Early-Age Cracking Behavior of Concrete Slabs with GFRP Reinforcement

Abstract

:1. Introduction

2. Materials

2.1. Concrete

2.2. GFRP and Steel Reinforcing Bars

3. Experimental Program

3.1. Plastic Shrinkage Test

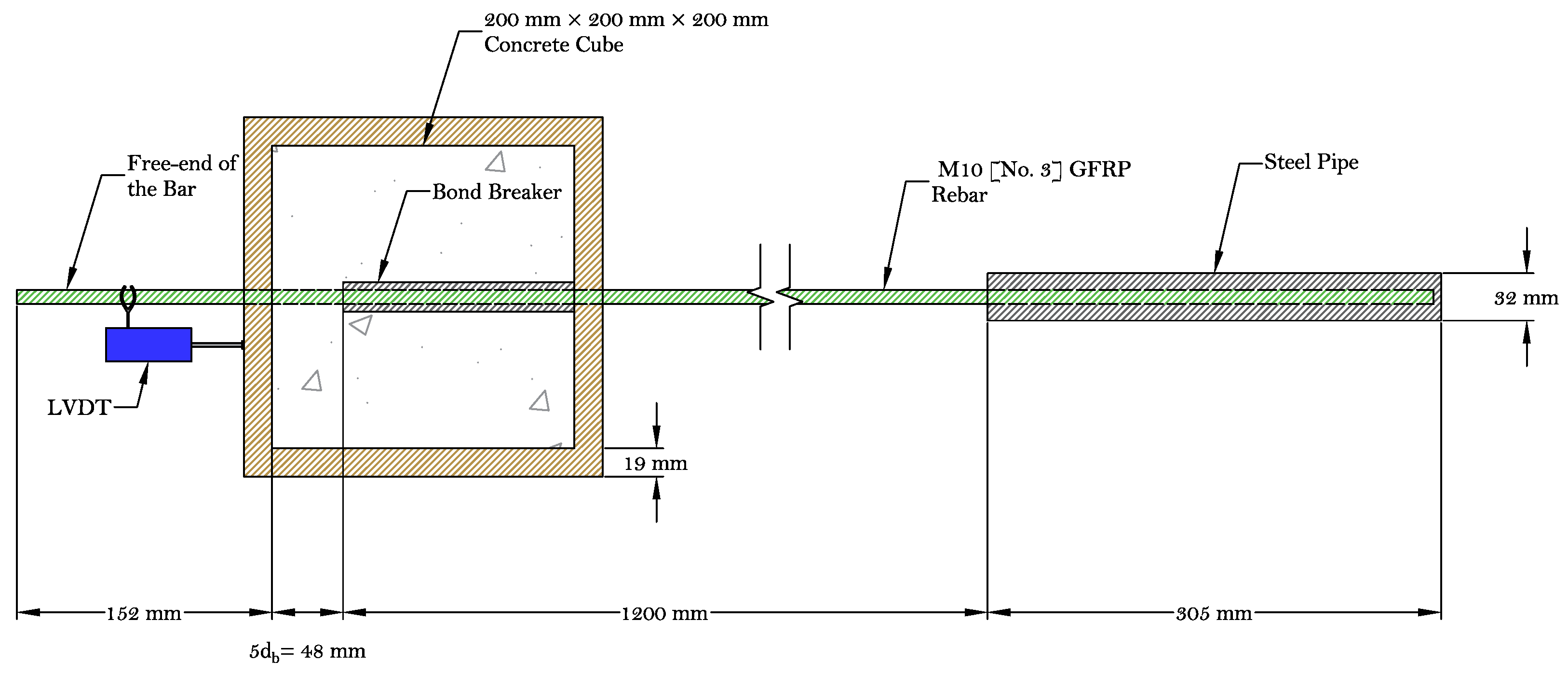

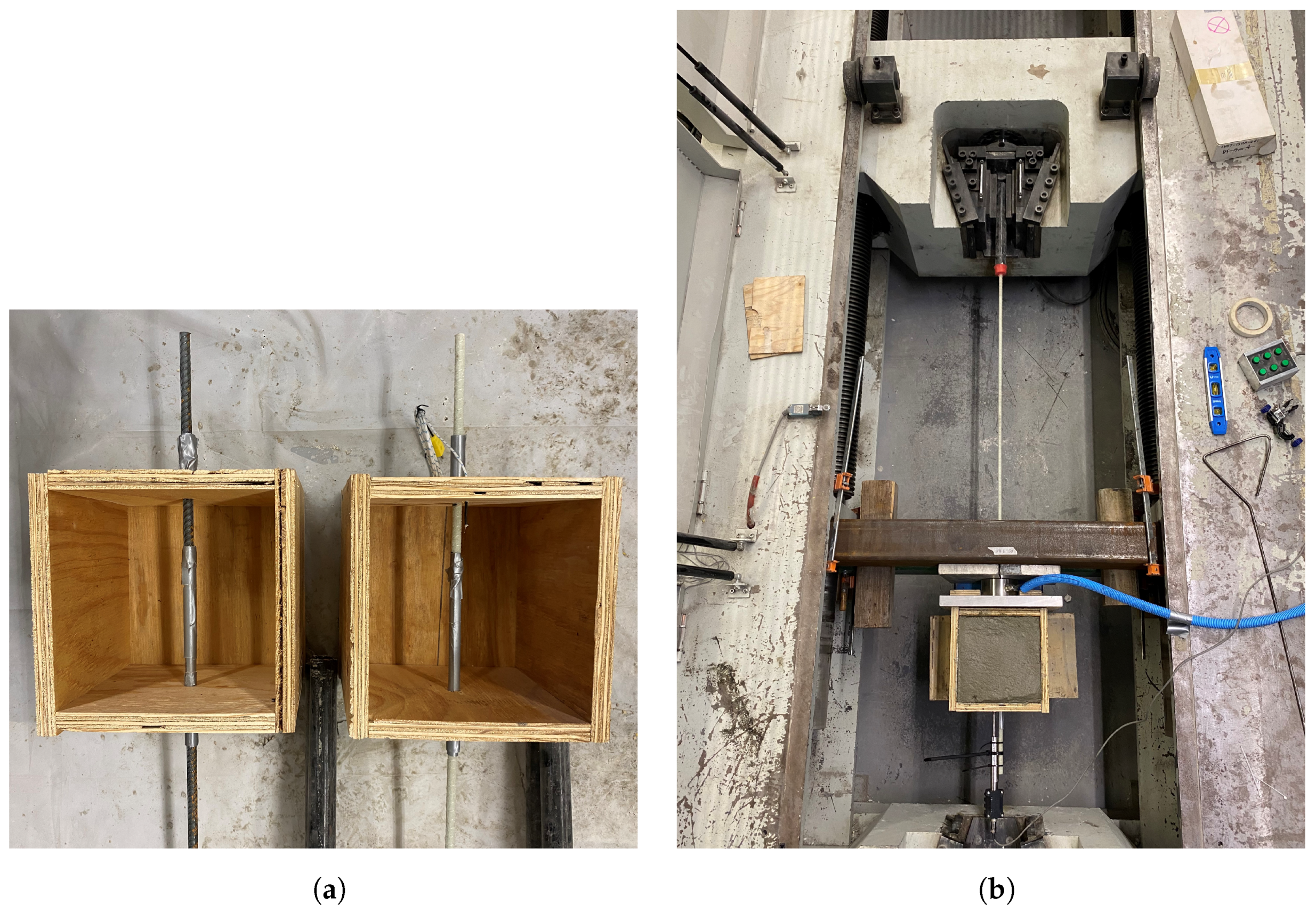

3.2. Early-Age Bond Test

3.3. Penetration Test

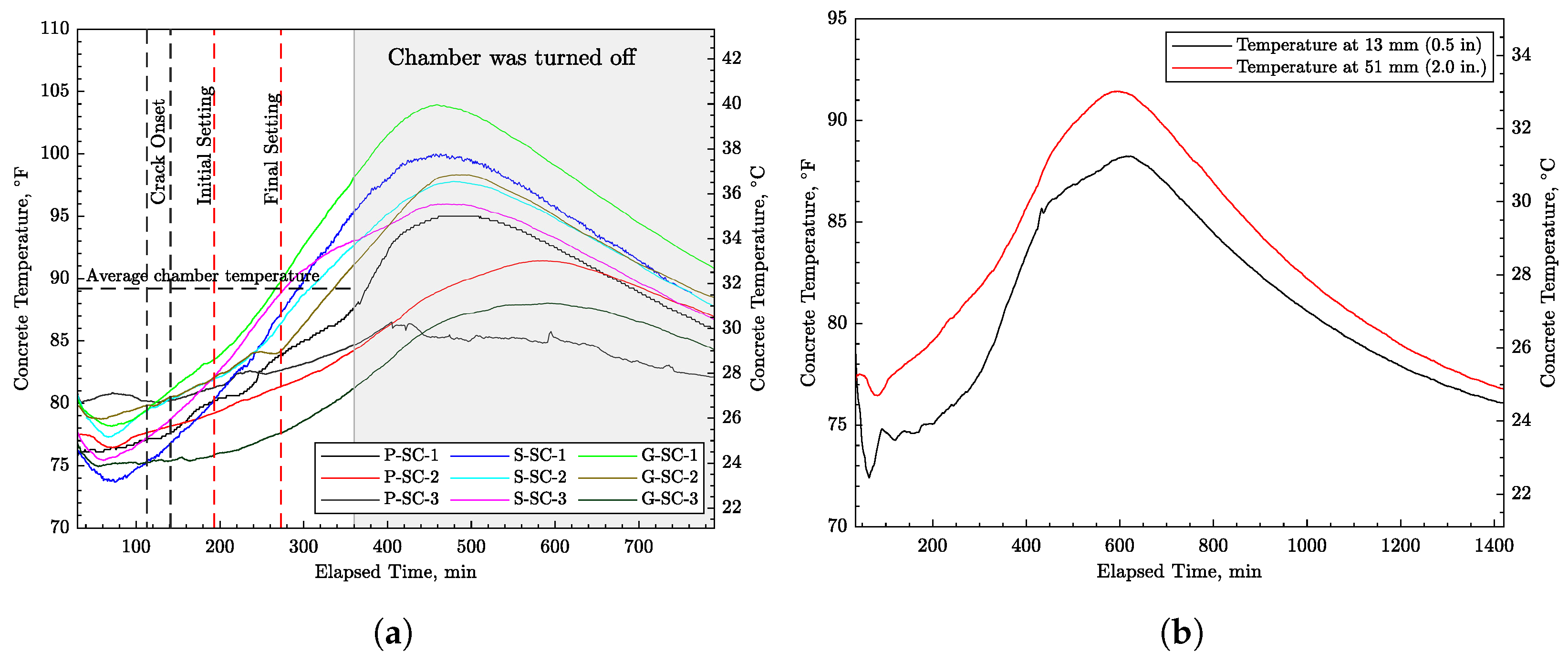

4. Experimental Results

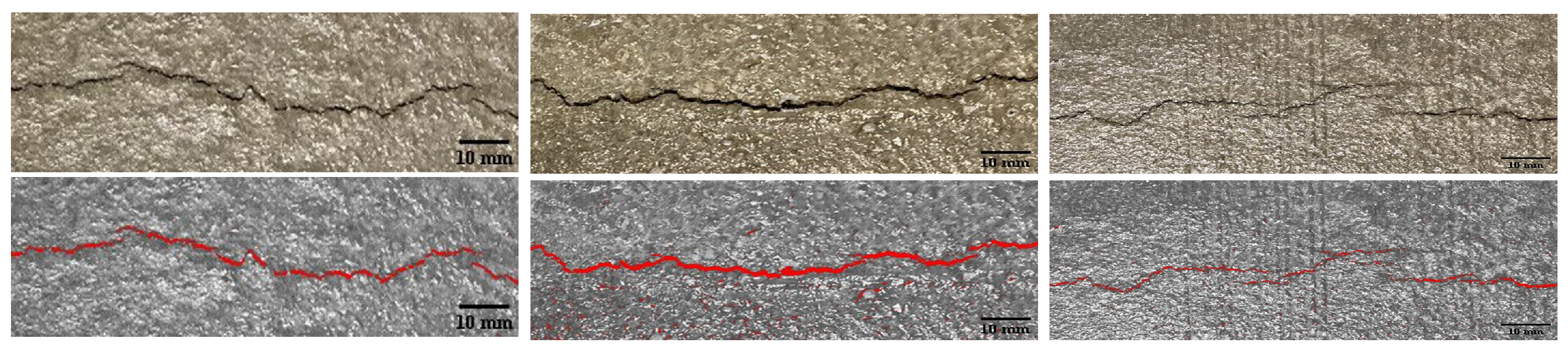

4.1. Plastic Shrinkage Test

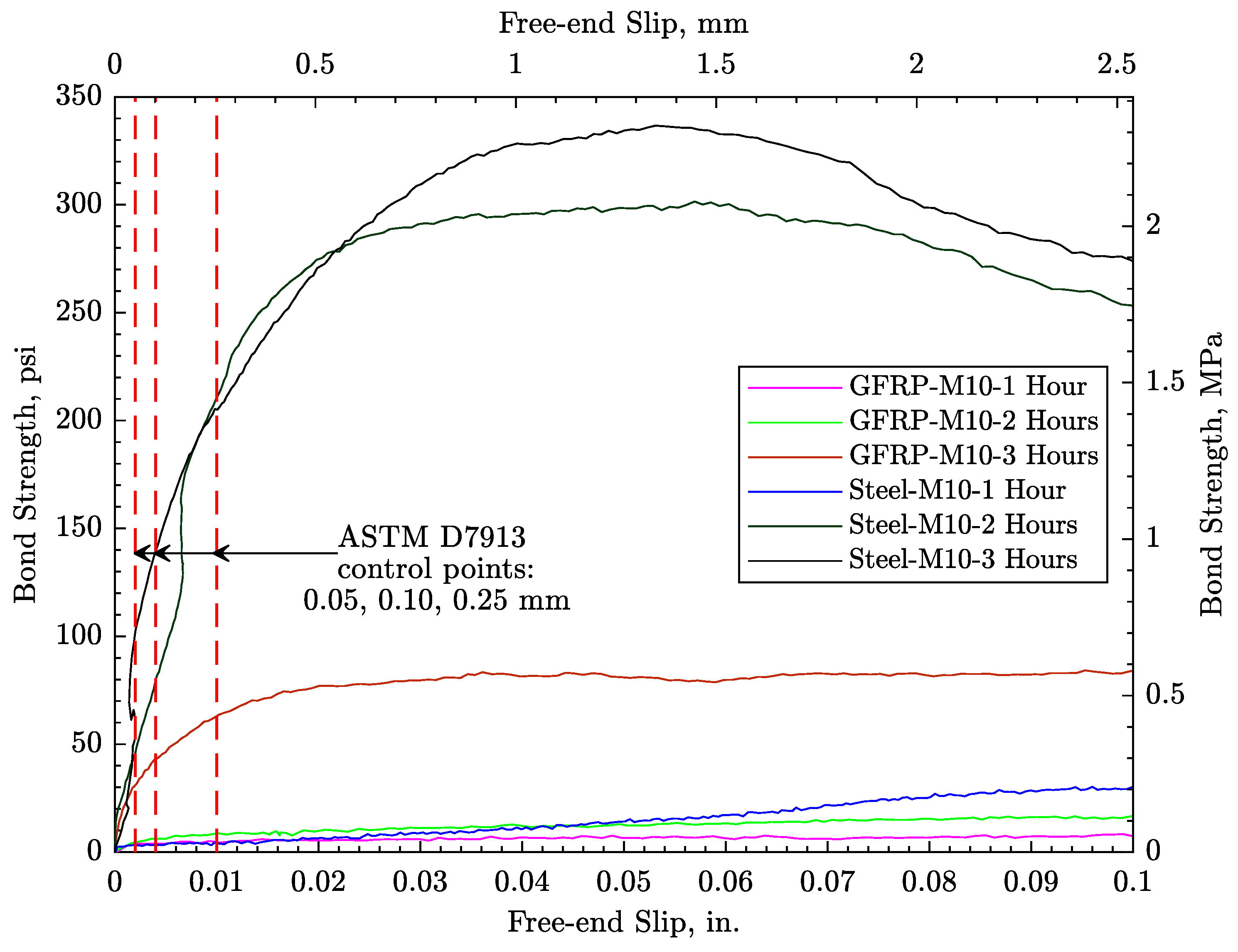

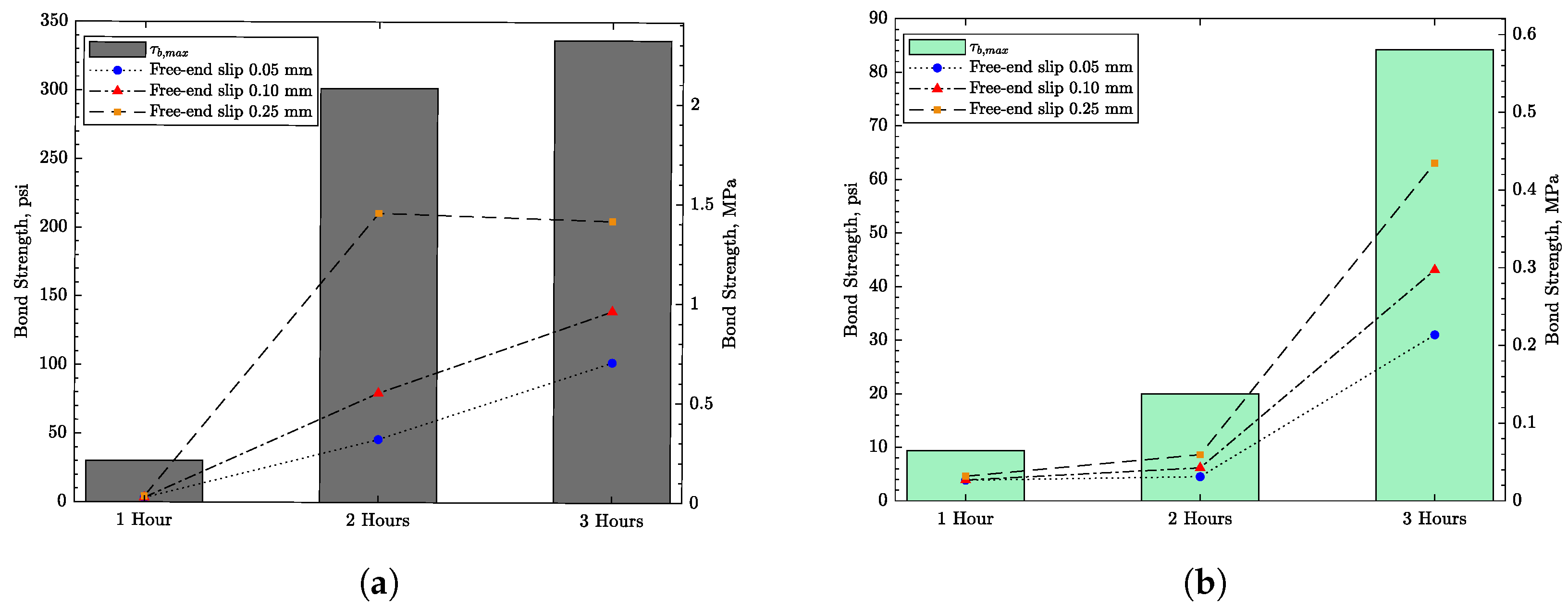

4.2. Early-Age Bond Test

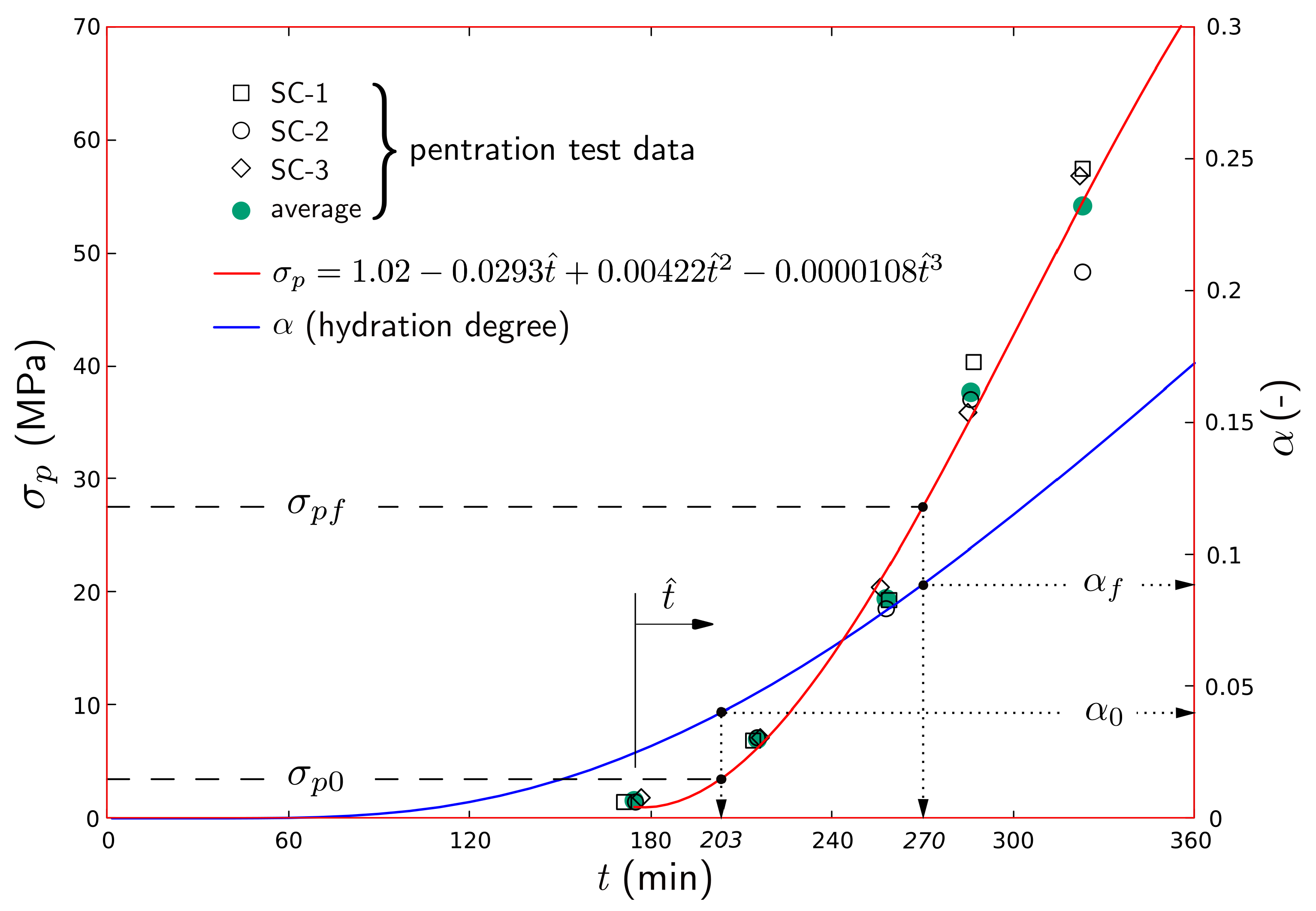

4.3. Penetration Test

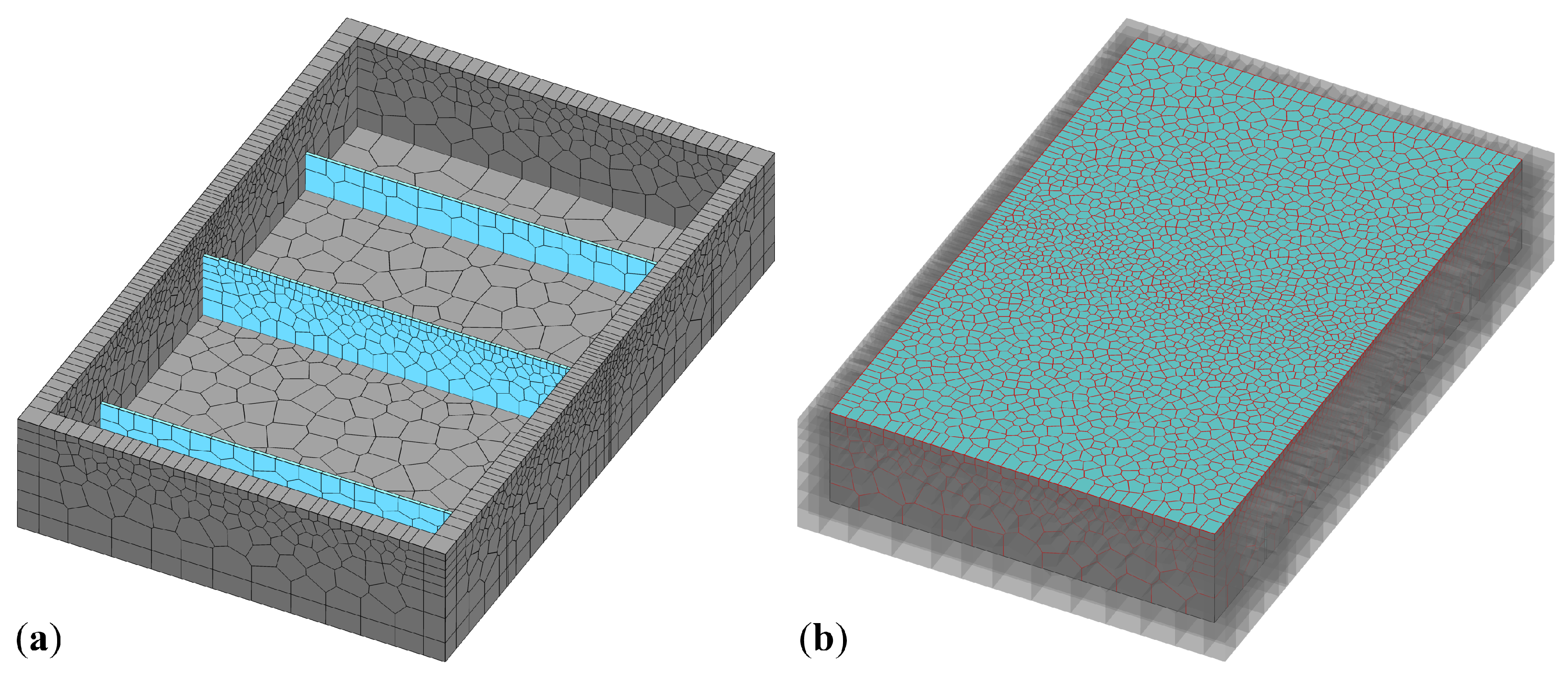

5. Modeling Approach

