Experimental Research on the Use of a Selected Multi-Criteria Method for the Cutting of Titanium Alloy with an Abrasive Water Jet

Abstract

1. Introduction

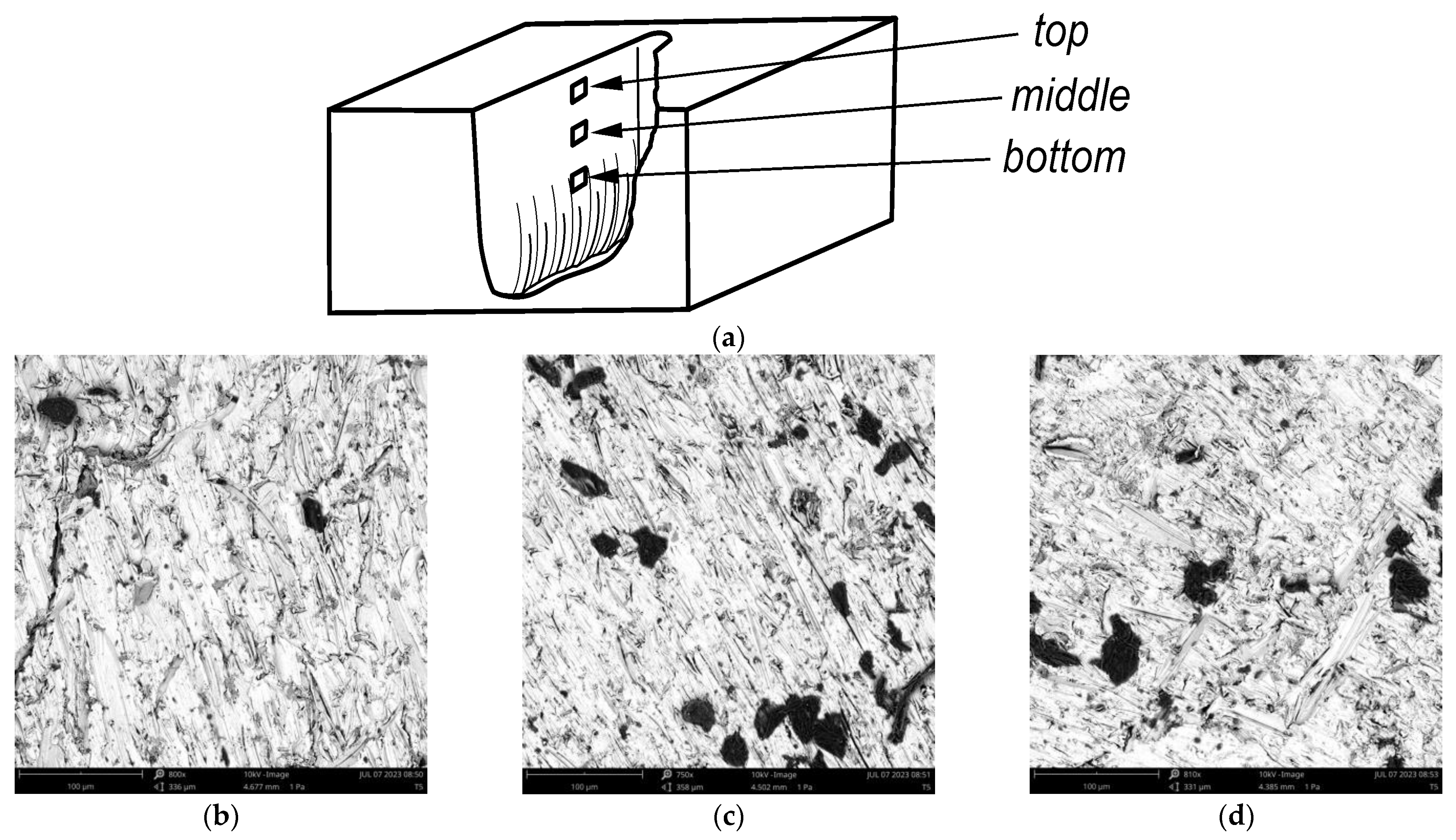

2. Materials and Method

2.1. Materials

2.2. The VIKOR Method

- m—number of options, n—number of initial conditions.

- ri,j is the normalized element of the decision matrix.

- fi,j—normalized matrix element,

- xi,j—element of the relative decision matrix.

- wi—attribute weight.

- ν—impact factor. The VIKOR coefficient can take any value between 0 and 1.

2.3. Experimental Setup and Equipment

- -

- The diameter of the water nozzle: 0.3 mm,

- -

- The diameter of the water-abrasive nozzle: 0.76 mm,

- -

- The distance of the nozzle from material: 4 mm.

