The Effect of Annealing on the Soft Magnetic Properties and Microstructure of Fe82Si2B13P1C3 Amorphous Iron Cores

Abstract

1. Introduction

2. Methods

- Annealing experiments:

- Magnetic field annealing (FA):

3. Results and Discussion

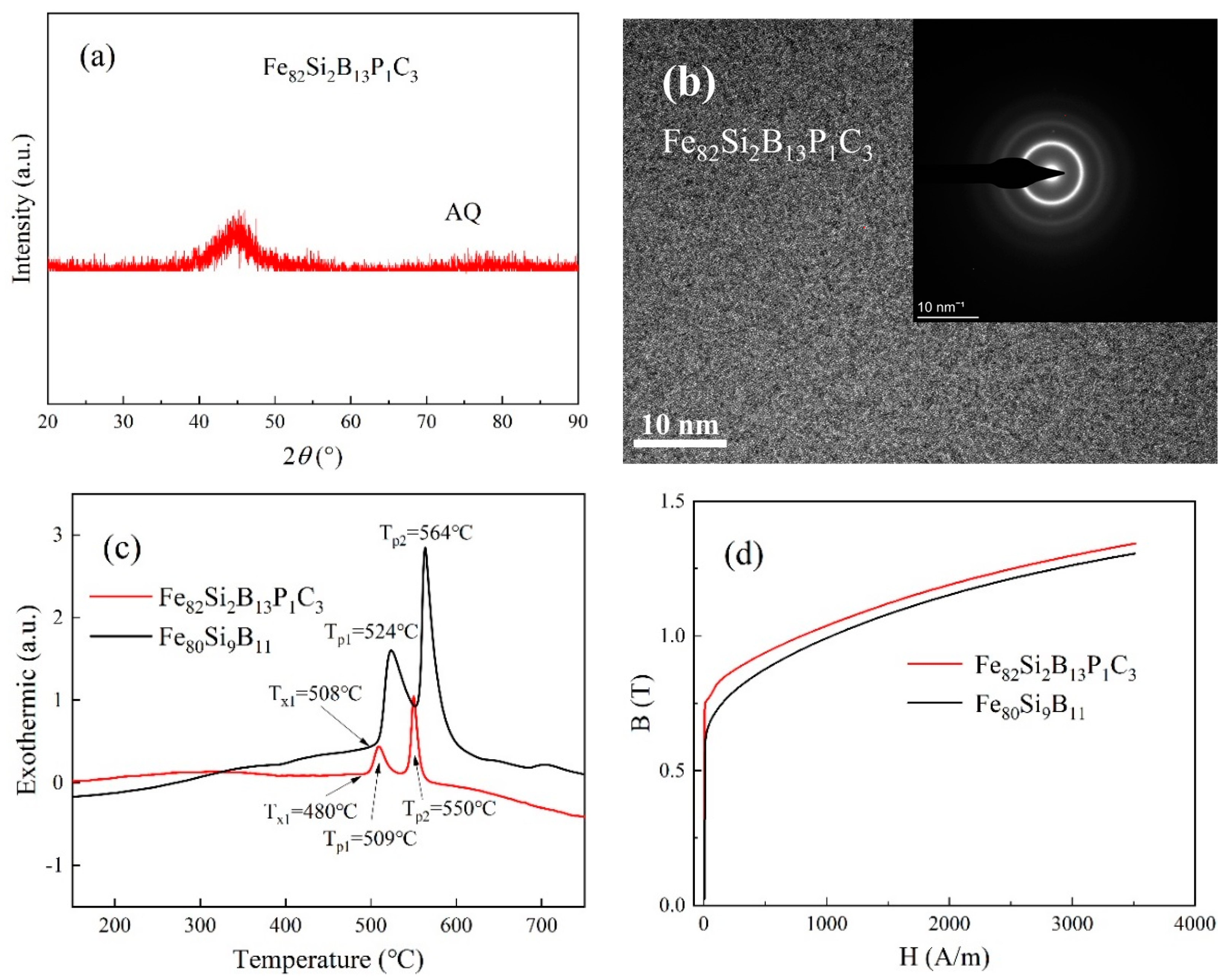

