A Comprehensive Understanding of Knife Cutting: Effects of Hardness, Blade Angle and the Micro-Geometry of Blade Edge on the Cutting Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Blade Steels

2.2. Knife Blade Fabrication and Cutting Tests

2.3. Materials Characterization

3. Results and Discussions

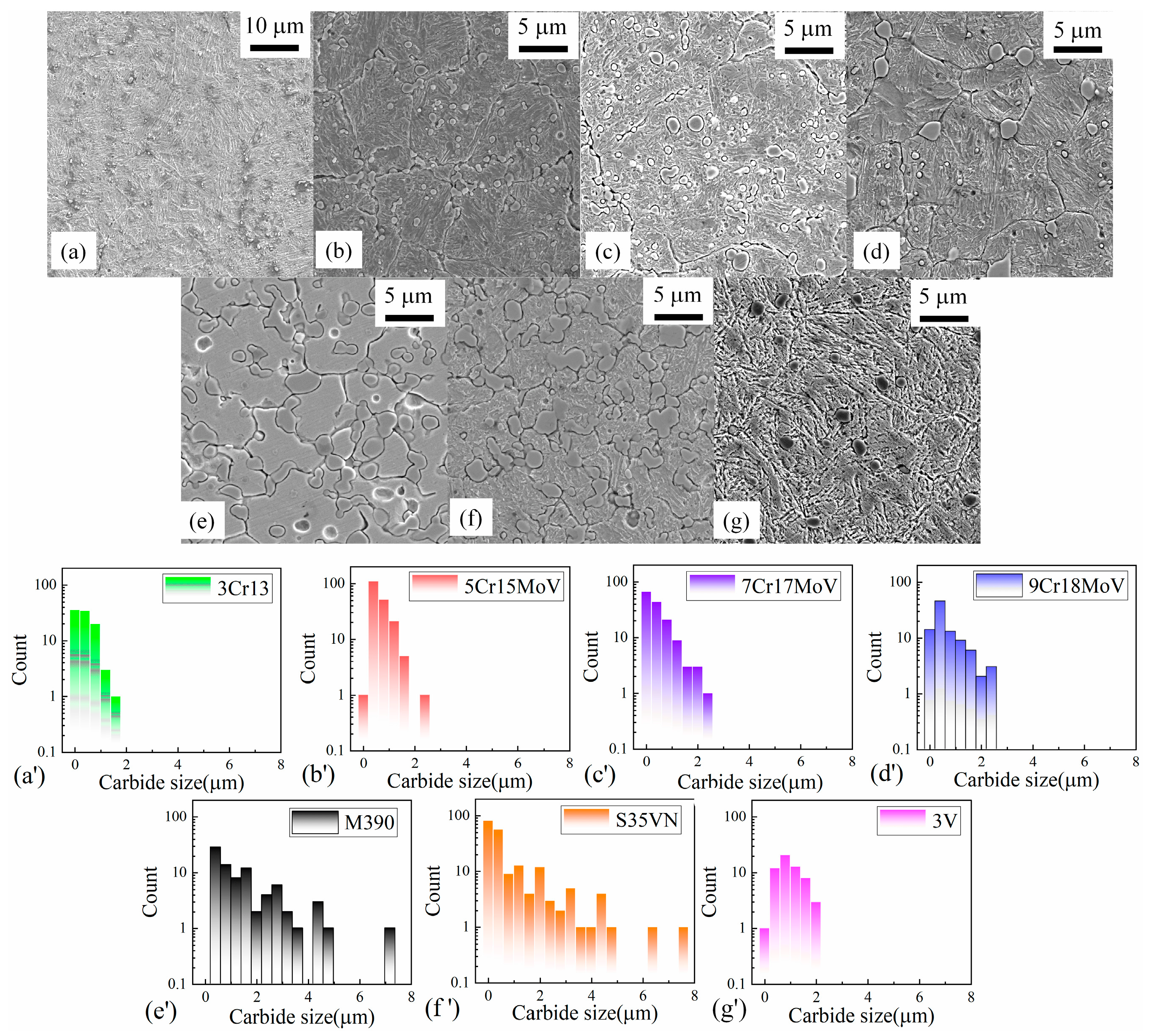

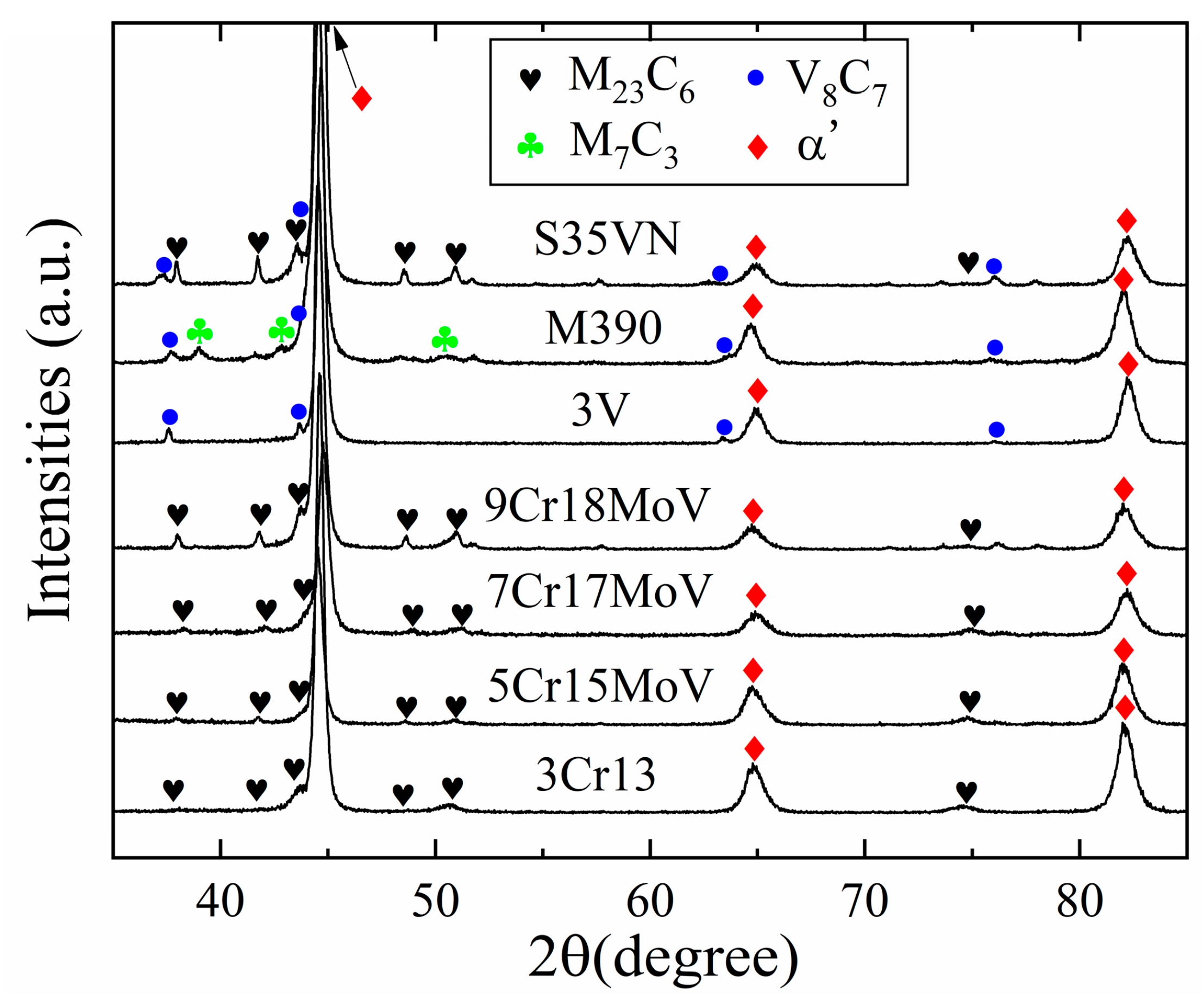

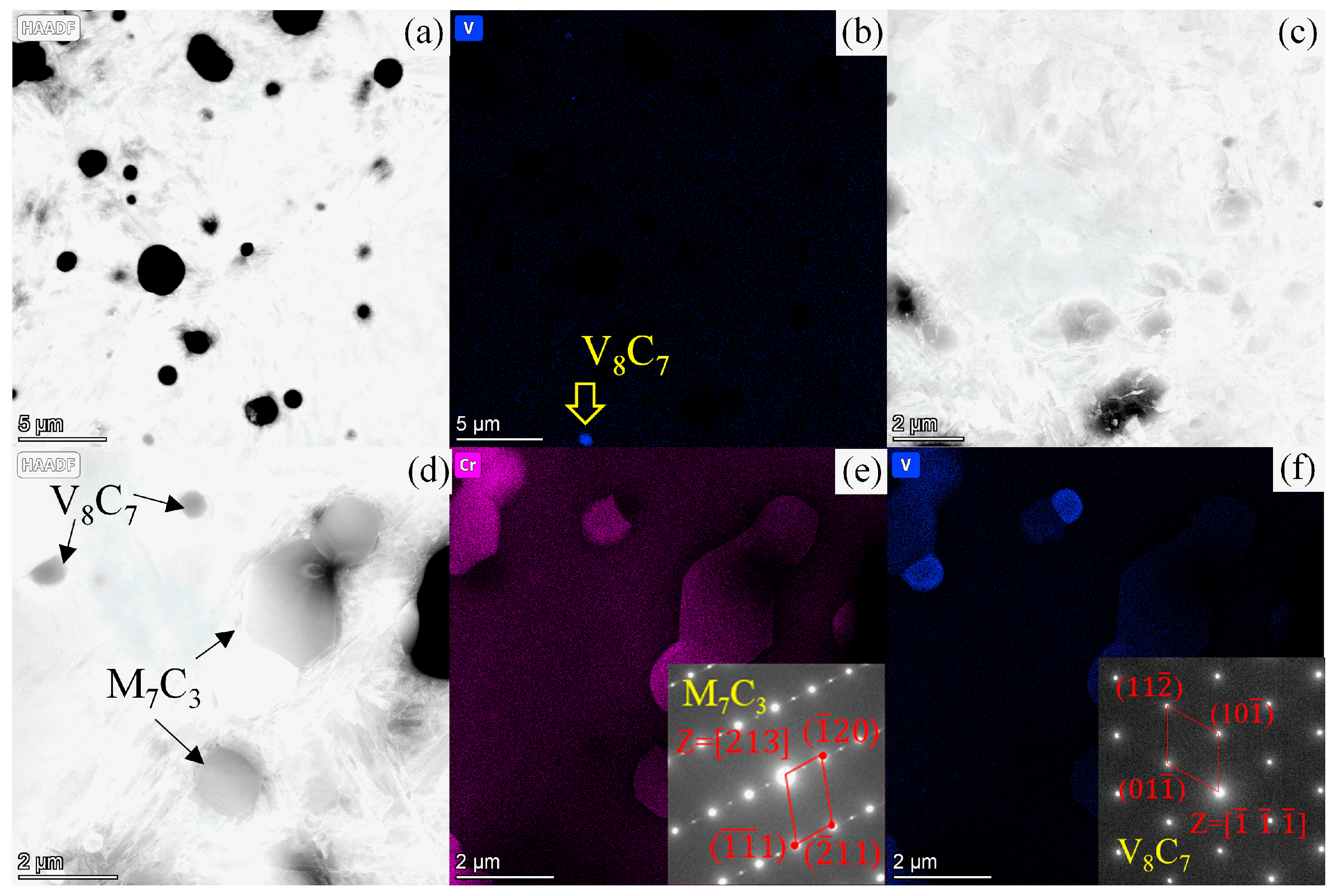

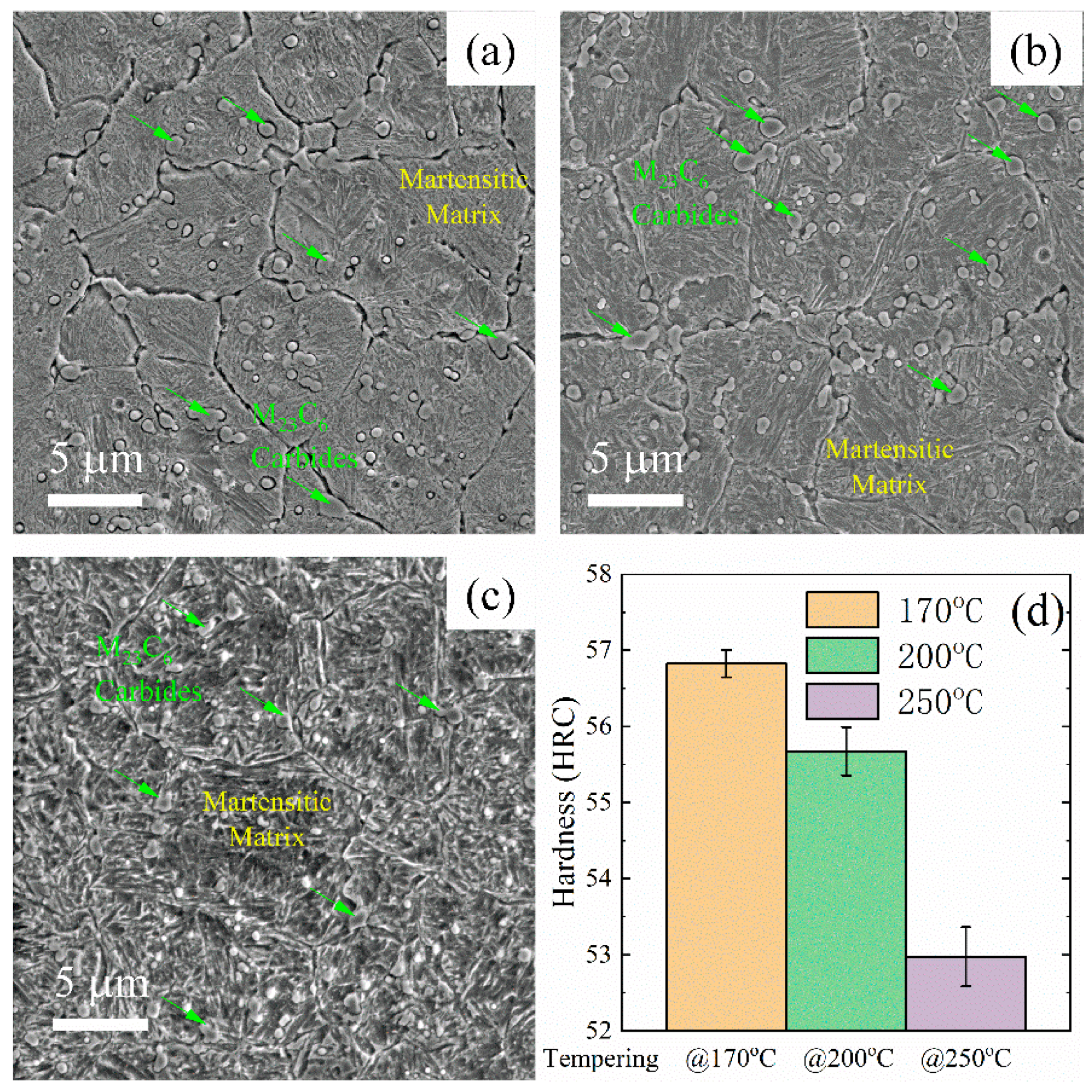

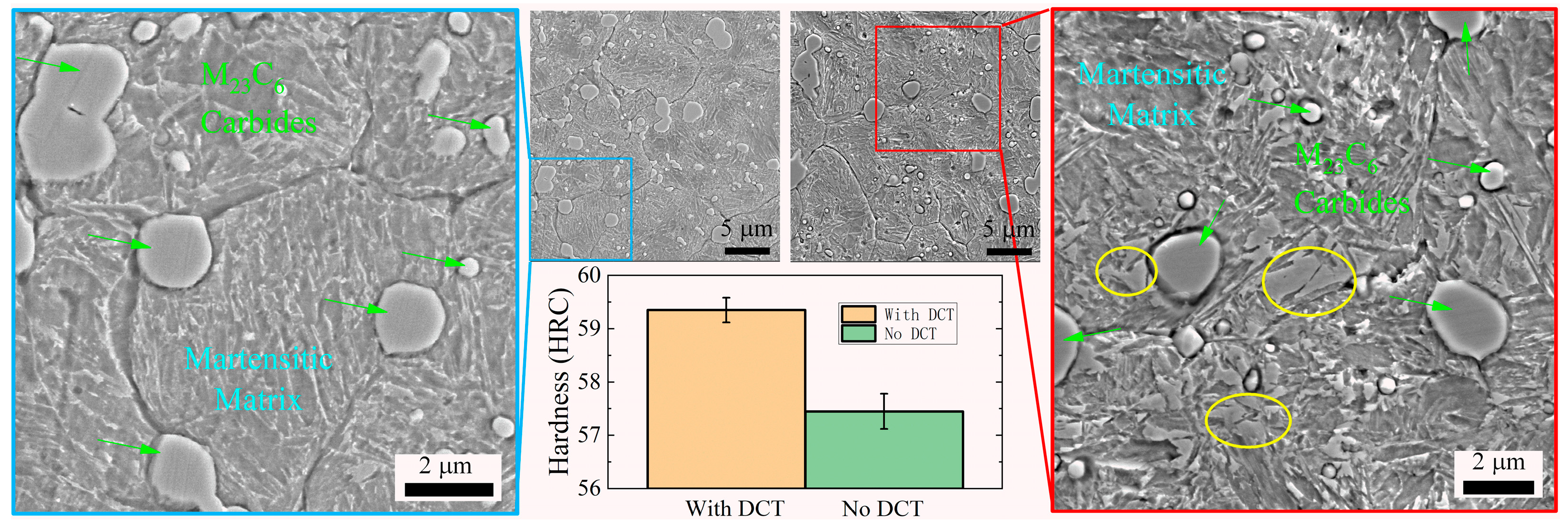

3.1. Microstructure and Phases of Blade Steels

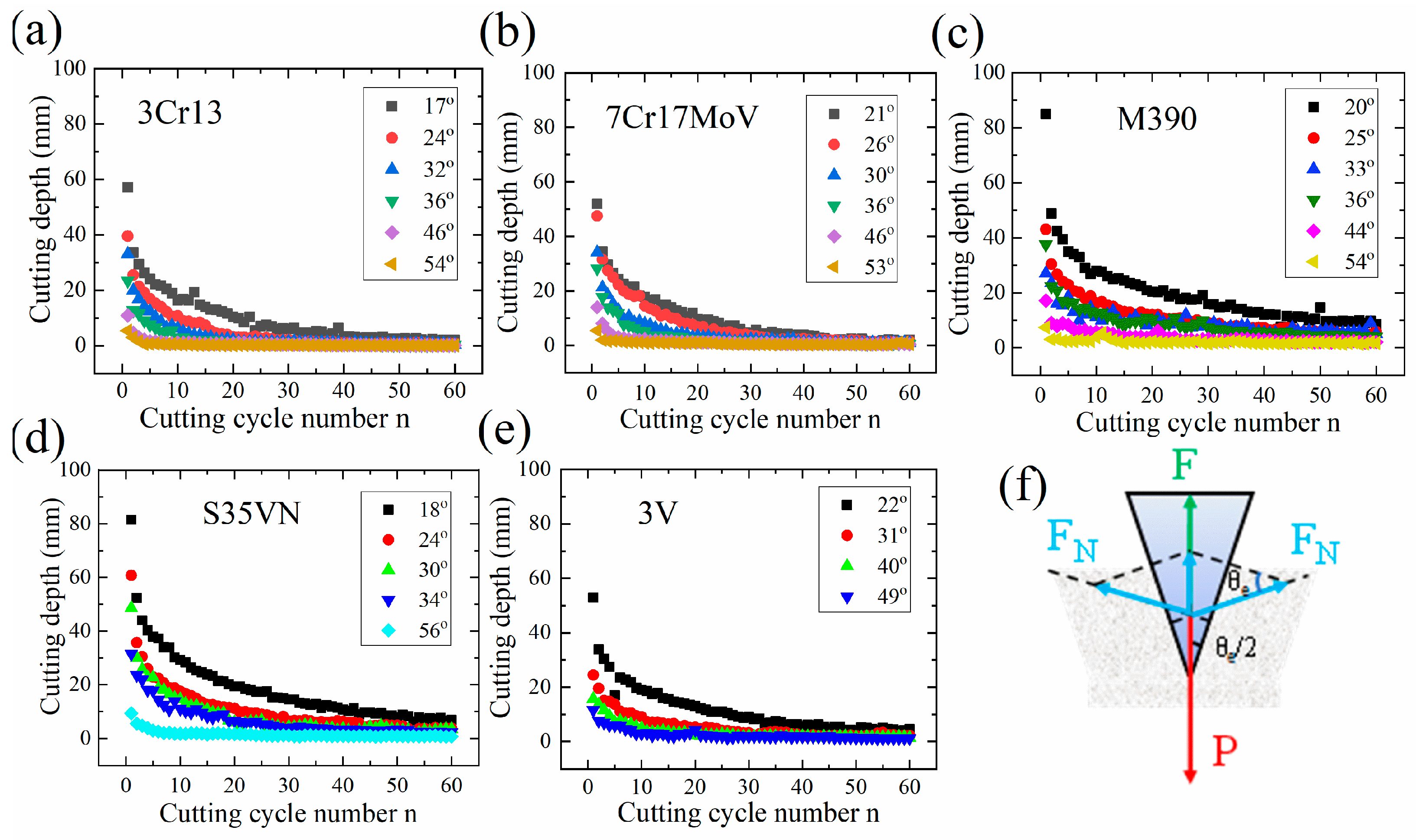

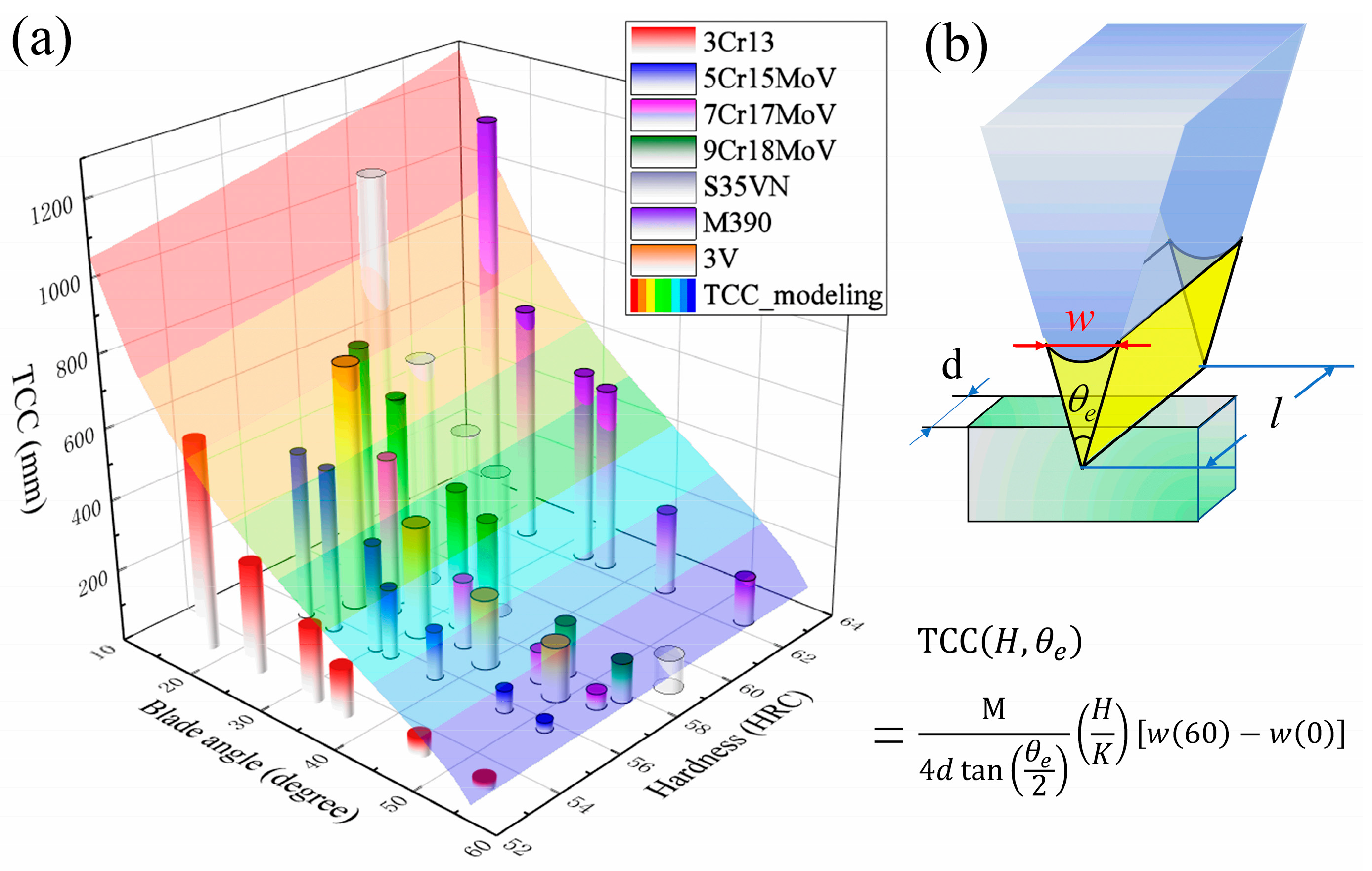