3. Results and Discussion

- -

- Water nozzle diameter: 0.3 mm,

- -

- Diameter of the water-abrasive nozzle focusing tube: 0.76 mm,

- -

- Nozzle-to-material distance: 4 mm.

- -

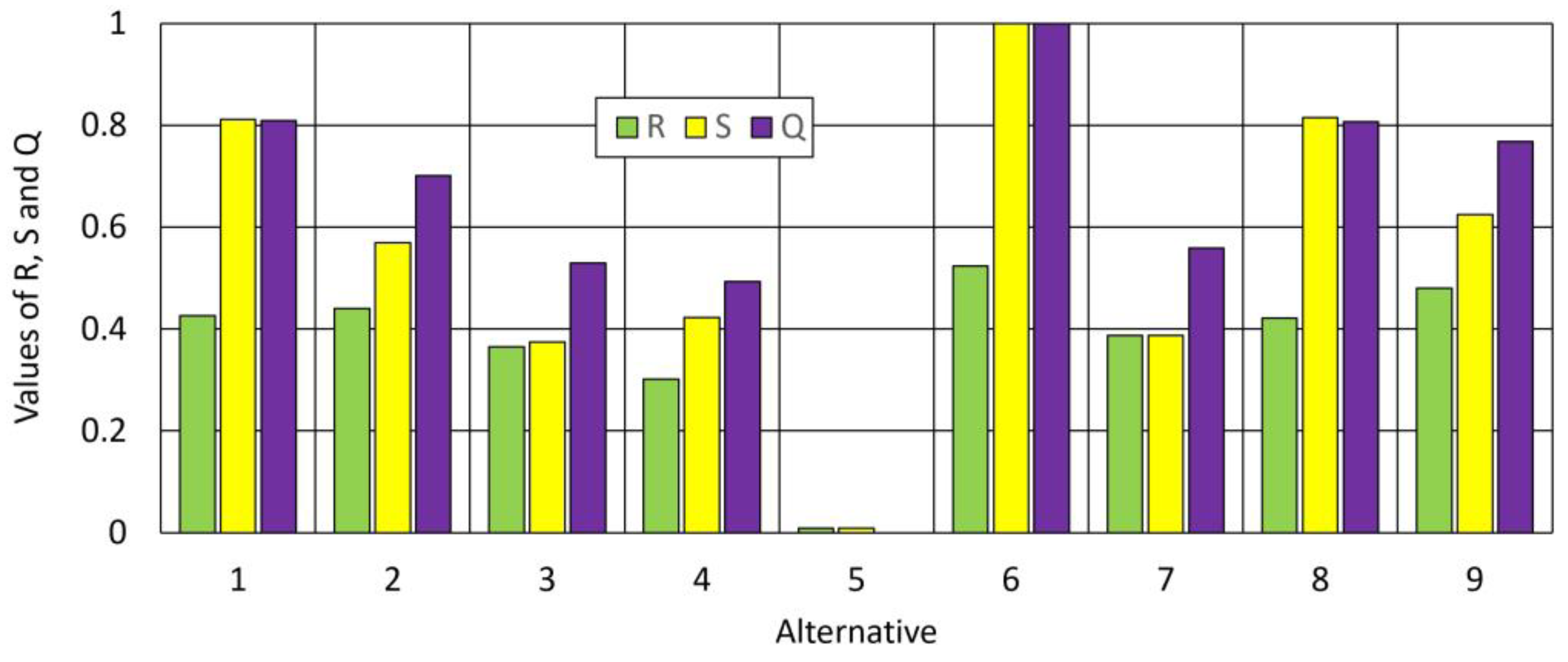

- Condition 1. Advantage is accepted: Q(A(2) − Q(A(1) ≥ 1/(m−1) where A(1) is the alternative highest ranked, and A(2) is the next alternative after Q and m is the number of alternatives.

- -

- Condition 2. Stability is accepted. This means that the alternative A(1) must also meet the requirement of the highest grade of S and/or R.

- -

- Solution 1. When Condition 1 is not met then the value of A(m) is determined by Q(A(m)) − Q(A(1)) < 1/(m−1) for the largest value of m (these alternatives are close to each other).

- -

- Solution 2. When Condition 2 is not met, the compromise is A(1) and A(2).

- -

- Solution 3. When Condition 1 and Condition 2 are not satisfied, the compromise solution is the smallest value of Q.

