Vibration Analysis and Damping Effect of Blade-Hard Coating Composite Structure Based on Base Excitation

Abstract

1. Introduction

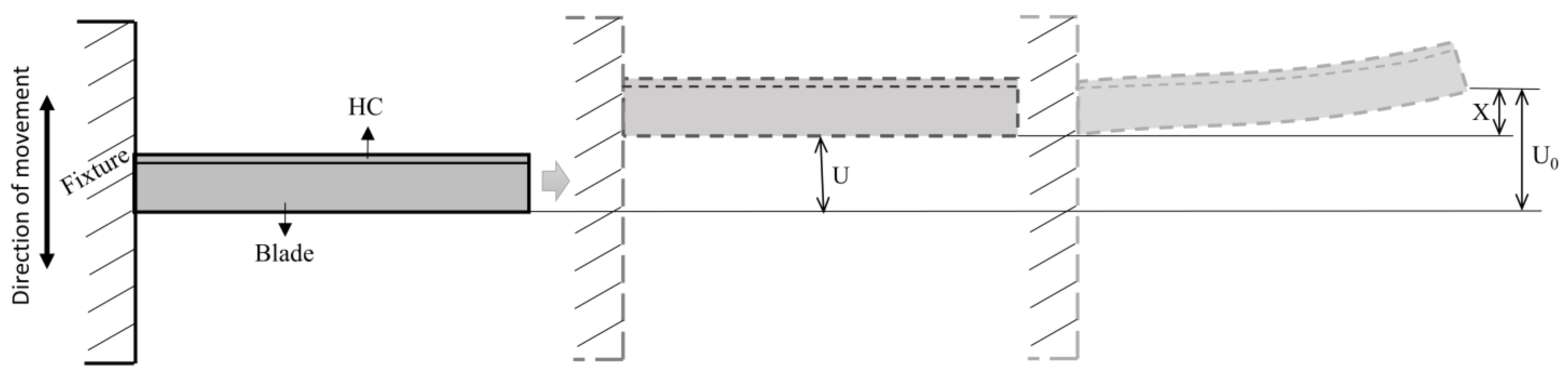

2. Vibration Response of the BHC by Base Excitation

3. Model of BHC Composite Structure

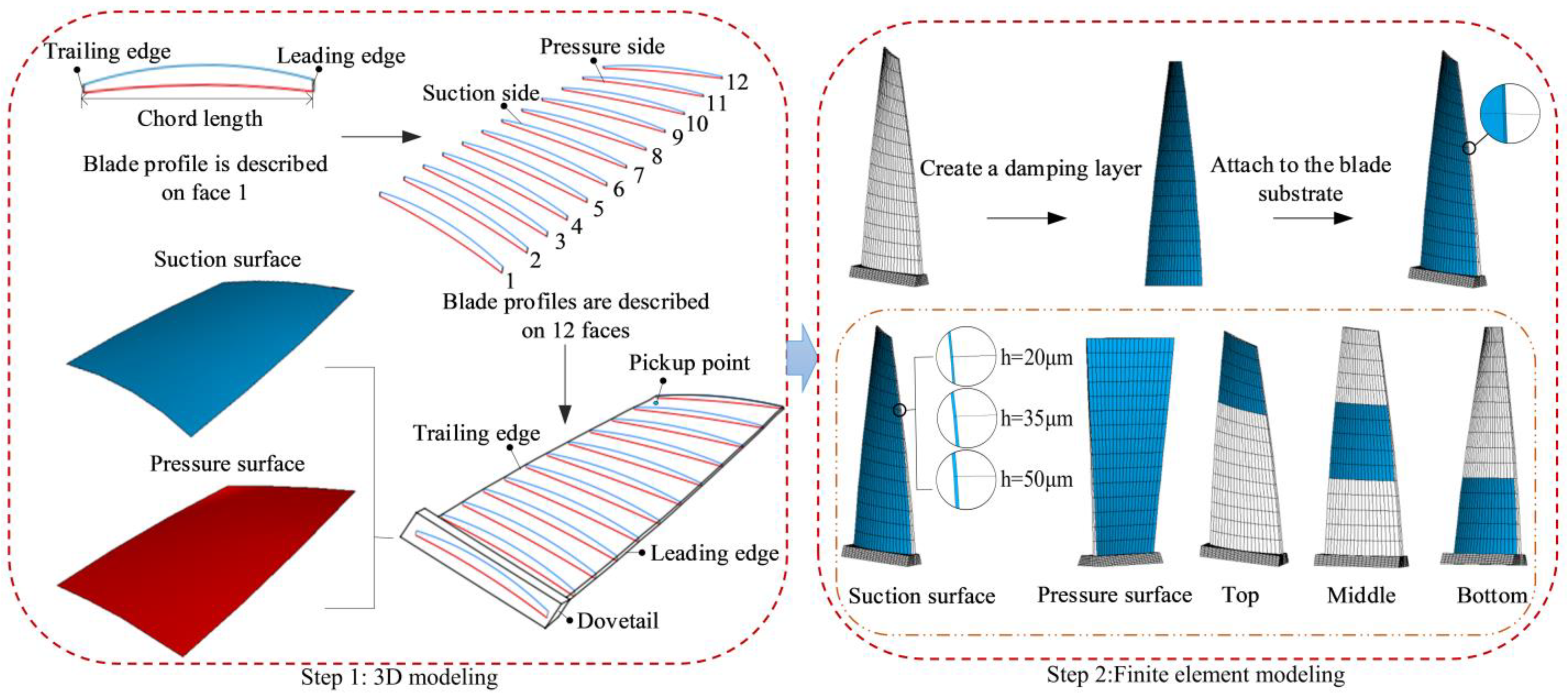

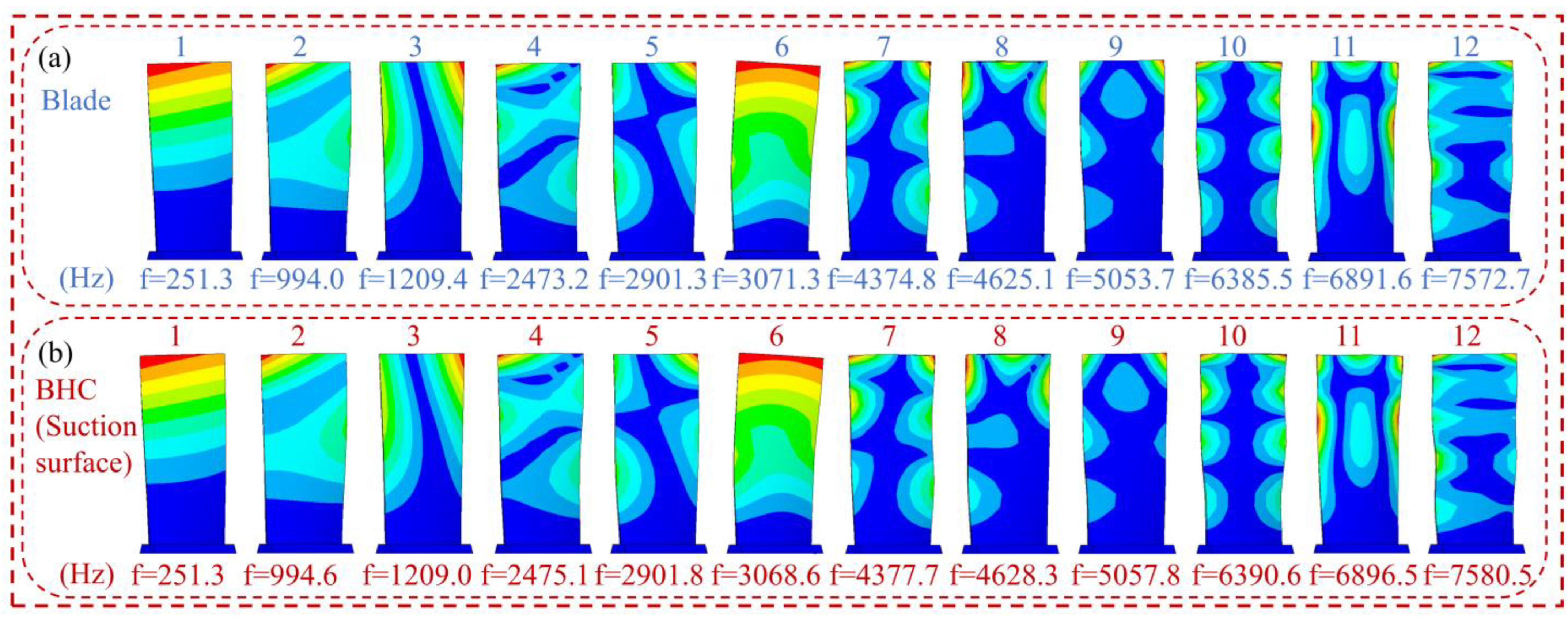

3.1. Finite Element Modeling Using ANSYS Software

