Gypsum-Based Humidity-Control Material: Preparation, Performance and Its Impact on Building Energy Consumption

Abstract

1. Introduction

2. Materials and Methods

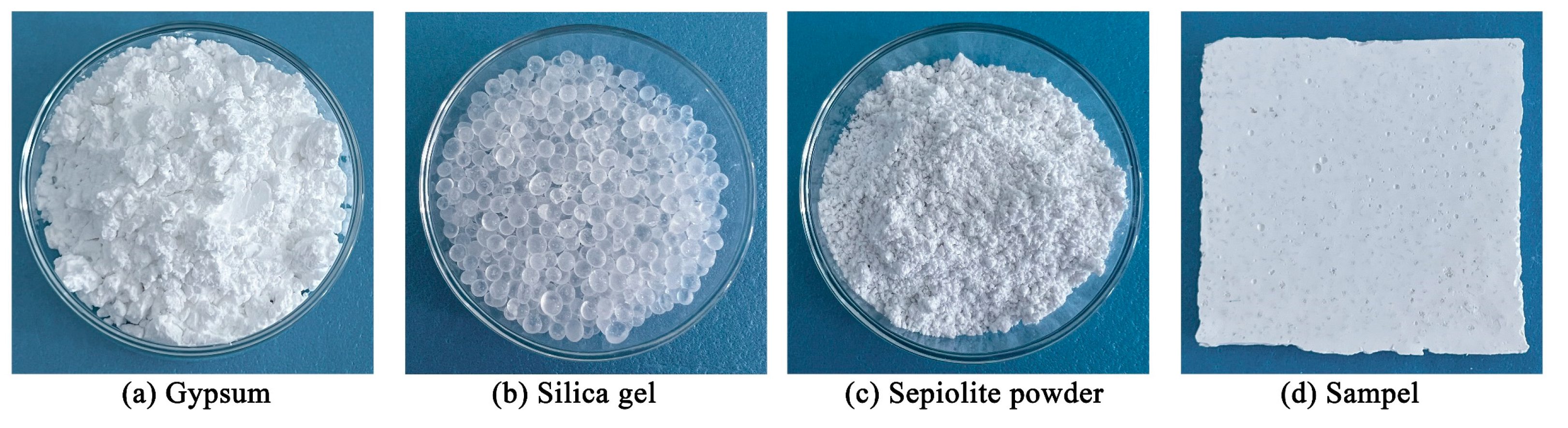

2.1. Materials

2.1.1. Preparation of Activated Sepiolite Powder

2.1.2. Preparation of Gypsum–Silica Gel Humidity-Control Material

2.1.3. Preparation of Gypsum-Based Humidity-Control Material

2.2. Testing Methods

2.2.1. Experimental Testing

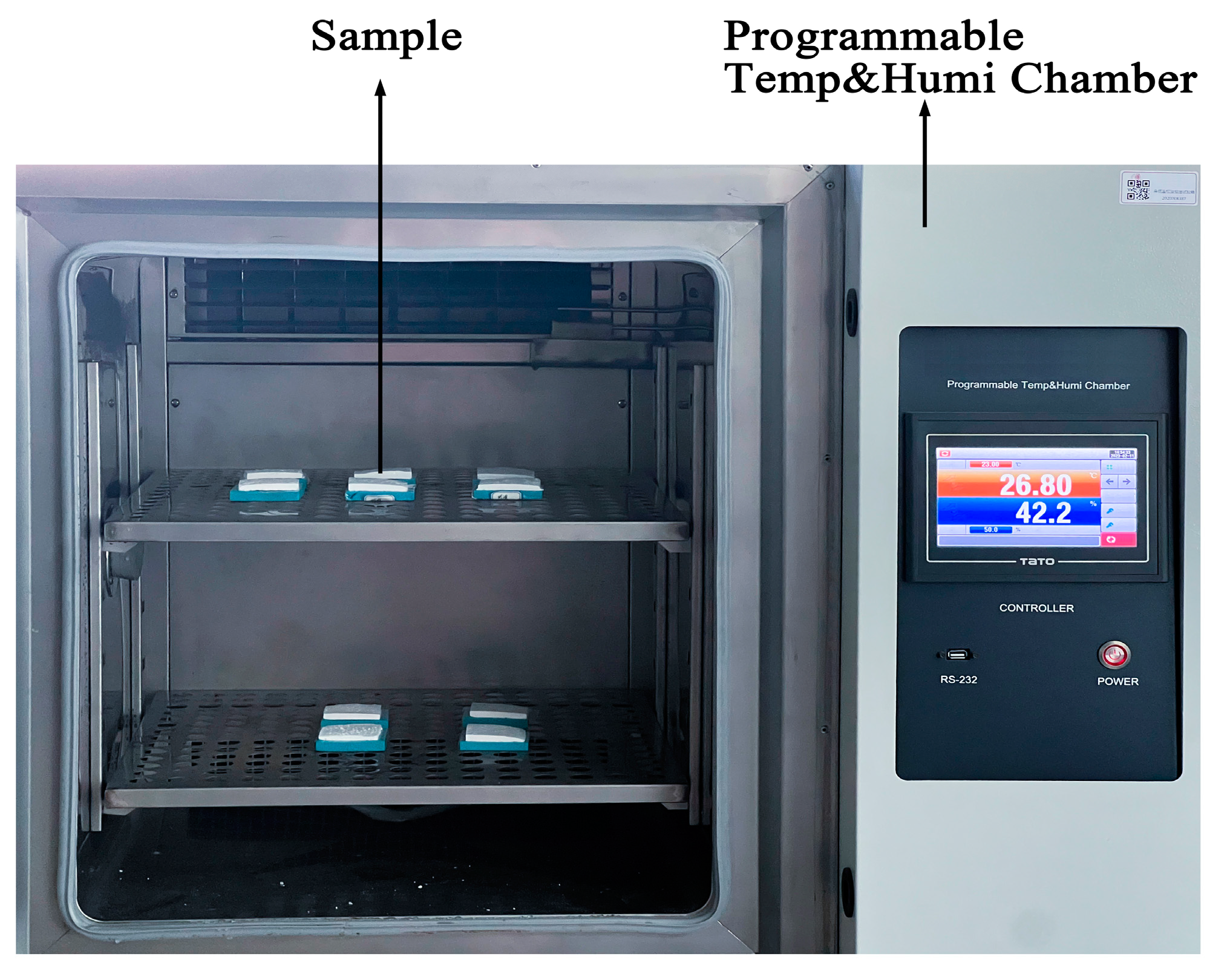

- Humidity-control performance

- 2.