- -

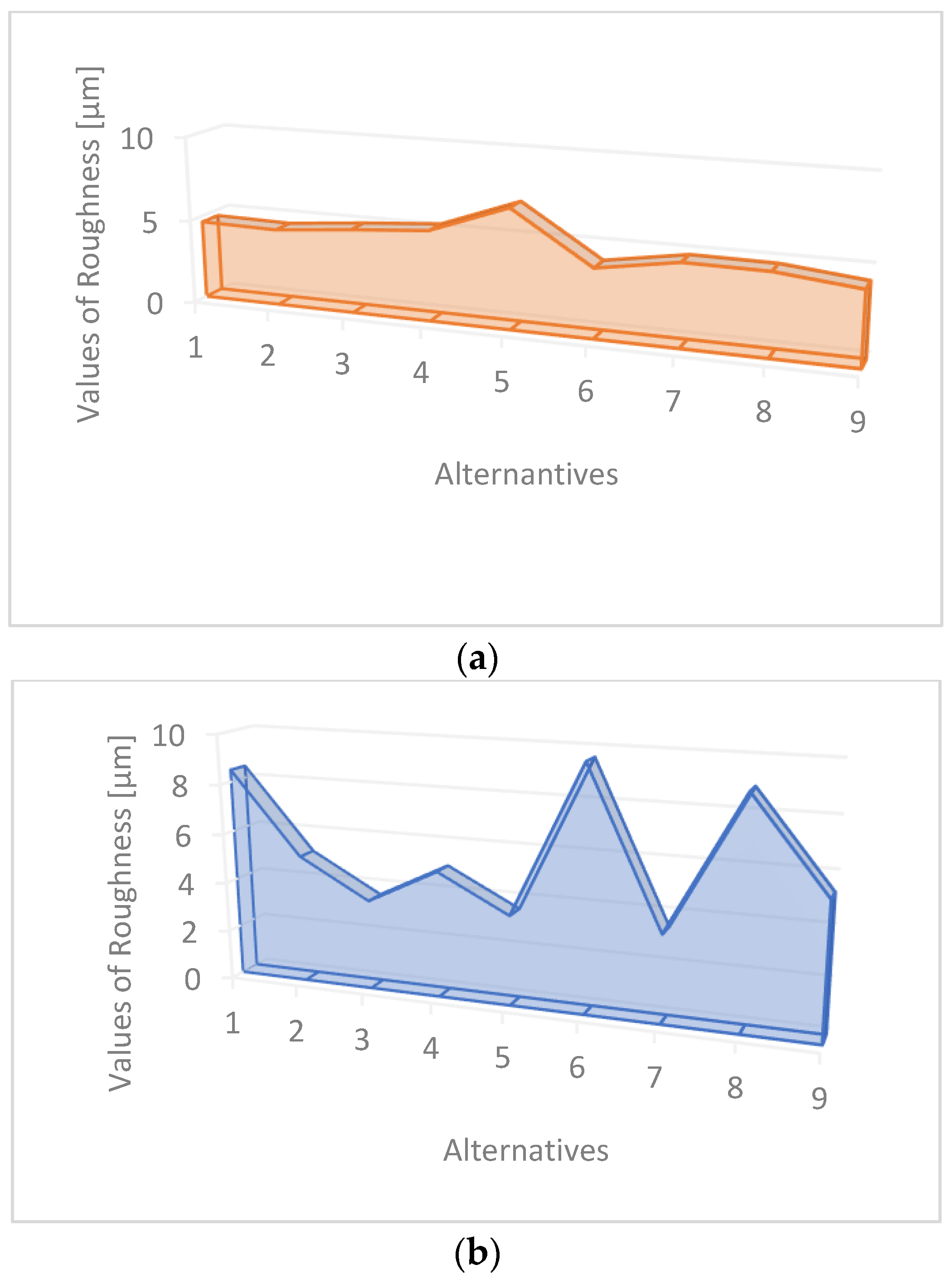

- Pressure is the most important factor and the smallest dispersion can be observed at 400 MPa;

- -

- The abrasive flow rate is a parameter that slightly affects the surface roughness;

- -

- The optimum traverse speed for minimum surface roughness.

- -

- Pressure = 400 MPa;

- -

- Abrasive flow rate = 450 g/min;

- -

- Traverse speed = 150 mm/min.

- -

- Determination of points: ideal and anti-ideal;

- -

- Calculation of the weighted average distance from the ideal point Si and the maximum weighted distance from the ideal point Ri for each object;

- -

- Determination of the comprehensive Qi index for each variant followed by the construction of three rankings based on the calculated values according to the principle: the lower the value of the index, the higher the position in the ranking;

- -

- Selecting the first variant from the Qi ranking and comparing it with the variant immediately after it in this ranking; two conditions are checked at this stage—acceptable advantage and acceptable stability of the decision—on the basis of the information obtained. It is decided which variant or variants are compromise solutions.