3.1. Structure and Performance Analysis of Fe82Si2B13P1C3 Ribbons

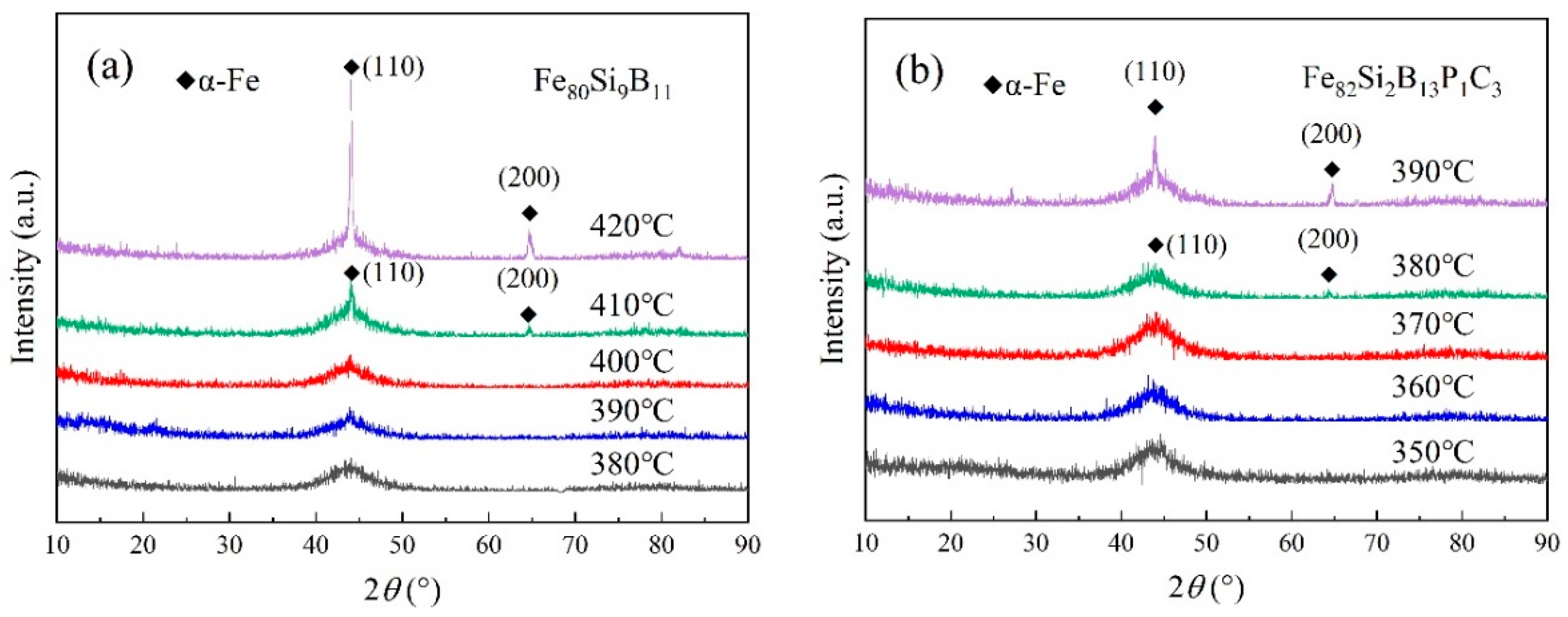

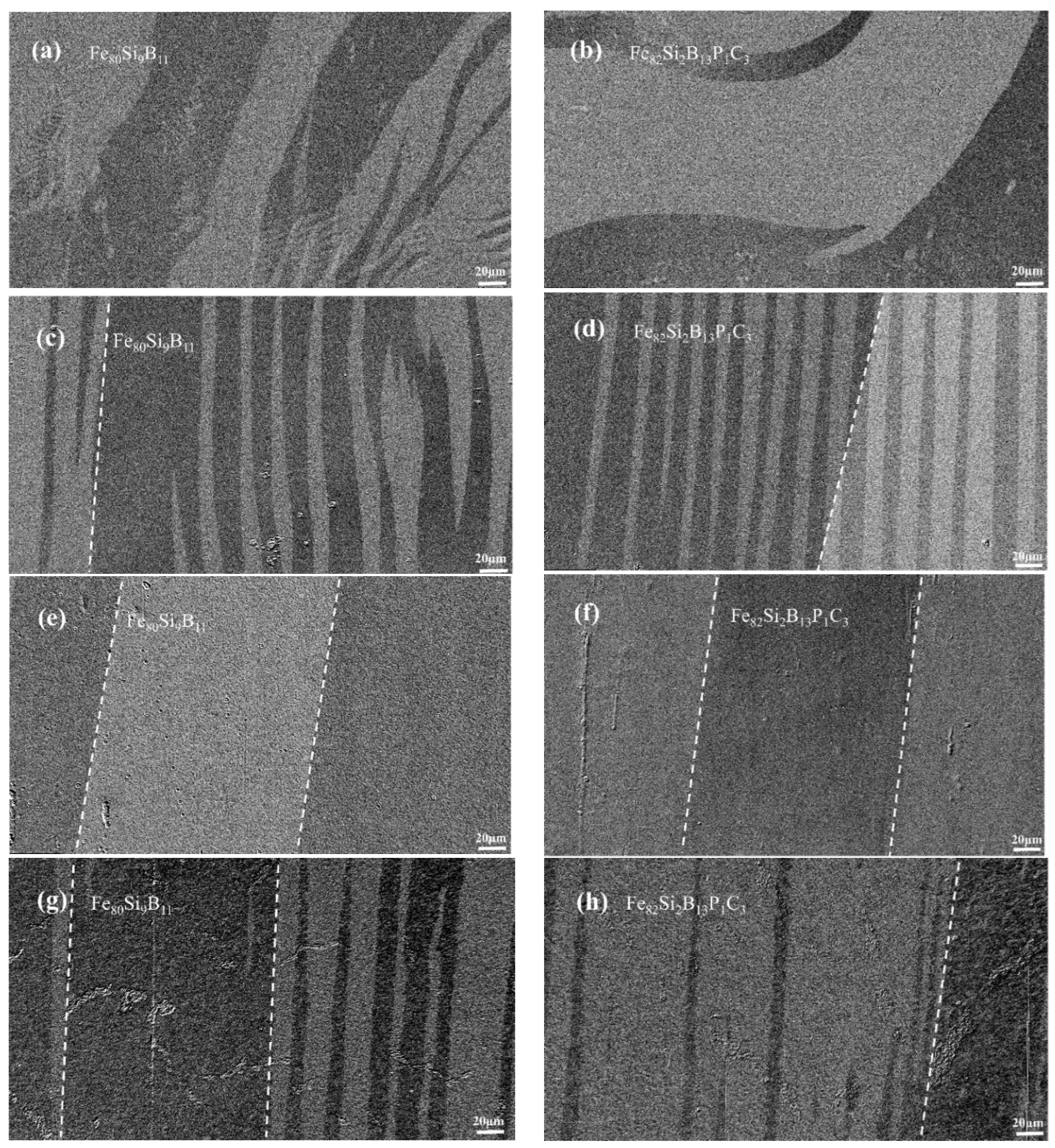

3.2. Effects of NA Processes on Magnetic Properties of Amorphous Iron Cores

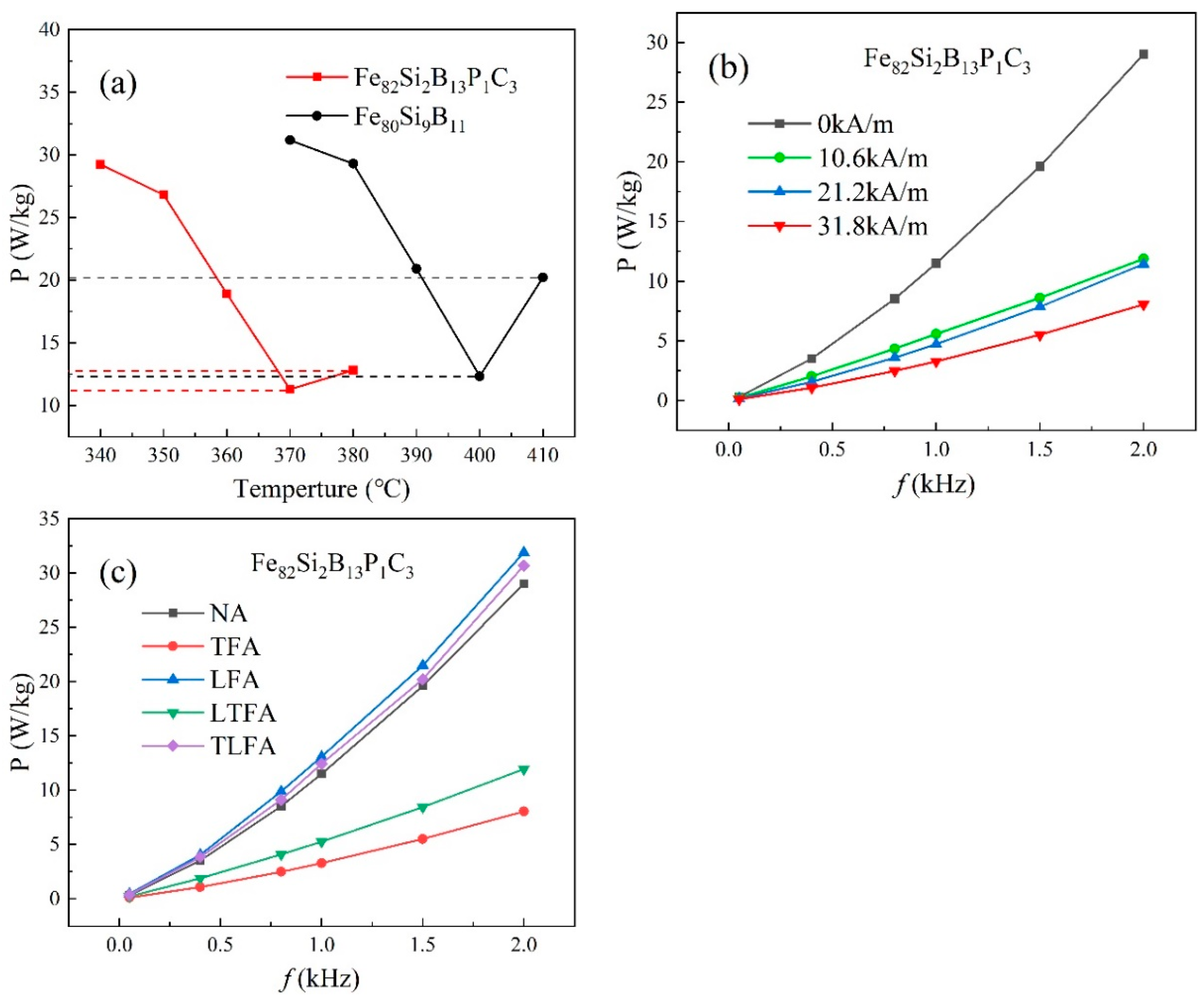

3.3. Effects of FA on Magnetic Properties of Amorphous Iron Cores

4. Conclusions

- (1)

- The Fe82Si2B13P1C3 amorphous iron core, subjected to TFA, demonstrated a lower loss of P1.4T,2kHz = 8.1 W/kg, which was 17% less than that of Fe80Si9B11 with a loss of P1.4T,2kHz = 9.8 W/kg. Furthermore, the Fe82Si2B13P1C3 amorphous iron core exhibited a higher B3500A/m value of 1.6 T under LFA, which was 0.05 T greater than the B3500A/m value of Fe80Si9B11 (B3500A/m = 1.55 T). The optimal heat treatment temperature for Fe82Si2B13P1C3 was 30 °C lower than that of Fe80Si9B11, contributing to improved toughness of the amorphous ribbons.

- (2)