3.2. Major Factors That Influence the Cutting Performance of Steel Blades

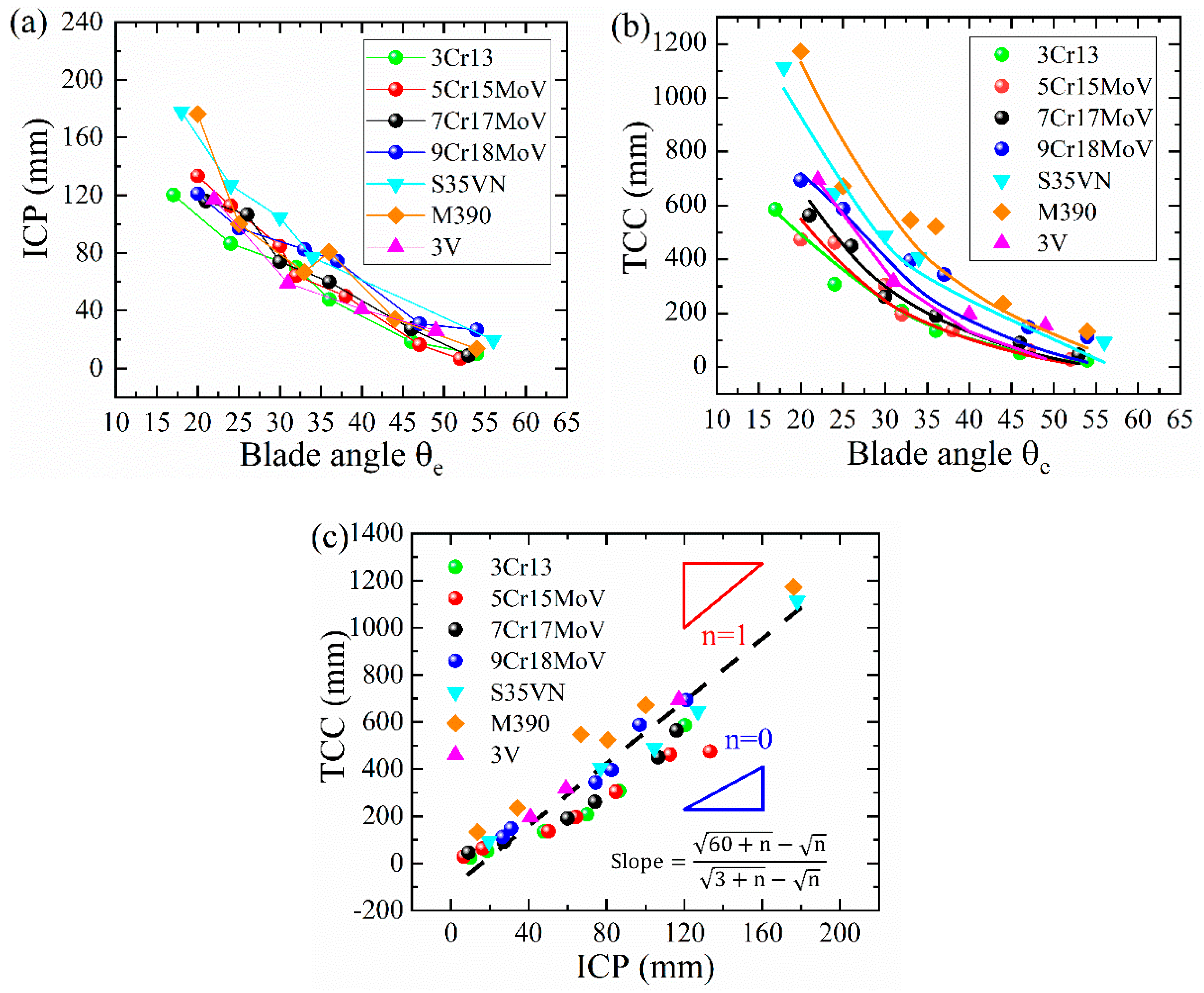

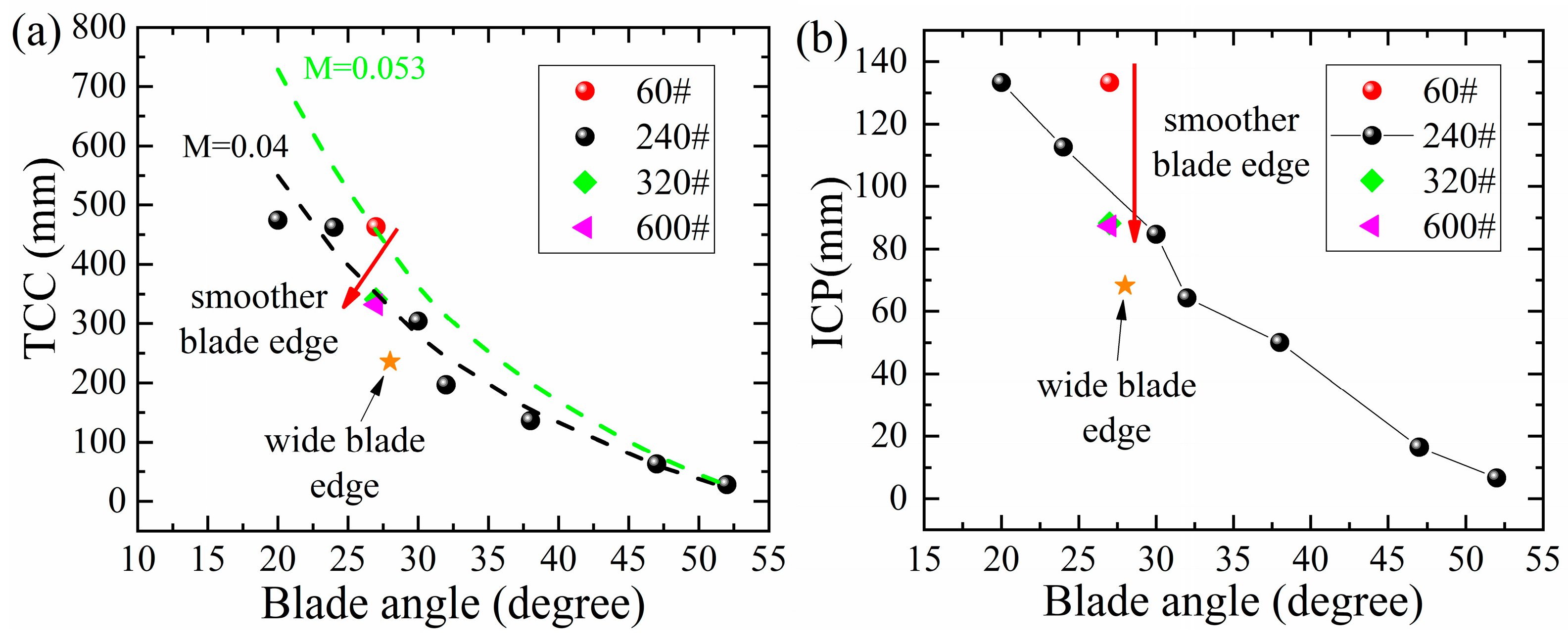

3.2.1. The Blade Angle θe

3.2.2. Hardness of the Blade Steels

3.2.3. Merits and Limitations of the Quantitative Model

3.3. Technical Analysis on the Geometry of Blade Edge

