Mechanical Characterization of MWCNT-Reinforced Cement Paste: Experimental and Multiscale Computational Investigation

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Work

2.1.1. Materials

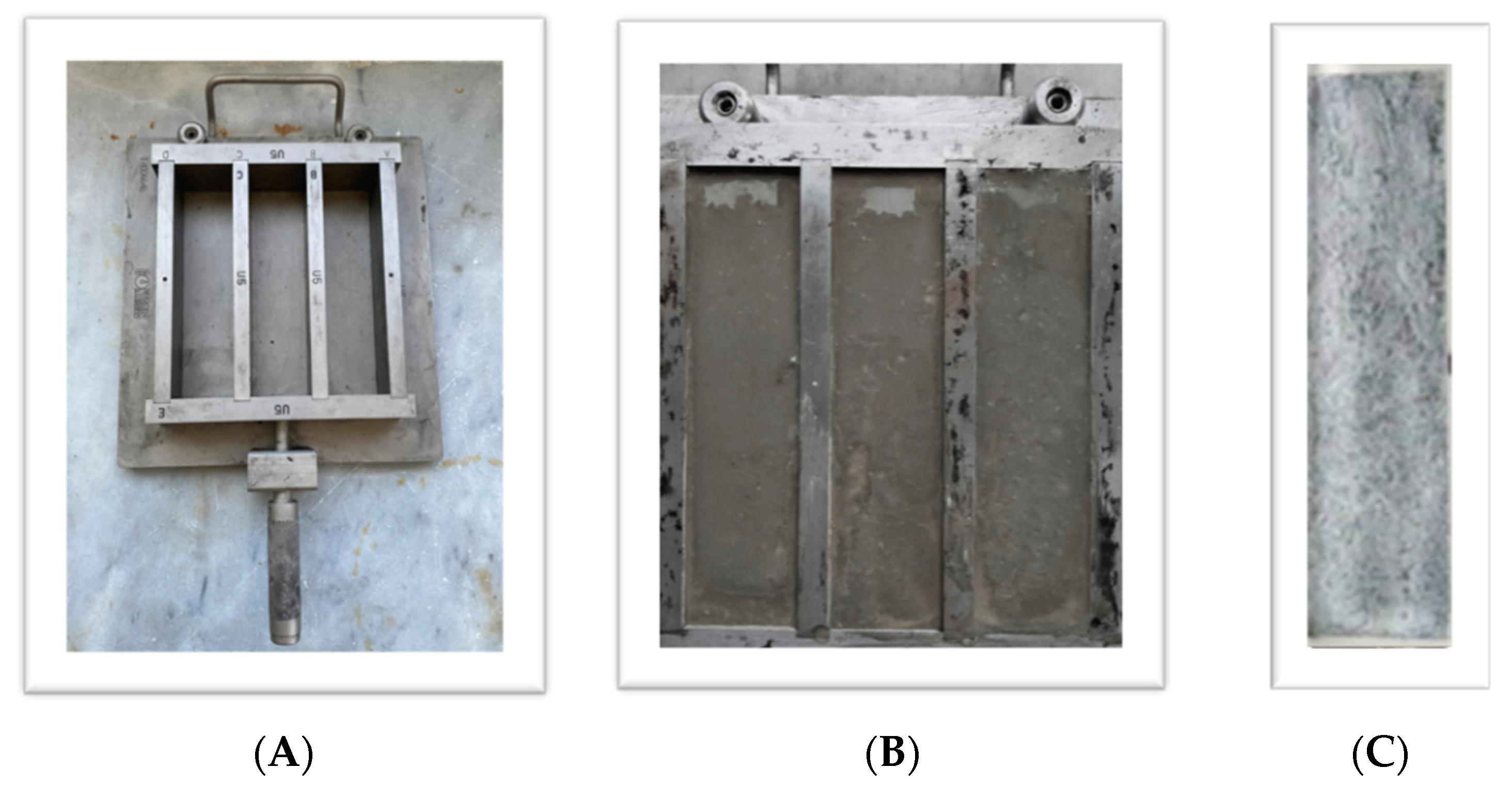

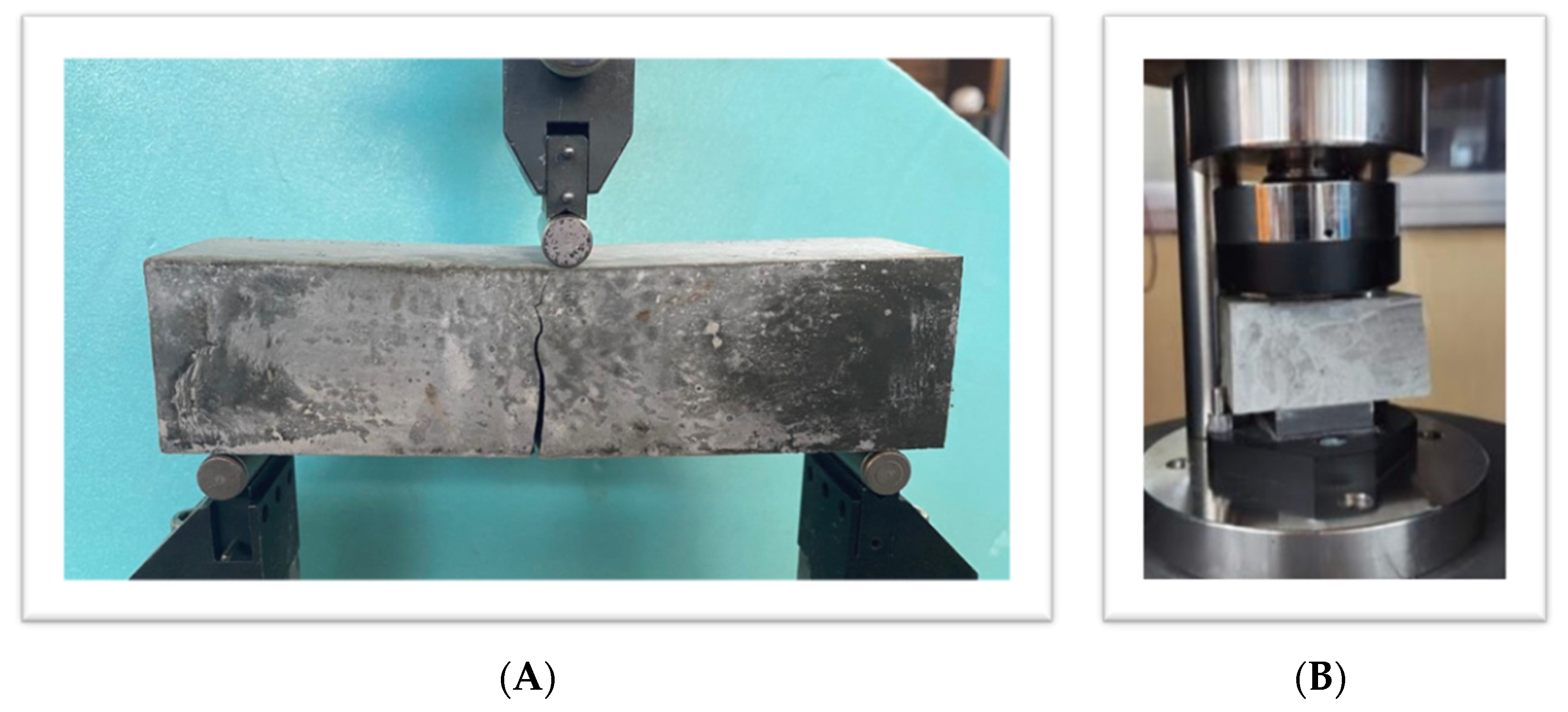

2.1.2. Mechanical Testing Procedure

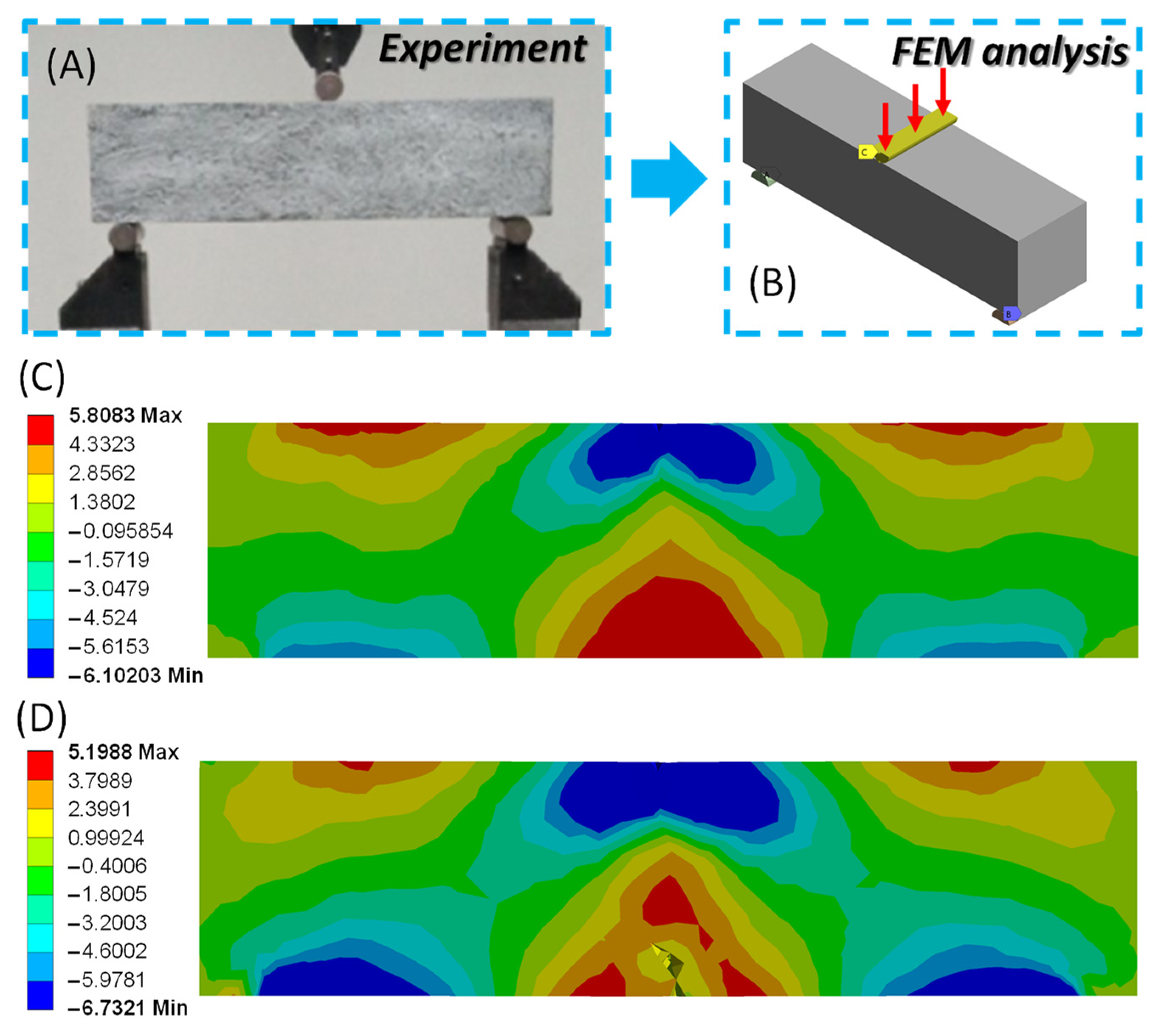

2.2. Numerical Multiscale Investigation

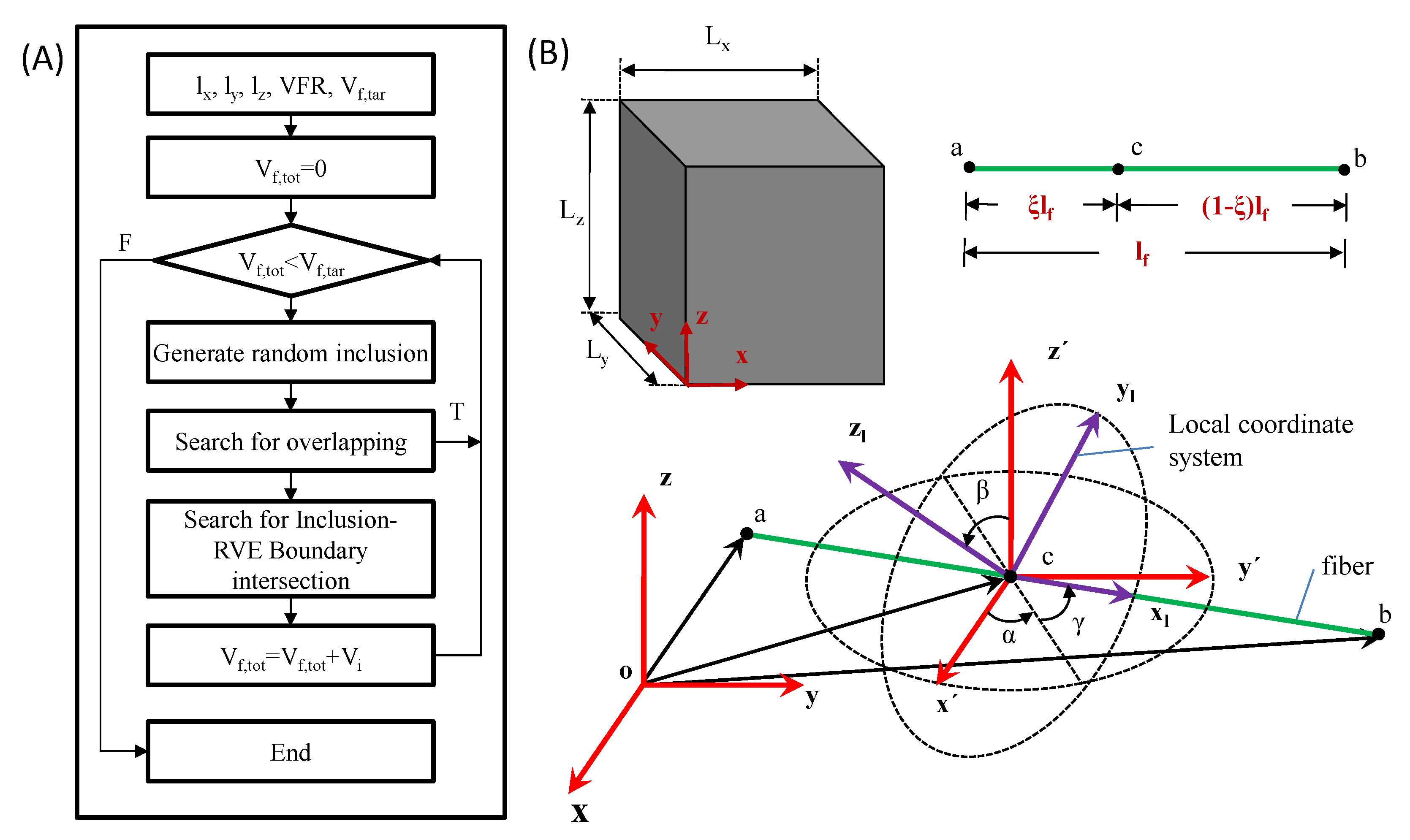

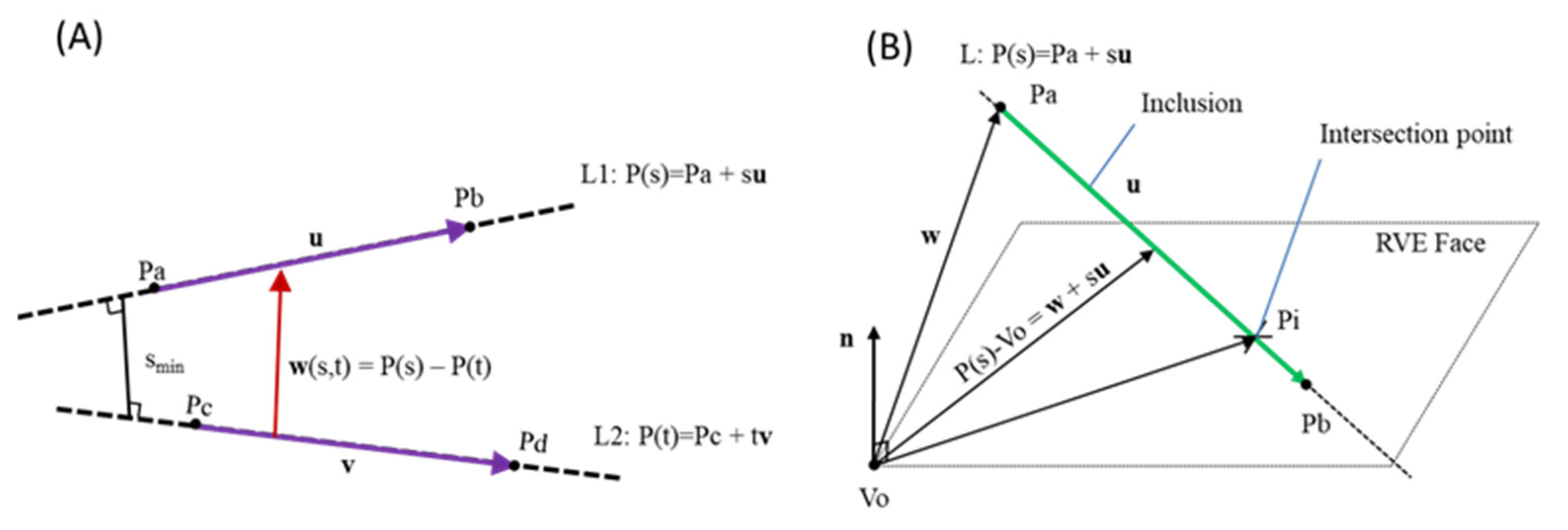

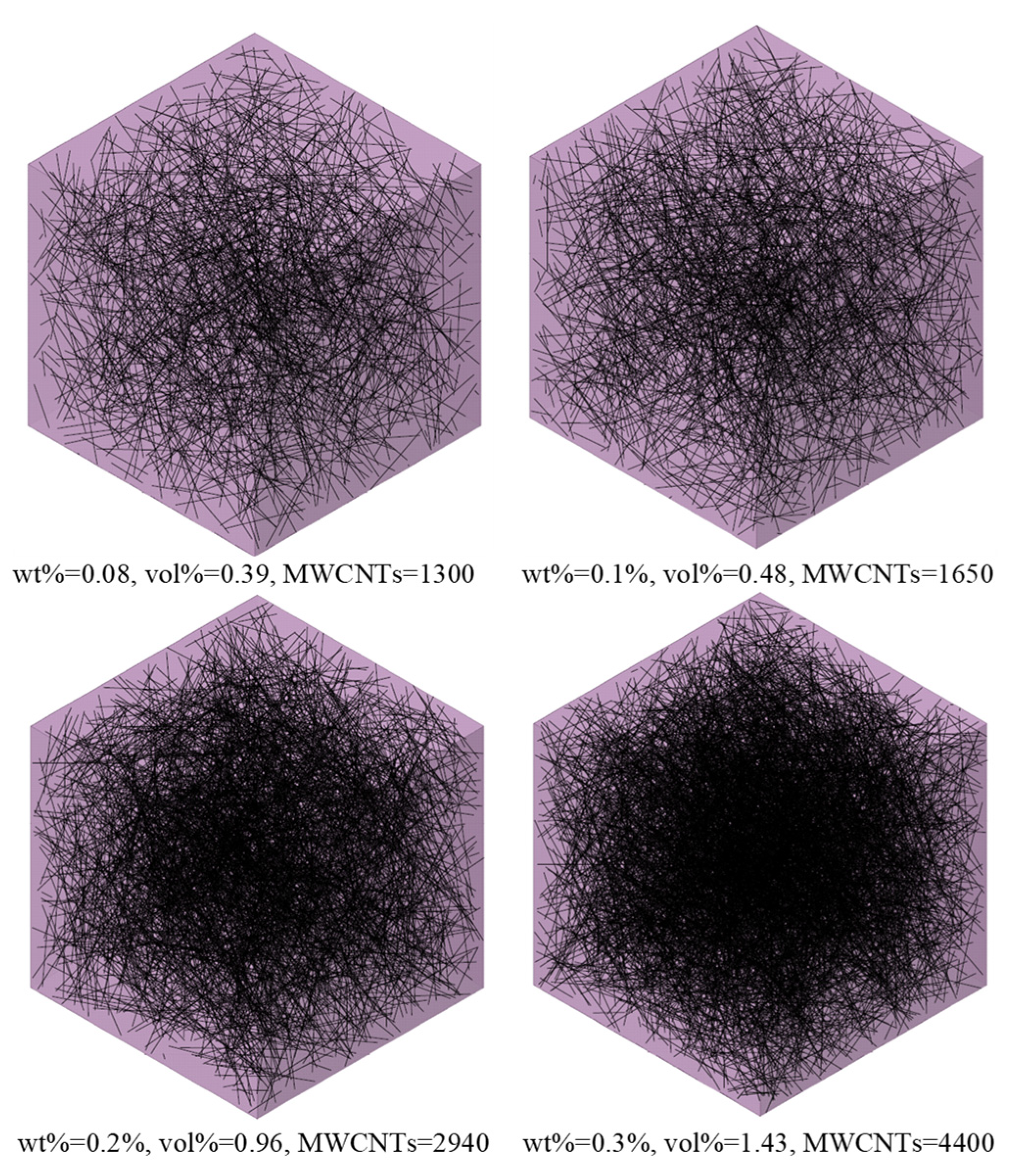

2.2.1. RVE Generation

2.2.2. Finite Element Modeling

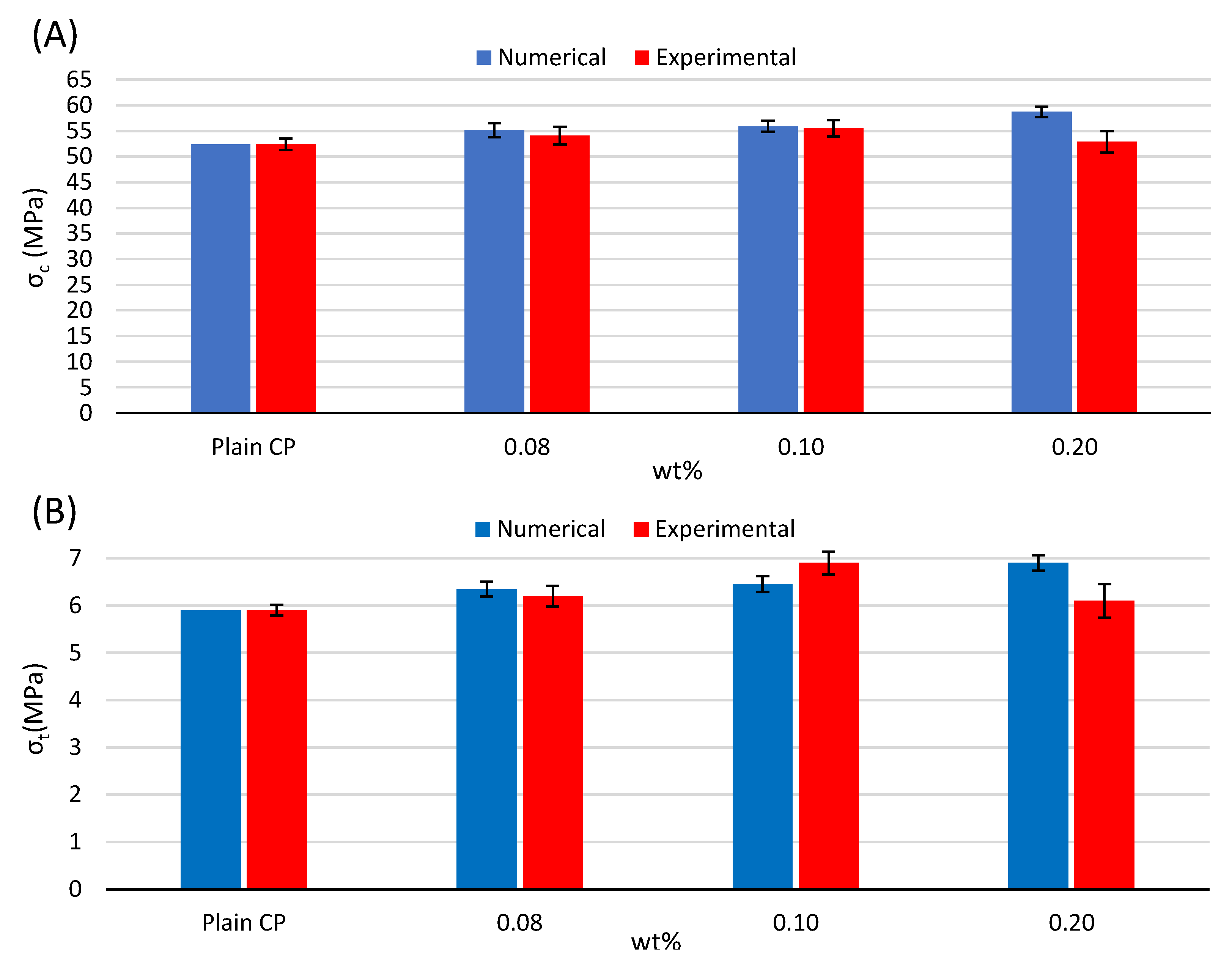

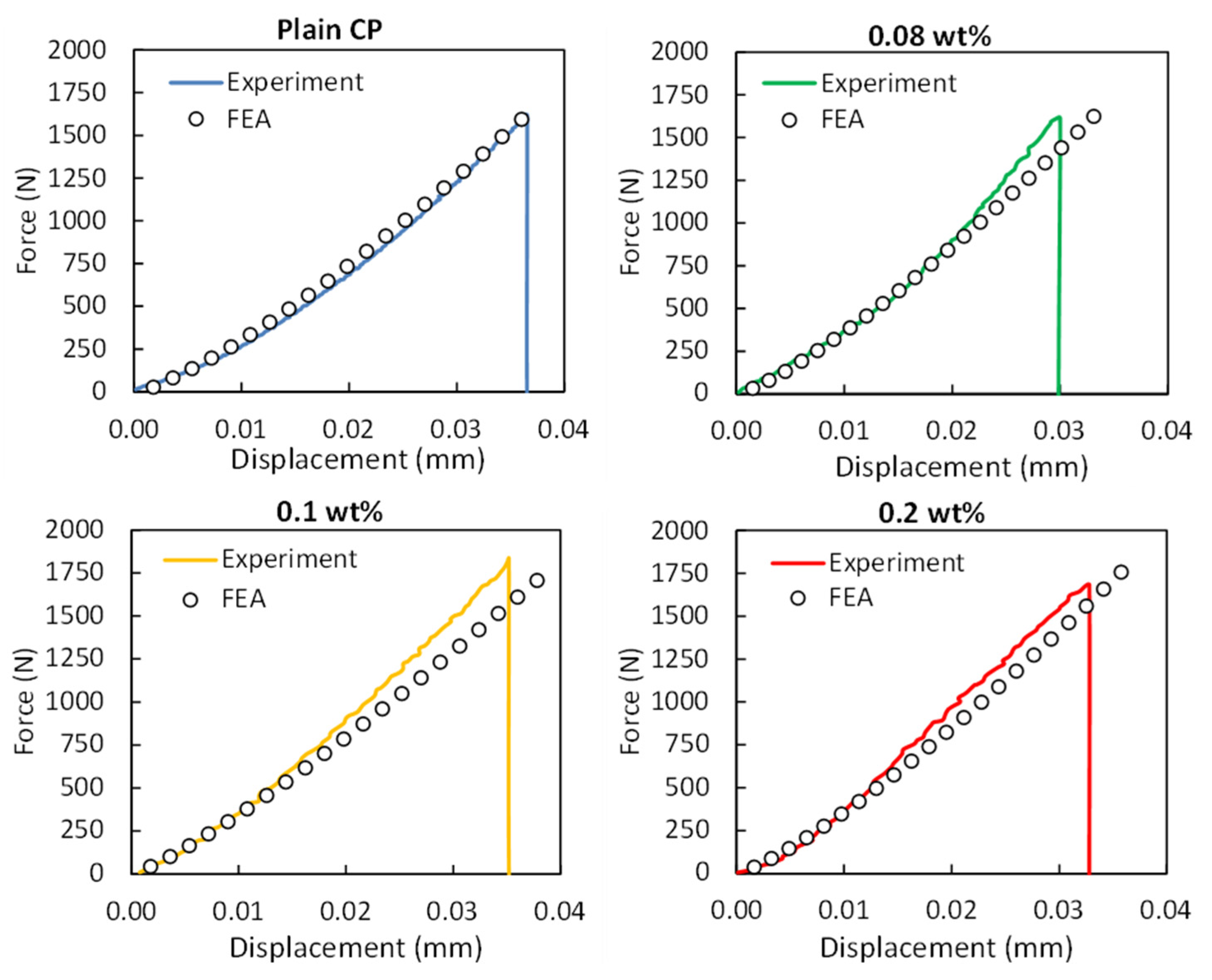

3. Results

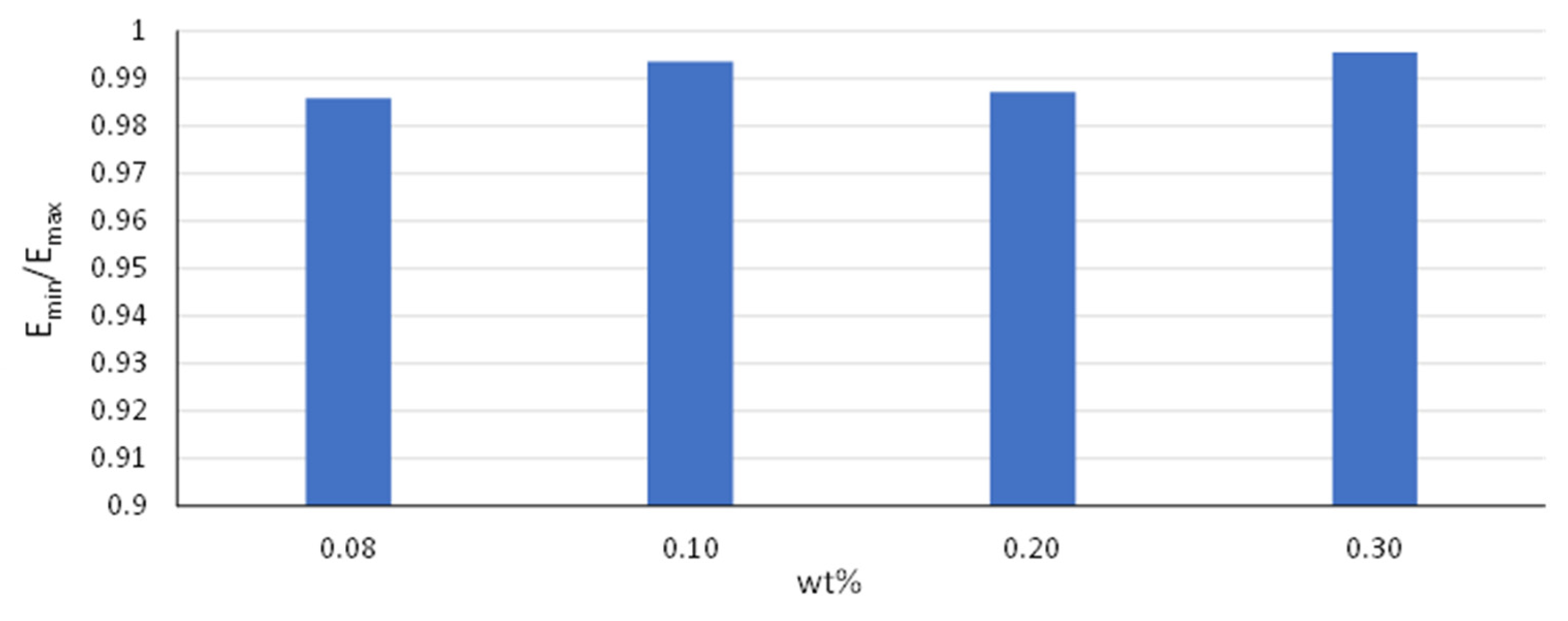

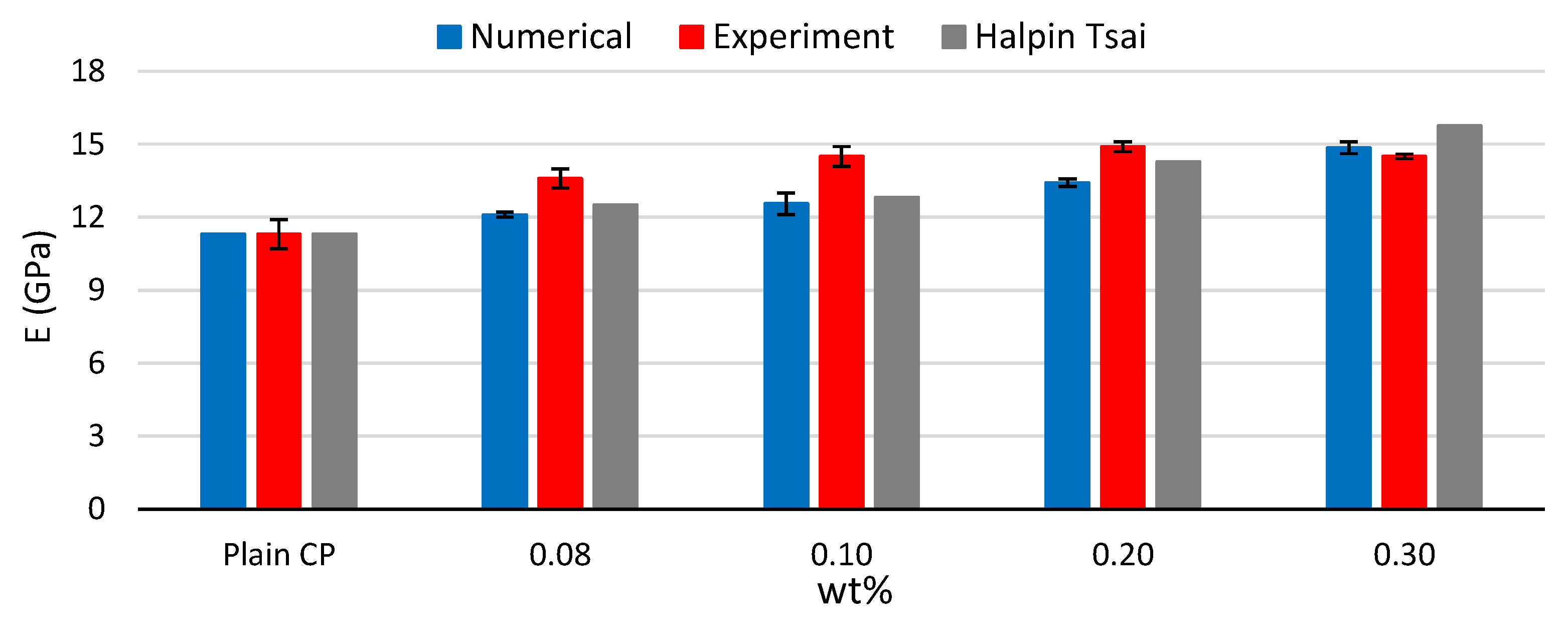

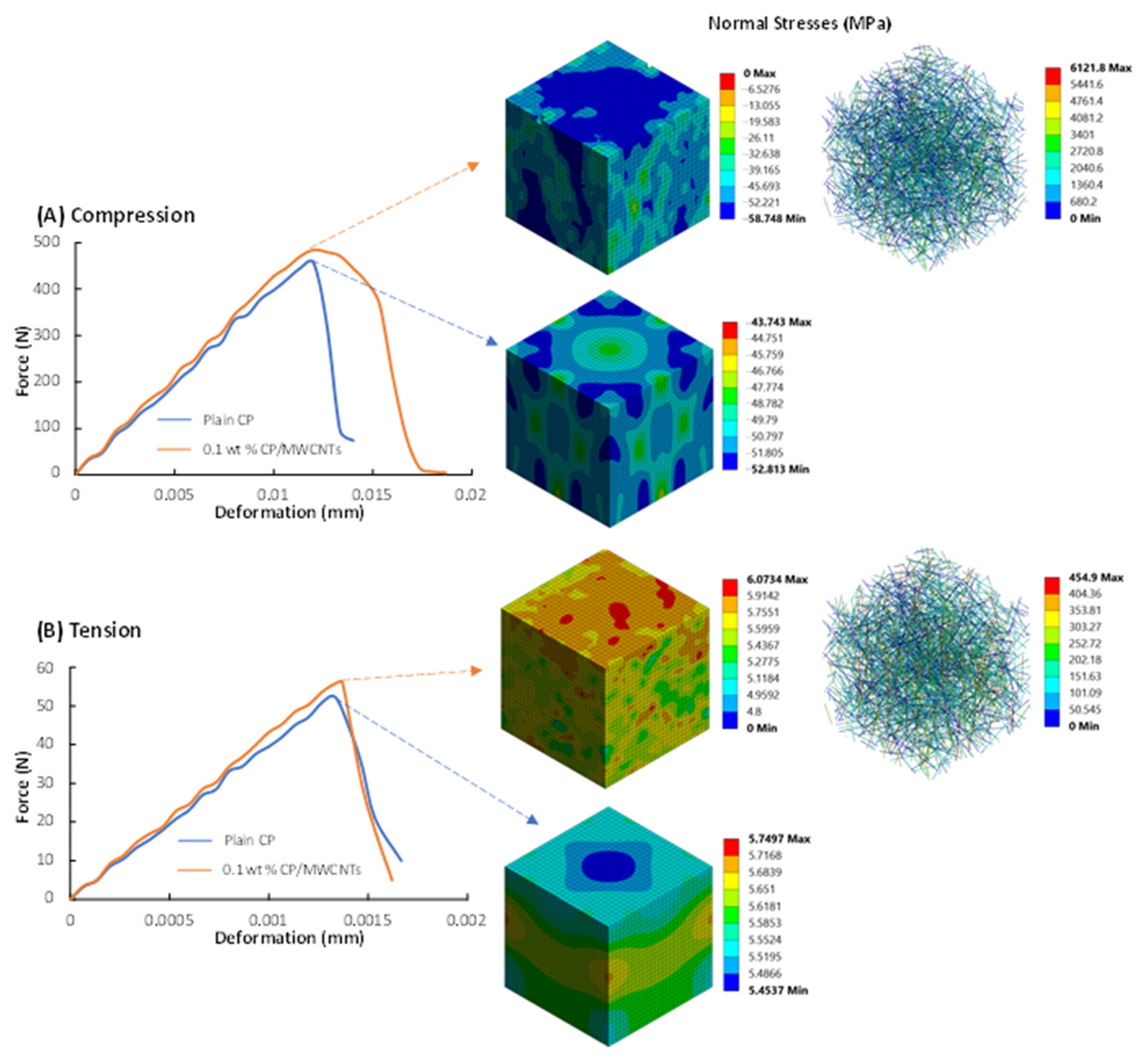

3.1. Nanoscale: RVE Analysis