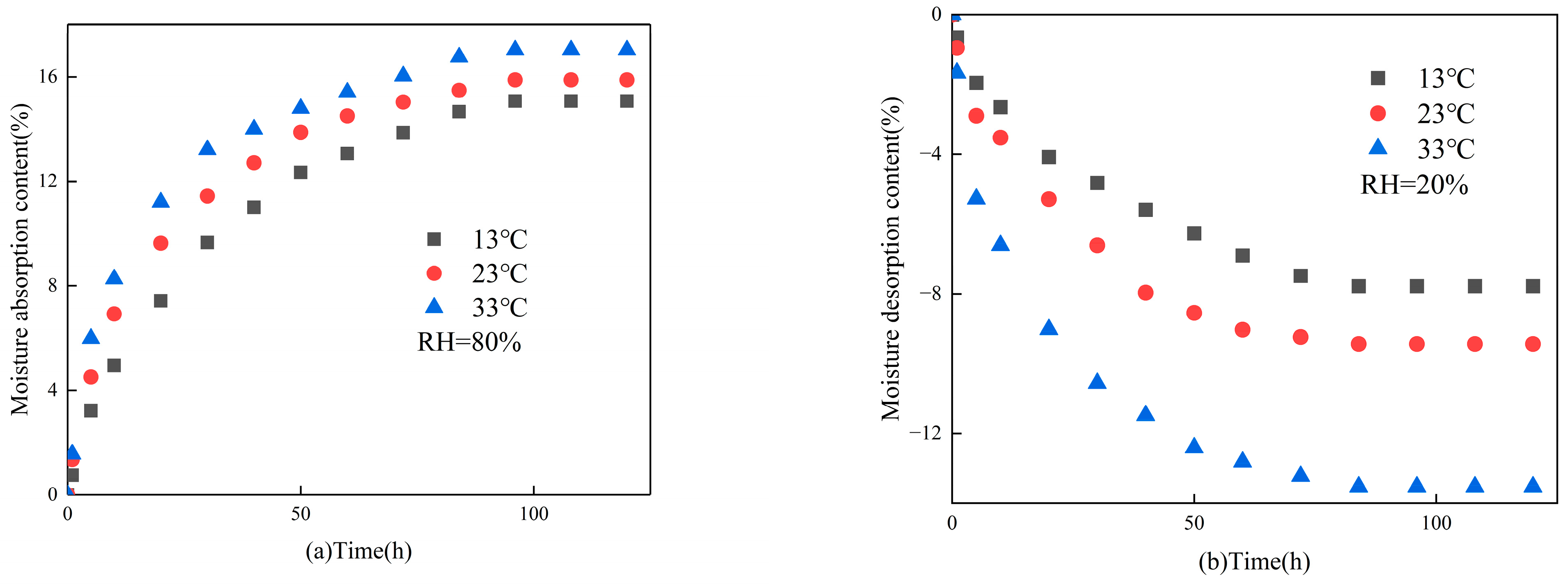

- The impact of the environment on humidity-control performance

- 3.