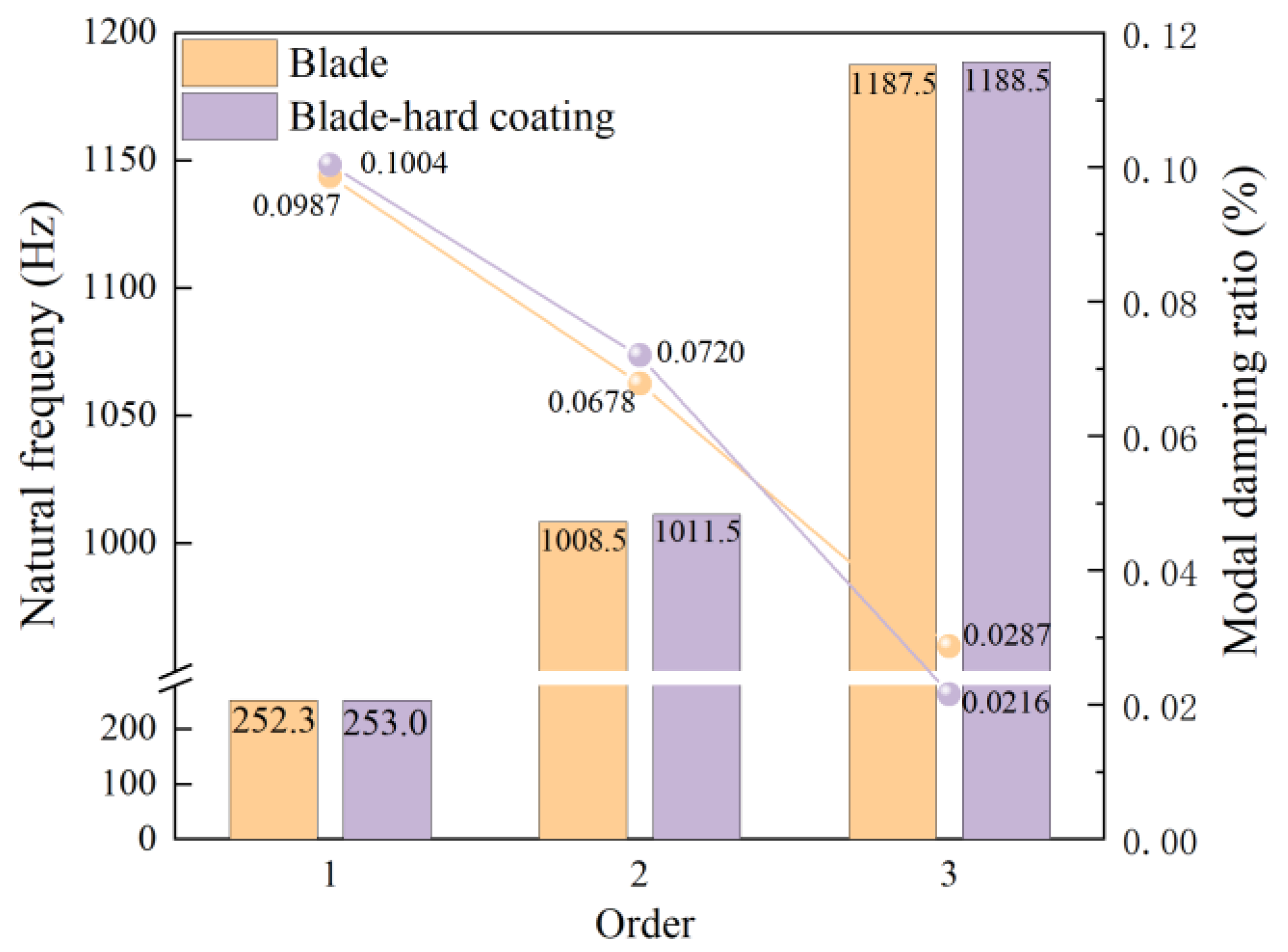

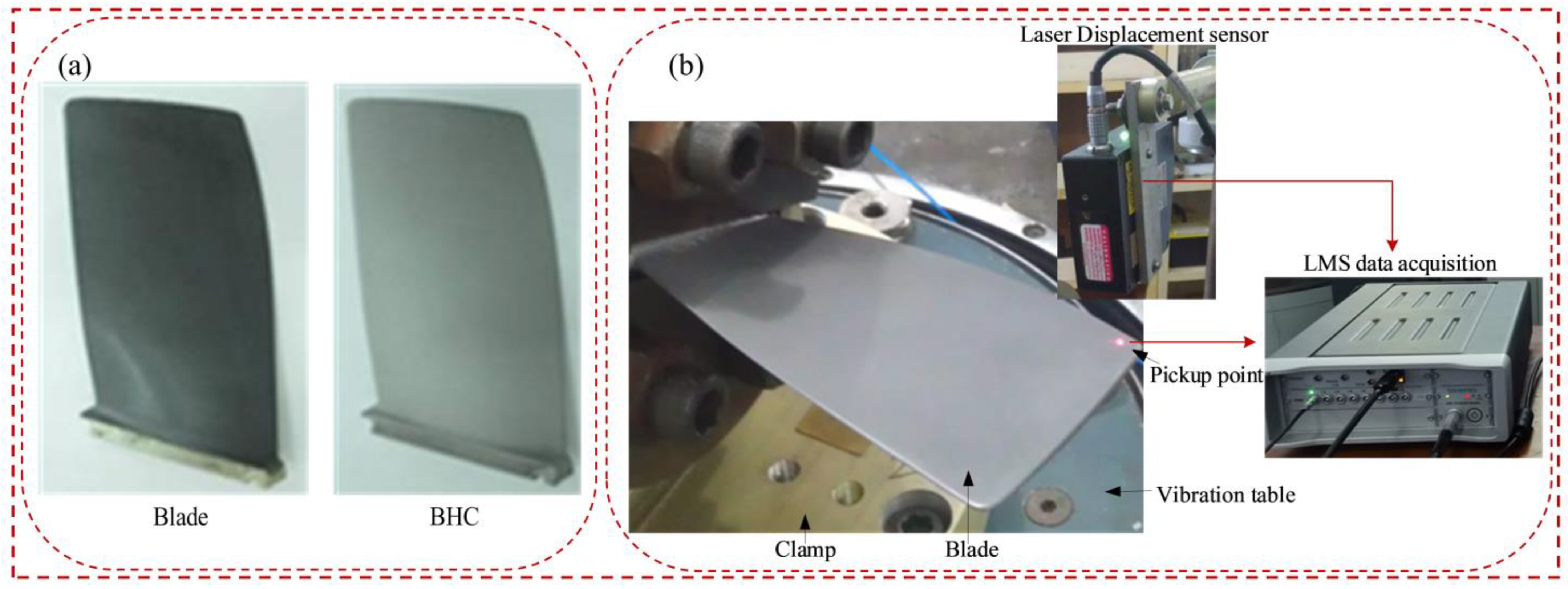

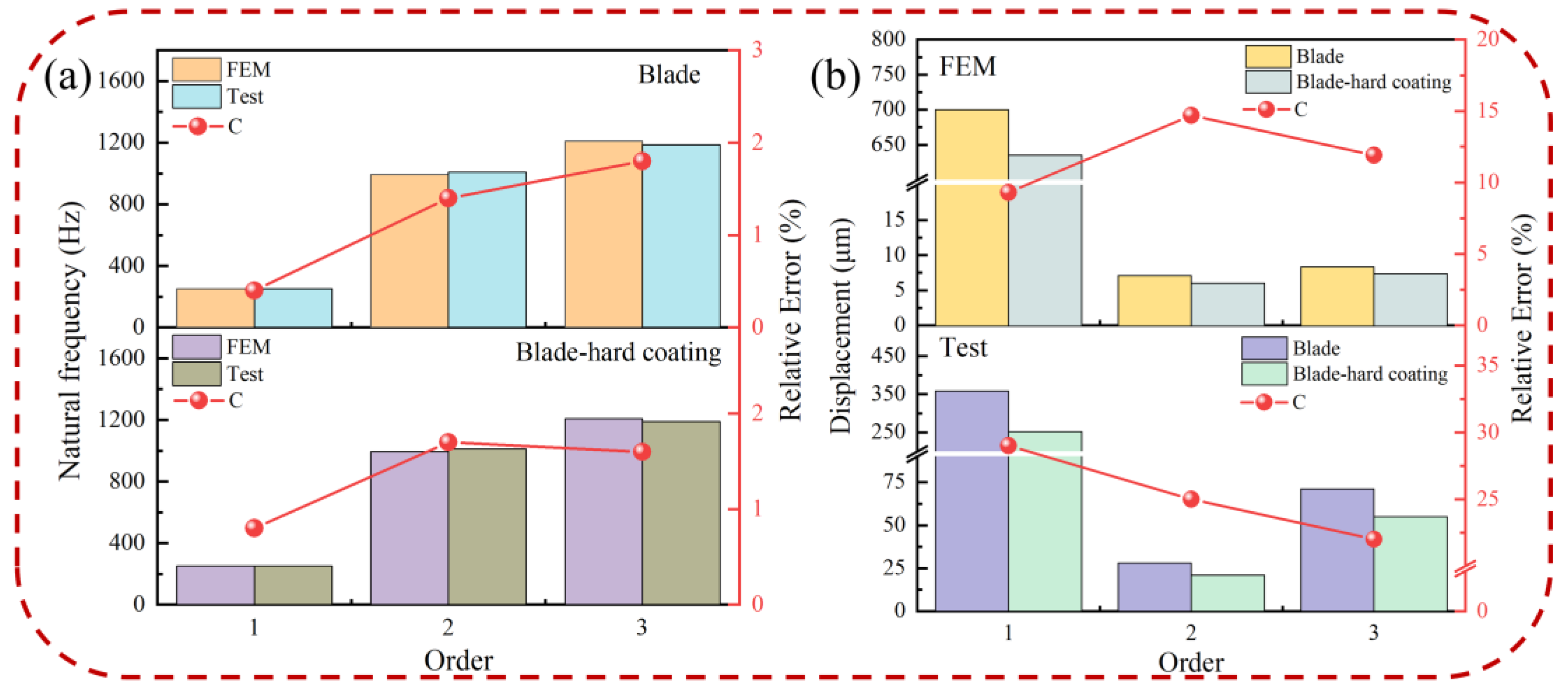

3.2. Experimental Verification of Finite Element Modeling Method of BHC

4. Effects of Material Parameters of HC on Vibration Reduction of the Blade

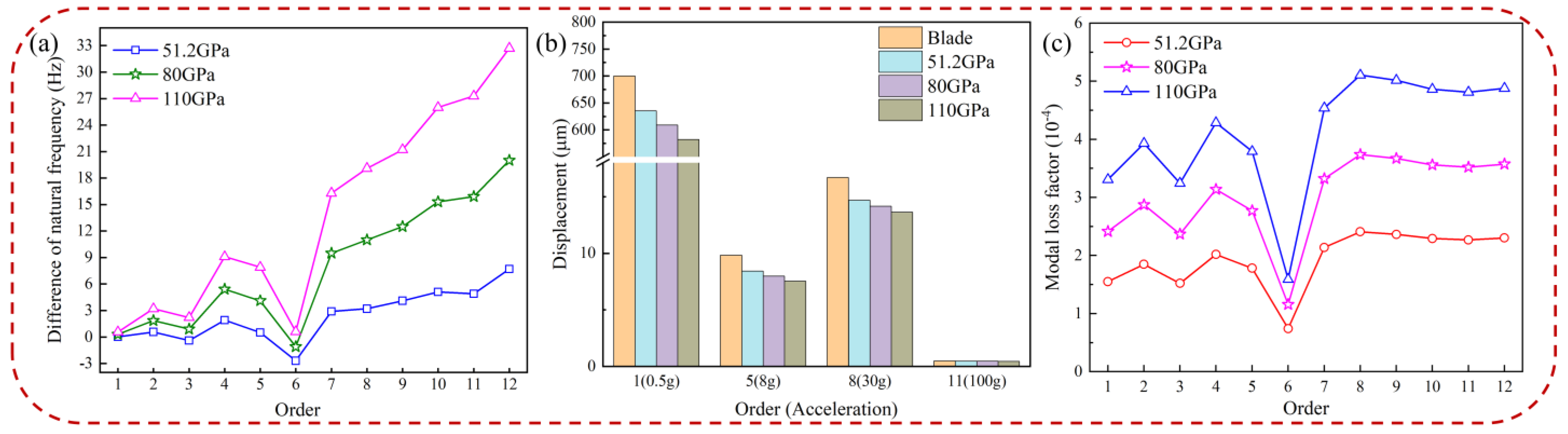

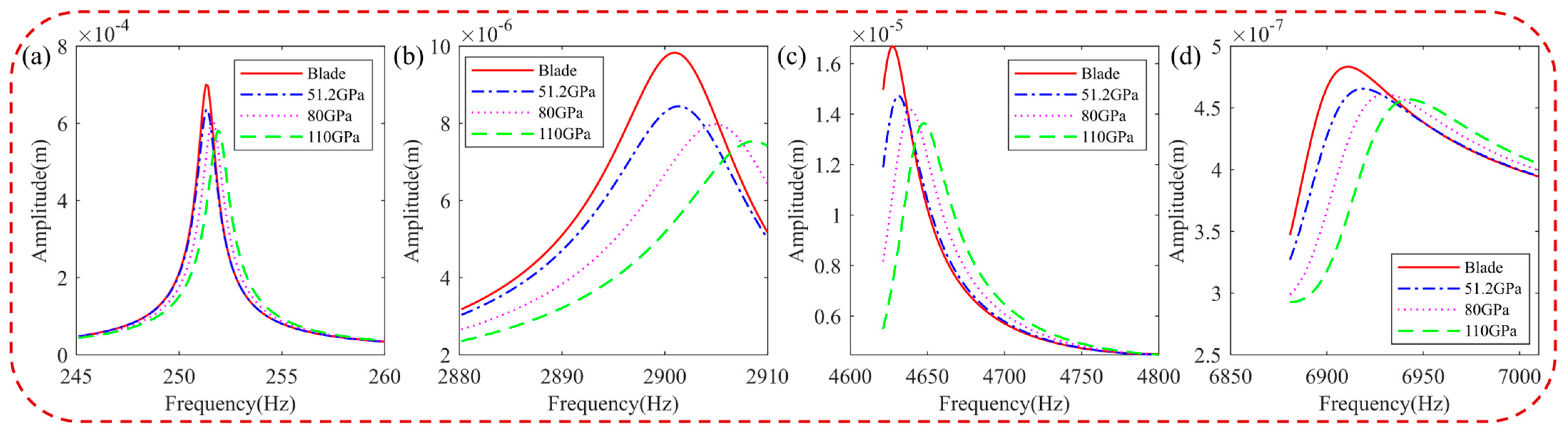

4.1. Case 1: Effect of the Storage Modulus of the HC Material

