Optical Characterization of Materials for Precision Reference Spheres for Use with Structured Light Sensors

Abstract

1. Introduction

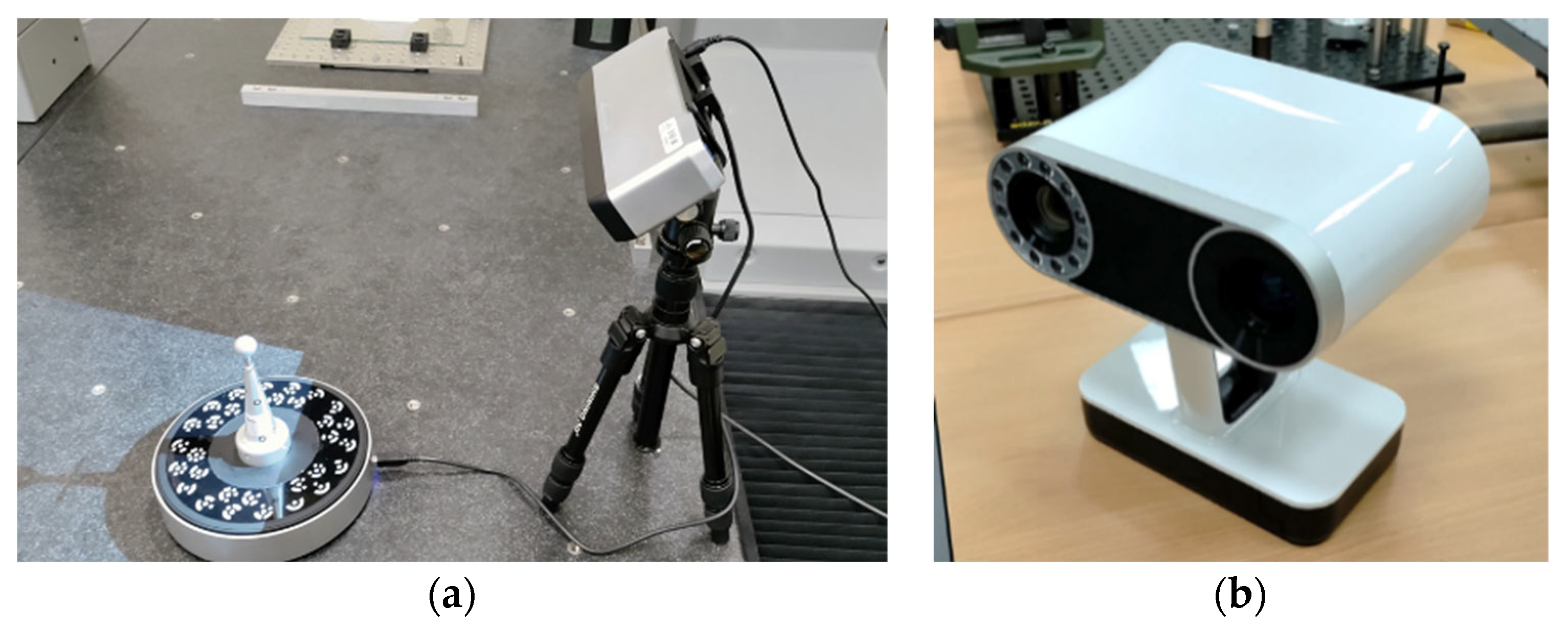

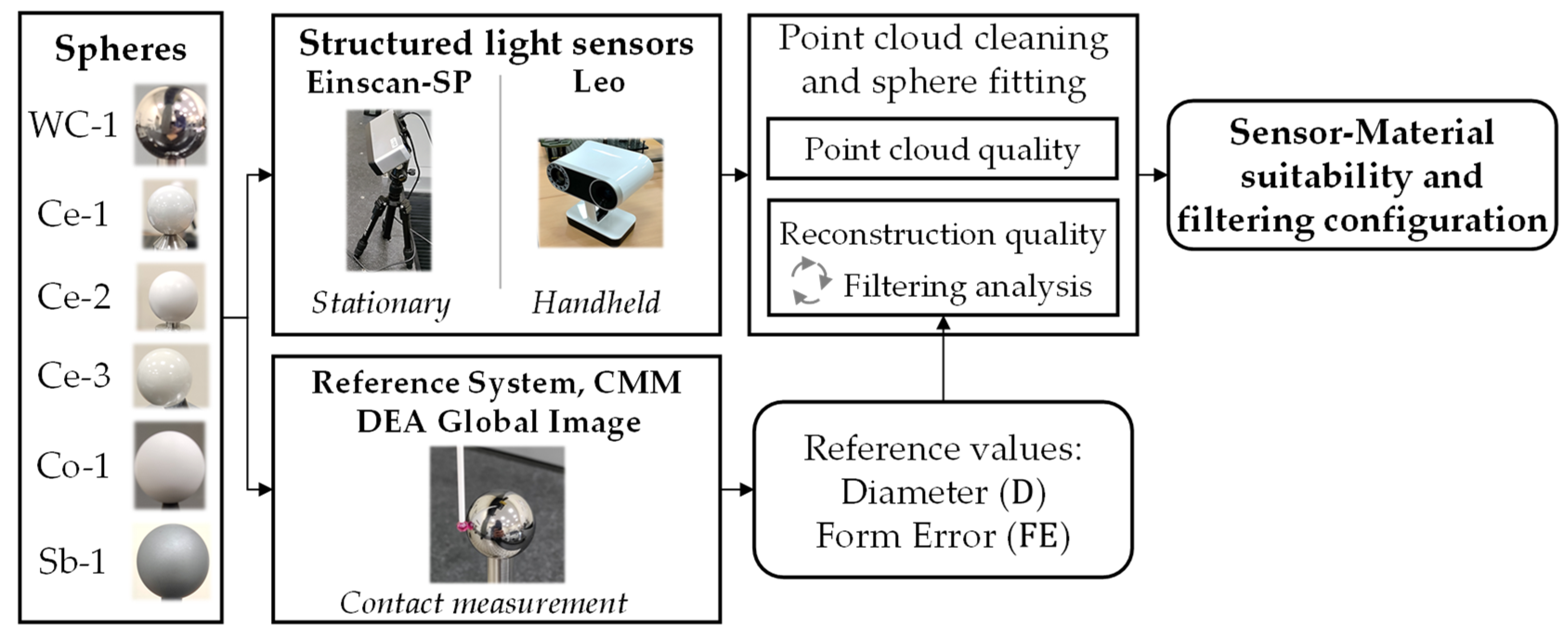

2. Materials and Methods

2.1. Materials

| Spec | Units | Einscan-SP | Leo |

|---|---|---|---|

| Camera resolution | MP | 1.3 | 2.3 |

| Light source | - | White light | 3D-VCSEL a, 2D-white light |

| Net weight | kg | 4.2 b | 2.6 |

| Working distance | mm | 290–480 | 350–1200 |

| Point accuracy | µm | 50 c | 100 + 300·L/1000 d |

| Max. scan volume | mm | 200 × 200 × 200 e | 244 × 142 g |

| mm | 1200 × 1200 × 1200 f | 838 × 488 h | |

| Single scan time | s | 4 | 0.023 |

| Manufacturer | - | Shining 3D | Artec 3D |

| Price | EUR | 3000 | 34,800 |

| Cloud generation | - | By external computer | By the device |

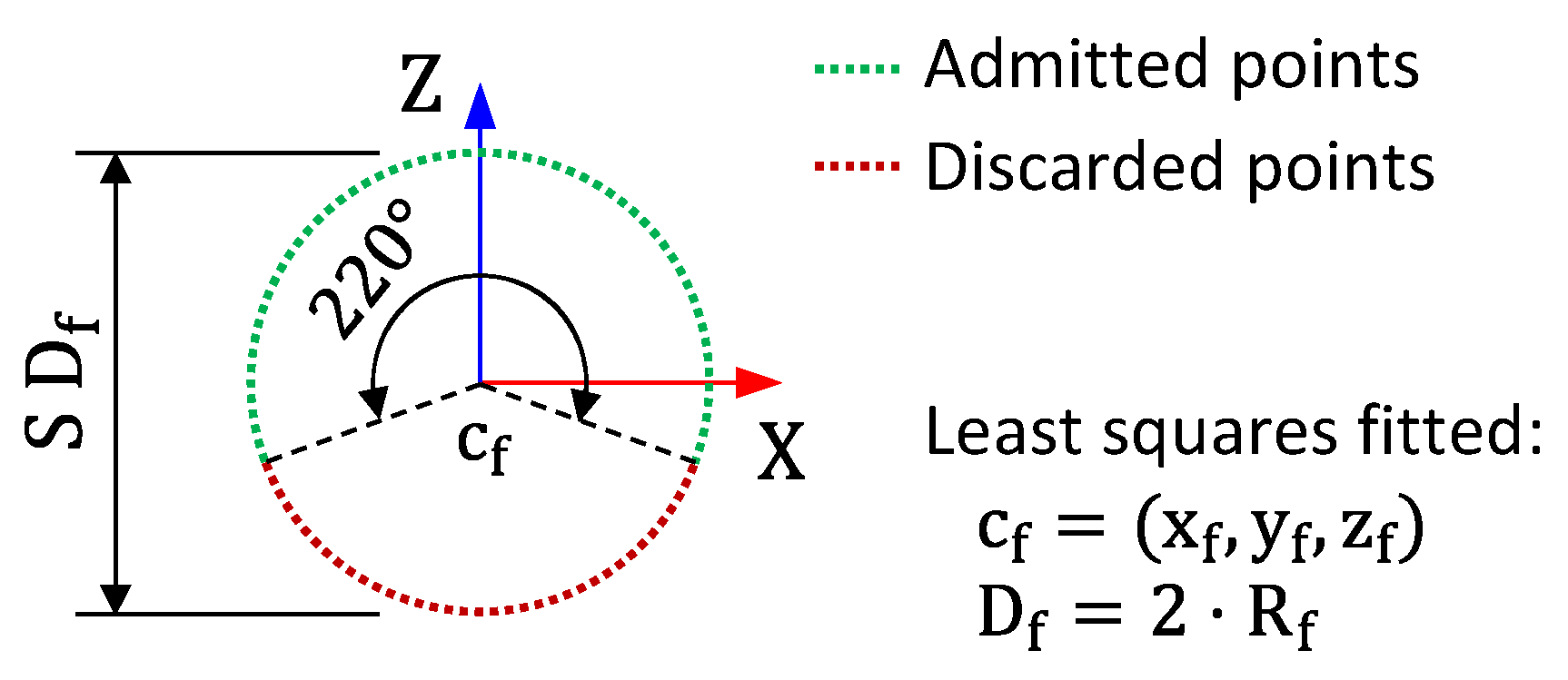

2.2. Methods

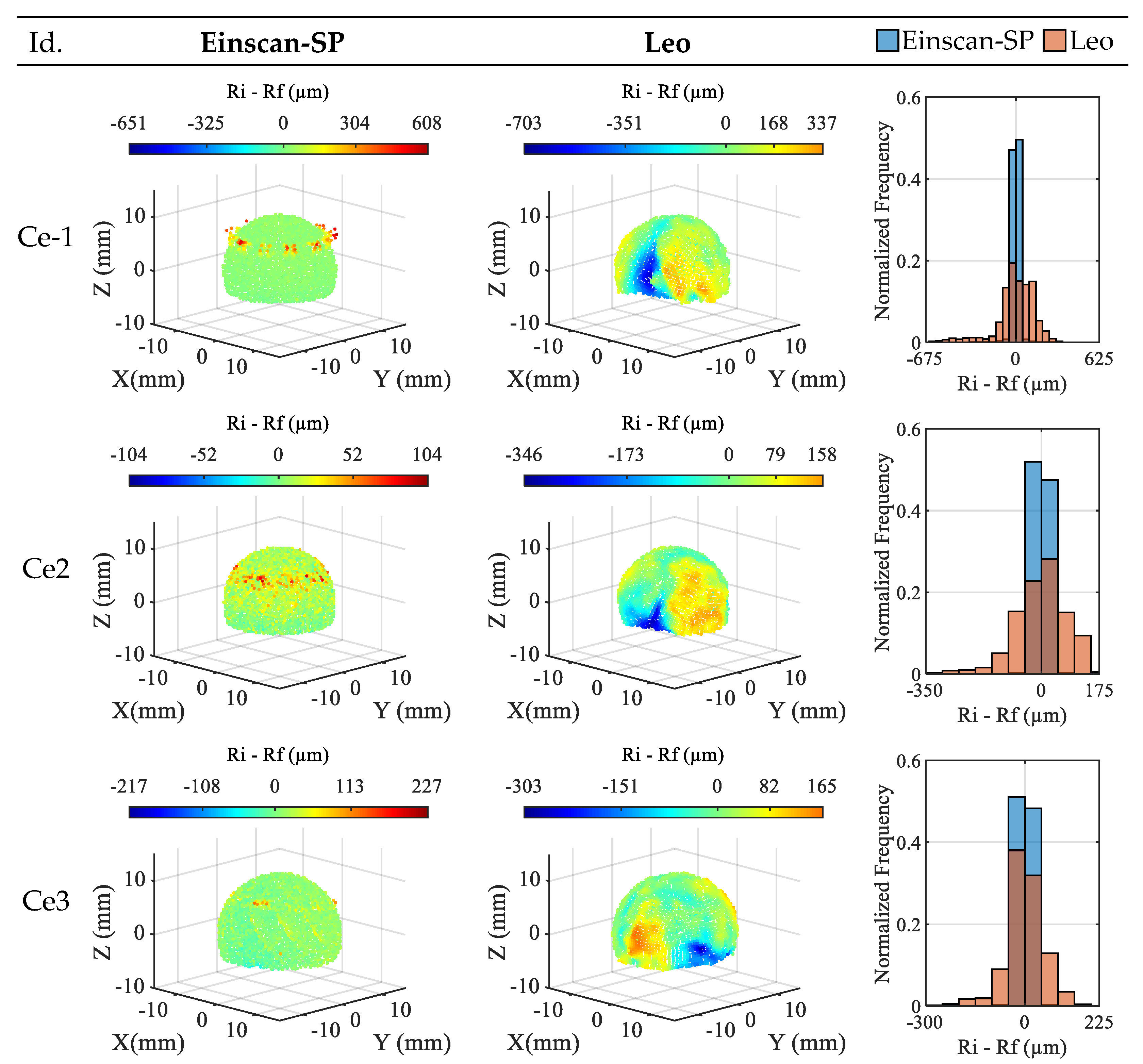

