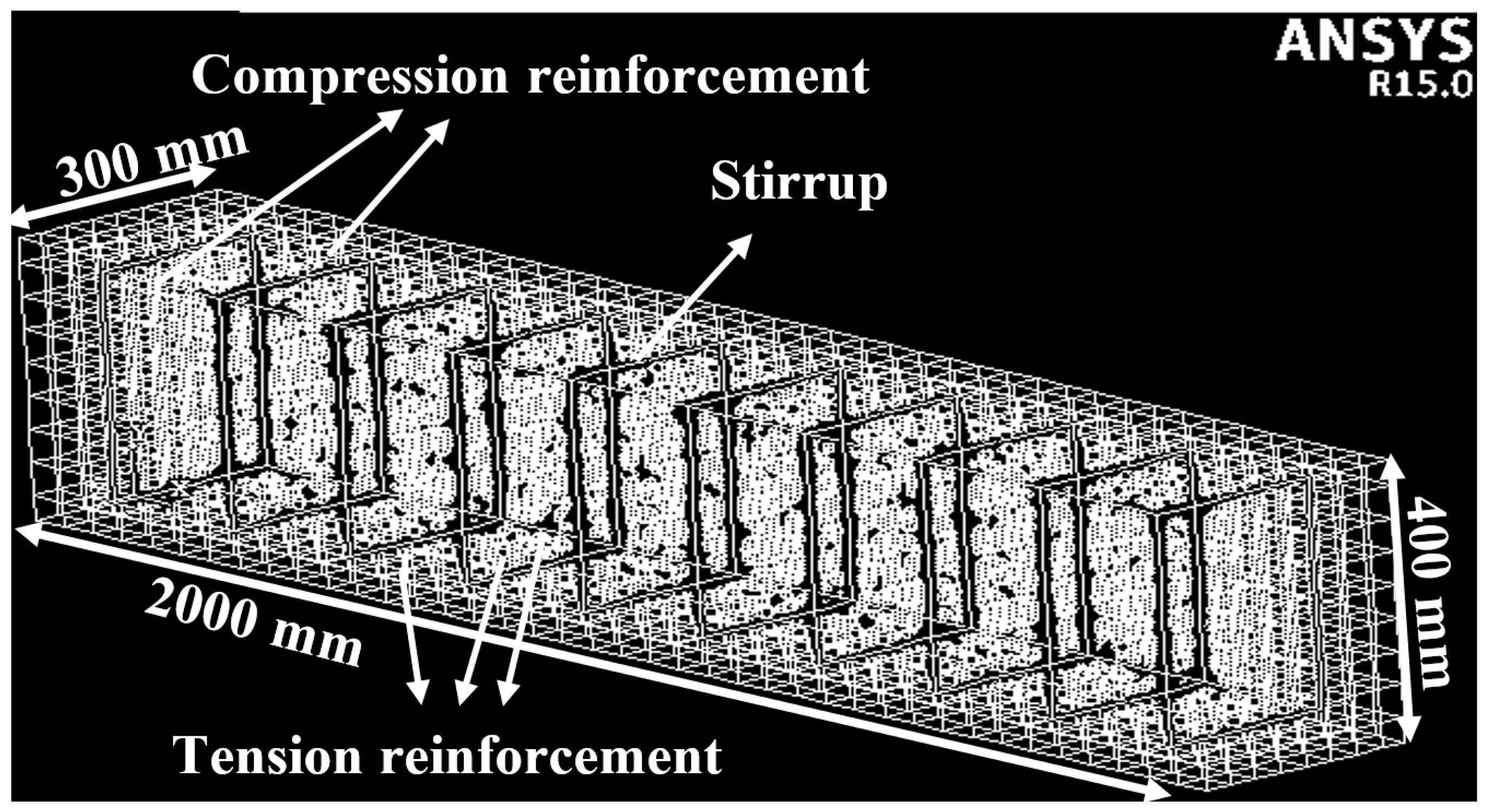

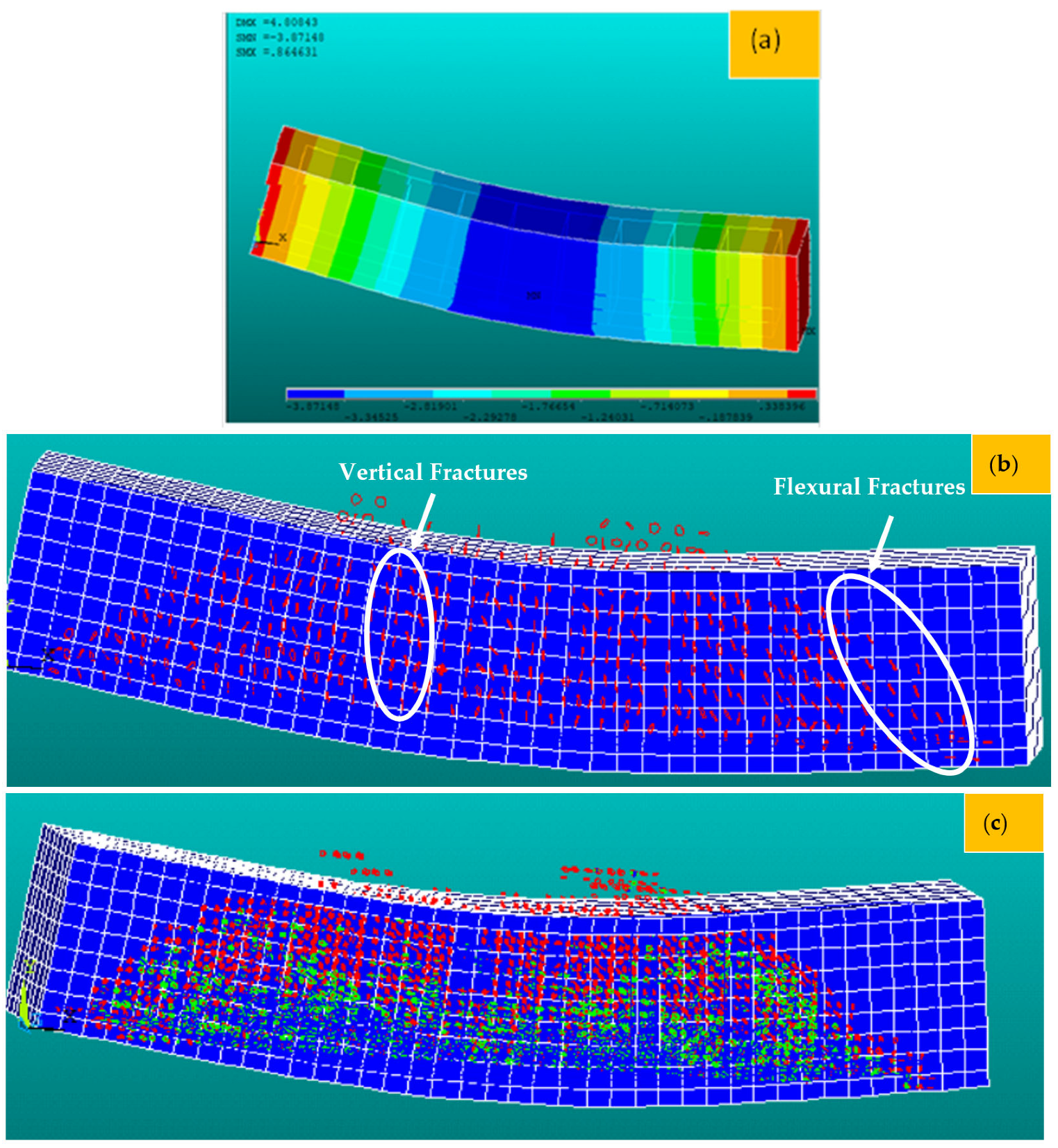

5. Three-Dimensional Finite Element Model (F-E-M) of R-C-Bs

6. Three-Dimensional F-E-M Results

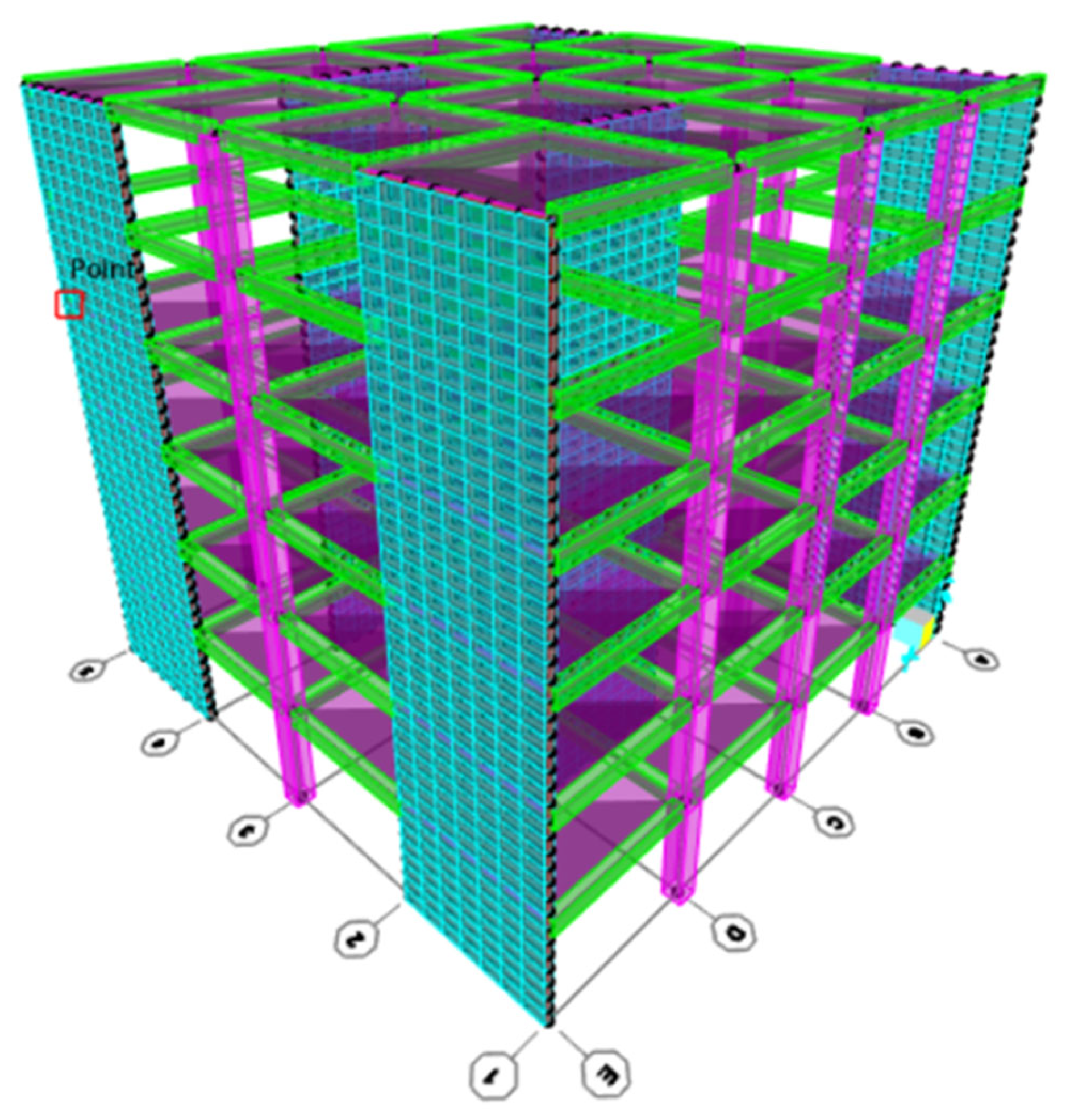

7. Example Study

8. Conclusions

- As stated by the slump test results, it was found that as the PW proportions in the concrete combination increased with a reduction in the compressive strength value of concrete after the 15% proportion.

- Based on the investigational test results, the maximum load-carrying value in the R-C-Bs reduced as the percentage of PW in the concrete combination increased. On the other hand, it was found that the maximum deformation performance of the R-C-Bs increased as the percentage of PW in the concrete combination increased.