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dyckhoff, H.; Souren, R. Integrating multiple criteria decision analysis and production theory for performance evaluation: Framework and review. Eur. J. Oper. Res. 2022, 297, 795–816. [Google Scholar] [CrossRef]

- Janošovský, J.; Boháčiková, V.; Kraviarová, D.; Variny, M. Multi-criteria decision analysis of steam reforming for hydrogen production. Energy Convers. Manag. 2022, 263, 115722. [Google Scholar] [CrossRef]

- Grisold, T.; Groß, S.; Stelzl, K.; Brocke, J.V.; Mendling, J.; Röglinger, M.; Rosemann, M. The Five Diamond Method for Explorative Business Process Management. Bus. Inf. Syst. Eng. 2022, 64, 149–166. [Google Scholar] [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J.C. Canteras-Jordana. A review of application of multi-criteria decision making methods in construction. Autom. Constr. 2014, 45, 151–162. [Google Scholar] [CrossRef]

- Basílio, M.P.; Pereira, V.; Costa, H.G.; Santos, M.; Ghosh, A. A Systematic Review of the Applications of Multi-Criteria Decision Aid Methods (1977–2022). Electronics 2022, 11, 1720. [Google Scholar] [CrossRef]

- Kluczek, A. Application of Multi-criteria Approach for Sustainability Assessment of Manufacturing Processes. Manag. Prod. Eng. Rev. 2016, 7, 62–78. [Google Scholar] [CrossRef]

- Khalili, N.R.; Duecker, S. Application of multi-criteria decision analysis in design of sustainable environmental management system framework. J. Clean. Prod. 2013, 47, 188–198. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Jagadish; Kumar, R.S.; Naidu, N.V.S. Optimization of Abrasive Water Jet Machining for Green Composites Using Multi-variant Hybrid Techniques. In Optimization of Manufacturing Processes; Gupta, K., Gupta, M.K., Eds.; Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2020; pp. 129–162. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A. WASPAS Optimization in Advanced Manufacturing. Procedia Comput. Sci. 2022, 207, 1193–1200. [Google Scholar] [CrossRef]

- Radomska-Zalas, A.; Perec, A.; Fajdek-Bieda, A. IT support for optimisation of abrasive water cutting process using the TOPSIS method. IOP Conf. Ser. Mater. Sci. Eng. 2019, 710, 012008. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A. Modeling of abrasive water suspension jet cutting process using response surface method. In Computational Technologies in Engineering (TKI’2018), Proceedings of the 15th Conference on Computational Technologies in Engineering, Jora Wielka, Poland, 16–19 October 2018; AIP Publishing: College Park, MD, USA, 2019; p. 020051. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A.; Kawecka, E. Efficiency of Tool Steel Cutting by Water Jet with Recycled Abrasive Materials. Materials 2022, 15, 3978. [Google Scholar] [CrossRef]

- Sayadi, M.K.; Heydari, M.; Shahanaghi, K. Extension of VIKOR method for decision making problem with interval numbers. Appl. Math. Model. 2009, 33, 2257–2262. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A. Application of the VIKOR method in multi-criteria optimization of treatment parameters with high-pressure water-abrasive jet. In Technologies of the Future Manufacturing Engineering and Machine Construction; Jacob of Paradies University: Gorzów, Poland, 2021. [Google Scholar]

- Radomska-Zalas, A. Selected Aspects of IT Support for the Optimization of Industrial Processes; Jacob of Paradies University: Gorzów, Poland, 2020. (In Polish) [Google Scholar]

- Cinelli, M.; Kadziński, M.; Gonzalez, M.; Słowiński, R. How to support the application of multiple criteria decision analysis? Let us start with a comprehensive taxonomy. Omega 2020, 96, 102261. [Google Scholar] [CrossRef] [PubMed]

- Patyk, R.; Kukielka, L.; Kaldunski, P.; Bohdal, L.; Chodor, J.; Kulakowska, A.; Kukielka, K.; Nagnajewicz, S. Experimental and numerical researches of duplex burnishing process in aspect of achieved productive quality of the product. In Proceedings of the 21st International Esaform Conference on Material Forming: Esaform 2018, Palermo, Italy, 23–25 April 2018; p. 070021. [Google Scholar] [CrossRef]

- Ahmed, T.M.; El Mesalamy, A.S.; Youssef, A.; El Midany, T.T. Improving surface roughness of abrasive waterjet cutting process by using statistical modeling. CIRP J. Manuf. Sci. Technol. 2018, 22, 30–36. [Google Scholar] [CrossRef]

- Anandatirthachar, N.C.; Srinivas, S.; Ramachandra, M. Abrasive Water Jet Cutting: A Risk-Free Technology for Machining Mg-Based Materials. In Magnesium—The Wonder Element for Engineering/Biomedical Applications; Gupta, M., Ed.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Xu, W.; Wu, Z.; Lu, W.; Yu, Y.; Wang, J.; Zhu, Z.; Wang, X. Investigation on Cutting Power of Wood–Plastic Composite Using Response Surface Methodology. Forests 2022, 13, 1397. [Google Scholar] [CrossRef]