- Isothermal moisture adsorption–desorption curve

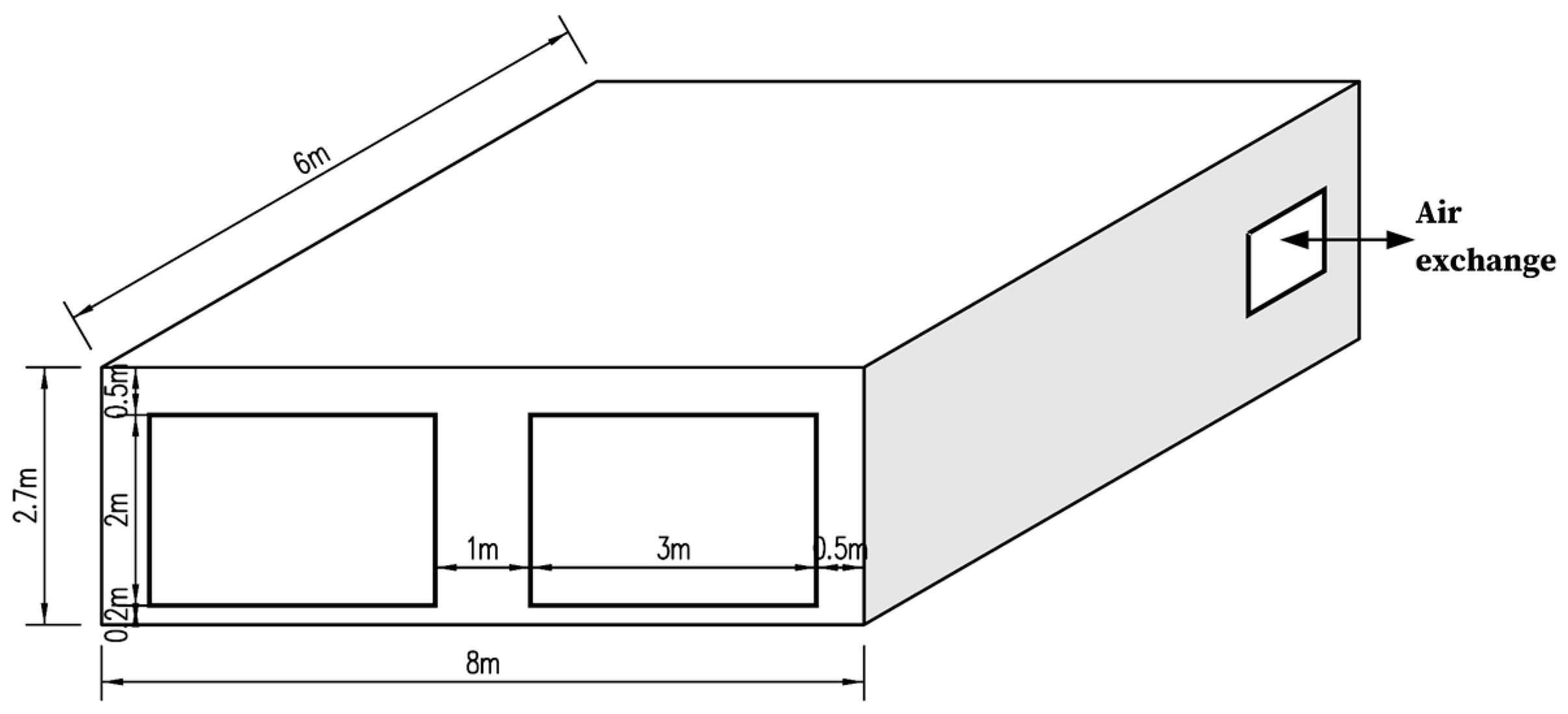

2.2.2. Simulation Testing

3. Results

3.1. Experimental Testing

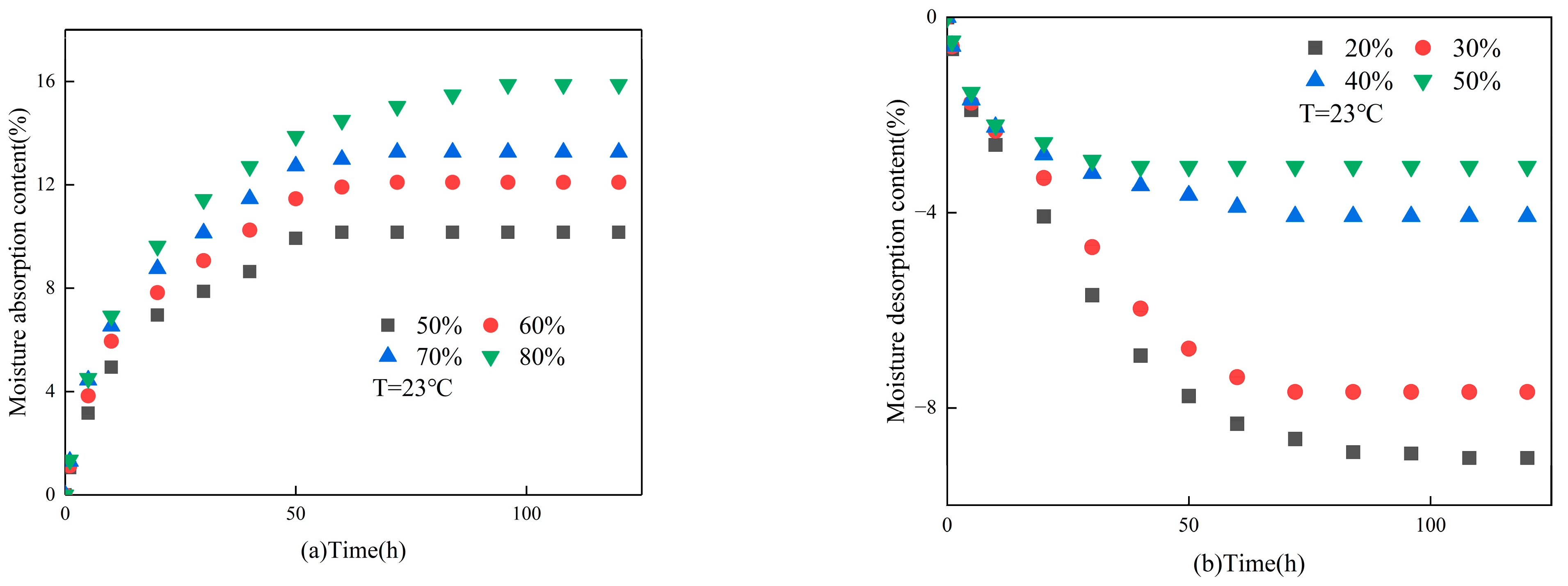

3.1.1. Humidity-Control Performance

3.1.2. The Impact of the Environment on Humidity-Control Performance

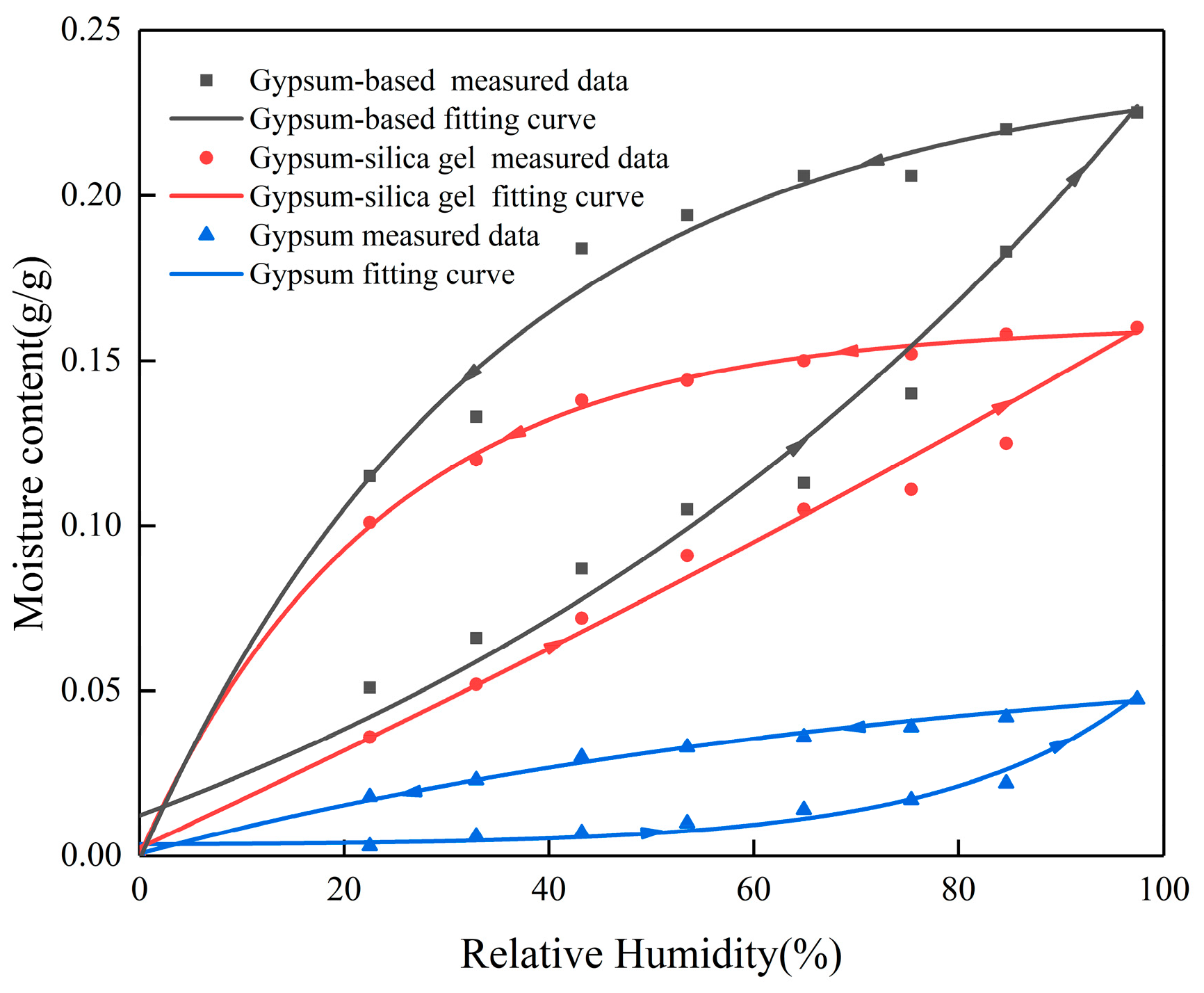

3.1.3. Isothermal Moisture Adsorption–Desorption Curve