4.2. Case 2: Effect of the Loss Factor of HC Material

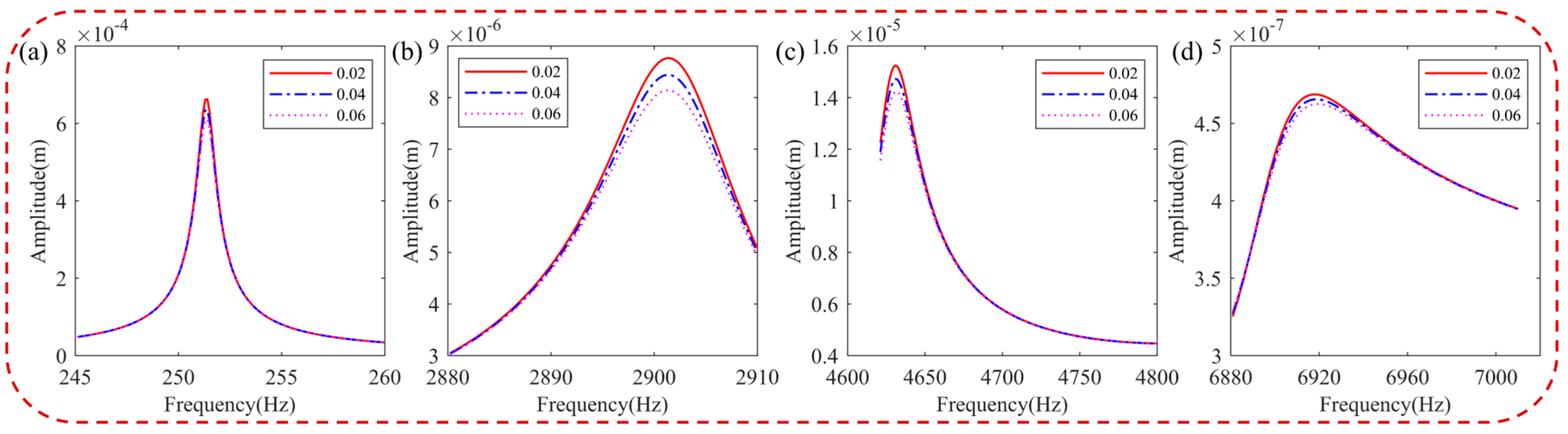

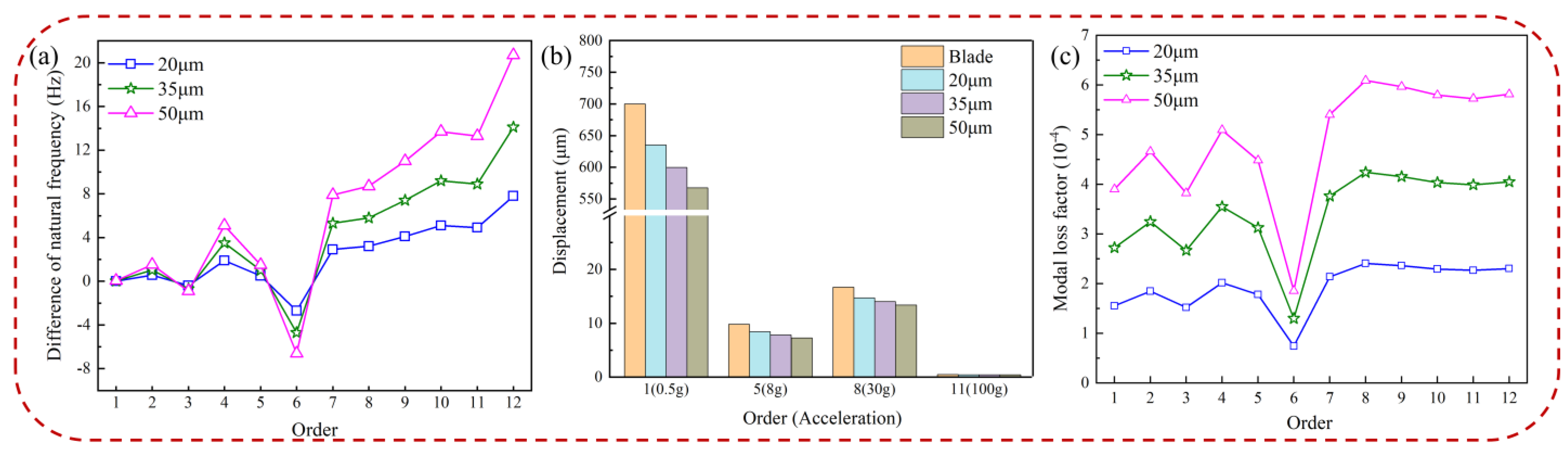

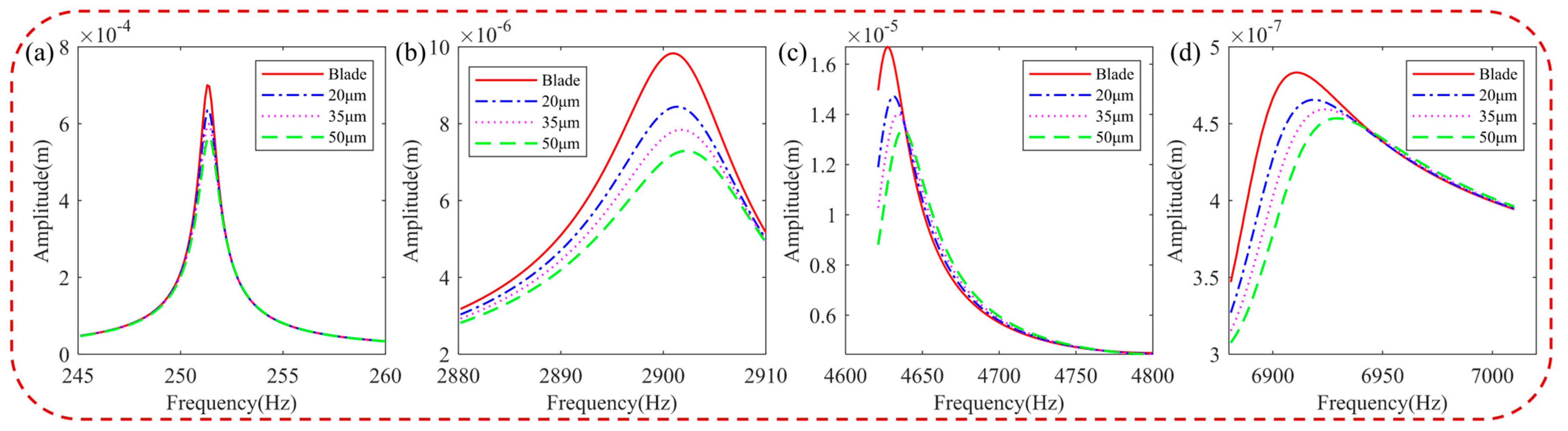

4.3. Case 3: Effect of the Thickness of HC Material

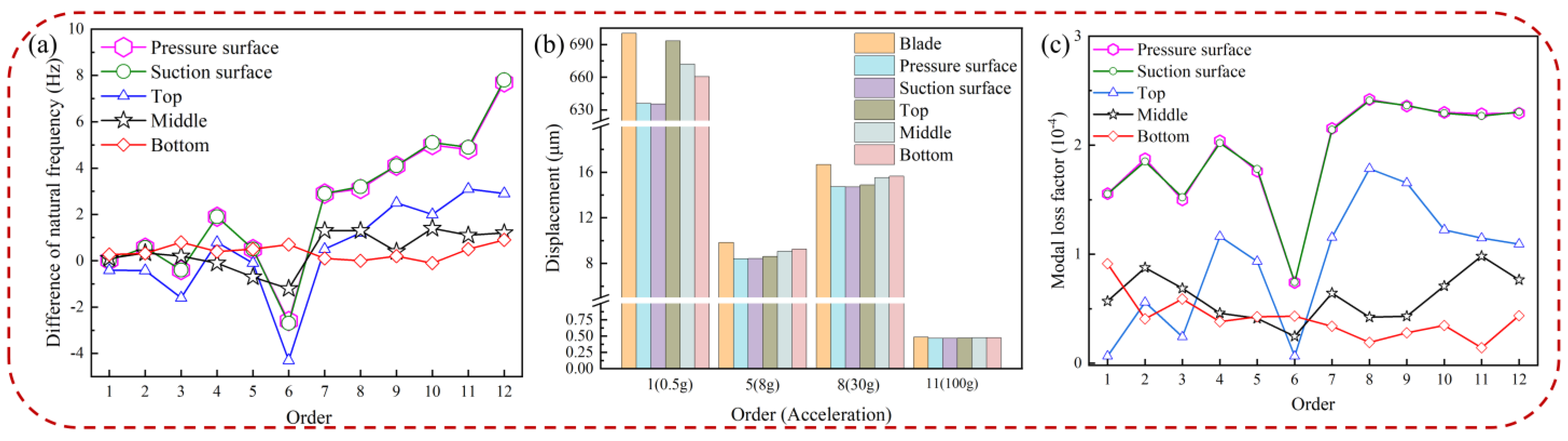

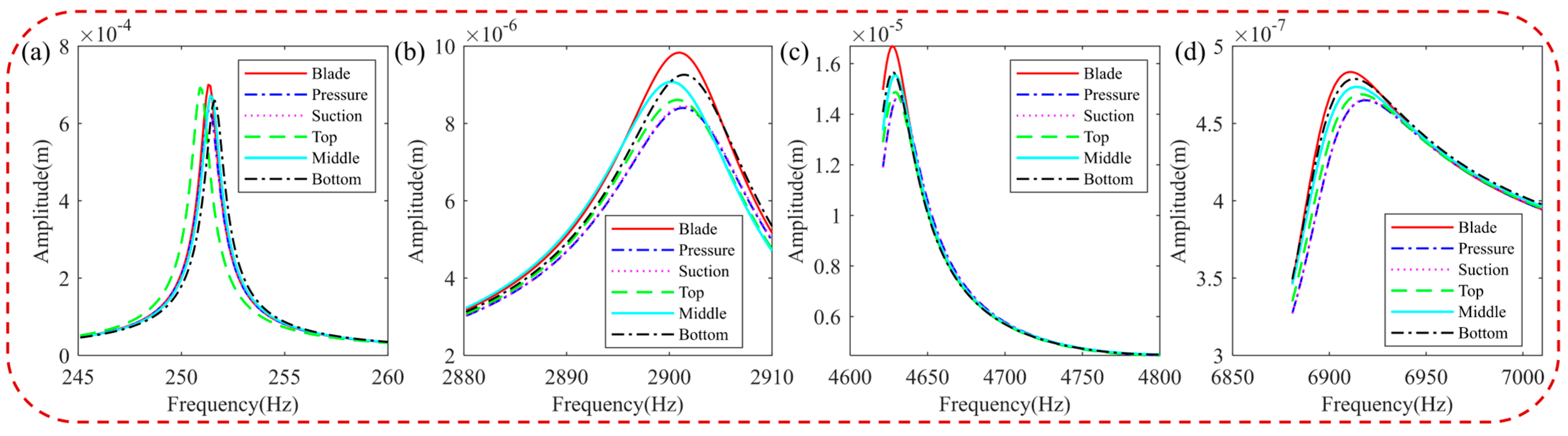

4.4. Case 4: Effect of the Position of HC

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Smith, G.W.; Birchak, J.R. Effect