- Cementitious materials hydration is based on the model proposed by Riding et al. [50]. The degree of cementitious materials reaction can be expressed by the amount of chemically combined water, or equivalently bywhere is the cumulative amount of heat produced by the hydration reaction (J/g) and is total heat available for reaction (J/g). The total available heat depends on the composition and proportioning of the cementitious materials [50].

- The temperature field within the model domain is simulated using a lattice composed of conduit elements. A convective boundary layer models the heat transfer between the exposed surface of the specimen and the environment. The convective heat exchange across the exposed surfaces (including the outer surfaces of the plywood formwork) depends on the difference between the solid surface temperature and that of the surrounding ambient mediumwhere is the coefficient of convective heat transfer, which can be modeled as follows [51]:where v is wind speed over the concrete surface. The heat of hydration is calculated at the lattice nodes and used as a source term in the thermal analyses.

- The humidity field is simulated using a parallel set of conduit elements based on the same set of nodal points and element connectivities. After the concrete sets, moisture transport is assumed to be governed by a diffusion process (i.e., according to Fick’s second law). A convective boundary layer accounts for moisture transfer between the drying surface of the concrete and the environment. The modeling of this layer is analogous to that of the temperature field expressed by Equation (2), although it is governed by different mechanisms.

- The solution process involves a time-stepping scheme in which the temperature and humidity fields are solved for each time step using the Crank–Nicholson method in conjunction with a fixed-point algorithm to achieve convergence.

- The simulated thermal and hygral fields produce thermal and hygral strains, respectively, within the mechanical component of the analysis framework, which is based on the rigid body–spring concept [52]. These strain increments produce stress that might lead to crack formation.

- Concrete property development, including strength and stiffness, depends on the degree of cementitious materials hydration. In particular, solidification theory is used to simulate creep processes and stiffness development [53,54]. The development of tensile strength is represented bywhere is the tensile strength at the ultimate degree of hydration, is the degree of hydration associated with setting, and the coefficient = 1 when the tensile strength is being modeled [55].

