Blast Resistance Capacities of Structural Panels Subjected to Shock-Tube Testing with ANFO Explosive

Abstract

1. Introduction

2. Experimental Program

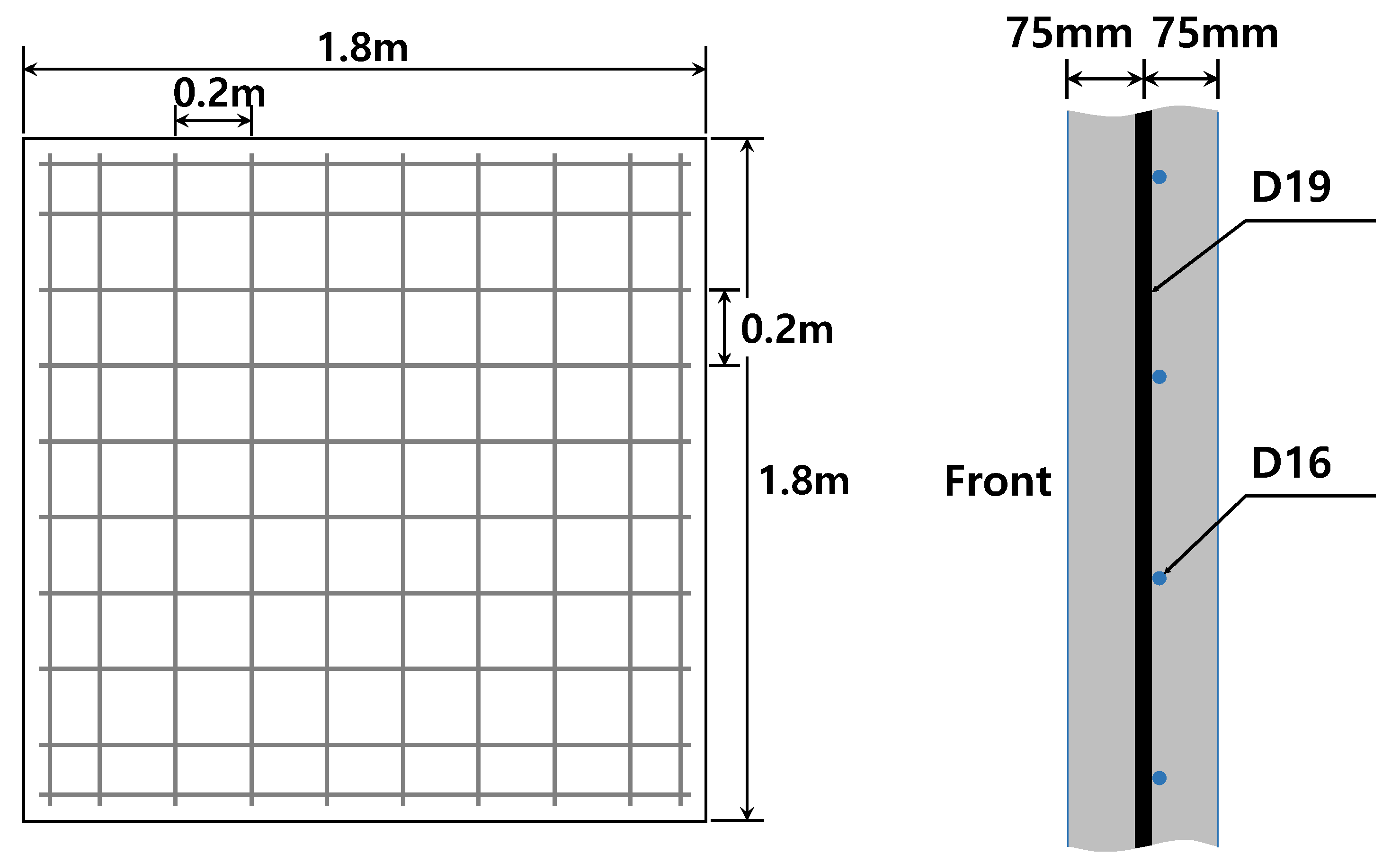

2.1. Sample Preparation

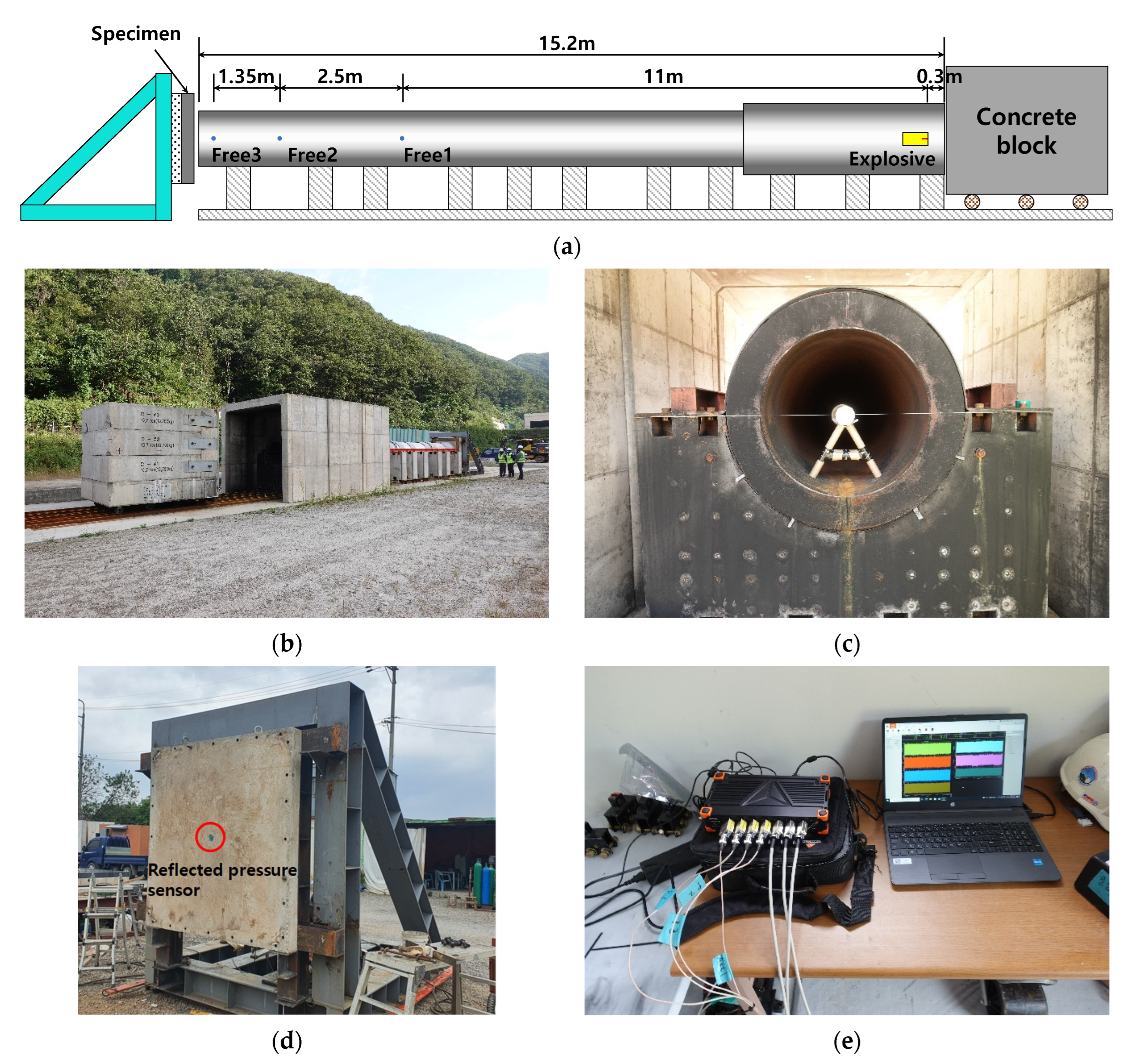

2.2. Shock-Tube Test

3. Experimental Results and Discussions

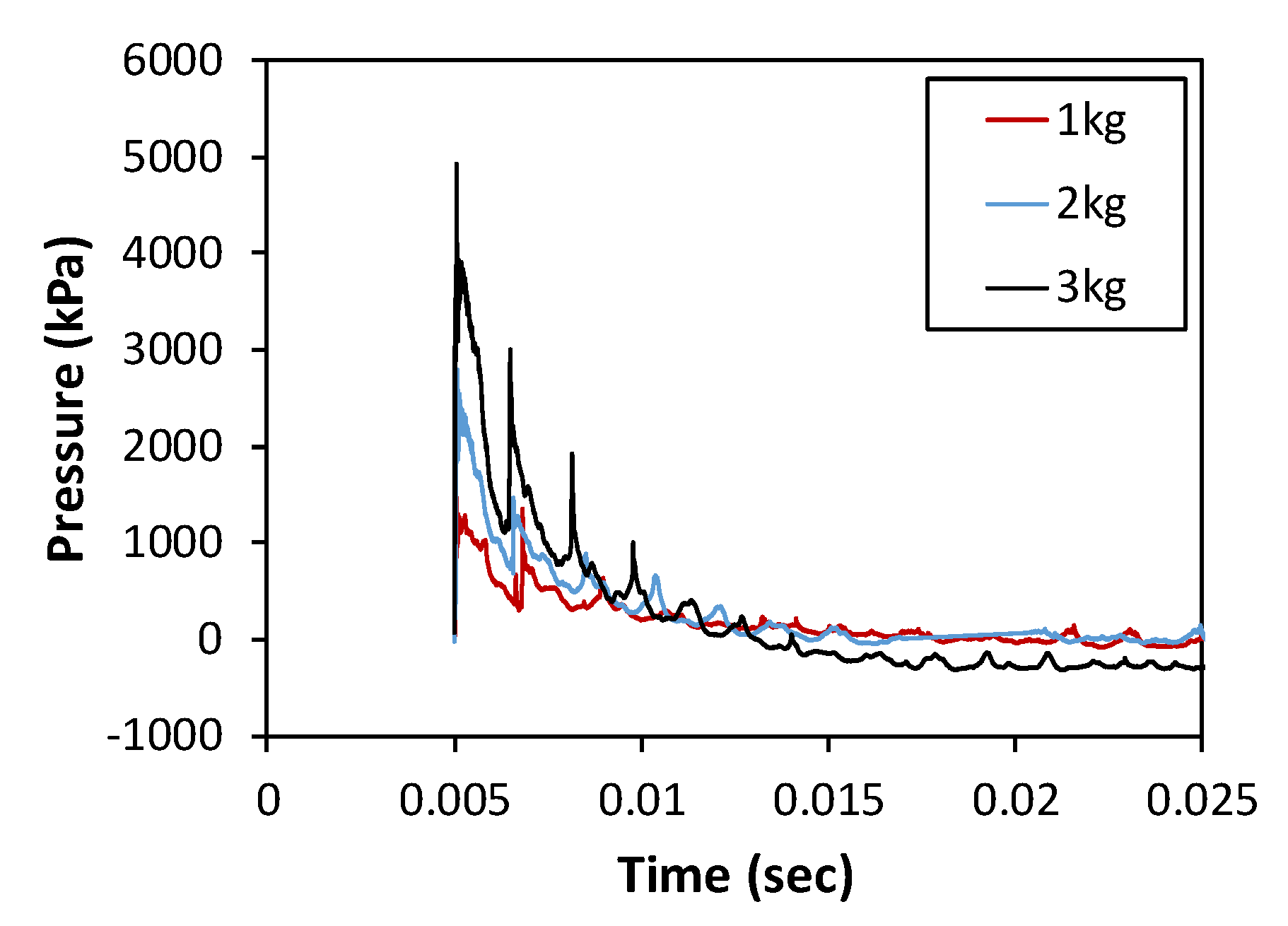

3.1. Characteristics of Incident Pressure in the Shock-Tube

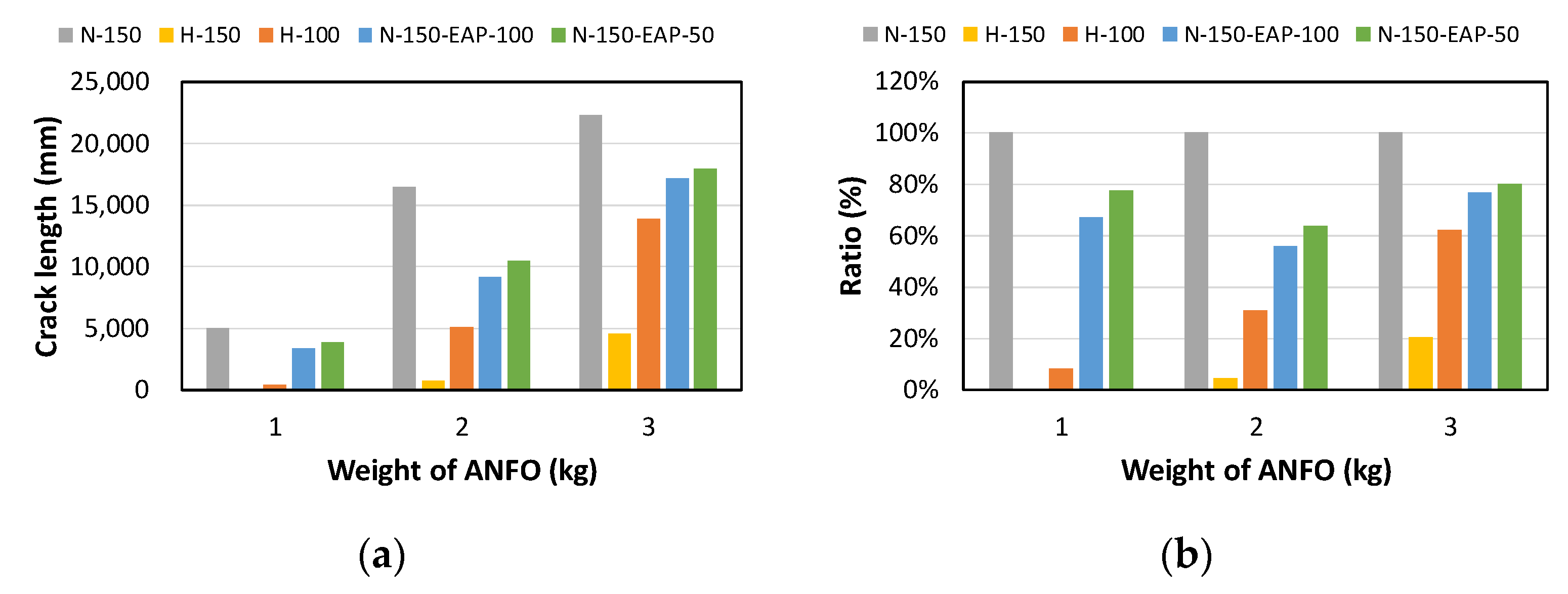

3.2. Explosion Resistance Performance of the Panels

4. Conclusions

- Several peaks were observed in the pressure–time curve owing to reflection by the mass concrete block located at the back end of the shock tube. The