- Zhu, Z.; Jin, D.; Wu, Z.; Xu, W.; Yu, Y.; Guo, X.; Wang, X. Assessment of Surface Roughness in Milling of Beech Using a Response Surface Methodology and an Adaptive Network-Based Fuzzy Inference System. Machines 2022, 10, 567. [Google Scholar] [CrossRef]

- Aydin, G.; Kaya, S.; Karakurt, I. Utilization of solid-cutting waste of granite as an alternative abrasive in abrasive waterjet cutting of marble. J. Clean. Prod. 2017, 159, 241–247. [Google Scholar] [CrossRef]

- Kaczmarek, Ł.; Zawadzki, P.; Stegliński, M.; Wójcik, R.; Klich, M.; Kyzioł, K.; Kottfer, D.; Januszewicz, B.; Pawłowski, W. The Effect of Two-Stage Age Hardening Treatment Combined with Shot Peening on Stress Distribution in the Surface Layer of 7075 Aluminum Alloy. Arch. Metall. Mater. 2015, 60, 1993–1998. [Google Scholar] [CrossRef][Green Version]

- Chen, W.-H.; Uribe, M.C.; Kwon, E.E.; Lin, K.-Y.A.; Park, Y.-K.; Ding, L.; Saw, L.H. A comprehensive review of thermoelectric generation optimization by statistical approach: Taguchi method, analysis of variance (ANOVA), and response surface methodology (RSM). Renew. Sustain. Energy Rev. 2022, 169, 112917. [Google Scholar] [CrossRef]

- Perec, A. Multiple Response Optimization of Abrasive Water Jet Cutting Process using Response Surface Methodology (RSM). Procedia Comput. Sci. 2021, 192, 931–940. [Google Scholar] [CrossRef]

- Williams, J.C. Titanium and Titanium Alloys: Scientific and Technological Aspects Volume 3; Springer US: Boston, MA, USA, 1982. [Google Scholar]

- Krishnaraj, V.; Samsudeensadham, S.; Sindhumathi, R.; Kuppan, P. A study on High Speed End Milling of Titanium Alloy. Procedia Eng. 2014, 97, 251–257. [Google Scholar] [CrossRef]

- Perec, A. Experimental research into alternative abrasive material for the abrasive water-jet cutting of titanium. Int. J. Adv. Manuf. Technol. 2018, 97, 1529–1540. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, C.-T. Design of titanium alloys by additive manufacturing: A critical review. Adv. Powder Mater. 2022, 1, 100014. [Google Scholar] [CrossRef]

- Hascalik, A.; Çaydaş, U.; Gürün, H. Effect of traverse speed on abrasive waterjet machining of Ti–6Al–4V alloy. Mater. Des. 2007, 28, 1953–1957. [Google Scholar] [CrossRef]

- Bańkowski, S.; Spadło, S. The Use of Abrasive Waterjet Cutting to Remove Flash from Castings. Arch. Foundry Eng. 2023, 19, 94–98. [Google Scholar] [CrossRef]

- Zhu, G.-N.; Hu, J.; Qi, J.; Gu, C.-C.; Peng, Y.-H. An integrated AHP and VIKOR for design concept evaluation based on rough number. Adv. Eng. Inform. 2015, 29, 408–418. [Google Scholar] [CrossRef]

- Chen, L.Y.; Wang, T.-C. Optimizing partners’ choice in IS/IT outsourcing projects: The strategic decision of fuzzy VIKOR. Int. J. Prod. Econ. 2009, 120, 233–242. [Google Scholar] [CrossRef]

- Khan, A.; Maity, K. Estimation of optimal cutting conditions during machining of CP-Ti grade 2 in fuzzy–VIKOR context: A hybrid approach. Grey Syst. 2020, 10, 293–310. [Google Scholar] [CrossRef]

- Barabas, S.A.; Florescu, A. Optimization Method of Abrasive Water Jet Cutting of Welded Overlay Materials. Metals 2019, 9, 1046. [Google Scholar] [CrossRef]

- Singh, H.; Bhoi, N.K.; Jain, P.K. Developments in abrasive water jet machining process—From 1980 to 2020. In Advanced Machining and Finishing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 217–252. [Google Scholar] [CrossRef]

- Perec, A.; Musial, W. Multiple Criteria Optimization of Abrasive Water Jet Cutting Using Entropy-VIKOR Approach. In Advances in Manufacturing Engineering and Materials II; Hloch, S., Klichová, D., Pude, F., Krolczyk, G.M., Chattopadhyaya, S., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2021; pp. 50–62. [Google Scholar] [CrossRef]

- Arif, M.; Suseno, J.E.; Isnanto, R.R. Multi-Criteria Decision Making with the VIKOR and SMARTER Methods for Optimal Seller Selection from Several E-Marketplaces. E3S Web Conf. 2020, 202, 14002. [Google Scholar] [CrossRef]