6. Simulation Results and Discussion

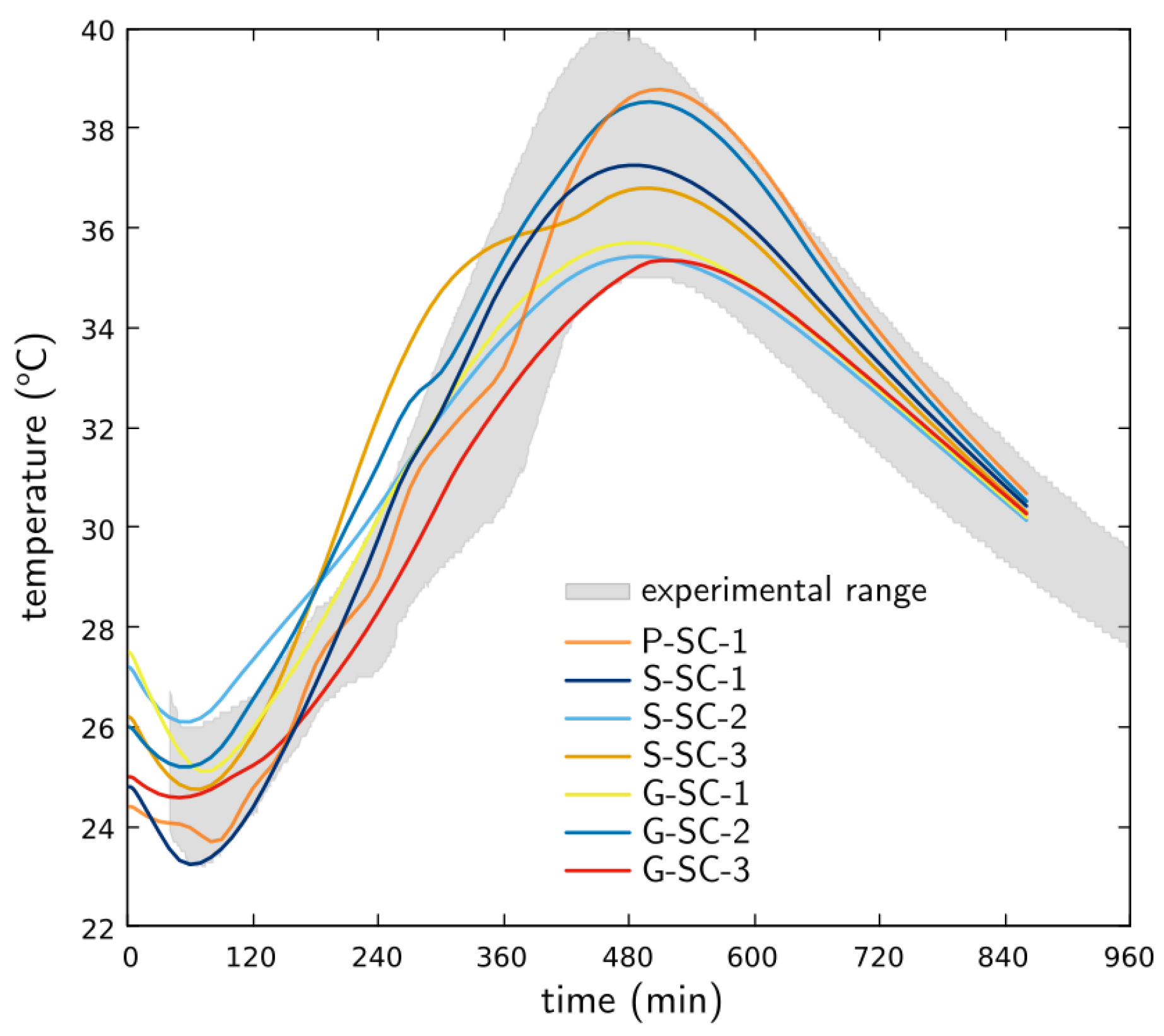

6.1. Thermal Analyses

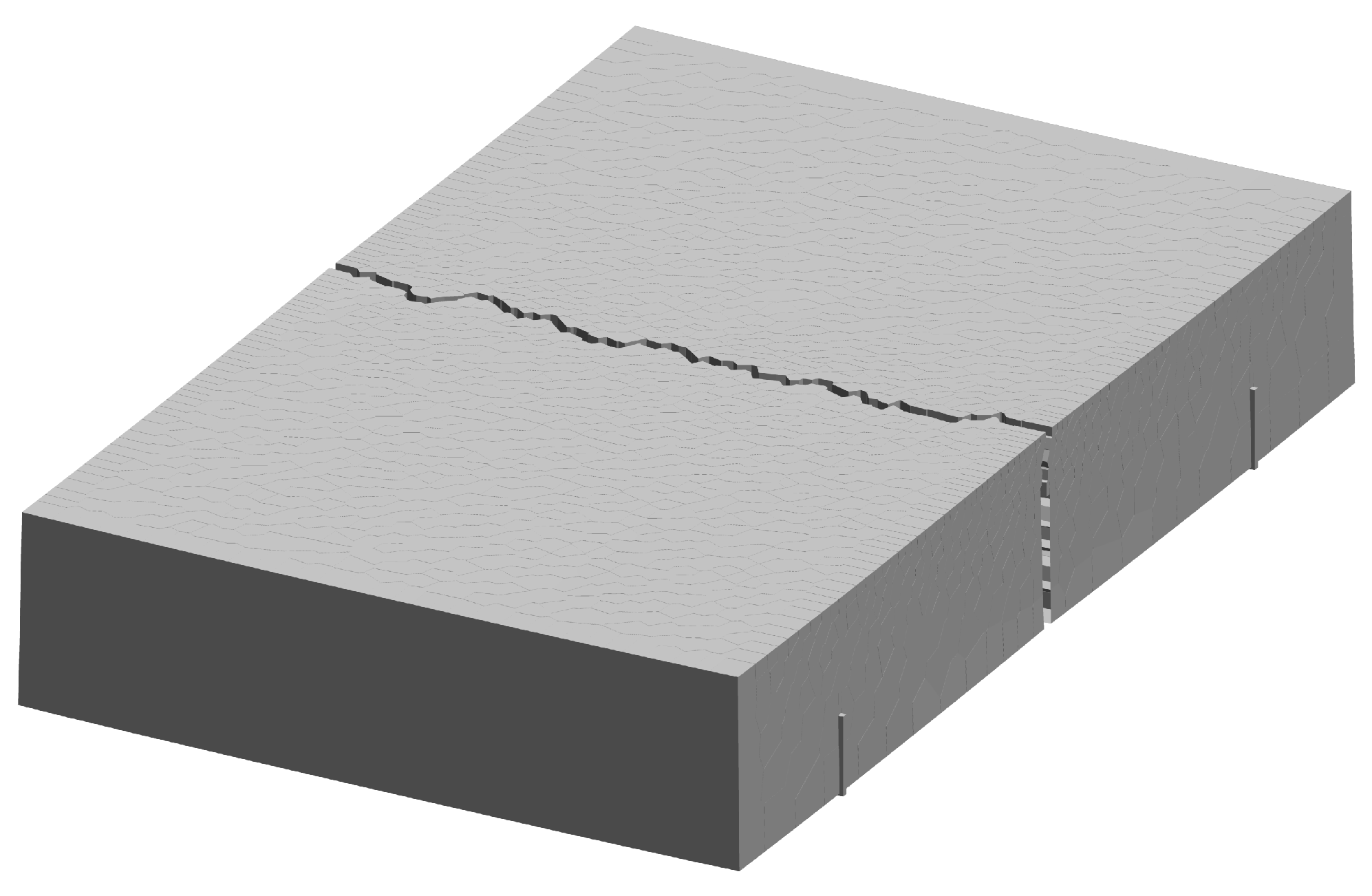

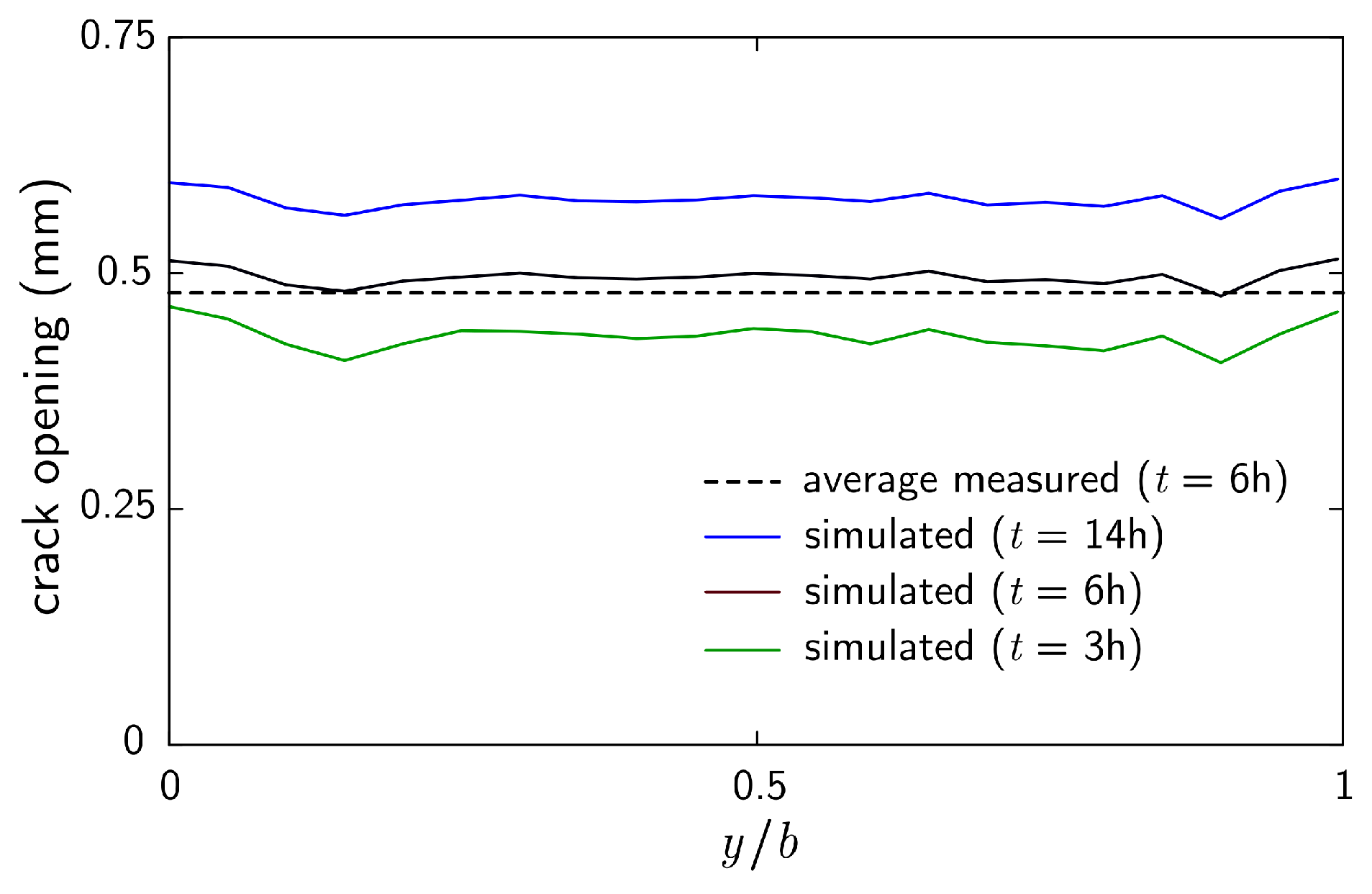

6.2. Cracking Behavior of Unreinforced Slab Specimens

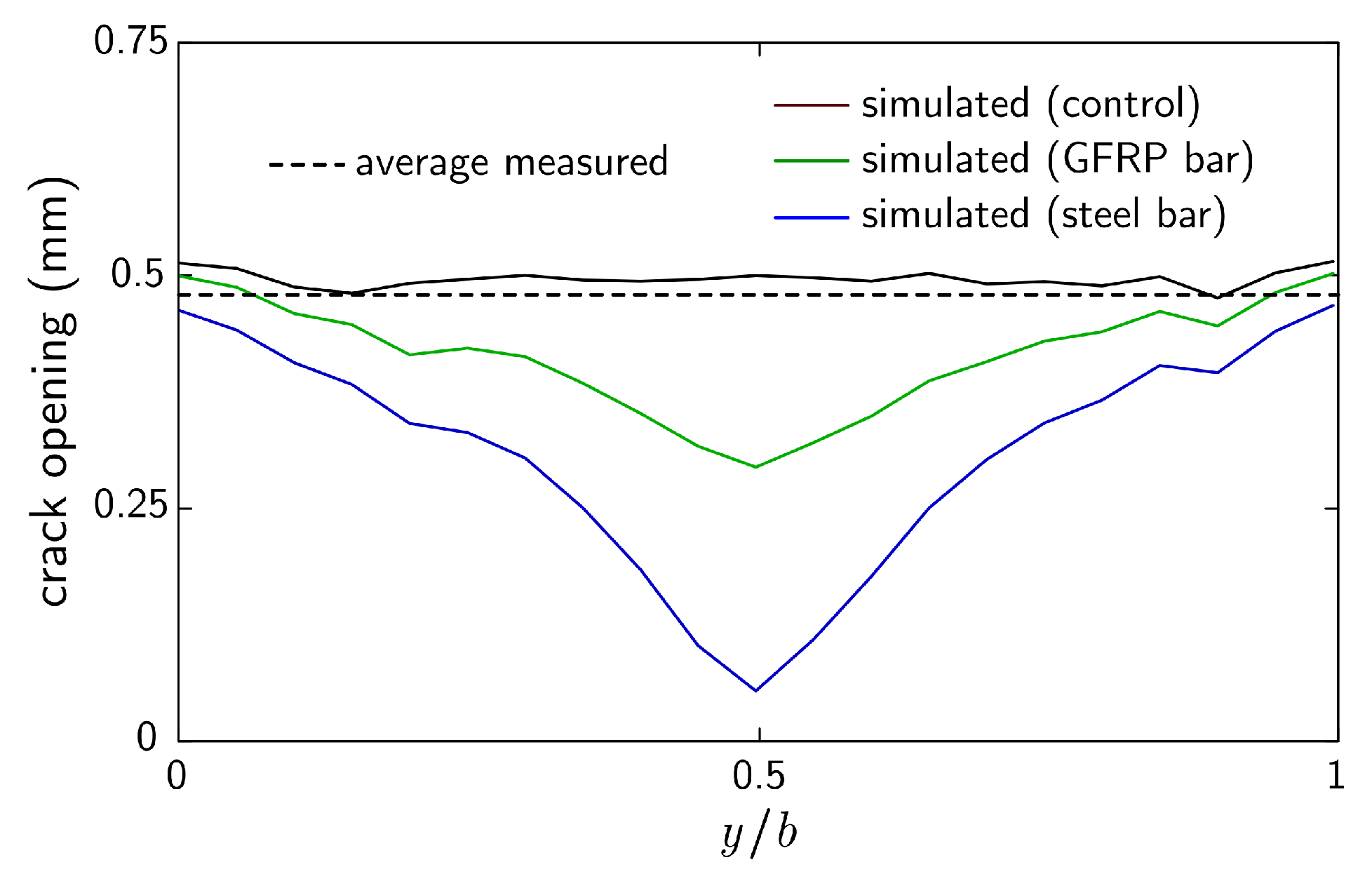

6.3. Cracking Behavior of Reinforced Slab Specimens

7. Conclusions

- Consistent cracking behavior of the control specimens was obtained by optimizing the concrete mixture design, controlling the environmental boundary conditions, and raising the initial temperature of the concrete, which increased the evaporation rate from the drying surface. The initial temperature was raised by heating the mixing water before its addition to the dry materials. Cracking initiated with the concrete in a plastic state prior to setting.

- For the test specimens considered herein, crack opening does not appear to be restricted in the vicinity of a bar; rather, openings are fairly uniform over the specimen width. In other words, the presence of reinforcing bars of either type, i.e., GFRP or steel, does not have an appreciable effect on time of plastic shrinkage crack initiation and ensuing crack opening.

- Bond strength between both types of reinforcement and the early-age concrete was measured and found to be small (e.g., the maximum bond strength at t = 2 h was only 0.14 MPa and 2.08 MPa for GFRP and steel bars, respectively). Such low bond strength might be responsible for the ineffectiveness of the reinforcement in restraining plastic shrinkage cracking.

- It was observed that the plastic shrinkage cracking can occur for evaporation rates that are even below the commonly accepted critical value of 1.0 kg/m/hr (0.2 lb/ft/hr).

- The proposed numerical analyses elucidate the roles of the various thermo-hygro-mechanical processes that affect early-age cracking of the specimens. In particular, by modeling plastic shrinkage as a bulk material phenomenon in the form of volumetric strain, the central device acts as a stress riser. The simulated cracking initiates from the device tip and propagates upward, as seen in other studies using images based on X-Ray radiography.