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Hu, H.; Xue, D.; Cheng, Q.; Yang, X.; Tang, W.; Qiao, G.; Zhang, X. Wavefront optical spacing of freeform surfaces and its measurement using CGH interferometry. Opt. Lasers Eng. 2023, 161, 107350. [Google Scholar] [CrossRef]

- Foix, S.; Alenya, G.; Torras, C. Lock-in time-of-flight (ToF) cameras: A survey. IEEE Sens. J. 2011, 11, 1917–1926. [Google Scholar] [CrossRef]

- O’Riordan, A.; Newe, T.; Dooly, G.; Toal, D. Stereo vision sensing: Review of existing systems. In Proceedings of the 12th International Conference on Sensing Technology (ICST), Limerik, Ireland, 3 December 2018. [Google Scholar]

- Danzl, R.; Helmli, F.; Scherer, S. Focus Variation-a Robust Technology for High Resolution Optical 3D Surface Metrology. Stroj. Vestn-J. Mech. E 2011, 57, 245–256. [Google Scholar] [CrossRef]

- Amann, M.C.; Bosch, T.M.; Lescure, M.; Myllylae, R.A.; Rioux, M. Laser ranging: A critical review of unusual techniques for distance measurement. Opt. Eng. 2001, 40, 10–19. [Google Scholar]

- Gorthi, S.S.; Rastogi, P. Fringe projection techniques: Whither we are? Opt. Lasers Eng. 2010, 48, 133–140. [Google Scholar] [CrossRef]

- Stevenson, W.H. Use of laser triangulation probes in coordinate measuring machines for part tolerance inspection and reverse engineering. Ind. Appl. Opt. Ins. Met. Sens. 1993, 1821, 406–414. [Google Scholar]

- Santolaria, J.; Pastor, J.J.; Brosed, F.J.; Aguilar, J.J. A one-step intrinsic and extrinsic calibration method for laser line scanner operation in coordinate measuring machines. Meas. Sci. Technol. 2009, 20, 045107. [Google Scholar] [CrossRef]

- Brosed, F.J.; Aguilar, J.J.; Guillomía, D.; Santolaria, J. 3D geometrical inspection of complex geometry parts using a novel laser triangulation sensor and a robot. Sensors 2010, 11, 90–110. [Google Scholar] [CrossRef] [PubMed]