- Perec, A.; Radomska-Zalas, A.; Fajdek-Bieda, A. Experimental Research into Marble Cutting by Abrasive Water Jet. FU Mech. Eng. 2022, 20, 145. [Google Scholar] [CrossRef]

- Spadło, S.; Krajcarz, D. Basic abrasive waterjet cutting process parameters. AUTOBUSY–Tech. Eksploat. Syst. Transp. 2018, 19, 654–657. [Google Scholar] [CrossRef]

- Mazurkiewicz, A. Czynniki wpływające na błąd kształtu i chropowatość powierzchni stali po cięciu strumieniem wodnościernym. Inżynieria Mater. 2008, 29, 686–689. [Google Scholar]

- Balamurugan, K.; Uthayakumar, M.; Sankar, S.; Hareesh, U.; Warrier, K. Predicting correlations in abrasive waterjet cutting parameters of Lanthanum phosphate/Yttria composite by response surface methodology. Measurement 2019, 131, 309–318. [Google Scholar] [CrossRef]

- Valíček, J.; Hloch, S.; Kozak, D. Surface geometric parameters proposal for the advanced control of abrasive waterjet technology. Int. J. Adv. Manuf. Technol. 2009, 41, 323–328. [Google Scholar] [CrossRef]

- Alinezhad, A.; Khalili, J. New methods and applications in multiple attribute decision making (MADM). In International Series in Operations Research & Management Science; Springer: Cham, Switzerland, 2019; Volume 277. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Kahraman, C.; Otay, I. Extension of VIKOR Method Using Circular Intuitionistic Fuzzy Sets. In Intelligent and Fuzzy Techniques for Emerging Conditions and Digital Transformation; Kahraman, C., Cebi, S., Onar, S.C., Oztaysi, B., Tolga, A.C., Sari, I.U., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2022; Volume 308. [Google Scholar] [CrossRef]

- Jefferson, A.J.; Arumugam, V.; Dhakal, H.N. Key stages of adhesively bonded repairs. In Repair of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 97–224. [Google Scholar] [CrossRef]

- Saxena, K.K.; Bellotti, M.; Qian, J.; Reynaerts, D.; Lauwers, B.; Luo, X. Overview of Hybrid Machining Processes. In Hybrid Machining; Elsevier: Amsterdam, The Netherlands, 2018; pp. 21–41. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Liyakath Ali Khan, S.A. Abrasive Water Jet Machining process: A state of art of review. J. Manuf. Process. 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Maurya, P.; Kamath, R.C.; Srinivas, V.G. Experimental investigation of suspension-type abrasive water jet machining of nitrile rubber for positive displacement motor applications. Int. J. Lightweight Mater. Manuf. 2023, 6, 367–378. [Google Scholar] [CrossRef]

- Manivannan, J.; Rajesh, S.; Mayandi, K.; Siva, I.; Sankar, I.; Satyanarayana, K.G. Satyanarayana. Abrasive water jet cutting and its optimization model for machining the sheep wool/polyester composites. In Wool Fiber Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 337–350. [Google Scholar] [CrossRef]

- Chakkravarthy, V.; Oliveira, J.; Mahomed, A.; Yu, N.; Manojkumar, P.; Lakshmanan, M.; Zhang, L.; Raja, V.; Jerome, S.; Prabhu, T.R.; et al. Effect of abrasive water jet peening on NaCl-induced hot corrosion behavior of Ti–6Al–4V. Vacuum 2023, 210, 111872. [Google Scholar] [CrossRef]