- Concrete temperatures, and as such the properties of the concrete, are influenced by the thermal properties of the formwork and related boundary conditions. The modeling of evaporative cooling was found to be essential in simulating the concrete temperatures, particularly early on in the testing period, where measured temperature tended to decrease with time.

- Our numerical analyses support the notion that discrete bar reinforcement does not prevent the formation of plastic shrinkage cracks. In contrast to the experimental observations, however, the presence of the bar reinforcement does restrict crack opening. Higher bond strength leads to smaller crack openings local to the bar. The differences between the measured and simulated opening profiles are grounds for further study.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| ACI | American Concrete Institute |

| FRP | Fiber-Reinforced Polymer |

| GFRP | Glass Fiber-Reinforced Polymer |

| LVDT | Linear Variable Differential Transformer |

| UTM | Universal Testing Machine |

| VCLM | Voronoi Cell–Lattice Model |

References

- Soroushian, P.; Mirza, F.; Alhozajiny, A. Plastic shrinkage cracking of polypropylene fiber reinforced concrete. Mater. J. 1993, 92, 553–560. [Google Scholar]

- Otieno, M.; Alexander, M.; Beushausen, H.D. Corrosion in cracked and uncracked concrete—Influence of crack width, concrete quality and crack reopening. Mag. Concr. Res. 2010, 62, 393–404. [Google Scholar] [CrossRef]

- Kayondo, M.; Combrinck, R.; Boshoff, W. State-of-the-art review on plastic cracking of concrete. Constr. Build. Mater. 2019, 225, 886–899. [Google Scholar] [CrossRef]

- Wittmann, F. On the action of capillary pressure in fresh concrete. Cem. Concr. Res. 1976, 6, 49–56. [Google Scholar] [CrossRef]

- Uno, P.J. Plastic shrinkage cracking and evaporation formulas. ACI Mater. J. 1998, 95, 365–375. [Google Scholar]

- Ravina, D.; Shalon, R. Plastic shrinkage cracking. ACI J. Proc. 1968, 65, 282–291. [Google Scholar]

- Boshoff, W.P.; Combrinck, R. Modelling the severity of plastic shrinkage cracking in concrete. Cem. Concr. Res. 2013, 48, 34–39. [Google Scholar] [CrossRef]

- Combrinck, R.; Steyl, L.; Boshoff, W.P. Influence of concrete depth and surface finishing on the cracking of plastic concrete. Constr. Build. Mater. 2018, 175, 621–628. [Google Scholar] [CrossRef]

