The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction

Abstract

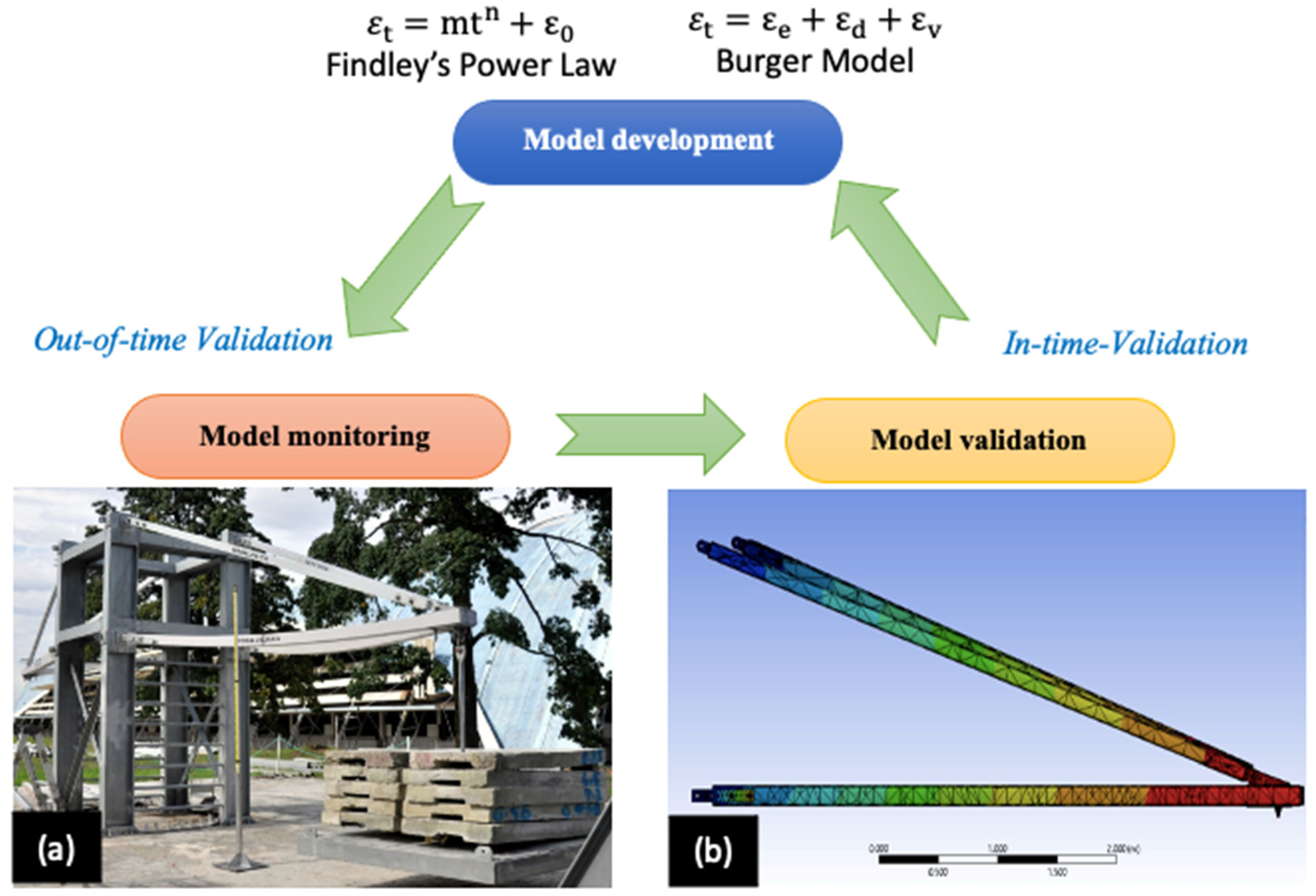

1. Introduction

2. Materials and Methodology

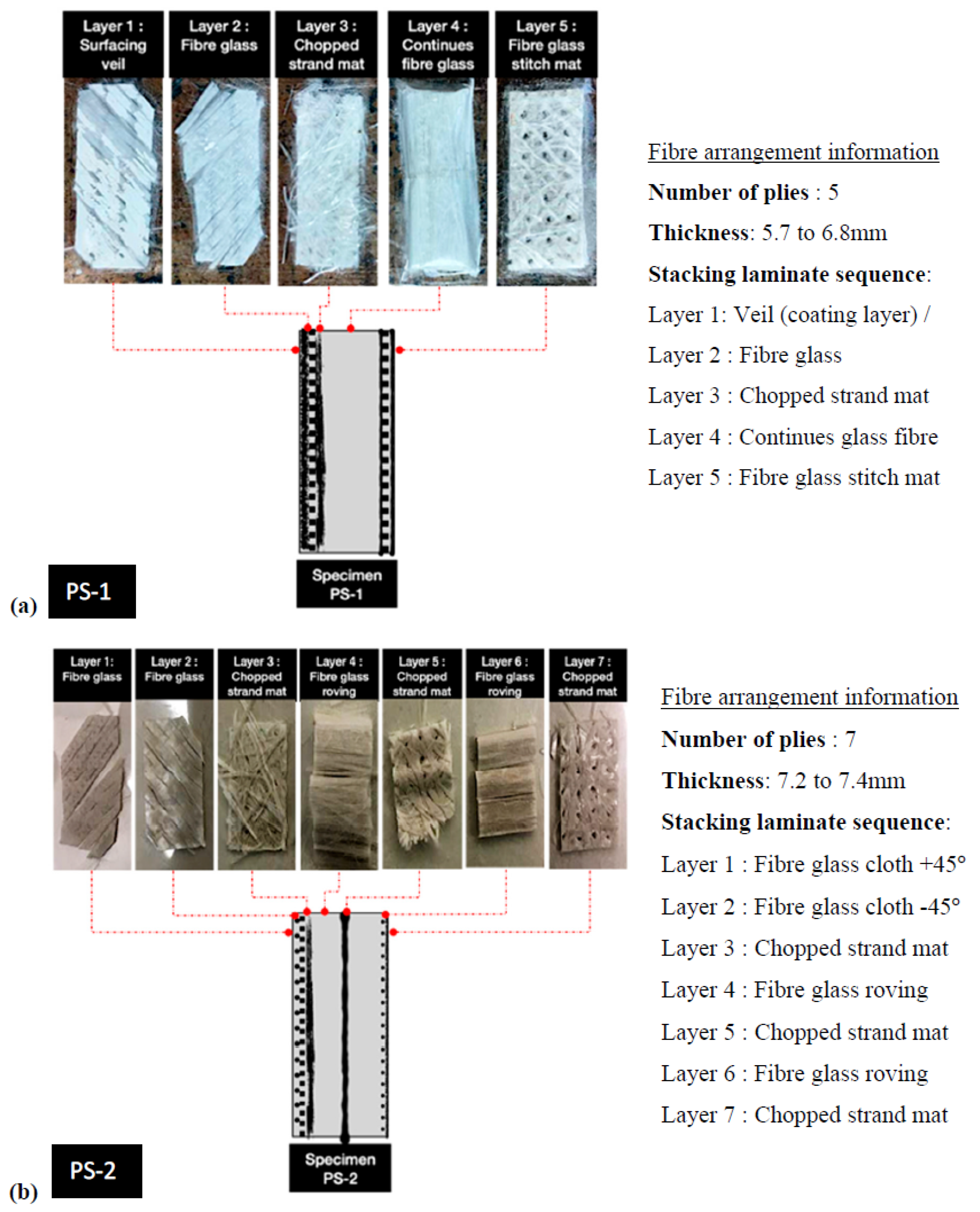

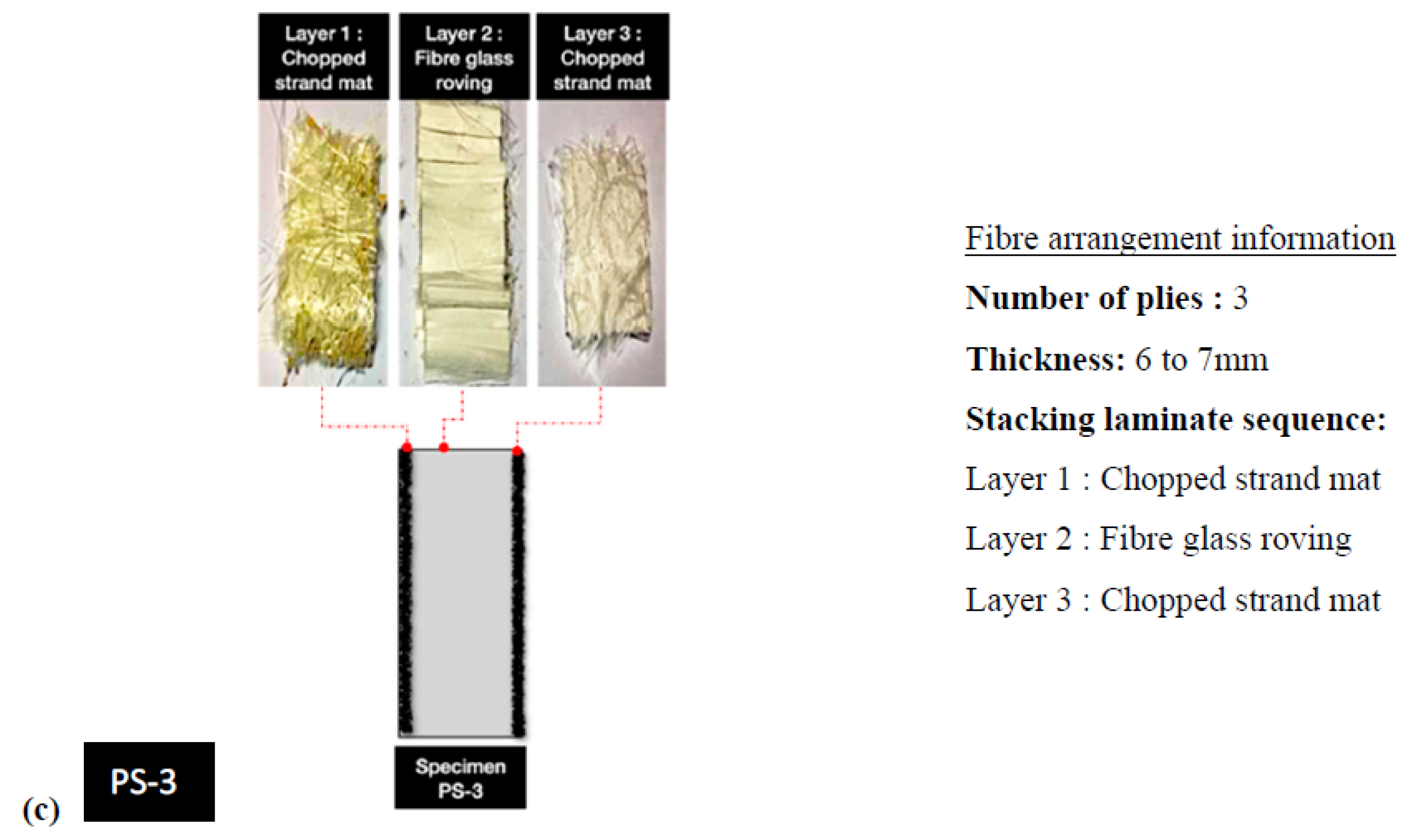

2.1. Pultrusion Glass Fibre-Reinforced Polymer (GFRP) Cross-Arm Tube

2.2. Fibre Volume Fraction and Density

2.3. Mechanical Test Composite Cross-Arm

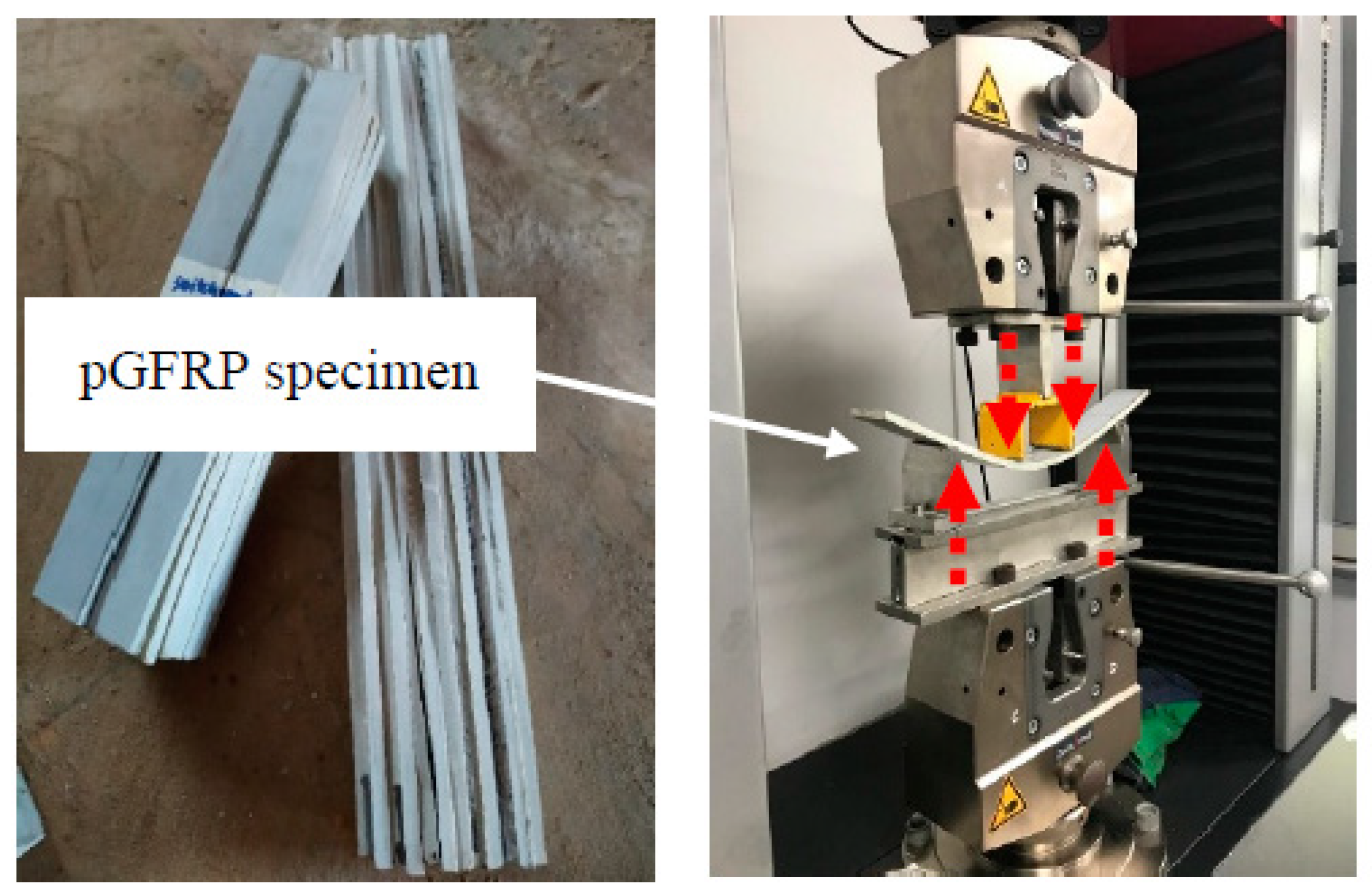

2.3.1. Quasi-Static Tensile Test

2.3.2. Quasi-Static Flexural 4-Points Bending Test

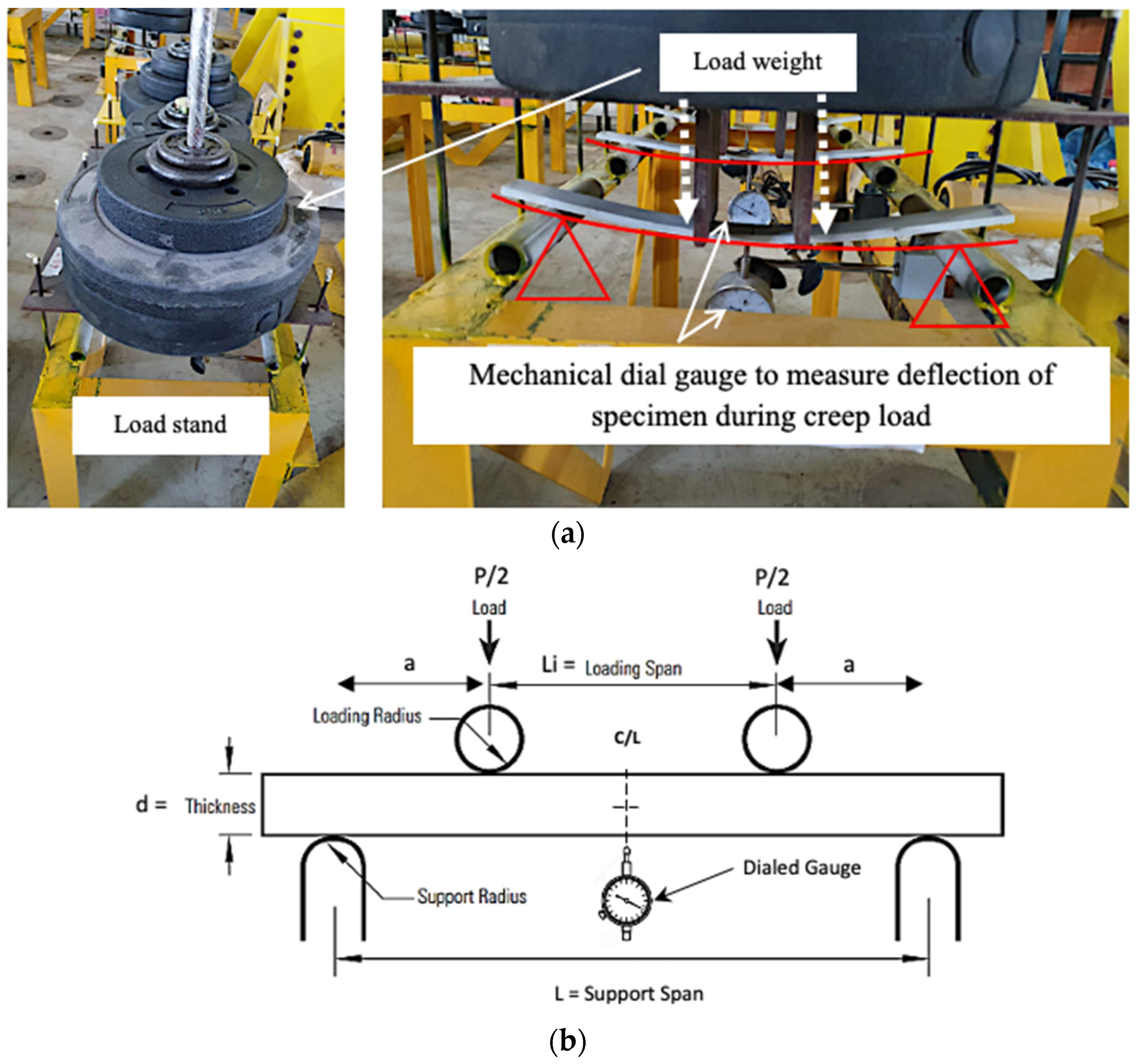

2.3.3. Flexural Creep Test

2.4. Stiffness Reduction over Time Analysis

2.4.1. Findley’s Power Law Model Flexural Creep Analysis

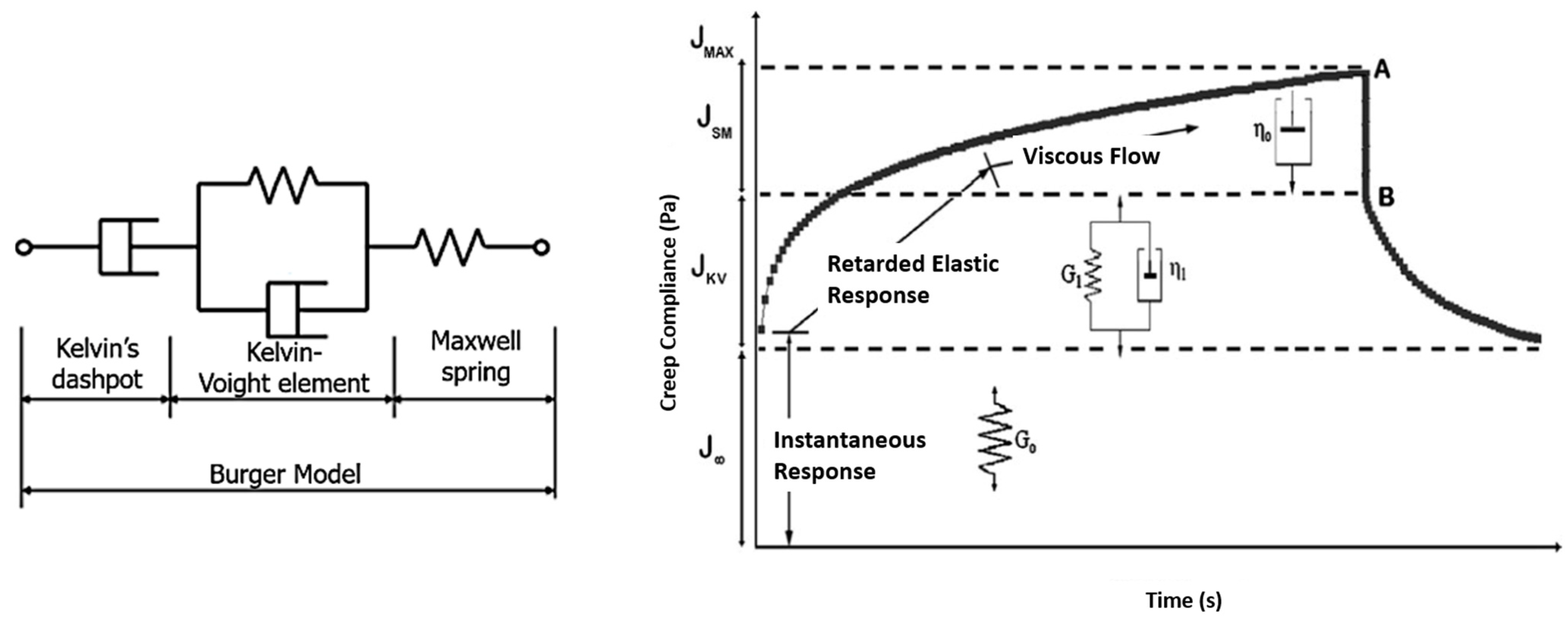

2.4.2. Burger Model Flexural Creep Analysis

3. Results and Discussion

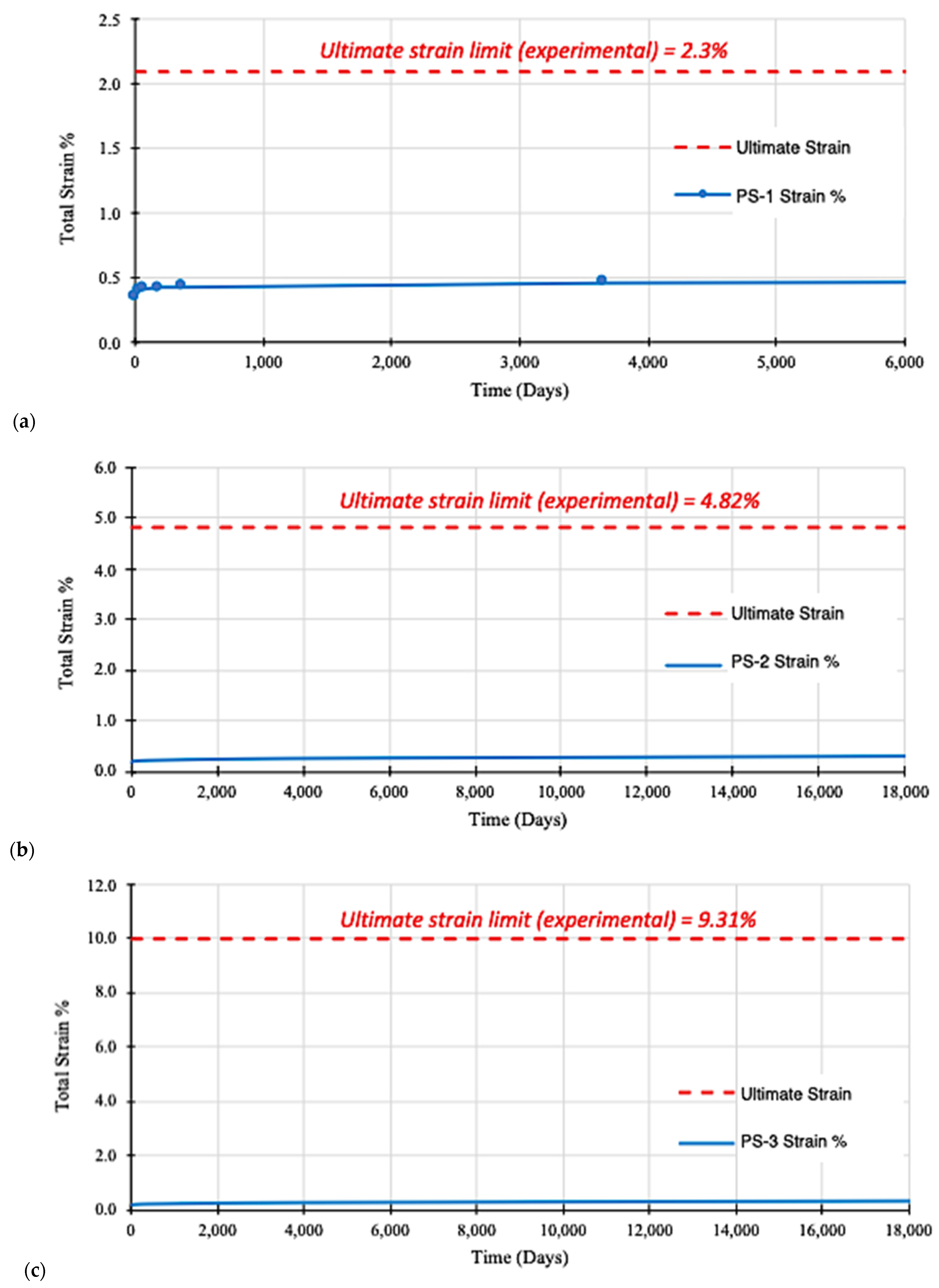