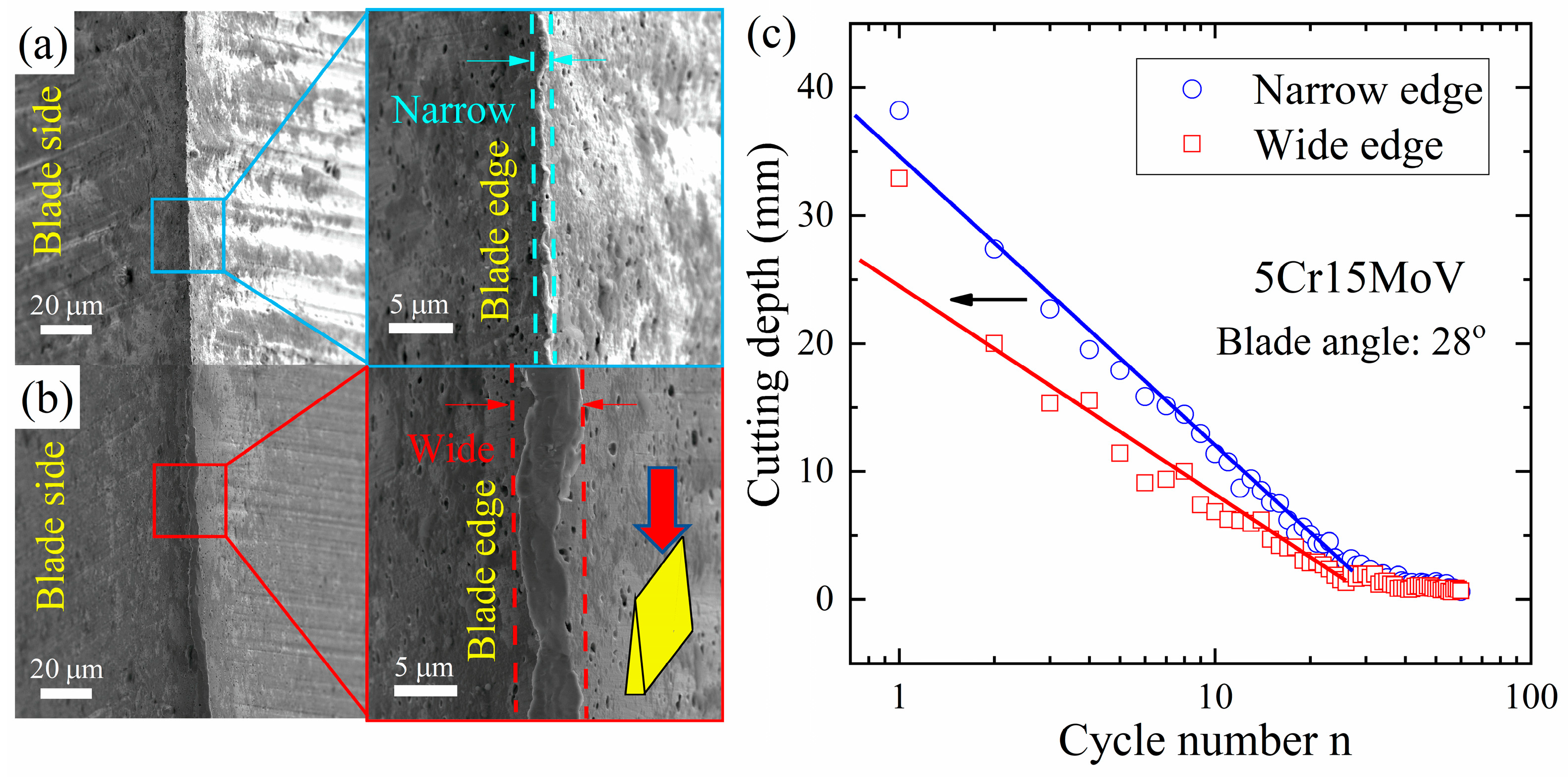

3.3.1. Width of Blade Edge w

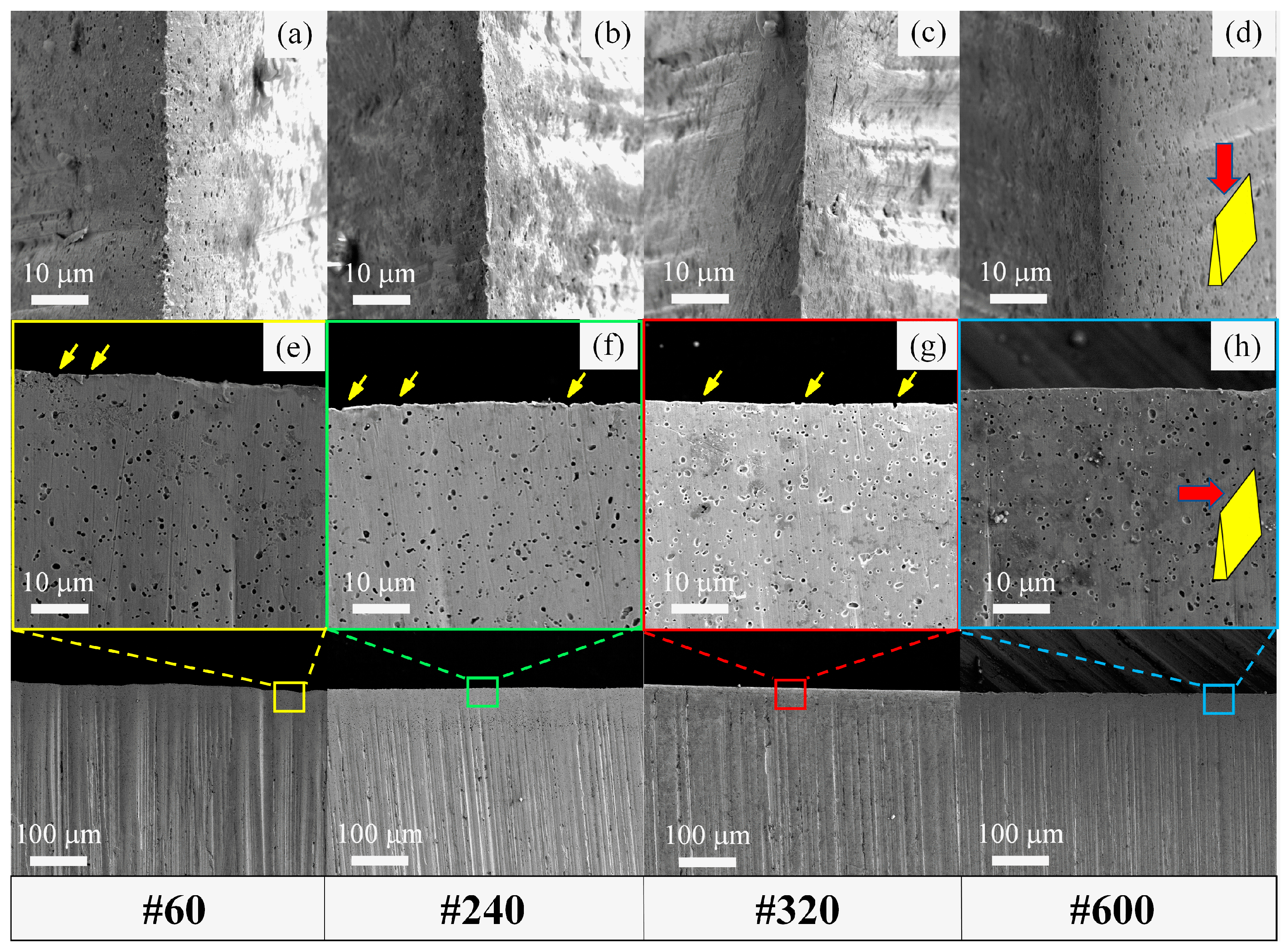

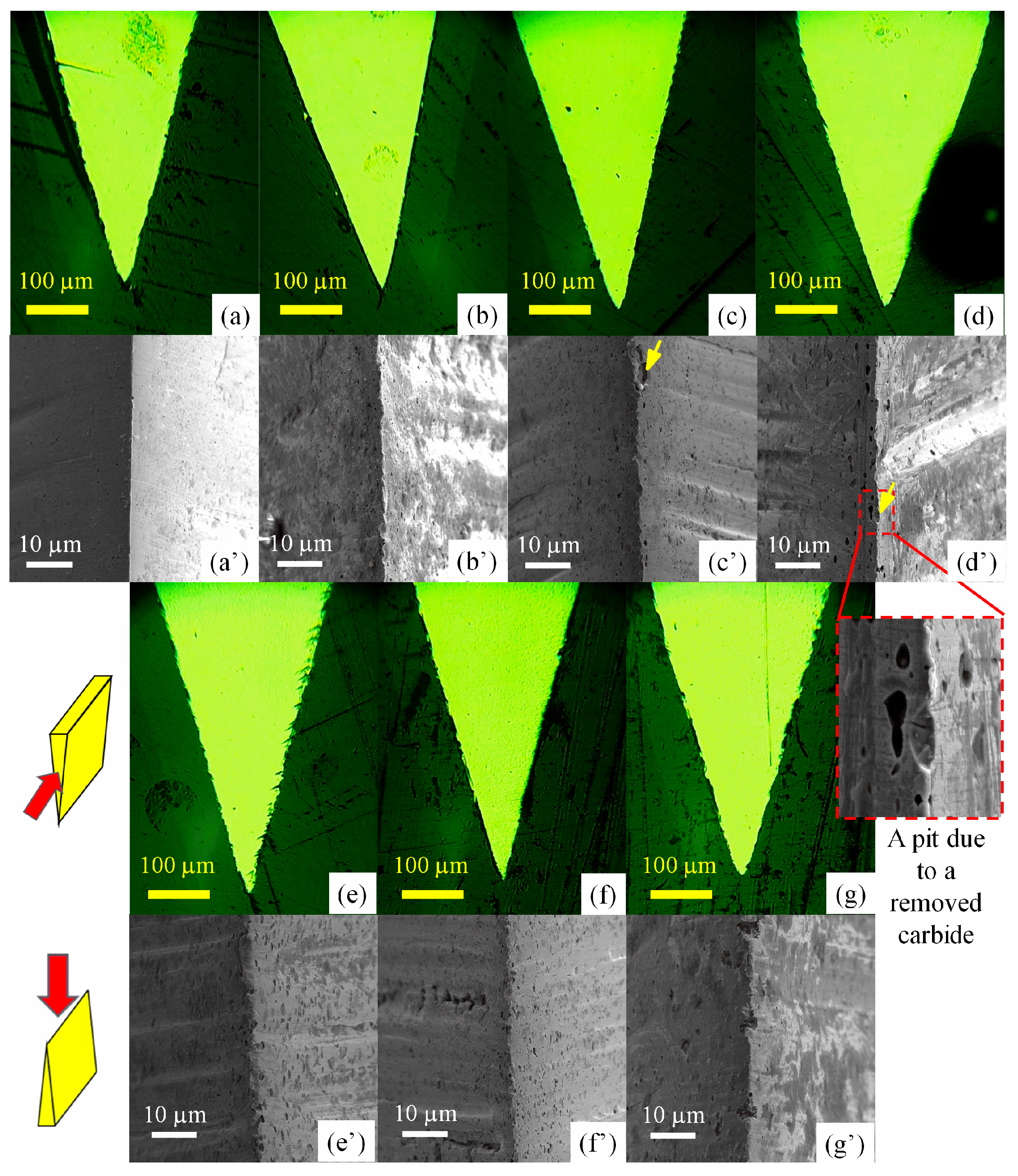

3.3.2. Micro-Geometries of Blade Edge

3.4. A General Quantitative Model

4. Conclusions

- A higher wear resistance/hardness and smaller blade angle were found to be favored