3.2. Macroscale: Three-Point Bending Tests and Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Naqi, A.; Abbas, N.; Zahra, N.; Hussain, A.; Shabbir, S.Q. Effect of multi-walled carbon nanotubes (MWCNTs) on the strength development of cementitious materials. J. Mater. Res. Technol. 2019, 8, 1203–1211. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Wang, K.; Han, B.; Sheng, D.; Shah, S.P. Investigation on physicochemical and piezoresistive properties of smart MWCNT/cementitious composite exposed to elevated temperatures. Cem. Concr. Compos. 2020, 112, 103675. [Google Scholar] [CrossRef]

- Cerro-Prada, E.; Pacheco-Torres, R.; Varela, F. Effect of multi-walled carbon nanotubes on strength and electrical properties of cement mortar. Materials 2021, 14, 79. [Google Scholar] [CrossRef] [PubMed]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Falara, M.G.; Nitodas, S.F. Fresh and mechanical properties, and strain sensing of nanomodified cement mortars: The effects of MWCNT aspect ratio, density and functionalization. Cement Concr. Compos. 2018, 82, 137–151. [Google Scholar] [CrossRef]

- Al-Rub, R.K.A.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Metaxa, Z.S.; Boutsioukou, S.; Amenta, M.; Favvas, E.P.; Kourkoulis, S.K.; Alexopoulos, N.D. Dispersion of Multi-Walled Carbon Nanotubes into White Cement Mortars: The Effect of Concentration and Surfactants. Nanomaterials 2022, 12, 1031. [Google Scholar] [CrossRef]

- Sindu, B.S.; Sasmal, S.; Gopinath, S. A multi-scale approach for evaluating the mechanical characteristics of carbon nanotube incorporated cementitious composites. Constr. Build. Mater. 2014, 50, 317–327. [Google Scholar] [CrossRef]