3.1. Creep Strain Failure—Reduction Factor,

3.2. Reduction Factor, —Findley’s Power Law Model Analysis

3.3. Reduction Factor, —Burger Model Analysis

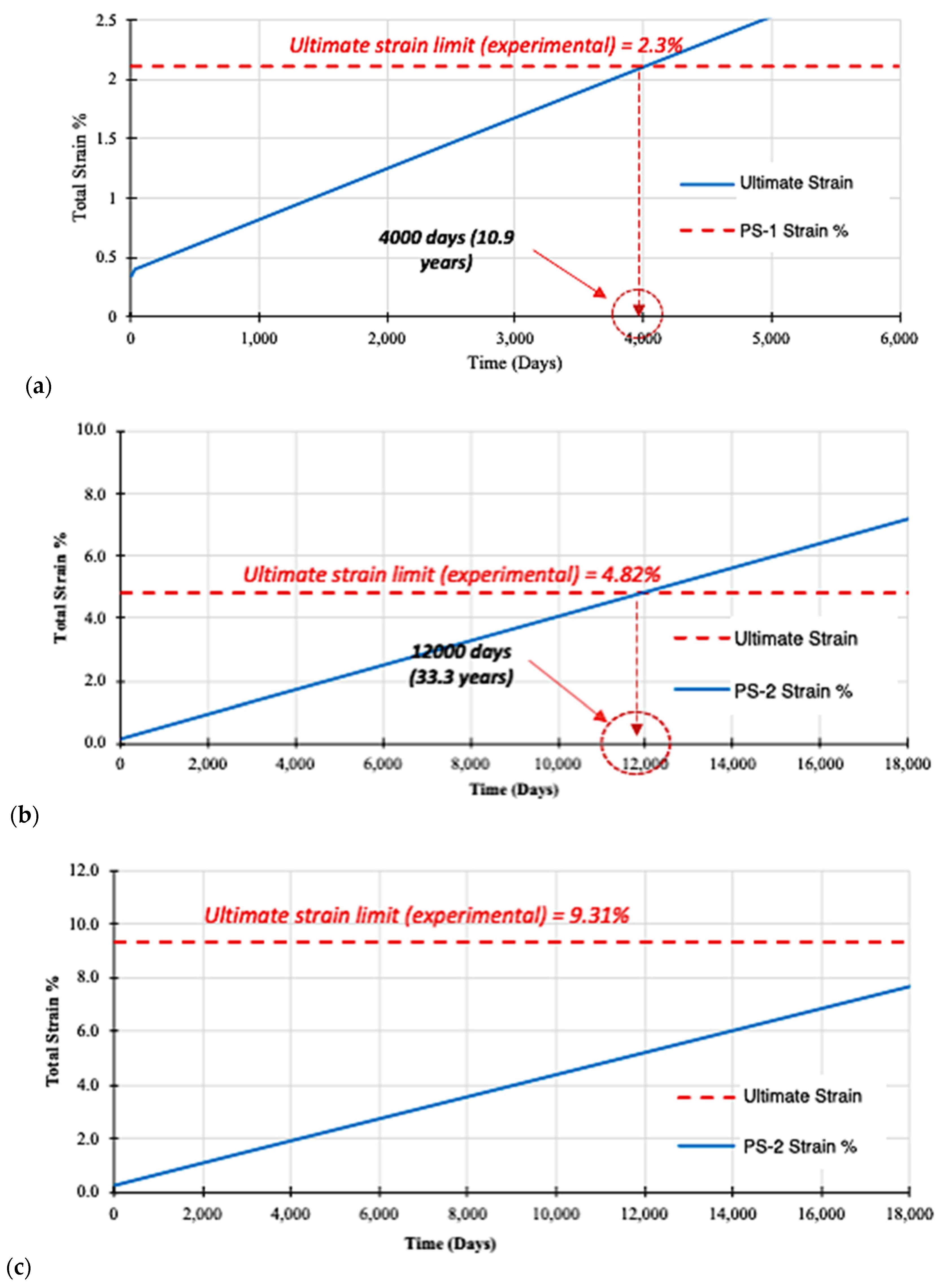

3.4. Life Span Prediction—Ultimate Strain Limit

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patel, P.; Chokshi, S. A Review of Fabrication Methods and Stacking Sequence Arrangements of Fiber for Composite. Int. J. Curr. Eng. Sci. Res. 2018, 5, 13–20. [Google Scholar]

- Abu Bakar, M.S.; Salit, M.S.; Mohamad Yusoff, M.Z.; Zainudin, E.S.; Ya, H.H. The crashworthiness performance of stacking sequence on filament wound hybrid composite energy absorption tube subjected to quasi-static compression load. J. Mater. Res. Technol. 2020, 9, 654–666. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Cai, H.; Lin, X.; Yi, W.; Zhang, J. Properties comparison of high density polyethylene composites filled with three kinds of shell fibers. Results Phys. 2019, 12, 1542–1546. [Google Scholar] [CrossRef]

- Moutee, M.; Fortin, Y.; Fafard, M. A global rheological model of wood cantilever as applied to wood drying. Wood Sci. Technol. 2007, 41, 209–234. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J.; Wolcott, M.P. Comparison of polylactide/nano-sized calcium carbonate and polylactide/montmorillonite composites: Reinforcing effects and toughening mechanisms. Polymer 2007, 48, 7632–7644. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Sa’Don, S.N.; Zahari, N.M.; Seman, S.A.H.A.; Razali, M.F.; Abas, A.; Ng, F.C. Stacking Sequence Effects on Performance of Composite Laminate Structure Subjected to Multi-Axial Quasi-Static Loading. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012030. [Google Scholar] [CrossRef]

- Kaboorani, A.; Blanchet, P.; Laghdir, A. A rapid method to assess viscoelastic and mechanosorptive creep in wood. Wood Fiber Sci. 2013, 45, 370–382. [Google Scholar]

- Sun, N.; Frazier, C.E. Time/temperature equivalence in the dry wood creep response. Holzforschung 2007, 61, 702–706. [Google Scholar] [CrossRef]

- Garrido, M.; Correia, J.R.; Keller, T. Effect of service temperature on the flexural creep of vacuum infused GFRP laminates used in sandwich floor panels. Compos. Part B Eng. 2016, 90, 160–171. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical Study of Composite Fiberglass Cross Arms under Statics Loading and Improvement with Sleeve Installation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012027. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Kamal, N.L.M.; Zainoodin, M.M.; Razali, M.F.; Abas, A.; Seman, S.A.H.A.; Ng, F.C. Effect of Laminate Properties on the Failure of Cross Arm Structure under Multi-Axial Load. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012029. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Itam, Z.; Bakar, H.A.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical Simulation on the Statics Deformation Study of Composite Cross Arms of Different Materials and Configurations. IOP Conf. Ser. Mater. Sci. Eng. 2019, 530, 012028. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability gap analysis for fiber-reinforced polymer composites in civil infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Berardi, V.P.; Perrella, M.; Feo, L.; Cricrì, G. Creep behavior of GFRP laminates and their phases: Experimental investigation and analytical modeling. Compos. Part B Eng. 2017, 122, 136–144. [Google Scholar] [CrossRef]