- Jotić, G.; Štrbac, B.; Toth, T.; Blanuša, V.; Dovica, M.; Hadžistević, M. The Analysis of Metrological Characteristics of Different Coordinate Measuring Systems. Teh. Vjesn. 2023, 30, 32–38. [Google Scholar]

- Southon, N.; Stavroulakis, P.; Goodridge, R.; Leach, R. In-process measurement and monitoring of a polymer laser sintering powder bed with fringe projection. Mater. Des. 2018, 157, 227–234. [Google Scholar] [CrossRef]

- Dickins, A.; Widjanarko, T.; Sims-Waterhouse, D.; Thompson, A.; Lawes, S.; Senin, N.; Leach, R. Multi-view fringe projection system for surface topography measurement during metal powder bed fusion. J. Opt. Soc. AM A 2020, 37, B93–B105. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Vallabh, C.K.P.; Xiong, Y.; Zhao, X. A systematic study and framework of fringe projection profilometry with improved measurement performance for in-situ LPBF process monitoring. Measurement 2022, 191, 110796. [Google Scholar] [CrossRef]

- Liu, Y.; Blunt, L.; Zhang, Z.; Rahman, H.A.; Gao, F.; Jiang, X. In-situ areal inspection of powder bed for electron beam fusion system based on fringe projection profilometry. Addit. Manuf. 2020, 31, 100940. [Google Scholar] [CrossRef]

- Pinto, T.; Kohler, C.; Albertazzi, A. Regular mesh measurement of large free form surfaces using stereo vision and fringe projection. Opt. Lasers Eng. 2012, 50, 910–916. [Google Scholar] [CrossRef]

- Nguyen, H.; Nguyen, D.; Wang, Z.; Kieu, H.; Le, M. Real-time, high-accuracy 3D imaging and shape measurement. Appl. Opt. 2015, 54, A9–A17. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Jia, S.; Dong, J.; Bao, Q.; Yang, J.; Lian, Q.; Li, D. Multi-frequency color-marked fringe projection profilometry for fast 3D shape measurement of complex objects. Opt. Express 2015, 23, 24152–24162. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, C.; Jiang, H.; Li, X. Multisensor registration using phase matching for large-scale fringe projection profilometry. Measurement 2021, 182, 109675. [Google Scholar] [CrossRef]

- Pan, J.; Huang, P.S.; Chiang, F.P. Color-coded binary fringe projection technique for 3-D shape measurement. Opt. Eng. 2005, 44, 023606. [Google Scholar] [CrossRef]

- Rieke-Zapp, D.; Royo, S. Structured light 3D scanning. In Digital Techniques for Documenting and Preserving Cultural Heritage, 1st ed.; Bentkowska-Kafel, A., MacDonald, L., Eds.; Arc Humanities Press: Yorkshire, UK, 2017; pp. 247–251. [Google Scholar]

- Srinivasan, V.; Liu, H.C.; Halioua, M. Automated phase-measuring profilometry of 3-D diffuse objects. Appl. Opt. 1984, 23, 3105–3108. [Google Scholar] [CrossRef]

- Zhang, Z.H. Review of single-shot 3D shape measurement by phase calculation-based fringe projection techniques. Opt. Lasers Eng. 2012, 50, 1097–1106. [Google Scholar] [CrossRef]

- Feng, S.; Zuo, C.; Zhang, L.; Tao, T.; Hu, Y.; Yin, W.; Quian, J.; Chen, Q. Calibration of fringe projection profilometry: A comparative review. Opt. Lasers Eng. 2021, 143, 106622. [Google Scholar] [CrossRef]

- Wu, Z.; Guo, W.; Zhang, Q. Two-frequency phase-shifting method vs. Gray-coded-based method in dynamic fringe projection profilometry: A comparative review. Opt. Lasers Eng. 2022, 153, 106995. [Google Scholar]

- Zhang, S. Absolute phase retrieval methods for digital fringe projection profilometry: A review. Opt. Lasers Eng. 2018, 107, 28–37. [Google Scholar] [CrossRef]

- Meana, V.; Cuesta, E.; Álvarez, B.J. Testing the Sandblasting Process in the Manufacturing of Reference Spheres for Non-Contact Metrology Applications. Materials 2021, 14, 5187. [Google Scholar] [CrossRef]

- Meana, V.; Cuesta, E.; Álvarez, B.J.; Giganto, S.; Martínez-Pellitero, S. Comparison of Chemical and Mechanical Surface Treatments on Metallic Precision Spheres for Using as Optical Reference Artifacts. Materials 2022, 15, 3741. [Google Scholar] [CrossRef]

- Shiou, F.J.; Chen, M.J. Intermittent process hybrid measurement system on the machining centre. Int. J. Prod. Res. 2003, 41, 4403–4427. [Google Scholar] [CrossRef]

- Shim, H.; Lee, S. Performance evaluation of time-of-flight and structured light depth sensors in radiometric/geometric variations. Opt. Eng. 2012, 51, 094401. [Google Scholar] [CrossRef]

- Blanco, D.; Valiño, G.; Fernández, P.; Rico, J.C.; Mateos, S. Influence of part material and sensor adjustment on the quality of digitised point-clouds using conoscopic holography. Precis. Eng. 2015, 42, 42–52. [Google Scholar] [CrossRef]

- Feng, S.; Zhang, L.; Zuo, C.; Tao, T.; Chen, Q.; Gu, G. High dynamic range 3d measurements with fringe projection profilometry: A review. Meas. Sci. Technol. 2018, 29, 122001. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, M.; Zhou, F.; You, D. Stable 3D measurement method for high dynamic range surfaces based on fringe projection profilometry. Opt. Lasers Eng. 2023, 166, 107542. [Google Scholar] [CrossRef]