- The percentage of PW in the concrete significantly affected the cracking performance of the R-C-Bs. Noteworthy perpendicular and deformation cracking were both seen in the R-C-Bs depending on the percentage of plastic waste.

- The F-E-M and experimental results show small ruptures with very similar formations. This suggests that F-E-M might be an excellent alternative to destructive lab experiments that can create alterations in conclusions. F-E-M simulation could be successfully used to estimate the real performance of R-C-Bs.

- The weight of a concrete construction was considered in terms of its R-C-Bs and columns. Numerous percentages of PW were chosen within the R-C-Bs and columns, and the influence of these on the construction’s forces was thoroughly defined. The forces on the construction decreased as the percentages of PW increased. The total shear forces on the constructions containing 0% and 30% PW were 853.6 and 801.07 kN, respectively.

- Considering the analyses and modeling results and the environmental effects of plastic materials, PW granules can be considered for use in concrete. In this way, environmental sustainability can be improved by preventing PW pollution. As a result of our analysis, we can state that PW granules partially contribute to concrete strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Wen, Z. The consumption and recycling collection system of PET bottles: A case study of Beijing, China. Waste Manag. 2013, 34, 987–998. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2007, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Haktanir, T.; Ari, K.; Altun, F.; Karahan, O. A comparative experimental investigation of concrete, reinforced-concrete and steel-fibre concrete pipes under three-edge-bearing test. Constr. Build. Mater. 2007, 21, 1702–1708. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.A.; Najafi, M.H. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Snelson, D.G.; Kinuthia, J.M. Resistance of mortar containing unprocessed pulverised fuel ash (PFA) to sulphate attack. Cem. Concr. Compos. 2010, 32, 523–531. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Park, J.J.; Kim, S.W.; Yoo, Y.S. Early age setting, shrinkage and tensile characteristics of ultra high-performance fiber reinforced concrete. Constr. Build. Mater. 2013, 41, 427–438. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Min, K.H.; Lee, J.H.; Yoon, Y.S. Shrinkage and cracking of restrained ultrahigh-performance fiber-reinforced concrete slabs at early age. Constr. Build. Mater. 2014, 73, 357–365. [Google Scholar] [CrossRef]

- Ramadevi, K.; Manju, R. Experimental investigation on the properties of concrete with plastic PET (bottle) fibre as fine aggregates. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 42–46. [Google Scholar]

- Baldenebro-Lopez, F.J.; Castorena-Gonzalez, J.H.; Velazquez-Dimas, J.I.; Ledezma-Sillas, J.E.; Herrera-Ramirez, J.M. Experimental study, simulation and model predictions of recycled PET strip-reinforced concrete flexion members. Int. J. Eng. Res. Appl. 2014, 4, 35–40. [Google Scholar]

- Nibudey, R.N.; Nagarnaik, P.B.; Parbat, D.K.; Pande, A.M. Shear strength of waste plastic (PET) fiber reinforced concrete. Int. J. Mod. Tre. Eng. Res. 2015, 2, 58–65. [Google Scholar]

- Jahami, A.; Khatib, J.; Baalbaki, O.; Sonebi, M. Prediction of Deflection in Reinforced Concrete Beams Containing Plastic Waste. In Proceedings of the 3rd International Conference on Bio-Based Building Materials, Belfast, UK, 26–28 June 2019. [Google Scholar] [CrossRef]

- Bischoff, P.H. Reevaluation of Deflection Prediction for Concrete Beams Reinforced with Steel and Fiber Reinforced Polymer Bars. J. Struct. Eng. 2005, 5, 752–762. [Google Scholar] [CrossRef]

- Bischoff, P.H. Rational Model for Calculating Deflection of Reinforced Concrete Beams and Slabs. Can. J. Civ. Eng. 2007, 34, 992–1002. [Google Scholar] [CrossRef]

- Branson, D.E. Instantaneous and Time Dependent Deflections of Simple and Continuous Reinforced Concrete Beams; Alabama Highway Department, Bureau of Public Roads: Aubur, AL, USA, 1965; pp. 1–78. [Google Scholar]