3.2. Simulation Testing

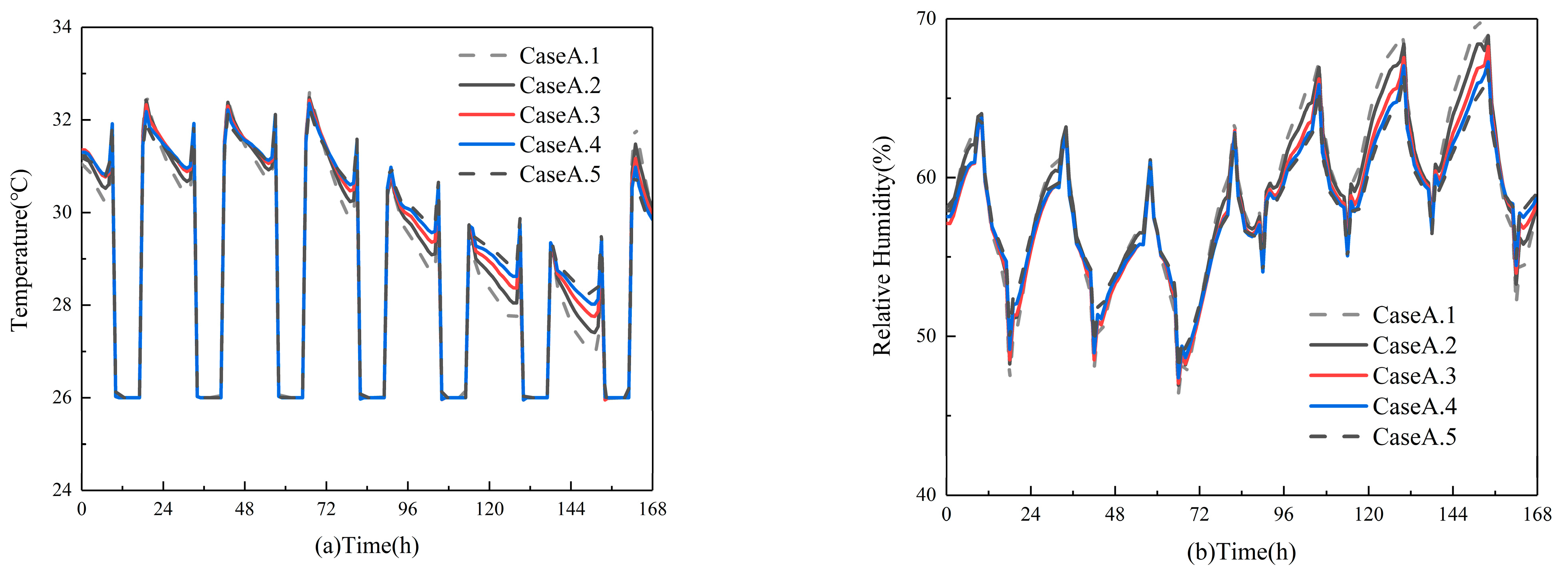

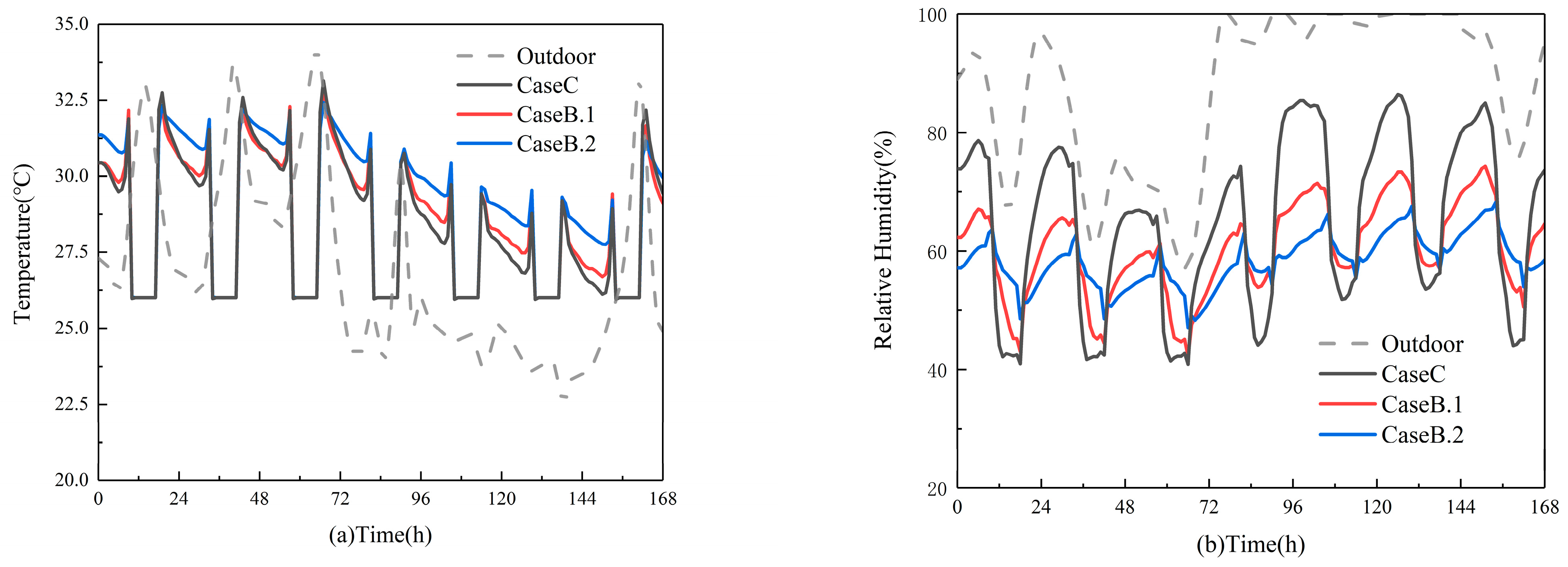

3.2.1. The Impact of Material Thickness on Indoor Air Parameters

3.2.2. The Impact of Material Area on Indoor Air Parameters

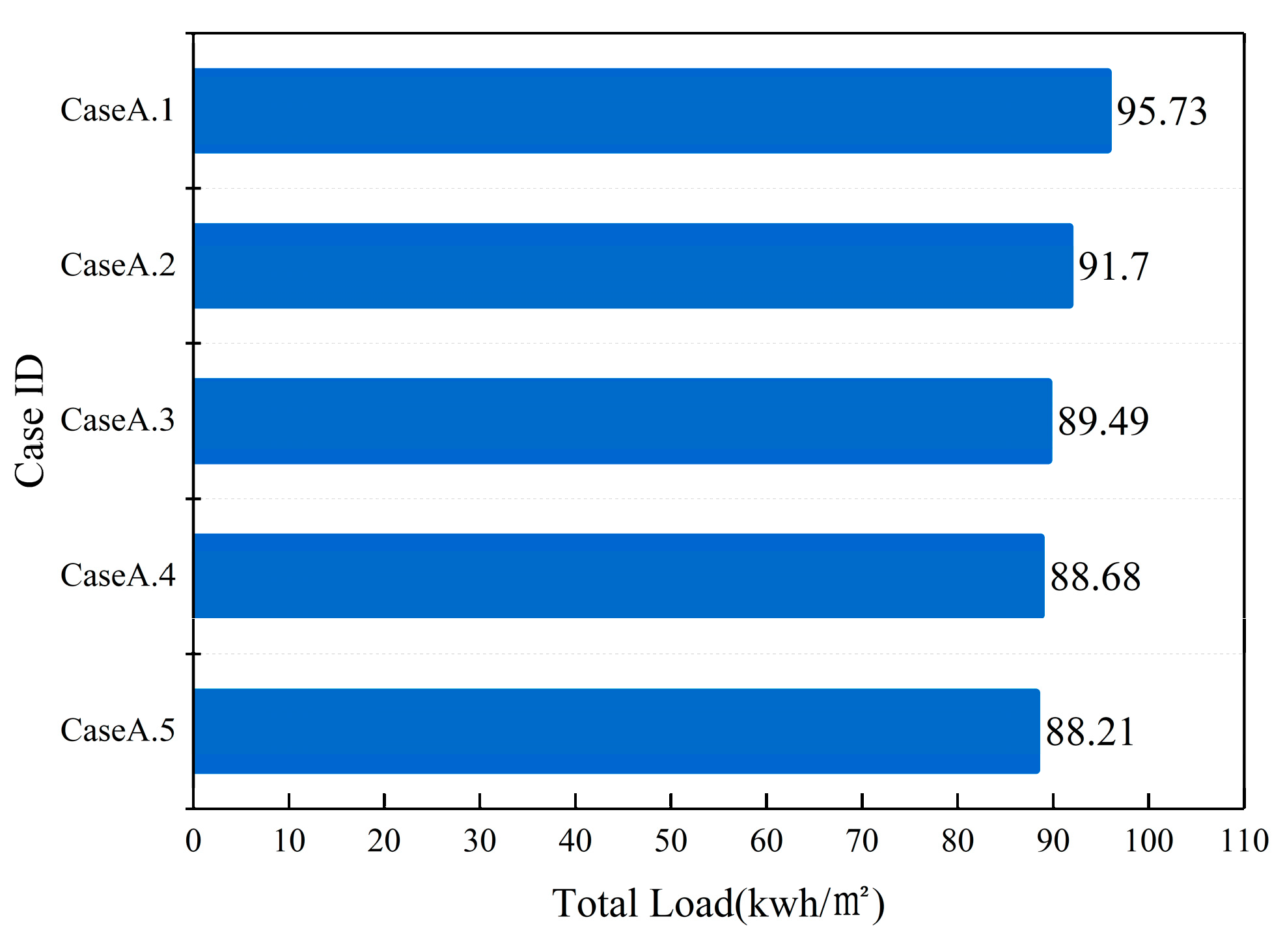

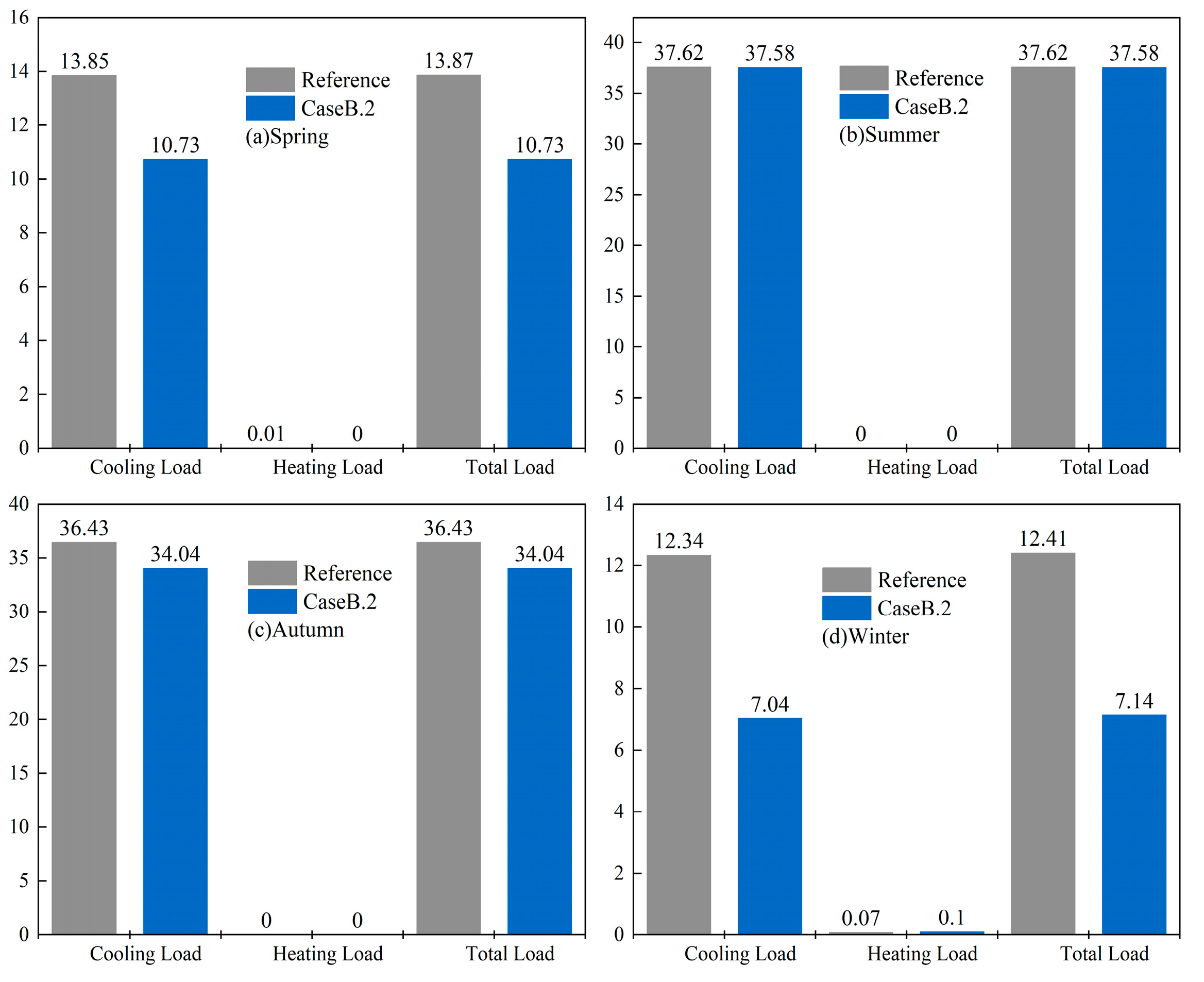

3.2.3. Analysis of Energy-Saving

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arundel, A.V.; Sterling, E.M.; Biggin, J.H.; Sterling, T.D. Indirect health effects of relative humidity in indoor environments. Environ. Health Perspect. 1986, 65, 351–361. [Google Scholar]

- Khaled, S.; Collet, F.; Prétot, S.; Bart, M. Effect of Air Velocity and Initial Conditioning on the Moisture Buffer Value of Four Different Building Materials. Materials 2023, 16, 3284. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Zhang, Z. Energy saving latent heat storage and environmental friendly humidity-controlled materials for indoor climate. Renew. Sustain. Energy Rev. 2012, 16, 3136–3145. [Google Scholar] [CrossRef]

- Atthajariyakul, S.; Leephakpreeda, T. Real-time determination of optimal indoor-air condition for thermal comfort, air quality and efficient energy usage. Energy Build. 2004, 36, 720–733. [Google Scholar] [CrossRef]