- Basyooni, M.A.; Ahmed, A.M.; Shaban, M. Plasmonic hybridization between two metallic nanorods. Optik 2018, 172, 1069–1078. [Google Scholar] [CrossRef]

- Nikolova, M.P.; Apostolova, M.D. Advances in Multifunctional Bioactive Coatings for Metallic Bone Implants. Materials 2022, 16, 183. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Chen, Q.; Zuo, C.; Li, R.; Shen, G.; Feng, F. Automatic identification and removal of outliers for high-speed fringe projection profilometry. Opt. Eng. 2013, 52, 013605. [Google Scholar] [CrossRef]

- Blanco, D.; Fernandez, P.; Cuesta, E.; Suárez, C.M. Influence of ambient light on the quality of laser digitized surfaces. In Proceedings of the World Congress on Engineering 2008, London, UK, 2 July 2008. [Google Scholar]

- Ghandali, P.; Khameneifar, F.; Mayer, J.R.R. A pseudo-3D ball lattice artifact and method for evaluating the metrological performance of structured-light 3D scanners. Opt. Lasers Eng. 2019, 121, 87–95. [Google Scholar] [CrossRef]

- Bonin, R.; Khameneifar, F.; Mayer, J.R.R. Evaluation of the metrological performance of a handheld 3D laser scanner using a pseudo-3D ball-lattice artifact. Sensors 2021, 21, 2137. [Google Scholar] [CrossRef]

- Dickin, F.; Pollard, S.; Adams, G. Mapping and correcting the distortion of 3D structured light scanners. Precis. Eng. 2021, 72, 543–555. [Google Scholar] [CrossRef]

- Schild, L.; Sasse, F.; Kaiser, J.P.; Lanza, G. Assessing the optical configuration of a structured light scanner in metrological use. Meas. Sci. Technol. 2022, 33, 085018. [Google Scholar] [CrossRef]

- ISO 10360-2; Geometrical Product Specifications (GPS)—Acceptance and Reverification Tests for Coordinate Measuring Machines (CMM). International Organization for Standardization (ISO): Geneva, Switzerland, 2009.

- Carmignato, S.; De Chiffre, L.; Bosse, H.; Leach, R.K.; Balsamo, A.; Estler, W.T. Dimensional artefacts to achieve metrological traceability in advanced manufacturing. CIRP Ann. 2020, 69, 693–716. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.; Bao, W.; Gao, J. A high-precision registration method based on auxiliary sphere targets. In Proceedings of the 2014 International Conference on Digital Image Computing: Techniques and Applications (DICTA), Wollongong, Australia, 25 November 2014. [Google Scholar]

- Wang, Y.; Shi, H.; Zhang, Y.; Zhang, D. Automatic registration of laser point cloud using precisely located sphere targets. J. Appl. Remote Sens. 2014, 8, 083588. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.; Gao, J.; Huang, Y.; Towers, D.P. High-Precision registration of point clouds based on sphere feature constraints. Sensors 2016, 17, 72. [Google Scholar] [CrossRef] [PubMed]

- Puerto, P.; Heißelmann, D.; Müller, S.; Mendikute, A. Methodology to Evaluate the Performance of Portable Photogrammetry for Large-Volume Metrology. Metrology 2022, 2, 320–334. [Google Scholar] [CrossRef]

- ZTA Zirconia Toughened Alumina; Sandoz. Available online: https://sandoz.ch/wp-content/uploads/2021/09/ZTA_zirconia_toughned.pdf (accessed on 25 January 2023).

- Einscan-SE/SP Desktop 3D Scanner; Shining 3D. Available online: https://encdn.shining3d.com/2020/08/SE-SPen.pdf (accessed on 25 January 2023).

- Einscan SE/SP User Manual, v3.0.0.1; Shining 3D. Available online: https://stomshop.pro/docs/shining-3d-einscan-se-sp-user-manual-eng.pdf (accessed on 25 January 2023).

- Leo a Smart Professional 3D Scanner for a Next-Generation User Experience; Artec3D. Available online: https://www.artec3d.com/files/pdf/Artec3D-Leo.pdf (accessed on 17 February 2023).