time difference between the first and second peaks decreased with the distance from the explosion source, and the pressure was significantly amplified owing to the overlap of the first and second pressure peaks at the Free 3 location;

- The blast pressure was amplified owing to multiple reflections of the pressure within the shock tube as the generated pressure passed through it. Thus, the measured pressure in the shock tube was significantly different from the pressure predicted by the method proposed in the UFC report;

- Among the specimens considered in this study, the HPFRCC panels demonstrated the best performance against blast pressure even for the thinner specimen. This was attributed to the improved material properties and the inclusion of steel fiber to restrain crack propagation;

- Polyurea can be effectively used to reinforce the tensile behavior of concrete structures and prevent the scattering of fragments;

- Energy-absorbing panels used in this study were found to be ineffective with regard to their energy absorption capacity. To increase the energy absorption capacity, the stiffness of the energy-absorbing panels should be reduced to allow deformation of the panel to dissipate the blast energy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tufekci, M.M.; Gokce, A. Development of heavyweight high performance fiber reinforced cementitious composites (HPFRCC)—Part I: Mechanical properties. Constr. Build. Mater. 2017, 148, 559–570. [Google Scholar] [CrossRef]

- Ren, G.M.; Wu, H.; Fang, Q.; Liu, J.Z. Effects of steel fiber content and type on static mechanical properties of UHPCC. Constr. Build. Mater. 2018, 163, 826–839. [Google Scholar] [CrossRef]

- Yu, K.Q.; Yu, J.T.; Dai, J.G.; Lu, Z.D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Kim, M.J.; Choi, H.J.; Shin, W.; Oh, T.; Yoo, D.Y. Development of impact resistant high-strength strain-hardening cementitious composites (HS-SHCC) superior to reactive powder concrete (RPC) under flexure. J. Build. Eng. 2021, 44, 102652. [Google Scholar] [CrossRef]