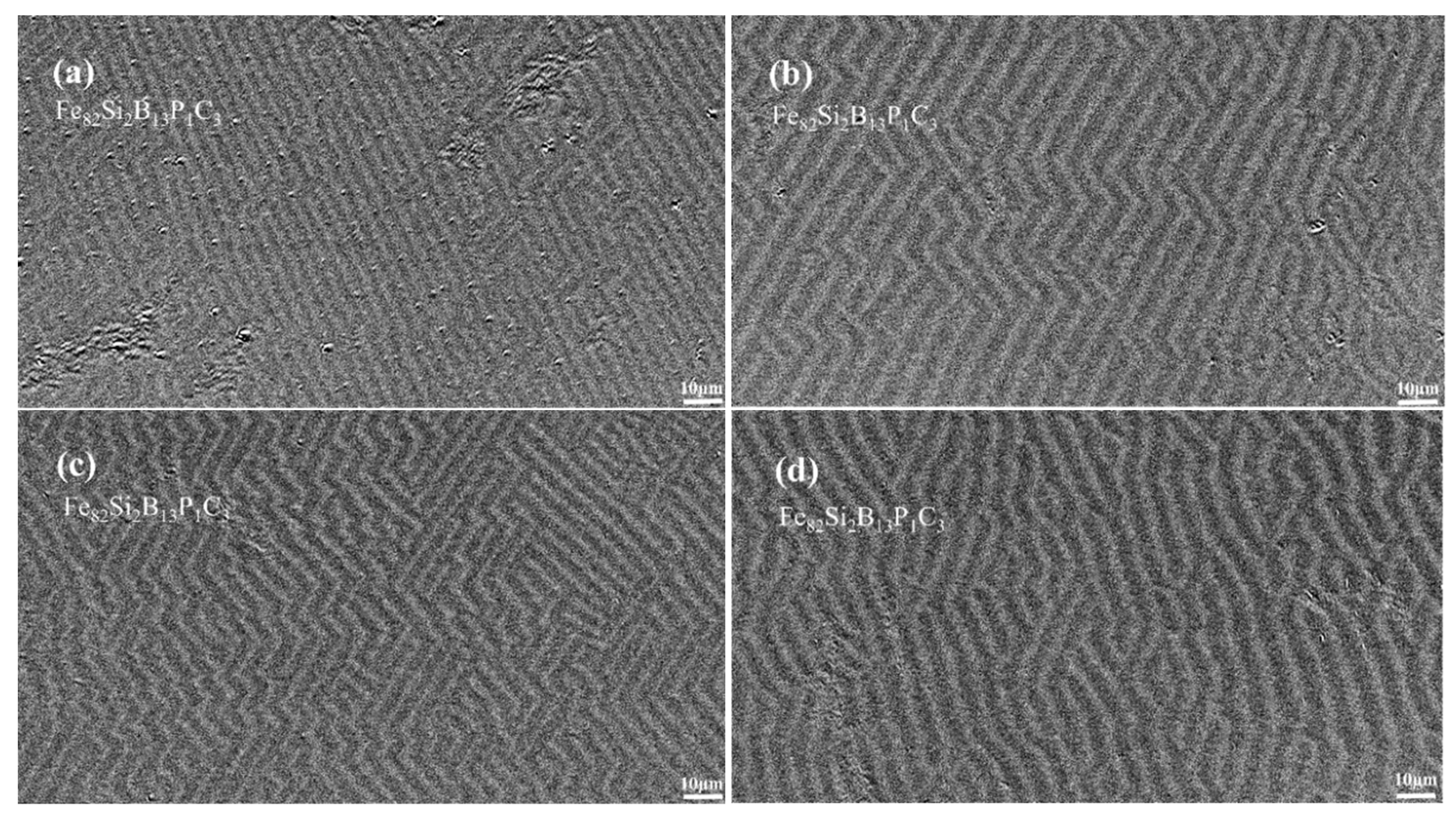

- As the heat treatment temperature of Fe82Si2B13P1C3 increased to 370 °C, the internal stress gradually dissipated, resulting in the disappearance of impurity domains, such as fingerprint domains. Moreover, the magnetic domains within the strip underwent a transformation, aligning themselves with the length direction of the strip. This led to the formation of wide strip domains with low resistance, facilitating easy magnetization and ultimately reducing the overall loss of the amorphous iron core.