- Šmilauer, V.; Hlaváček, P.; Padevět, P. Micromechanical analysis of cement paste with carbon nanotubes. Acta Polytech. 2012, 52, 22–28. [Google Scholar] [CrossRef]

- Eftekhari, M.; Mohammadi, S.; Khanmohammadi, M. A hierarchical nano to macro multiscale analysis of monotonic behavior of concrete columns made of CNT-reinforced cement composite. Constr. Build. Mater. 2018, 175, 134–143. [Google Scholar] [CrossRef]

- Papadopoulos, V.; Impraimakis, M. Multiscale modeling of carbon nanotube reinforced concrete. Compos. Struct. 2017, 182, 251–260. [Google Scholar] [CrossRef]

- Talayero, C.; Aït-Salem, O.; Gallego, P.; Páez-Pavón, A.; Merodio-Perea, R.G.; Lado-Touriño, I. Computational Prediction and Experimental Values of Mechanical Properties of Carbon Nanotube Reinforced Cement. Nanomaterials 2021, 11, 2997. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Hill, R. Elastic properties of reinforced solids: Some theoretical principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Würkner, M.; Berger, H.; Gabbert, U. Numerical investigations of effective properties of fiber reinforced composites with parallelogram arrangements and imperfect interface. Compos. Struct. 2014, 116, 388–394. [Google Scholar] [CrossRef]

- Tian, W.; Qi, L.; Zhou, J.; Liang, J.; Ma, Y. Representative volume element for composites reinforced by spatially randomly distributed discontinuous fibers and its applications. Compos. Struct. 2015, 131, 366–373. [Google Scholar] [CrossRef]