- Fang, L.; Clausen, G.; Fanger, P.O. Impact of Temperature and Humidity on Perception of Indoor Air Quality during Immediate and Longer Whole-Body Exposures. Indoor Air 1998, 8, 276–284. [Google Scholar] [CrossRef]

- China Building Energy Conservation Association. China Building Energy Consumption Annual Report 2020. J. BEE 2021, 49, 1–6. [Google Scholar]

- He, X.; Zhang, H.; Qiu, L.; Mao, Z.; Shi, C. Hygrothermal performance of temperature-humidity controlling materials with different compositions. Energy Build. 2021, 236, 110792. [Google Scholar] [CrossRef]

- Mingyu, H.; Ye, L.; Xingguo, G.; Xiangwei, L.; Zhangjun, L.; Chao, F. Effect of Diatomite/Sphagnum Composite Humidity-Controlling Materials on Temperature and Humidity Control. Build. Sci. 2019, 35, 50–59. [Google Scholar]

- Ran, M. Review of Research and Application of Air Humidity Controlling Materials in Japan. Mater. Rep. 2002, 16, 42–44. [Google Scholar]

- Nishito, I.; Miyano, A.; Yan, Q. About the changes in indoor humidity. Trans. Archit. Inst. Jpn. 1952, 44, 73–81. [Google Scholar]

- Osanyintola, O.F.; Simonson, C.J. Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy Build. 2006, 38, 1270–1282. [Google Scholar] [CrossRef]

- Zhang, H.; Yoshino, H.; Hasegawa, K.; Liu, J.; Zhang, W.; Xuan, H. Practical moisture buffering effect of three hygroscopic materials in real-world conditions. Energy Build. 2017, 139, 214–223. [Google Scholar] [CrossRef]

- Colinart, T.; Glouannec, P.; Pierre, T.; Chauvelon, P.; Magueresse, A. Experimental Study on the Hygrothermal Behavior of a Coated Sprayed Hemp Concrete Wall. Buildings 2013, 3, 79–99. [Google Scholar] [CrossRef]

- Gómez, I.; Guths, S.; Souza, R.; Millan, J.A.; Martín, K.; Sala, J.M. Moisture buffering performance of a new pozolanic ceramic material: Influence of the film layer resistance. Energy Build. 2011, 43, 873–878. [Google Scholar] [CrossRef]

- Kim, H.-J. The Hygric Performances of Moisture Adsorbing/Desorbing Building Materials. Aerosol Air Qual. Res. 2010, 10, 625–634. [Google Scholar] [CrossRef]

- Zhang, H.; Yoshino, H.; Hasegawa, K. Assessing the moisture buffering performance of hygroscopic material by using experimental method. Build. Environ. 2012, 48, 27–34. [Google Scholar] [CrossRef]

- Ge, H.; Yang, X.; Fazio, P.; Rao, J. Influence of moisture load profiles on moisture buffering potential and moisture residuals of three groups of hygroscopic materials. Build. Environ. 2014, 81, 162–171. [Google Scholar] [CrossRef]

- Simonson, C.J.; Salonvaara, M.; Ojanen, T. Moderating Indoor Conditions with Hygroscopic Building Materials and Outdoor Ventilation/Discussion. Ashrae Trans. 2004, 110, 804–819. [Google Scholar]

- Zhang, M.; Qin, M.; Rode, C.; Chen, Z. Moisture buffering phenomenon and its impact on building energy consumption. Appl. Therm. Eng. 2017, 124, 337–345. [Google Scholar] [CrossRef]

- Xu, Z.; Liting, Y. Recent progress on composite humidity control materials. Chem. Ind. Eng. Prog. 2020, 39, 1378–1388. [Google Scholar]

- Guanyi, C.; Xiaoling, B.; Xiumei, Z.; Qiang, L. Research on characteristics of biomass-based humidity-controlling materials. HV&AC 2007, 37, 14–17. [Google Scholar]

- Hongyi, J.; Yiping, W.; Hailaing, W. Explorative Research of the Organic Humidity Controlling Materials. J. Wuhan Univ. Technol. 2007, 28, 6–8. [Google Scholar]

- Roels, S.; Janssen, H.; Carmeliet, J.; Diepens, J.; de Wit, M. Hygric buffering capacities of uncoated and coated gypsum board. In Research in Building Physics and Building Engineering; CRC Press: Boca Raton, FL, USA, 2006; pp. 27–32. [Google Scholar]

- Zhang, Y.; Chen, J.; Liang, X.; Wei, X.; Zhang, Z.; Wang, R. Experimental Research on the Effect of Humidity Controlling Materials on Indoor Humidity Environment. J. BEE 2016, 44, 48–51+87. [Google Scholar]

- Pedram, S.; Tariku, F. Moisture Buffering Effect of Gypsum Board in a Marine Climate: A Field Experimental Study. Adv. Mater. Res. 2014, 1051, 763–773. [Google Scholar] [CrossRef]

- Jianli, S.; Hao, Z.; Li, D. Preparation of composite material of gypsum-based double-shell micro-nano phase change capsules and performance research of temperature-humidity control. Acta Energiae Solaris Sin. 2016, 37, 1481–1487. [Google Scholar]

- Zong, Z.; Chen, D.; Zhao, C.; Tang, G.; Ji, Y.; Zhang, H.; Lv, Z. Application of Ce–Eu/TiO2 phase change material as the wall material to improve the indoor environment. J. Mater. Res. 2021, 36, 615–627. [Google Scholar] [CrossRef]

- Jiang, H.; Luan, C. Preparation and absorption/desorption performance of gypsum-based humidity controlling materials. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 684–686. [Google Scholar] [CrossRef]

- Shang, J.L.; Zong, Z.F.; Zhang, H. Synthesis and analysis of new humidity-controlling composite materials. Int. J. Miner. Metall. Mater. 2017, 24, 594–602. [Google Scholar] [CrossRef]