of Internal Stress Distribution on Magnetomechanical Damping. J. Appl. Phys. 1968, 39, 2311–2316. [Google Scholar] [CrossRef]

- Blackwell, C.; Palazotto, A.; George, T.J.; Cross, C.J. The evaluation of the damping characteristics of a hard coating on titanium. Shock. Vib. 2007, 14, 37–51. [Google Scholar] [CrossRef]

- Ivancic, F.; Palazotto, A.; Cross, C. The Effect of a Hard Coating on the Damping and Fatigue Life of Titanium. In Proceedings of the 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Norfolk, VA, USA, 7–10 April 2003; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2003. [Google Scholar]

- Torvik, P.J. Determination of mechanical properties of non-linear coatings from measurements with coated beams. Int. J. Solids Struct. 2009, 46, 1066–1077. [Google Scholar] [CrossRef]

- Yan, X.; Gao, J.; Sun, W.; Xu, K. A new finite element model for vibration analysis of a coated blisk with variable coating thickness. J. Low Freq. Noise Vib. Act. Control. 2021, 40, 784–801. [Google Scholar] [CrossRef]

- Kuang, Z.; Shi, P.; Wu, Z.; Bi, J.; Zhu, P. Finite element reduction modeling and vibration analysis of mistuned coating thickness blisk. J. Phys. Conf. Ser. 2021, 1820, 012067. [Google Scholar] [CrossRef]