to raise the cutting depth. The cutting performance can be adjusted by proper heat treatments (e.g., DCT and tempering);

- Sharpness was found to be sensitive to the micro-geometry of the blade edges, which may result from the grinding finish or the carbide/matrix microstructures of the steels;

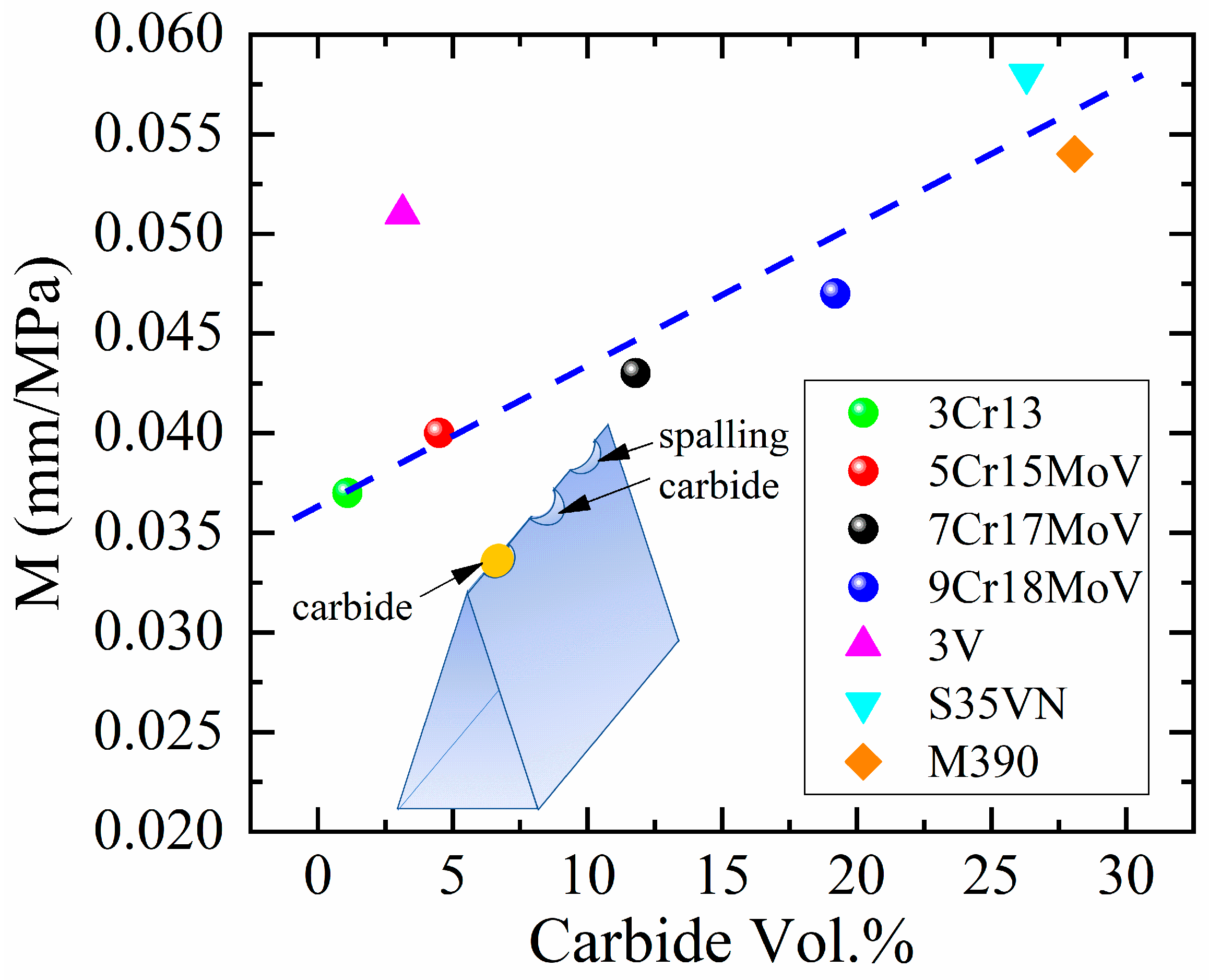

- According to a quantitative analysis on the cutting data, the cutting depth coefficient M can be generalized to represent the roughness of a blade edge. The M values for almost all steels were found to follow a linear relation with the carbide volumetric fraction. More carbides result in a rougher blade edge;