- Weiss, W.J. Prediction of Early-Age Shrinkage Cracking in Concrete Elements; Northwestern University: Evanston, IL, USA, 1999. [Google Scholar]

- Ghoddousi, P.; Javid, A.A.S. Effect of reinforcement on plastic shrinkage and settlement of self-consolidating concrete as repair material. Mater. Struct. 2012, 45, 41–52. [Google Scholar] [CrossRef]

- Sule, M.; van Breugel, K. Cracking behaviour of reinforced concrete subjected to early-age shrinkage. Mater. Struct. 2001, 34, 284–292. [Google Scholar] [CrossRef]

- Nanni, A.; De Luca, A.; Zadeh, H.J. Reinforced Concrete with FRP Bars: Mechanics and Design; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Bank, L.C. Composites for Construction: Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Taerwe, L.; Matthys, S. FRP for concrete construction: Activities in Europe. Concr. Int. 1999, 21, 33–36. [Google Scholar]

- Fukuyama, H. FRP composites in Japan. Concr. Int. 1999, 21, 29–32. [Google Scholar]

- Benmokrane, B.; Mohamed, H. Use of fibre-reinforced polymer (FRP) rebars for building durable concrete infrastructure. In Insights and Innovations in Structural Engineering, Mechanics and Computation; CRC Press: Boca Raton, FL, USA, 2016; pp. 1518–1523. [Google Scholar]

- Villen Salan, E. A monumental flood mitigation channel in Saudi Arabia. Concr. Int. 2021, 43, 10. [Google Scholar]

- Roghani, H.; De Caso, F.; Nanni, A. Constructability of Slabs-on-Ground with FRP Meshes as Secondary Reinforcement. In Proceedings of the FRPRCS-15 & APFIS-2022, Shenzhen, China, 10–16 December 2022. [Google Scholar]

- Solyom, S.; Baláz, G.L. Bond of FRP bars with different surface characteristics. Constr. Build. Mater. 2020, 264, 119839. [Google Scholar] [CrossRef]

- Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of bond characterization on load-mean strain and tension stiffening behavior of concrete elements reinforced with embedded FRP reinforcement. Materials 2022, 15, 799. [Google Scholar] [CrossRef]

- Abed, M.A.; Alkurdi, Z.; Fořt, J.; Černý, R.; Solyom, S. Bond behavior of FRP bars in lightweight SCC under direct pull-out conditions: Experimental and numerical investigation. Materials 2022, 15, 3555. [Google Scholar] [CrossRef]

- Ekenel, M.; Roghani, H.; y Basalo, F.D.C.; Nanni, A. Evaluation of FRP Bars & Meshes Used as Secondary Reinforcement for Nonstructural Concrete Members for Building Code Compliance. Spec. Publ. 2022, 356, 109–119. [Google Scholar]

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1991.

- Almusallam, A.; Maslehuddin, M.; Abdul-Waris, M.; Khan, M. Effect of mix proportions on plastic shrinkage cracking of concrete in hot environments. Constr. Build. Mater. 1998, 12, 353–358. [Google Scholar] [CrossRef]

- Slowik, V.; Schmidt, M.; Fritzsch, R. Capillary pressure in fresh cement-based materials and identification of the air entry value. Cem. Concr. Compos. 2008, 30, 557–565. [Google Scholar] [CrossRef]

- Eskandarsefat, S. Investigation on the effects of mix water temperature on High-Early strength cement concrete properties—An experimental work and a case study. J. Build. Eng. 2018, 20, 208–212. [Google Scholar] [CrossRef]

- ASTM C1579-21; Standard Test Method for Evaluating Plastic Shrinkage Cracking of Restrained Fiber Reinforced Concrete (Using a Steel Form Insert). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D7913/D7913M-14; Standard Test Method for Bond Strength of Fiber-Reinforced Polymer Matrix Composite Bars to Concrete by Pullout Testing. ASTM International: West Conshohocken, PA, USA, 2020.

- Özkal, F.M.; Polat, M.; Yağan, M.; Öztürk, M.O. Mechanical properties and bond strength degradation of GFRP and steel rebars at elevated temperatures. Constr. Build. Mater. 2018, 184, 45–57. [Google Scholar] [CrossRef]

- ASTM C403/C403M-16; Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance. ASTM International: West Conshohocken, PA, USA, 2016.

- ACI 305R-20; Guide to Hot Weather Concreting. American Concrete Institute: Farmington Hills, MI, USA, 2020.

- ASTM D7957/D7957M-22; Standard Specification for Solid Round Glass Fiber Reinforced Polymer Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2022.

- Herrmann, H.J.; Roux, S. Statistical Models for the Fracture of Disordered Media; Elsevier: Amsterdam, The Netherlands, 1990; p. 353. [Google Scholar] [CrossRef]

- Bolander, J.E.; Eliáš, J.; Cusatis, G.; Nagai, K. Discrete mechanical models of concrete fracture. Eng. Fract. Mech. 2021, 257, 108030. [Google Scholar] [CrossRef]

- Rasmussen, L.L.; de Assis, A.P. Elastically-homogeneous lattice modelling of transversely isotropic rocks. Comput. Geotech. 2018, 104, 96–108. [Google Scholar] [CrossRef]

- Eliáš, J. Elastic properties of isotropic discrete systems: Connections between geometric structure and Poisson’s ratio. Int. J. Solids Struct. 2020, in press. [Google Scholar] [CrossRef] [Green Version]

- Lilliu, G.; van Mier, J. 3D lattice type fracture model for concrete. Eng. Fract. Mech. 2003, 70, 927–941. [Google Scholar] [CrossRef]

- Çopuroğlu, O.; Schlangen, E. Modeling of frost salt scaling. Cem. Concr. Res. 2008, 38, 27–39. [Google Scholar] [CrossRef]

- Smith, J.; Cusatis, G.; Pelessone, D.; Landis, E.; O’Daniel, J.; Baylot, J. Discrete modeling of ultra-high-performance concrete with application to projectile penetration. Int. J. Impact Eng. 2014, 65, 13–32. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Schlangen, E. Lattice modeling of rapid chloride migration in concrete. Cem. Concr. Res. 2014, 61–62, 49–63. [Google Scholar] [CrossRef]

- Eddy, L.; Nagai, K. Numerical simulation of beam-column knee joints with mechanical anchorages by 3D rigid body spring model. Eng. Struct. 2016, 126, 547–558. [Google Scholar] [CrossRef]

- Qiao, D.; Nakamura, H.; Yamamoto, Y.; Miura, T. Modeling of corrosion-induced damage in reinforced concrete considering electro-mechanical coupling. J. Adv. Concr. Technol. 2016, 14, 664–678. [Google Scholar] [CrossRef] [Green Version]

- Hwang, Y.K.; Bolander, J.E.; Lim, Y.M. Simulation of concrete tensile failure under high loading rates using three-dimensional irregular lattice models. Mech. Mater. 2016, 101, 136–146. [Google Scholar] [CrossRef]

- Alnaggar, M.; Di Luzio, G.; Cusatis, G. Modeling time-dependent behavior of concrete affected by alkali silica reaction in variable environmental conditions. Materials 2017, 10, 471. [Google Scholar] [CrossRef] [Green Version]

- Fahy, C.; Wheeler, S.J.; Gallipoli, D.; Grassl, P. Corrosion induced cracking modelled by a coupled transport-structural approach. Cem. Concr. Res. 2017, 94, 24–35. [Google Scholar] [CrossRef]

- Boumakis, I.; Luzio, G.D.; Marcon, M.; Vorel, J.; Wan-Wendner, R. Discrete element framework for modeling tertiary creep of concrete in tension and compression. Eng. Fract. Mech. 2018, 200, 263–282. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Meng, Y.; Jiradilok, P.; Matsumoto, K.; Nagai, K.; Asamoto, S. Expansive cracking and compressive failure simulations of ASR and DEF damaged concrete using a mesoscale discrete model. Cem. Concr. Compos. 2019, 104, 103404. [Google Scholar] [CrossRef]