- Yan, X.; Du, D.; Liu, H.; Xu, K.; Sun, W. Nonlinear vibration analysis of coated blisks in the presence of stiffness mistuning identification. Mech. Syst. Signal Process. 2022, 165, 108338. [Google Scholar] [CrossRef]

- Chen, Y.; Zhai, J.; Han, Q. Vibration and damping analysis of the bladed disk with damping hard coating on blades. Aerosp. Sci. Technol. 2016, 58, 248–257. [Google Scholar] [CrossRef]

- Gao, F.; Sun, W.; Gao, J. Optimal design of the hard-coating blisk using nonlinear dynamic analysis and multi-objective genetic algorithm. Compos. Struct. 2019, 208, 357–366. [Google Scholar] [CrossRef]

- Xu, K.; Yan, X.; Du, D.; Sun, W. Control of mistuning level using hard coating for blisks based on mistuning identification technique. Aerosp. Sci. Technol. 2021, 111, 106526. [Google Scholar] [CrossRef]

- Xu, K.; Sun, W.; Gao, J.; Yan, X. The equivalent modeling of hard-coating blisk based on mistuning identification. Aerosp. Sci. Technol. 2019, 94, 105396. [Google Scholar] [CrossRef]

- Xu, K.; Yan, X.; Du, D.; Sun, W. Identification and influence factors analysis of blade crack mistuning in hard-coated blisk based on modified component mode mistuning reduced-order model. J. Low Freq. Noise Vib. Act. Control. 2021, 40, 1401–1424. [Google Scholar] [CrossRef]

- Gao, F.; Sun, W. Nonlinear finite element modeling and vibration analysis of the blisk deposited strain-dependent hard coating. Mech. Syst. Signal Process. 2019, 121, 124–143. [Google Scholar] [CrossRef]

- Gao, F.; Sun, W. Vibration characteristics and damping analysis of the blisk-deposited hard coating using the rayleigh-ritz method. Coatings 2017, 7, 108. [Google Scholar] [CrossRef]

- Gao, F.; Sun, W. Reduced-order modeling for and vibration characteristics analysis of a hard-coated mistuned blisk. Coatings 2017, 7, 103. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Yan, W.Q.; Chen, L.; Liao, B.; Hua, Q.S.; Zhang, X. A hard yet tough CrAlSiN nanocomposite coating for blades deposited by filtered cathode vacuum arc. Surf. Interfaces 2021, 25, 101156. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhao, Y.; Chen, Y.; Zhai, J.; Han, Q.; Du, Y. Fatigue crack retardation by the application of hard damping coating to blades under resonance. J. Cent. South Univ. 2023, 30, 1095–1106. [Google Scholar] [CrossRef]

- Yuan, Z.; Han, Y.; Zang, S.; Chen, J.; He, G.; Chai, Y.; Yang, Z.; Fu, Q. Damage evolution behavior of TiN/Ti multilayer coatings under high-speed impact conditions. Surf. Coat. Technol. 2021, 426, 127807. [Google Scholar] [CrossRef]

- Zhang, W.; Niu, Y.; Behdinan, K. Vibration characteristics of rotating pretwisted composite tapered blade with graphene coating layers. Aerosp. Sci. Technol. 2020, 98, 105644. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, Q.; Zhai, J. Experimental investigation on fatigue of blade specimen subjected to resonance and effect of a damping hard coating treatment. J. Cent. South Univ. 2021, 28, 445–453. [Google Scholar] [CrossRef]

- Rouleau, L.; De Smet, O.; Deü, J. Vibration prediction of rotating composite fan blades comprising viscoelastic damping treatments. J. Sound Vib. 2022, 536, 117135. [Google Scholar] [CrossRef]

- Luo, H.; Chen, R.; Guo, S.; Fu, J. Topology optimization of hard-coating thin plate for maximizing modal loss factors. Coatings 2021, 11, 774. [Google Scholar] [CrossRef]

- Tassini, N.; Patsias, S.; Lambrinou, K. Ceramic coatings: A phenomenological modeling for damping behavior related to microstructural features. Mater. Sci. Eng. A 2006, 442, 509–513. [Google Scholar] [CrossRef]

- Tassini, N.; Lambrinou, K.; Mircea, I.; Bartsch, M.; Patsias, S.; Van der Biest, O. Study of the amplitude-dependent mechanical behaviour of yttria-stabilised zirconia thermal barrier coatings. J. Eur. Ceram. Soc. 2007, 27, 1487–1491. [Google Scholar] [CrossRef]

- Li, H.; Ying, L.; Sun, W. Analysis of nonlinear vibration of hard coating thin plate by finite element iteration method. Shock. Vib. 2014, 2014, 941709. [Google Scholar] [CrossRef]

- Yu, L.; Ma, Y.; Zhou, C.; Xu, H. Damping efficiency of the coating structure. Int. J. Solids Struct. 2005, 42, 3045–3058. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Z.; Sun, H.; Sun, W.; Wen, B. Theoretical study on the influence of hard coating on vibration characteristics of fiber-reinforced composite thin shell. Coatings 2018, 8, 87. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Yang, J.; Han, Q. Nonlinear vibration analysis of a hard-coating cylindrical shell with elastic constraints by finite element method. Nonlinear Dyn. 2017, 90, 2879–2891. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Sun, W.; Song, H. A nonlinear analytical formula for forced vibration analysis of the hard-coating cylindrical shell based on the strain energy density principle. Aerosp. Sci. Technol. 2019, 92, 326–336. [Google Scholar] [CrossRef]

- Cui, Z.; Yu, X.; Ran, Z.; Liu, J.; Li, C.; Gao, L. Vibration Reduction Characteristics and Vibration Control of Aviation Hydraulic Pipeline by Hard Coating. Coatings 2022, 12, 775. [Google Scholar] [CrossRef]

- Du, D.; Sun, W.; Yan, X.; Liu, X.; Ma, H.; Li, H. Modelling and vibration evaluations of rotational mistuning-connecting disk-drum coupling structures with partial hard-coating damping treatment. Appl. Math. Model. 2023, 116, 593–623. [Google Scholar] [CrossRef]

- Araki, Y.; Kawabata, S.; Asai, T.; Masui, T. Response of vibration-isolated object to ground motions with intense vertical accelerations. Eng. Struct. 2011, 33, 3610–3619. [Google Scholar] [CrossRef]