- Khatiba, J.; Jahamib, A.; Elkordib, A.; Baalbak, O. Structural performance of reinforced concrete beams containing plastic waste caps. Mag. Civ. Eng. 2019, 91, 73–79. [Google Scholar]

- Diana, A.I.N.; Fansuri, S.; Fatoni, A.F. An Experimental Study of Plastic Waste as Fine Aggregate Substitute for Environmentally Friendly Concrete. Adv. Technol. Innov. 2021, 6, 179–190. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.A.; AL-Shareef, N.H.; Jaber, H.; Hassan, R.F.; Hussein, H.H.; Al-Salim, N.H. Experimental investigation of flexural and shear behaviors of reinforced concrete beam containing fine plastic waste aggregates. Structures 2022, 43, 834–846. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and fracture characteristics of self-compacting concretes containing different percentage of plastic waste powder. Constr. Build Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Rahim, A.A.F. Experimental behavior and analysis of high strength concrete beams reinforced with PET waste fiber. Constr. Build Mater. 2020, 244, 118350. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Con. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Al-Hadithi, A.I.; Abbas, M.A. The effects of adding waste plastic fibers on the mechanical properties and shear strength of reinforced concrete beams. Iraq J. Civ. Eng. 2018, 12, 110–124. [Google Scholar] [CrossRef]

- Nibudey, R.N.; Nagarnaik, P.B.; Parbat, D.K.; Pande, A.M. Strength and fracture properties of post consumed waste plastic fiber reinforced concrete. Int. J. Civ. Struct. Environ. Infrastruct. Eng. Res. Dev. 2013, 3, 9–16. [Google Scholar]

- Aziz, K.A.; Kuhair, H.M. Mechanical properties for ordinary concrete containing waste plastic fibers. Iraq J. Civ. Eng. 2017, 11, 33–44. [Google Scholar] [CrossRef]

- Karalar, M. Experimental and Numerical Investigation on Flexural and Crack Failure of Reinforced Concrete Beams with Bottom Ash and Fly Ash. Iran J. Sci. Technol Trans. Civ. Eng. 2020, 44, 331–354. [Google Scholar] [CrossRef]

- Özkiliç, Y.O.; Zeybek, Ö.; Bahrami, A.; Çelik, A.I.; Mydin, M.A.O.; Karalar, M.; Roy, K.; Jagadesh, P. Optimum Usage of Waste Marble Powder to Reduce the Use of Cement toward Eco-friendly Concrete. J. Mater. Res. Technol. 2023, 25, 4819. [Google Scholar] [CrossRef]

- Başaran, B.; Aksoylu, C.; Özkılıç, Y.O.; Karalar, M.; Hakamy, A. Shear behaviour of reinforced concrete beams utilizing waste marble powder. Structures 2023, 54, 1090–1100. [Google Scholar] [CrossRef]

- Çelik, A.I.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, M.A.O.; Alomayri, T.; Özkiliç, Y.O. Use of Waste Glass Powder toward more Sustainable Geopolymer Concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Özkiliç, Y.O.; Başaran, B.; Aksoylu, C.; Karalar, M.; Martins, C.H. Mechanical Behavior in terms of Shear and Bending Performance of Reinforced Concrete Beam Using Waste Fire Clay as Replacement of Aggregate. Case Stud. Constr. Mater. 2023, 18, e02104. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri, M.M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M. Flexural Behavior of Reinforced Concrete Beams using Waste Marble Powder towards Application of Sustainable Concrete. Front. Mater. 2022, 9, 1068791. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkılıç, Y.O.; Sabri, M.M.S. Use of Recycled Coal Bottom Ash in Reinforced Concrete Beams as Replacement for Aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- ANSYS, version 19; ANSYS Inc.: Canonsburg, PA, USA, 1998.