- Zhao, X.; Gui, Z.; Chen, X.; Zhang, W.; Yang, P.; Zheng, J.; Liu, A. Finite element analysis and experiment study on the elastic properties of randomly and controllably distributed carbon fiber-reinforced hydroxyapatite composites. Ceram. Int. 2021, 47, 12613–12622. [Google Scholar] [CrossRef]

- Stefanou, G.; Savvas, D.; Papadrakakis, M. Stochastic finite element analysis of composite structures based on material microstructure. Compos. Struct. 2015, 132, 384–392. [Google Scholar] [CrossRef]

- Breuer, K.; Stommel, M. Prediction of short fiber composite properties by an artificial neural network trained on an RVE database. Fibers 2021, 9, 8. [Google Scholar] [CrossRef]

- Wriggers, P.; Moftah, S.O. Mesoscale models for concrete: Homogenisation and damage behaviour. Finite Elem. Anal. Des. 2006, 42, 623–636. [Google Scholar] [CrossRef]

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites–a review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Falara, M.; Thomoglou, A.; Goundakou, F.; Elenas, A. Carbon nanotubes’ amount and type: Crucial parameters in mechanical performance enhancement on cement paste nanocomposites. J. Phys. Conf. Ser. 2022, 2321, 012003. [Google Scholar]

- Thomoglou, A.K.; Falara, M.G.; Gkountakou, F.I.; Elenas, A.; Chalioris, C.E. Influence of Different Surfactants on Carbon Fiber Dispersion and the Mechanical Performance of Smart Piezoresistive Cementitious Composites. Fibers 2022, 10, 49. [Google Scholar] [CrossRef]

- Thomoglou, A.K.; Falara, M.G.; Gkountakou, F.I.; Elenas, A.; Chalioris, C.E. Smart Cementitious Sensors with Nano-, Micro-, and Hybrid-Modified Reinforcement: Mechanical and Electrical Properties. Sensors 2023, 23, 2405. [Google Scholar] [CrossRef]