- Baggio, D.; Soudki, K.; Noël, M. Strengthening of shear critical RC beams with various FRP systems. Constr. Build. Mater. 2014, 66, 634–644. [Google Scholar] [CrossRef]

- Wu, Z.; Li, W.; Sakuma, N. Innovative externally bonded FRP/concrete hybrid flexural members. Compos. Struct. 2006, 72, 289–300. [Google Scholar] [CrossRef]

- Iqbal, N.; Sharma, P.K.; Kumar, D.; Roy, P.K. Protective polyurea coatings for enhanced blast survivability of concrete. Constr. Build. Mater. 2018, 175, 682–690. [Google Scholar] [CrossRef]

- Chen, Y.S.; Wang, B.; Zhang, B.; Zheng, Q.; Zhou, J.N.; Jin, F.N.; Fan, H.L. Polyurea coating for foamed concrete panel: An efficient way to resist explosion. Def. Technol. 2020, 16, 136–149. [Google Scholar] [CrossRef]

- Xu, S.; Yuan, P.; Liu, J.; Yu, X.; Hao, Y.; Hu, F.; Su, Y. Experimental and numerical investigation of G-UHPC based novel multi-layer protective slabs under contact explosions. Eng. Fail. Anal. 2022, 142, 106830. [Google Scholar] [CrossRef]

- Zhao, C.; Lu, X.; Wang, Q.; Gautam, A.; Wang, J.; Mo, Y.L. Experimental and numerical investigation of steel-concrete (SC) slabs under contact blast loading. Eng. Struct. 2019, 196, 109337. [Google Scholar] [CrossRef]

- Li, Q.; Chen, B.; Xu, S.; Zhou, F.; Yin, X.; Jiang, X.; Wu, P. Experiment and numerical investigations of ultra-high toughness cementitious composite slabs under contact explosions. Int. J. Impact Eng. 2022, 159, 104033. [Google Scholar] [CrossRef]

- Xu, S.; Wu, P.; Li, Q.; Zhou, F.; Chen, B. Experimental investigation and numerical simulation on the blast resistance of reactive powder concrete subjected to blast by embedded explosive. Cem. Concr. Compos. 2021, 119, 103989. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Jung, W.; Han, D. Testing the anti-explosion protection of HPFRCC for ready-mixed concrete system based on fiber selection and resistance to live explosives. Case Stud. Constr. Mater. 2022, 17, e01249. [Google Scholar] [CrossRef]

- Ha, J.H.; Yi, N.H.; Choi, J.K.; Kim, J.H.J. Experimental study on hybrid CFRP-PU strengthening effect on RC panels under blast loading. Compos. Struct. 2011, 93, 2070–2082. [Google Scholar] [CrossRef]

- Deb, S.; Samuelraj, I.O.; Mitra, N.; Jagadeesh, G. Microstructural Response of Shock-Loaded Concrete, Mortar, and Cementitious Composite Materials in a Shock Tube Setup. J. Mater. Civ. Eng. 2019, 31, 1–10. [Google Scholar] [CrossRef]

- KS F 2405:2010; Standard Test Method for Compressive Strength of Concrete. Korean Standards Association: Seoul, Republic of Korea, 2017.

- ASTM-C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Department of Defense, U.S. UNIFIED FACILITIES CRITERIA (UFC)-Structures to Resist the Effects of Accidental Explosions; Department of Defense, U.S.: Pentagon, VA, USA, 2008. [Google Scholar]

| NC (fc = 30 MPa) | HPFRCC (fc = 100 MPa) | ||

|---|---|---|---|

| Water-to-Binder ratio | 0.37 | 0.28 | |

| Mix Composition (kg/m3) | Water | 122 | 248.4 |

| Cement | 377 | 704.4 | |

| Silica Fume | - | 70.5 | |

| Fly Ash | - | 140.9 | |

| Ground Granulated Blast Furnace Slag (GGBS) | 42 | - | |

| Silica Flour | - | 140.9 | |

| Silica Sand | - | 845.3 | |

| Fine Aggregate | 831 | - | |

| Coarse Aggregate | 978 | - | |

| Superplasticizer (SP) | - | 11.1 | |

| Shrinkage-Reducing Admixture (SRA) | - | 4.6 | |

| Steel Fiber (SF) | - | 156.0 | |

| Diameter (μm) | Length (mm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | |

|---|---|---|---|---|---|

| Steel fiber | 200 | 19.5 | 7.8 | 2500 | 200 |

| Specimen | Thickness (mm) | ANFO (kg) | Reinforcing Steel | Reinforcement | |

|---|---|---|---|---|---|

| Variable | Remarks | ||||

| N-150 | 150 | 1 kg 2 kg 3 kg | D19@200 mm (V) D16@200 mm (H) | - | - |

| H-150 | 150 | HPFRCC | - | ||

| H-100 | 100 | - | |||

| N-150-Po | 150 | Polyurea | - | ||

| N-150-EAP-100 | 150 | Steel energy-absorbing panel | Grid size 100 mm × 100 mm | ||

| N-150-EAP-50 | 150 | Grid size 50 mm × 50 mm | |||

| Specimen | ANFO (kg) | Free 1 | Free 2 | Free 3 | Time Difference | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Peak1 (kPa) | Peak2 (kPa) | Peak1 (kPa) | Peak2 (kPa) | Peak1 (kPa) | Peak2 (kPa) | Free 1 (s) | Free 2 (s) | Free 3 (s) | ||

| N-150 | 1 | 386.0 | 226.3 | 327.0 | 385.0 | 290.5 | 885.2 | 0.016644 | 0.00961 | 0.001268 |

| 2 | 616.4 | 422.0 | 528.3 | 567.7 | 622.3 | 1719.2 | 0.014246 | 0.00768 | 0.001024 | |

| 3 | 888.9 | 517.6 | 771.4 | 820.1 | 1006.9 | 2849.5 | 0.012574 | 0.007276 | 0.00103 | |

| H-150 | 1 | 323.5 | 130.8 | 260.4 | 226.3 | 296.2 | 630.9 | 0.016886 | 0.01027 | 0.001142 |

| 2 | 625.0 | 368.2 | 502.3 | 598.1 | 598.9 | 1590.6 | 0.01386 | 0.007988 | 0.001084 | |

| 3 | 726.8 | 310.0 | 636.4 | 657.8 | 703.2 | 2041.1 | 0.013594 | 0.008118 | 0.001048 | |

| H-100 | 1 | 342.3 | 147.5 | 280.8 | 237.6 | 311.8 | 674.4 | 0.016826 | 0.009602 | 0.00123 |

| 2 | 840.4 | 413.2 | 541.5 | 631.9 | 608.4 | 1649.5 | 0.014286 | 0.007818 | 0.001096 | |

| 3 | 972.5 | 503.2 | 819.9 | 825.8 | 874.4 | 2548.3 | 0.012446 | 0.007236 | 0.000758 | |

| N-150-Po | 1 | 323.0 | 172.0 | 287.0 | 301.4 | 312.9 | 713.0 | 0.016694 | 0.009464 | 0.00124 |

| 2 | 622.6 | 360.5 | 525.6 | 682.4 | 597.9 | 1721.5 | 0.013596 | 0.00759 | 0.001058 | |

| 3 | 902.6 | 551.8 | 780.4 | 904.9 | 851.5 | 2881.4 | 0.012148 | 0.007312 | 0.001068 | |

| N-150-EAP-100 | 1 | 401.0 | 223.4 | 353.9 | 378.6 | 386.5 | 867.5 | 0.017044 | 0.009962 | 0.001212 |

| 2 | 649.9 | 437.7 | 568.0 | 606.6 | 623.2 | 1696.8 | 0.013836 | 0.007896 | 0.000968 | |

| 3 | 913.2 | 462.5 | 824.6 | 741.6 | 879.0 | 2661.8 | 0.01181 | 0.007482 | 0.001156 | |

| N-150-EAP-50 | 1 | 388.7 | 235.4 | 351.6 | 340.3 | 381.0 | 867.0 | 0.016784 | 0.009962 | 0.001216 |

| 2 | 620.6 | 463.7 | 524.2 | 581.9 | 593.3 | 1604.6 | 0.014282 | 0.008474 | 0.000968 | |

| 3 | 888.1 | 507.6 | 776.2 | 793.5 | 860.9 | 2739.3 | 0.012248 | 0.007574 | 0.001068 | |

| Location | ANFO (kg) | Scaled Distance (ft/lb1/3) | UFC 3-340-02 [18] | Experiment | ||