- Mancusi, G.; Spadea, S.; Berardi, V.P. Experimental analysis on the time-dependent bonding of FRP laminates under sustained loads. Compos. Part B Eng. 2013, 46, 116–122. [Google Scholar] [CrossRef]

- Wong, S.; Shanks, R. Creep behaviour of biopolymers and modified flax fibre composites. Compos. Interfaces 2008, 15, 131–145. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Fu, H.; Dun, M.; Wang, H.; Wang, W.; Ou, R.; Wang, Y.; Liu, T.; Wang, Q. Creep response of wood flour-high-density polyethylene/laminated veneer lumber coextruded composites. Constr. Build. Mater. 2020, 237, 117499. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Supian, A.B.M.; Usman, F.; Asyraf, M.R.M.; Atiqah, M.A. Flexural Creep Behaviour of Pultruded GFRP Composites Cross-Arm: A Comparative Study on the Effects of Stacking Sequence. Polymers 2022, 14, 1330. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- D’Antino, T.; Pisani, M.A. Long-term behavior of GFRP reinforcing bars. Compos. Struct. 2019, 227, 111283. [Google Scholar] [CrossRef]

- Jorik, S.; Lion, A.; Johlitz, M. Design of the novel tensile creep experimental setup, characterisation and description of the long-term creep performance of polycarbonate. Polym. Test. 2019, 75, 151–158. [Google Scholar] [CrossRef]

- Xu, Y.; Lee, S.Y.; Wu, Q. Creep analysis of bamboo high-density polyethylene composites: Effect of interfacial treatment and fiber loading level. Polym. Compos. 2011, 32, 692–699. [Google Scholar] [CrossRef]

- Mahmood, T.; Kanapathipillai, S.; Chowdhury, M. A model for creep life prediction of thin tube using strain energy density as a function of stress triaxiality under quasistatic loading employing elastic-creep & elastic-plastic-creep deformation. Front. Mech. Eng. 2013, 8, 181–186. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22, 793–803. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khalid, M.Y.; Imran, R.; Ali, U.; Koc, M. Utilization of banana fiber-reinforced hybrid composites in the sports industry. Materials 2020, 13, 3167. [Google Scholar] [CrossRef]

- Correia, J.; Cabral-Fonseca, S. Durability of glass fibre reinforced polyester (GFRP) pultruded profiles used in civil engineering applications. In Proceedings of the Composites in Construction 2005—Third International Conference, Lyon, France, 11–13 July 2005; pp. 1–9. [Google Scholar]

- Zafar, A.; Bertocco, F.; Schjødt-Thomsen, J.; Rauhe, J.C. Investigation of the long term effects of moisture on carbon fibre and epoxy matrix composites. Compos. Sci. Technol. 2012, 72, 656–666. [Google Scholar] [CrossRef]

- Bank, L.C.; Mosallam, A.S. Creep and failure of a full-size fiber-reinforced plastic pultruded frame. Compos. Eng. 1992, 2, 213–227. [Google Scholar] [CrossRef]

- Mottram, J.T. Short- and long-term structural properties of pultruded beam assemblies fabricated using adhesive bonding. Compos. Struct. 1993, 25, 387–395. [Google Scholar] [CrossRef]

- Shao, Y.; Shanmugam, J. Deflection Creep of Pultruded Composite Sheet Piling. J. Compos. Constr. 2004, 8, 471–479. [Google Scholar] [CrossRef]

- Harries, K.A.; Guo, Q.; Cardoso, D. Creep and creep buckling of pultruded glass-reinforced polymer members. Compos. Struct. 2017, 181, 315–324. [Google Scholar] [CrossRef]

- Sá, M.F.; Gomes, A.M.; Correia, J.R.; Silvestre, N. Creep behavior of pultruded GFRP elements—Part 2: Analytical study. Compos. Struct. 2011, 93, 2409–2418. [Google Scholar] [CrossRef]

- Ghyslaine, M.; Yaghoub, M. Compression Creep of Pultruded E-Glass-Reinforced-Plastic Angles. J. Mater. Civ. Eng. 1995, 7, 269–276. [Google Scholar] [CrossRef]

- Scott, D.W.; Zureick, A.-H. Compression creep of a pultruded E-glass/vinylester composite. Compos. Sci. Technol. 1998, 58, 1361–1369. [Google Scholar] [CrossRef]

- Yeol, C.; Yuan, R.L. Time-Dependent Deformation of Pultruded Fiber Reinforced Polymer Composite Columns. J. Compos. Constr. 2003, 7, 356–362. [Google Scholar] [CrossRef]

- Beloshenko, V.; Voznyak, Y.; Voznyak, A.; Savchenko, B. New approach to production of fiber reinforced polymer hybrid composites. Compos. Part B Eng. 2017, 112, 22–30. [Google Scholar] [CrossRef]

- Othman, A.; Abdullah, S.; Ariffin, A.K.; Mohamed, N.A.N. Investigating the quasi-static axial crushing behavior of polymeric foam-filled composite pultrusion square tubes. J. Mater. 2014, 63, 446–459. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Physical analysis and statistical investigation of tensile and fatigue behaviors of glass fiber-reinforced polyester via novel fibers arrangement. J. Compos. Mater. 2022, 57, 147–166. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2019, 53, 709–718. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Knight, V.F.; Nurazzi, N.M.; Jenol, M.A.; Misenan, M.S.M.; Janudin, N.; Kasim, N.A.M.; Shukor, M.F.A.; Ilyas, R.A.; Asyraf, M.R.M.; et al. The Frontiers of Functionalized Nanocellulose-Based Composites and Their Application as Chemical Sensors. Polymers 2022, 14, 4461. [Google Scholar] [CrossRef]

- Norizan, M.N.; Shazleen, S.S.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.R.M.; Zainudin, E.S.; Abdullah, N.; Samsudin, M.S.; Kamarudin, S.H.; Norrrahim, M.N.F. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials 2022, 12, 3483. [Google Scholar] [CrossRef]

- Rahman, I.; Singh, P.; Dev, N.; Arif, M.; Yusufi, F.N.K.; Azam, A.; Alam, M.M.; Singh, S.; Chohan, J.S.; Kumar, R.; et al. Improvements in the Engineering Properties of Cementitious Composites Using Nano-Sized Cement and Nano-Sized Additives. Materials 2022, 15, 8066. [Google Scholar] [CrossRef]

- Syamsir, A.; Nadhirah, A.; Mohamad, D.; Beddu, S. Performance Analysis of Full Assembly Glass Fiber-Reinforced Polymer Composite Cross-Arm in Transmission Tower. Polymers 2022, 14, 18. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Anggraini, V.; Muda, Z.C.; Nor, N.M. Numerical Modelling of Glass Fiber Reinforced Polymer (GFRP) Cross Arm. Int. J. Recent Technol. Eng. 2019, 8, 1684–1689. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Chandrasekar, M. Fundamentals of creep, testing methods and development of test rig for the full-scale crossarm: A review. J. Teknol. 2019, 81, 13402. [Google Scholar] [CrossRef]