- An exceptionally high M value of 0.051 mm/MPa was observed in 3V, which probably arises from a robust, rough blade edge due to the fine vanadium carbide being strongly bonded with the steel matrix;

- It is indicated that a rougher micro-geometry of a blade made of harder steel is the most favorable for a better cutting performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, B.; Jiang, X.; Wu, R.; Wei, B.; Hu, T.; Pan, C. Formation of Black Patina on an Ancient Chinese Bronze Sword of the Warring States Period. Appl. Surf. Sci. 2018, 455, 724–728. [Google Scholar] [CrossRef]

- Sapiro, D.; Webler, B. Fabrication of a Bronze Age Sword Using Ancient Techniques. JOM 2016, 68, 3180–3185. [Google Scholar] [CrossRef]

- Xu, W.; Wang, J.; Deng, Y.; Li, J.; Yan, T.; Zhao, S.; Yang, X.; Xu, E.; Wang, W.; Liu, D. Advanced Cutting Techniques for Solid Food: Mechanisms, Applications, Modeling Approaches, and Future Perspectives. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1568–1597. [Google Scholar] [CrossRef] [PubMed]

- Mason, A.; Romanov, D.; Cordova-Lopez, L.E.; Korostynska, O. Smart Knife: Integrated Intelligence for Robotic Meat Cutting. IEEE Sens. J. 2022, 22, 20475–20483. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, M.; Liao, Z.; Feng, J.; Xu, D.; Cheng, J. On the Improvement of the Ductile Removal Ability of Brittle KDP Crystal via Temperature Effect. Ceram. Int. 2021, 47, 33127–33139. [Google Scholar] [CrossRef]

- Liu, Q.; Liao, Z.; Axinte, D. Temperature Effect on the Material Removal Mechanism of Soft-Brittle Crystals at Nano/Micron Scale. Int. J. Mach. Tools Manuf. 2020, 159, 103620. [Google Scholar] [CrossRef]

- Liu, Q.; Cheng, J.; Liao, Z.; Luo, X.; Yang, Y.; Li, M.; Yang, H.; Tan, C.; Wang, G.; Ding, W.; et al. Research on the Light Intensity Modulation and Characterizing Methods of Surface Texture on KDP Optics Generated in Fly-Cutting and Micro Ball-End Milling Processes. CIRP J. Manuf. Sci. Technol. 2023, 41, 30–43. [Google Scholar] [CrossRef]

- Takekoshi, K.; Gotoh, M. Studies on Micro-Structure of a Knife-Edge and Degradation of Cutting Performance. Nippon. Kikai Gakkai Ronbunshu C Hen/Trans. Jpn. Soc. Mech. Eng. Part C 2004, 70, 2155–2162. [Google Scholar] [CrossRef]

- Marsot, J.; Claudon, L.; Jacqmin, M. Assessment of Knife Sharpness by Means of a Cutting Force Measuring System. Appl. Ergon. 2007, 38, 83–89. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dowd, P.C.; Dempsey, P.G. A Technique for Field Measurement of Knife Sharpness. Appl. Ergon. 2005, 36, 635–640. [Google Scholar] [CrossRef] [PubMed]

- Karltun, J.; Vogel, K.; Bergstrand, M.; Eklund, J. Maintaining Knife Sharpness in Industrial Meat Cutting: A Matter of Knife or Meat Cutter Ability. Appl. Ergon. 2016, 56, 92–100. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, Y.; Wang, C.; Chen, B. Understanding the Cutting Mechanisms of Composite Structured Soft Tissues. Int. J. Mach. Tools Manuf. 2021, 161, 103685. [Google Scholar] [CrossRef]

- Spagnoli, A.; Terzano, M.; Brighenti, R.; Artoni, F.; Ståhle, P. The Fracture Mechanics in Cutting: A Comparative Study on Hard and Soft Polymeric Materials. Int. J. Mech. Sci. 2018, 148, 554–564. [Google Scholar] [CrossRef]

- McCarthy, C.T.; Hussey, M.; Gilchrist, M.D. On the Sharpness of Straight Edge Blades in Cutting Soft Solids: Part I—Indentation Experiments. Eng. Fract. Mech. 2007, 74, 2205–2224. [Google Scholar] [CrossRef]

- McCarthy, C.T.; Annaidh, A.N.; Gilchrist, M.D. On the Sharpness of Straight Edge Blades in Cutting Soft Solids: Part II—Analysis of Blade Geometry. Eng. Fract. Mech. 2010, 77, 437–451. [Google Scholar] [CrossRef]

- Schuldt, S.; Arnold, G.; Kowalewski, J.; Schneider, Y.; Rohm, H. Analysis of the Sharpness of Blades for Food Cutting. J. Food Eng. 2016, 188, 13–20. [Google Scholar] [CrossRef]

- Rodríguez, J.S.; Duran, J.F.; Aguilar, Y.; Alcázar, G.A.P.; Zambrano, O.A. Failure Analysis in Sugar Cane Cutter Base Blades. Eng. Fail. Anal. 2020, 112, 104503. [Google Scholar] [CrossRef]

- Roscioli, G.; Taheri-Mousavi, S.M.; Tasan, C.C. How Hair Deforms Steel. Science 2020, 369, 689–694. [Google Scholar] [CrossRef]

- Gregory, G.E.; Hamby, R.C. Sharp Edge Cutting Technology—A Review of Hand Held and and Machine Knives/Blands and Their Sharp Edge Retention. Surf. Eng. 2000, 16, 373–378. [Google Scholar] [CrossRef]

- Verhoeven, J.D.; Pendray, A.H.; Clark, H.F. Wear Tests of Steel Knife Blades. Wear 2008, 265, 1093–1099. [Google Scholar] [CrossRef]

- ISO 8442-5:2004; Materials and Articles in Contact with Foodstuffs—Cutlery and Table Holloware—Part 5: Specification for Sharpness and Edge Retention Test of Cutlery. American National Standards Institute (ANSI): Washington, DC, USA, 2007. Available online: https://www.iso.org/standard/30037.html (accessed on 19 November 2021).