|---|---|---|---|---|---|---|

| Peak Pressure (Free a) (kPa) | Peak Pressure (Surface b) (kPa) | 1st Peak Pressure (Peak1) (kPa) | 2nd Peak Pressure (Peak2) (kPa) | |||

| Free 1 | 1 kg | 30.66 | 8.96 | 12.41 | 360.76 | 211.98 |

| 2 kg | 24.33 | 13.10 | 15.86 | 662.49 | 410.89 | |

| 3 kg | 21.26 | 14.13 | 20.00 | 882.02 | 475.42 | |

| Free 2 | 1 kg | 37.62 | 6.34 | 10.00 | 310.11 | 311.54 |

| 2 kg | 29.86 | 9.65 | 12.41 | 531.66 | 611.43 | |

| 3 kg | 26.09 | 12.07 | 14.13 | 768.13 | 790.61 | |

| Free 3 | 1 kg | 41.39 | 5.86 | 7.58 | 346.50 | 944.29 |

| 2 kg | 32.85 | 8.62 | 11.03 | 607.34 | 1663.68 | |

| 3 kg | 28.70 | 10.34 | 12.41 | 862.67 | 2620.23 | |

| Specimen | ANFO (kg) | Acceleration (g) | Reflected Pressure (kPa) | Impulse (kPa∙s) | Duration (s) | Crack Length (mm) |