| Element | Contents [%] |

|---|---|

| Carbon | 0.08 max |

| Nitrogen | 0.05 max |

| Oxygen | 0.20 max |

| Hydrogen | 0.0125 max |

| Vanadium | 3.50–4.50 |

| Aluminum | 5.50–6.75 |

| Iron | 0.25 max |

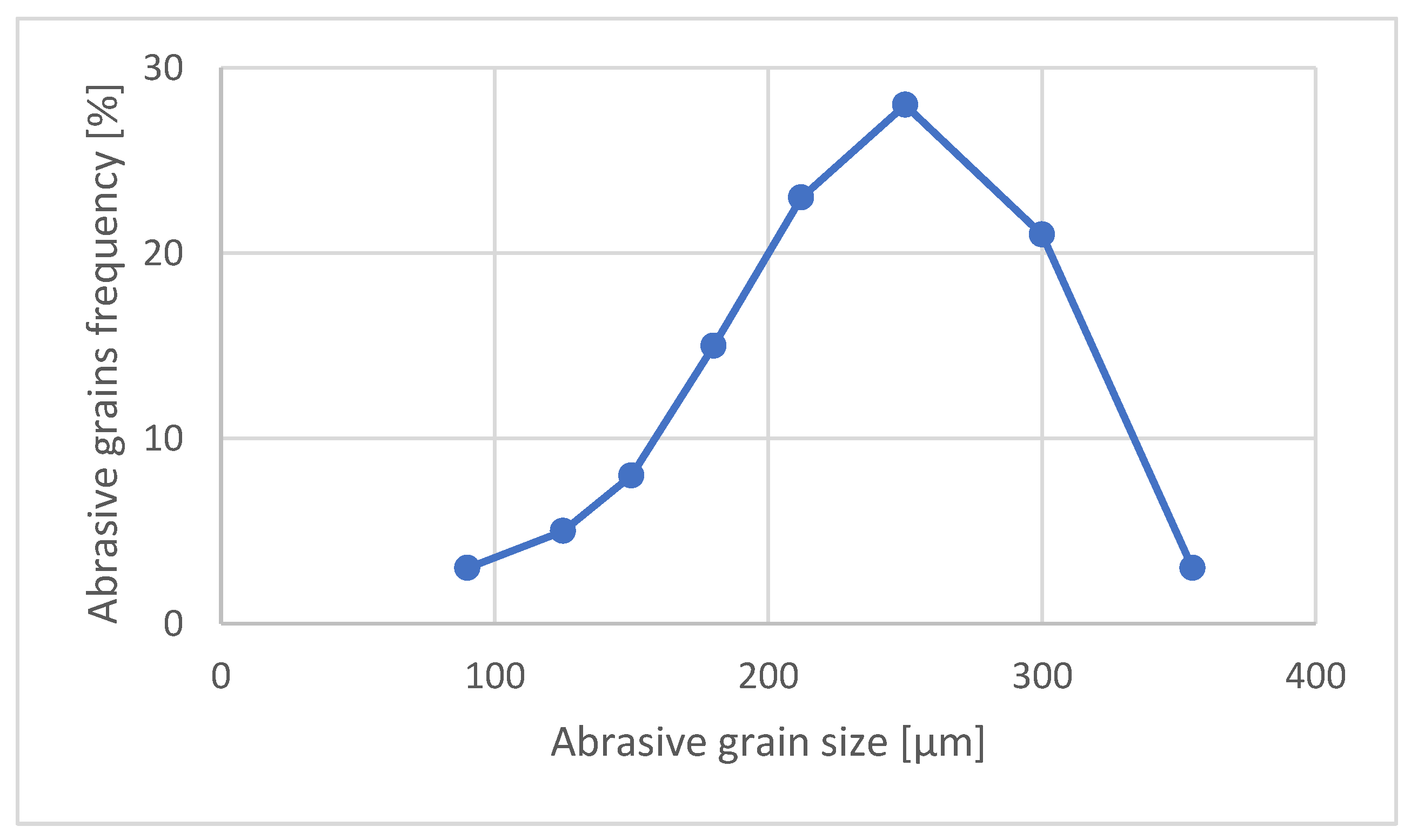

| Feature | Unit | Values | |

|---|---|---|---|

| Fe3Al2(SiO4)3+ Mg3Al2(SiO4)3+ Ca3Al2(SiO4)3 | % | 92.0–98.0 | |

| Chemical composition | Fe3O4+ NaCa2(Mg, Fe, Al)3(SiAl)8O22(OH)2+ KAlSi3O8+ (Ca, K, Na, Fe, Mg, Mn, Li, Al)2-3 (OH, F)2(Si, Al4O10) | % | 4.0–8.0 |

| CaCO3 | % | <0.2 | |

| SiO2 | % | <0.5 | |

| ZrSiO4 | % | <0.2 | |

| Melting temperature | °C | 1315 | |

| Density | kg/m3 | 3900–4100 | |

| No. | Input Parameters | Output Parameters | |||

|---|---|---|---|---|---|

| Beneficial | Non-Beneficial | ||||

| Abrasive Flow Rate [g/min] | Pressure [MPa] | Traverse Speed [mm/min] | Cutting Depth [mm] | Roughness Sq [mm] | |