- SAP2000. Integrated Finite Elements Analysis and Design of Structures; Computers and Structures, Inc.: Berkeley, CA, USA, 2008. [Google Scholar]

- Koh, C.G.; Ang, K.K.; Zhang, L. Effects of repeated loading on creep deflection of reinforced concrete beams. Eng. Struct. 1997, 19, 2–18. [Google Scholar] [CrossRef]

- Sun, D.; Huang, C.; Cao, Z.; Wu, K.; Zhang, L. Reliability assessment of concrete under external sulfate attack. Case Stud. Constr. Mater. 2021, 15, e00690. [Google Scholar] [CrossRef]

- Sun, D.; Cao, Z.; Huang, C.; Wu, K.; De Schutter, G.; Zhang, L. Degradation of concrete in marine environment under coupled chloride and sulfate attack: A numerical and experimental study. Case Stud. Constr. Mater. 2022, 17, e01218. [Google Scholar] [CrossRef]

| Specimen Number | Statement |

|---|---|

| 1 | Reference concrete |

| 2 | 5% plastic waste |

| 3 | 15% plastic waste |

| 4 | 30% plastic waste |

| 5 | 45% plastic waste |

| Material | Reference | 5% Plastic Waste | 15% Plastic Waste | 30% Plastic Waste | 45% Plastic Waste |

|---|---|---|---|---|---|

| Cement (kg) | 415 | 415 | 415 | 415 | 415 |

| Sand (kg) | 850 | 805 | 720 | 595 | 470 |

| 15 mm lightweight aggregates (kg) | 67 | 67 | 67 | 67 | 67 |

| 6 mm lightweight aggregates (kg) | 333 | 333 | 333 | 333 | 333 |

| Water (kg) | 180 | 180 | 180 | 180 | 180 |

| PW granules (kg) | 0 | 15 | 45 | 90 | 135 |

| Superplasticizer (mL) | 2050 | 2050 | 2100 | 2300 | 2700 |

| Estimated density (kg) | 1845 | 1815 | 1760 | 1680 | 1600 |

| Components | Weight Per Unit of Volume (%) |

|---|---|

| Portland Cement Clinker | 45–64 |

| Limestone | 0–5 |

| Gypsum | 3–6 |

| Calcium Oxide | 0–5 |

| Magnesium Oxide | 0–5 |

| Natural Pozzolan | 36–55 |

| Specimen | Reference (MPa) | 5% (MPa) | 15% (MPa) | 30% (MPa) | 45% (MPa) |

|---|---|---|---|---|---|

| Specimen A | 40.3 | 41.5 | 42.4 | 33.4 | 29.7 |

| Specimen B | 39.6 | 40.8 | 41.6 | 31.6 | 28.5 |

| Specimen C | 40.1 | 43.01 | 39.44 | 28.9 | 30.9 |

| Average | 40 | 41.77 | 41.48 | 31.29 | 29.73 |

| R-C-Bs Including 0% | |||

|---|---|---|---|

| Modal Analysis Result | |||

| Section | Max. Shear Force (kN) | Section | Max. Moment Force (kN.M) |

| F279 | 853.6 | F248 | 2031.65 |

| Dead Load | |||

| Section | Max. Shear Force (kN) | Section | Max. Moment Force (kN.M) |

| F252 | 68.35 | F245 | 64.47 |

| R-C-Bs Including 30% | |||

|---|---|---|---|

| Modal Analysis Result | |||

| Section | Max. Shear Force (kN) | Section | Max. Moment Force (kN.M) |

| F279 | 801.07 | F248 | 1906.62 |

| Dead Load | |||

| Section | Max. Shear Force (kN) | Section | Max. Moment Force (kN.M) |

| F252 | 64.26 | F245 | 61.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korkut, F.; Karalar, M. Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste. Materials 2023, 16, 5538. https://doi.org/10.3390/ma16165538

Korkut F, Karalar M. Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste. Materials. 2023; 16(16):5538. https://doi.org/10.3390/ma16165538

Chicago/Turabian StyleKorkut, Fuat, and Memduh Karalar. 2023. "Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste" Materials 16, no. 16: 5538. https://doi.org/10.3390/ma16165538

APA StyleKorkut, F., & Karalar, M. (2023). Investigational and Numerical Examination on Bending Response of Reinforced Rubberized Concrete Beams Including Plastic Waste. Materials, 16(16), 5538. https://doi.org/10.3390/ma16165538