- Hibbeler, R. Structural Analysis, 9th ed.; Pearson: London, UK, 2015. [Google Scholar]

- Findley, W.N. Creep characteristics of plastics. Symp. Plast. ASTM 1944, 118–134. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Utilization of bracing arms as additional reinforcement in pultruded glass fiber-reinforced polymer composite cross-arms: Creep experimental and numerical analyses. Polymers 2021, 13, 620. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Pérez, C.J.; Alvarez, V.A.; Vázquez, A. Creep behaviour of layered silicate/starch-polycaprolactone blends nanocomposites. Mater. Sci. Eng. A 2008, 480, 259–265. [Google Scholar] [CrossRef]

- Chandra, P.K.; Sobral, P.J.D.A. Calculation of viscoelastic properties of edible films: Application of three models. Ciência Tecnol. Aliment. 2006, 20, 250–256. [Google Scholar] [CrossRef]

- Dogan, M.; Kayacier, A.; Toker, Ö.S.; Yilmaz, M.T.; Karaman, S. Steady, Dynamic, Creep, and Recovery Analysis of Ice Cream Mixes Added with Different Concentrations of Xanthan Gum. Food Bioprocess Technol. 2013, 6, 1420–1433. [Google Scholar] [CrossRef]

- Hao, A.; Chen, Y.; Chen, J.Y. Creep and recovery behavior of kenaf/polypropylene nonwoven composites. J. Appl. Polym. Sci. 2014, 131, 8864–8874. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Kalita, K.; Cep, R.; Chakraborty, S. A Comparative Analysis on Prediction Performance of Regression Models during Machining of Composite Materials. MDPI Mater. 2021, 14, 15. [Google Scholar] [CrossRef] [PubMed]

- Barbero, E.; Ferna, J.; Navarro, C. Statistical analysis of the mechanical properties of composite materials. Compos. Part B Eng. 2000, 31, 375–381. [Google Scholar] [CrossRef]

- Glaeser, A.M. The use of transient FGM interlayers for joining advanced ceramics. Compos. Part B 1997, 8368, 71–84. [Google Scholar] [CrossRef]

| Material | Type of Specimen | Type of Loading | Testing Duration | References |

|---|---|---|---|---|

| GFRP/Vinyl ester | Frame | Flexural (3/4-points) | 3500–10,000 h | [29] |

| GFRP/Polyester | Beam assembly | 24 h | [30] | |

| Sheet piling | 9000 h | [31] | ||

| Coupon | 720–1000 h | [19,32] | ||

| Section profile | 270–1600 h | [33] | ||

| GFRP/Vinyl ester | Prismatic | Compression | 2500–10,000 h | [34,35,36] |

| GFRP/Polyester | Columns |

| Properties | pGFRP Specimens | ||

|---|---|---|---|

| PS-1 | PS-2 | PS-3 | |

| Density (kg/m3) | 1.83 | 1.85 | 1.87 |

| Fibre volume fraction, (%) | 61.95 | 67.40 | 60.85 |

| No. | Specimens | Mechanical Properties | |

|---|---|---|---|

| Max. Tensile Force (kN) | Load (kgf) | ||

| 1 | PS-1 | 61.91 | 6310.60 |

| 2 | PS-2 | 29.53 | 3009.79 |

| 3 | PS-3 | 73.57 | 7499.08 |

| No. | Specimen | Mechanical Properties | |

|---|---|---|---|

| Max. Flexural Force (N) | Load (kgf) | ||

| 1 | PS-1 | 972.6 | 99.1 |

| 2 | PS-2 | 1207.15 | 123 |

| 3 | PS-3 | 759.06 | 77.4 |

| Parameter | PS-1 | PS-2 | PS-3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Stress Level | Stress Level | Stress Level | |||||||

| 12% | 24% | 37% | 12% | 24% | 37% | 12% | 24% | 37% | |

| Thickness d (mm) | 6 | 6 | 6 | 7.2 | 7.2 | 7.2 | 5.2 | 5.2 | 5.2 |

| Applied Load (N) | 116.4 | 233.0 | 360.5 | 144.8 | 289.7 | 446.6 | 91.1 | 182.2 | 280.9 |

| Stress σ (MPa) | 29.87 | 59.78 | 92.50 | 25.80 | 51.62 | 79.58 | 31.12 | 62.24 | 95.96 |

| (10−3) | 0.0026 | 0.0039 | 0.0055 | 0.0042 | 0.0046 | 0.0073 | 0.0045 | 0.0050 | 0.0075 |

| n | 0.1481 | 0.3461 | 0.1481 | 0.1586 | 0.3238 | 0.3446 | 0.343 | 0.1099 | 0.1722 |

| m (ε %) | 0.0301 | 0.0055 | 0.0301 | 0.0309 | 0.0057 | 0.0095 | 0.0044 | 0.0451 | 0.0292 |

| E0 (GPa) | 11.6 | 15.5 | 17.0 | 6.1 | 11.2 | 10.9 | 6.99 | 12.4 | 12.8 |

| Et = σ/m (GPa) | 99.2 | 1086.9 | 307.3 | 83.5 | 905.5 | 837.6 | 707.3 | 138.0 | 328.6 |

| t (hours) | 720 | 720 | 720 | ||||||

| Reduction Factor χ(t) | 0.89 | 0.91 | 0.90 | ||||||

| E(t) (GPa) | 13.12 | 8.6 | 9.69 | ||||||

| Reduction (Strain),% | 0% | 14% | 15% | 17% | 19% | 25% | 29% | |

|---|---|---|---|---|---|---|---|---|

| PS-1 | Total Deflection (mm) | 35.7 | 41.3 | 41.9 | 43.0 | 43.8 | 47.0 | 50.0 |

| Max Equivalent Strain (%) | 0.35 | 0.41 | 0.41 | 0.42 | 0.43 | 0.46 | 0.49 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18,250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

| Reduction (strain),% | 0% | 11% | 13% | 15% | 16% | 23% | 28% | |

| PS-2 | Total Deflection (mm) | 18.37 | 20.17 | 20.55 | 21.32 | 21.96 | 25.13 | 28.90 |

| Max Equivalent Strain (%) | 0.18 | 0.20 | 0.20 | 0.21 | 0.22 | 0.25 | 0.29 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18,250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

| Reduction (strain),% | 0% | 12% | 15% | 20% | 24% | 40% | 53% | |

| PS-3 | Total Deflection (mm) | 20.62 | 22.59 | 22.89 | 23.48 | 23.93 | 25.97 | 28.10 |

| Max Equivalent Strain (%) | 0.24 | 0.26 | 0.26 | 0.27 | 0.27 | 0.30 | 0.32 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18,250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