- ASTMC348; Standard Test Method for Flexural Strength of Hydraulic-Cementmortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- ASTMC349; Standard Test Method for Flexural Strength of Hydraulic-Cementmortars. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- Bargmann, S.; Klusemann, B.; Markmann, J.; Schnabel, J.E.; Schneider, K.; Soyarslan, C.; Wilmers, J. Generation of 3D representative volume elements for heterogeneous materials: A review. Prog. Mater. Sci. 2018, 96, 322–384. [Google Scholar] [CrossRef]

- Bailakanavar, M.; Liu, Y.; Fish, J.; Zheng, Y. Automated modeling of random inclusion composites. Eng. Comput. 2014, 30, 609–625. [Google Scholar] [CrossRef]

- The MathWorks Inc. MATLAB Version: 9.13.0 (R2022b); The MathWorks Inc.: Natick, MA, USA, 2022. [Google Scholar]

- Ansys® Academic Research Mechanical, Release 23.1.

- Riedel, W.; Kawai, N.; Kondo, K.I. Numerical assessment for impact strength measurements in concrete materials. Int. J. Impact Eng. 2009, 36, 283–293. [Google Scholar] [CrossRef]

- Rousakis, T.; Anagnostou, E.; Fanaradelli, T. Advanced Composite Retrofit of RC Columns and Frames with Prior Damages—Pseudodynamic Finite Element Analyses and Design Approaches. Fibers 2021, 9, 56. [Google Scholar] [CrossRef]

- Savvas, D.N.; Papadopoulos, V.; Papadrakakis, M. The effect of interfacial shear strength on damping behavior of carbon nanotube reinforced composites. Int. J. Solids Struct. 2012, 49, 3823–3837. [Google Scholar] [CrossRef]

- Gao, J.; Yang, X.; Huang, L. Numerical prediction of mechanical properties of rubber composites reinforced by aramid fiber under large deformation. Compos. Struct. 2018, 201, 29–37. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Béchet, E.; Geuzaine, C.; Noels, L. Imposing periodic boundary condition on arbitrary meshes by polynomial interpolation. Comput. Mater. Sci. 2012, 55, 390–406. [Google Scholar] [CrossRef]

- Qi, L.; Tian, W.; Zhou, J. Numerical evaluation of effective elastic properties of composites reinforced by spatially randomly distributed short fibers with certain aspect ratio. Compos. Struct. 2015, 131, 843–851. [Google Scholar] [CrossRef]

- García-Macías, E.; Guzmán, C.F.; Flores, E.I.S.; Castro-Triguero, R. Multiscale modeling of the elastic moduli of CNT-reinforced polymers and fitting of efficiency parameters for the use of the extended rule-of-mixtures. Compos. Part B Eng. 2019, 159, 114–131. [Google Scholar] [CrossRef]

- Kari, S.; Berger, H.; Gabbert, U. Numerical evaluation of effective material properties of randomly distributed short cylindrical fibre composites. Comput. Mater. Sci. 2007, 39, 198–204. [Google Scholar] [CrossRef]

- Makar, J.M.; Beaudoin, J.J. Carbon nanotubes and their application in the construction industry. In Proceedings of the 1st International Symposium on Nanotechnology in Construction, Ottawa, ON, Canada, 22–25 June 2003. [Google Scholar]

- Lu, Z.; Yuan, Z.; Liu, Q. 3D numerical simulation for the elastic properties of random fiber composites with a wide range of fiber aspect ratios. Comput. Mater. Sci. 2014, 90, 123–129. [Google Scholar] [CrossRef]

- Eleftherios, T.; Gergidis, L.N.; Paipetis, A.S. Computational multi-scale modelling of fiber-reinforced composite materials. Key Eng. Mater. 2020, 827, 263–268. [Google Scholar] [CrossRef]

- Affdl, J.H.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Danoglidis, P.A.; Shah, S.P. High modulus concrete: Effects of low carbon nanotube and nanofiber additions. Theor. Appl. Fract. Mech. 2019, 103, 102295. [Google Scholar] [CrossRef]

- Vareli, I.; Tzounis, L.; Tsirka, K.; Kavvadias, I.E.; Tsongas, K.; Liebscher, M.; Elenas, A.; Gergidis, L.N.; Barkoula, N.M.; Paipetis, A.S. High-performance cement/SWCNT thermoelectric nanocomposites and a structural thermoelectric generator device towards large-scale thermal energy harvesting. J. Mater. Chem. C 2021, 9, 14421–14438. [Google Scholar] [CrossRef]

| Chemical Composition and Properties | % by Mass | % w/w |

|---|---|---|

| Clinker | 95–100 | |

| Minor additional constituents | 0–5 | |

| Gypsum | - | |

| Sulfate content SO3 | ≤4.0 | |

| Chloride content | ≤1.0 | |

| C3A in clinker | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kavvadias, I.E.; Tsongas, K.; Bantilas, K.E.; Falara, M.G.; Thomoglou, A.K.; Gkountakou, F.I.; Elenas, A. Mechanical Characterization of MWCNT-Reinforced Cement Paste: Experimental and Multiscale Computational Investigation. Materials 2023, 16, 5379. https://doi.org/10.3390/ma16155379

Kavvadias IE, Tsongas K, Bantilas KE, Falara MG, Thomoglou AK, Gkountakou FI, Elenas A. Mechanical Characterization of MWCNT-Reinforced Cement Paste: Experimental and Multiscale Computational Investigation. Materials. 2023; 16(15):5379. https://doi.org/10.3390/ma16155379

Chicago/Turabian StyleKavvadias, Ioannis E., Konstantinos Tsongas, Kosmas E. Bantilas, Maria G. Falara, Athanasia K. Thomoglou, Fani I. Gkountakou, and Anaxagoras Elenas. 2023. "Mechanical Characterization of MWCNT-Reinforced Cement Paste: Experimental and Multiscale Computational Investigation" Materials 16, no. 15: 5379. https://doi.org/10.3390/ma16155379

APA StyleKavvadias, I. E., Tsongas, K., Bantilas, K. E., Falara, M. G., Thomoglou, A. K., Gkountakou, F. I., & Elenas, A. (2023). Mechanical Characterization of MWCNT-Reinforced Cement Paste: Experimental and Multiscale Computational Investigation. Materials, 16(15), 5379. https://doi.org/10.3390/ma16155379