- Pellicano, F. Dynamic instability of a circular cylindrical shell carrying a top mass under base excitation: Experiments and theory. Int. J. Solids Struct. 2011, 48, 408–427. [Google Scholar] [CrossRef]

- Zhou, K.; Wang, Y.; Qiao, B.; Fu, S.; Luo, X.; Chen, X. Single-sensor-based dynamic response reconstruction of blades under base excitation. Mech. Syst. Signal Process. 2023, 192, 110217. [Google Scholar] [CrossRef]

- Česnik, M.; Slavič, J.; Čermelj, P.; Boltežar, M. Frequency-based structural modification for the case of base excitation. J. Sound Vib. 2013, 332, 5029–5039. [Google Scholar] [CrossRef]

- Kuang, Z.; Shi, P.; Wu, Z.; Yang, P.; Wu, G. Finite element analysis for vibration response of Viscoelastic composite plate under base excitation. J. Ningxia Univ. 2022, 43, 261–265+272. [Google Scholar]

- Chen, Y. Mechanical Parameters Identification of Hard Coating Material and Its Mechanism of Vibration Suppression. Master’s Thesis, Northeastern University, Shenyang, China, 2013. [Google Scholar]

- Xu, K.; Yan, X.; Xu, D.; Du, D.; Sun, W. Detection of blade substrate crack parameters of hard-coated blisk based on mistuning identification technology. Mech. Syst. Signal Process. 2022, 165, 108381. [Google Scholar] [CrossRef]

| Structure | Material | E/GPa | Density/(Kg/m3) | Loss Factor | Poisson’s Ratio |

|---|---|---|---|---|---|

| Blade | 1Cr11Ni2W2MoV | 214 | 7800 | 0.0007 | 0.3 |

| HC | NiCrAlY | 51.2 | 2840.7 | 0.04 | 0.31 |

| Blade Type | Working Conditions | Solid186 | |||

|---|---|---|---|---|---|

| Cases | Constant Parameters | Vary Parameters | Element Number | Node Number | |

| Blade | 3020 | 14,903 | |||

| BHC | Case1: Storage modulus Ec/GPa | Hc = 20 μm; = 0.04; suction surface | Ec = 51.2, 80, 110 | 3320 | 16,210 |

| Case2: Loss factor | Ec = 51.2 GPa; Hc = 20 μm; suction surface | = 0.02, 0.04, 0.06 | |||

| Case3: HC thickness Hc/μm | Ec = 51.2 GPa; = 0.04; suction surface | Hc = 20, 35, 50 | |||

| Case4: HC position | Ec = 51.2 GPa; Hc = 20 μm; = 0.04 | Top, Middle, Bottom, Suction surface, Pressure surface | 4220 3320 | 20,270 16,210 | |

| Orders | 1 (0.5 g) | 5 (8 g) | 8 (30 g) | 11 (100 g) | |

|---|---|---|---|---|---|

| Parameters | |||||

| Blade | 700.153 | 9.831 | 16.69 | 0.4833 | |

| Ec = 51.2 GPa | 635.3 | 8.44 | 14.7 | 0.466 | |

| Ec = 80 GPa | 608.77 | 7.977 | 14.17 | 0.461 | |

| Ec = 110 GPa | 582.21 | 7.533 | 13.646 | 0.457 | |

| Order | 1 (0.5 g) | 5 (8 g) | 8 (30 g) | 11 (100 g) | |

|---|---|---|---|---|---|

| Parameters | |||||

| lade | 700.153 | 9.831 | 16.69 | 0.4833 | |

| = 0.02 | 662.7 | 8.8 | 15.2 | 0.469 | |

| = 0.04 | 635.3 | 8.4 | 14.7 | 0.466 | |

| = 0.06 | 610.1 | 8.1 | 14.2 | 0.463 | |

| Order | 1 (0.5 g) | 5 (8 g) | 8 (30 g) | 11 (100 g) | |

|---|---|---|---|---|---|

| Parameters | |||||

| Blade | 700.153 | 9.831 | 16.69 | 0.4833 | |

| Hc = 20 μm | 635.3 | 8.44 | 14.7 | 0.466 | |

| Hc = 35 μm | 599.839 | 7.8415 | 14.0266 | 0.459 | |

| Hc = 50 μm | 567.544 | 7.2929 | 13.3855 | 0.4535 | |

| Order | 1 (0.5 g) | 5 (8 g) | 8 (30 g) | 11 (100 g) | |

|---|---|---|---|---|---|

| Parameters | |||||

| Blade | 700.153 | 9.831 | 16.690 | 0.483 | |

| Pressure surface | 635.717 | 8.400 | 14.719 | 0.465 | |

| Suction surface | 635.300 | 8.440 | 14.700 | 0.466 | |

| Top | 693.223 | 8.609 | 14.875 | 0.469 | |

| Middle | 672.014 | 9.078 | 15.539 | 0.476 | |

| Bottom | 660.502 | 9.259 | 15.650 | 0.478 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Guo, T.; Liu, W.; Wang, Z.; Zhang, Y. Vibration Analysis and Damping Effect of Blade-Hard Coating Composite Structure Based on Base Excitation. Materials 2023, 16, 5432. https://doi.org/10.3390/ma16155432

Wang J, Guo T, Liu W, Wang Z, Zhang Y. Vibration Analysis and Damping Effect of Blade-Hard Coating Composite Structure Based on Base Excitation. Materials. 2023; 16(15):5432. https://doi.org/10.3390/ma16155432

Chicago/Turabian StyleWang, Jiao, Tianyu Guo, Wenyue Liu, Ziwei Wang, and Yuehao Zhang. 2023. "Vibration Analysis and Damping Effect of Blade-Hard Coating Composite Structure Based on Base Excitation" Materials 16, no. 15: 5432. https://doi.org/10.3390/ma16155432

APA StyleWang, J., Guo, T., Liu, W., Wang, Z., & Zhang, Y. (2023). Vibration Analysis and Damping Effect of Blade-Hard Coating Composite Structure Based on Base Excitation. Materials, 16(15), 5432. https://doi.org/10.3390/ma16155432