| PS-1 | Loading (%) | Stress σ, (MPa) | A = (10−3) | B (10−4) | C (10−3) | D (10−7) | = σ/εo (GPa) |

| 12 | 46.85 | 2.57 | 4.78 | 761.51 | 5.32 | 18.25 | |

| 24 | 59.78 | 3.85 | 2.12 | 257.19 | 3.05 | 15.52 | |

| 37 | 92.50 | 5.46 | 4.78 | 760.31 | 5.31 | 16.91 | |

| Average | 3.90 | 593.00 | 4.56 | 16.89 | |||

| PS-2 | Loading (%) | Stress σ, (MPa) | A = (10−3) | B (10−4) | C (10−3) | D (10−7) | = σ/εo (GPa) |

| 12 | 37.43 | 4.24 | 5.54 | 612.34 | 4.57 | 8.83 | |

| 24 | 63.30 | 4.62 | 2.10 | 264.51 | 3.39 | 13.69 | |

| 37 | 91.62 | 7.32 | 3.41 | 279.36 | 8.31 | 12.52 | |

| Average | 3.68 | 385.40 | 5.42 | 11.68 | |||

| PS-3 | Loading (%) | Stress σ, (MPa) | A = (10−3) | B (10−4) | C (10−3) | D (10−7) | = σ/εo (GPa) |

| 12 | 53.16 | 4.45 | 1.32 | 384.95 | 4.68 | 11.94 | |

| 24 | 84.16 | 5.01 | 6.38 | 1002.82 | 4.78 | 16.81 | |

| 37 | 117.84 | 7.51 | 4.88 | 500.67 | 4.29 | 15.69 | |

| Average | 4.20 | 629.48 | 4.58 | 14.81 | |||

| Parameter | PS-1 | PS-2 | PS-3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Stress Level, σ | Stress Level, σ | Stress Level, σ | |||||||

| 12% | 24% | 37% | 12% | 24% | 37% | 12% | 24% | 37% | |

| Thickness (d), mm | 6 | 6 | 6 | 7.2 | 7.2 | 7.2 | 5.2 | 5.2 | 5.2 |

| Applied Load (N) | 116.4 | 233.0 | 360.5 | 144.8 | 289.7 | 446.6 | 91.1 | 182.2 | 280.9 |

| Stress (σ), Mpa | 29.87 | 59.78 | 92.50 | 25.80 | 51.62 | 79.58 | 31.12 | 62.24 | 95.96 |

| A = ε0 | 0.003 | 0.004 | 0.006 | 0.004 | 0.005 | 0.007 | 0.0045 | 0.0050 | 0.0075 |

| B (10−4) | 4.78 | 2.12 | 4.78 | 5.54 | 2.10 | 3.41 | 1.32 | 6.38 | 4.88 |

| C (10−3) | 761.51 | 257.19 | 760.31 | 612.34 | 264.51 | 279.36 | 384.95 | 1002.8 | 500.67 |

| D (10−7) | 5.32 | 3.05 | 5.31 | 4.57 | 3.39 | 8.31 | 4.68 | 4.78 | 4.29 |

| Eb = σ/B (103) | 62.4 | 282.3 | 193.3 | 46.6 | 246.4 | 233.4 | 236.5 | 97.5 | 196.3 |

| Ed = σ/D (105) | 561.6 | 1957.2 | 1741.1 | 564.7 | 1523.0 | 957.6 | 664.6 | 1301.4 | 2237.6 |

| E0 (Gpa) | 11.6 | 15.5 | 17.0 | 6.1 | 11.2 | 10.9 | 6.99 | 12.4 | 12.8 |

| t (hour’s) | 720 | 720 | 720 | ||||||

| Reduction Factor χ(t) | 0.86 | 0.89 | 0.89 | ||||||

| E(t) (Gpa) | 12.71 | 8.37 | 9.62 | ||||||

| Reduction (Strain) | 0% | 27% | 29% | 37% | 47% | 85% | 96% | |

|---|---|---|---|---|---|---|---|---|

| PS-1 | Total Deflection (mm) | 35.68 | 41.35 | 42.58 | 47.79 | 55.81 | 198.10 | 829.61 |

| Max Equivalent Strain (%) | 0.35 | 0.41 | 0.42 | 0.47 | 0.55 | 1.96 | 8.15 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

| Reduction (strain) | 0% | 11% | 16% | 31% | 46% | 89% | 98% | |

| PS-2 | Total Deflection (mm) | 18.37 | 20.56 | 21.75 | 26.54 | 33.91 | 164.63 | 744.78 |

| Max Equivalent Strain (%) | 0.18 | 0.19 | 0.21 | 0.25 | 0.33 | 1.61 | 7.26 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

| Reduction (strain) | 0% | 10% | 15% | 28% | 43% | 87% | 97% | |

| PS-3 | Total Deflection (mm) | 20.62 | 22.91 | 24.06 | 28.62 | 35.65 | 160.31 | 713.33 |

| Max Equivalent Strain (%) | 0.24 | 0.25 | 0.26 | 0.31 | 0.39 | 1.76 | 7.75 | |

| Time (Days) | 0 | 30 | 60 | 180 | 365 | 3650 | 18250 | |

| Time (Months) | 0 | 1 | 2 | 6 | 12 | 120 | 608.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abu Bakar, M.S.; Syamsir, A.; Alhayek, A.; Asyraf, M.R.M.; Itam, Z.; Shaik, S.M.M.; Abd Aziz, N.; Jamal, T.; Mohd Mansor, S.A. The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction. Materials 2023, 16, 5328. https://doi.org/10.3390/ma16155328

Abu Bakar MS, Syamsir A, Alhayek A, Asyraf MRM, Itam Z, Shaik SMM, Abd Aziz N, Jamal T, Mohd Mansor SA. The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction. Materials. 2023; 16(15):5328. https://doi.org/10.3390/ma16155328

Chicago/Turabian StyleAbu Bakar, Mohd Supian, Agusril Syamsir, Abdulrahman Alhayek, Muhammad Rizal Muhammad Asyraf, Zarina Itam, Shaikh Muhammad Mubin Shaik, Nurhanani Abd Aziz, Tarique Jamal, and Siti Aminah Mohd Mansor. 2023. "The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction" Materials 16, no. 15: 5328. https://doi.org/10.3390/ma16155328

APA StyleAbu Bakar, M. S., Syamsir, A., Alhayek, A., Asyraf, M. R. M., Itam, Z., Shaik, S. M. M., Abd Aziz, N., Jamal, T., & Mohd Mansor, S. A. (2023). The Reduction Factor of Pultrude Glass Fibre-Reinforced Polyester Composite Cross-Arm: A Comparative Study on Mathematical Modelling for Life-Span Prediction. Materials, 16(15), 5328. https://doi.org/10.3390/ma16155328