- (3)

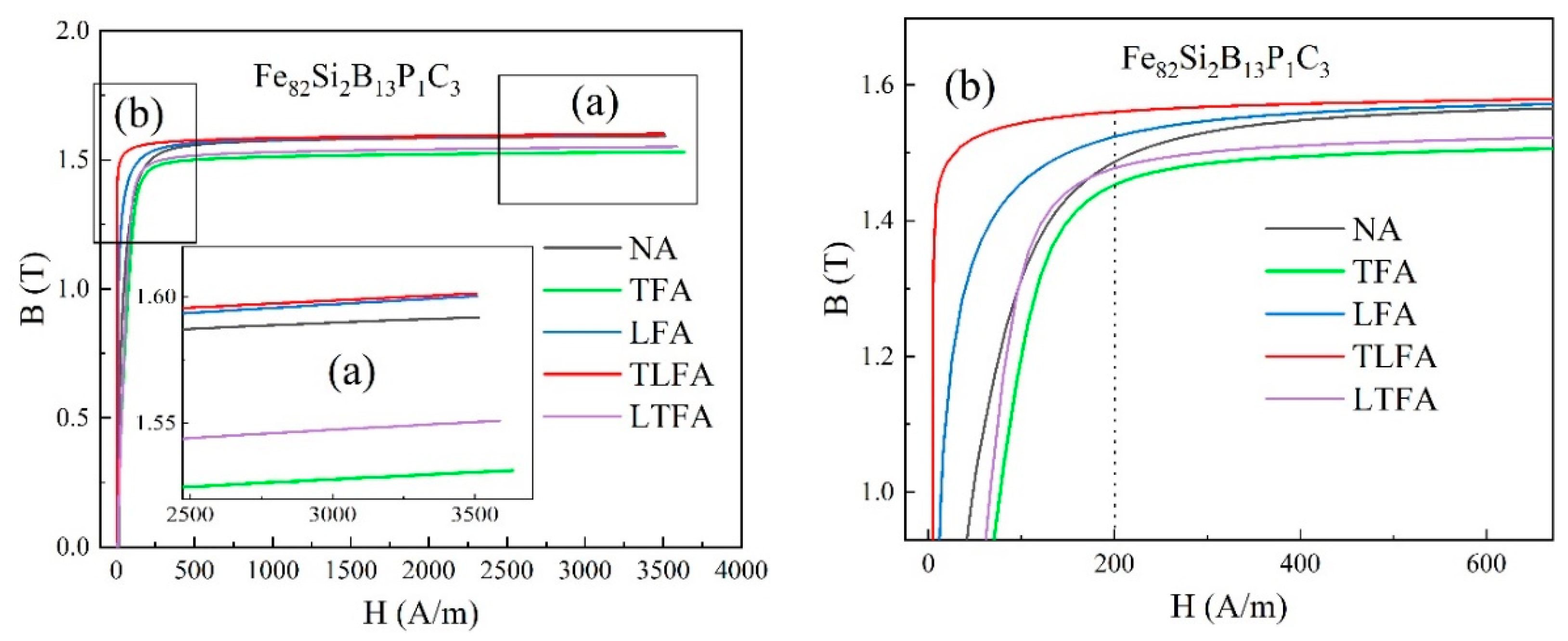

- For Fe82Si2B13P1C3 amorphous iron cores under an applied excitation of 3500 A/m, the Bm values of the treatment processes were arranged in ascending order as TFA < LTFA < NA < LFA < TLFA. Particularly, the Bm values of LFA and TLFA closely overlapped, with both reaching 1.6 T.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft magnetic materials for a sustainable and electrified world. Science 2018, 362, eaao0195. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Fan, T.; Li, Q.; Wen, X. Development of a high power density motor made of amorphous alloy cores. IEEE Trans. Ind. Electron. 2013, 61, 4510–4518. [Google Scholar] [CrossRef]

- Wang, W.H. Development and implication of amorphous alloys. Bull. Chin. Acad. Sci. 2022, 37, 352–359. (In Chinese) [Google Scholar]

- Wang, Z.; Masaki, R.; Morinaga, S.; Enomoto, Y.; Itabashi, H.; Ito, M.; Tanigawa, S. Development of an axial gap motor with amorphous metal cores. IEEE Trans. Ind. Appl. 2011, 47, 1293–1299. [Google Scholar] [CrossRef]

- Hong, D.-K.; Joo, D.; Woo, B.-C.; Jeong, Y.-H.; Koo, D.-H. Investigations on a super high speed motor-generator for microturbine applications using amorphous core. IEEE Trans. Magn. 2013, 49, 4072–4075. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Z.; Zhang, G.; Zheng, W.; Cao, X.; Hui, X.; Zhou, S. The role of P content on the glass-forming ability and the magnetic properties of FeSiBPC amorphous alloys. J. Mater. Sci. Mater. Electron. 2022, 33, 10259–10266. [Google Scholar] [CrossRef]