- Shen, L.; Li, W.; Zhou, X.; Feng, J.; Luzio, G.D.; Ren, Q.; Cusatis, G. Multiphysics Lattice Discrete Particle Model for the simulation of concrete thermal spalling. Cem. Concr. Compos. 2020, 106, 103457. [Google Scholar] [CrossRef] [Green Version]

- Pan, Y.; Prado, A.; Porras, R.; Hafez, O.M.; Bolander, J.E. Lattice modeling of early-age behavior of structural concrete. Materials 2017, 10, 231. [Google Scholar] [CrossRef] [Green Version]

- Riding, K.A.; Poole, J.L.; Folliard, K.J.; Juenger, M.C.; Schindler, A.K. Modeling hydration of cementitious systems. ACI Mater. J. 2012, 109, 225–234. [Google Scholar]

- Bentz, D.P. A computer model to predict the surface temperature and time-of-wetness of concrete pavements and bridge decks. In NIST Interagency/Internal Report 6551; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Kawai, T. New discrete models and their application to seismic response analysis of structures. Nucl. Eng. Des. 1978, 48, 207–229. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Prasannan, S. Solidification theory for concrete creep. I: Formulation. J. Eng. Mech. ASCE 1989, 115, 1691–1703. [Google Scholar] [CrossRef] [Green Version]

- Di Luzio, G.; Cusatis, G. Solidification–microprestress–microplane (SMM) theory for concrete at early age: Theory, validation and application. Int. J. Solids Struct. 2013, 50, 957–975. [Google Scholar] [CrossRef] [Green Version]

- De Schutter, G.; Taerwe, L. Degree of hydration-based description of mechanical properties of early age concrete. Mater. Struct. 1996, 29, 335–344. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Mater. Constr. 1983, 16, 155–177. [Google Scholar] [CrossRef] [Green Version]

- Berton, S.; Bolander, J.E. Crack band model of fracture in irregular lattices. Comput. Methods Appl. Mech. Eng. 2006, 195, 7172–7181. [Google Scholar] [CrossRef]

- Kang, J.; Kim, K.; Lim, Y.M.; Bolander, J.E. Modeling of fiber-reinforced cement composites: Discrete representation of fiber pullout. Int. J. Solids Struct. 2014, 51, 1970–1979. [Google Scholar] [CrossRef] [Green Version]

- Focacci, F.; Nanni, A.; Bakis, C.E. Local bond-slip relationship for FRP reinforcement in concrete. J. Compos. Constr. 2000, 4, 24–31. [Google Scholar] [CrossRef] [Green Version]

- Ghourchian, S.; Wyrzykowski, M.; Plamondon, M.; Lura, P. On the mechanism of plastic shrinkage cracking in fresh cementitious materials. Cem. Concr. Res. 2019, 115, 251–263. [Google Scholar] [CrossRef]

- Schindler, A.; Ruiz, J.; Rasmussen, R.; Chang, G.; Wathne, L. Concrete pavement temperature prediction and case studies with the FHWA HIPERPAV models. Cem. Concr. Compos. 2004, 26, 463–471. [Google Scholar] [CrossRef]

- Scherer, G.W.; Zhang, J.; Quintanilla, J.A.; Torquato, S. Hydration and percolation at the setting point. Cem. Concr. Res. 2012, 42, 665–672. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, J.; Ichimaru, S.; Bolander, J.E. Multi-field models of fiber reinforced concrete for structural applications. Appl. Sci. 2020, 11, 184. [Google Scholar] [CrossRef]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

| Item | wt% |

|---|---|

| CaO | 64.1 |

| SiO | 20.3 |

| AlO | 4.8 |

| FeO | 3.5 |

| MgO | 0.9 |

| SO | 2.7 |

| NaO | 0.12 |

| KO | 0.30 |

| Loss on ignition | 2.5 |

| Constituent | kg/m | lb/yd |

|---|---|---|

| Portland Cement Type I/II | 517 | 871 |

| Water | 291 | 491 |

| Coarse Aggregate # 89 | 669 | 1128 |

| Fine Aggregate (Sand) | 860 | 1449 |

| Unit Weight | 2337 | 3939 |

| w/c | 0.56 | |

| GFRP Rebar | Bar Designation No. | Fiber Type | Nominal Diameter, mm [in] | Nominal Cross-Sectional Area, mm [in] | Measured Cross-Sectional Area, mm [in] | Fiber Content, % |

|---|---|---|---|---|---|---|

| M10 [3] | Glass | 9.5 [0.375] | 71 [0.11] | 87.67 [0.136] | 80 |

| Guaranteed Tensile Strength, MPa [ksi] | Modulus of Elasticity, GPa [Msi] | Mean Ultimate Tensile Strain | Guaranteed Bond Strength, MPa [ksi] |

|---|---|---|---|

| 952 [138.1] | 60.5 [8.78] | 1.9 | 1.84 [0.27] |

| Specimen ID | Reinforcement | Crack Onset, min | Crack Area, mm [in] | Crack Length, mm [in] | Crack Width, mm [in] |

|---|---|---|---|---|---|

| P-SC-1 | Plain | 139 | 133.5 [0.207] | 345.4 [13.6] | 0.39 [0.015] |

| P-SC-2 | Plain | 132 | 137.4 [0.213] | 290.0 [11.4] | 0.47 [0.019] |

| P-SC-3 | Plain | 131 | 202.6 [0.314] | 375.8 [14.8] | 0.54 [0.021] |

| S-SC-1 | Steel | 113 | 246.5 [0.382] | 353.1 [13.9] | 0.70 [0.027] |

| S-SC-2 | Steel | 141 | 73.5 [0.114] | 188.0 [7.4] | 0.39 [0.015] |

| S-SC-3 | Steel | 131 | 129.7 [0.201] | 342.9 [13.5] | 0.38 [0.015] |

| G-SC-1 | GFRP | 115 | 112.9 [0.175] | 340.4 [13.4] | 0.33 [0.013] |

| G-SC-2 | GFRP | NA | 58.1 [0.090] | 139.7 [5.5] | 0.42 [0.016] |

| G-SC-3 | GFRP | 120 | 219.4 [0.340] | 322.6 [12.7] | 0.68 [0.027] |

| Specimen ID | Elapsed Time, min | Penetration Resistance, MPa [psi] | Set Type | ASTM Set Time, min | Fit Curve Set Time, min |

|---|---|---|---|---|---|

| 171 | 1.4 [204] | ||||

| 214 | 6.9 [1000] | Initial set (IS) | 196 | ||

| 1 | 259 | 19.3 [2800] | |||

| 287 | 40.3 [5840] | Final set (FS) | 280 | ||

| 323 | 57.4 [8320] | ||||

| 175 | 1.4 [204] | ||||

| 215 | 7.2 [1040] | Initial set (IS) | 194 | IS = 203 | |

| 2 | 258 | 18.5 [2680] | |||

| 286 | 37 [5360] | Final set (FS) | 292 | FS = 270 | |

| 323 | 48.3 [7000] | ||||

| 177 | 1.9 [272] | ||||

| 216 | 7.2 [1040] | Initial set (IS) | 187 | ||

| 3 | 256 | 20.4 [2960] | |||

| 285 | 35.9 [5200] | Final set (FS) | 288 | ||

| 322 | 56.8 [8240] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roghani, H.; Nanni, A.; Bolander, J.E. Early-Age Cracking Behavior of Concrete Slabs with GFRP Reinforcement. Materials 2023, 16, 5489. https://doi.org/10.3390/ma16155489

Roghani H, Nanni A, Bolander JE. Early-Age Cracking Behavior of Concrete Slabs with GFRP Reinforcement. Materials. 2023; 16(15):5489. https://doi.org/10.3390/ma16155489

Chicago/Turabian StyleRoghani, Hossein, Antonio Nanni, and John E. Bolander. 2023. "Early-Age Cracking Behavior of Concrete Slabs with GFRP Reinforcement" Materials 16, no. 15: 5489. https://doi.org/10.3390/ma16155489

APA StyleRoghani, H., Nanni, A., & Bolander, J. E. (2023). Early-Age Cracking Behavior of Concrete Slabs with GFRP Reinforcement. Materials, 16(15), 5489. https://doi.org/10.3390/ma16155489