|---|---|---|---|---|---|---|

| N-150 | 1 | 2983.37 | 1750 | 3.72 | 0.01563 | 5028.1 |

| 2 | 3221.26 | 2792 | 5.24 | 0.01202 | 16,485.5 | |

| 3 | - | 4909 | 7.50 | 0.00810 | 22,357.8 | |

| H-150 | 1 | 2243.77 | 1389 | 3.72 | 0.01129 | - |

| 2 | 3268.71 | 2806 | 5.24 | 0.01123 | 804.9 | |

| 3 | 5800.75 | 4098 | 7.50 | 0.01039 | 4601.8 | |

| H-100 | 1 | 1498.88 | 1480 | 2.94 | 0.01119 | 427.1 |

| 2 | 3721.99 | 3743 | 6.15 | 0.01048 | 5130.9 | |

| 3 | 3366.87 | 4901 | 8.29 | 0.01004 | 13,911.9 | |

| N-150-Po | 1 | 1612.43 | 1471 | 2.97 | 0.01376 | - |

| 2 | 4623.5 | 3040 | 5.90 | 0.01105 | - | |

| 3 | 8770.76 | 4400 | 7.99 | 0.00910 | - | |

| N-150-EAP-100 | 1 | 1825.27 | 1487 | 4.17 | 0.01544 | 3379.7 |

| 2 | 13,437.6 | 2822 | 4.43 | 0.00597 | 9202.1 | |

| 3 | 10,999.33 | 4461 | 3.67 | 0.00348 | 17,224.9 | |

| N-150-EAP-50 | 1 | 2848.79 | 1476 | 4.80 | 0.01474 | 3896.9 |

| 2 | 4100.79 | 2761 | 5.24 | 0.00907 | 10,514.6 | |

| 3 | 11,784.96 | 4613 | 9.07 | 0.00909 | 17,957.2 |

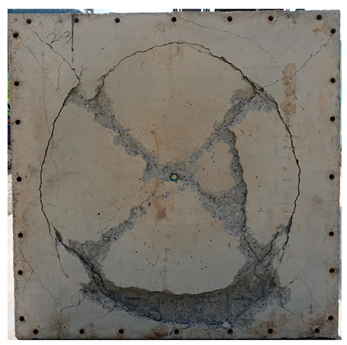

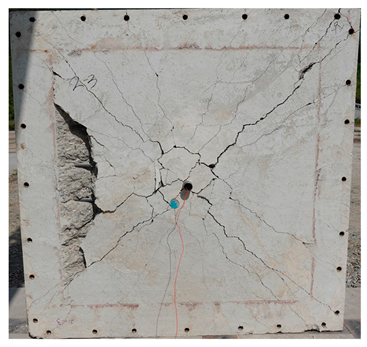

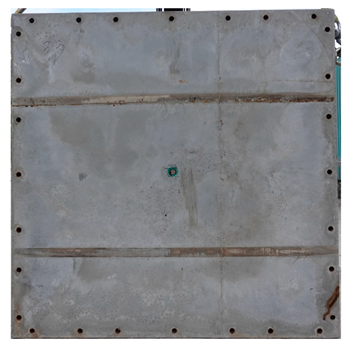

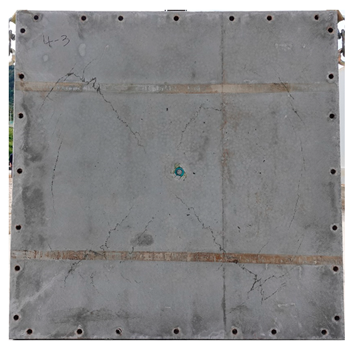

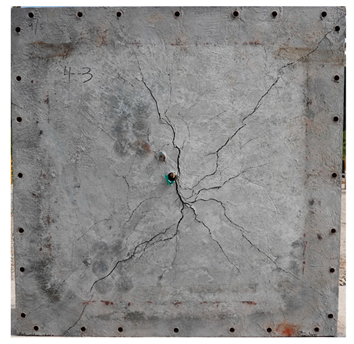

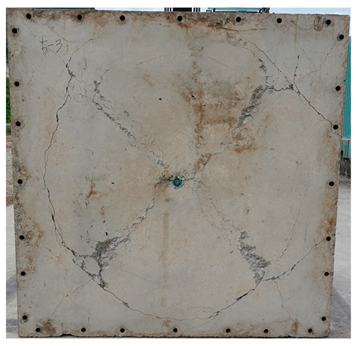

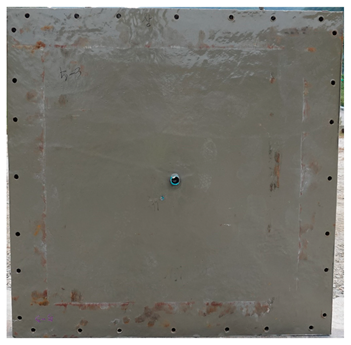

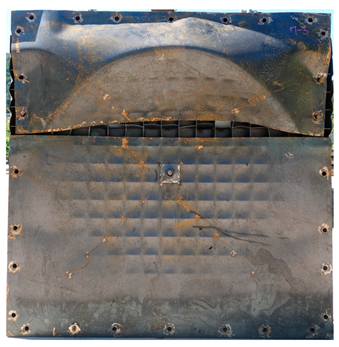

| Front | Rear | |

|---|---|---|

| N-150 |  |  |

| H-150 |  |  |

| H-100 |  |  |

| N-150-Po |  |  |

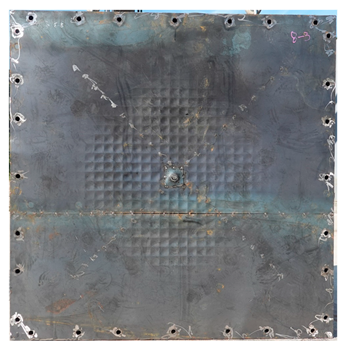

| N-150-EAP-100 |  |  |

| N-150-EAP-50 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, G.-K.; Moon, J.H.; Shin, H.-S.; Kim, S.-W. Blast Resistance Capacities of Structural Panels Subjected to Shock-Tube Testing with ANFO Explosive. Materials 2023, 16, 5274. https://doi.org/10.3390/ma16155274

Park G-K, Moon JH, Shin H-S, Kim S-W. Blast Resistance Capacities of Structural Panels Subjected to Shock-Tube Testing with ANFO Explosive. Materials. 2023; 16(15):5274. https://doi.org/10.3390/ma16155274

Chicago/Turabian StylePark, Gang-Kyu, Jae Heum Moon, Hyun-Seop Shin, and Sung-Wook Kim. 2023. "Blast Resistance Capacities of Structural Panels Subjected to Shock-Tube Testing with ANFO Explosive" Materials 16, no. 15: 5274. https://doi.org/10.3390/ma16155274

APA StylePark, G.-K., Moon, J. H., Shin, H.-S., & Kim, S.-W. (2023). Blast Resistance Capacities of Structural Panels Subjected to Shock-Tube Testing with ANFO Explosive. Materials, 16(15), 5274. https://doi.org/10.3390/ma16155274