- Wang, A.; Zhao, C.; Men, H.; He, A.; Chang, C.; Wang, X.; Li, R.-W. Fe-based amorphous alloys for wide ribbon production with high Bs and outstanding amorphous forming ability. J. Alloys Comp. 2015, 630, 209–213. [Google Scholar] [CrossRef]

- Zhang, Q.; Hui, X.; Li, Z.; Zhang, G.; Lin, J.; Li, X.; Zheng, W.; Cao, X.; Zhou, S. Effect of pre-oxidation treatment on corrosion resistance of FeCoSiBPC amorphous alloy. Materials 2022, 15, 3206. [Google Scholar] [CrossRef]

- Aljerf, M.; Georgarakis, K.; Yavari, A.R. Shaping of metallic glasses by stress-annealing without thermal embrittlement. Acta Mater. 2011, 59, 3817–3824. [Google Scholar] [CrossRef]

- Morsdorf, L.; Pradeep, K.G.; Herzer, G.; Kovács, A.; Dunin-Borkowski, R.E.; Povstugar, I.; Konygin, G.; Choi, P.; Raabe, D. Phase selection and nanocrystallization in Cu-free soft magnetic FeSiNbB amorphous alloy upon rapid annealing. J. Appl. Phys. 2016, 119, 124903. [Google Scholar] [CrossRef]

- Wang, F.; Inoue, A.; Han, Y.; Kong, F.L.; Zhu, S.L.; Shalaan, E.; Marzouki, F.A.; Obaid, A. Excellent soft magnetic Fe-Co-B-based amorphous alloys with extremely high saturation magnetization above 1.85 T and low coercivity below 3 A/m. J. Alloys Comp. 2017, 711, 132–142. [Google Scholar] [CrossRef]

- Miguel, C.; Zhukov, A.P.; Val, J.J.; Arellano, A.R.; González, J. Effect of stress and/or field annealing on the magnetic behavior of the (Co77Si13.5B9.5)90Fe7Nb3 amorphous alloy. J. Appl. Phys. 2005, 97, 034911. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, A.; Yue, S.; Liu, T.; He, A.; Chang, C.; Wang, X.M.; Liu, C.T. Significant improvement of soft magnetic properties for Fe(Co)BPSiC amorphous alloys by magnetic field annealing. J. Alloys Comp. 2018, 742, 220–225. [Google Scholar] [CrossRef]

- Li, H.; He, A.; Wang, A.; Xie, L.; Li, Q.; Zhao, C.; Zhang, G.Y.; Chen, P.B. Improvement of soft magnetic properties for distinctly high Fe content amorphous alloys via longitudinal magnetic field annealing. J. Magn. Magn. Mater. 2019, 471, 110–115. [Google Scholar] [CrossRef]

- Suzuki, K.; Herzer, G. Magnetic-field-induced anisotropies and exchange softening in Fe-rich nanocrystalline soft magnetic alloys. Scr. Mater. 2012, 67, 548–553. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, S.; Zhang, G.; Zheng, W. Highly Ductile and Ultra-Thick P-Doped FeSiB Amorphous Alloys with Excellent Soft Magnetic Properties. Materials 2018, 11, 1148. [Google Scholar] [CrossRef]

- Turnbull, D. Under what conditions can a glass be formed? Contemp. Phys. 1969, 10, 473–488. [Google Scholar] [CrossRef]

- Turnbull, D.; Cohen, M.H. Free-volume model of the amorphous phase: Glass transition. J. Chem. Phys. 1961, 34, 120–125. [Google Scholar] [CrossRef]

- Gruszka, K.M.; Nabiałek, M.; Błoch, K.; Olszewski, J. Effect of heat treatment on the shape of the hyperfine field induction distributions and magnetic properties of amorphous soft magnetic Fe62Co10Y8B20 alloy. J. Nukl. 2015, 60, 23–27. [Google Scholar] [CrossRef][Green Version]

- Zeper, W.B.; Greidanus, F.; Carcia, P.F.; Fincher, C.R. Perpendicular magnetic anisotropy and magneto-optical Kerr effect of vapor-deposited Co/Pt-layered structures. J. Appl. Phys. 1989, 65, 4971–4975. [Google Scholar] [CrossRef]