| 1 | 250 | 360 | 50 | 8.47 | 4.64 |

| 2 | 250 | 380 | 150 | 5.16 | 4.56 |

| 3 | 250 | 400 | 250 | 3.61 | 4.99 |

| 4 | 350 | 360 | 150 | 5.05 | 5.35 |

| 5 | 350 | 380 | 250 | 3.59 | 7.07 |

| 6 | 350 | 400 | 50 | 9.64 | 4.08 |

| 7 | 450 | 360 | 250 | 3.48 | 4.86 |

| 8 | 450 | 380 | 50 | 8.93 | 4.82 |

| 9 | 450 | 400 | 150 | 5.35 | 4.33 |

| Criterium | Cutting Depth [mm] | Roughness Sq [μm] |

|---|---|---|

| entropy | 0.537320329 | 0.608208812 |

| dispersion | 0.462679671 | 0.391791188 |

| weight | 0.54 | 0.46 |

| Beneficial | Non-Beneficial | |

|---|---|---|

| Cutting Depth | Roughness Sq | |

| [mm] | [μm] | |

| alternative1 | 8.47 | 4.64 |

| alternative2 | 5.16 | 4.56 |

| alternative3 | 3.61 | 4.99 |

| alternative4 | 5.05 | 5.35 |

| alternative5 | 3.59 | 7.07 |

| alternative6 | 9.64 | 4.08 |

| alternative7 | 3.48 | 4.86 |

| alternative8 | 8.93 | 4.82 |

| alternative9 | 5.35 | 4.33 |

| Beneficial | Non-Beneficial | |

|---|---|---|

| Cutting Depth [mm] | Roughness Sq [μm] | |

| alternative1 | 0.444439 | 0.3072390 |

| alternative2 | 0.270756 | 0.3019417 |

| alternative3 | 0.189425 | 0.3304143 |

| alternative4 | 0.264985 | 0.3542518 |

| alternative5 | 0.188375 | 0.4681421 |

| alternative6 | 0.505832 | 0.2701584 |

| alternative7 | 0.182603 | 0.3218063 |

| alternative8 | 0.468577 | 0.3191577 |

| alternative9 | 0.280726 | 0.2867122 |

| R | S | Q | |

|---|---|---|---|

| alternative1 | 0.425849 | 0.811450 | 0.809727 |

| alternative2 | 0.439869 | 0.569691 | 0.701410 |

| alternative3 | 0.364513 | 0.374559 | 0.529915 |

| alternative4 | 0.301424 | 0.422746 | 0.493022 |

| alternative5 | 0.008500 | 0.008500 | 0 |

| alternative6 | 0.523988 | 1 | 1 |

| alternative7 | 0.387295 | 0.387295 | 0.558436 |

| alternative8 | 0.421147 | 0.815452 | 0.807185 |

| alternative9 | 0.480176 | 0.624680 | 0.768236 |

| R Value | Rank in R | S Value | Rank in S | Q Value | Rank in Q | |

|---|---|---|---|---|---|---|

| alternative1 | 0.425849 | 6 | 0.811450 | 7 | 0.809727 | 8 |

| alternative2 | 0.439869 | 7 | 0.569691 | 5 | 0.701410 | 5 |

| alternative3 | 0.364513 | 3 | 0.374559 | 2 | 0.529915 | 3 |

| alternative4 | 0.301424 | 2 | 0.422746 | 4 | 0.493022 | 2 |

| alternative5 | 0.008500 | 1 | 0.008500 | 1 | 0 | 1 |

| alternative6 | 0.523988 | 9 | 1 | 9 | 1 | 9 |

| alternative7 | 0.387295 | 4 | 0.387295 | 3 | 0.558436 | 4 |

| alternative8 | 0.421147 | 5 | 0.815452 | 8 | 0.807185 | 7 |

| alternative9 | 0.480176 | 8 | 0.624680 | 6 | 0.768236 | 6 |

| Condition 1 | Acceptance |

| Condition 2 | Acceptance |

| Selected solution | Solution 3 |

| No. | Input Parameters | Output Parameters | |||

|---|---|---|---|---|---|

| Beneficial | Non-Beneficial | ||||

| Abrasive Flow Rate [g/min] | Pressure [MPa] | Traverse Speed [mm/min] | Cutting Depth [mm] | Roughness Sq [mm] | |

| 5 | 350 | 380 | 250 | 3.59 | 7.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radomska-Zalas, A. Experimental Research on the Use of a Selected Multi-Criteria Method for the Cutting of Titanium Alloy with an Abrasive Water Jet. Materials 2023, 16, 5405. https://doi.org/10.3390/ma16155405

Radomska-Zalas A. Experimental Research on the Use of a Selected Multi-Criteria Method for the Cutting of Titanium Alloy with an Abrasive Water Jet. Materials. 2023; 16(15):5405. https://doi.org/10.3390/ma16155405

Chicago/Turabian StyleRadomska-Zalas, Aleksandra. 2023. "Experimental Research on the Use of a Selected Multi-Criteria Method for the Cutting of Titanium Alloy with an Abrasive Water Jet" Materials 16, no. 15: 5405. https://doi.org/10.3390/ma16155405

APA StyleRadomska-Zalas, A. (2023). Experimental Research on the Use of a Selected Multi-Criteria Method for the Cutting of Titanium Alloy with an Abrasive Water Jet. Materials, 16(15), 5405. https://doi.org/10.3390/ma16155405