- Lee, J.-K.; Kim, T.-Y. Evaluation of Humidity Control Ceramic Paint Using Gypsum Binder. J. Korean Ceram. Soc. 2018, 55, 74–79. [Google Scholar] [CrossRef]

- Jianli, S.; Dan, C.; Bin, W. Preparation of the biomass porous phase change materials and its thermal and moisture properties. New Chem. Mater. 2015, 43, 107–109+113. [Google Scholar]

- Guitang, X.; Jun, Z.; Ming, Y.; Yuchuan, W.; Guochang, J.; Zhiguo, J. Research and Application Status of Humidity-controlling Materials. Mater. Rep. 2021, 35, 634–638. [Google Scholar]

- Jihui, W.; Zhiwei, W. Advances in Humidity-controlling Composite Materials. Mater. Rep. 2007, 21, 55–58. [Google Scholar]

- Xi, L.; Maoyu, R. Gypsum-based silica gel humidity-controlling composite materials: Preparation, characterization, and performance. J. Wuhan Univ. Technol. Mater. Sci. Ed. Accepted.

- Luan, C. The Preparation and Performance of Gypsum-Based Humidity Controlling Materials. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2008. [Google Scholar]

- GB/T 20313-2006; Hygrothermal Performance of Building Materials and Products—Determination of Moisture Content by Drying at Elevated Temperature. China Building Materials Industry Association: Beijing, China, 2006.

| Material | Material Mass Ratio | Material to Water Mass Ratio |

|---|---|---|

| activated sepiolite power | 80% sepiolite power + 20% calcium chloride | - |

| gypsum–silica gel material | 60% gypsum + 40% silica gel | 1:0.7 |

| gypsum-based material | 80% gypsum–silica gel material + 20% activated sepiolite power | |

| gypsum material | 100% gypsum |

| Construction | Material | d (m) | K (W/m·K) | U (W/m2·K) | ||

|---|---|---|---|---|---|---|

| Wall (from outer layer to inner layer) | Wooden board | 0.01 | 530 | 900 | 0.14 | 0.474 |

| Rock wool board | 0.066 | 60 | 850 | 0.04 | - | |

| Concrete | 0.1 | 1400 | 1000 | 0.51 | - | |

| gypsum-based material | - | 1000 | 2250 | 0.45 | - | |

| Roof (from outer layer to inner layer) | Cement panel | 0.012 | 1130 | 840 | 0.255 | 0.307 |

| Rock wool board | 0.066 | 60 | 850 | 0.04 | - | |

| gypsum-based material | - | 1000 | 2250 | 0.45 | - | |

| Floor (from outer layer to inner layer) | Thermal insulating | 1 | 60 | 850 | 0.04 | 0.04 |

| layer | - | - | - | - | - | |

| gypsum-based material | - | 1000 | 2250 | 0.45 | - | |

| Window | Double glazing unit | - | - | - | - | 1.99 |

| Conditions | Office Case |

|---|---|

| Occupied period | 8:00–18:00 |

| Unoccupied period | The rest of the day |

| Air conditioning running time | Occupied period |

| Air conditioning running temperature (°C) | 18–26 |

| Air conditioning running relative humidity (%) | 30–70 |

| Air change rate (ACH) | 0.5 |

| Air infiltration | No |

| Case ID | Thickness (m) | Area (m2) |

|---|---|---|

| Case A.1 | 0.01 | 159.6 |

| Case A.2 | 0.02 | |

| Case A.3 | 0.03 | |

| Case A.4 | 0.04 | |

| Case A.5 | 0.05 | |

| Case B.1 | 0.03 | 63.6 |

| Case B.2 | 159.6 | |

| Case C | - | 0 |

| Parameters | Gypsum-Based Material | Gypsum–Silica Gel Material | Gypsum | |

|---|---|---|---|---|

| Absorption process | y0 | −0.08307 | −0.654 | 0.00327 |

| A1 | 0.09532 | 0.65651 | 2.5 × 10−4 | |

| t1 | −82.5884 | −455.15 | −18.7285 | |

| R2 | 0.97 | 0.98 | 0.97 | |

| Desorption process | y0 | 0.24001 | 0.16084 | 0.06589 |

| A1 | −0.24108 | −0.16068 | −0.06519 | |

| t1 | 34.41 | 23.24 | 78.49 | |

| R2 | 0.99 | 0.99 | 0.98 |

| City | Load and Efficiency | Case ID | |

|---|---|---|---|

| Reference | CaseB.2 | ||

| Beijing | Total load (kwh/m2) | 77.88 | 62.84 |

| Energy saving (%) | - | 19.31 | |

| Paris | Total load (kwh/m2) | 60.77 | 49.54 |

| Energy saving (%) | - | 18.48 | |

| Atlanta | Total load (kwh/m2) | 112.13 | 91.9 |

| Energy saving (%) | - | 18.04 | |

| Xiamen | Total load (kwh/m2) | 100.34 | 89.49 |

| Energy saving (%) | - | 10.81 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Ran, M. Gypsum-Based Humidity-Control Material: Preparation, Performance and Its Impact on Building Energy Consumption. Materials 2023, 16, 5211. https://doi.org/10.3390/ma16155211

Li X, Ran M. Gypsum-Based Humidity-Control Material: Preparation, Performance and Its Impact on Building Energy Consumption. Materials. 2023; 16(15):5211. https://doi.org/10.3390/ma16155211

Chicago/Turabian StyleLi, Xi, and Maoyu Ran. 2023. "Gypsum-Based Humidity-Control Material: Preparation, Performance and Its Impact on Building Energy Consumption" Materials 16, no. 15: 5211. https://doi.org/10.3390/ma16155211

APA StyleLi, X., & Ran, M. (2023). Gypsum-Based Humidity-Control Material: Preparation, Performance and Its Impact on Building Energy Consumption. Materials, 16(15), 5211. https://doi.org/10.3390/ma16155211