- Liu, J.P.; Fullerton, E.; Gutfleisch, O.; Sellmyer, D.J. Nanoscale Magnetic Materials and Applications; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Ri, M.C.; Ding, D.W.; Sohrabi, S.; Sun, B.A.; Wang, W.H. Stress relief by annealing under external stress in Fe-based metallic glasses. J. Appl. Phys. 2018, 124, 165108. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, A.; He, A.; Yue, S.; Chang, C.; Wang, X.; Li, R.-W. Correlation between soft-magnetic properties and Tx1-Tc in high Bs FeCoSiBPC amorphous alloys. J. Alloys Comp. 2016, 659, 193–197. [Google Scholar] [CrossRef]

| Item | Tx1 (°C) | Tp1 (°C) | Tp2 (°C) | ΔTp = Tp2 − Tp1 (°C) |

|---|---|---|---|---|

| Fe82Si2B13P1C3 | 480 | 509 | 550 | 41 |

| Fe80Si9B11 | 508 | 524 | 564 | 40 |

| Difference (TFe82Si2B13P1C3 − TFe80Si9B11) | −28 | −15 | −14 | 1 |

| Item | P1.4T,2kHz (W/kg) | P1.4T,2kHz (W/kg) | ΔP1.4T,2kHz (W/kg) | B3500A/m (T) |

|---|---|---|---|---|

| Fe82Si2B13P1C3 | 29 (370 °C) | 47 (380 °C) | 18 | 1.59 (380 °C) |

| Fe80Si9B11 | 36 (400 °C) | 58 (410 °C) | 22 | 1.55 (410 °C) |

| Difference (Fe82Si2B13P1C3 − Fe80Si9B11) | −7 | −11 | −4 | 0.04 |

| Item | P1.4T,2kHz (W/kg) 10.6 kA/m | P1.4T,2kHz (W/kg) 10.6 kA/m | P1.4T,2kHz (W/kg) 31.8 kA/m | P1.4T,2kHz (W/kg) LTFA | P1.4T,2kHz (W/kg) TLFA |

|---|---|---|---|---|---|

| Fe82Si2B13P1C3 | 11.3 (370 °C) | 12.8 (380 °C) | 8.1 (370 °C) | 11.9 (370 °C) | 30.7 (370 °C) |

| Fe80Si9B11 | 12.3 (400 °C) | 20.2 (410 °C) | 9.8 (400 °C) | 12.5 (400 °C) | 32.1 (400 °C) |

| Difference (P Fe82Si2B13P1C3 − P Fe80Si9B11) | −1 | −7.4 | −1.7 | −0.6 | −1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Zhang, G.; Zhang, Q.; Yu, H.; Li, Z.; Gu, M.; Song, S.; Zhou, S.; Qu, X. The Effect of Annealing on the Soft Magnetic Properties and Microstructure of Fe82Si2B13P1C3 Amorphous Iron Cores. Materials 2023, 16, 5527. https://doi.org/10.3390/ma16165527

Zheng W, Zhang G, Zhang Q, Yu H, Li Z, Gu M, Song S, Zhou S, Qu X. The Effect of Annealing on the Soft Magnetic Properties and Microstructure of Fe82Si2B13P1C3 Amorphous Iron Cores. Materials. 2023; 16(16):5527. https://doi.org/10.3390/ma16165527

Chicago/Turabian StyleZheng, Wei, Guangqiang Zhang, Qian Zhang, Haichen Yu, Zongzhen Li, Mingyu Gu, Su Song, Shaoxiong Zhou, and Xuanhui Qu. 2023. "The Effect of Annealing on the Soft Magnetic Properties and Microstructure of Fe82Si2B13P1C3 Amorphous Iron Cores" Materials 16, no. 16: 5527. https://doi.org/10.3390/ma16165527

APA StyleZheng, W., Zhang, G., Zhang, Q., Yu, H., Li, Z., Gu, M., Song, S., Zhou, S., & Qu, X. (2023). The Effect of Annealing on the Soft Magnetic Properties and Microstructure of Fe82Si2B13P1C3 Amorphous Iron Cores. Materials, 16(16), 5527. https://doi.org/10.3390/ma16165527