- Wu, D.; Zhang, Q.; Liu, W. Effect of Alloying Elements on the Sharpness Retention of Knife Blades Made of High Carbon Martensitic Stainless Steels. Metals 2022, 12, 472. [Google Scholar] [CrossRef]

- Wu, D.; Qu, S.; Zhang, Q.; Zhou, H. Enhanced Wear Resistance of Blades Made of Martensitic Steels: A Study of Diverse a’-Matrix/Carbide Microstructures. Mater. Charact. 2023, 201, 112939. [Google Scholar] [CrossRef]

- Zhu, Q.T.; Li, J.; Zhang, J.; Shi, C. Bin Effect of Primary Carbides on the Sharpness of Kitchen Knives Made of 8Cr13MoV Steel. J. Mater. Eng. Perform. 2019, 28, 4511–4521. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Shi, C.; Li, J. Evolution of Carbides and Performance of Knives Made of Aged 8Cr13MoV Steel. Mater. Sci. Technol. 2019, 35, 1988–1996. [Google Scholar] [CrossRef]

- Sakon, S.; Hamada, T.; Umesaki, N. Improvement in Wear Characteristics of Electric Hair Clipper Blade Using High Hardness Material. Mater. Trans. 2007, 48, 1131–1136. [Google Scholar] [CrossRef][Green Version]

- Tokoroyama, T.; Mohd, N.; Umehara, N. Evaluating Shaver Sharpness by Measuring the Pulling Force on Artificial Hair. J. Adv. Mech. Des. Syst. Manuf. 2007, 1, 661–668. [Google Scholar] [CrossRef][Green Version]

- Roscioli, G.; Repka, M.; Pedrazzini, S.; Tasan, C.C. Chemo-Mechanical Effects on the Cutting-Induced Mixed-Mode II-III Fracture of Martensitic Stainless Steels: An in-Situ Investigation. Acta Mater. 2022, 231, 117803. [Google Scholar] [CrossRef]

- Wu, D.; Qu, S.; Zhang, Q.; Zhou, H. A Quantitative Model That Correlates Sharpness Retention and Abrasive Wear of Knife Blades. Wear 2023, 518–519, 204634. [Google Scholar] [CrossRef]

- McGorry, R.W.; Dowd, P.C.; Dempsey, P.G. The Effect of Blade Finish and Blade Edge Angle on Forces Used in Meat Cutting Operations. Appl. Ergon. 2005, 36, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Ohmura, T.; Hara, T.; Tsuzaki, K. Evaluation of Temper Softening Behavior of Fe-C Binary Martensitic Steels by Nanoindentation. Scr. Mater. 2003, 49, 1157–1162. [Google Scholar] [CrossRef]

- Ma, D.; Chi, H.; Zhou, J.; Yong, Q. Microstructure and Mechanical Properties of Martensitic Stainless Steel 6Cr15MoV. J. Iron Steel Res. Int. 2012, 19, 56–61. [Google Scholar] [CrossRef]

- Hao, X.; Xi, T.; Xu, Z.; Liu, L.; Yang, C.; Yang, K. Effect of Tempering Temperature on the Microstructure, Corrosion Resistance, and Antibacterial Properties of Cu-Bearing Martensitic Stainless Steel. Mater. Corros. 2021, 72, 1668–1676. [Google Scholar] [CrossRef]

- Zhu, Q.T.; Li, J.; Shi, C.B.; Yu, W.T. Effect of Quenching Process on the Microstructure and Hardness of High-Carbon Martensitic Stainless Steel. J. Mater. Eng. Perform. 2015, 24, 4313–4321. [Google Scholar] [CrossRef]

- Stepień, P. Micro-Geometrical Characteristics of the Cutting Edge as the Intersection of Two Rough Surfaces. Wear 2010, 269, 249–261. [Google Scholar] [CrossRef]

- Takekoshi, K.; Gotoh, M. Durability of Cutting Performance of a Knife and Micro-Structural Change of a Knife Edge. JSME Int. J. Ser. C Mech. Syst. Mach. Elem. Manuf. 2003, 46, 1151–1159. [Google Scholar] [CrossRef][Green Version]

- Michaud, P.; Delagnes, D.; Lamesle, P.; Mathon, M.H.; Levaillant, C. The Effect of the Addition of Alloying Elements on Carbide Precipitation and Mechanical Properties in 5% Chromium Martensitic Steels. Acta Mater. 2007, 55, 4877–4889. [Google Scholar] [CrossRef]

- Wang, C.; Pureza, J.M.; Yang, Y.; Chung, Y.W. Investigation of Hardness and Fracture Toughness Properties of Fe/VC Multilayer Coatings with Coherent Interfaces. Surf. Coat. Technol. 2016, 288, 179–184. [Google Scholar] [CrossRef]

- Bai, H.; Zhong, L.; Cui, P.; Lv, Z.L.; Xu, Y. Preparation of V8C7-Fe/Iron Dual-Scale Composite via Two-Step in Situ Reaction. J. Mater. Res. Technol. 2020, 9, 4114–4122. [Google Scholar] [CrossRef]

- Shi, R.; Ma, Y.; Wang, Z.; Gao, L.; Yang, X.S.; Qiao, L.; Pang, X. Atomic-Scale Investigation of Deep Hydrogen Trapping in NbC/α-Fe Semi-Coherent Interfaces. Acta Mater. 2020, 200, 686–698. [Google Scholar] [CrossRef]

- Lu, S.; Ågren, J.; Vitos, L. Ab Initio Study of Energetics and Structures of Heterophase Interfaces: From Coherent to Semicoherent Interfaces. Acta Mater. 2018, 156, 20–30. [Google Scholar] [CrossRef]

| Steels | C | Si | V | Cr | Mo | Others * | Fe |

|---|---|---|---|---|---|---|---|

| 3Cr13 | 0.29 | 0.435 | 0.044 | 13.914 | - | 0.55 | Bal. |

| 5Cr15MoV | 0.50 | 0.393 | 0.115 | 14.705 | 0.596 | 1.03 | Bal. |

| 7Cr17MoV | 0.65 | 1.814 | 0.125 | 17.048 | 0.422 | 0.756 | Bal. |

| 9Cr18MoV | 0.96 | 1.92 | 0.126 | 17.966 | 1.023 | 1.046 | Bal. |

| 3V | 0.84 | 0.96 | 2.426 | 6.7 | 1.186 | 0.637 | Bal. |

| S35VN | 1.36 | 0.523 | 3.028 | 13.913 | 1.844 | 0.634 | Bal. |

| M390 | 1.988 | 0.555 | 4.057 | 20.244 | 0.861 | 1.628 | Bal. |

| Tempering Temperature (°C) | Hardness (HRC) | |

|---|---|---|

| 5Cr15MoV | 9Cr18MoV | |

| 170 | 56.83 ± 0.18 | / |

| 200 | 55.68 ± 0.32 | 59.35 ± 0.23 (with DCT) 57.45 ± 0.33 (without DCT) |

| 250 | 52.98 ± 0.39 | / |

| Steels | HRC Hardness [23] | K (×10−3) [23] | Carbide Fraction (Vol.%) [23] | M (mm/MPa) |

|---|---|---|---|---|

| 3Cr13 | 53.2 | 1.098 | 1.1 | 0.037 |

| 5Cr15MoV | 55.7 | 1.18 | 4.5 | 0.04 |

| 7Cr17MoV | 57.2 | 1.038 | 11.8 | 0.043 |

| 9Cr18MoV | 57.8 | 0.956 | 19.2 | 0.047 |

| 3V | 56.9 | 0.904 | 3.14 | 0.051 |

| S35VN | 58.9 | 0.955 | 26.3 | 0.058 |

| M390 | 62.4 | 0.651 | 28.1 | 0.054 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Liu, F.; Wu, D.; Qu, S.; Liu, W.; Chen, Z. A Comprehensive Understanding of Knife Cutting: Effects of Hardness, Blade Angle and the Micro-Geometry of Blade Edge on the Cutting Performance. Materials 2023, 16, 5375. https://doi.org/10.3390/ma16155375

Zhang Q, Liu F, Wu D, Qu S, Liu W, Chen Z. A Comprehensive Understanding of Knife Cutting: Effects of Hardness, Blade Angle and the Micro-Geometry of Blade Edge on the Cutting Performance. Materials. 2023; 16(15):5375. https://doi.org/10.3390/ma16155375

Chicago/Turabian StyleZhang, Qinyi, Feng Liu, Dong Wu, Shikang Qu, Wei Liu, and Zhangxiao Chen. 2023. "A Comprehensive Understanding of Knife Cutting: Effects of Hardness, Blade Angle and the Micro-Geometry of Blade Edge on the Cutting Performance" Materials 16, no. 15: 5375. https://doi.org/10.3390/ma16155375

APA StyleZhang, Q., Liu, F., Wu, D., Qu, S., Liu, W., & Chen, Z. (2023). A Comprehensive Understanding of Knife Cutting: Effects of Hardness, Blade Angle and the Micro-Geometry of Blade Edge on the Cutting Performance. Materials, 16(15), 5375. https://doi.org/10.3390/ma16155375