| Id. | Material | Finishing | Nominal D (mm) |

|---|---|---|---|

| WC-1 | Tungsten carbide | Polished | 25 |

| Ce-1 | ZrO2 | Polished | 20 |

| Ce-2 | ZTA 1 | Matte | 20 |

| Ce-3 | Al2O3 | Polished | 22 |

| Co-1 | Coated steel | Coated—Mate | 25 |

| Sb-1 | Stainless steel | Sandblasted | 25 |

|  |  |  |  |  |

| WC-1 | Ce-1 | Ce-2 | Ce-3 | Co-1 | Sb-1 |

| Id. | Material | Finishing | CMM Measurement | |

|---|---|---|---|---|

| (mm) | (µm) | |||

| WC-1 | Tungsten carbide | Polished | 24.9994 | 0.4 |

| Ce-1 | ZrO2 | Polished | 19.9995 | 0.8 |

| Ce-2 | ZTA | Mate | 20.0012 | 0.8 |

| Ce-3 | Al2O3 | Polished | 22.0005 | 1.5 |

| Co-1 | Coated steel | Coated—Mate | 25.4878 | 4.6 |

| Sb-1 | Stainless steel | Sandblasted | 25.0055 | 2.9 |

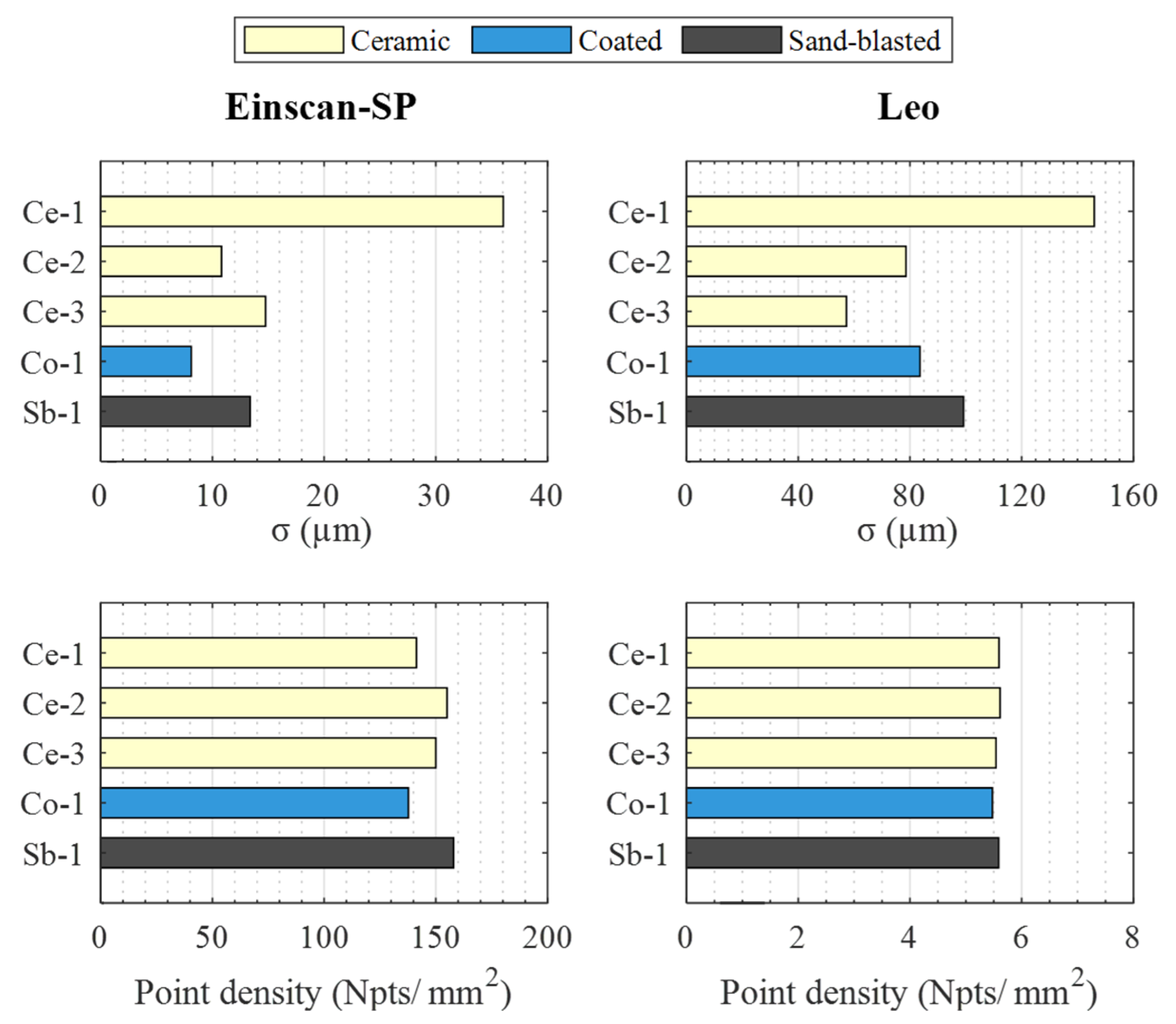

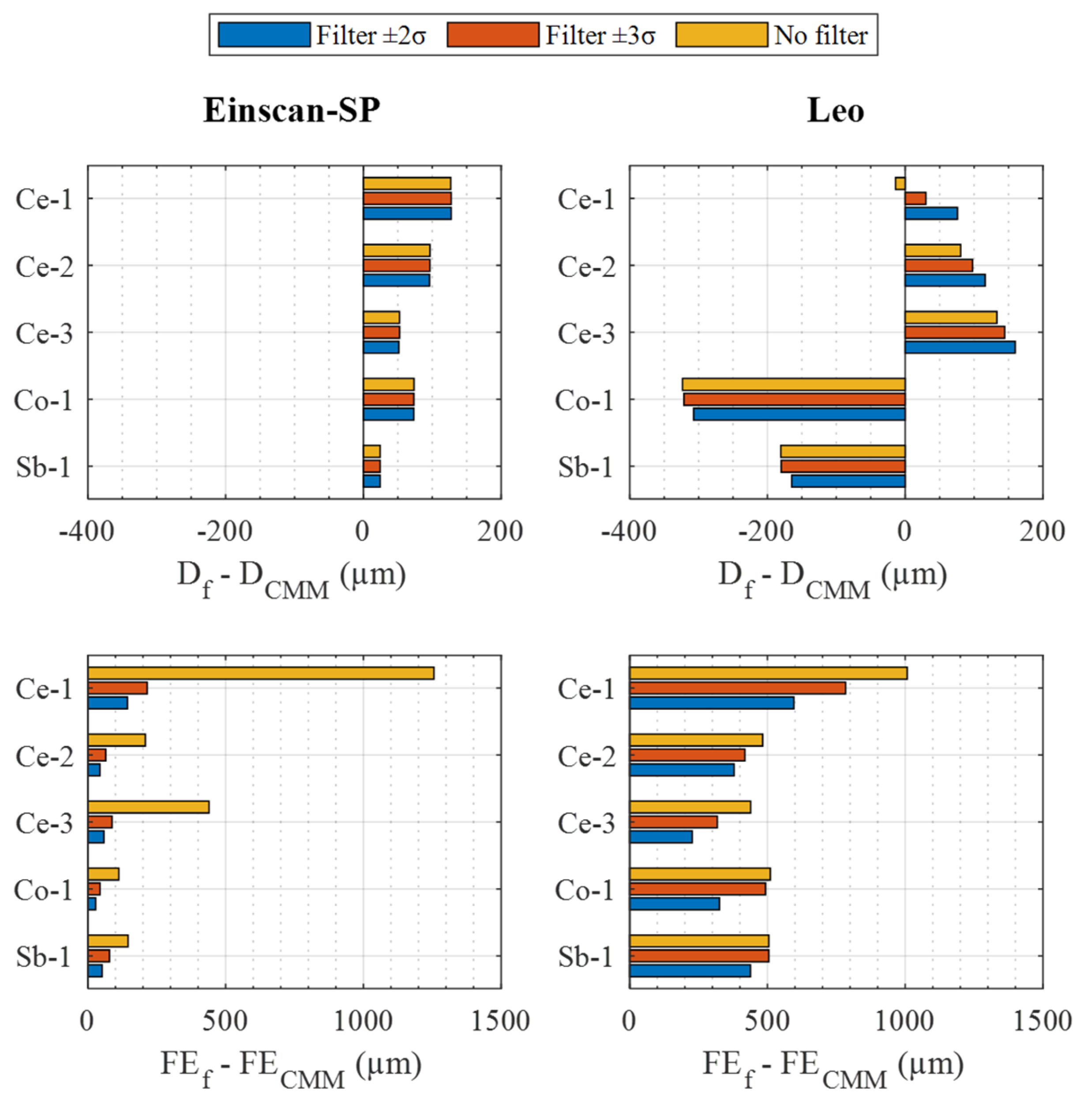

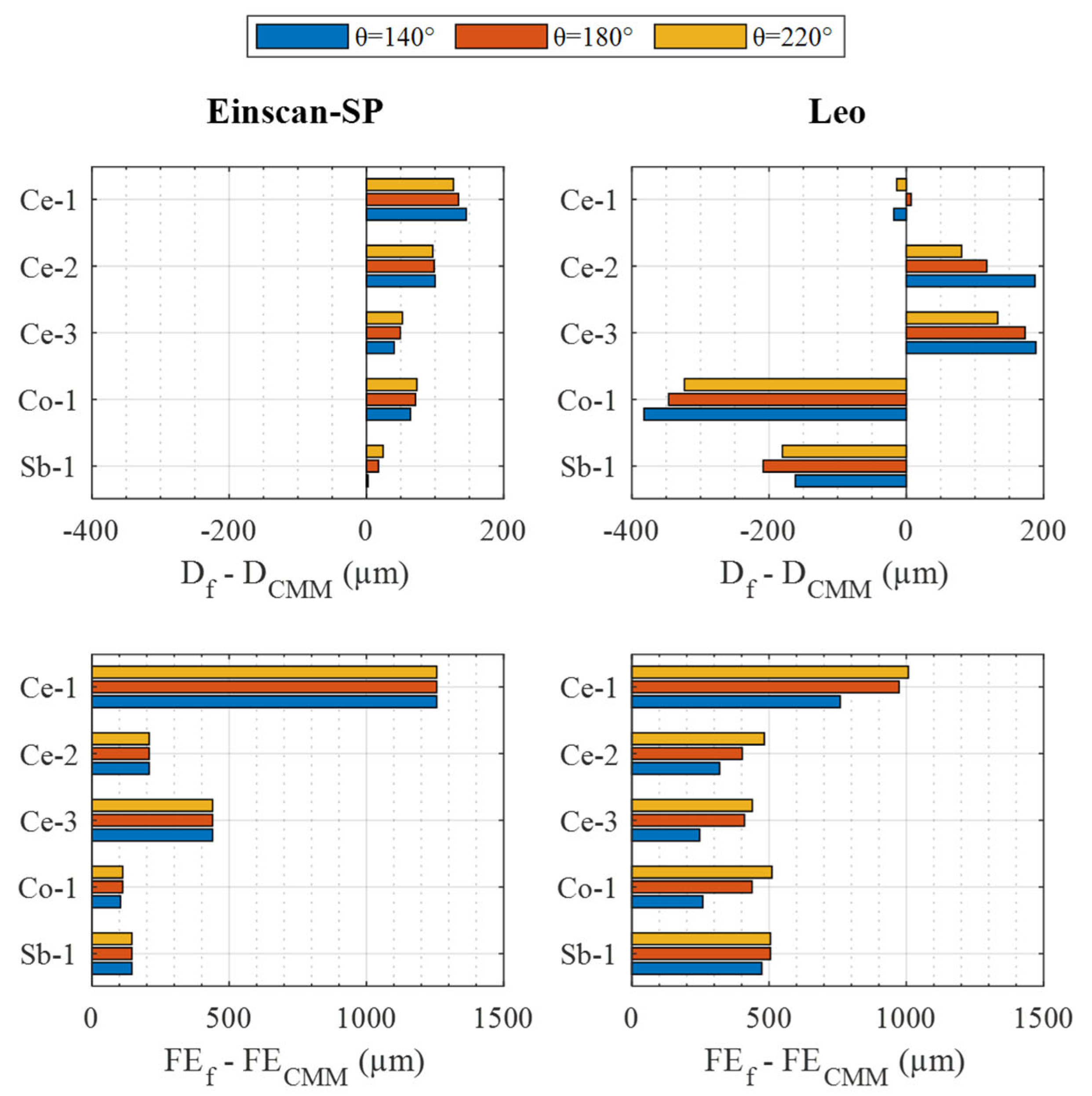

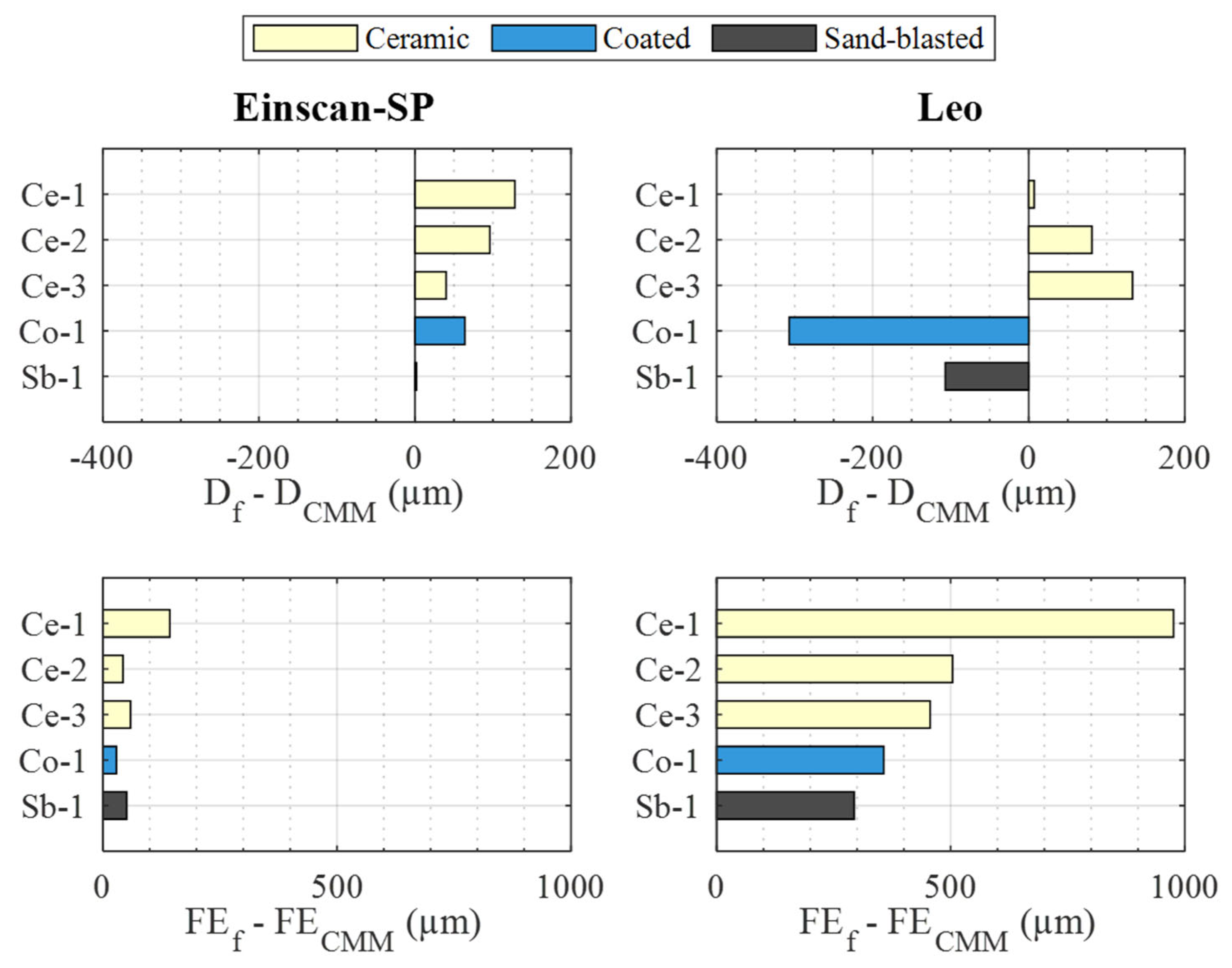

| Einscan-SP | Leo | |||||||

|---|---|---|---|---|---|---|---|---|

| θ | k | θ | ||||||

| Id. | - | ° | µm | µm | - | ° | µm | µm |

| Ce-1 | 2 | 220 | 128 | 143 | 0 | 180 | 7 | 976 |

| Ce-2 | 2 | 220 | 96 | 43 | 0 | 220 | 81 | 504 |

| Ce-3 | 2 | 140 | 40 | 59 | 0 | 220 | 133 | 456 |

| Co-1 | 2 | 140 | 64 | 29 | 2 | 220 | −307 | 357 |

| Sb-1 | 2 | 140 | 2 | 51 | 2 | 140 | −107 | 294 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zapico, P.; Meana, V.; Cuesta, E.; Mateos, S. Optical Characterization of Materials for Precision Reference Spheres for Use with Structured Light Sensors. Materials 2023, 16, 5443. https://doi.org/10.3390/ma16155443

Zapico P, Meana V, Cuesta E, Mateos S. Optical Characterization of Materials for Precision Reference Spheres for Use with Structured Light Sensors. Materials. 2023; 16(15):5443. https://doi.org/10.3390/ma16155443

Chicago/Turabian StyleZapico, Pablo, Victor Meana, Eduardo Cuesta, and Sabino Mateos. 2023. "Optical Characterization of Materials for Precision Reference Spheres for Use with Structured Light Sensors" Materials 16, no. 15: 5443. https://doi.org/10.3390/ma16155443

APA StyleZapico, P., Meana, V., Cuesta, E., & Mateos, S. (2023). Optical Characterization of Materials for Precision Reference Spheres for Use with Structured Light Sensors. Materials, 16(15), 5443. https://doi.org/10.3390/ma16155443